Coke oven ascension pipe heat exchanger raw gas outlet temperature interlock control device and process

A technology of outlet temperature and interlock control, which is applied to the discharge device of retort gas, the heating of coke oven, coke oven, etc. It can solve the problems of unsuitable control of raw gas outlet temperature, potential safety hazards, slagging, etc., and reduce furnace roof Effects of debugging jobs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

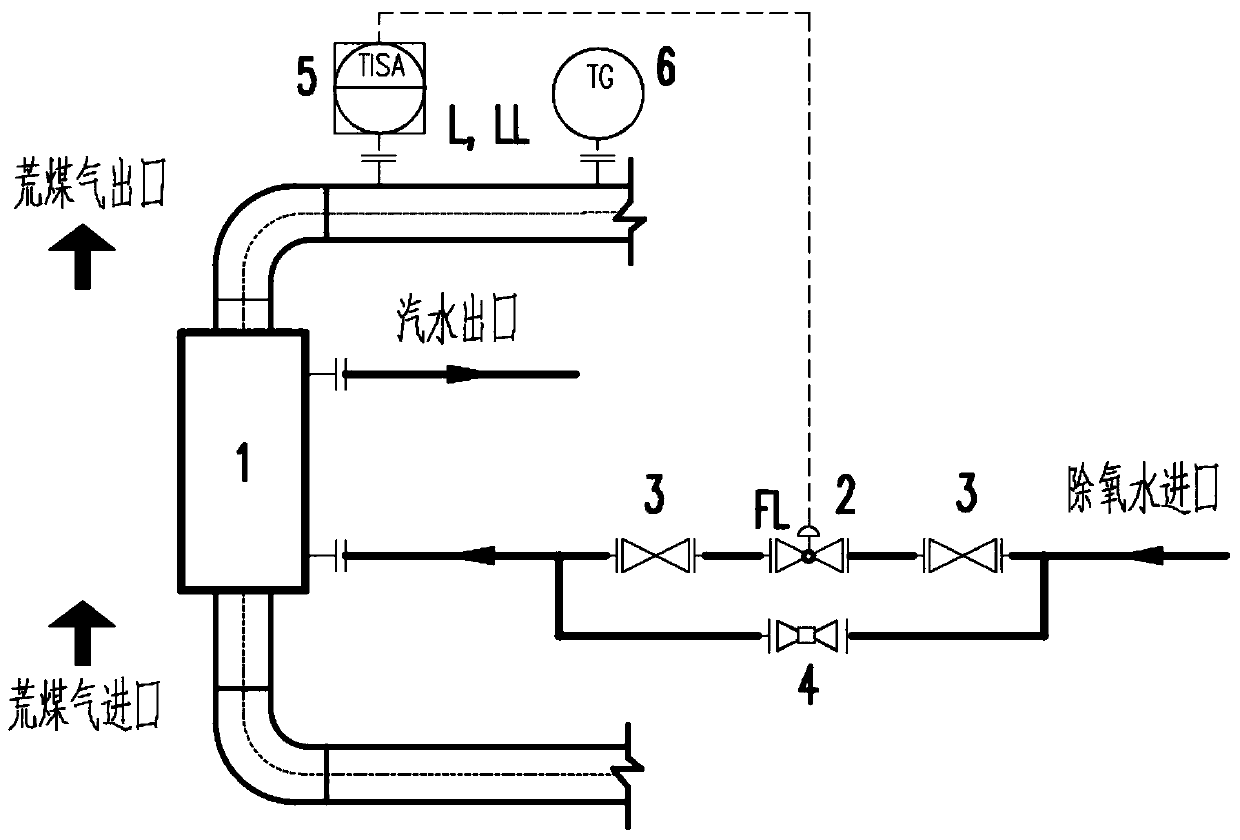

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as figure 1 As shown, a coke oven riser heat exchanger raw gas outlet temperature interlock control device, including the coke oven riser heat exchanger 1, the coke oven riser heat exchanger is provided with deoxygenated water inlet, raw gas inlet, soda Outlet with raw gas outlet.

[0028] Coke oven riser heat exchanger 1 adopts standpipe casing type coke oven riser heat exchanger, which uses the sensible heat of coke oven raw gas to produce low-pressure steam. The outlet temperature is 400-550°C.

[0029] The raw gas outlet is provided with a temperature upper panel indicator 5 and an on-site thermometer 6 in sequence. The temperature upper plate indicator 6 has its own indication, interlock and alarm functions, and two temperature thresholds of L and LL are set: low value (450°C<t≤500°C); low and low value (t≤450°C).

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com