Fully-woven upper sheet ironing setter

A technology for ironing and setting machine and sheet material, which is applied in the direction of fabric surface trimming, textile and papermaking, heating/cooling fabrics, etc., and can solve the requirements that cannot meet the setting requirements of full woven shoe upper materials, is not suitable for woven shoe uppers, and can not meet the production cost. High problems, to achieve the effect of small thermal expansion coefficient, high friction coefficient, and large thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

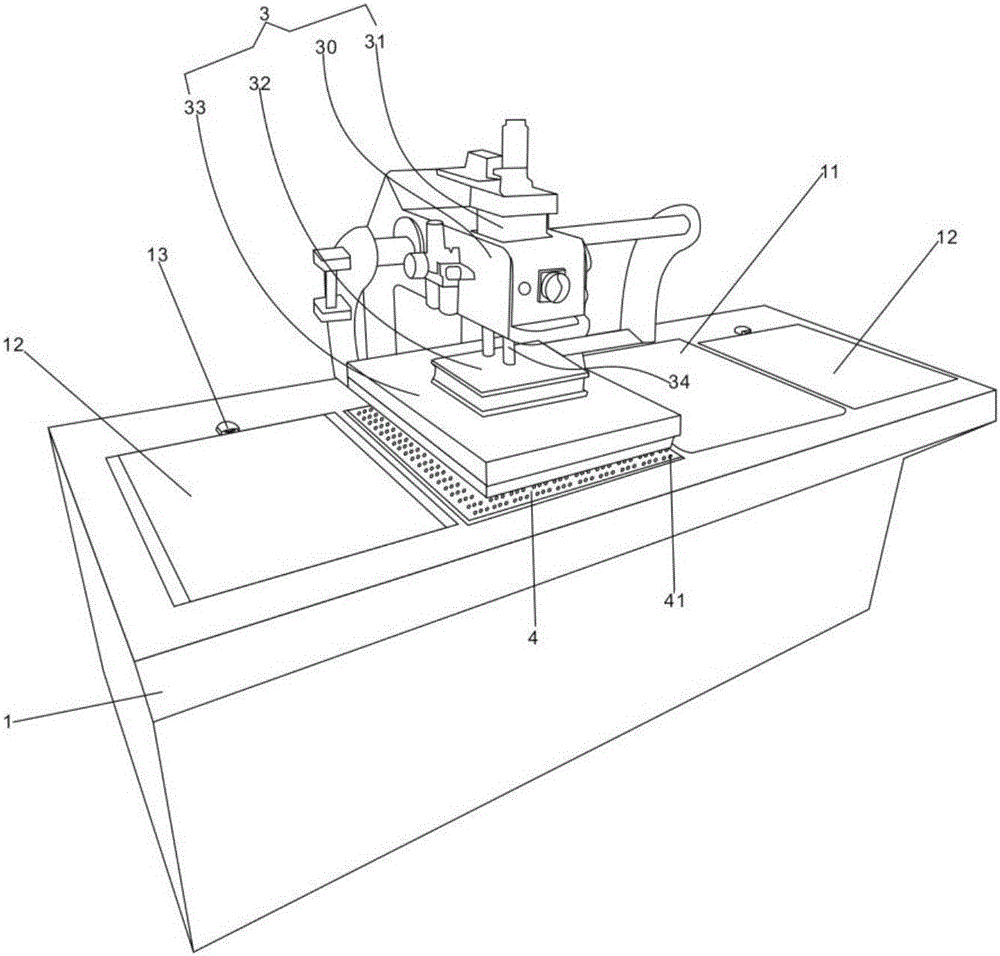

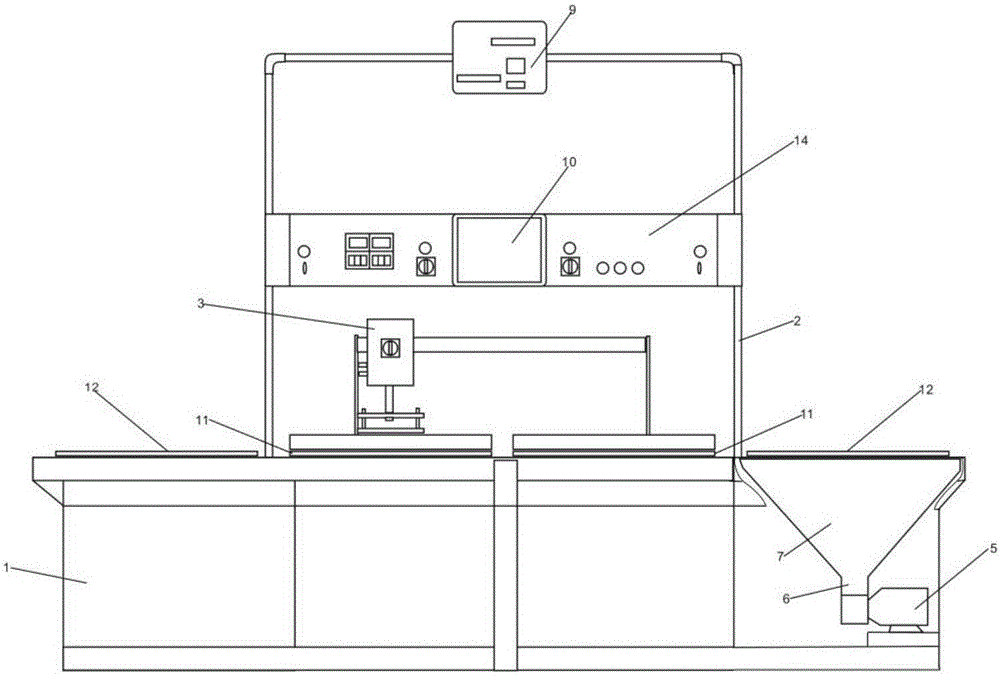

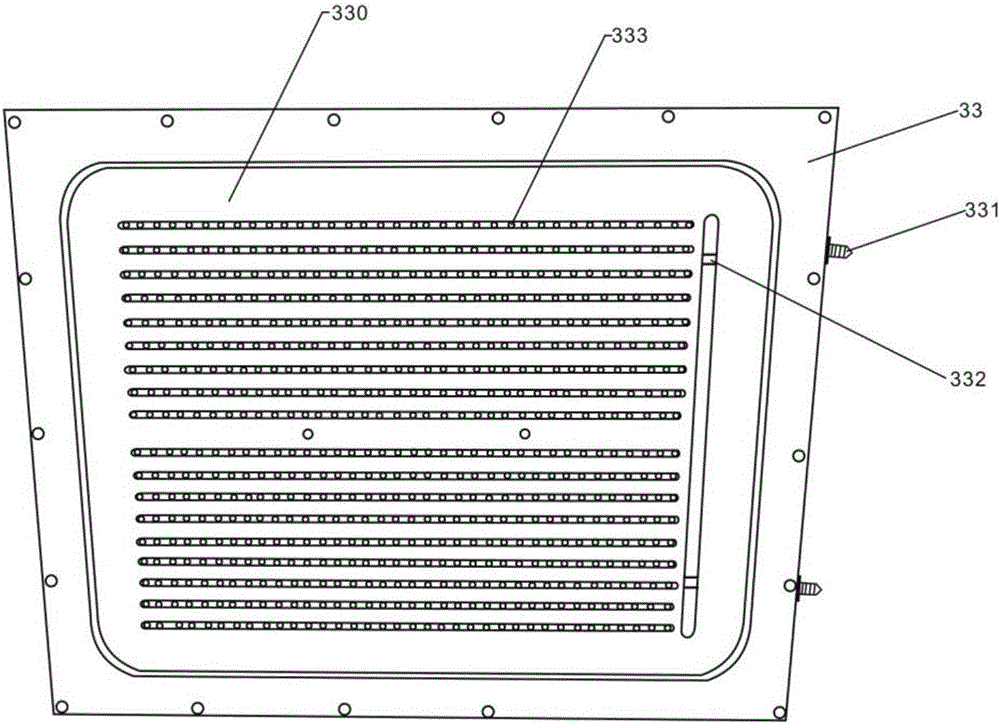

[0022] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

[0023] A double-station fully woven shoe upper sheet ironing machine, as attached figure 1 , 2 As shown, the main body is a workbench 1 with a steel material structure. The workbench top forms two ironing areas 11 and two cooling areas 12. The two ironing areas are located in the middle of the table, and the two cooling areas are respectively located in the ironing area. side. A light touch push switch 13 is respectively installed on the upper edge of the cooling zone. A frame 2, a steam ironing device 3, and a control device 14 are installed at the rear of the workbench. The steam ironing device is fixed on the frame and installed on the upper part of the ironing area.

[0024] A slide bar and a push-pull cylinder are installed on the back side of the workbench, and the steam ironing device is movably installed on the slide bar and connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com