Patents

Literature

68results about How to "Protect the production environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

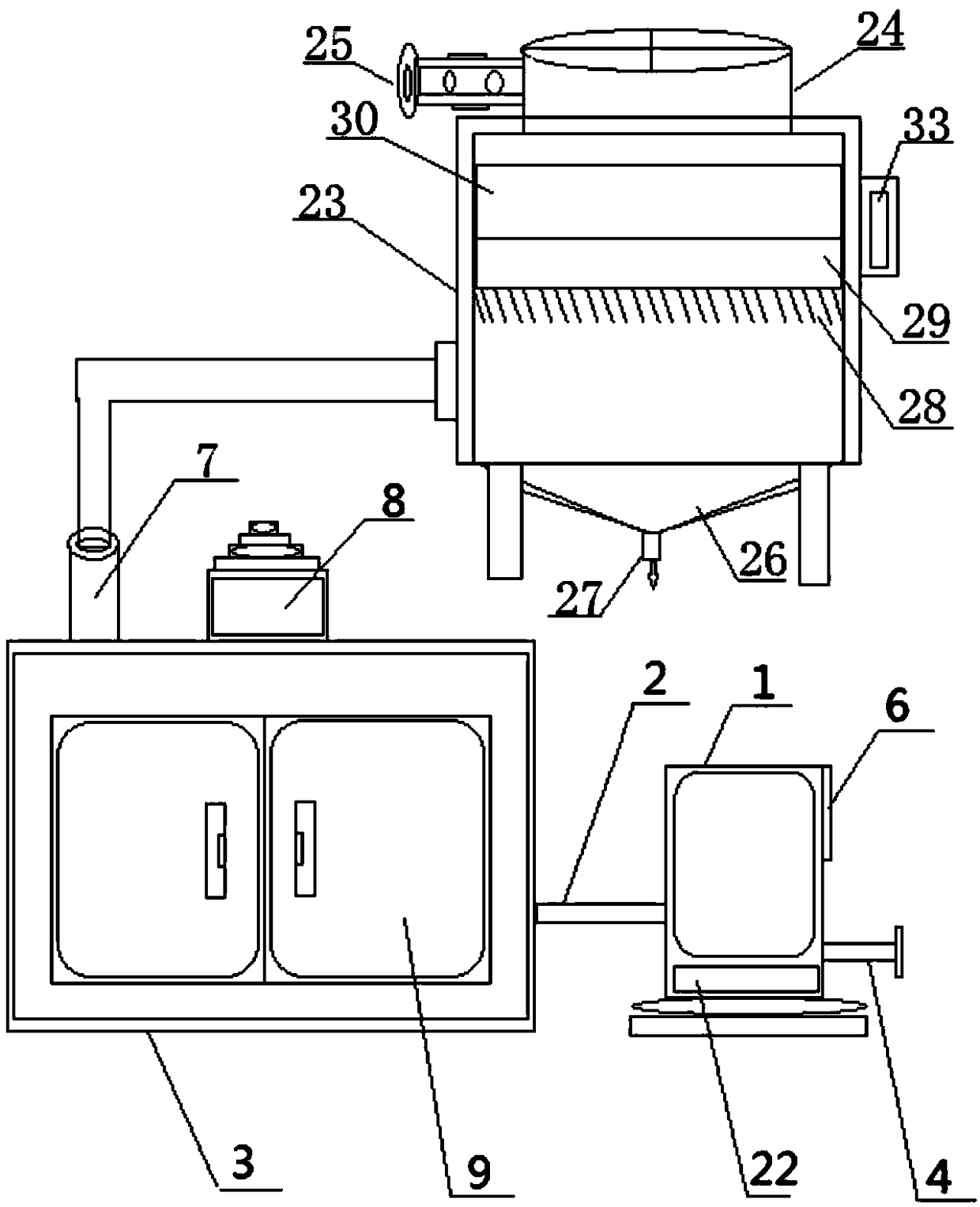

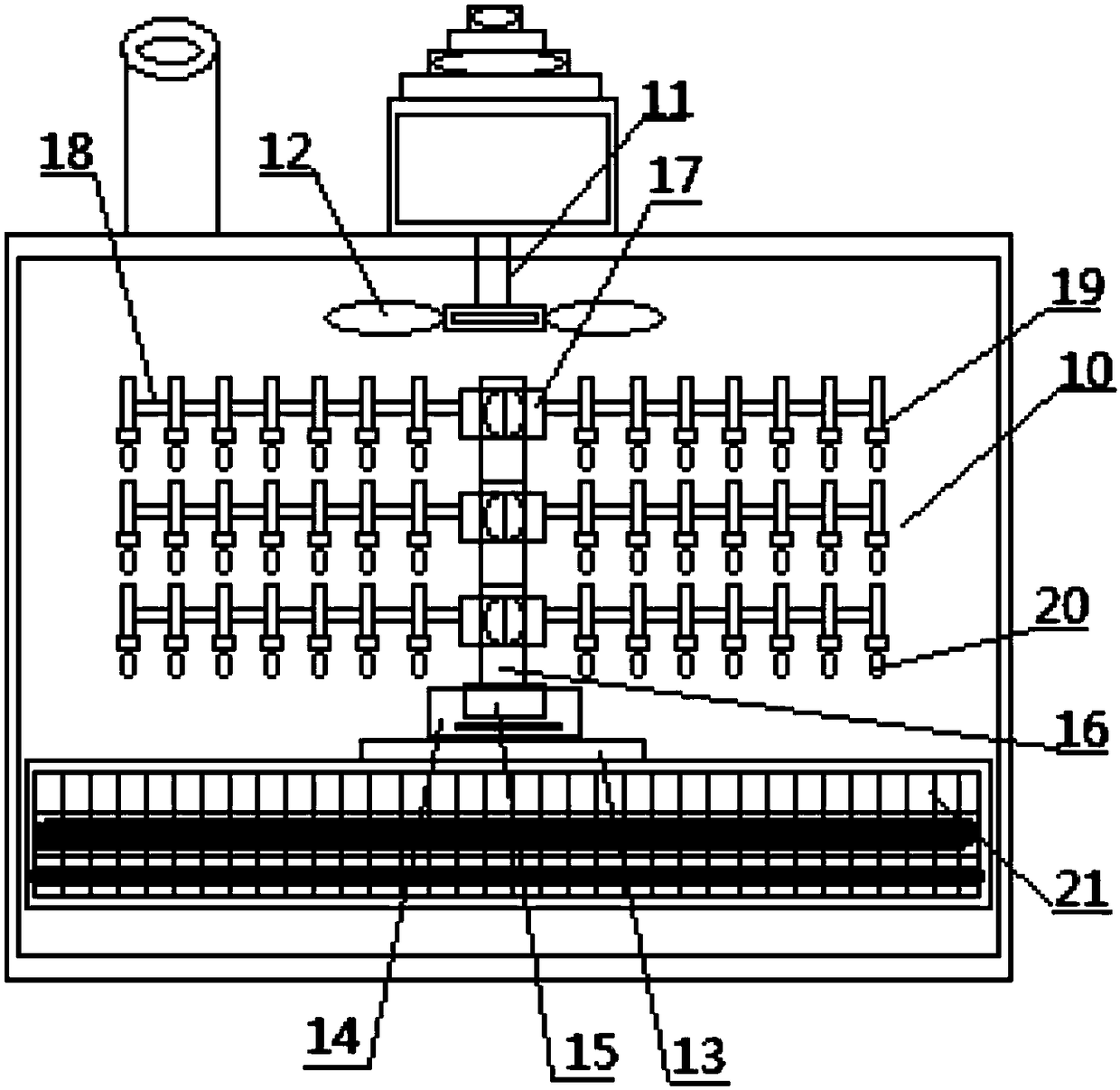

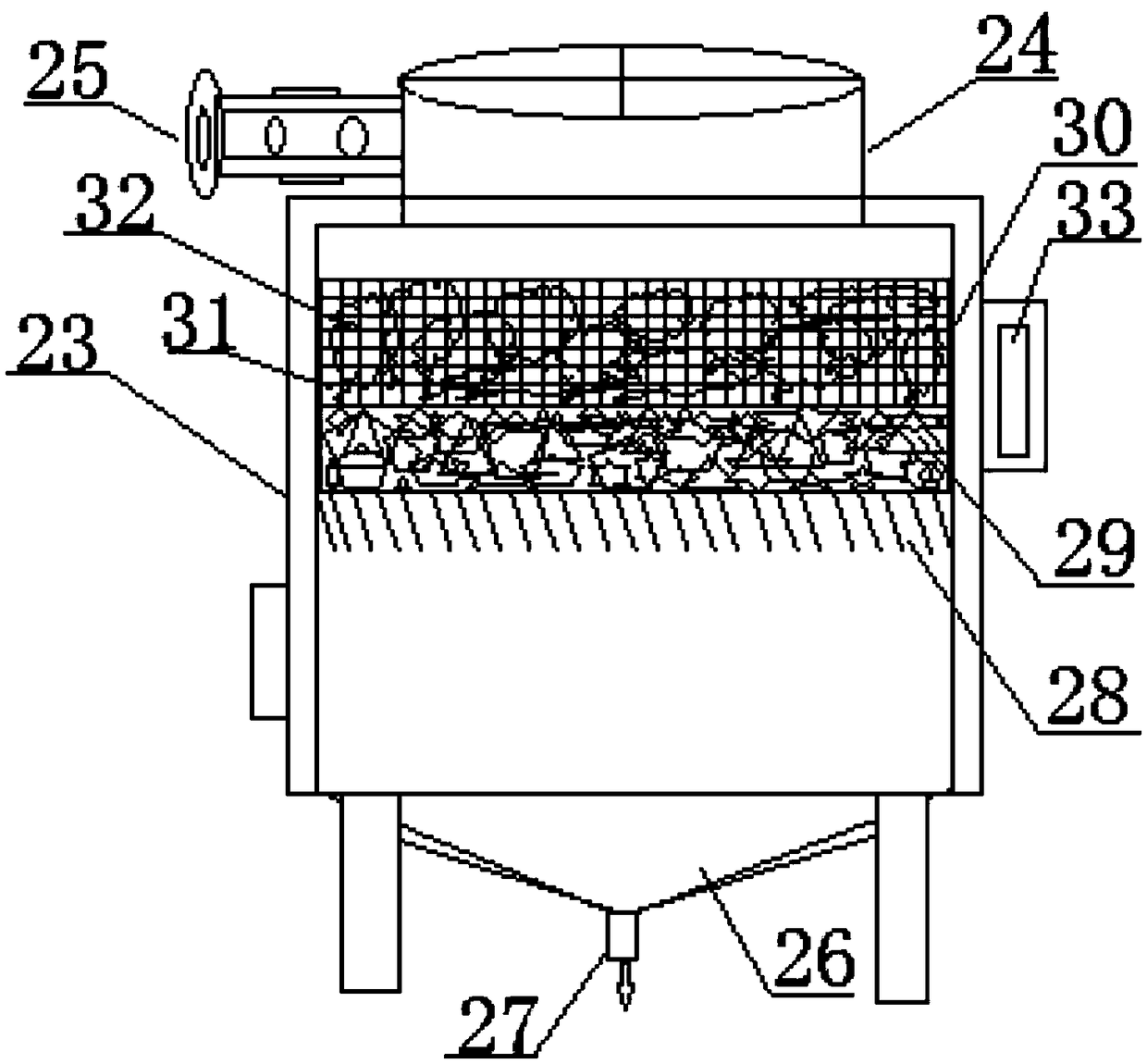

Continuous production method of insoluble sulfur

InactiveCN103193205AGuaranteed batch stabilityAvoid pollutionSulfur preparation/purificationPhysical chemistryEngineering

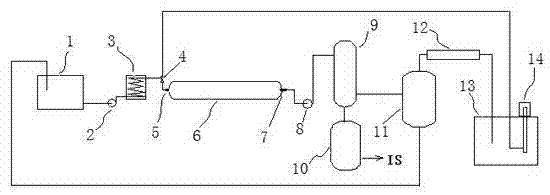

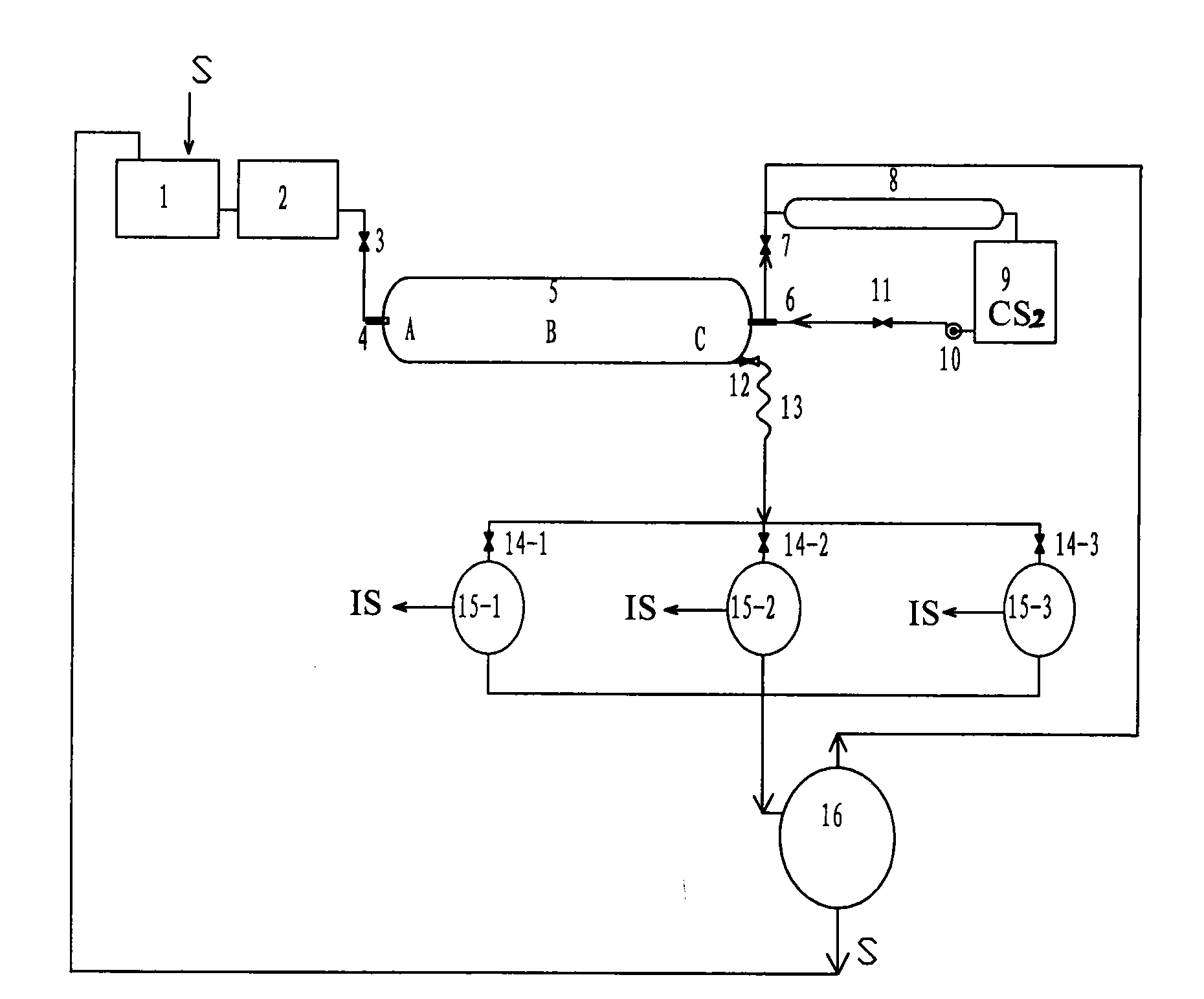

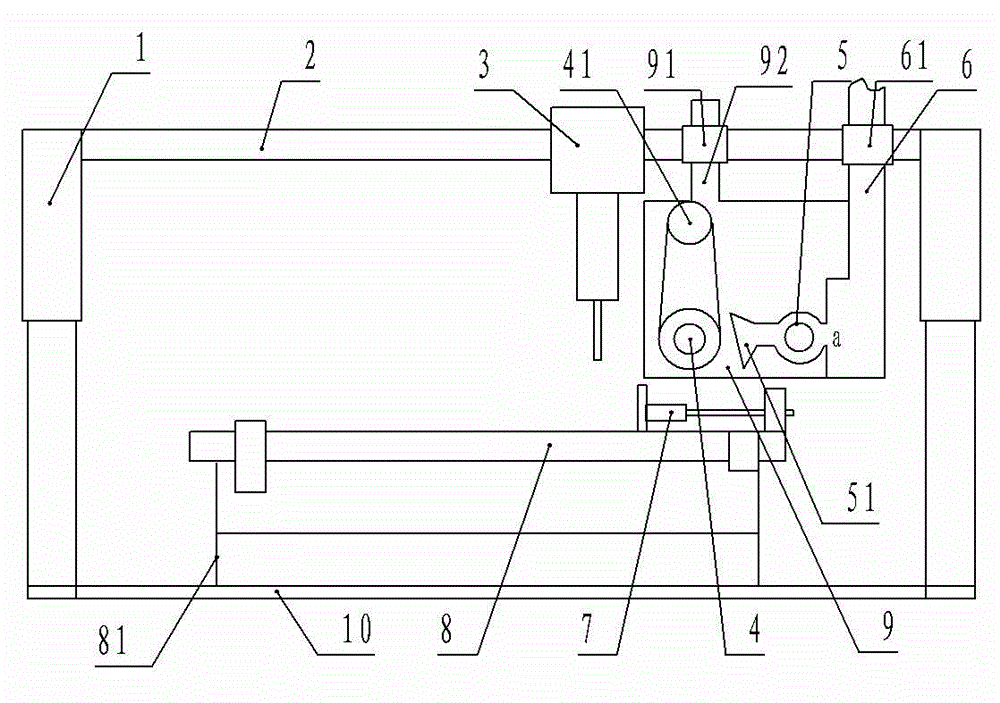

A continuous production method of insoluble sulfur comprises the steps of sulfur melting, extraction, curing, crushing and drying. The continuous production method of insoluble sulfur is carried out under a totally closed condition. The method concretely comprises the following steps: 1, placing sulfur in a sulfur melting pool (1), melting, pumping the molten sulfur to a heating coil tube (3) through a metering pump (2), heating, and mixing high-temperature sulfur with low-temperature carbon disulfide in an ejector (4) to complete quenching; 2, letting the quenched mixed liquid comprising insoluble sulfur and carbon disulfide into a continuous-rotation rotary kiln (6) through a rotary joint (5) to form a mixed liquid containing cured insoluble sulfur particles and carbon disulfide; 3, conveying the mixed liquid obtained in step 2 to a crushing pump (8), and crushing; 4, sending the mixed liquid containing crushed insoluble sulfur and carbon disulfide to a material crushing pot (9), and carrying out solid-liquid separation through a filter screen; and 5, sending insoluble sulfur to a vacuum dryer (10), and drying. The method has the advantages of continuous production of the insoluble sulfur under the totally closed condition, safety, environmental protection, stable product quality, high efficiency, and low energy consumption.

Owner:江西恒兴源化工有限公司

Method for producing insoluble sulfur

InactiveCN101337660AProduction safety and environmental protectionAvoid pollutionSulfur preparation/purificationSulfurNitrogen

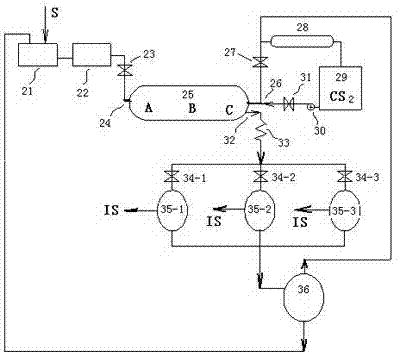

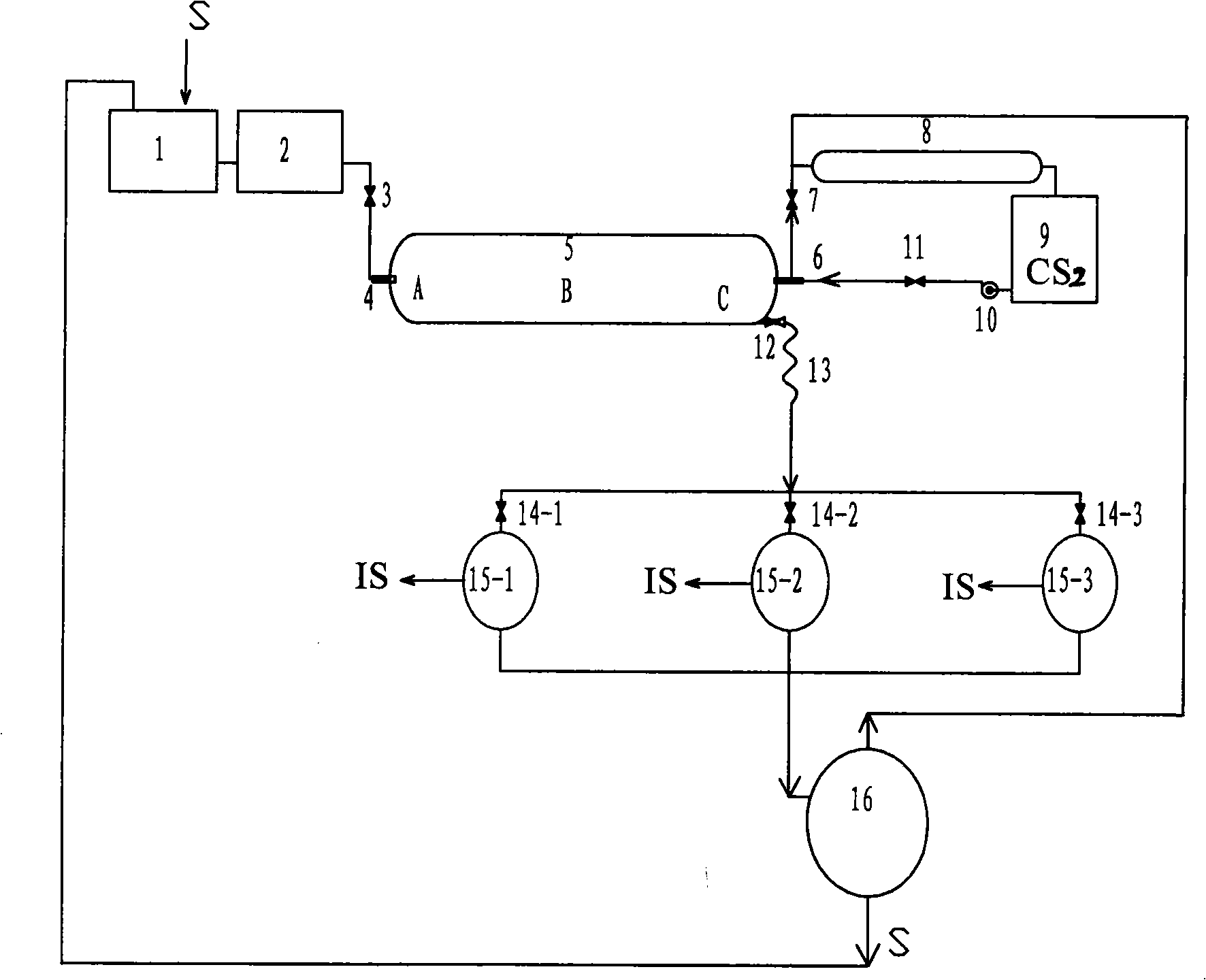

The invention discloses a method for producing insoluble sulfur, which comprises the steps of melting sulfur, extracting, drying and pulverizing. By using the method, the insoluble sulfur is continuously produced under the totally-enclosed condition of normal pressure, nitrogen of normal pressure is used for sealing a heating groove, and the extracting step and the pulverizing step are completed in the same reactor. The specific operation steps are as follows in sequence: (1) melting the sulfur and heating up; (2) extracting and pulverizing; and (3) drying to obtain products produced through the method. The method has the advantages that: (1) the insoluble sulfur is continuously produced under the totally-enclosed condition of the normal pressure, and nitrogen is used for sealing the upper space of the sulfur heating groove, thereby resulting in no oxide leakage of carbon bisulfide and sulfur, and achieving safe and environmental-friendly production; (2) the pulverizing and quenching processes are finished in the same multifunctional rotary reactor, thus saving pulverizing devices, avoiding dust pollution when pulverizing, and protecting production environment.

Owner:广州市烨荣贸易有限公司

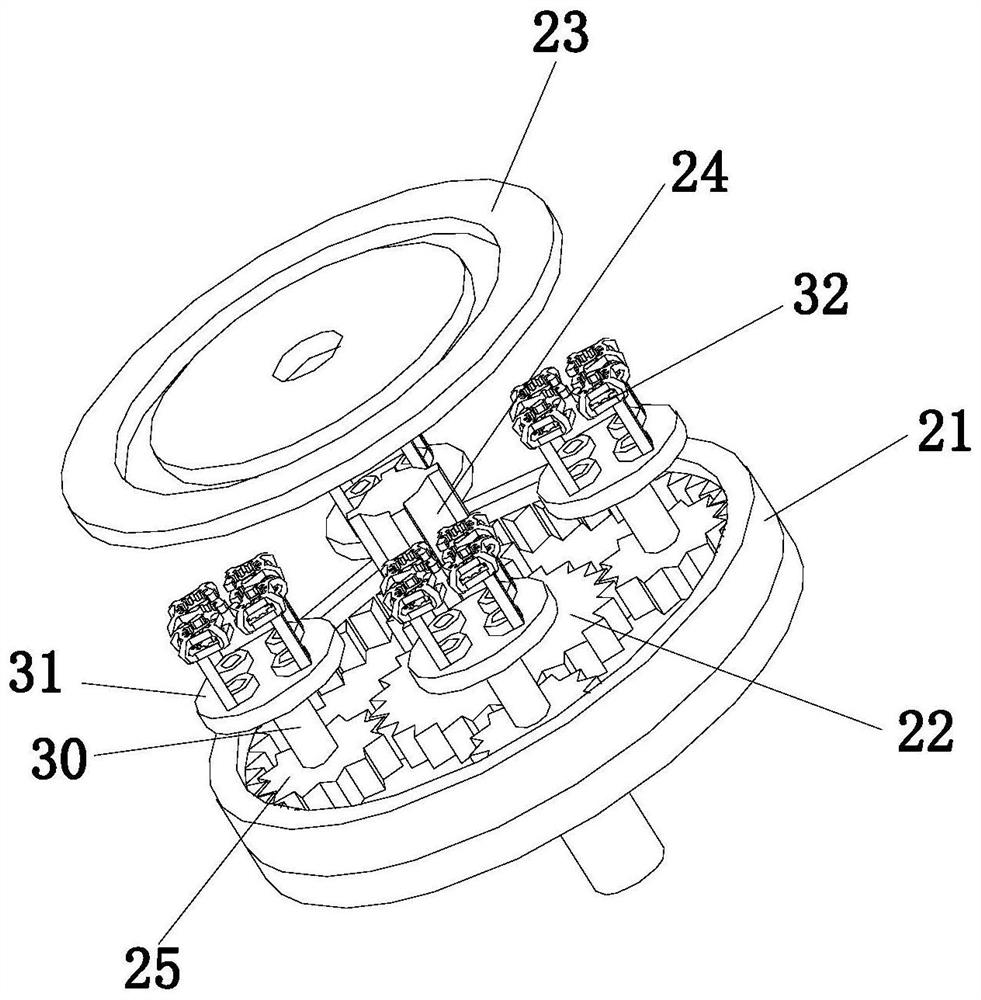

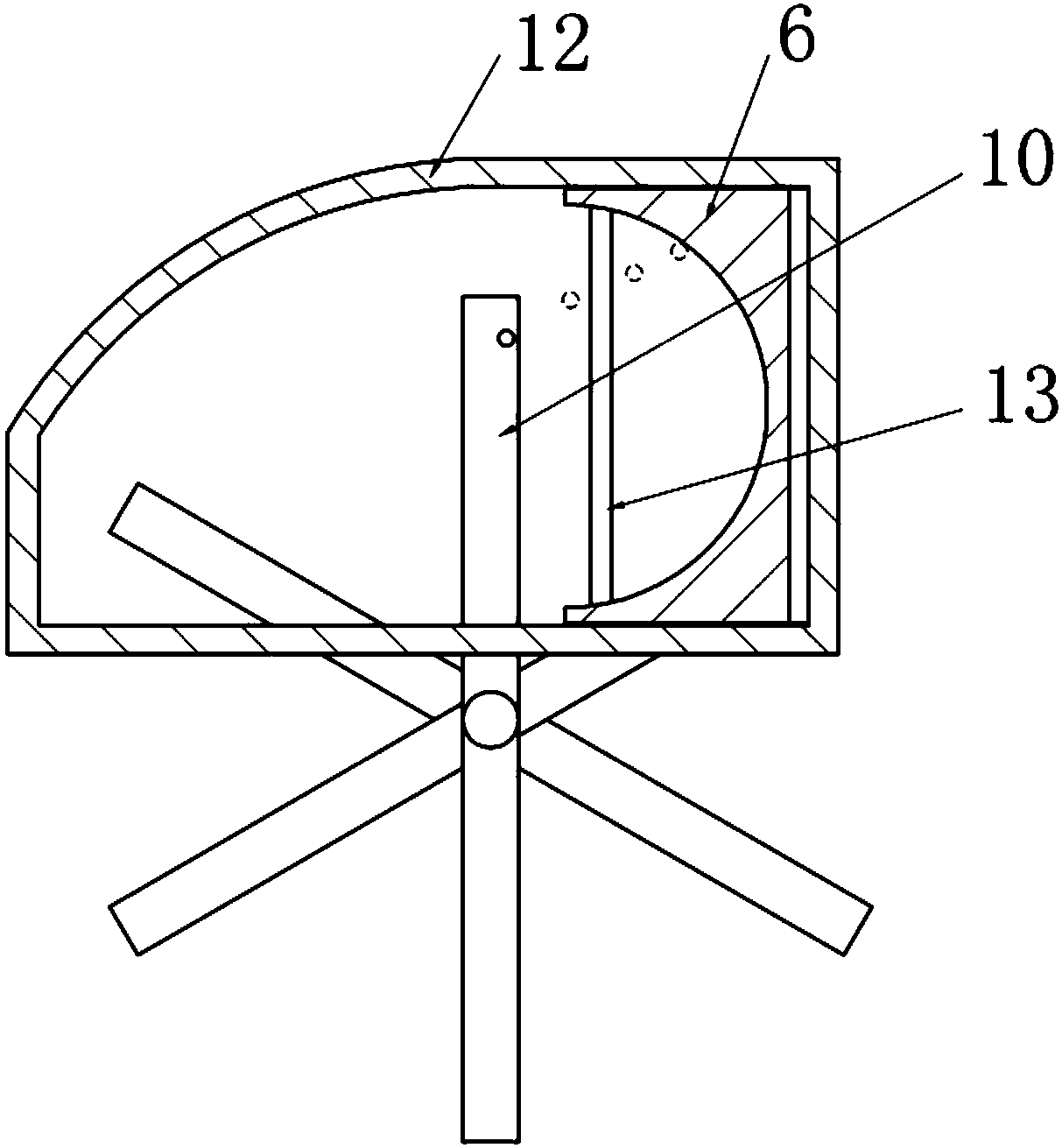

Stem cell centrifugal device

InactiveCN112371354AImprove centrifugation efficiencyQuality improvementCentrifugesHematological testEngineering

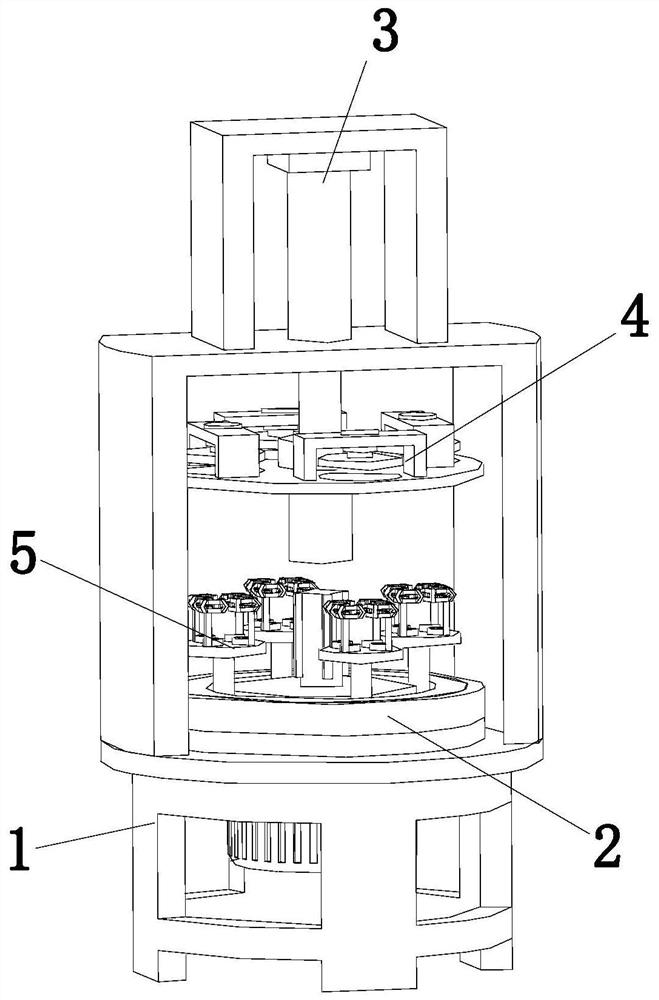

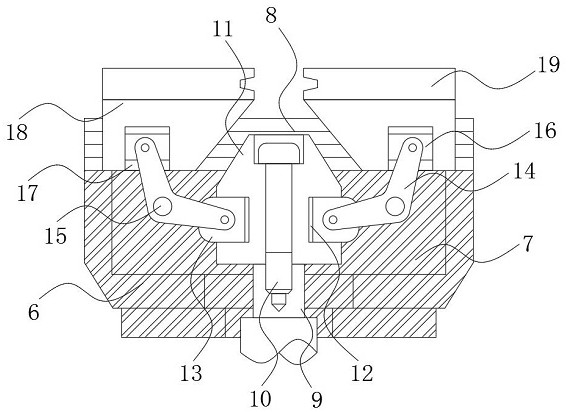

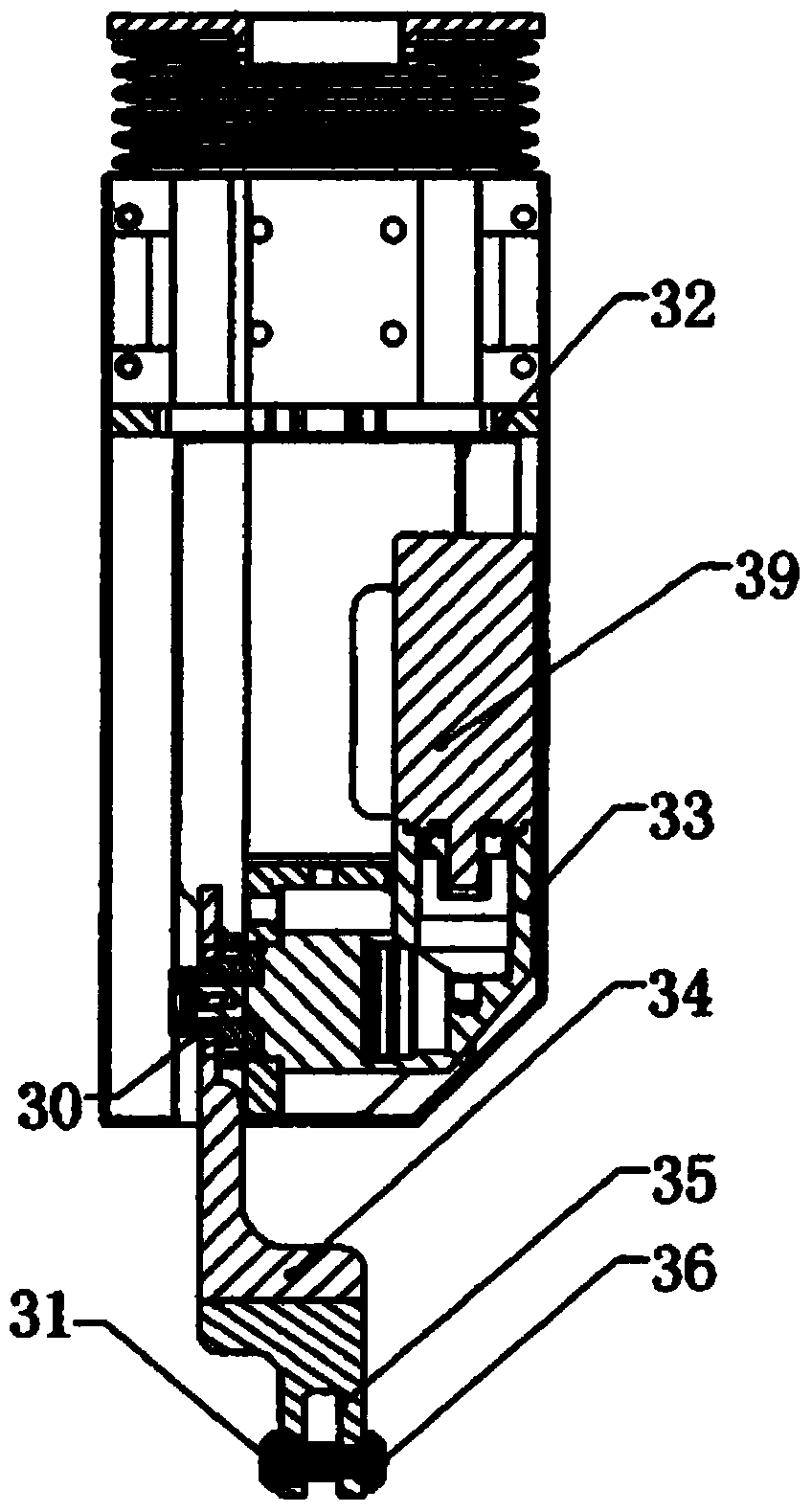

The invention discloses a stem cell centrifugal device, and belongs to the technical field of stem cell centrifugation. The stem cell centrifugal device comprises a supporting and fixing device, a rotating device, a downwards-pressing device, a rotating plate cover and four centrifugal device bodies, wherein the supporting and fixing device is arranged on a horizontal plane, the rotating device isarranged at the top of the supporting and fixing device, the four centrifugal device bodies are distributed and mounted on the top of the rotating device in a rectangular shape, the downwards-pressing device is mounted at the upper end of the supporting and fixing device and located on the upper portion of the rotating device, and the rotating plate cover is mounted at the lower end of the downwards-pressing device. According to the stem cell centrifugal device, a test tube containing stem cell blood can be firmly fixed through the four centrifugal device bodies, then a test tube opening is sealed through the downwards-pressing device and the cover rotating plate, the centrifugal device bodies are pushed through the rotating device to centrifuge the stem cell blood, and therefore the device is high in centrifugal efficiency on the stem cells in the blood, and good in centrifugal effect, meanwhile, splashing is not likely to happen in a routine process, environmental protection and lowcost are achieved, and stability during centrifugation is good.

Owner:杨慧慧

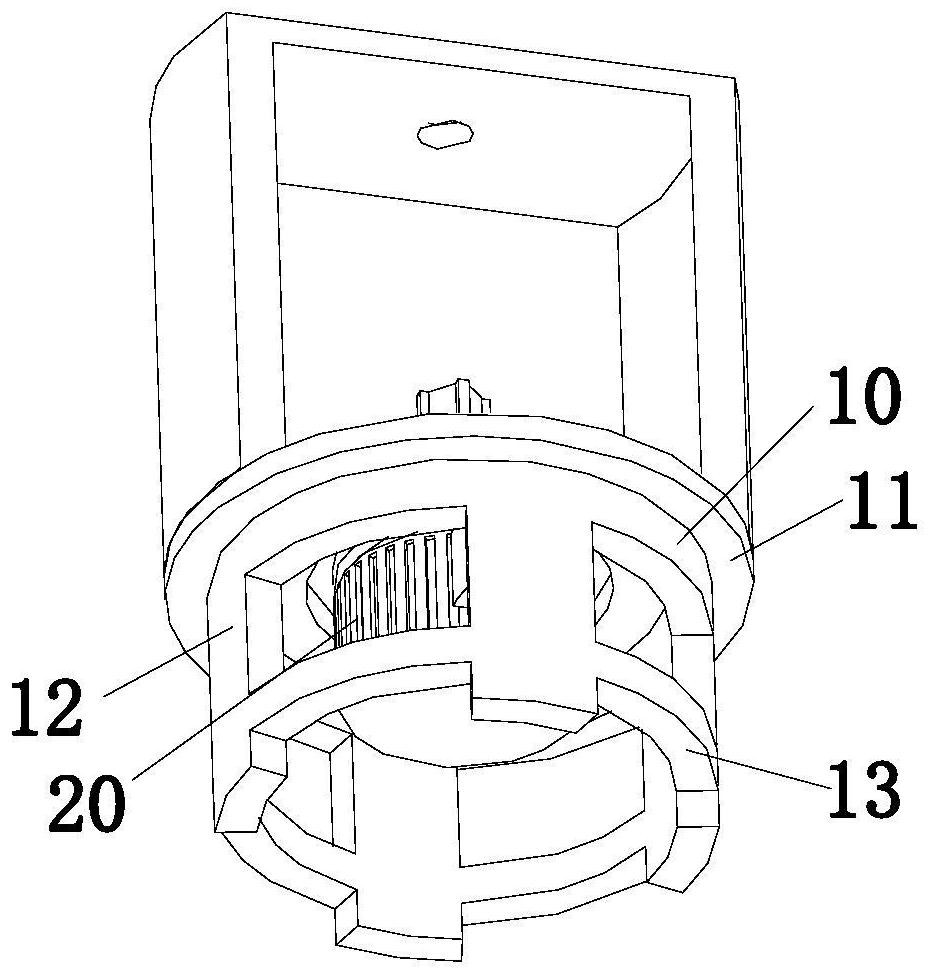

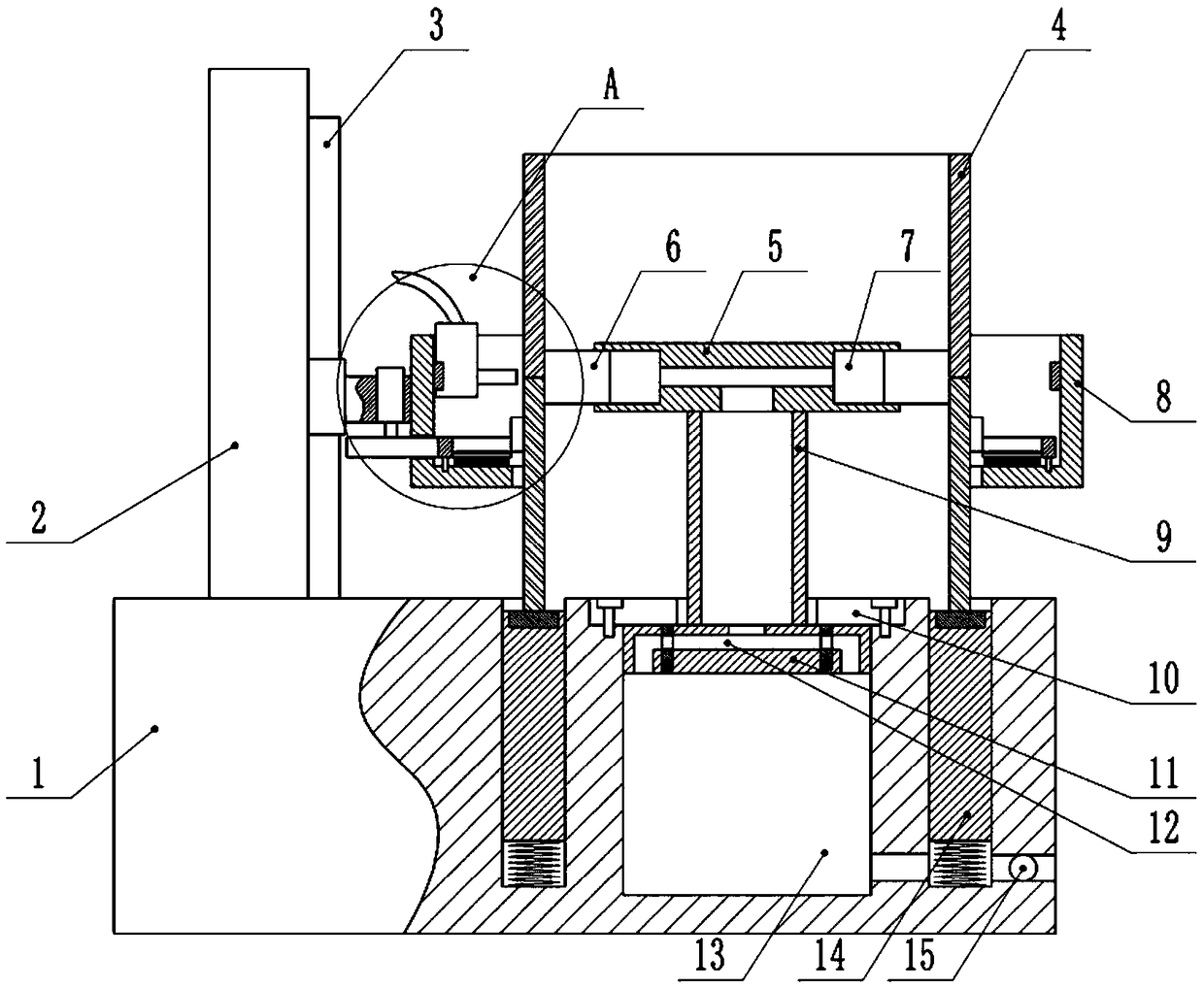

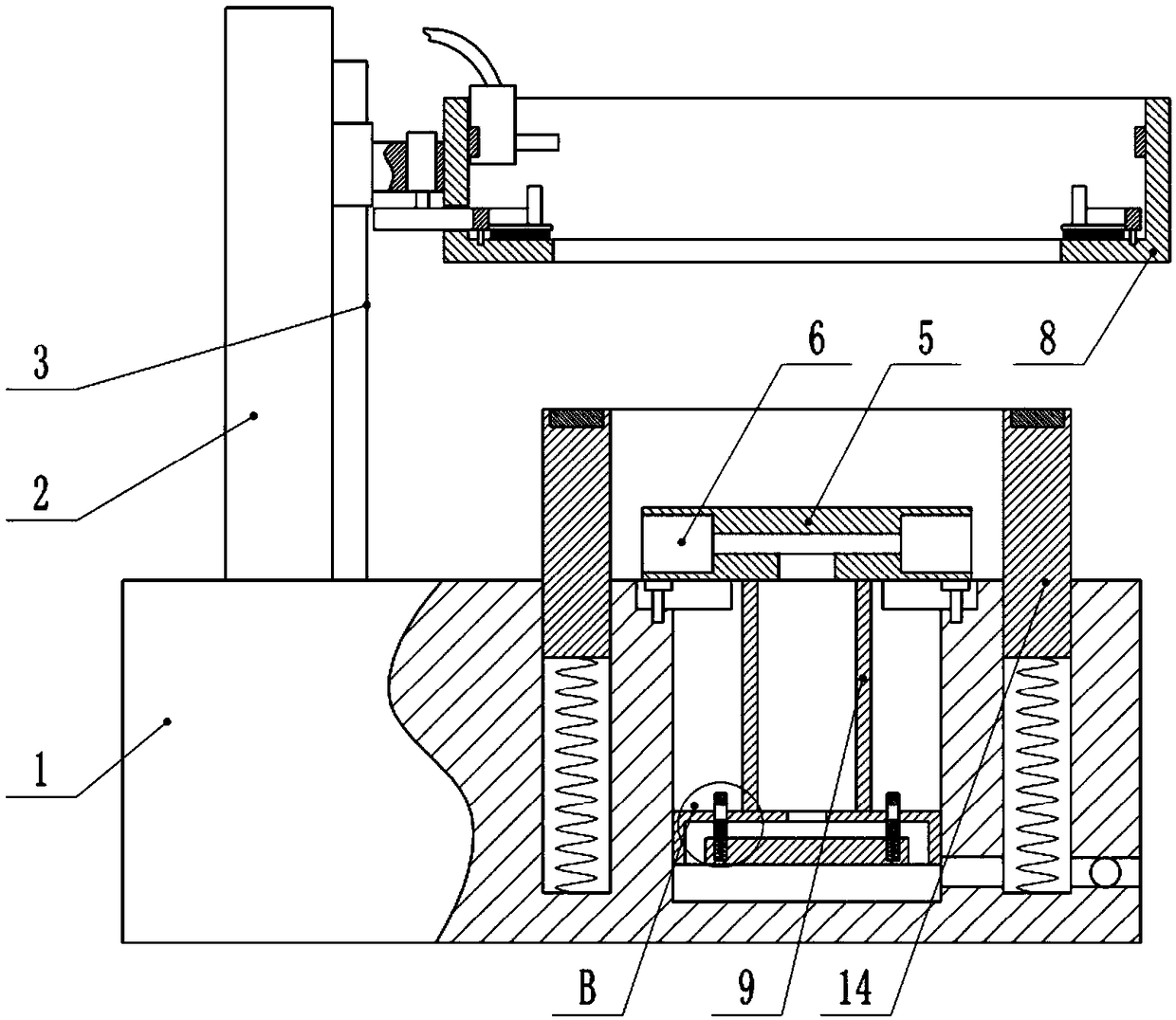

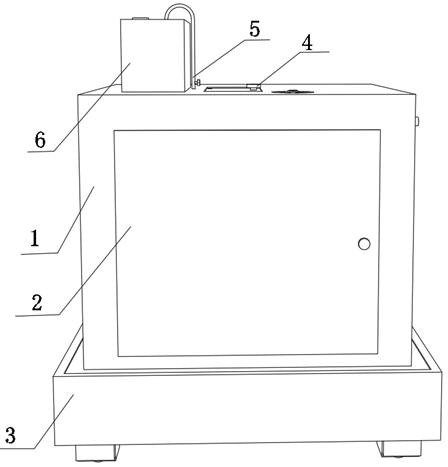

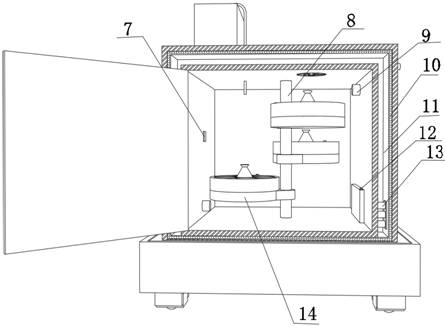

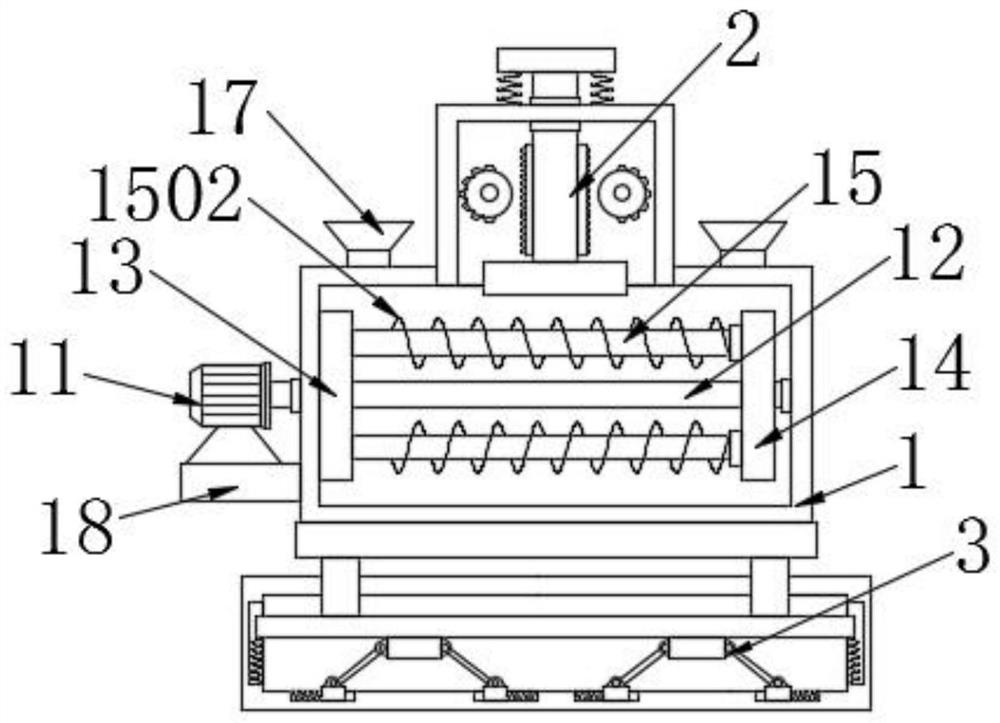

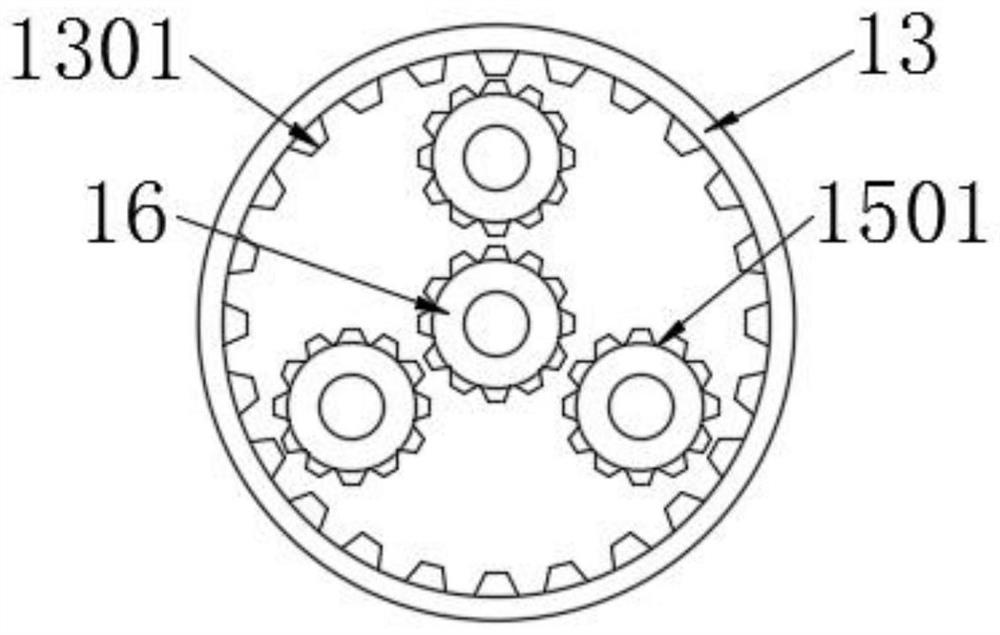

Synchronous gear ring machining-oriented production equipment with depth measurement function

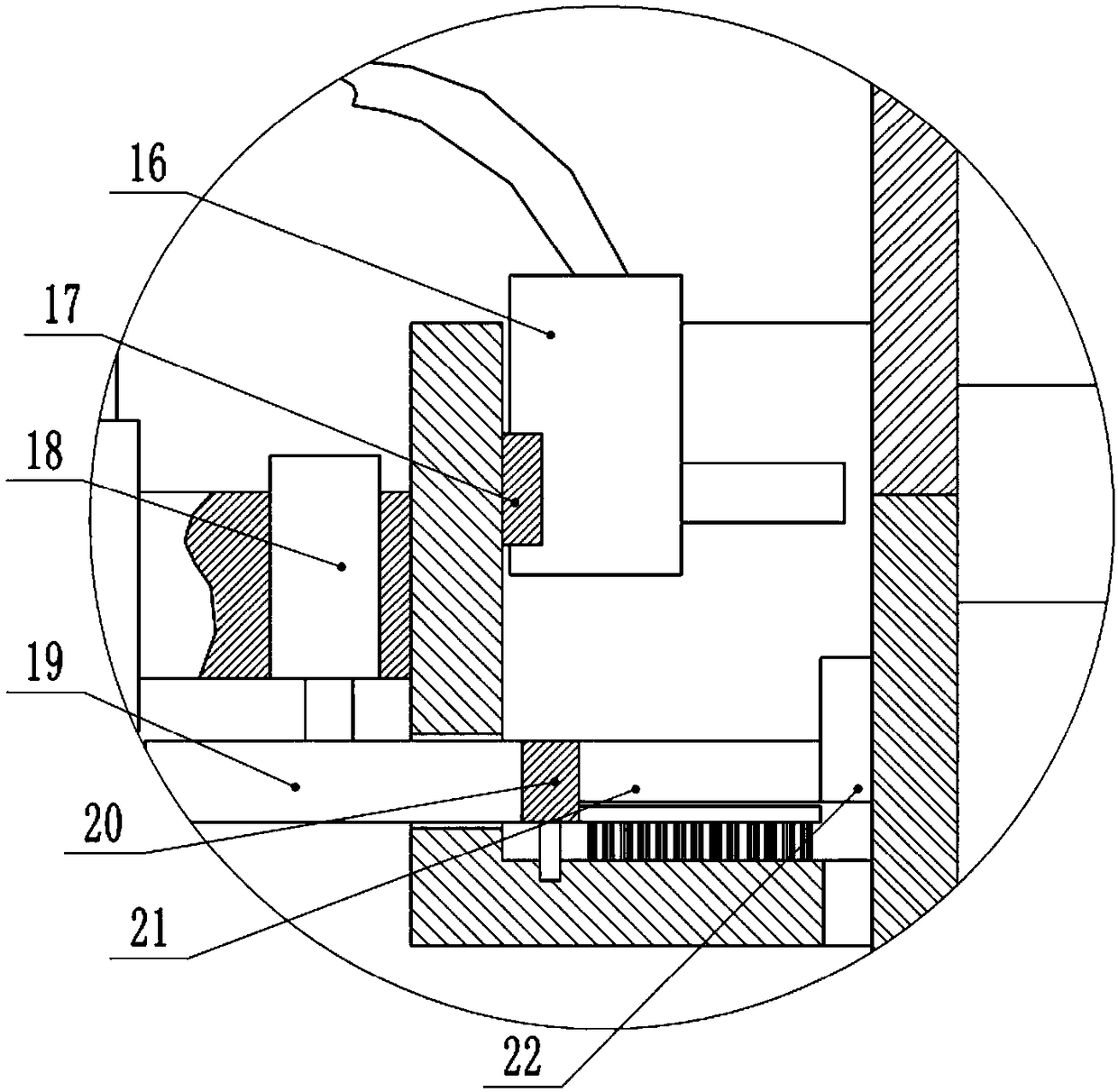

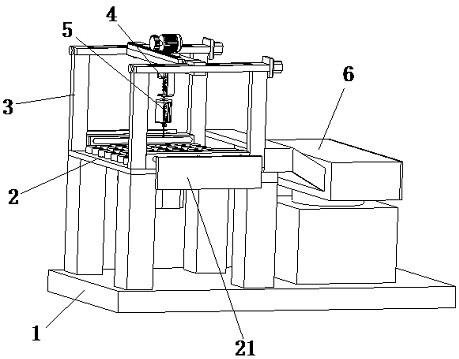

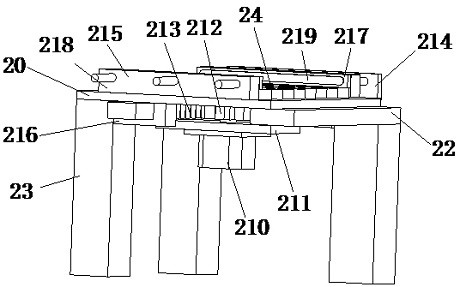

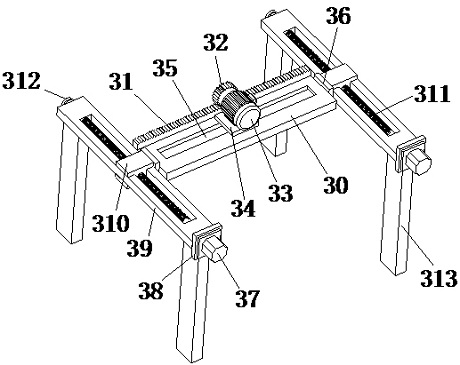

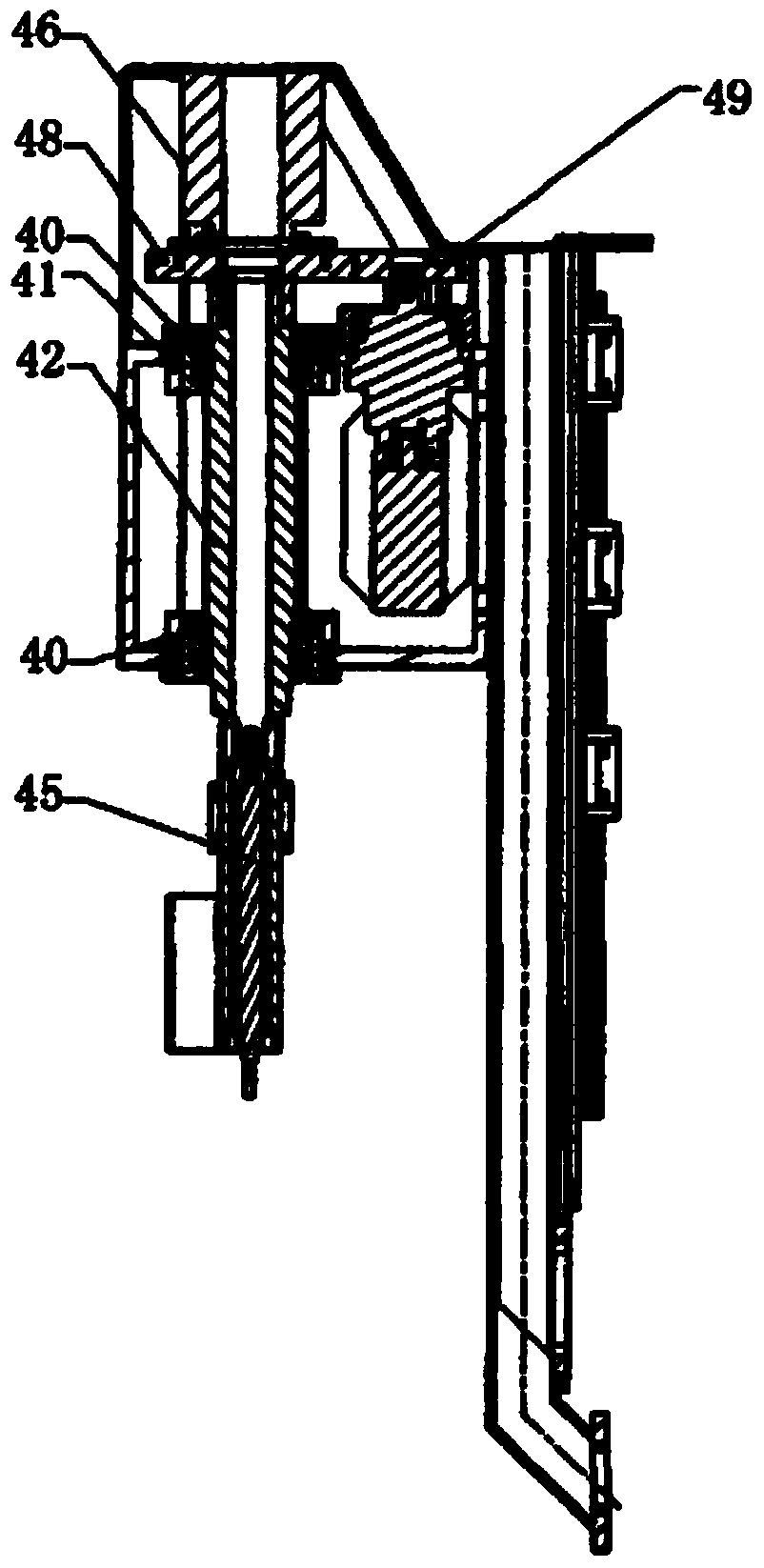

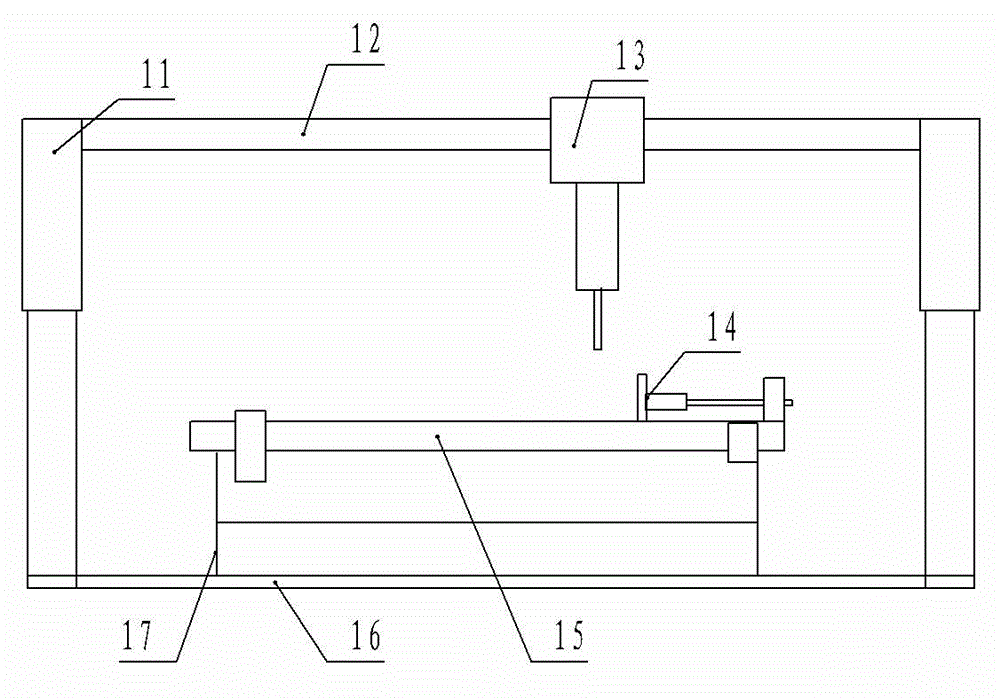

InactiveCN112197735AWith depth measurement functionExtended maintenance intervalsMeasurement devicesWork holdersMotor vehicle partControl engineering

The invention discloses asynchronous gear ring machining-oriented production equipment with a depth measurement function and belongs to the technical field of automobile part detection. The equipmentcomprises a base, a self-centering lever clamp, a linear guide rail lead screw mechanism, a synchronous belt clutch mechanism and a depth and inner diameter measuring mechanism; a control end is arranged at one end of the base; the top end of a support is provided with a ram. According to the synchronous gear ring machining-oriented production equipment with the depth measurement function, a depthand inner diameter measuring mechanism is arranged, the linear guide rail screw rod mechanism assists the depth and inner diameter measuring mechanism to descend to a specified height under the guidance of a fixing pin to accurately and quickly measure the depth of an inner cavity of a synchronous gear ring material, and then a worm is separated from a spiral sleeve under the action of the worm and threaded hubs to drive an elastic pin to expand and deform, so that the inner diameter of the synchronous gear ring material can be measured. The flow design is adopted, the speed and precision arehigh, rapid conveying detection of large-batch materials can be achieved through the continuous conveying of a conveying belt, so that the production efficiency is greatly improved.

Owner:深圳市辉迪机电科技有限公司

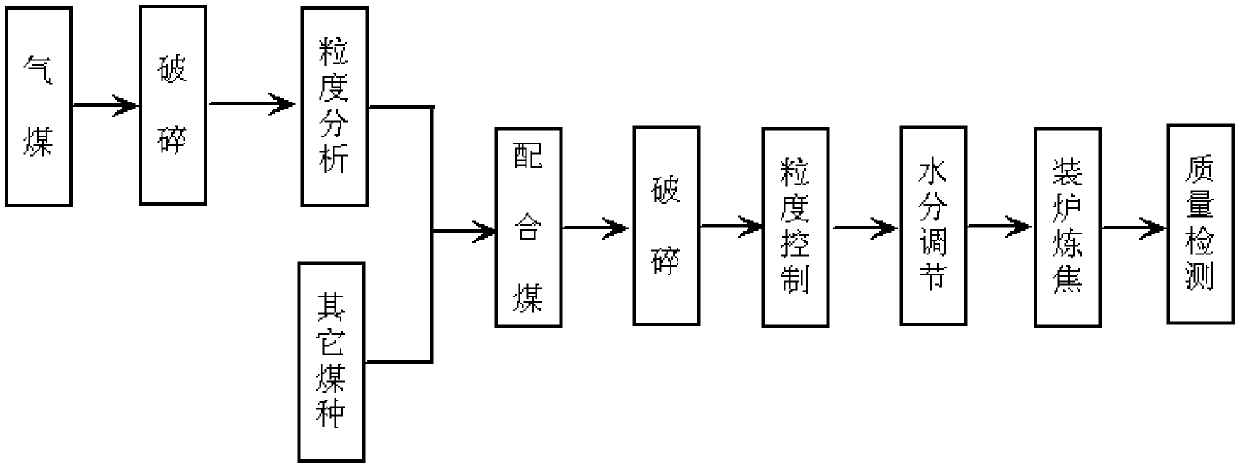

Method for improving cold strength of coke

InactiveCN110607184AIncrease cold strengthImprove quality requirementsCoke ovensMass ratioGranularity

The invention discloses a method for improving the cold strength of coke, which comprises the following steps: 1, gas coal crushing: gas coal with the granularity of less than 6 mm from a production plant is fed into a crusher for crushing, performing screening analysis on the granularity of the gas coal after crushing according to the requirement of the proportion of the granularity of less than3 mm in the crushed gas coal to be 48-53%; 2, blending of blended coal: the crushed gas coal is blended with 1 / 3 coking coal, fat coal and lean coal according to the requirements of coal blending, themass ratio of the gas coal in the whole blended coal is 25.5-27%, the ash content Ad of the blended coal is 8-10%, and the volatile matter VMd of the blended coal is 26-28%; 3, crushing and mixing ofthe blended coal: the blended coal is added into a crusher for repeated crushing, the groove spacing of the crusher is 3-4 mm, and the mass ratio of the blended coal with the particle size smaller than 3 mm after crushing is 84-86%; and 4, moisture adjustment and preparation of high-strength coke.

Owner:BAOSHAN IRON & STEEL CO LTD

Welding device for incinerator manufacturing

ActiveCN108994499AEasy to operateConvenient for centralized processingWelding/cutting auxillary devicesAuxillary welding devicesSlagEngineering

The invention belongs to the technical field of welding and particularly discloses a welding device for incinerator manufacturing. The welding device comprises a base; a supporting plate is fixedly mounted on the base; a slag collecting box is disposed on the supporting plate; a welding head is rotationally disposed in the slag collecting box; a clamping mechanism and a driving mechanism which isused for driving the clamping mechanism to rotate are disposed on the slag collecting box; a columnar cavity and an annular cavity are formed in the base; an annular plate is slideably mounted in theannular cavity; first elastic parts are arranged between the annular plate and the annular cavity; a movable body is slideably mounted in the columnar cavity; an air cavity is formed in the movable body; sliding cavities are formed in the side wall of the movable body; positioning blocks are slideably mounted in the sliding cavities; air channels which communicate with the columnar cavity are formed in the lower portion of the air cavity; plug bodies are slideably mounted on the air channels; second elastic parts are connected between the plug bodies and a movable column; notches which can communicate with the air channels are formed in the plug bodies; and stop blocks are disposed on the base. By means of the scheme, during welding, automatic alignment of two sections of a furnace body can be achieved, collection of welding slag can be achieved, and the whole working efficiency is improved.

Owner:CHONGQING SHANGZE ELECTROMECHANICAL

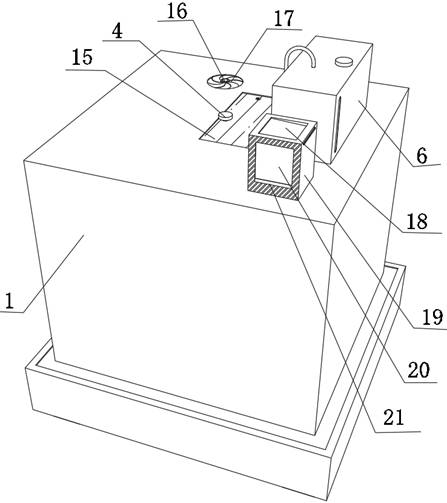

Cutting device for gypsum brick production

PendingCN112571644AEasy to changeSave human effortWorking accessoriesStone-like material working toolsBrickMining engineering

The invention discloses a cutting device for gypsum brick production, and belongs to the technical field of gypsum brick cutting, The cutting device comprises a floor, a bearing assembly, a moving assembly, a lifting rotating assembly, a cutting assembly and a dust collection assembly, wherein the floor is laid on the horizontal plane, the bearing assembly is vertically installed on the floor, themoving assembly is vertically installed at the top of the bearing assembly, the lifting rotating assembly is installed at the bottom of the moving assembly, the cutting assembly is installed at the bottom of the lifting rotating assembly and located at the upper end of the bearing assembly, one end of the dust collection assembly is installed on the back face of the bearing assembly, and the other end of the dust collection assembly is arranged on the floor. According to the cutting device for gypsum brick production, gypsum bricks can be cut through the assemblies, the radian direction can also be changed in the cutting process, meanwhile, dust generated in the cutting process is absorbed, high-efficiency and high-level cutting can be achieved, dust can be prevented from polluting the production environment, and the cutting device is quite environmentally friendly.

Owner:常德环创力达环保科技有限公司

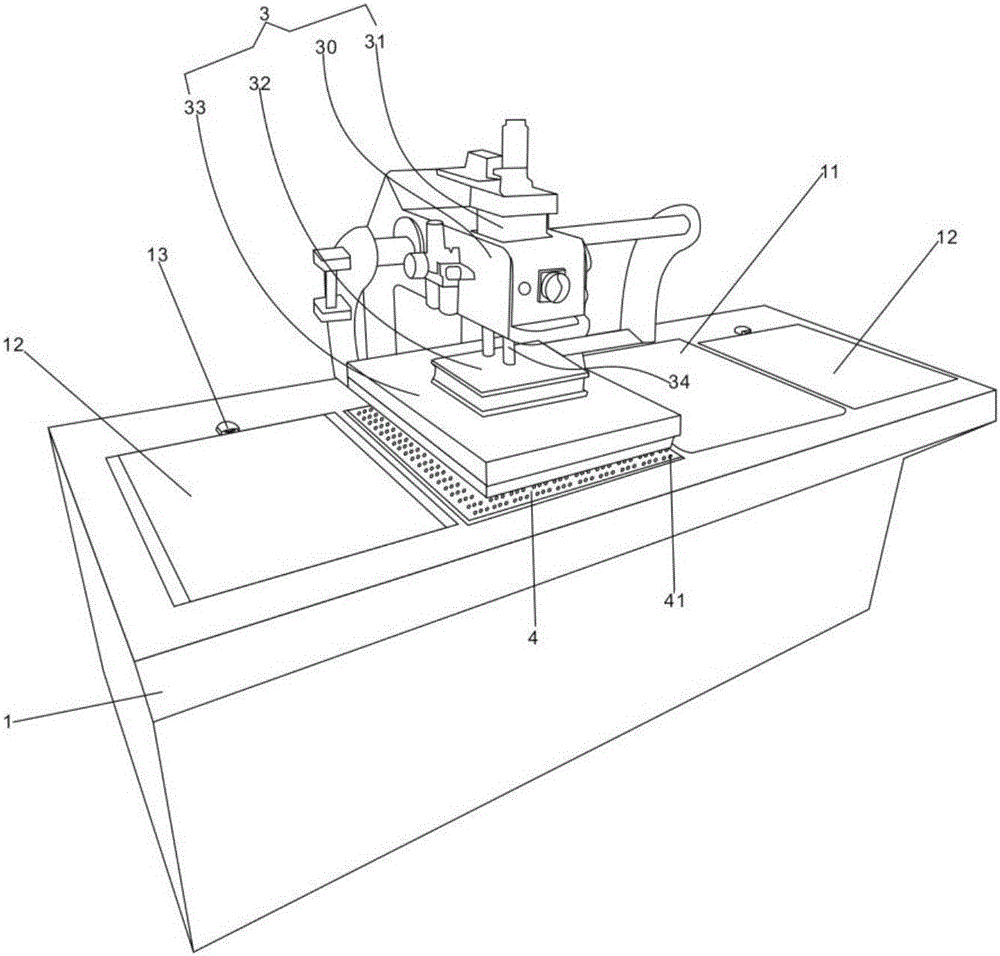

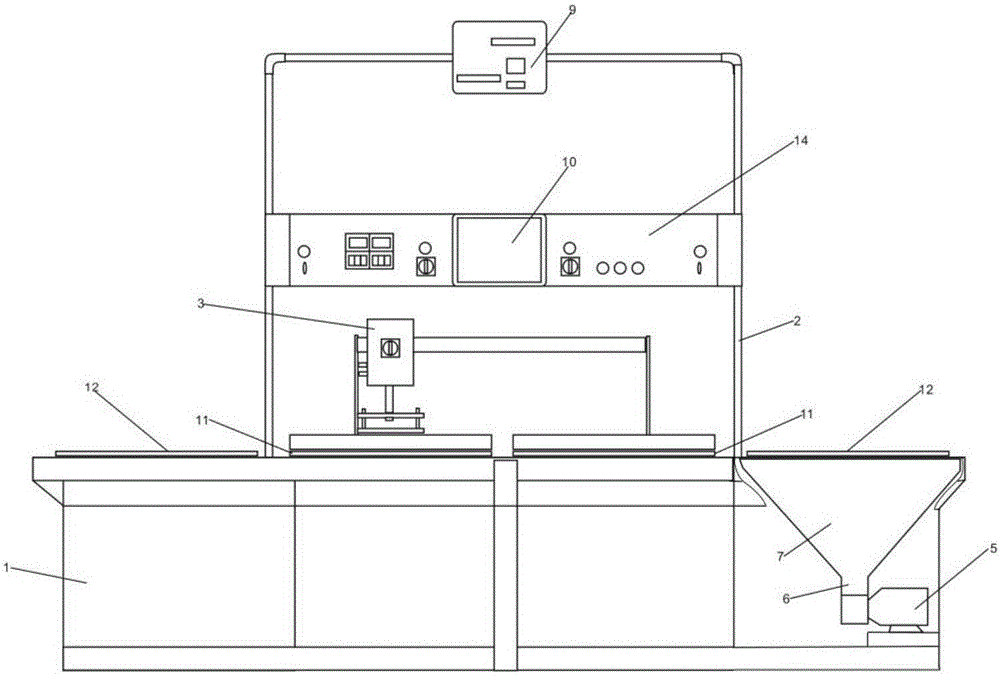

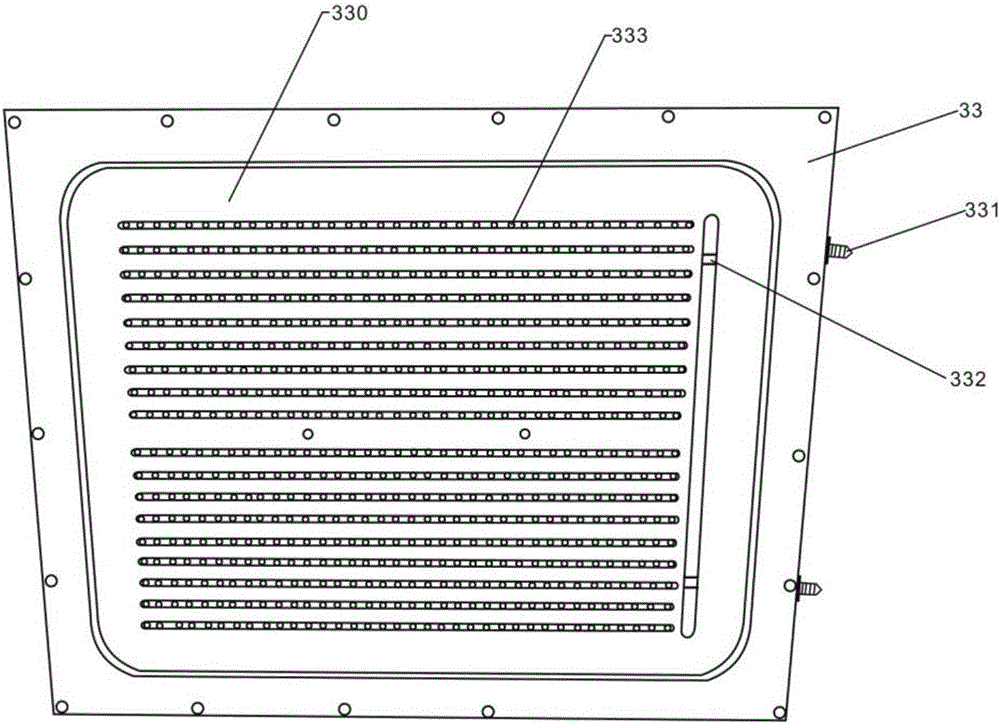

Fully-woven upper sheet ironing setter

InactiveCN106676805AImprove thermal conductivitySmall coefficient of thermal expansionHeating/cooling textile fabricsLight touchSetter

The invention discloses a fully-woven upper sheet ironing setter which comprises a workbench, a machine frame, a steam ironing device and a control device, wherein the machine frame, the steam ironing device and the control device are mounted on the workbench; the surface of the workbench comprises ironing regions and cooling regions; emery sheet fixing plates are mounted in the ironing regions, are thin plates of which the surfaces are coated with an emery coating, and are provided with penetration holes; cover lids, air pipes and cooling fans are connected in the workbench at the lower parts of the cooling regions; the steam ironing device is mounted at the upper parts of the ironing regions, and comprises a cylinder base, a cylinder, a lifting plate and a steam ironing plate; light touch push switches are mounted on the edges of the upper ends of the cooling regions, and are connected with a delay control line to control the cooling fans. The ironing setter also comprises a projection control device and a projector, wherein the ironing regions are covered by a projection region of the projector. The emery sheet fixing plates can be matched with sheet fixing claw pieces. According to the ironing setter, an upper sheet can be set more rapidly and smoothly, operation is convenient, the labor intensity and the production cost are reduced, and the production efficiency and benefits are improved.

Owner:金翰

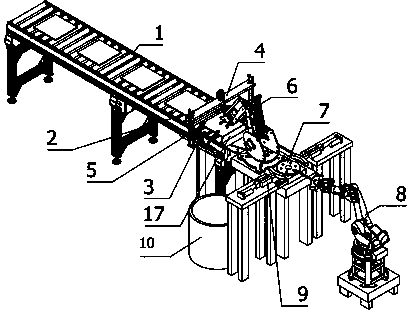

Positioning and cutting edge grinding device for round glass

ActiveCN110666618APrecise positioningEasy to operateEdge grinding machinesWorking accessoriesStructural engineeringMachining

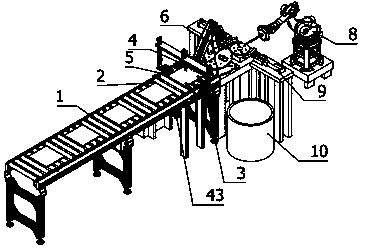

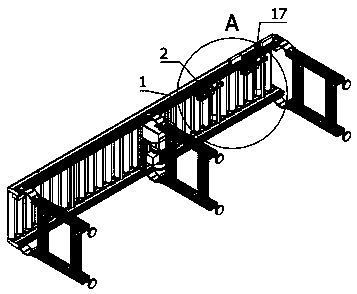

The invention relates to the field of machining, and particularly relates to a positioning and cutting edge grinding device for round glass. The positioning and cutting edge grinding device comprisesa roller conveyor, a first material blocking assembly, a cutting positioning assembly, an annular cutting assembly, a fragment breaking assembly, a material taking manipulator, a rotary table, an edgegrinding manipulator capable of polishing round glass epitaxy at multiple angles, two-group grinding and positioning assemblies and a material receiving box, the grinding and positioning assemblies are symmetrically arranged on the two sides of the rotary table, the material receiving box is arranged at the side of the rotary table, the first material blocking assembly is arranged in the middle of the roller conveyor in a lifting manner, the cutting and positioning assembly is arranged at the output end of the roller conveyor in a lifting manner, the annular cutting assembly is arranged justabove the output end of the roller conveyor in a lifting mode. According to the positioning and cutting edge grinding device, full-automatic production is achieved through positioning and cutting edgegrinding device of the round glass, a series of operations such as cutting, edge grinding, chamfering and the like can be performed on the glass to be processed, the glass to be processed can be accurately positioned, and the glass waste residues can be subjected to centralized recycling treatment.

Owner:福州宏毓建材有限公司

Polishing device for hardware processing

InactiveCN108544331AContinuous and effective heat dissipationSave resourcesGrinding machinesGrinding/polishing safety devicesAir cycleReduction drive

The invention discloses a polishing device for hardware processing, and relates to the technical field of hardware processing. A load bearing plate is included, and the top of the load bearing plate is fixedly connected with a sound insulating frame; the left side of the top of the load bearing plate is fixedly connected with a cold air cyclic refrigerating device, and a dust removing device is fixedly connected with the bottom end in the sound insulating frame; an operation plate with holes is arranged in the sound insulating frame, and the top of the operation plate with holes is fixedly connected with a supporting plate; the left and right sides of the top of the supporting plate are each fixedly connected with a fixed plate, and the left side of the inner wall of the sound insulating frame is fixedly connected with a motor box; and a motor is fixedly connected in the motor box, and an output shaft of the motor is fixedly connected with a polishing wheel through a speed reducer. Thepolishing device for hardware processing achieves the purposes that cyclic cooling of air is achieved, cooling is continuously and effectively performed on the device, liquid nitrogen resources are saved, initial cost is reduced, dust is purified, the protection environment is protected, and the body health of production workers is guaranteed.

Owner:湖州吉斯安机械有限公司

Sanitary and environmentally-friendly smoking apparatus used for producing smoked sausages

PendingCN109430364AEvenly smokedEasy to hangHuman health protectionCombination devicesEngineeringBlowing down

The invention provides sanitary and environmentally-friendly smoking apparatus used for producing smoked sausages, and adapts to large-scale industrial production of smoked sausages. When being in use, the sanitary and environmentally-friendly smoking apparatus used for producing smoked sausages is simple and convenient in sausage hanging process, stable in overall structure, convenient to assemble, and capable of performing smoking on a plurality of sausages. Moreover, the smoking apparatus is capable of ensuring uniform smoking effect on the sausages; sausage-hanging racks are not liable tobe blown down by high wind; and eating of the sausages by birds and polluting of the sausages by flies are also avoided. The smoking apparatus used for producing smoked sausages is capable of performing smoking on a large amount of sausages in one time, so that, production efficiency is improved; smoke flow rate during the sausage smoking process can be raised so as to ensure sausage smoking efficiency; and a smoke production box is arranged, so that, the smoke production box is separated from a smoking box so as to prevent sausages from pollution by ash when combustible materials are being combusted for producing smoke. By performing purification on smoke, possibility of contamination on sausages by smoke is reduced, so that, taste of the sausages can be beneficially guaranteed; moreover,relatively good purification and environment protection effects are achieved by avoiding direct discharge of untreated smoke into the air. Thus, environmental pollution is reduced.

Owner:王程

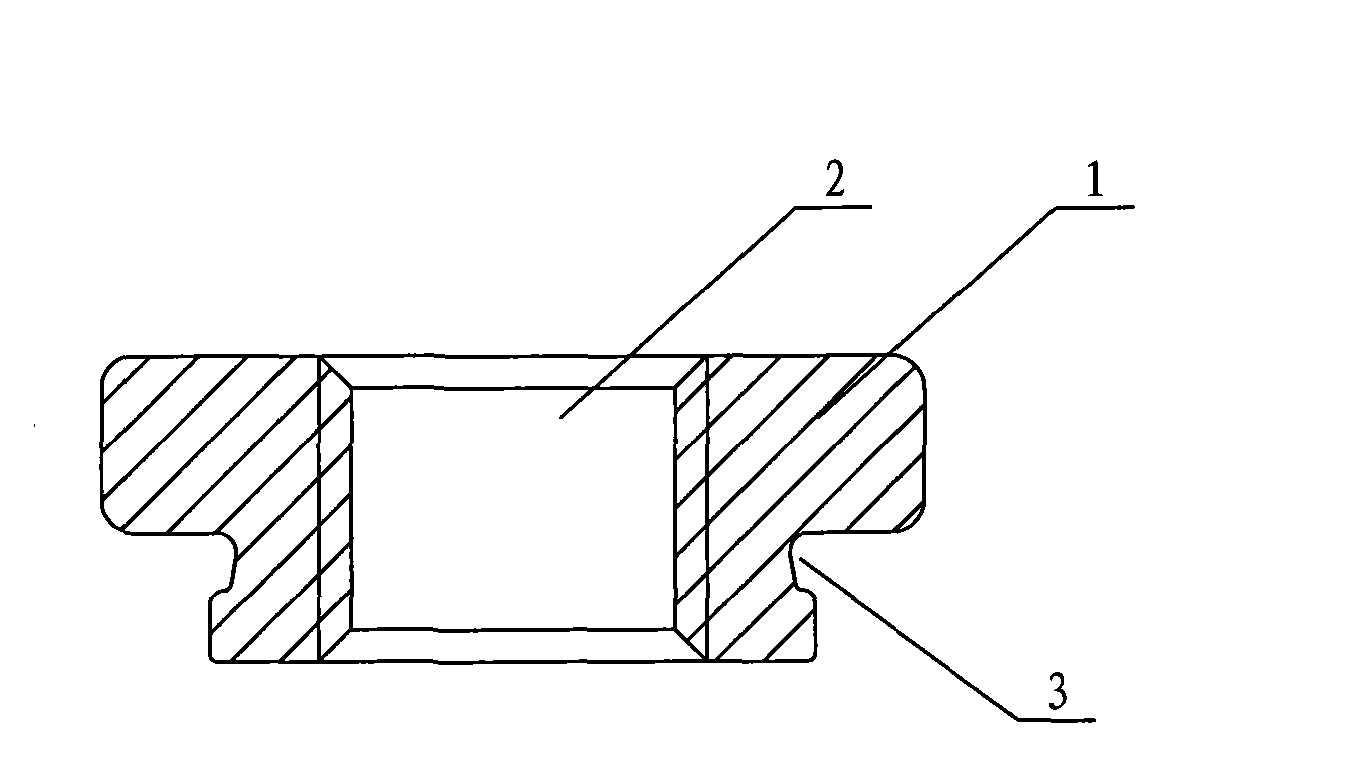

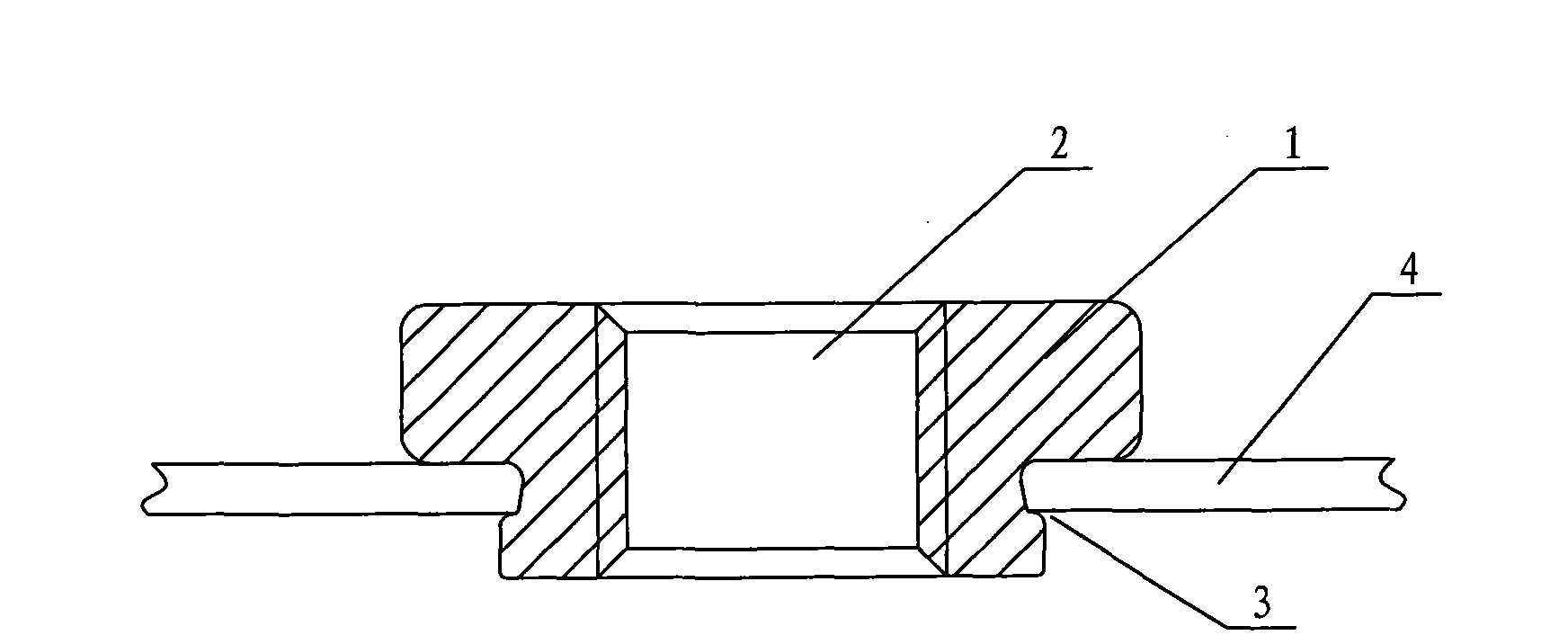

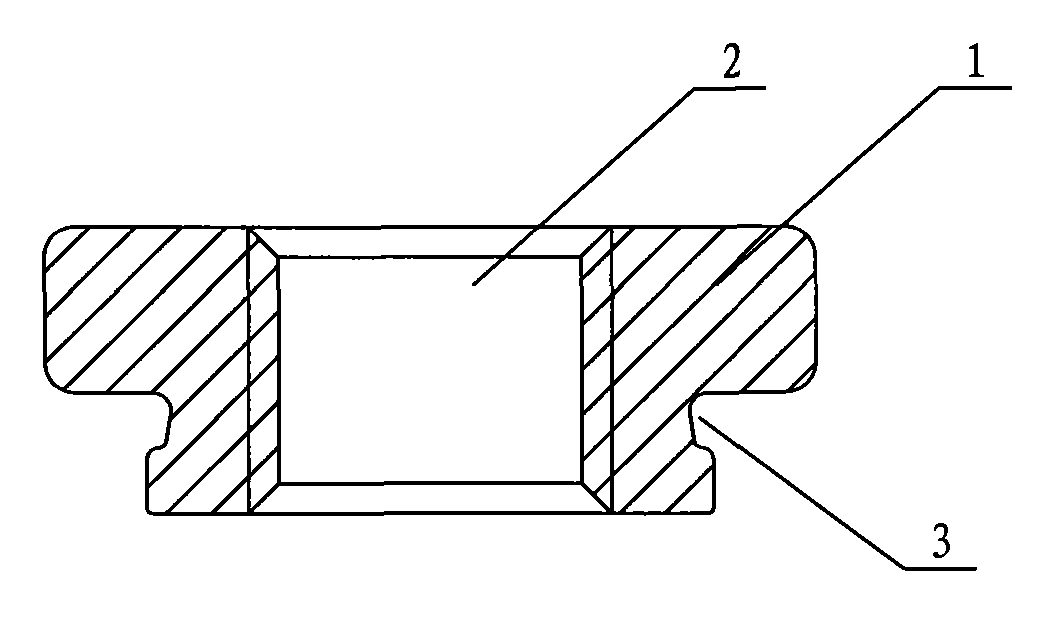

Inlaid nut of self-punching type

InactiveCN102072236AThere will be no damage to the thread mouthProtect the production environmentNutsElectricityPunching

The invention discloses an inlaid nut of self-punching type, comprising a nut body. The nut body is arranged to be a reverse ladderlike body with a wide top and a narrow bottom, a slot is arranged between the upper layer and the lower layer of the nut body, and the nut body is also provided with a longitudinal through hole. The invention has the advantages that: (1) simple operation process and greatly improved working efficiency; (2) convenience of use and high contraposition accuracy; (3) firmer fixation; (4) effective protection of sheet metal pieces after surface treatment and favorable improvement of the whole performance of the product; (5) favorable environmental protection; and (6) electricity saving and effectively reduced production cost.

Owner:HUBEI BOSHILONG TECH

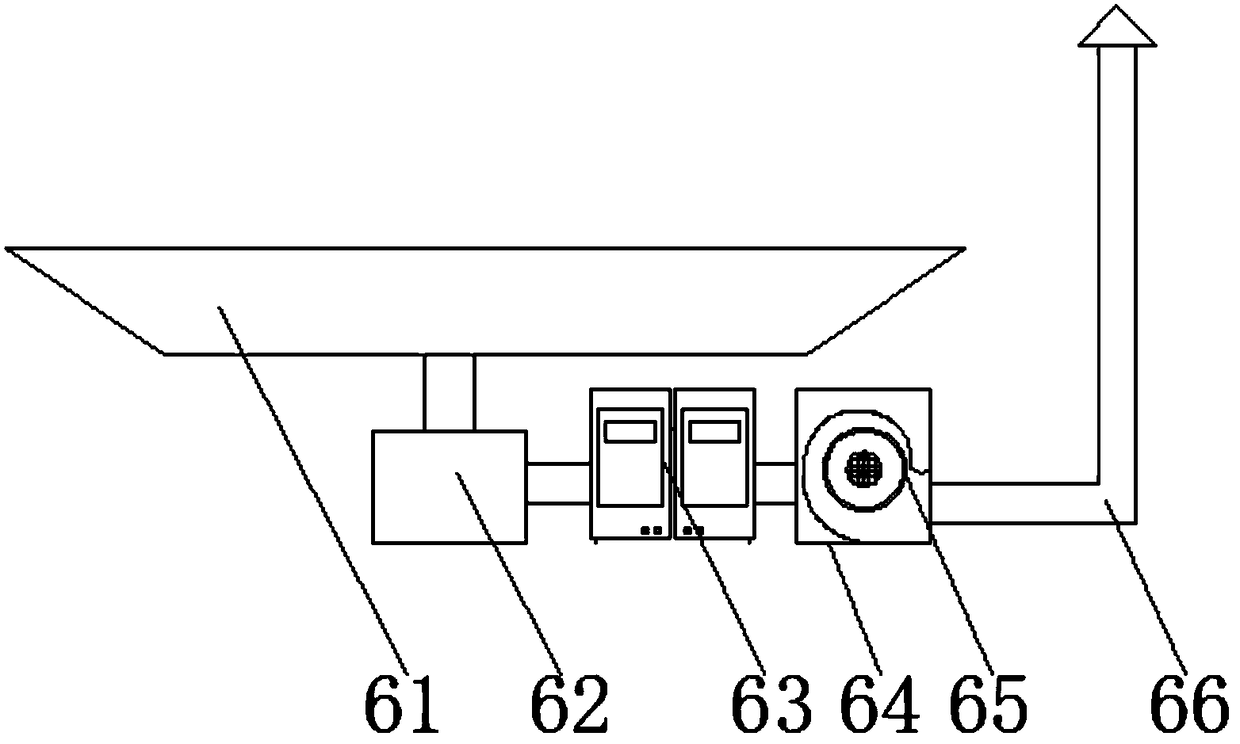

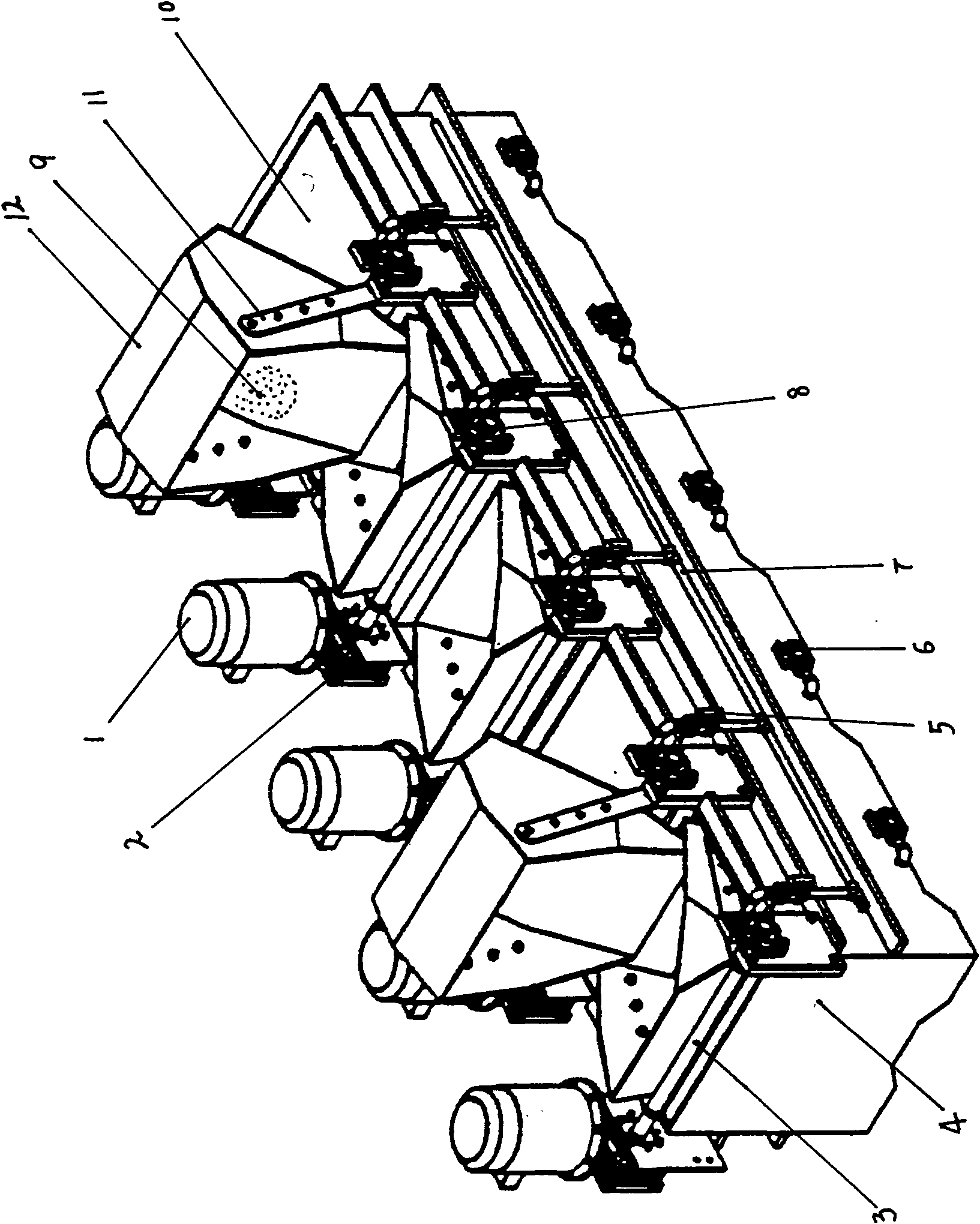

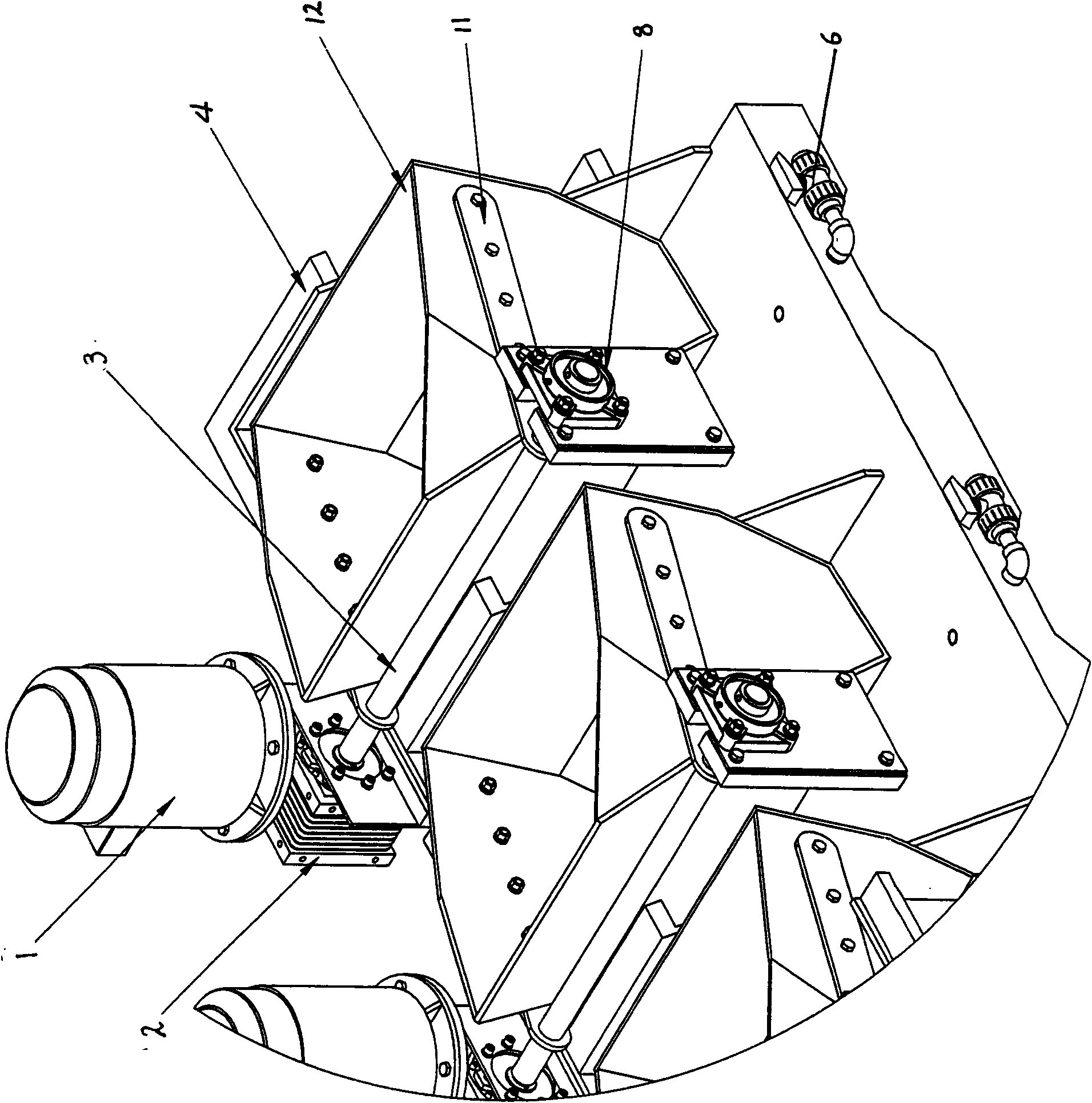

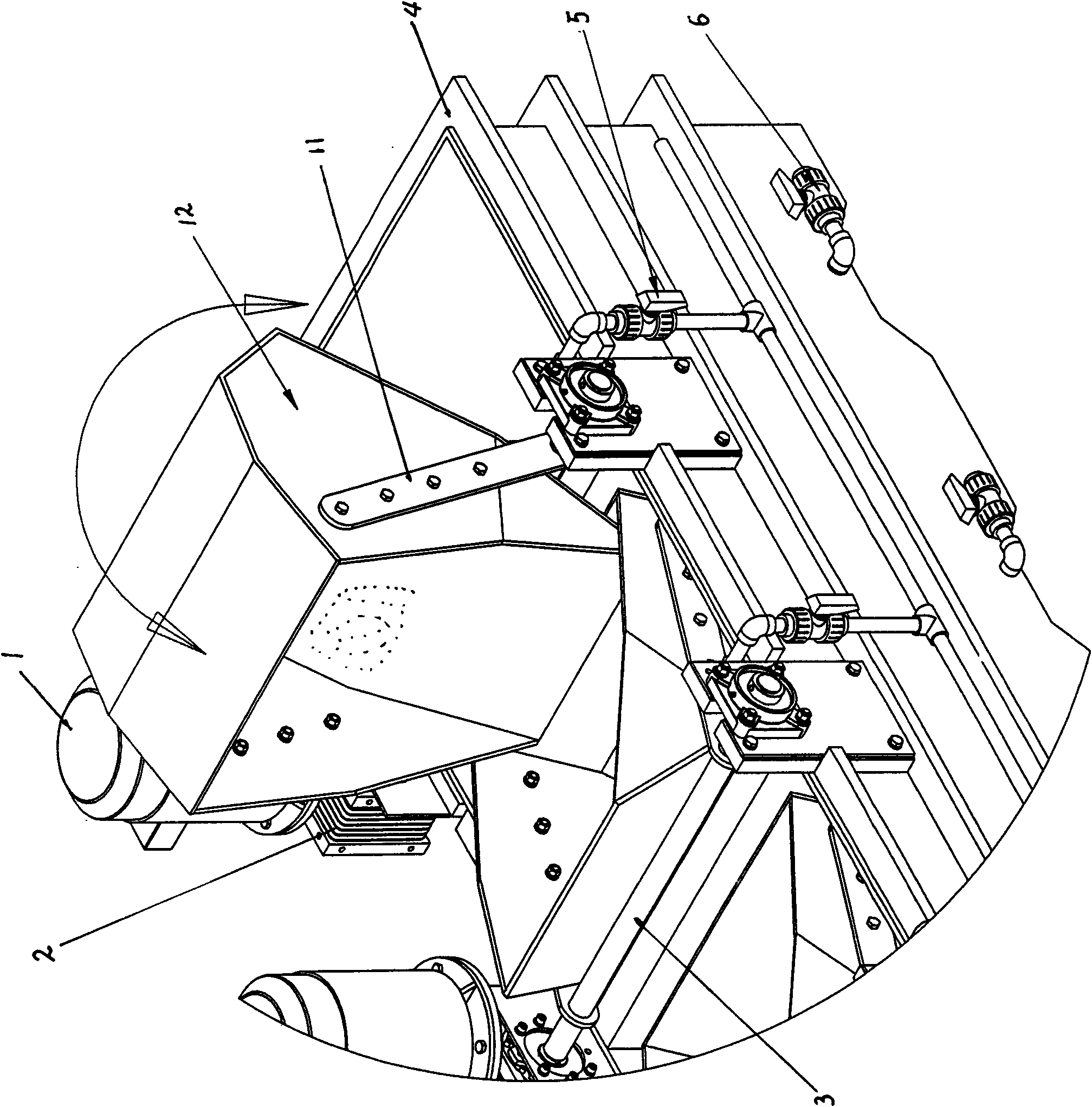

Groove cutting device of sliding adjustment cutting head with smoke sucking device

InactiveCN103521903AChange the processing technologyFully automatedWelding/cutting auxillary devicesDirt cleaningNumerical controlPulp and paper industry

The invention relates to a groove cutting device of a sliding adjustment cutting head with a smoke sucking device. The groove cutting device comprises the cutting head, the cutting head is installed on a fixed base, the upper end of the fixed base and the lower end of the fixed base are in hinge connection with a fixed connecting rod and a sliding connecting rod respectively, the fixed connecting rod is fixedly connected with a push mechanism, the push mechanism is provided with two vertical guide rails, a sliding block is installed between the two guide rails, the other end of the sliding connecting rod is in hinge connection with the sliding block, the upper portion of the push mechanism is connected with a deflection driving device, the deflection driving device is installed below a rotating mechanism, an exhaust fan is installed on the rotating mechanism, an air inlet of the exhaust fan is connected with a draught hood through a stainless steel hose, and an air outlet of the exhaust fan enables smoke to be discharged through a pipeline. The groove cutting device is applied to a numerical control plasma groove device, changes the traditional processing technology, and achieves full automation. The exhaust fan is arranged above the cutting head to suck the smoke generated during high-temperature cutting, and the production environment is protected.

Owner:昆山乾坤机器制造有限公司

Circuit board cleaning agent

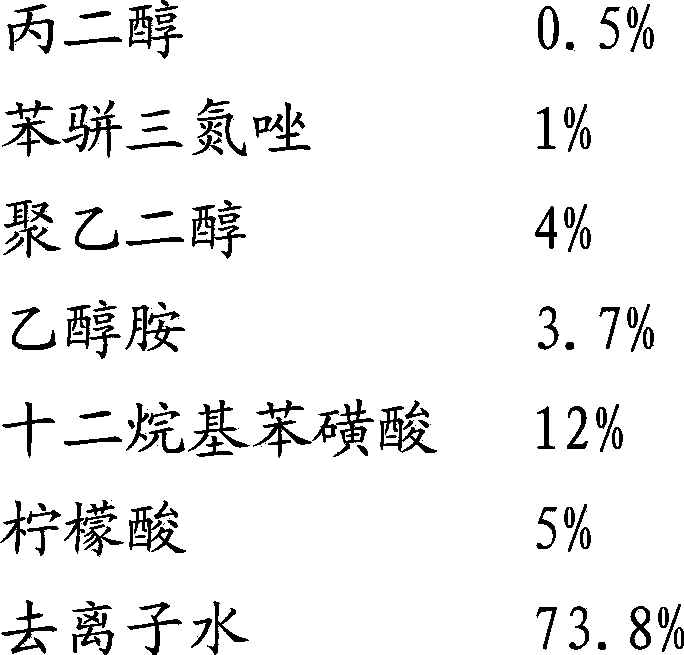

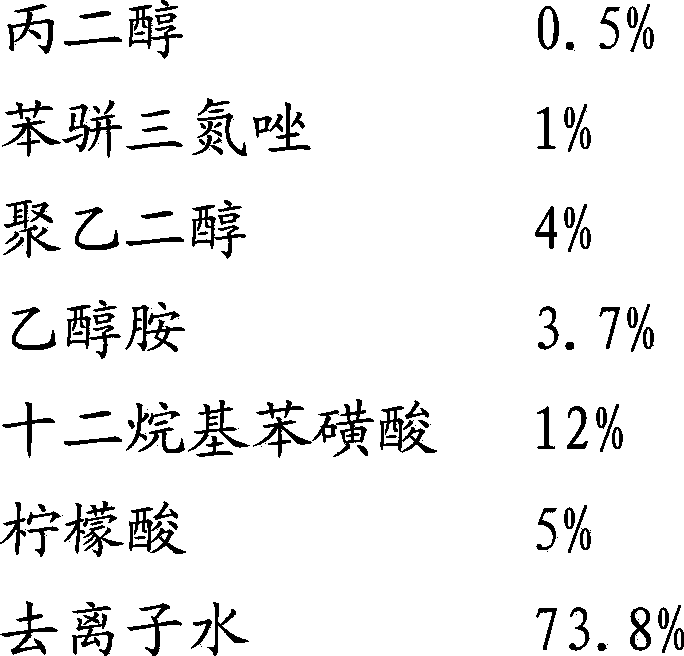

InactiveCN103834490AImprove efficiencyKeep healthyAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsPolyethylene glycolEngineering

The invention discloses a circuit board cleaning agent which comprises the following components: propylene glycol, benzotriazole, polyethylene glycol, ethanol amine, dodecylbenzene sulfonic acid, citric acid and deionized water. By adopting the circuit board cleaning agent disclosed by the invention, the aims of improving the service efficiency of the cleaning agent, protecting the production environment and guaranteeing the physical health of workers are achieved.

Owner:KUNSHAN TAROKO ELECTRONICS MATERIAL TECH

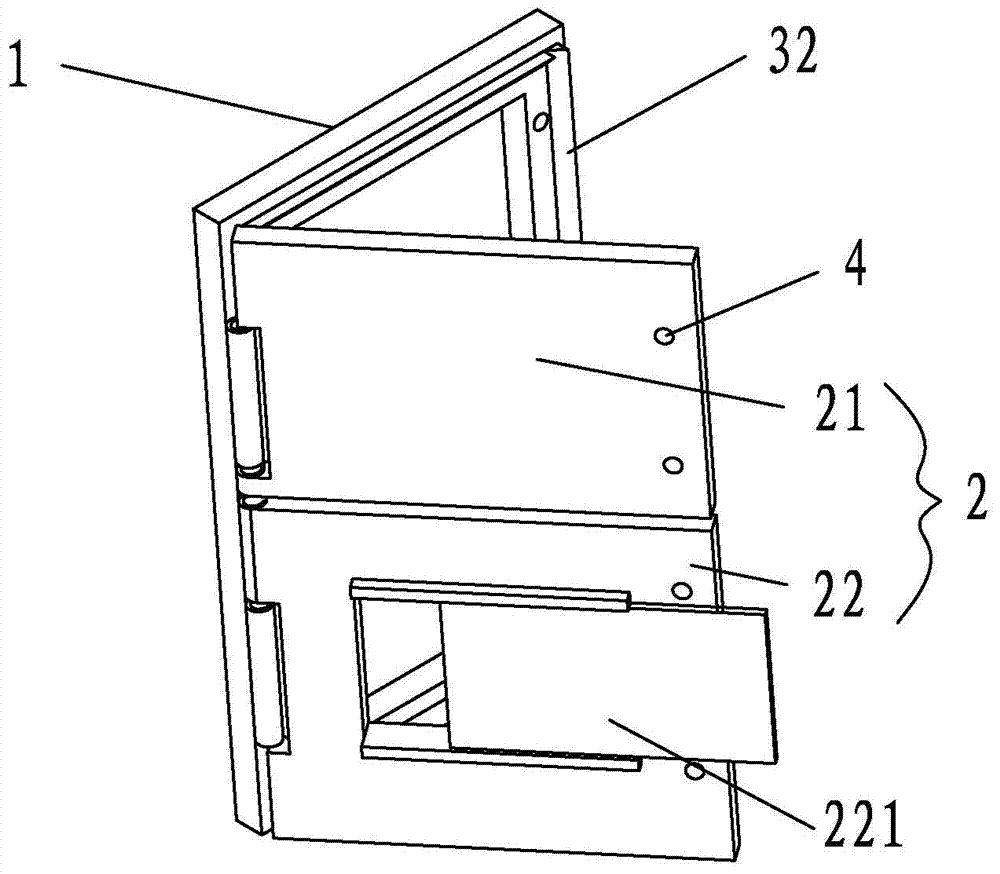

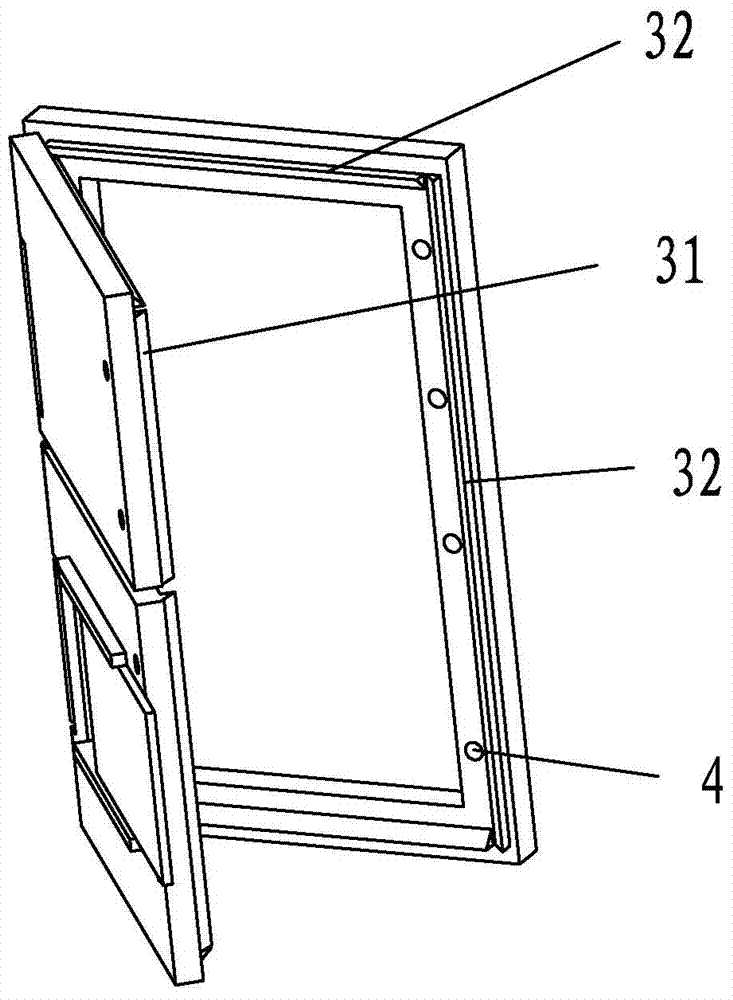

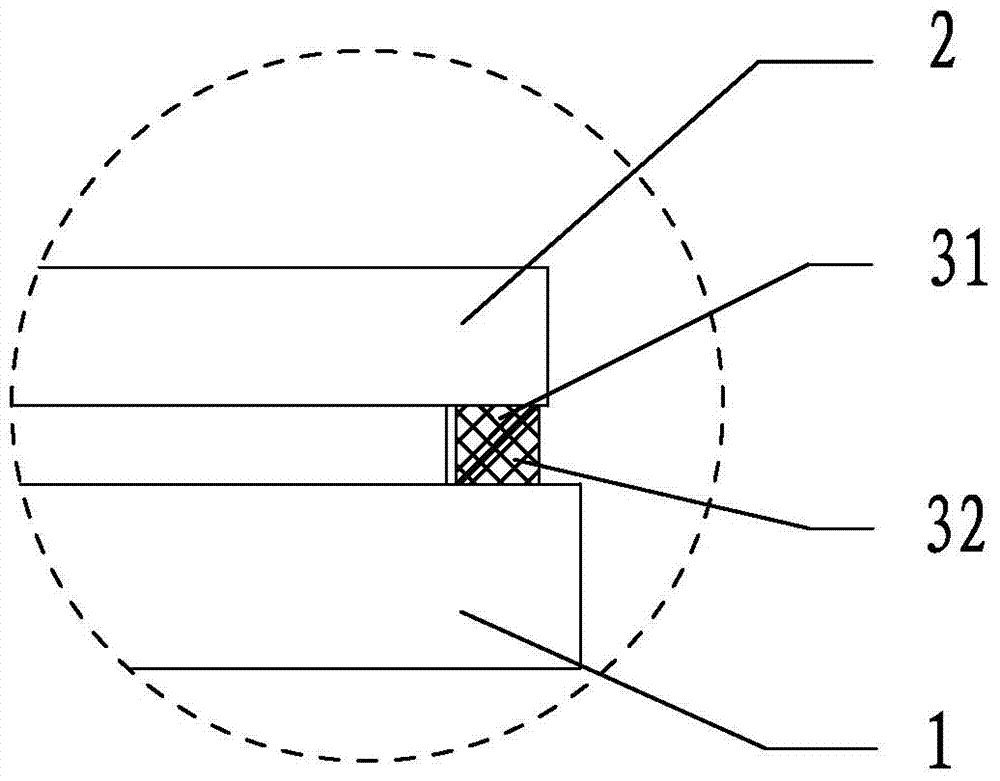

Improved structure for vibrating screen cover plate

ActiveCN103934196AReduce overflowIncrease production capacitySievingEngine sealsMechanical engineeringHinge angle

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

Shot blasting structure

ActiveCN108188940AAvoid pollutionImprove rust removal effectAbrasive machine appurtenancesCleaning using gasesGear wheelEngineering

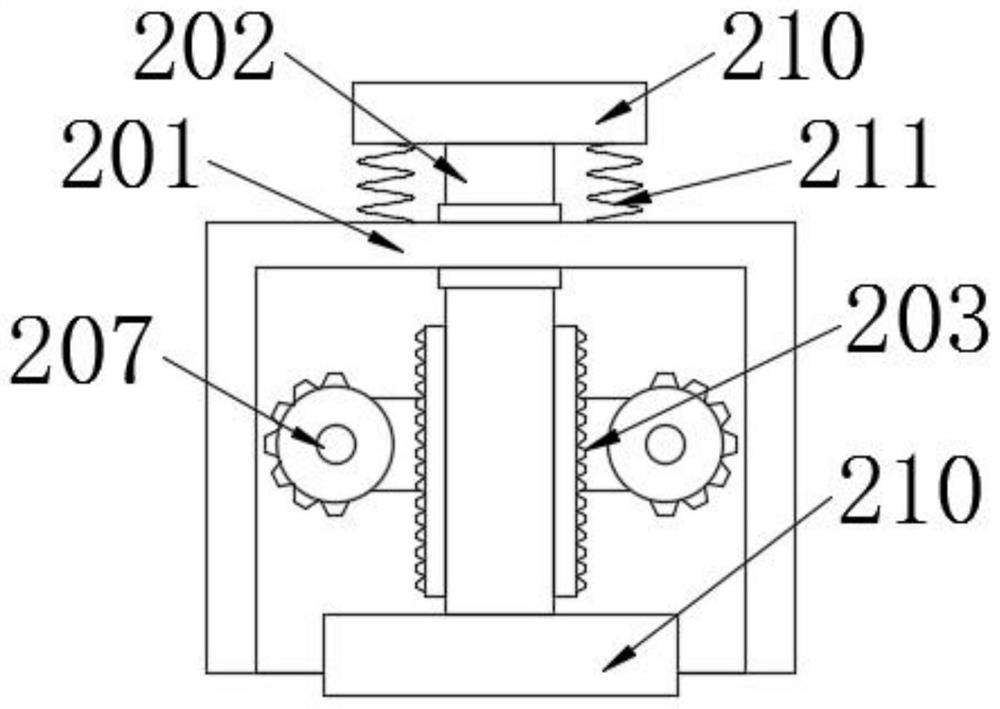

The invention belongs to the field of shot blasting devices, and particularly relates to a shot blasting structure. According to the scheme, the shot blasting structure is mainly characterized in thata partition plate which partitions a tank body into a screening cavity and a shot outlet cavity is arranged in the tank body; a vibration mechanism for vibrating steel shots up and down is arranged in the screening cavity; a rotary blade is arranged on the upper portion of the partition plate; the blade is inclined downwards in the rotation direction; the screening cavity is located in the rotation speed of the blade; a sliding plate is slidably connected with the inner wall of the shot outlet cavity; the steel shots can collide with the sliding plate after colliding with the rotary blade; asliding rack is fixedly connected with the sliding plate; a winding gear is engaged with the sliding rack; a winding shaft is connected with the winding gear coaxially, unidirectionally and rotationally; a reset spring is arranged between the sliding plate and the tank body; wet cloth is wound on the winding shaft; a plurality of air outlets are formed in the tank body; the air outlets are locatedover the blade; and the wet cloth is located above the air outlets. The steel shots collide mutually through vibration, and thus rust stains on the surfaces of the steel shots are removed and prevented from contaminating the steel shots again.

Owner:江苏明亮减速机部件制造有限公司

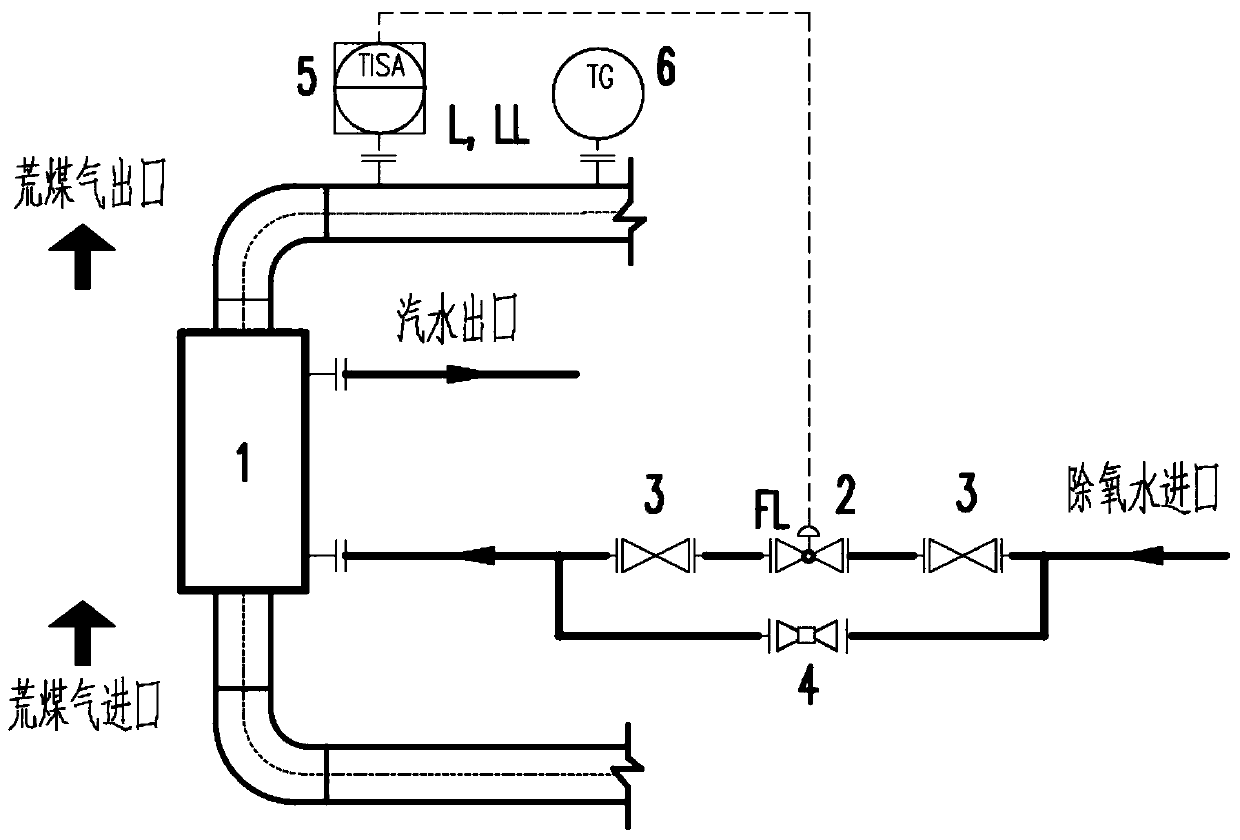

Coke oven ascension pipe heat exchanger raw gas outlet temperature interlock control device and process

PendingCN110699094AReduce furnace top commissioning workRealize automatic controlEnergy inputDistillation gas withdrawalCoke oven gasProcess engineering

The invention belongs to the field of coke oven ascension pipe waste heat utilization, and particularly relates to a coke oven ascension pipe heat exchanger raw gas outlet temperature interlock control device and process. The device comprises a coke oven ascension pipe heat exchanger, and the coke oven ascension pipe heat exchanger is provided with a deoxygenated water inlet, a raw coke oven gas inlet, a steam-water outlet and a raw coke oven gas outlet; the raw coke oven gas outlet is sequentially provided with a temperature upper disc indicator and an on-site thermometer; a regulating valvegroup is arranged at the deoxygenated water inlet and sequentially comprises a first gate valve, a regulating valve and a second gate valve, and a throttle valve is arranged on a bypass; the temperature upper disc indicator is connected with the regulating valve of the deoxygenated water inlet, can monitor the temperature of the raw coke oven gas outlet of the riser heat exchanger on line, and control water inlet flow amount by using temperature signals and ascension pipe heat exchanger water inlet regulating valve interlocking, thereby the stable operation of the system is ensured. Control issimple and feasible, cost is saved, and raw coke oven gas quality of a downstream chemical production section is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Stem cell culture device and culture method thereof

InactiveCN113136335AEasy to addQuick addBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyAnimal science

The invention discloses a stem cell culture device and a culture method thereof, and relates to the technical field of stem cell culture. The problem that nutrient solution adding efficiency is low is solved. The device comprises a machine body, a liquid box is arranged on the outer wall of the top of the machine body, a liquid conveying pipe is arranged on the outer wall of the top of the liquid box, a one-way valve is arranged on the circumferential outer wall of the liquid conveying pipe, and the other end of the liquid conveying pipe penetrates through the outer wall of the top of the machine body; an adjusting hand is arranged on the outer wall of the top of the machine body, a rotating column is arranged on the inner wall of the top of the machine body, the input end of the rotating column is connected with the output end of the adjusting hand through a transmission shaft, and three connecting bases are arranged on the circumferential outer wall of the rotating column. The culture method of the device comprises the following steps: after culture dishes are sequentially placed on a placing disc, an ultraviolet lamp is turned on to continuously sterilize the organism for 30 to 100 minutes. A nutrient solution is rapidly added, the culture device does not need to be repeatedly opened, pollution hidden dangers are reduced, the culture increase rate is increased, and the working time is greatly saved.

Owner:湖北明德健康科技有限公司

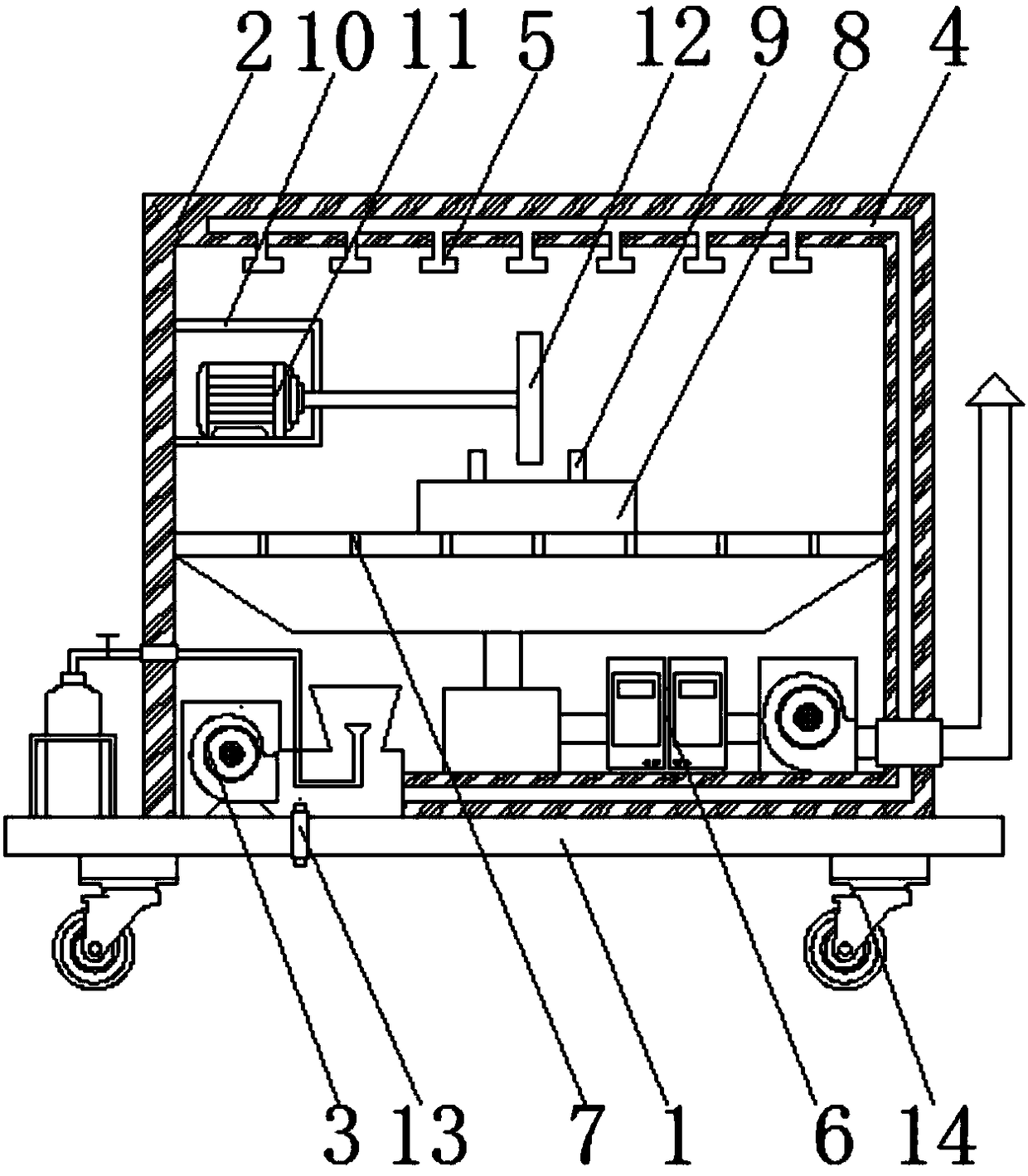

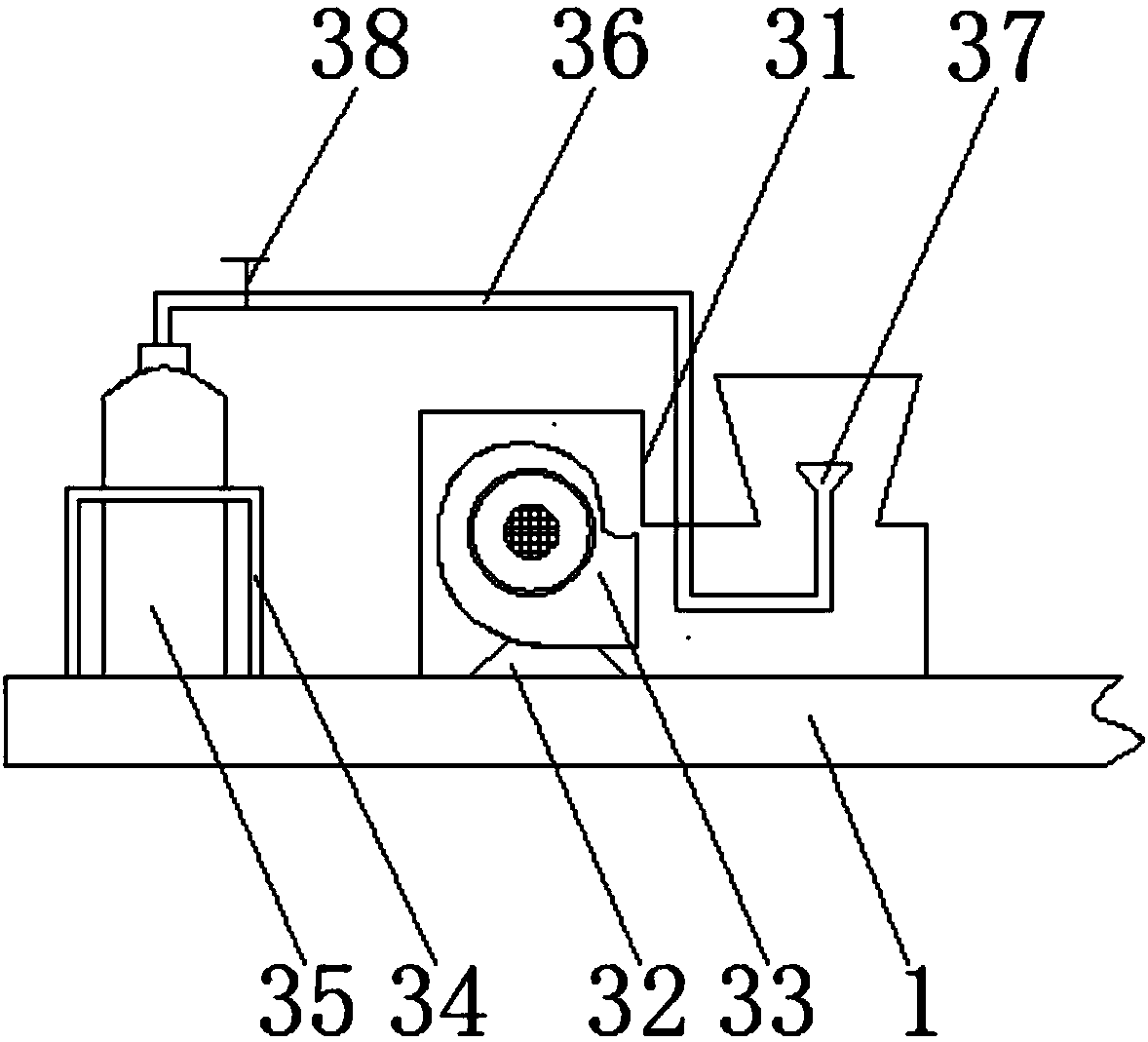

Barrel plating automatic washing device

InactiveCN103028567ASimple and fast operationEasy to cleanCleaning using liquidsElectric machineryInlet valve

The invention relates to a barrel plating automatic washing device. The barrel plating automatic washing device comprises a tank body, hoppers, motors, gearboxes, rotating shaft rods, water inlet valves and drain valves. The tank body is a one-piece tank body. A plurality of washing pools are arranged in the tank body. The hoppers and an overturning device are arranged on the tank body. The hoppers are fixed on the rotating shaft rods through swing arms. One ends of the rotating shaft rods are installed on the gearboxes, and the other ends of the rotating shaft rods are installed on bearing supports. Through motor rotation and power transmission of the gearboxes, the rotating shaft rods drive the hoppers to rotate together, and therefore the purpose of automatic cleaning is achieved. According to the barrel plating automatic washing device, overturning of the motors and the hoppers and flow rates of cleaning fluid are controlled by a computer controller, the degree of automation is high, washing efficiency is high, water consumption quantities are accurately controlled, labor intensity of workers is greatly relieved, workshop working environment is cleaned, and the barrel plating automatic washing device has popularization prospects.

Owner:禤伟光

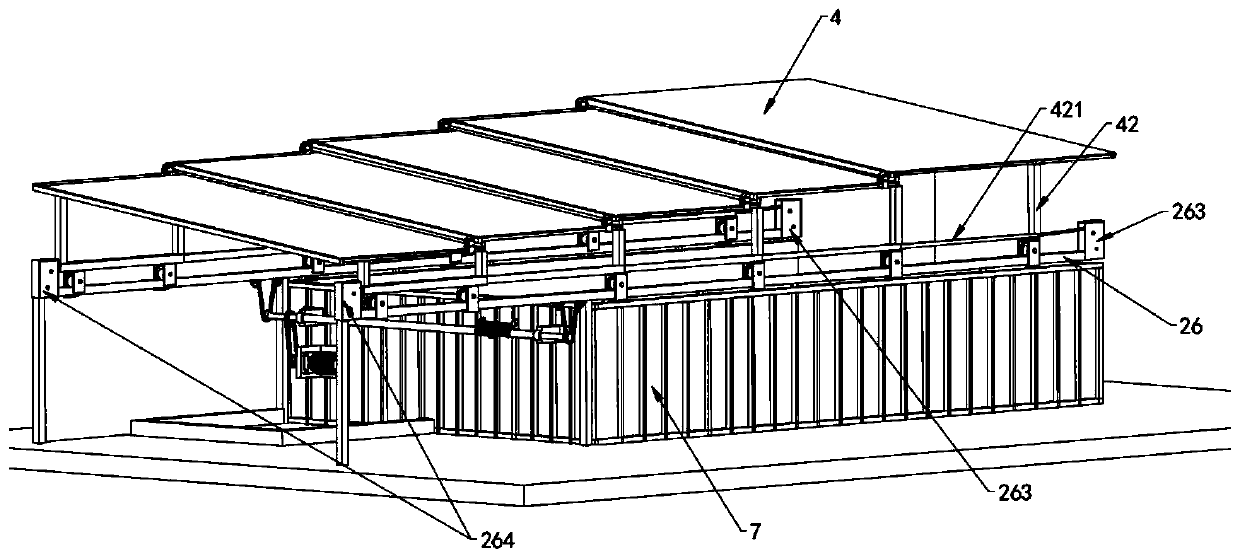

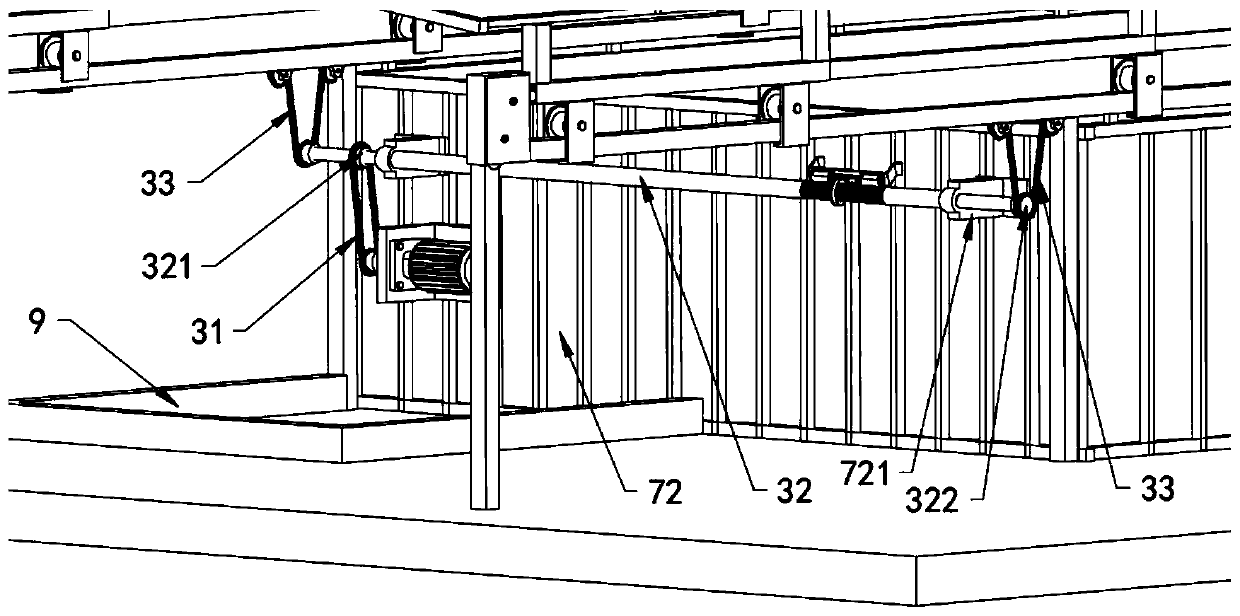

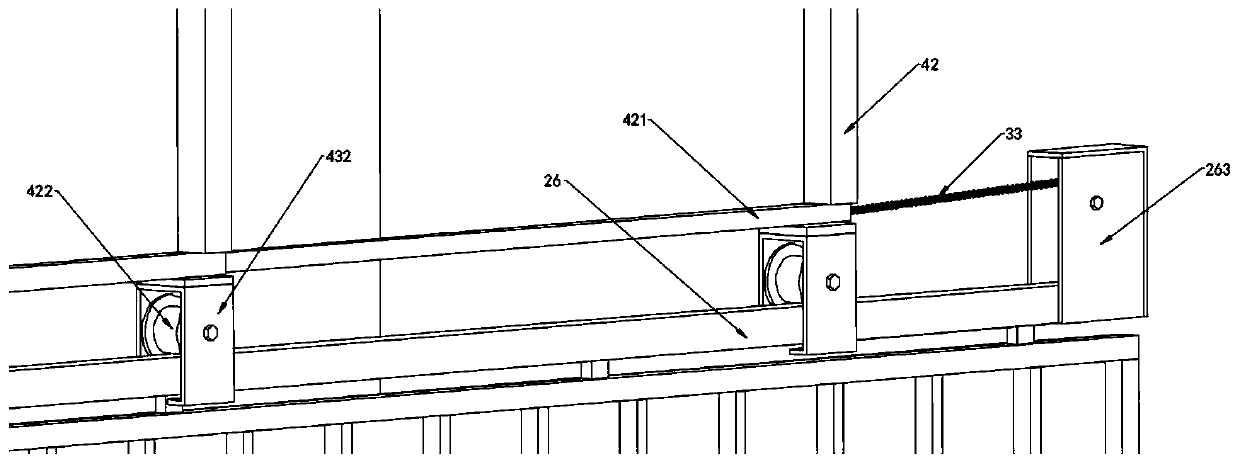

Mobile ceiling and mobile shed stacking bin

ActiveCN110439166AGuaranteed stable workExtended service lifeBuilding roofsElectrical and Electronics engineeringLoad bearing

Owner:BEIJING LANGDE COAL MINE MACHINERY

Aldehyde removal method of pentaerythritol

InactiveCN102603480AReduce unit consumptionReduce work intensityOrganic compound preparationHydroxy compound preparationPentaerythritolTower

The invention discloses an aldehyde removal method of pentaerythritol. Pentaerythritol condensation liquid is delivered into an aldehyde removal tower through an inlet located at the upper part of the aldehyde removal tower for aldehyde removal, after aldehyde is removed, formaldehyde is discharged from the top of the aldehyde removal tower, and liquid with aldehyde removed is extracted from the bottom of the aldehyde removal tower. Through the method provided by the invention, the best effect of removal formaldehyde can be achieved, so that the aldehyde content of the liquid with aldehyde removed is decreased to below 0.5g / l, and the unit formaldehyde consumption is decreased. A production environment of pentaerythritol is effectively protected, the operation is stable, the quality of pentaerythritol products and a recovery rate of formaldehyde are improved, 4525 tons of formaldehyde can be recycled calculated based on 30000 tons of annual output of pentaerythritol, and the saved formaldehyde can create benefit of about 5200000 yuan every year. The control pressure of the aldehyde removal tower is decreased to 198kPa from 220kPa, the production load of equipment is reduced, the service life of the equipment is prolonged, the maintenance to production equipment and the working strength of workers are reduced, and the work efficiency of workers is improved.

Owner:贵州金江化工有限公司

Method for producing insoluble sulfur

InactiveCN101337660BProduction safety and environmental protectionAvoid pollutionSulfur preparation/purificationNitrogenNitrogen gas

The invention discloses a method for producing insoluble sulfur, which comprises the steps of melting sulfur, extracting, drying and pulverizing. By using the method, the insoluble sulfur is continuously produced under the totally-enclosed condition of normal pressure, nitrogen of normal pressure is used for sealing a heating groove, and the extracting step and the pulverizing step are completed in the same reactor. The specific operation steps are as follows in sequence: (1) melting the sulfur and heating up; (2) extracting and pulverizing; and (3) drying to obtain products produced through the method. The method has the advantages that: (1) the insoluble sulfur is continuously produced under the totally-enclosed condition of the normal pressure, and nitrogen is used for sealing the upper space of the sulfur heating groove, thereby resulting in no oxide leakage of carbon bisulfide and sulfur, and achieving safe and environmental-friendly production; (2) the pulverizing and quenching processes are finished in the same multifunctional rotary reactor, thus saving pulverizing devices, avoiding dust pollution when pulverizing, and protecting production environment.

Owner:广州市烨荣贸易有限公司

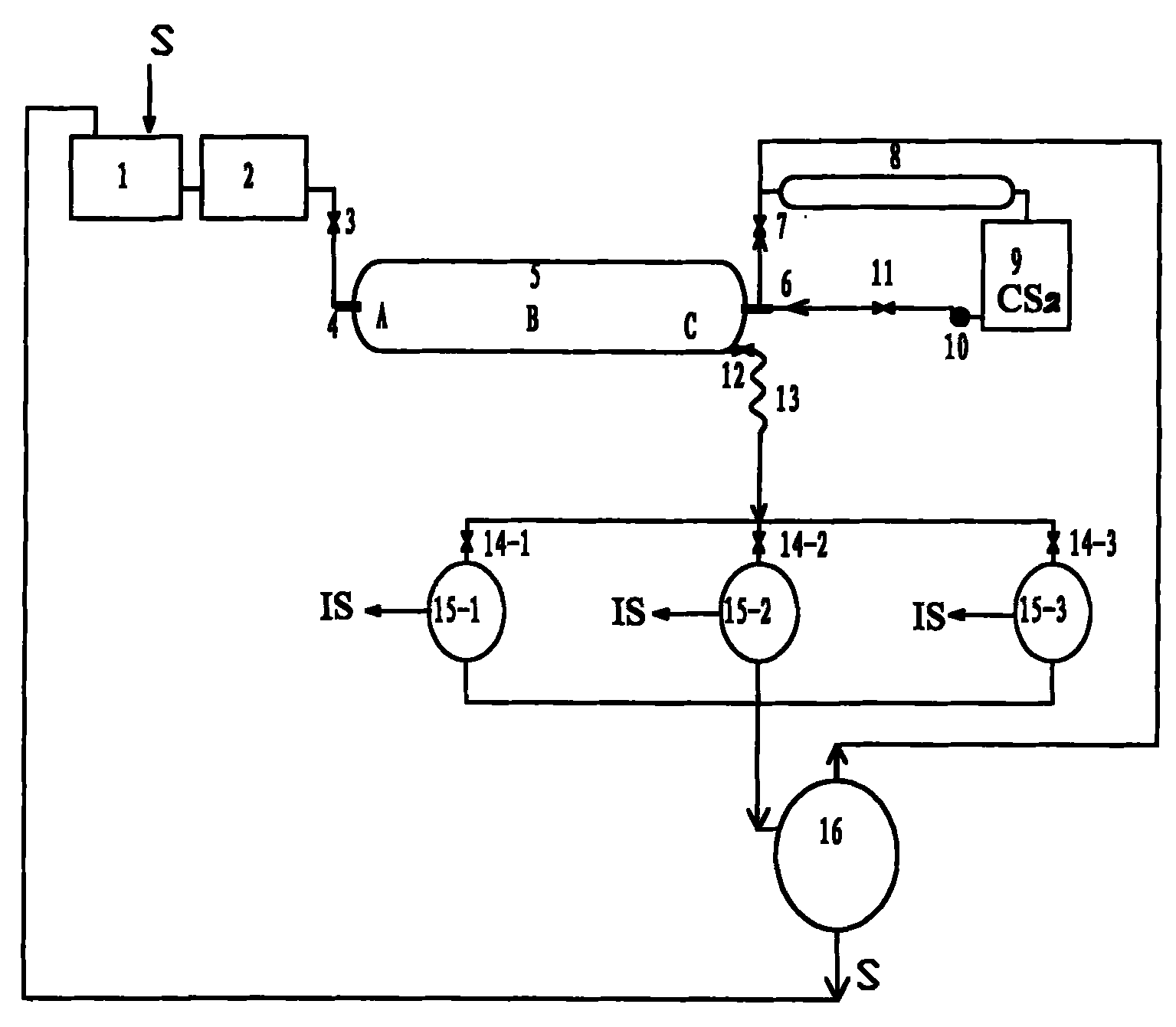

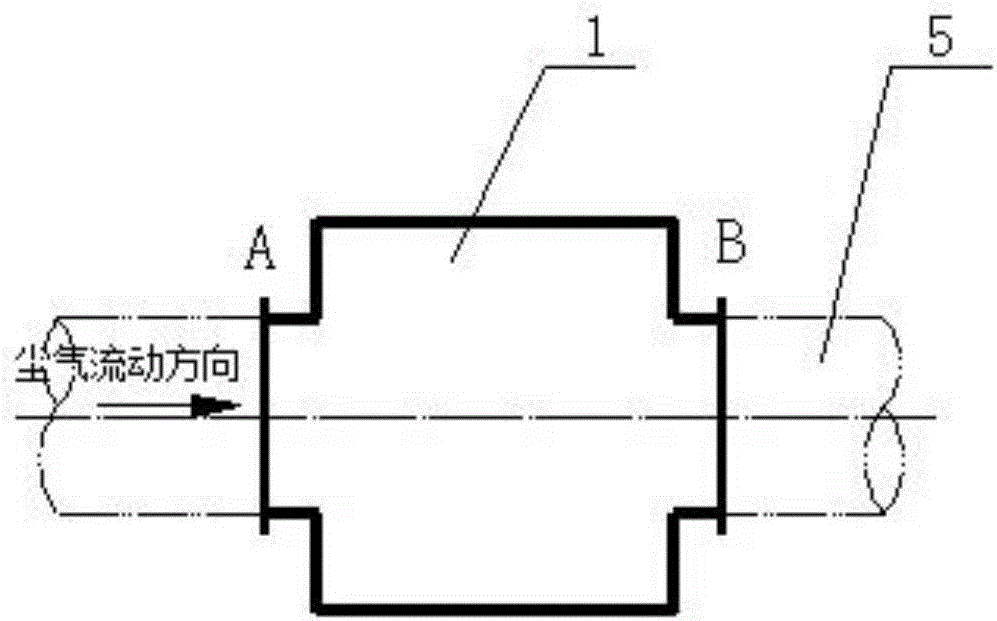

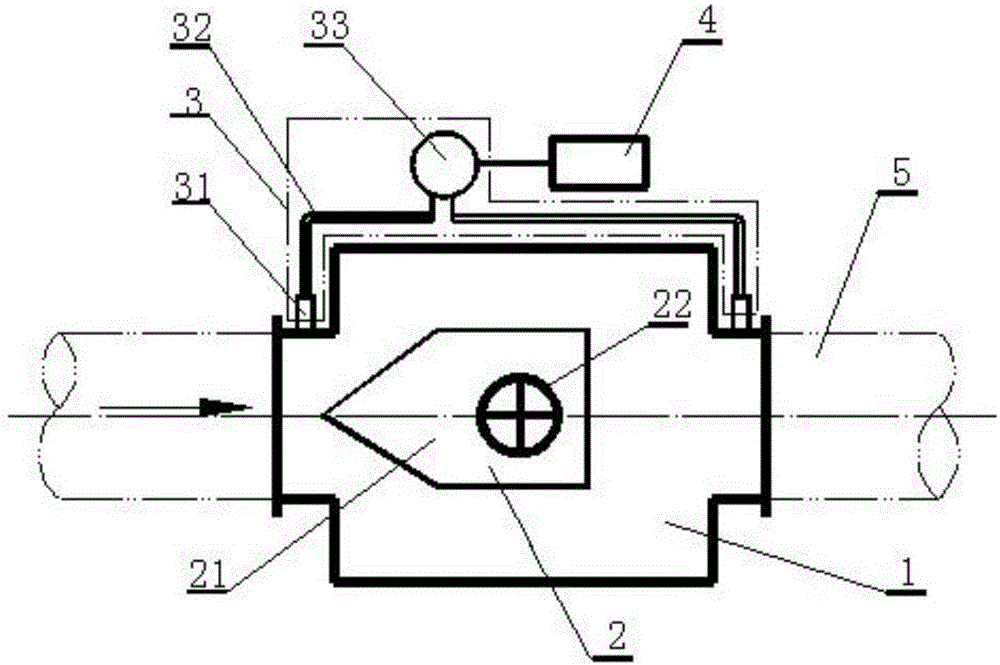

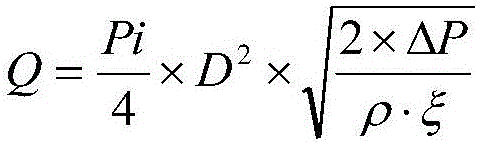

Dust removal pipeline dust gas flow adjustment system

InactiveCN105807793AGuaranteed uptimeReal-time monitoring of dust and gas flowFlow control using electric meansDifferential pressureOptimal control

The invention relates to a dust removal pipeline dust gas flow adjustment system.The system comprises a barrel, a dust gas flow adjustment unit, a differential pressure detection unit and a control unit, the barrel is installed on a dust removal pipeline, the barrel is internally provided with the dust gas adjustment unit, the differential pressure detection unit is arranged outside the barrel, and the output end of the differential pressure detection unit is connected with the control end of the dust gas flow adjustment unit through the control unit.According to the dust removal pipeline dust gas flow adjustment system, the dust gas flow in a dust removal pipeline can be online monitored in real time, rapid and effective adjustment is conducted according to needs, the dust removal system can reach an ideal state of design, it is guaranteed that the dust removal system operates safely, stably and reliably, and the production environment is protected; meanwhile, by means of measurement and adjustment on the dust gas flow in the dust removal pipelines at all dust sources, the optimal control flow of the dust sources is obtained, valuable measured data is accumulated for the design and production, and optimization of the design and production is achieved gradually.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Low-energy-consumption hybrid white smoke elimination device

ActiveCN103920376AReduce moistureGood maintenance costDispersed particle separationHybrid typeTherapeutic effect

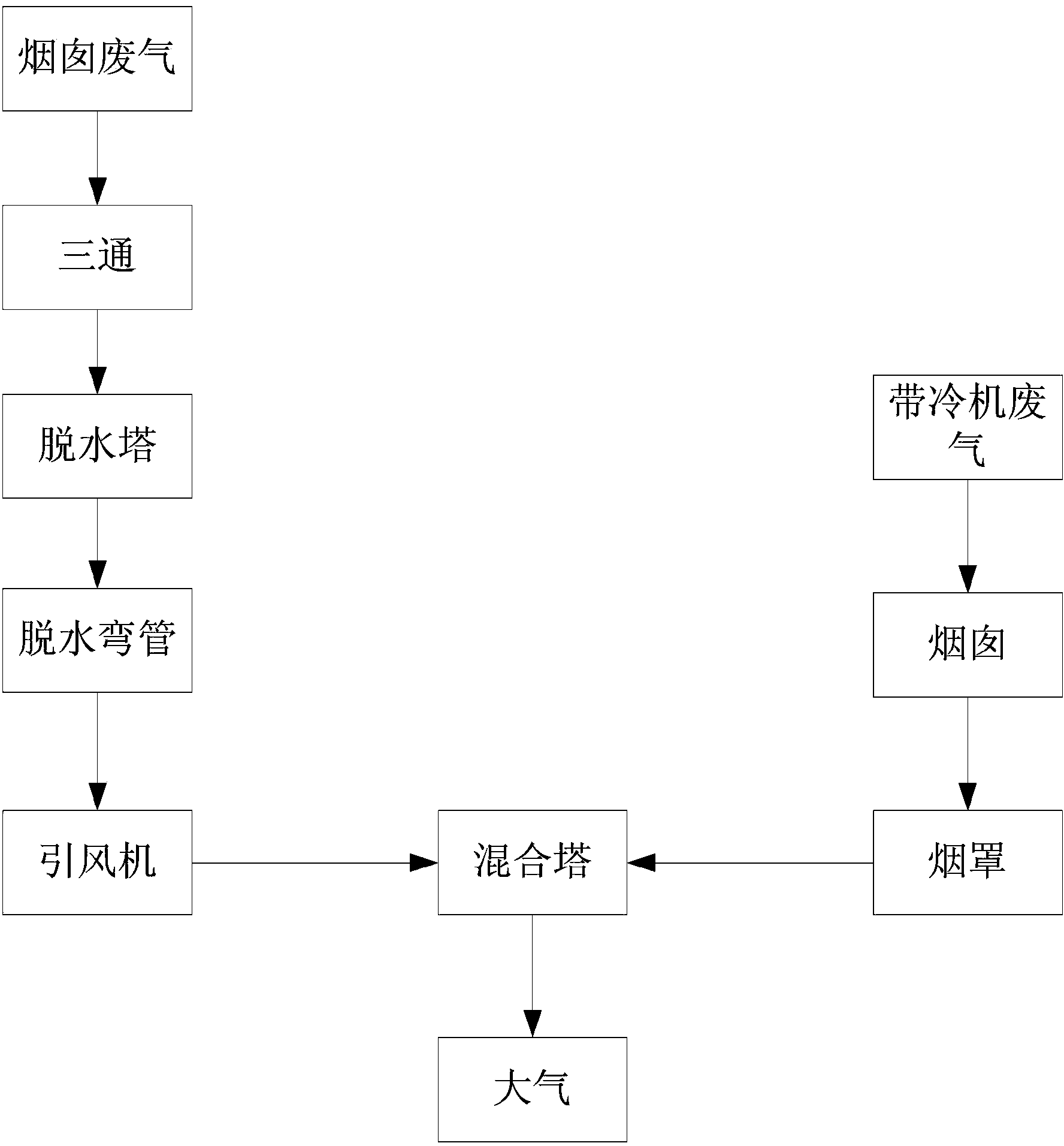

The invention discloses a low-energy-consumption hybrid white smoke elimination device, which comprises a mixing tower, wherein three openings are formed in the mixing tower; two of the openings are air inlets and are respectively connected with a multiple layered dehydration guide device of chimney exhaust gas and a belt cooler exhaust gas conveying device; the other opening is an air outlet and is directly connected with outside air; the multiple layered dehydration guide device of chimney exhaust gas comprises a T-joint and a dehydration tower, a dehydration elbow and an draught fan which are connected with the T-joint in sequence; the air outlet of the draught fan is connected on the mixing tower through a pipeline; the belt cooler exhaust gas conveying device comprises a belt cooler; a chimney is arranged on the belt cooler; a smoke hood is arranged at the top end of the chimney and is connected with the mixing tower through a pipeline. According to the low-energy-consumption hybrid white smoke elimination device, not only is the installation and maintenance cost of the device reduced, but also is the operation cost of the device reduced; the treatment effect of white smoke is greatly improved.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

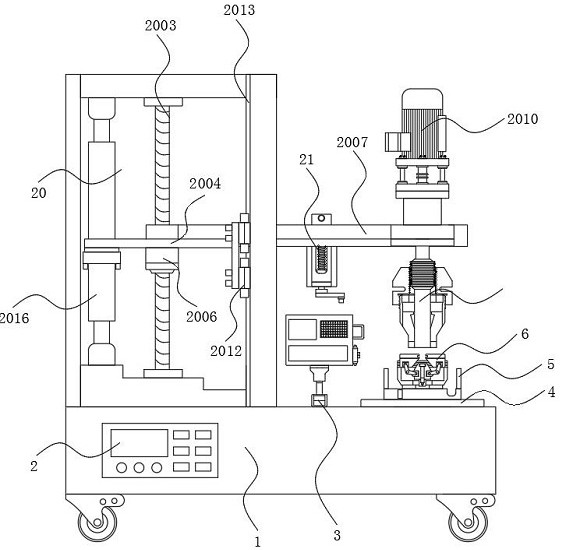

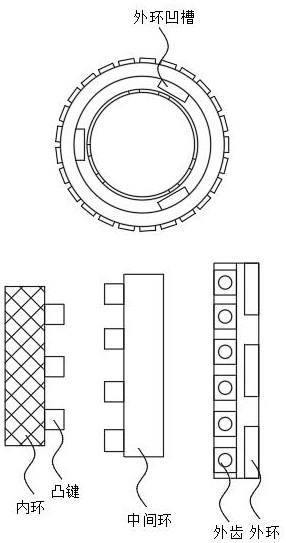

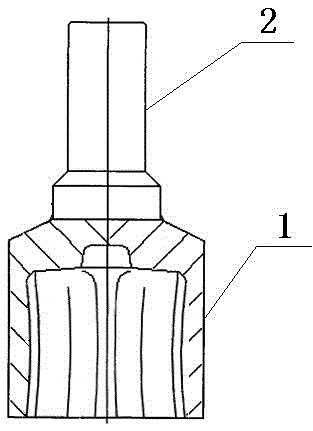

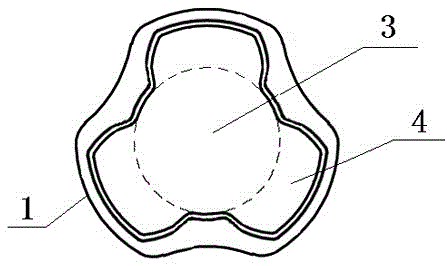

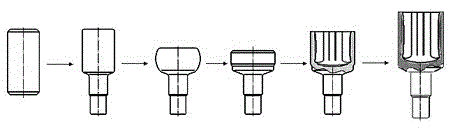

Finishing Forming Method and Finishing Punch of Three-Ballway Constant Velocity Universal Joint Cylindrical Shell

The invention discloses a method for finishing a cylindrical shell of a three-ball-groove constant velocity universal joint. The method comprises the warm forging step and the cold-finishing plastic forming step, wherein the cold-finishing plastic forming step is a thinning and stretching cold-finishing process, a finishing male die is sleeved with a blank, the action that centripetal force is exerted by a cold-finishing female die on the blank to the finishing male die is adopted, the blank receives force under the action of the cold-finishing female die and plastically deforms, the blank is tightly attached to the finishing male die and flows in the movement direction of the female die, and therefore the inner wall of a shell body of the cylindrical shell is made to be a protruding arc face; three circular arc protruding blocks are evenly arranged on the outer wall of a cylinder of the finishing male die, a male die head is of an arc face structure, and the outer wall of the finishing male die is of a concave arc face structure in the length direction of the finishing male die. Grooves, produced through the finishing male die and the finishing method, of the cylindrical shell are free of drum-shaped errors, transmission of a transmission shaft is smooth, assembly is easy, the match accuracy is good, and the service life is long.

Owner:江苏威鹰机械有限公司

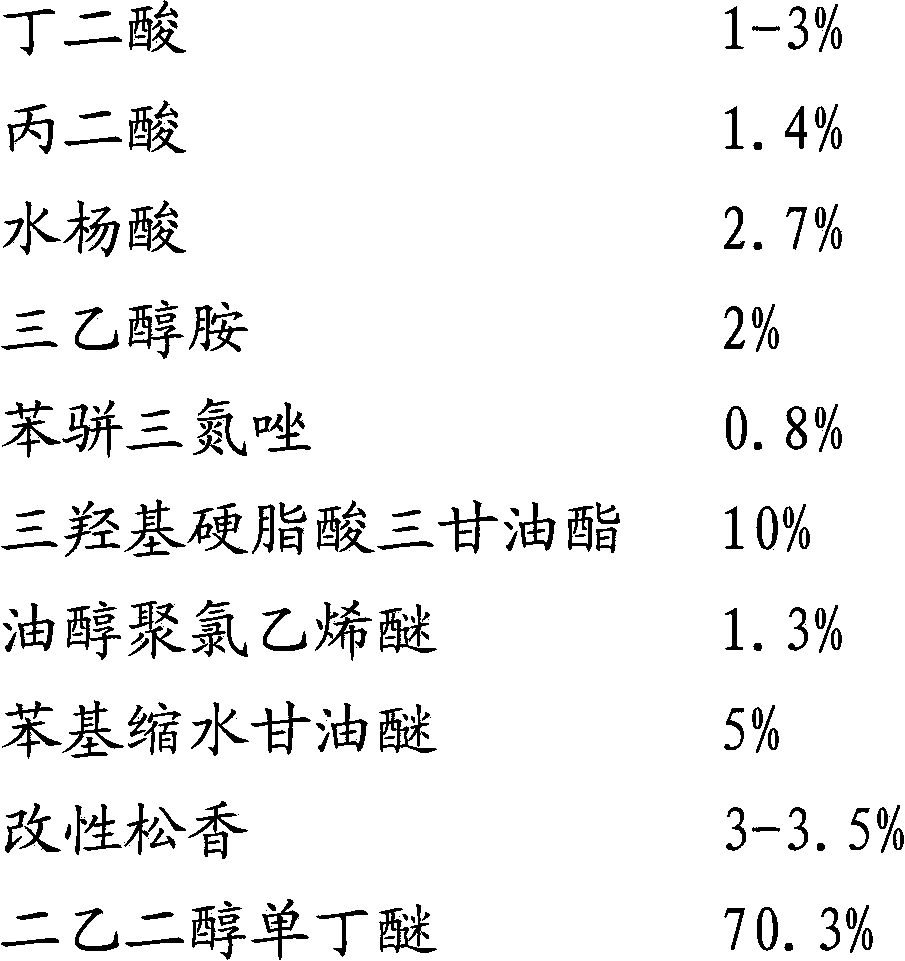

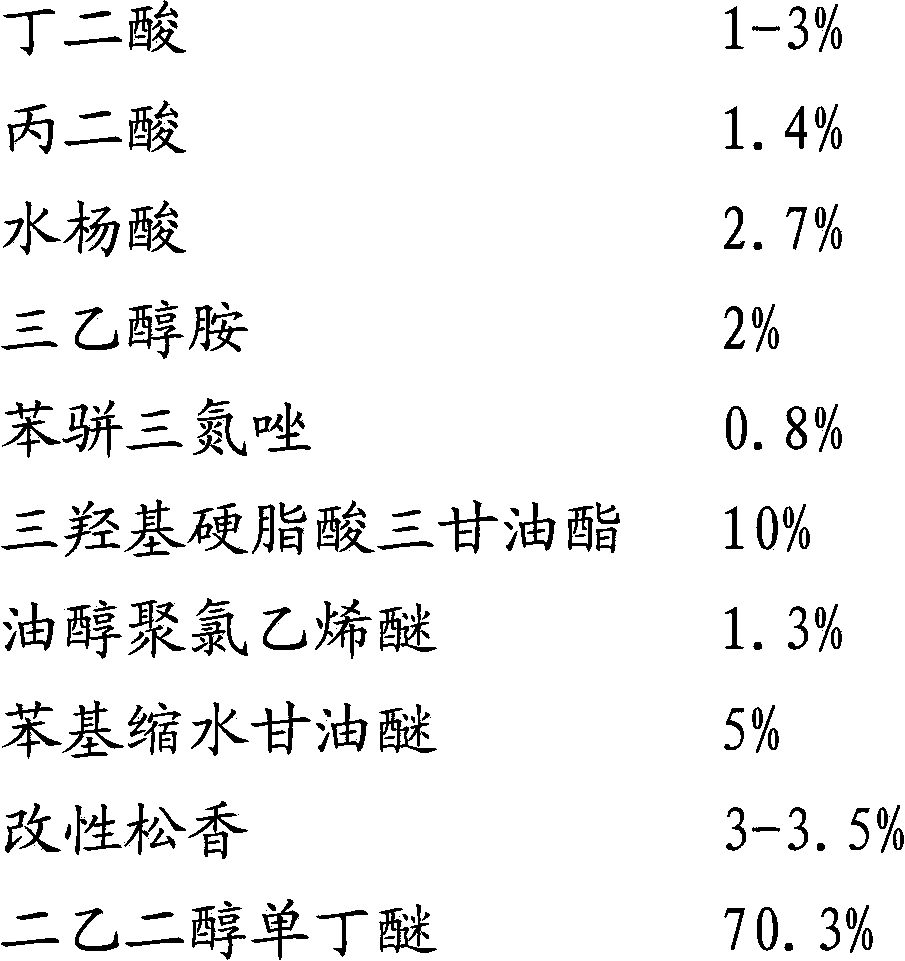

Novel soldering flux

InactiveCN103831547AHigh activityKeep healthyWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherHydroxystearic Acid

The invention discloses novel soldering flux. The novel soldering flux comprises succinic acid, malonic acid, salicylic acid, triethanolamine, benzotriazole, three hydroxy stearic acid glyceride, oleyl alcohol polyvinyl chloride ether, phenyl glycidyl ether, modified rosin and diethylene glycol monobutyl ether. The purposes of improving the activity of the soldering flux, protecting production environments and guaranteeing the body health of workers are achieved.

Owner:KUNSHAN TAROKO ELECTRONICS MATERIAL TECH

High-performance non-elastomer ternary blending composite material and preparation method thereof

PendingCN112809957AImprove interfacial adhesionAvoid damageVibration suppression adjustmentsElastomerAnoxomer

The invention discloses a high-performance non-elastomer ternary blending composite material and a preparation method thereof. The high-performance non-elastomer ternary blending composite material is prepared by the following steps that S1, the following raw materials, by weight, 10-30 parts of ultra-high molecular weight polyethylene, 5-10 parts of block co-polypropylene, 65-90 parts of polypropylene and 0.5-1.5 parts of an antioxidant are weighted; S2, ultra-high molecular weight polyethylene is put into internal mixing equipment for internal mixing, the temperature ranges from 170-180 DEG C, and the time ranges from 50-60min; S3, the block co-polypropylene, the polypropylene and an antioxidant are put into the internal mixing equipment in the S2 for the internal mixing, a mixture is obtained, the temperature is 180-190 DEG C, and the time is 60-70min; and S4, single-screw extrusion granulation is carried out on the mixture obtained in S3 to prepare the ternary blending composite material at the temperature of 210 DEG C for 40-50min.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Slag removal electric welding machine

InactiveCN104439783AProtect the production environmentIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesSlagElectric machinery

The invention discloses a slag removal electric welding machine, and belongs to the technical field of welding equipment. The slag removal electric welding machine comprises a welding gun which is connected with a guide rail cross beam in a sliding mode and a welding platform which is arranged below the welding gun. A grinding wheel which is driven by a motor and a suction nozzle which is used for sucking welding slag through a suction fan are sequentially arranged on one side of the welding gun through a mounting plate. The problems that operation is inconvenient, efficiency is low, people are likely to be injured, and components and parts can be damaged are solved. The slag removal electric welding machine can solve the problems that the production efficiency is low and dust is likely to be generated to seriously pollute the workshop environment when welding flux residual slag is polished.

Owner:LIUZHOU ANLONG MACHINERY EQUIP

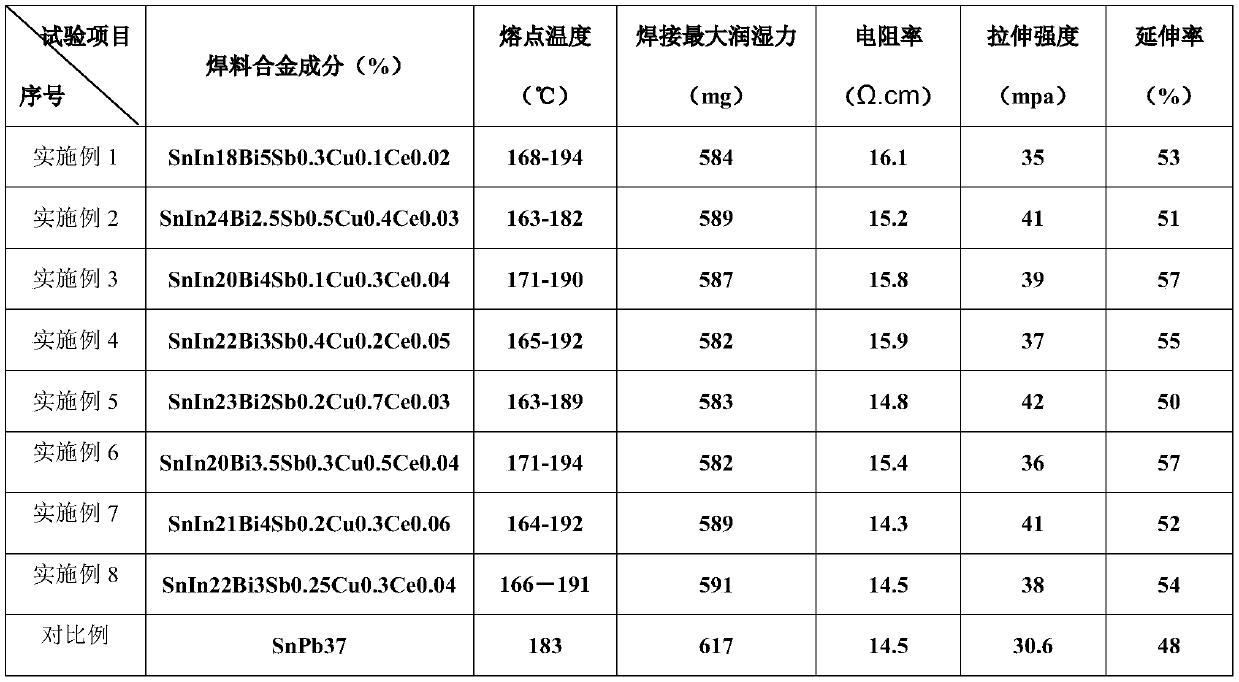

Low-temperature lead-free alloy flux and preparation method thereof

ActiveCN109894768AUniform refinement of metallographic structurePromote wetting and spreadingWelding/cutting media/materialsSoldering mediaElectricityAlloy

The invention discloses a low-temperature lead-free alloy flux and a preparation method thereof. The low-temperature lead-free alloy flux comprises the following raw materials in parts by weight: 18-24% of In, 2-5% of Bi, 0.1-0.4% of Sb, 0.1-0.7% of Cu, 0.02-0.06% of Ce and the balance of Sn. The melting point of the low-temperature lead-free flux is within 163-194 DEG C; the alloy flux is uniformand fine in metallographic structure, excellent in wetting spreadability, firm in bonding with a substrate welding disc and welded parts, bright and full in welding spot and excellent in mechanical performance and electric performance; and the low-temperature lead-free alloy flux preferably meets the process requirements of using the low-temperature lead-free alloy flux in the lead-free process of the electronic industry, and meets relevant regulations of energy conservation, emission reduction and environmental protection.

Owner:THOUSAND ISLAND METAL FOIL

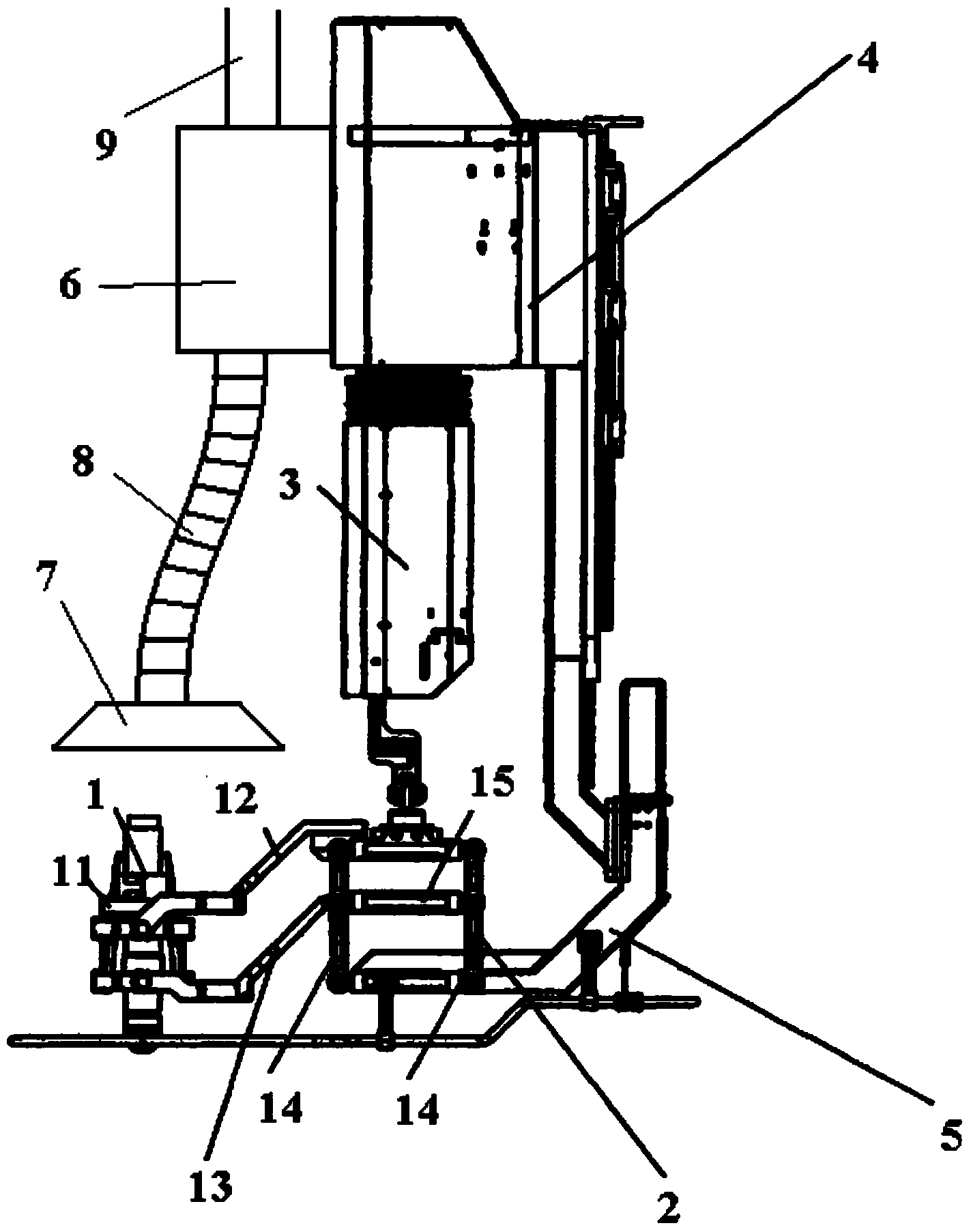

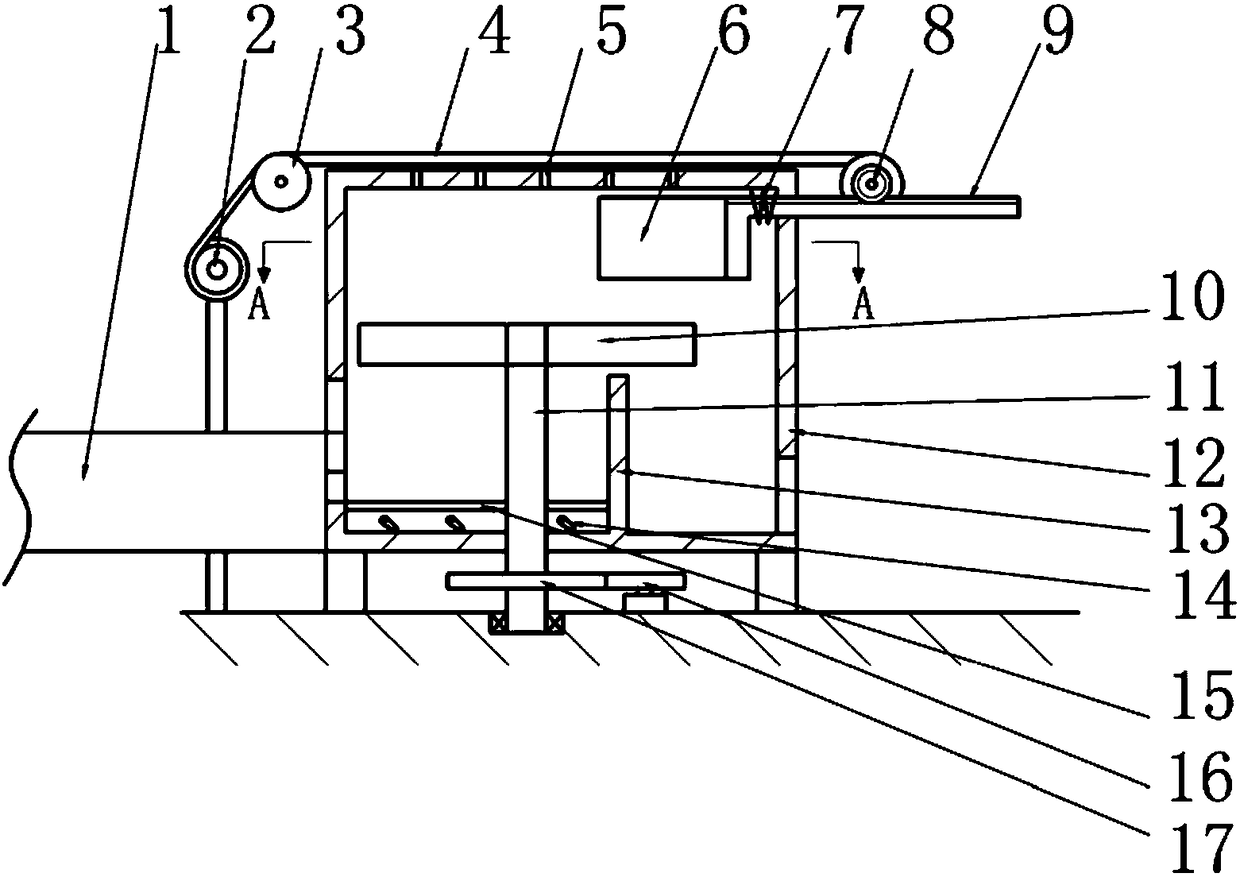

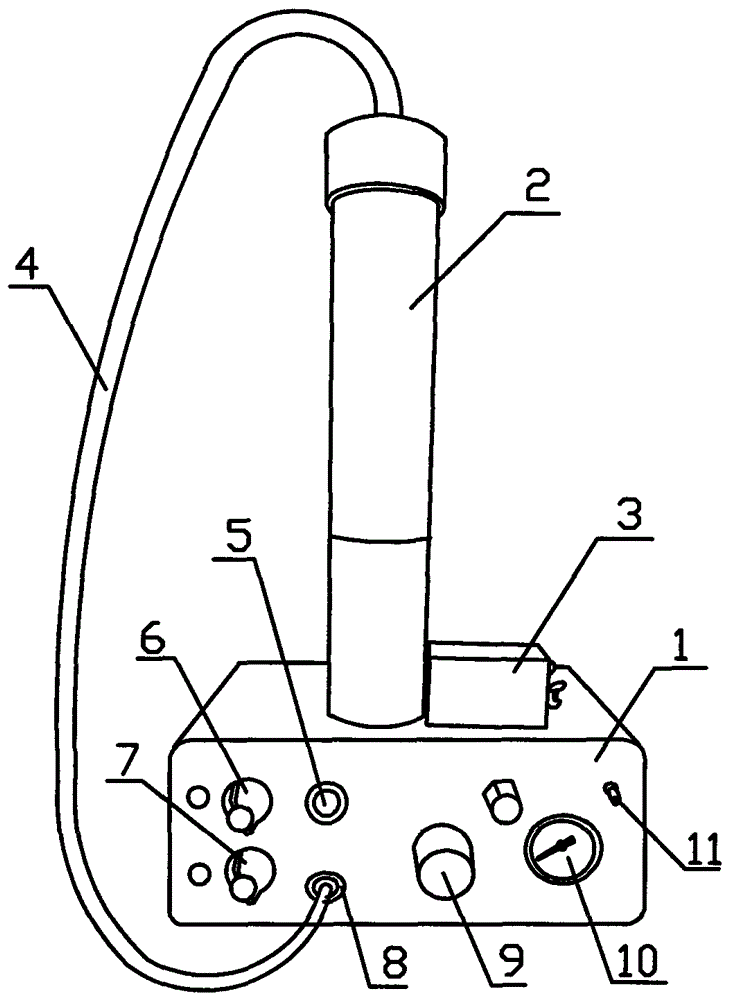

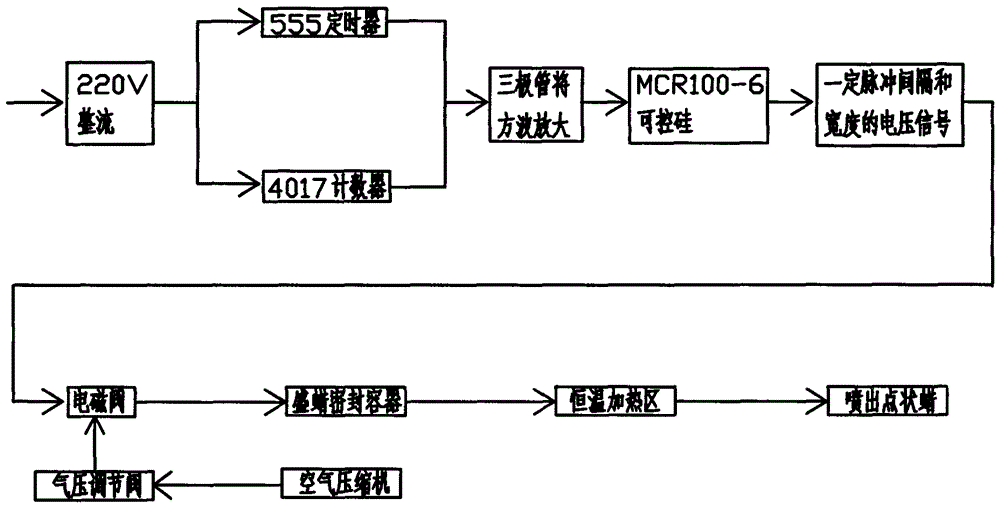

An online coater for enameled wire

InactiveCN103680756BProtect the production environmentImprove performanceCable/conductor manufactureWaxAtmospheric pressure

The invention discloses a novel on-line coater for an enameled wire. The novel on-line coater comprises an adjusting device (1), a sealed wax accommodating device (2), and a coating device (3) which are sequentially connected with one another, wherein an air inlet (5) connected with an air compressor and an air outlet (8) connected with the sealed wax accommodating device (2) through an air pipe (4) are formed in the adjusting device (1); an electromagnetic valve, as well as a pulse adjusting device and an air pressure adjusting device (9) which are both connected with the electromagnetic valve, is sequentially arranged between the air inlet (5) and the air outlet (8); the coating device (3) connected with the sealed wax accommodating device (2) comprises a temperature adjustable heating device and a needle-shaped nozzle. The novel on-line coater provided by the invention has the benefits of reliable performance, energy saving, environmental friendliness, low manufacturing cost, convenience, and practicability.

Owner:TONGLING JINTIAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com