Novel soldering flux

A flux, a new type of technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of strong volatility, low insulation resistance, easy leakage risk, etc., and achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The invention provides a new type of flux, whose working principle is to add diethylene glycol monobutyl ether and 3-3.5% modified rosin to the flux to improve the activity of the flux, protect the production environment and ensure The health of the staff.

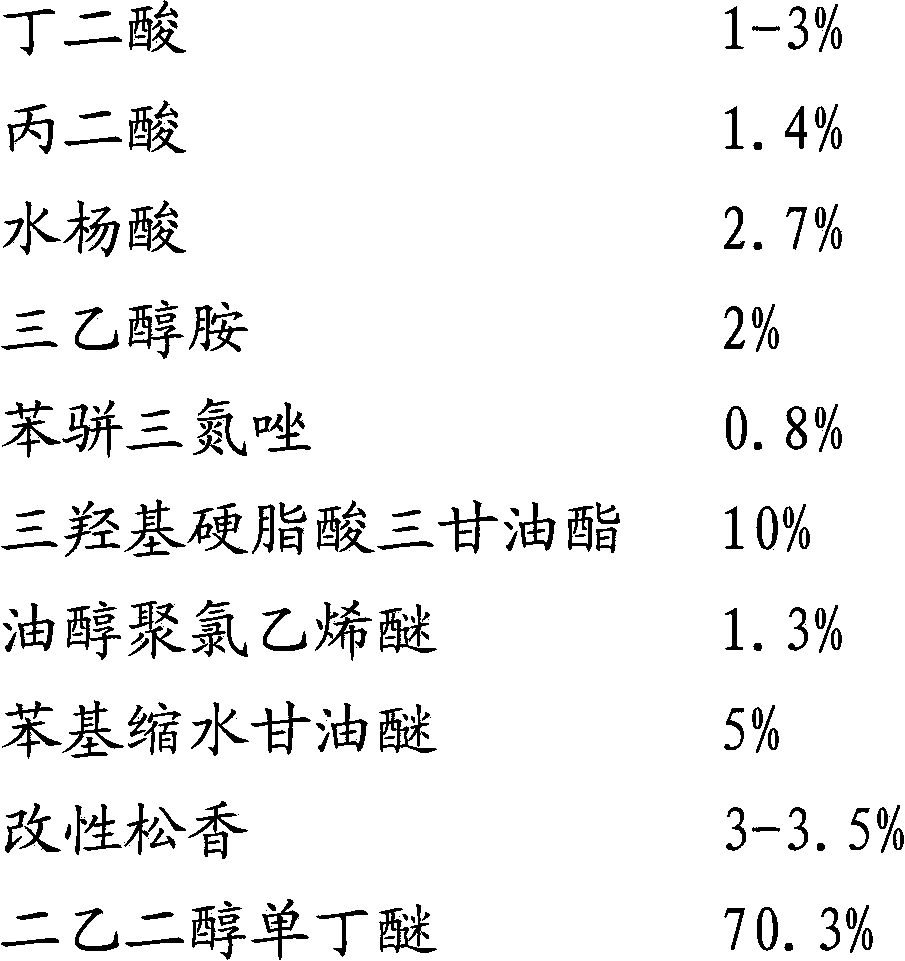

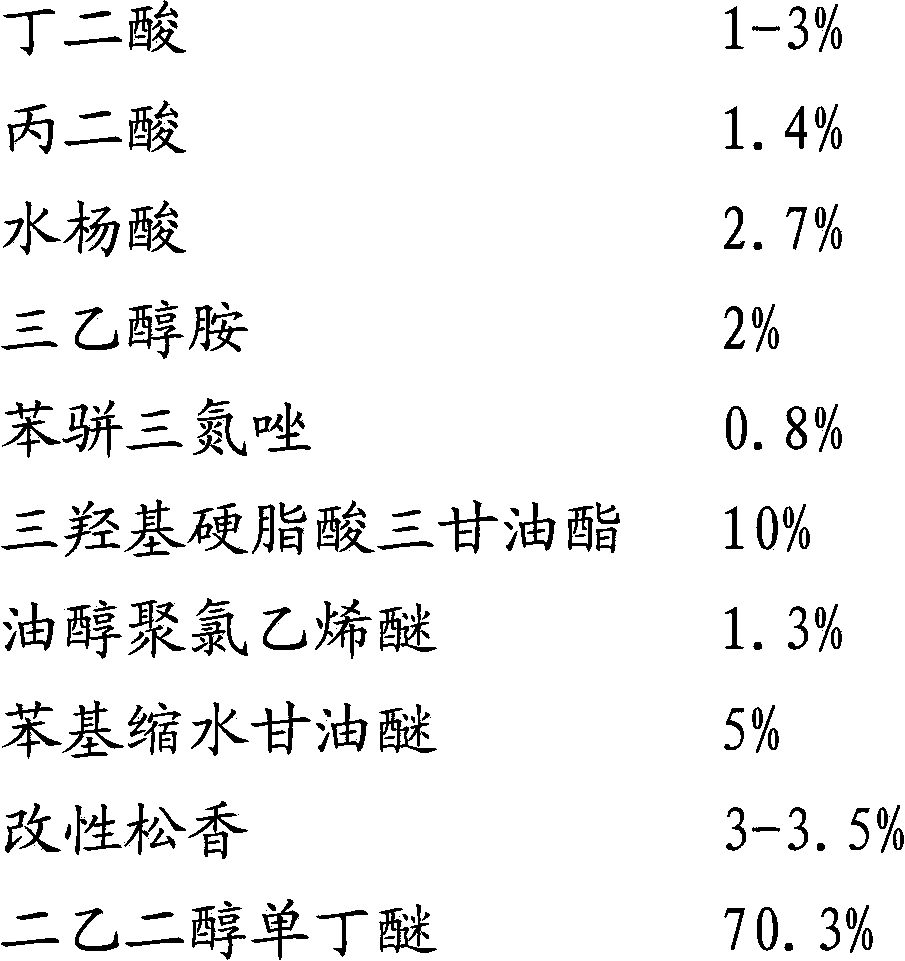

[0009] A new type of flux, calculated by content percentage, it includes the following components:

[0010]

[0011] Process steps:

[0012] 1. Add the above raw materials into the reaction kettle according to the content ratio;

[0013] 2. Stir for 2-3 hours to fully dissolve the raw materials;

[0014] 3. Let stand for half an hour, filter and pack the product.

[0015] Through the above method, a new type of flux provided by the present invention can improve the activity of flux and protect the production environment by adding diethylene glycol monobutyl ether and 3-3.5% modified rosin to the flux. and ensure the health of staff.

[0016] What is described above is only a preferred embodiment of a novel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com