Novel fluid bed drier

A technology of boiling drying and dryer, which is applied in the direction of drying solid materials, drying granular materials, and drying solid materials by heating, etc. It can solve the preventive measures for dust spillage in boiling dryers, shorten the cycle of cleaning filters, return air outlets, etc. Unqualified dust particles in the clean area and other problems, to achieve the effect of protecting the production environment, ensuring cleanliness requirements, and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

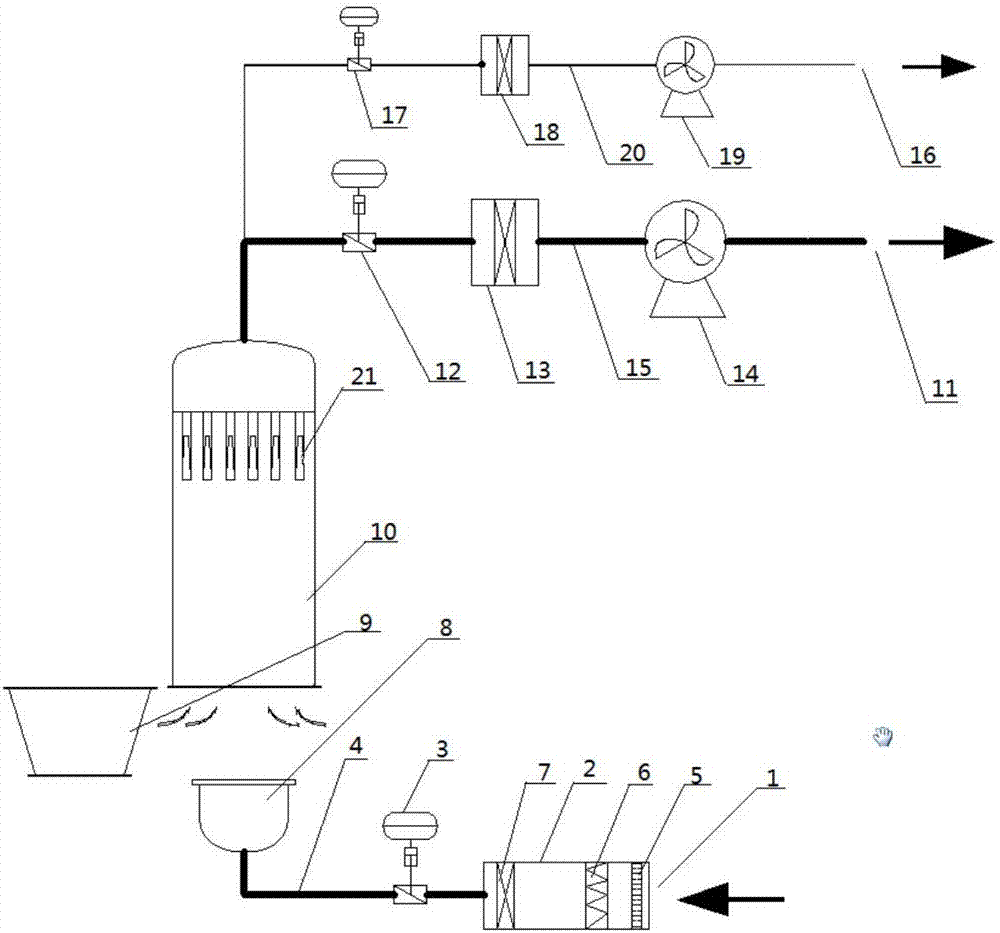

[0019] The structure of the new boiling dryer is as follows: figure 1 shown.

[0020] The new boiling dryer is composed of an air inlet system, a drying body and an exhaust system. Among them, the air intake system (1) consists of a fresh air treatment box (2), an air intake pneumatic valve (3) and an air intake duct (4). The fresh air treatment box (2) has a primary filter (5), a medium Filter (6) and sub-high-efficiency filter (7), if necessary, also can have heater in the fresh air processing box (2); Drying machine body comprises bottom bin (8), feed bin (9) and boiling bin (10) Consists of two sets of exhaust systems, one set is a dry exhaust system (11), including a dry exhaust pneumatic valve (12), a dry exhaust filter (13), a dry exhaust fan (14) and a dry exhaust duct (15) composition; the other is dust removal exhaust system (16), comprises dust removal exhaust air valve (17), dust removal exhaust filter (18), dust removal exhaust fan (19) and dust removal exhaust ...

Embodiment 2

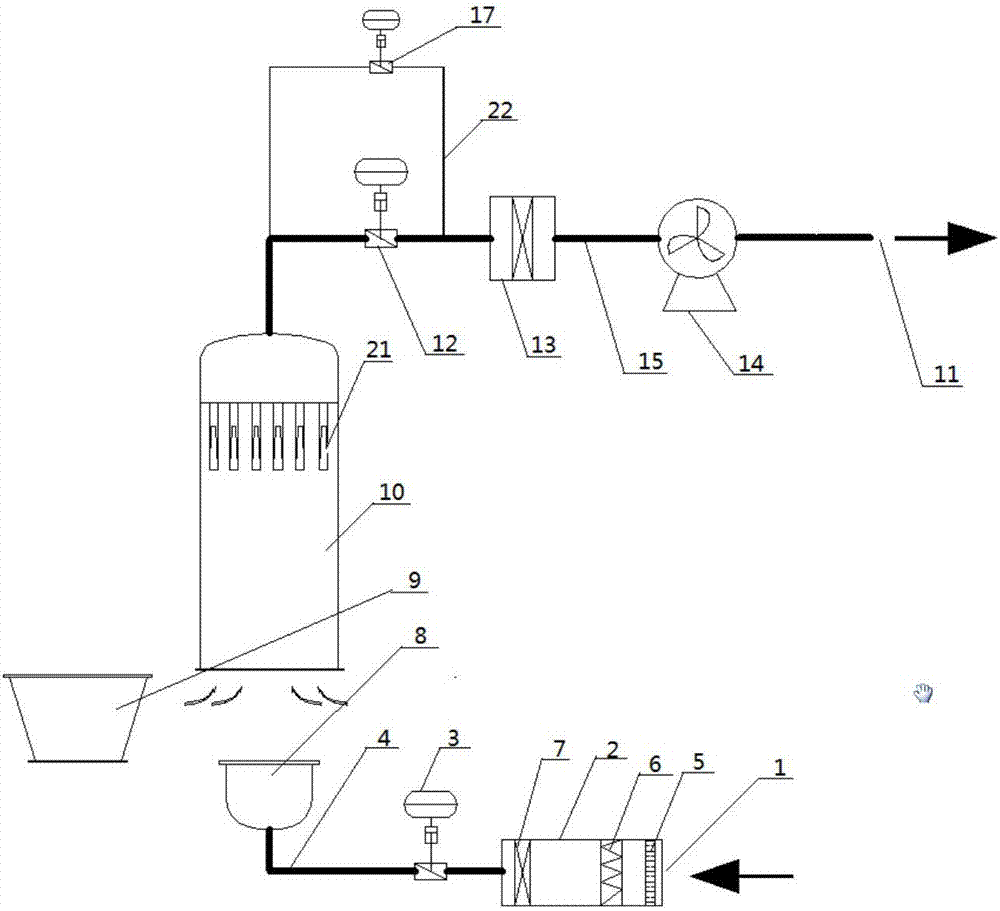

[0040] The structure of the new boiling dryer is as follows: figure 2 shown.

[0041] The new boiling dryer is composed of an air inlet system, a drying body and an exhaust system. Among them, the air intake system (1) consists of a fresh air treatment box (2), an air intake pneumatic valve (3) and an air intake duct (4). The fresh air treatment box (2) has a primary filter (5), a medium filter (6) and sub-high-efficiency filter (7); the drying body comprises a bottom bin (8), a feed bin (9) and a boiling bin (10) to form. A bag filter (21) is arranged in the boiling bin (10).

[0042] The dry exhaust system and the dust removal exhaust system are combined to form an exhaust system, including a dry exhaust duct (15), a bypass pipeline (22), a dry exhaust pneumatic valve (12), a dust removal and exhaust pneumatic valve (17 ), a drying exhaust filter (13) and a drying exhaust fan (14). Add a bypass pipeline (22) with a smaller pipe diameter at both ends of the dry exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com