Dust removal pipeline dust gas flow adjustment system

A flow adjustment and flow regulation technology, applied in the direction of flow control using electrical devices, etc., can solve the problems of multiple pipeline branches in the system, pollution of the production environment, labor and time consumption, etc., to achieve convenient installation and use, protection of production environment, and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

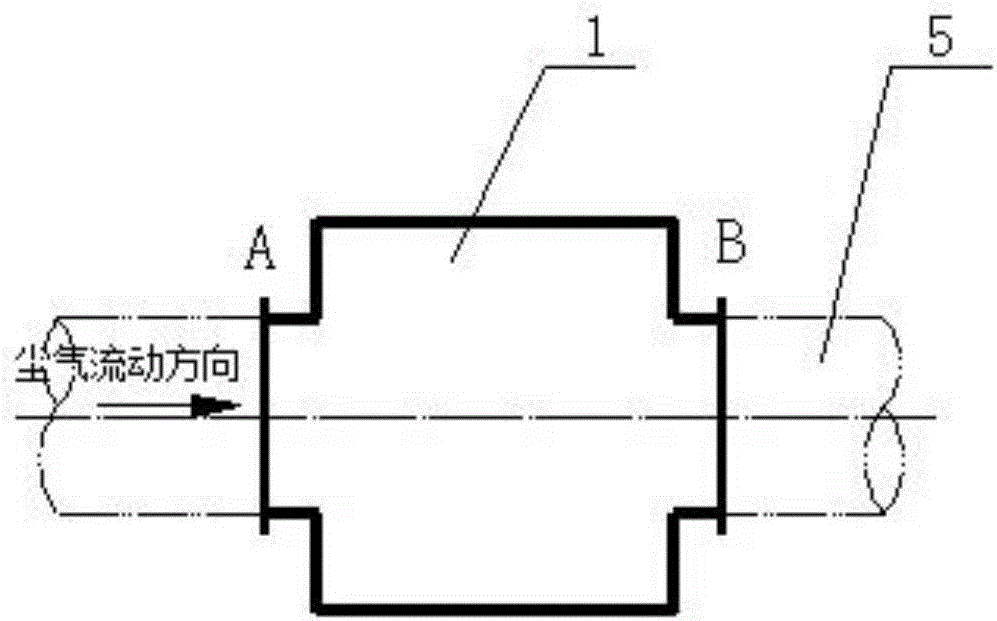

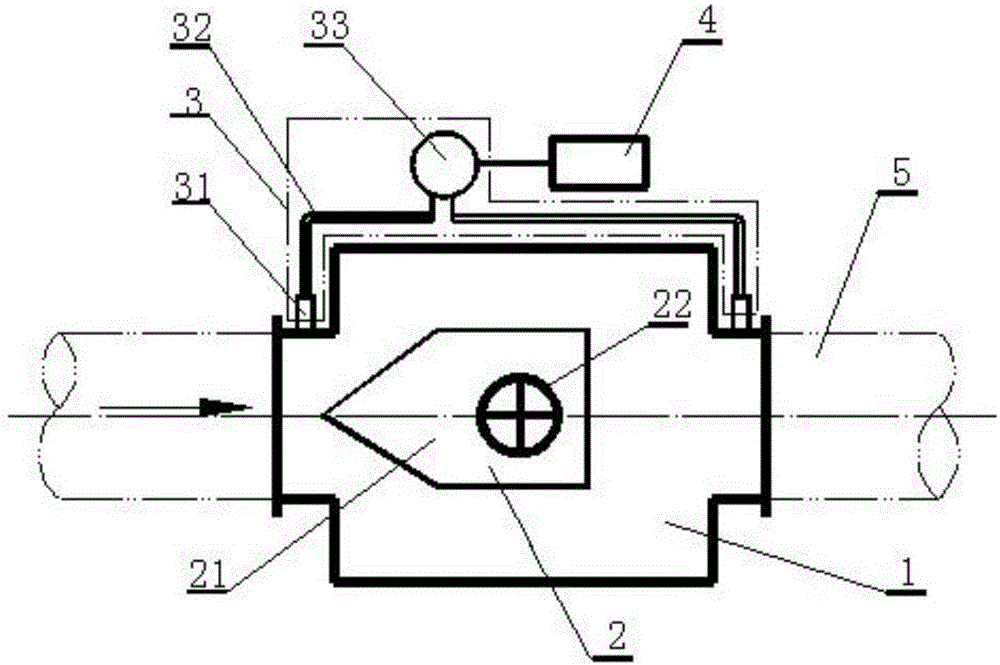

[0030] Such as figure 1 and figure 2 As shown, the dust gas flow adjustment system of the dust removal pipeline according to the present invention includes a cylinder body 1, a dust gas flow adjustment unit 2, a pressure difference detection unit 3 and a control unit 4, and the cylinder body 1 is installed on the dust removal pipeline 5 The cylinder body 1 is equipped with a dust gas flow regulating unit 2, and the cylinder body 1 is equipped with a differential pressure detection unit 3, and the output end of the differential pressure detection unit 3 is connected to the control terminal of the dust gas flow regulating unit 2 through the control unit 4.

[0031] Both ends of the cylinder body 1 have a diameter matched with the dust removal pipeline 5, and the dust gas flow adjustment unit 2 is a throttling body. Through manual or electric adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com