High-performance non-elastomer ternary blending composite material and preparation method thereof

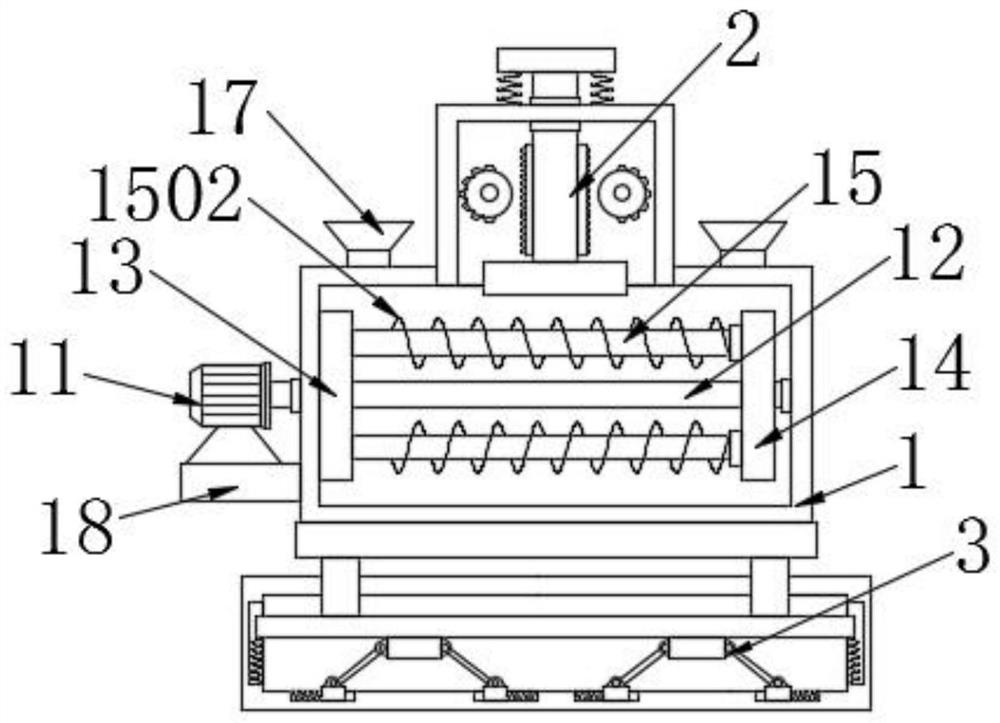

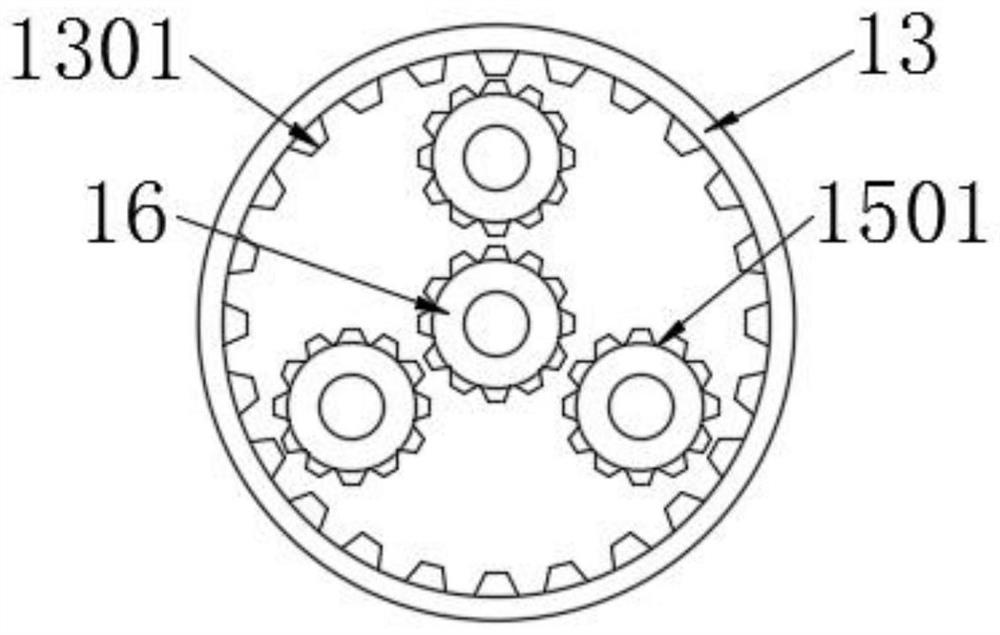

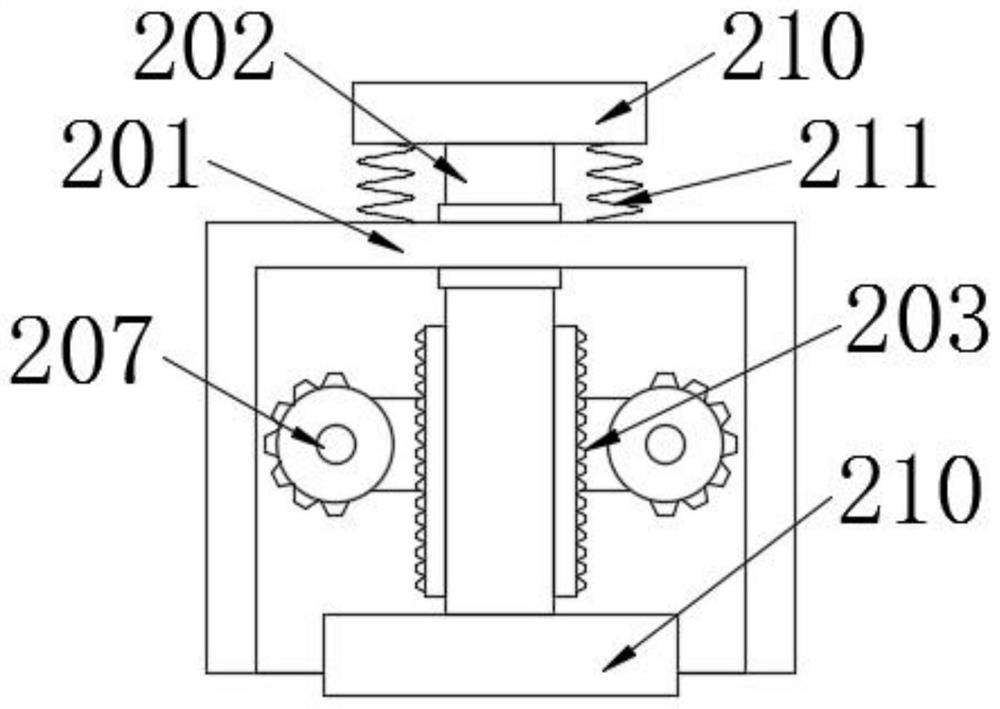

A non-elastomeric, composite material technology, used in mechanical equipment, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of affecting the production environment, low mixing efficiency, waste of time and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A high-performance non-elastomer ternary blend composite material, prepared by the following steps:

[0055] S1. Weigh the following raw materials in parts by weight: 10 parts of ultra-high molecular weight polyethylene, 5 parts of block copolymerized polypropylene, 65 parts of polypropylene and 0.5 parts of antioxidant;

[0056] S2, put the ultra-high molecular weight polyethylene into the banburying equipment for banburying, the temperature is 170°C, and the time is 50min;

[0057] S3, put the block copolymerized polypropylene, polypropylene and antioxidant into the banburying equipment in S2 for banburying to obtain a mixture, the temperature is 180°C, and the time is 60min;

[0058] S4. Extrude and granulate the mixture in S3 to obtain a ternary blend composite material at a temperature of 210° C. for 40 minutes.

[0059] The antioxidant is one or more of hindered phenolic antioxidants and phosphite antioxidants mixed in any proportion;

[0060] The melt index of ...

Embodiment 2

[0062] A high-performance non-elastomer ternary blend composite material, prepared by the following steps:

[0063] S1. Weigh the following raw materials in parts by weight: 20 parts of ultra-high molecular weight polyethylene, 8 parts of block copolymerized polypropylene, 75 parts of polypropylene and 1 part of antioxidant;

[0064] S2. Put the ultra-high molecular weight polyethylene into the banburying equipment for banburying, the temperature is 175°C, and the time is 55min;

[0065] S3, put the block copolymerized polypropylene, polypropylene and antioxidant into the banburying equipment in S2 for banburying to obtain the mixture, the temperature is 185°C, and the time is 65min;

[0066] S4. Extrude and granulate the mixture in S3 to obtain a ternary blend composite material at a temperature of 210° C. for 45 minutes.

[0067] The antioxidant is one or more of hindered phenolic antioxidants and phosphite antioxidants mixed in any proportion;

[0068] The melt index of t...

Embodiment 3

[0070] A high-performance non-elastomer ternary blend composite material, prepared by the following steps:

[0071] S1. Weigh the following raw materials in parts by weight: 30 parts of ultra-high molecular weight polyethylene, 10 parts of block copolymerized polypropylene, 90 parts of polypropylene and 1.5 parts of antioxidant;

[0072] S2, put the ultra-high molecular weight polyethylene into the banburying equipment for banburying, the temperature is 180°C, and the time is 60min;

[0073] S3, put the block copolymerized polypropylene, polypropylene and antioxidant into the banburying equipment in S2 for banburying to obtain a mixture, the temperature is 190°C, and the time is 70min;

[0074] S4. Extrude and granulate the mixture in S3 to obtain a ternary blend composite material at a temperature of 210° C. for 50 minutes.

[0075] The antioxidant is one or more of hindered phenolic antioxidants and phosphite antioxidants mixed in any proportion;

[0076] The melt index of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com