Patents

Literature

38results about How to "Good maintenance cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating As polluted soil

InactiveCN1397390ADoes not destroy physical and chemical propertiesFix fixesContaminated soil reclamationPollution soilBiology

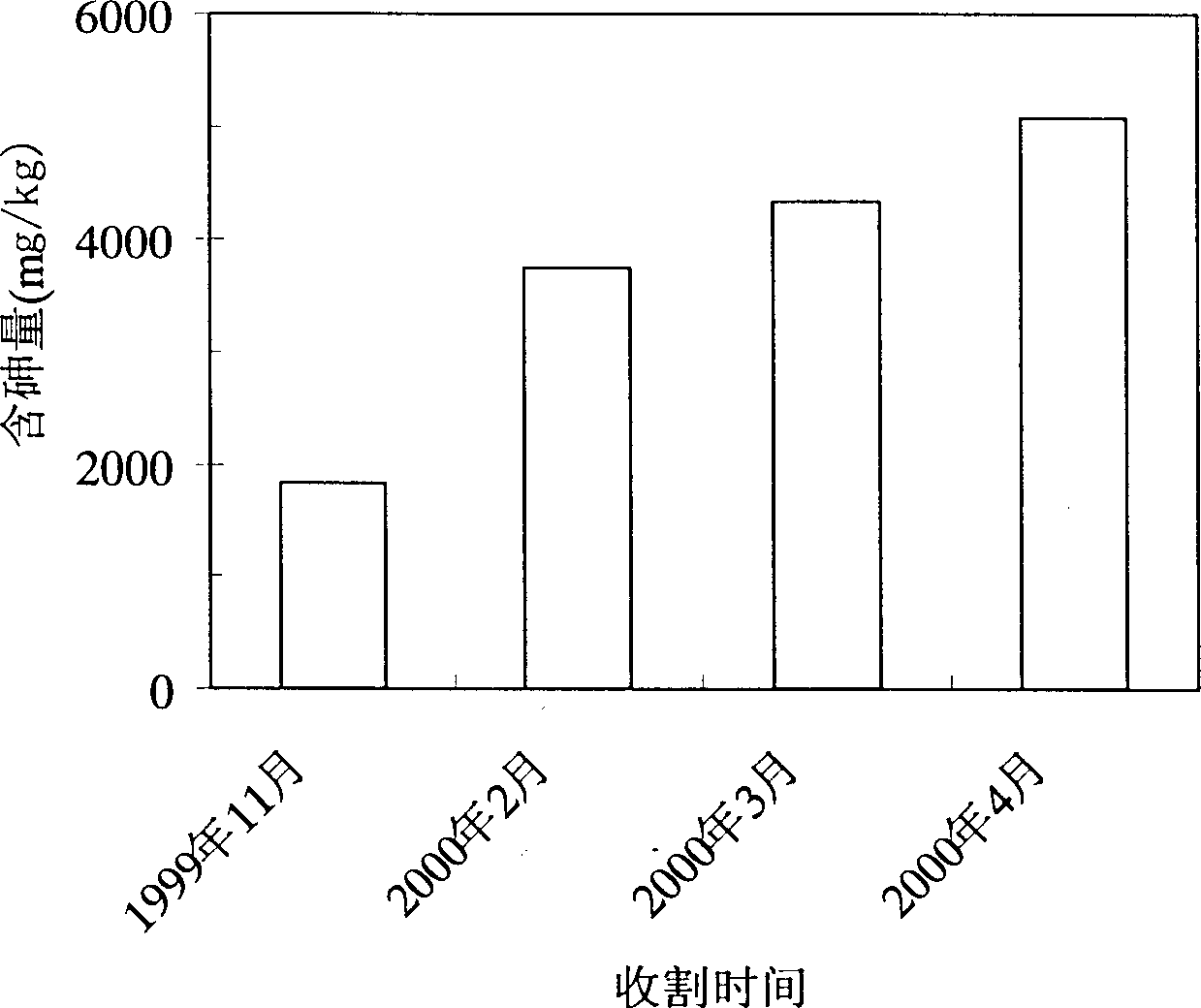

A method for treating the As-polluted soil features that the Chinese brake herbs are planted in said soil for absorbing the As from the soil and the their leaves are removed periodically (5-6 months). For acid soil, the lime or alkaline fertilizer can be applied to increase its pH value.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

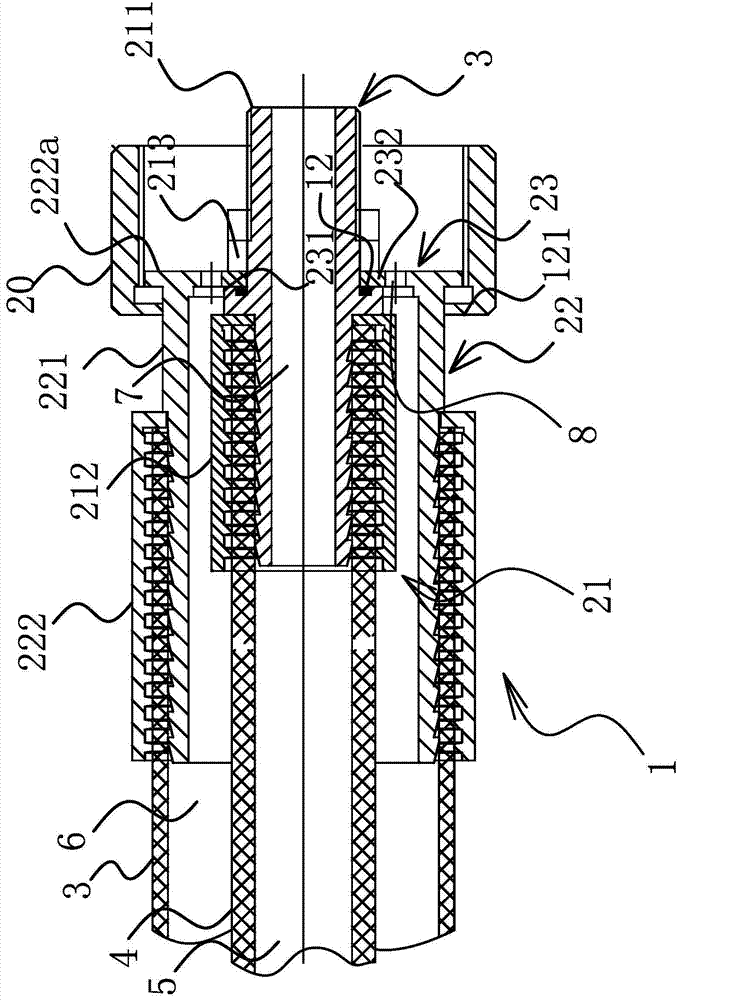

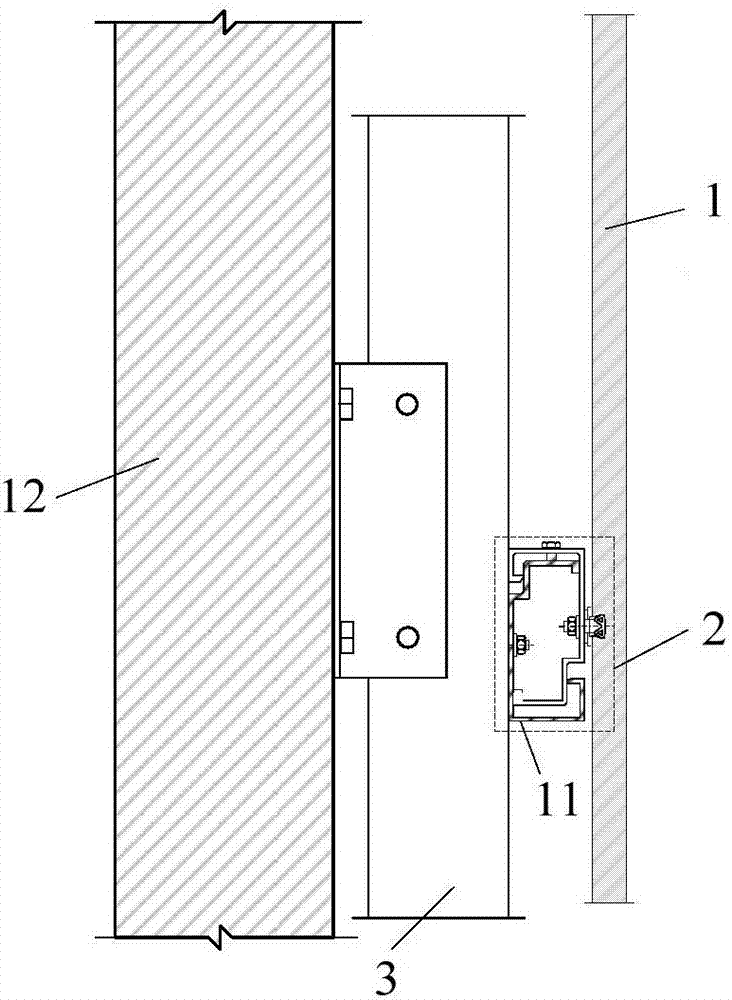

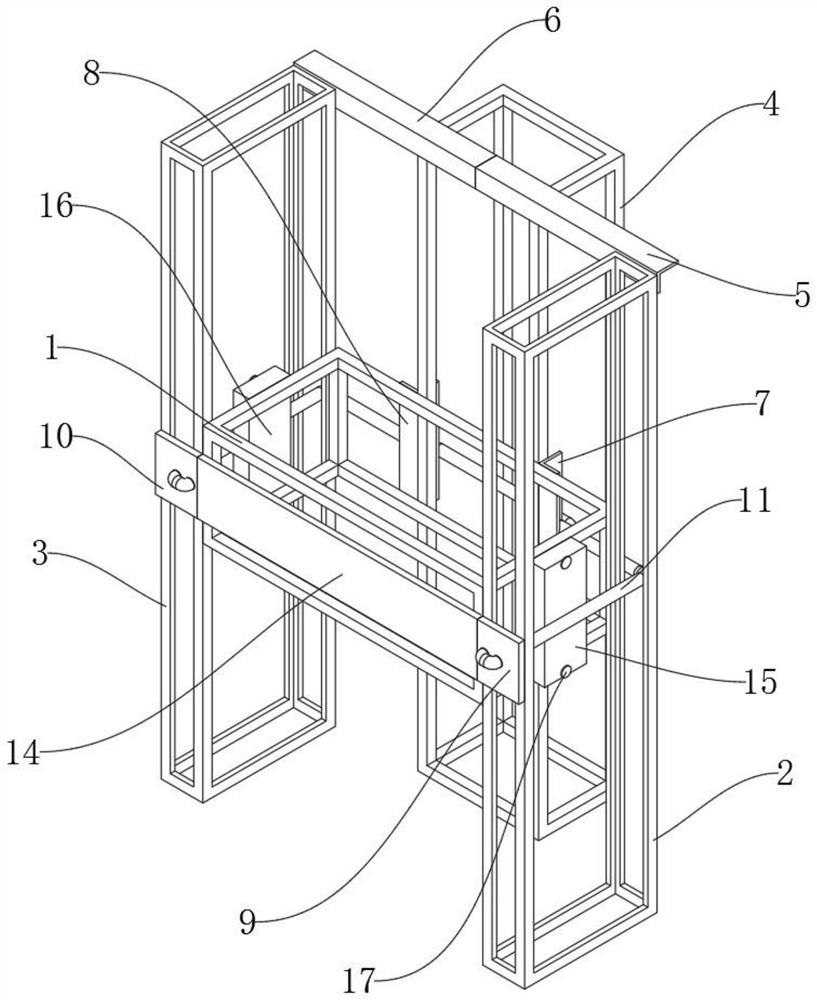

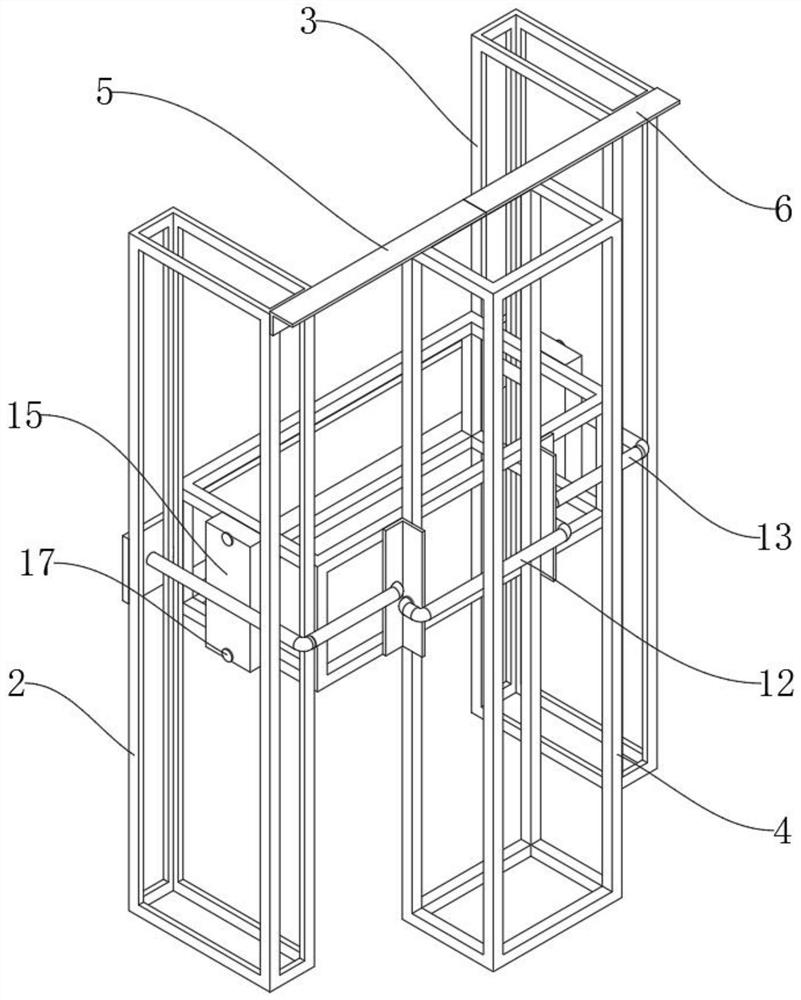

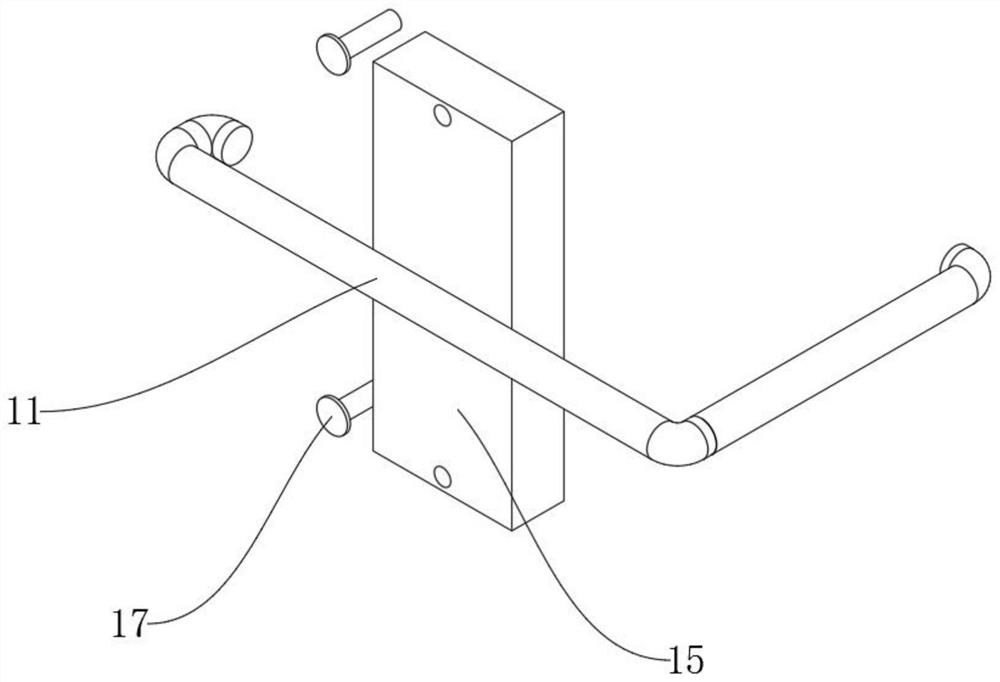

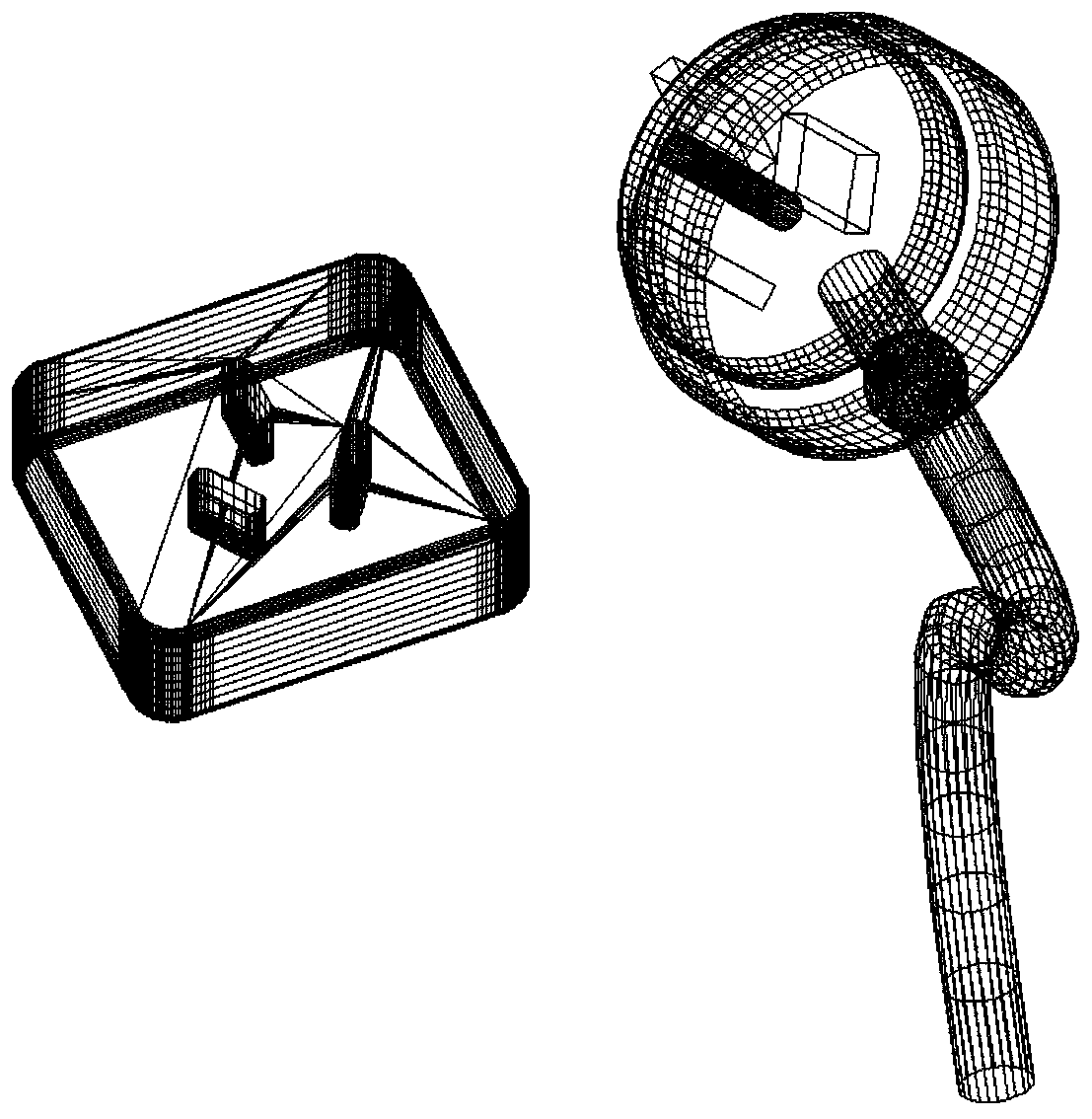

Linear motor drive device of shifting door

InactiveCN102877735ASimple structureReliable principlePower-operated mechanismStructural associationFriction lossStator

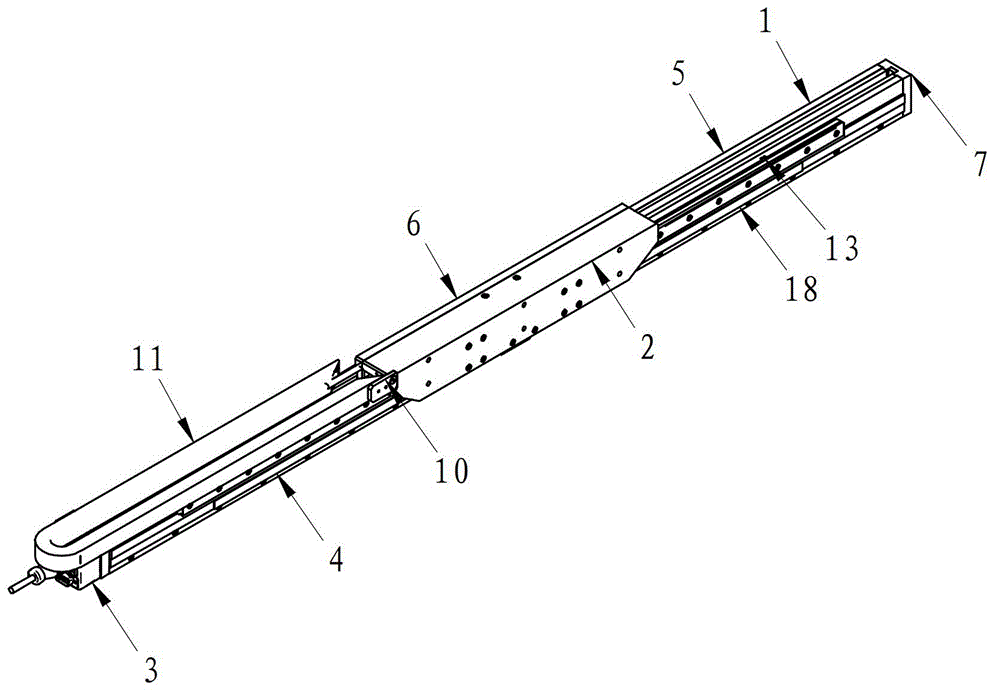

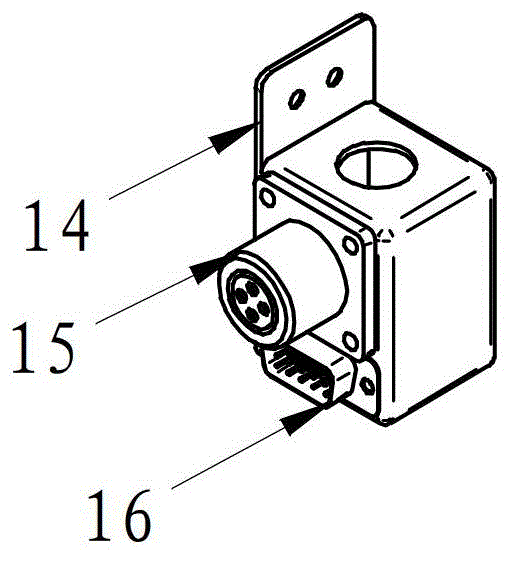

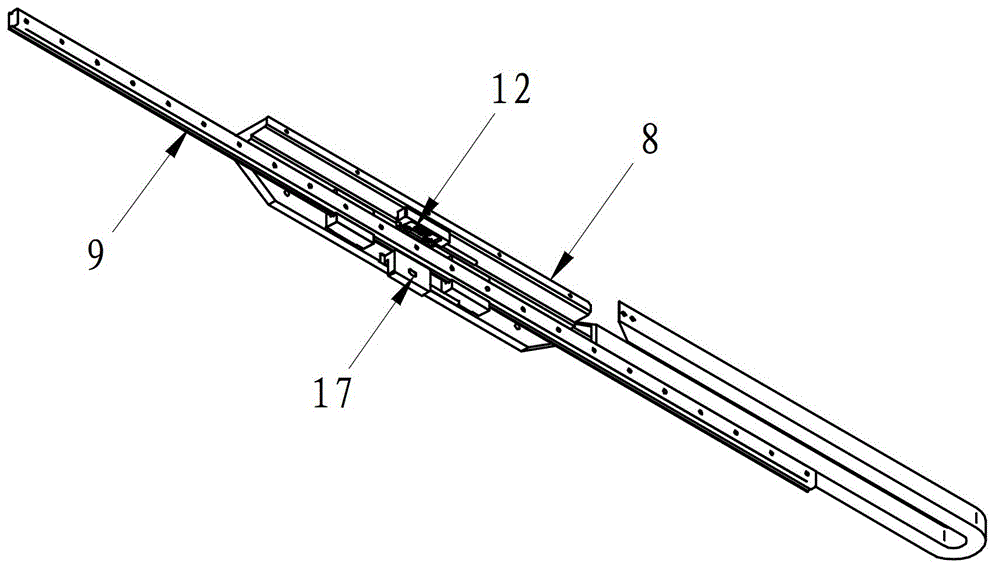

The invention belongs to the technical field of door devices of subway equipment and relates to a linear motor drive device of a shifting door. A linear motor component is composed of a linear motor stator, a linear motor rotor and a limit base. The limit base is fixed at two ends of the linear motor stator through bolts; a slide component is composed of a slide base, a linear guide rail component, a drag chain plate which are matchedly assembled, a drag chain and a Hall component, wherein the slide base is connected with the linear motor rotator and the linear guide rail component respectively through holts, the linear guide rail component is fixed on one side of the linear motor stator through a bolt, the Hall component is fixed on the slide base through a bolt, and Hall magnetic steel is attached and fixed on the linear motor stator; a number reading head is fixed on the slide base, and a magnetic railing ruler is attached on one side of the linear motor stator; and the Hall magnetic steel is distributed at two ends and in the middle of a whole stroke. The linear motor drive device of the shifting door is simple in structure, reliable in principle, mature in manufacture process, low in manufacture cost, good in operation safety, long in service life, environment friendly, small in noise and occupied space, and free of friction loss.

Owner:青岛同日电机有限公司

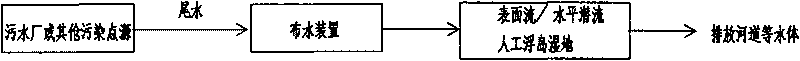

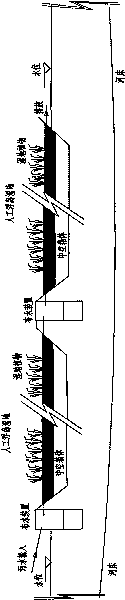

Advanced water treatment method by utilizing artificial floating island wetland

InactiveCN101700933ADoes not affect flood control and drainageImprove water treatment effectSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandFlood control

The invention provides an advanced water treatment method by utilizing an artificial floating island wetland, an artificial floating island is adopted as a carrier of an artificial wetland, the artificial wetland is floated on the water surface of a river channel or a lake out of water to form the artificial floating island, point source sewage on the river side or the lake bank is evenly distributed in the artificial floating island wetland by a water distributing device and not contacted with the external river water or lake water, and the sewage is treated by the artificial wetland in the artificial floating island wetland and directly drained after being treated. The invention is specially used for blocking sewage that is directly drained to water bodies, such as river channels, lakes, and the like and achieves landscape water drainage after advanced treatment. The invention fully utilizes the areas of the river channel and the lake body, does not influence flood control and stagnant water drainage or occupy the land area, has better water treatment effect compared with the common artificial floating island technology and achieves the same effect with the artificial wetland on the land. The invention has very large application potential in the drainage standard administration to tail water of sewage plants, industrial, living and commercial pollution point sources concentrated in urban areas.

Owner:NANJING UNIV

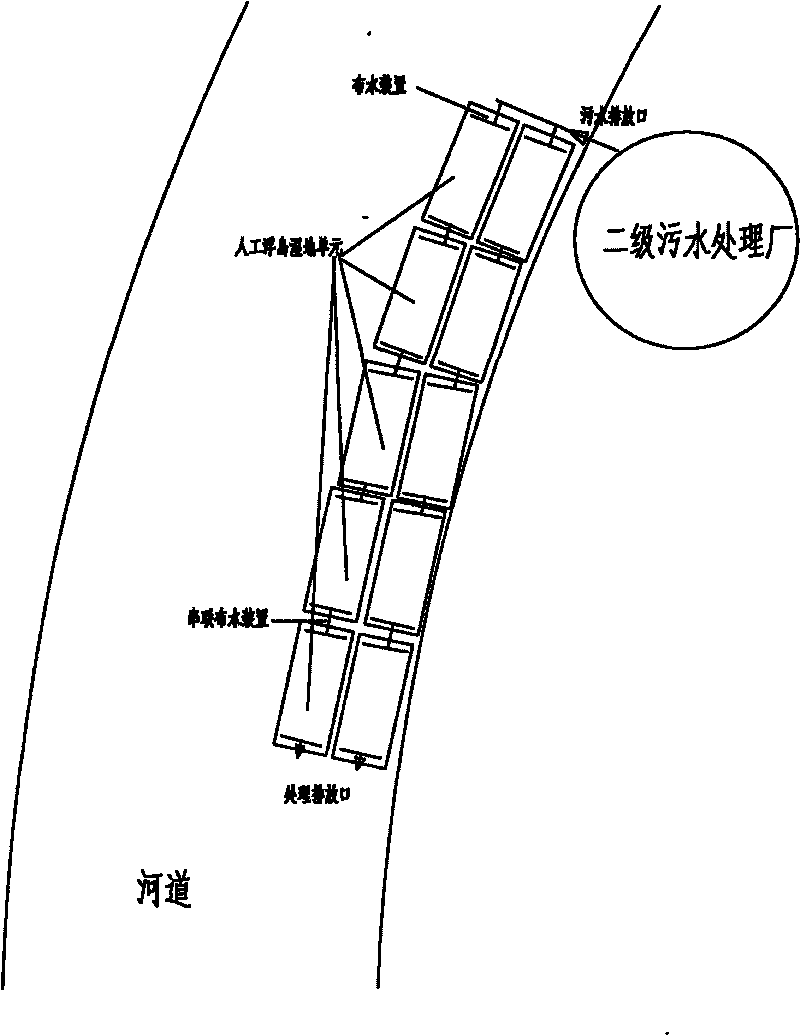

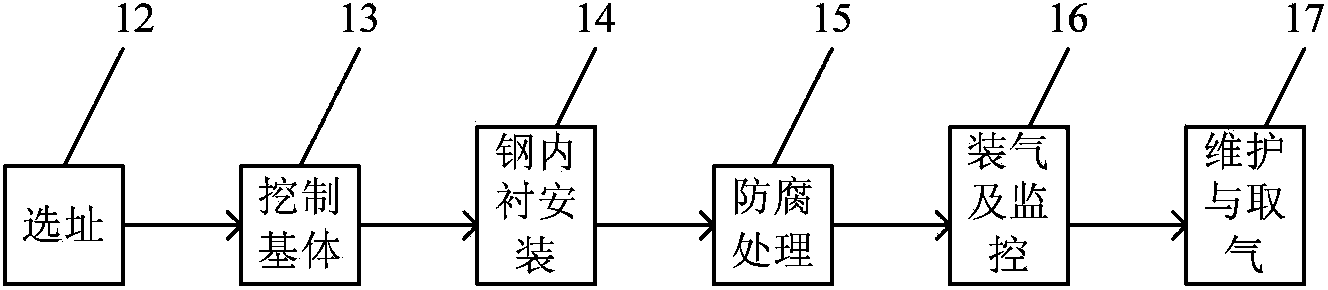

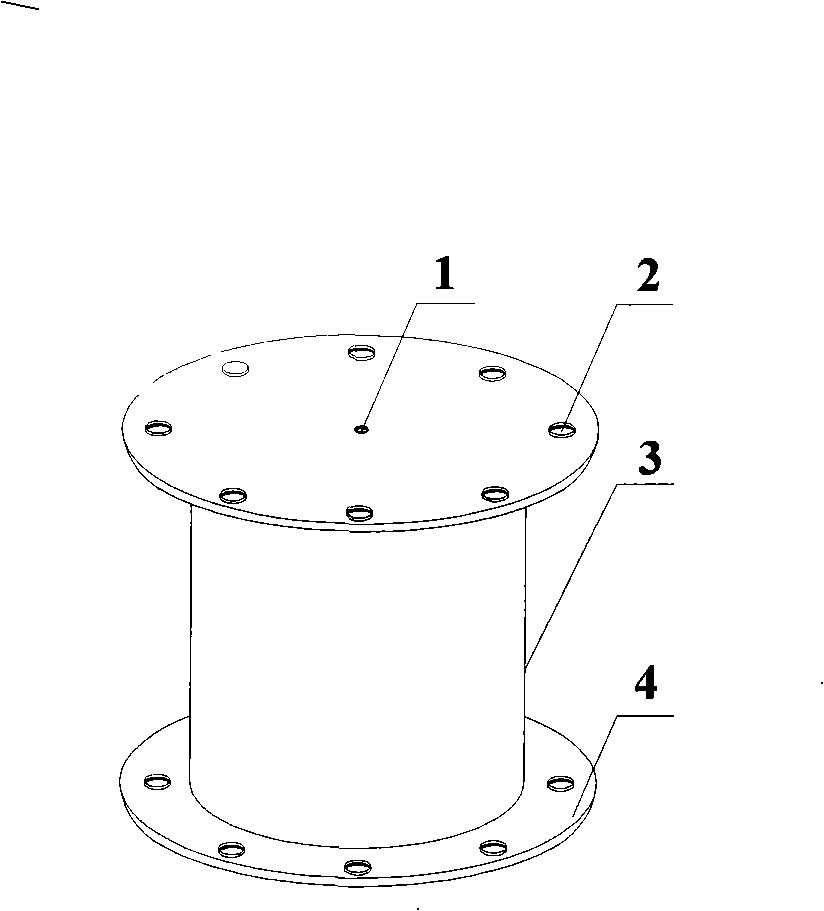

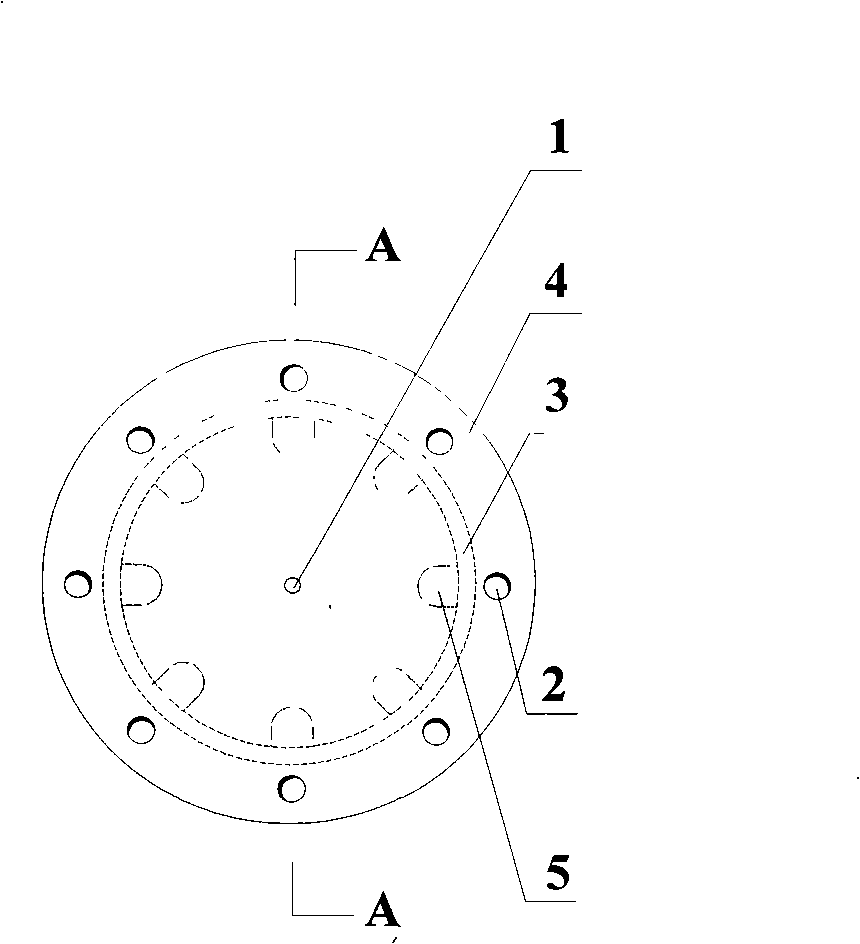

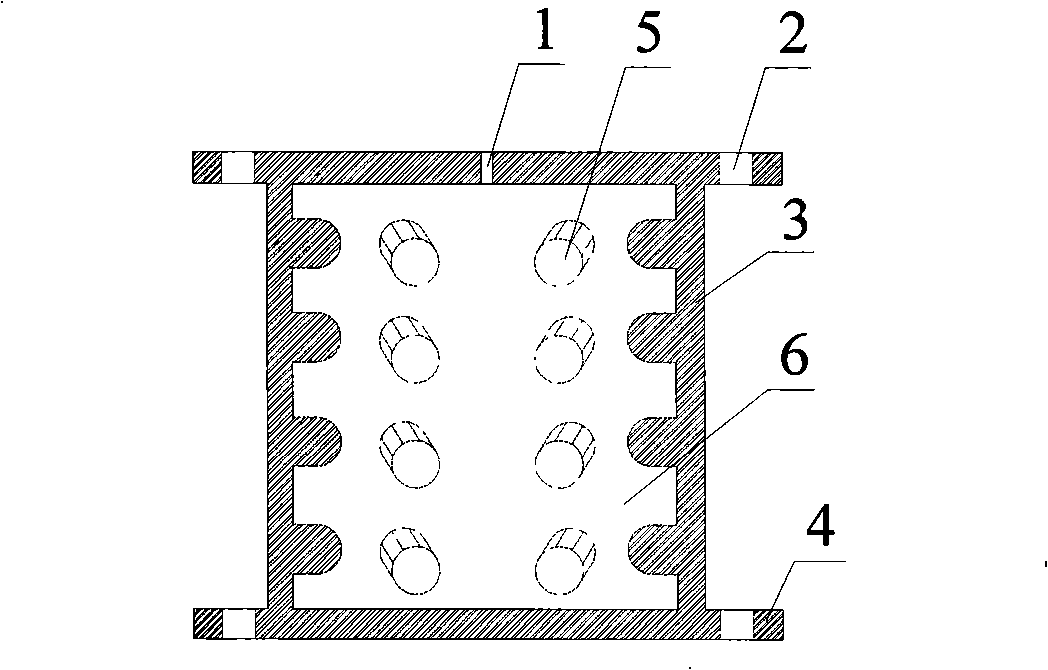

High-pressure gas preservation method

InactiveCN103423583AStrong construction adaptabilityImprove securityMining devicesContainer filling methodsWater contentRebar

The invention belongs to the technical field of gas storage, and relates to a preservation method of high-pressure gas deeply embedded underground. According to the invention, an area with hard geological structure is selected as a gas preservation site; a base is dug on the selected gas preservation site; a construction channel or a working chamber is preserved in the base; a cylindrical steel liner is welded in the inner cavity of the base through the construction tunnel and the working chamber; network steel bar concrete or network steel bar asphalt mixture is filled in the space between the steel liner and the base, and an anti-corrosion treatment is carried out on the periphery of the steel liner; compressed gas to be stored is filled into the steel liner through a gas inlet pipe and a valve on the top of the steel liner under the control of a compression pump, and the state in the steel liner is controlled through a monitoring device; high-pressure gas stored in the steel liner is monitored regularly, such that gas pressure, temperature, water content, and density parameters of high-pressure gas stored in the steel liner are controlled in real time. The process principle is reliable, storage safety is good, control is flexible, operation cost is low, and the method is environment-friendly.

Owner:COOEC ENPAL ENG

Twisting-resistant self-restoring lead core shape memory alloy damper

InactiveCN101514569AImprove vibration damping effectImprove energy consumptionShock proofingVertical vibrationShape-memory alloy

A twisting-resistant self-restoring lead core shape memory alloy damper consists of a shape memory alloy cylinder, shape memory alloy extruding beads, shape memory alloy flanges and a lead core. The damper is characterized in that the shape memory alloy extruding beads are symmetrically distributed along the peripheral radial direction of the shape memory alloy cylinder which is fully filled with lead; the damper is fixed at a part in need of twist control through the flanges; when the upper and lower flanges have relative twisting motion, the shape memory alloy cylinder and the lead core consume energy, and the extruding beads extrude the lead core to consume energy, so that the three parts provide strong twisting-resistant energy consumption capability; and when the vibration is over, the damper automatically restores to the primary position. The damper has advantages of strong twisting-resistant energy consumption capability, low maintenance cost, repeated use, self restoration, simple structure, easy installation and the like, simultaneously has vertical vibration energy consumption capability, and can achieve multi-dimensional passive control of the structure.

Owner:DALIAN UNIV OF TECH

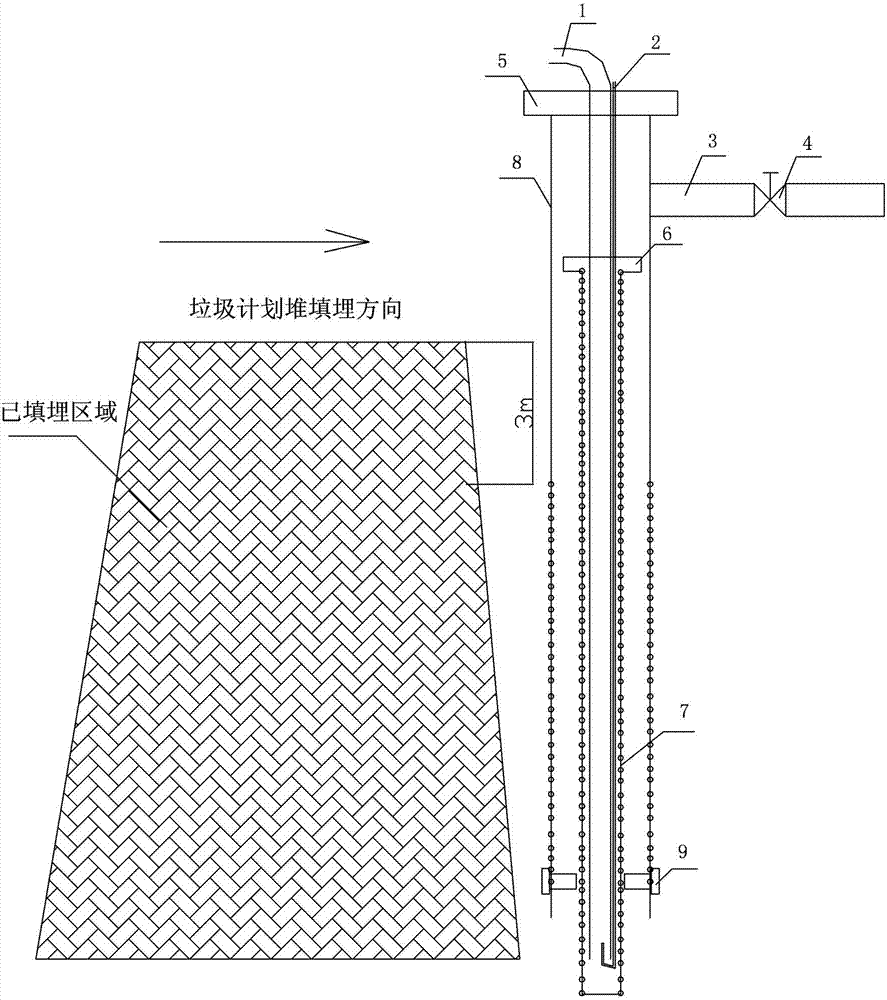

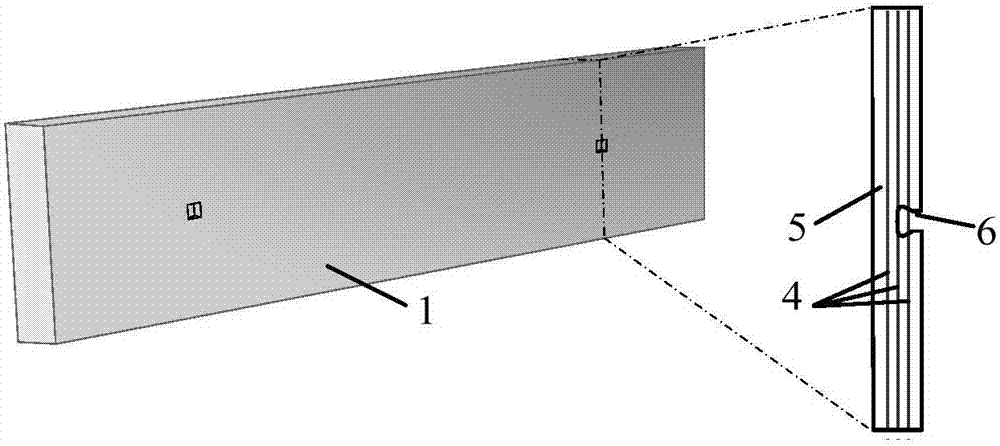

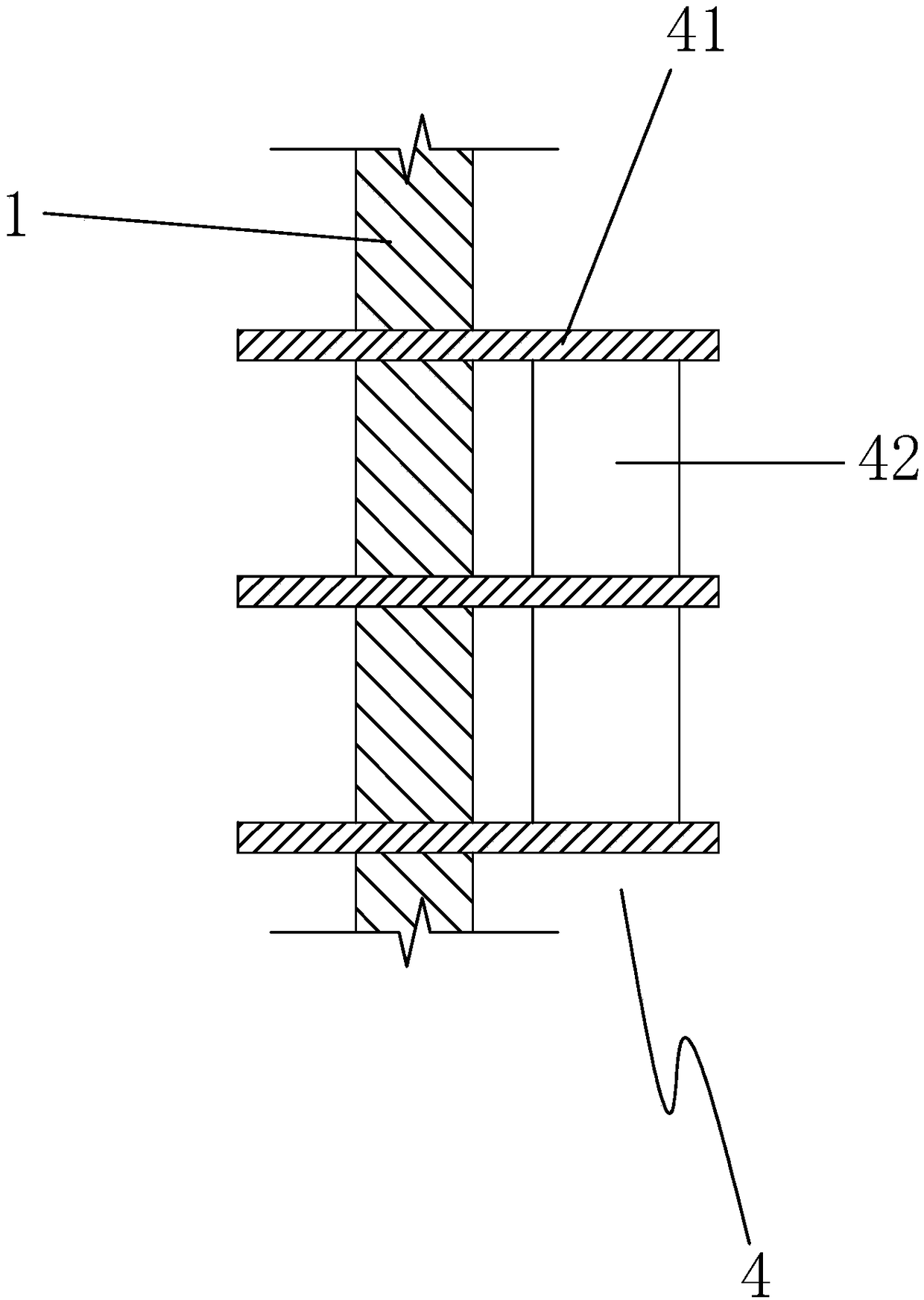

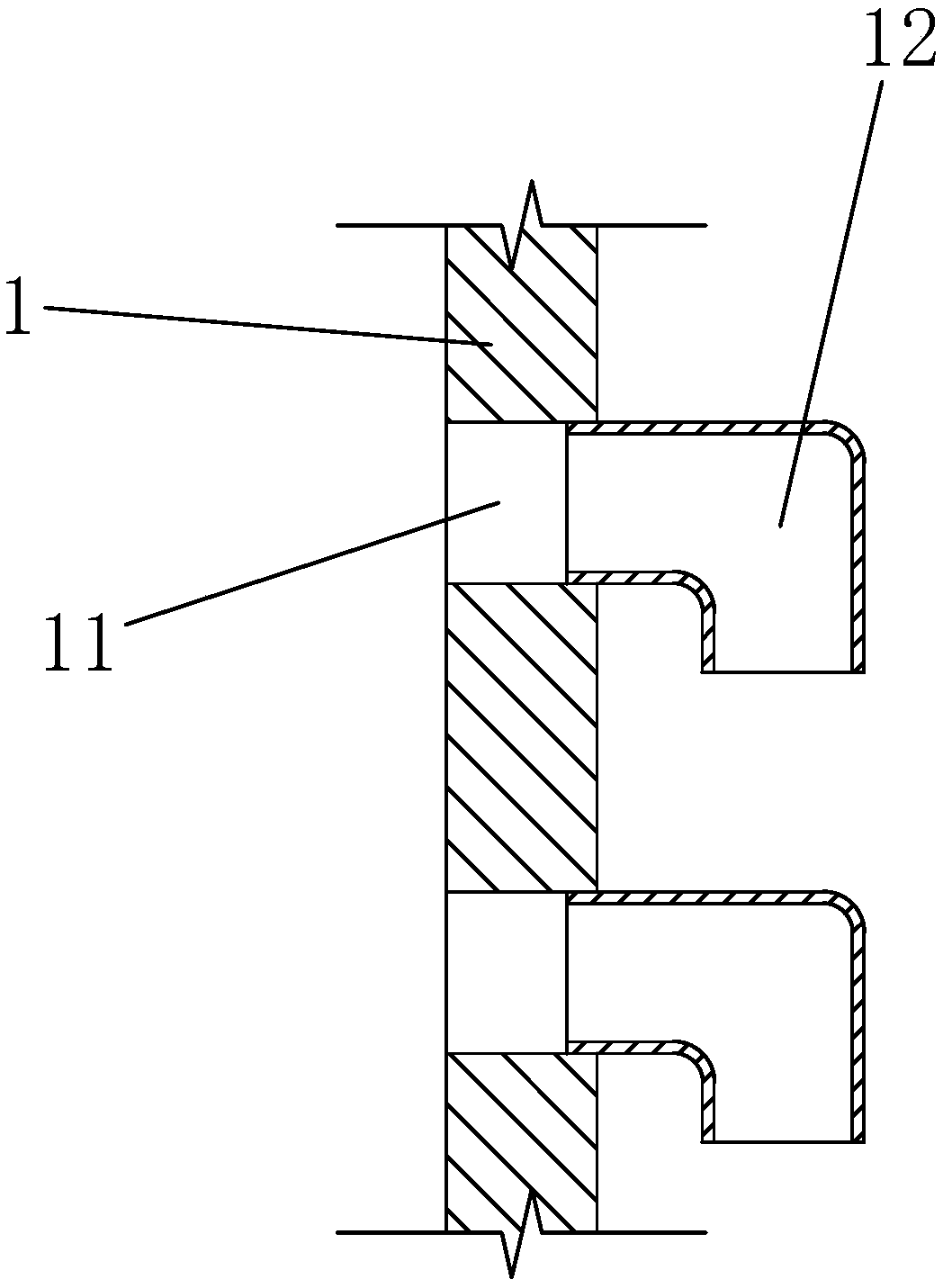

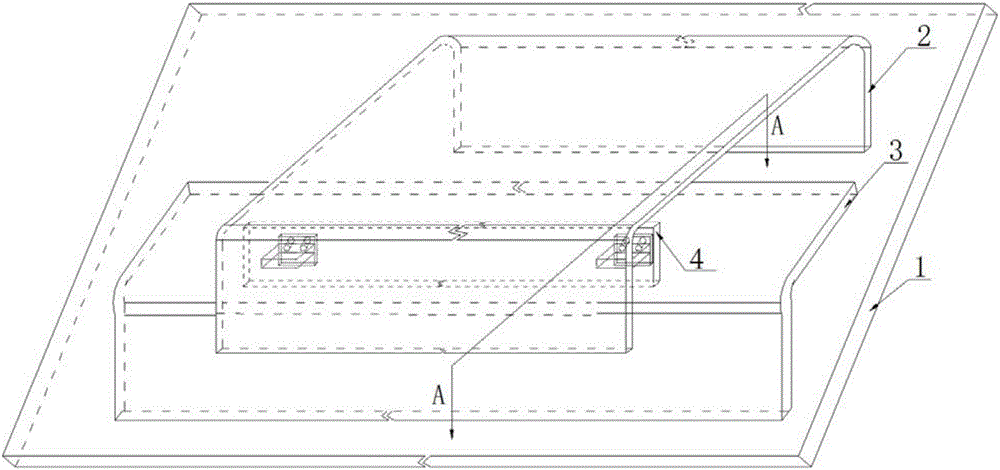

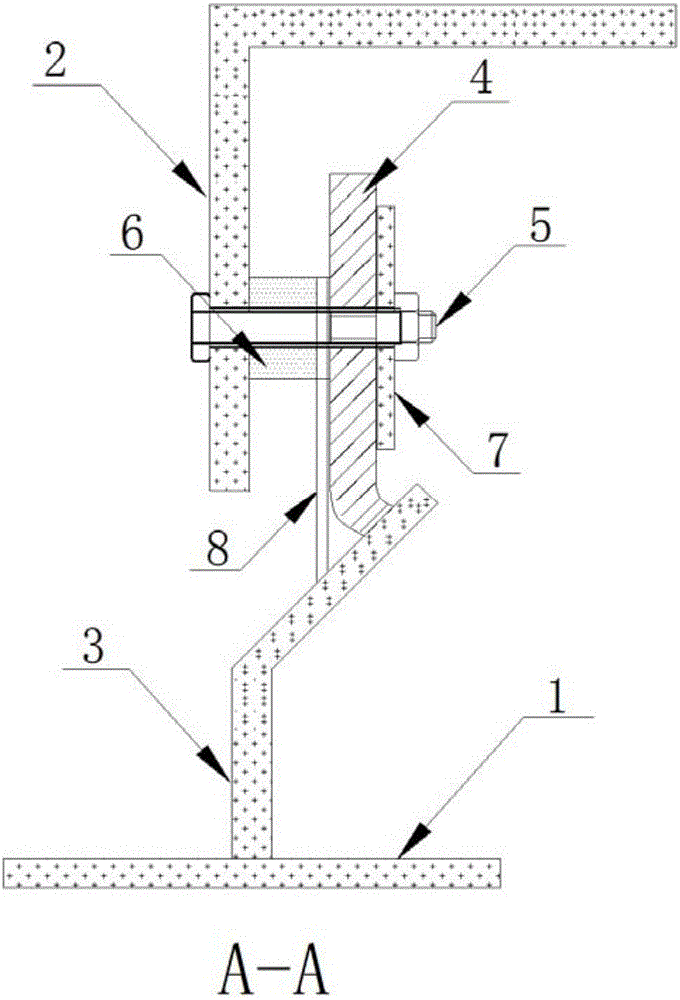

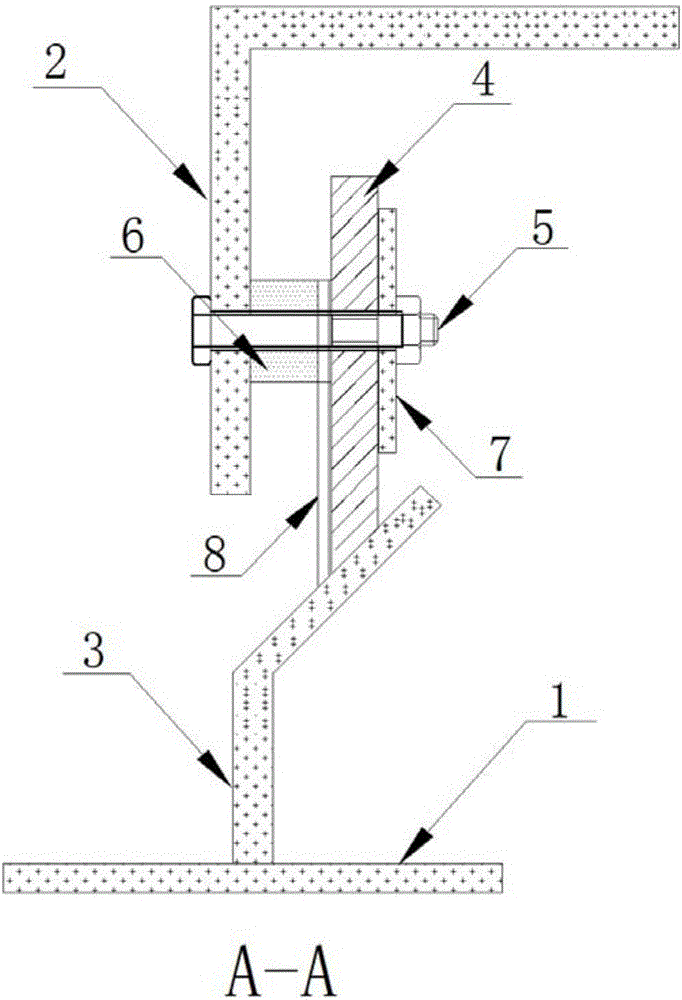

Pre-buried elevating landfill gas collecting well

InactiveCN102896131ASimple structureReasonable designLandfill technologiesSolid waste disposalEconomic benefitsEnvironmental engineering

The invention relates to a landfill gas collecting well which is used for collection of garbage landfill gas. A pre-buried elevating landfill gas collecting well provided by the invention comprises a gas collection pipe and an exhaust pipe, wherein the exhaust pipe is installed at the upper part of the gas collection pipe and is used for connecting a branch exhaust pipe to realize gas collection, a well mouth valve is arranged on the exhaust pipe and is used for controlling negative pressure and collection flow of the landfill gas collecting well, the gas collection pipe is composed of an outer gas collection pipe and an inner gas collection floral pipe, the outer gas collection pipe is composed of an outer gas collection solid pipe at an upper part and an outer gas collection floral pipe at a lower part, and the inner gas collection floral pipe is arranged in the outer gas collection pipe. According to the invention, the pre-buried elevating landfill gas collecting well has a simple structure and reasonable design, the characteristics of a simple process, convenient construction, a fast well forming speed, a mature construction process, strong environmental adaptability and a good gas collection effect are obtained, and low cost and economic benefits are achieved.

Owner:HENAN BCCY IND

Novel bed sewage ecological restoration technology

InactiveCN103043797AReduce operating costsSave spaceClimate change adaptationSustainable biological treatmentNatural ecosystemEngineering

The present invention provides a novel bed sewage ecological restoration technology. According to the present invention, submerged plants are combined with the network bed technology to realize the full absorption of nutrients by the plants, and ultimately the purpose of recovering the natural ecosystem is achieved. The stain resistant, high temperature resistant and low temperature resistant submerged plants are selected to ultimately realize the riverway aquatic plant decontaminating function yearly. Net cages can be hung under the network beds to farm fishes, snails, shellfishes, and the like. During the restoration of the water, aquatic products can also be obtained. Compared with the conventional water environmental restoration methods, the novel bed sewage ecological restoration technology is more ecological, more environmental-friendly, more energy-efficient, and more economical, makes up for the defect of clearing contamination by changing water, overcomes the limitations of bottom in the restoration waters, and has broader application and simple maintenance.

Owner:XINCHANG GUANYANG TECH DEV

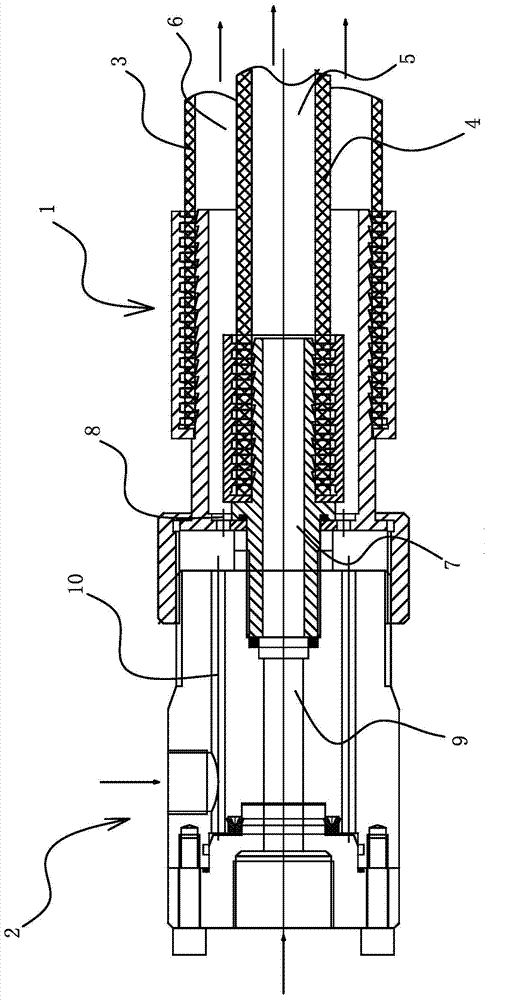

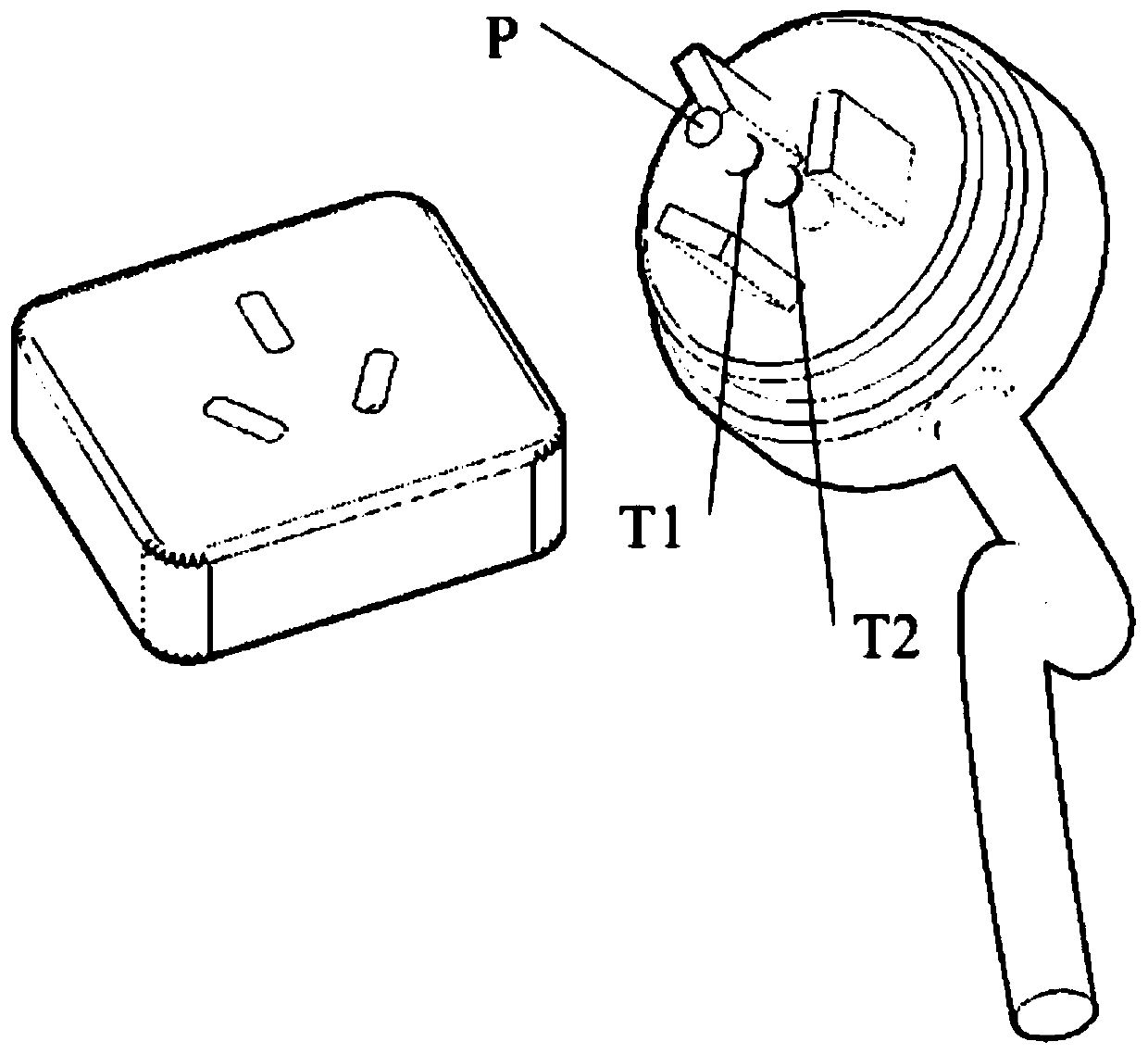

Gas-water joint assembly

The invention belongs to the technical field of connecting hoses, relates to hose joints, in particular to a gas-water joint assembly and solves the technical problems such as unreasonable design of the prior art. The assembly comprises an outer connecting joint and a pipe end joint; the pipe end joint is connected with an outer hose and an inner hose arranged in the outer hose in a penetrating mode; the inner hose is provided with a water flow channel; a gas flow channel is formed between the outer hose and the inner hose; the pipe end joint is provided with a water passing channel and a gas passing channel, which are mutually separated; the water flow channel is communicated with the water passing channel; the gas flow channel is communicated with the gas passing channel; the outer connecting joint is provided with a water inlet / outlet channel and a gas inlet / outlet channel, which are mutually separated; the outer connecting joint and the pipe end joint are fixedly connected by a positioning structure. The gas-water joint assembly has the advantages that 1, the design is reasonable, the structure is simple and water flows and gas flows can be stably outputted; 2, the structural strength is high, the airtightness is good and the gas-water joint assembly is suitable for different weathers and environments; 3, the cost and maintenance cost are low, the assembly and disassembly are convenient and the service life is long.

Owner:江苏科能电力机械有限公司

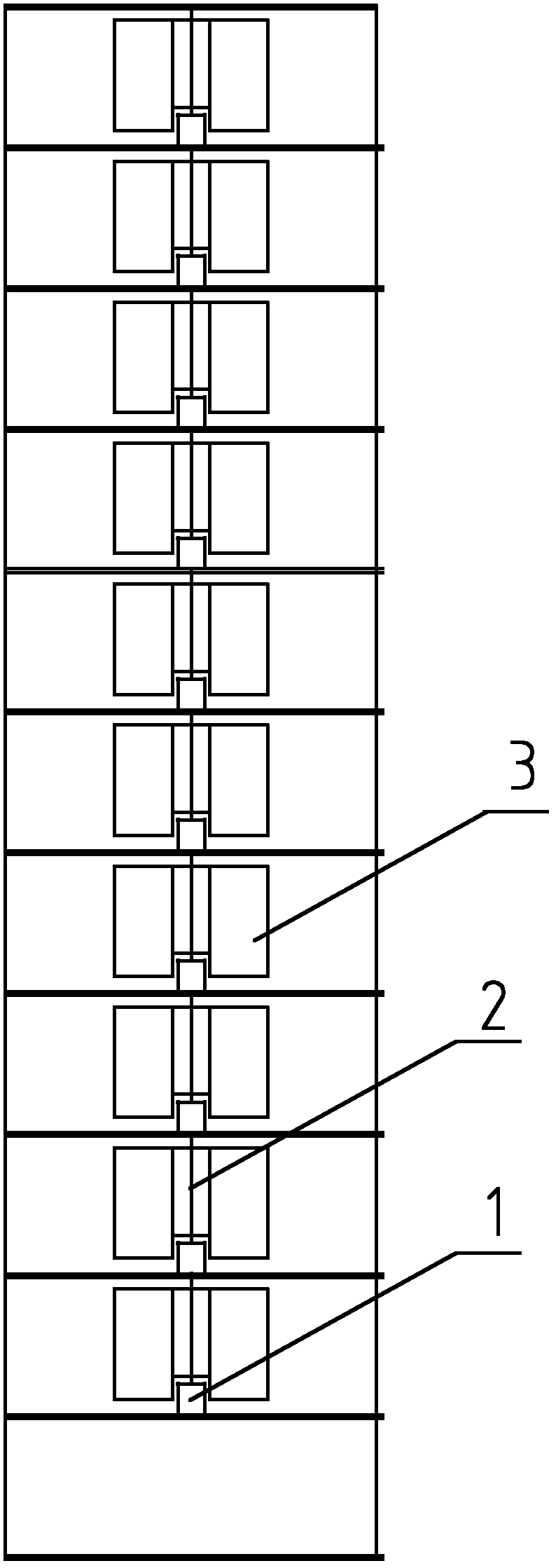

Wind power station and power generation method thereof

InactiveCN102606407AEfficient use ofTake advantage ofWind motor supports/mountsMachines/enginesElectricityPower station

The invention relates to the field of energy conversion, in particular to a wind power station and a power generation method thereof, which can effectively utilize wind energy to generate electricity, reduce construction cost, prolong service life and be convenient to overhaul. The wind power station comprises a vertical wind wheel set comprising a plurality of wind wheels vertically arranged or a horizontal wind wheel set comprising a plurality of wind wheels horizontally arranged, and a support framework, wherein each wind wheel of the vertical wind wheel set is connected with a power generator through a vertical shaft, each or each group of horizontal wind wheels are connected with a power generator through a horizontal shaft, the support framework comprises a plurality of layers arranged from bottom to top, a plurality of vertical wind wheels are respectively arranged on the layers, or a plurality of wind wheels of each group of vertical wind wheels are respectively installed on the same layer of the support framework, each vertical wind wheel or each horizontal wind wheel comprises a plurality of wind blades, and a plurality of fan blades are arranged surrounding the vertical shafts or the horizontal shafts and rotate around the vertical shafts and the horizontal shafts.

Owner:偏允让

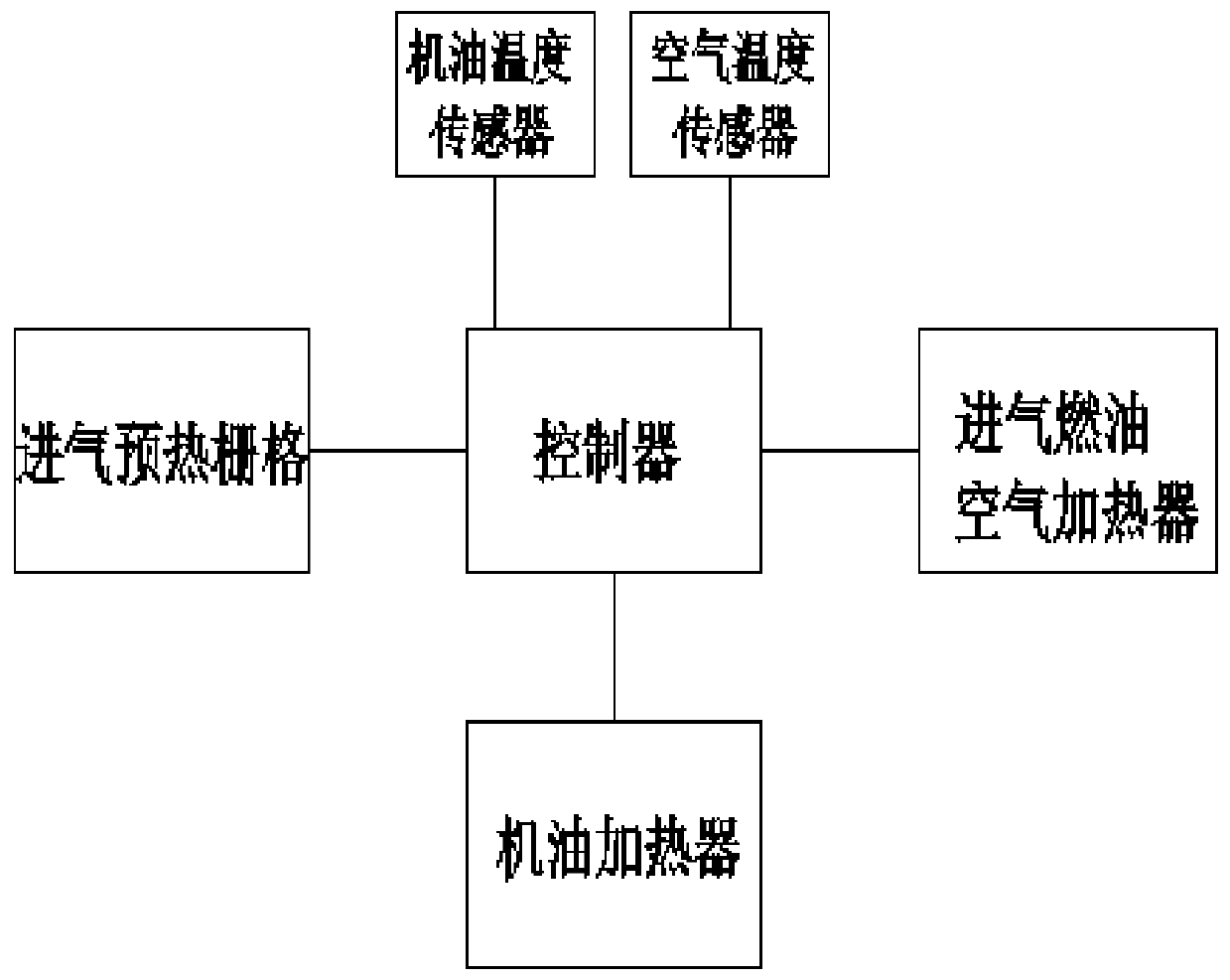

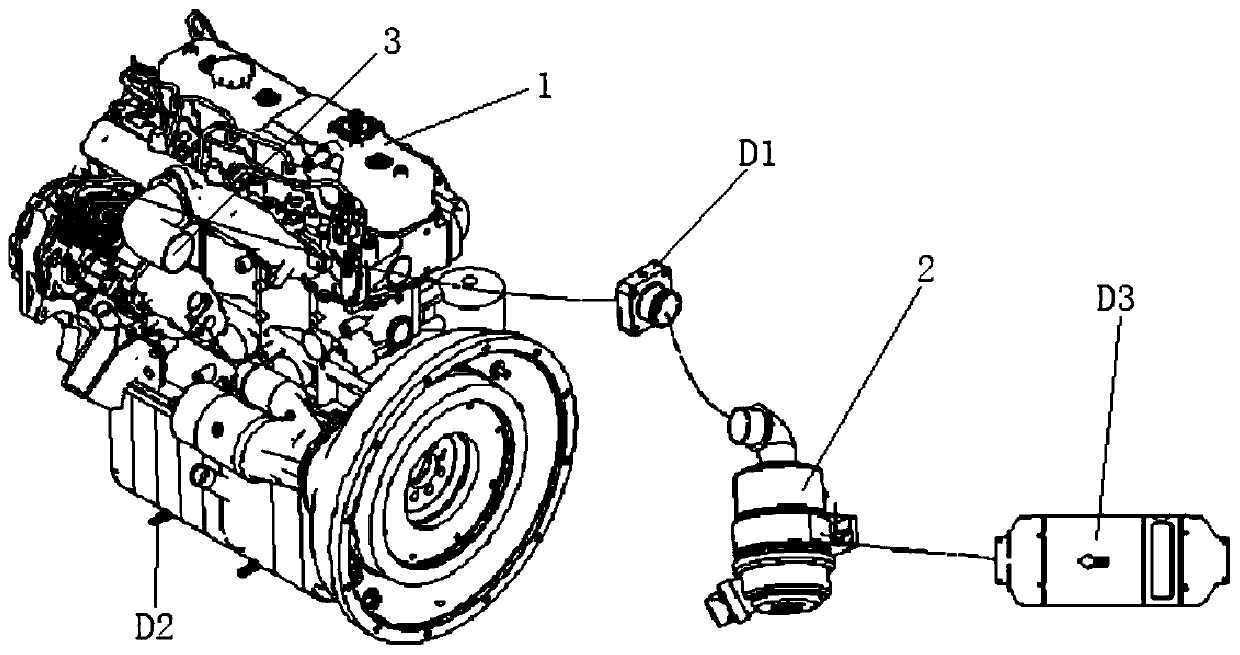

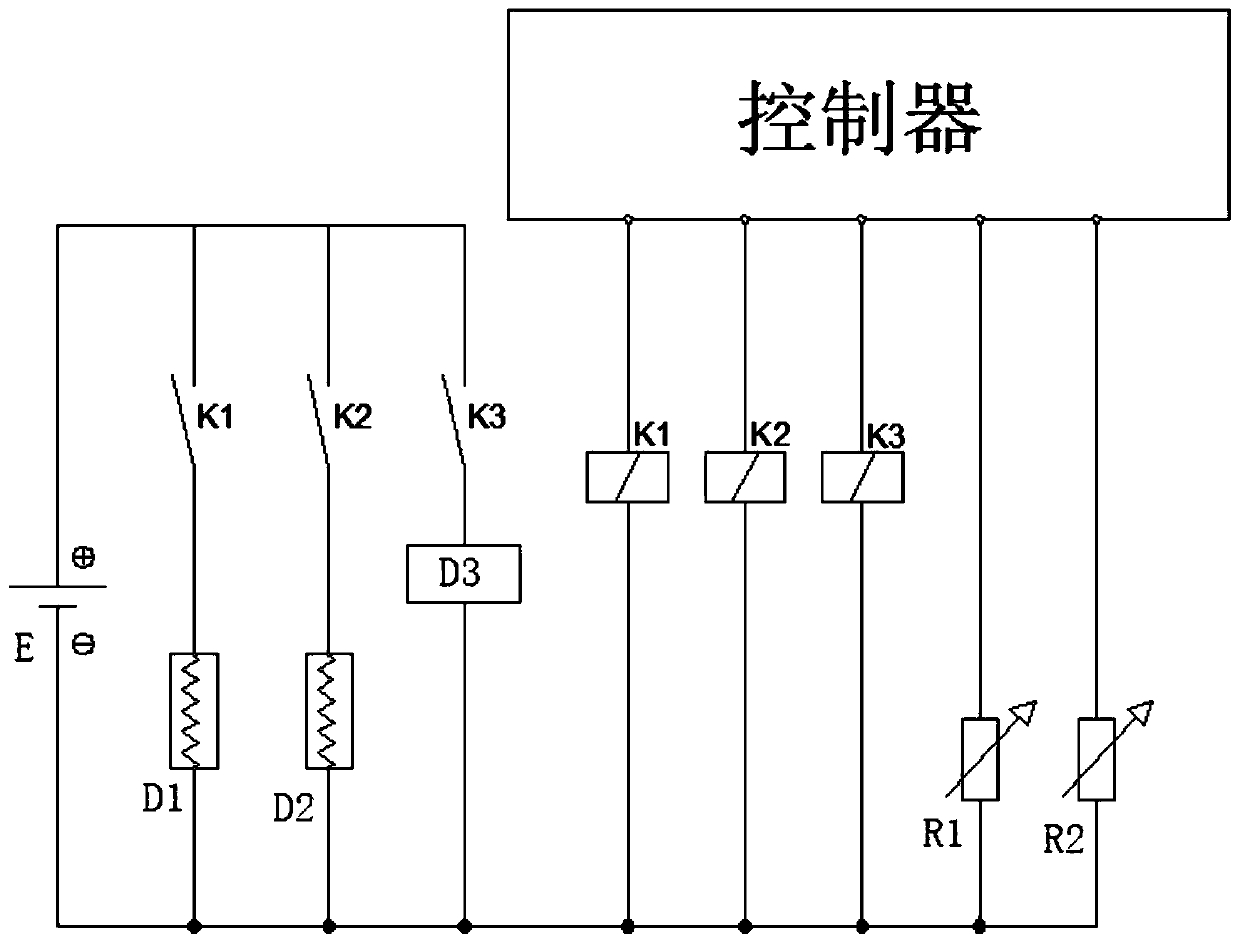

Diesel generating set with good low-temperature starting performance and low-temperature starting method

PendingCN110529320AImprove cold start performanceAvoid the Cons of an Oil ChangeMachines/enginesThermal treatment of fuelFuel oilOil temperature

The invention relates to the technical field of diesel generating sets, and discloses a diesel generating set with good low-temperature starting performance and a low-temperature starting method. Thediesel generating set with the good low-temperature starting performance comprises a controller of the diesel generating set, an intake preheating grid and an intake fuel air heater which are respectively used for heating the intake air of an engine of the diesel generating set, a direct-current engine oil heater used for heating the engine oil of the diesel generating set, an engine oil temperature sensor which is used for detecting the temperature of the engine oil and an air temperature sensor used for detecting the temperature of the surrounding environment, and the air inlet preheating grid, the air inlet fuel oil air heater, the direct-current engine oil heater, the engine oil temperature sensor and the air temperature sensor are respectively connected with the controller. Accordingto the present invention, the low-temperature starting performance of the diesel generating set is improved, and meanwhile the later-period unit maintenance cost is reduced.

Owner:江苏法尔胜动力科技有限公司

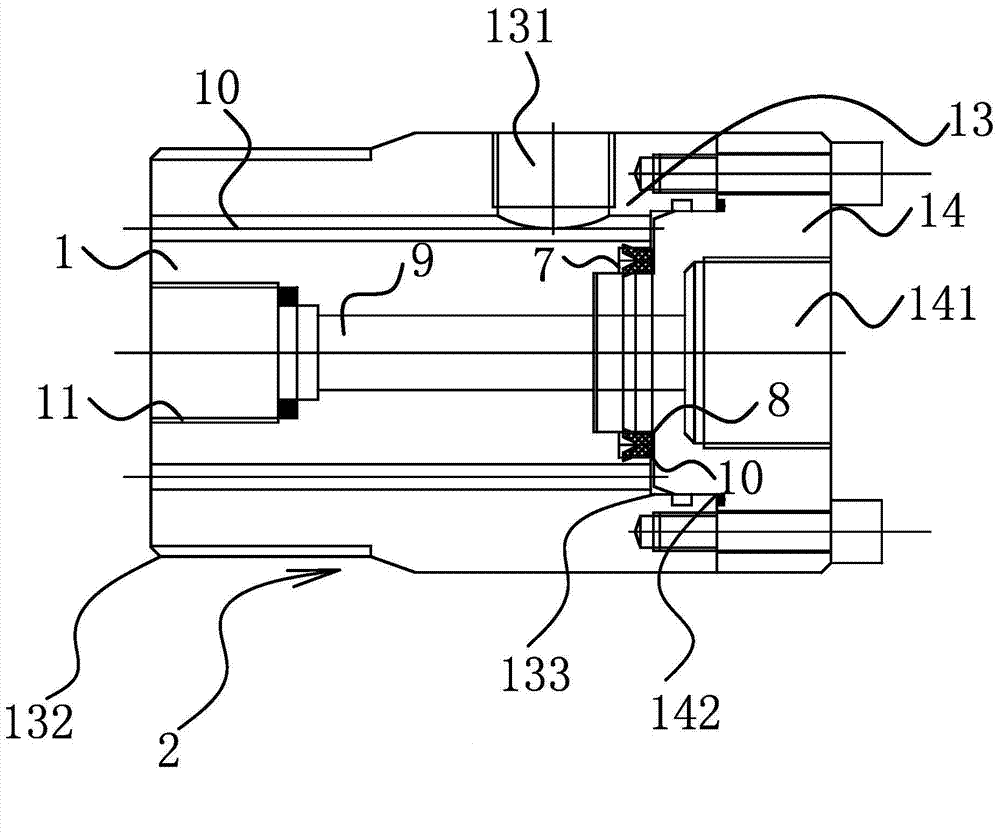

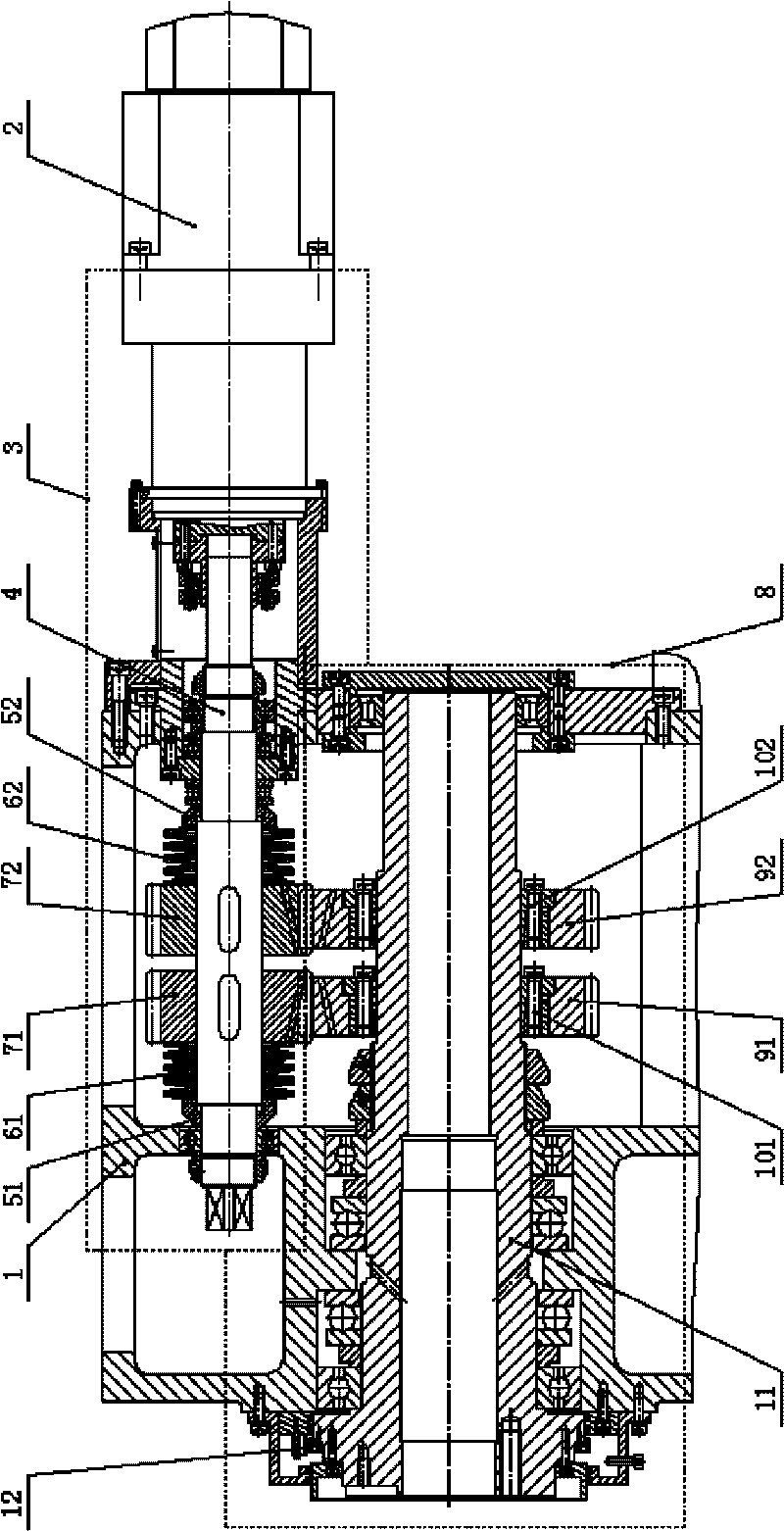

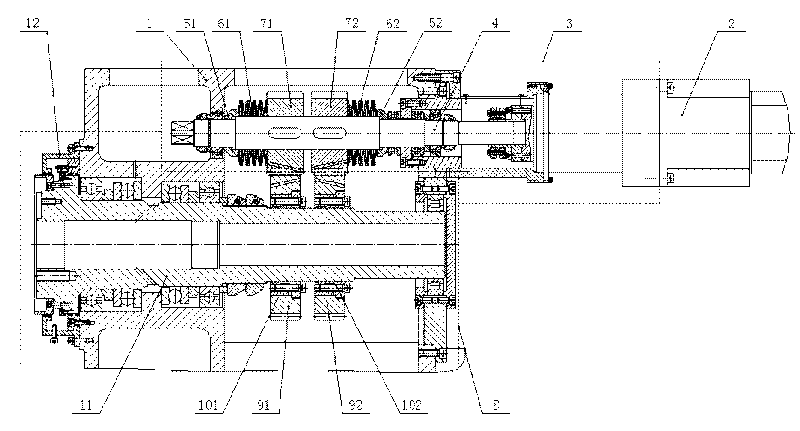

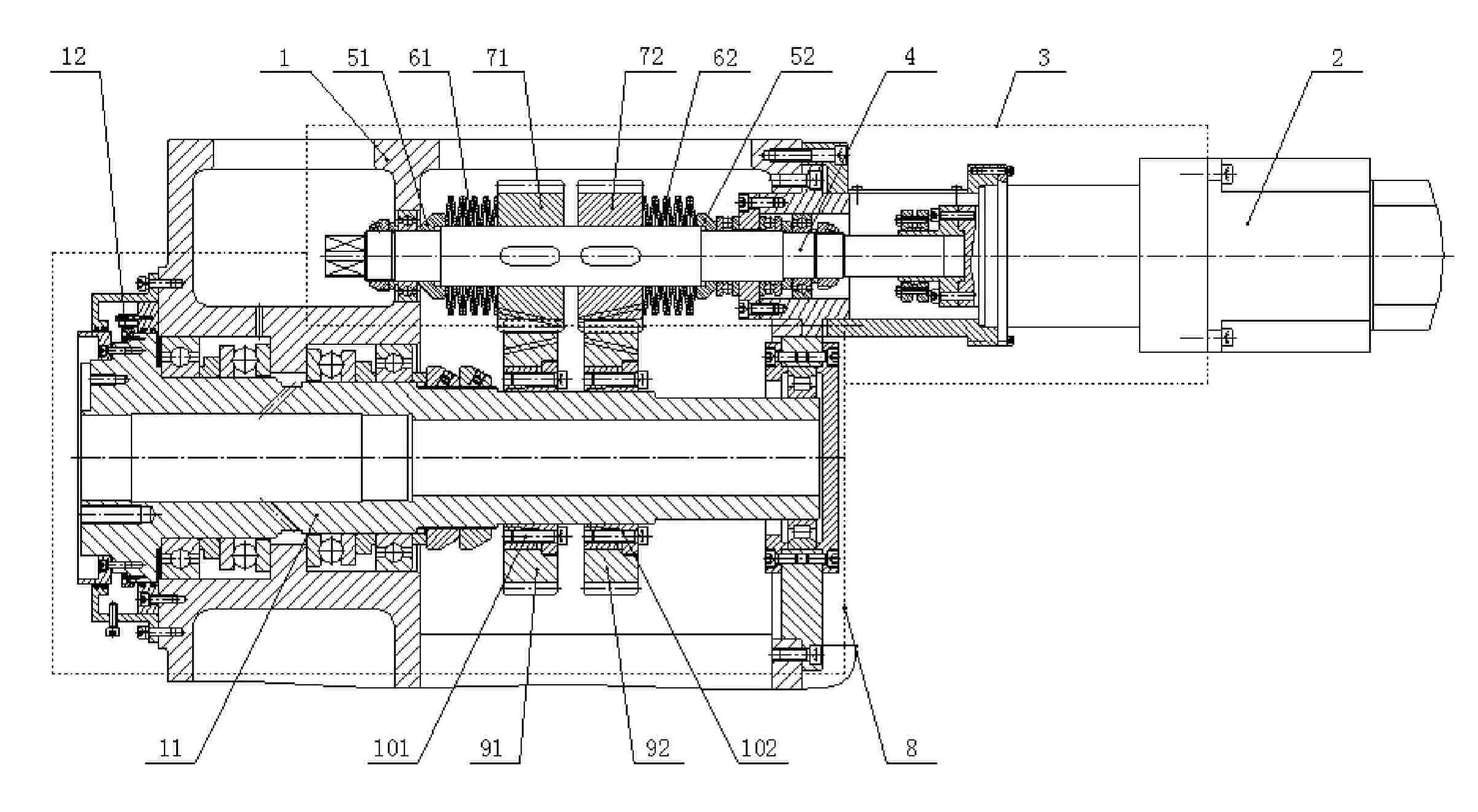

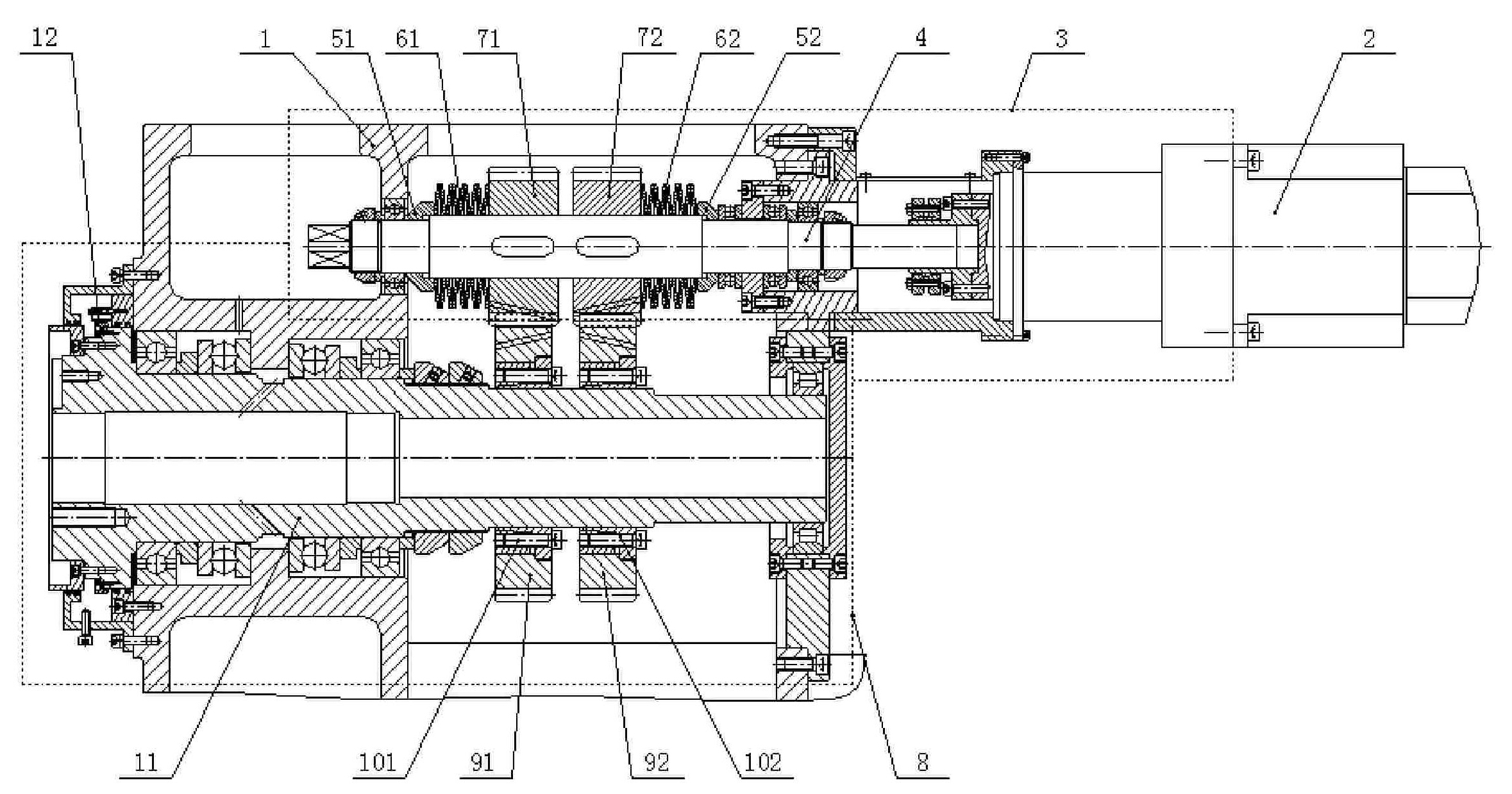

Automatic backlash-eliminating scale-dividing device used for numeral control helical deep hole broacher

InactiveCN101716736ALow costImprove securityPrecision positioning equipmentBroaching accessoriesDrive wheelGrating

The invention belongs to the technical field of broacher devices, in particular to an automatic backlash-eliminating dividing device used for a numeral control helical deep hole broacher. The device comprises a box body, an alternating current servo motor, an input-output mechanism, and a circular grating detection mechanism. In the device, scale division is controlled directly through the alternating current servo motor; and through pushing a driving axle to glide axially by an adjusting washer and a disc spring, the driving axle and a double-tooth backlash-eliminating mechanism consisting of driven wheels can automatically compensate to eliminate backlashes after a gear is worn. The driving device of the invention has the advantages of low cost and maintenance cost, high safety, and good reliability.

Owner:MIANYANG WEIBO ELECTRONICS

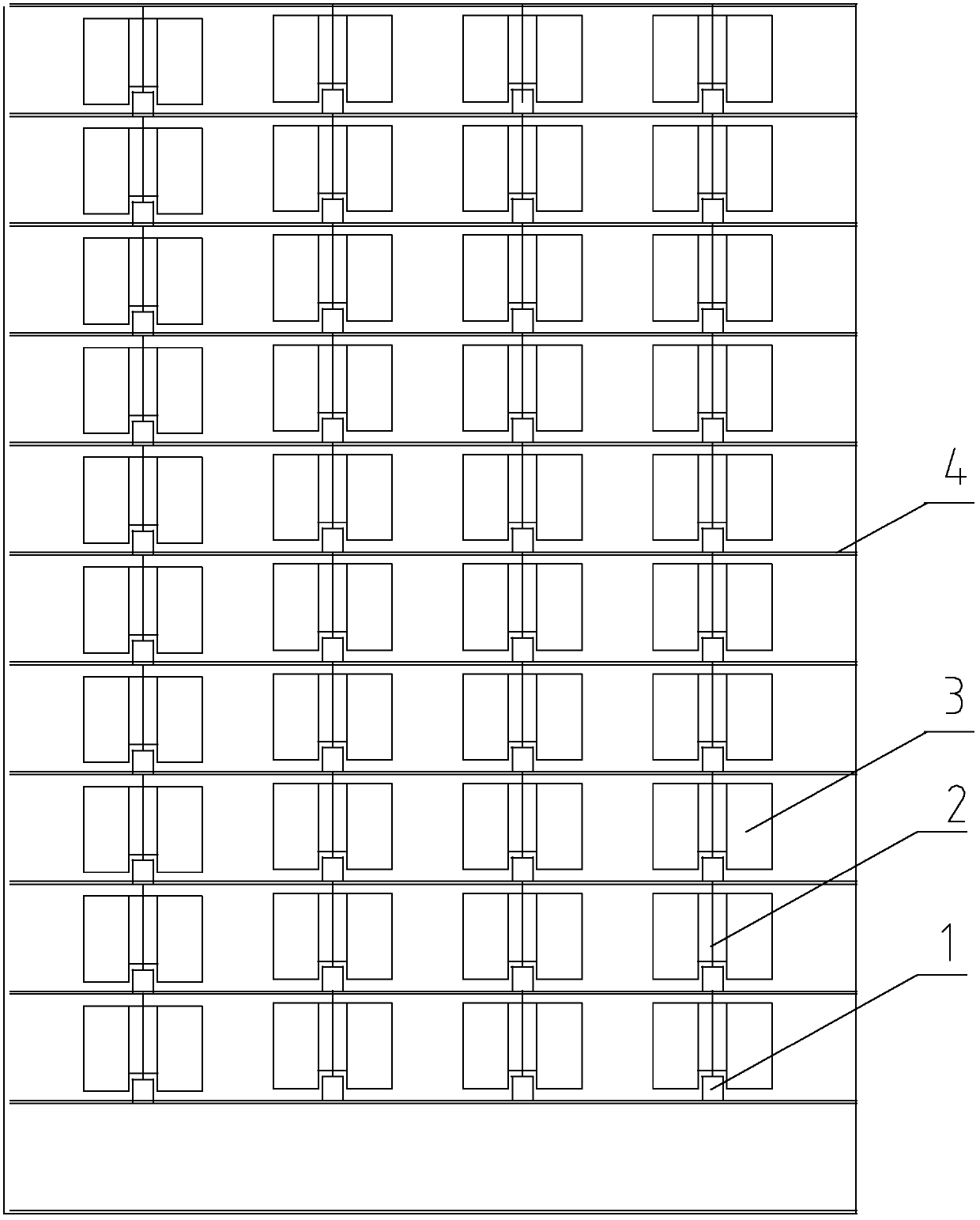

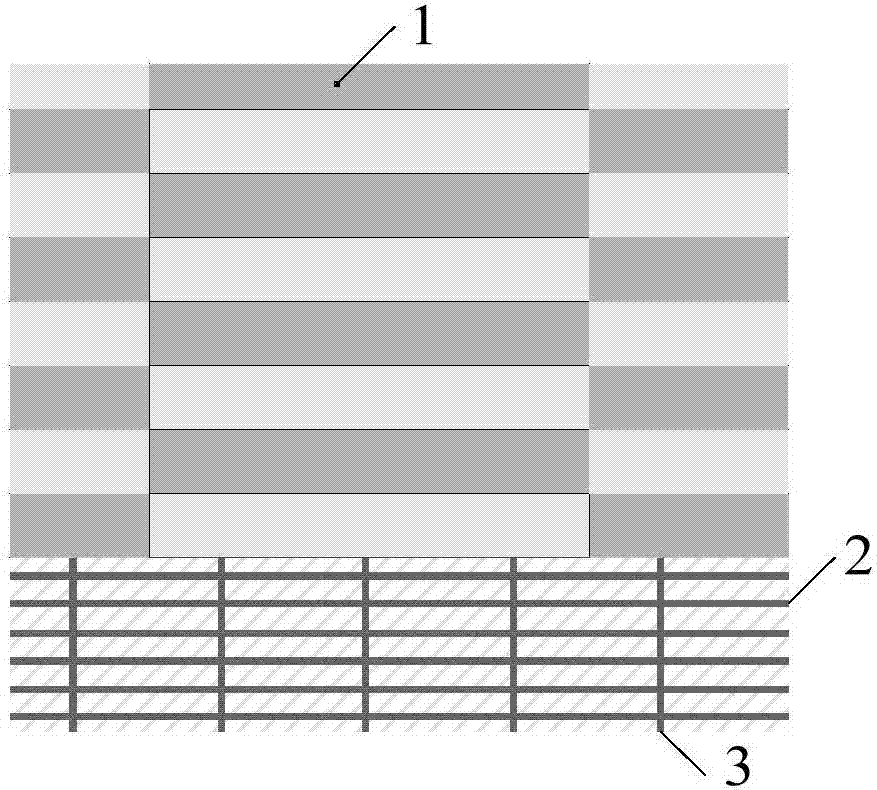

Textile concrete externally-hung curtain wall and preparation method thereof

InactiveCN106968374AImprove bearing capacityStrong crack control abilityConstruction materialWallsFiberCrack resistance

The invention belongs to the technical field of building materials and relates to a textile concrete externally-hung curtain wall. The curtain wall is formed by compounding textiles and high-performance fine concrete externally doped with chopped fibers. The number of layers of the textiles in the curtain wall can be adjusted according to the actual project needs; and the appearance modeling of the curtain wall can be determined by manufacturing corresponding formworks according to actual projects during test block pouring. The novel curtain wall disclosed by the invention can effectively replace a traditional curtain wall material, can be widely applied to high-rise building outer wall vertical faces under various complex environments, and has wide application prospects. The curtain wall disclosed by the invention has the advantages of being easy and convenient to manufacture, thin in wall, low in weight, low in installation and transportation expense, convenient to assemble and the like during manufacturing and installation, and has the characteristics of being high in bearing force, good in crack resistance, good in durability, attractive in appearance and the like in the use performance.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

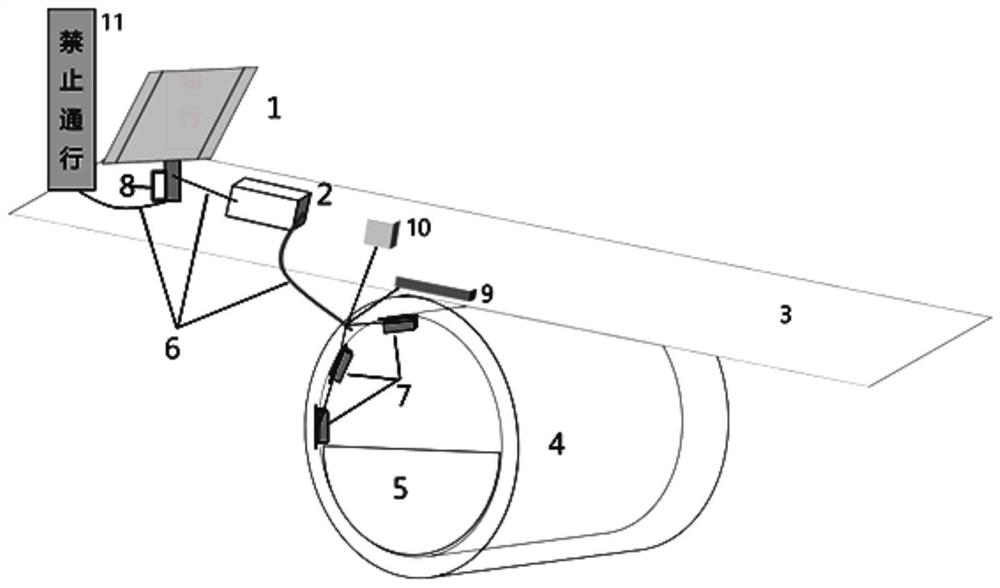

Underneath pass culvert road traffic safety assessment device and method, medium and equipment

PendingCN112508370AReduce power consumptionReduce maintenance costsClimate change adaptationResourcesRoad traffic safetySecurity assessment

The invention relates to an underneath pass culvert road traffic safety assessment device and method, a medium and equipment, and the method comprises the steps: triggering water sensors preset at different positions of the inner side wall of a culvert to carry out the data collection through the water level when the water level in the culvert changes, and transmitting the data to a preset intelligent control unit; a soil pressure gauge and a soil water content monitor which are arranged in the road surface in advance collect state data of the road surface in real time and transmit the state data to the intelligent control unit; the intelligent control unit analyzes the water level condition according to the received information, evaluates the road pressure resistance, determines whether to give an alarm or not, and determines whether the vehicle can pass or not; and an alarm is generated and transmitted to the electronic display board to display passing prohibition, so that vehicles are prevented from passing in time. Operators can be effectively prompted to timely open the gate to drain water, and damage to facilities such as a bridge floor and a roadbed is prevented.

Owner:CRSC COMM & INFORMATION GRP CO LTD

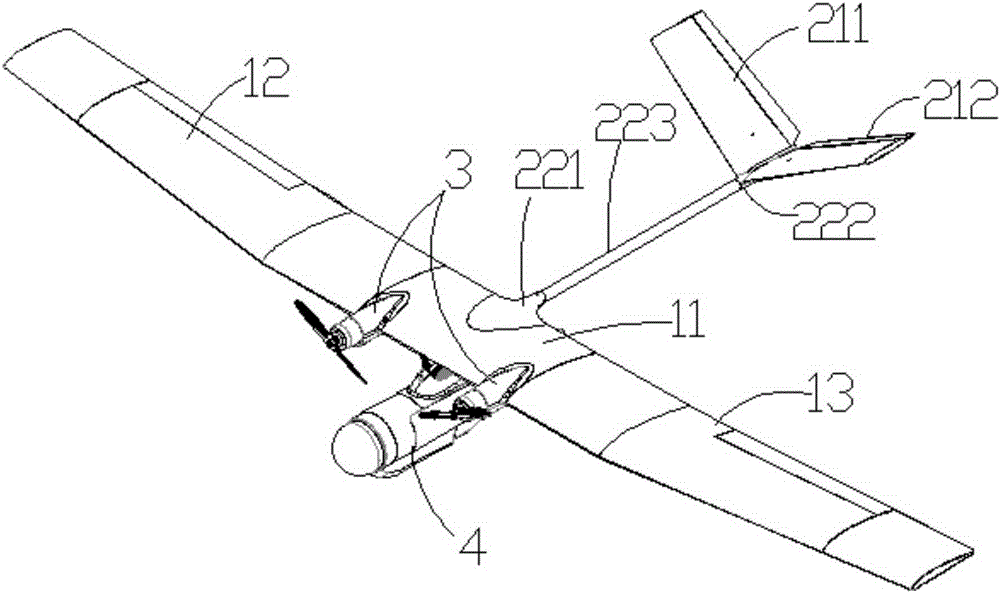

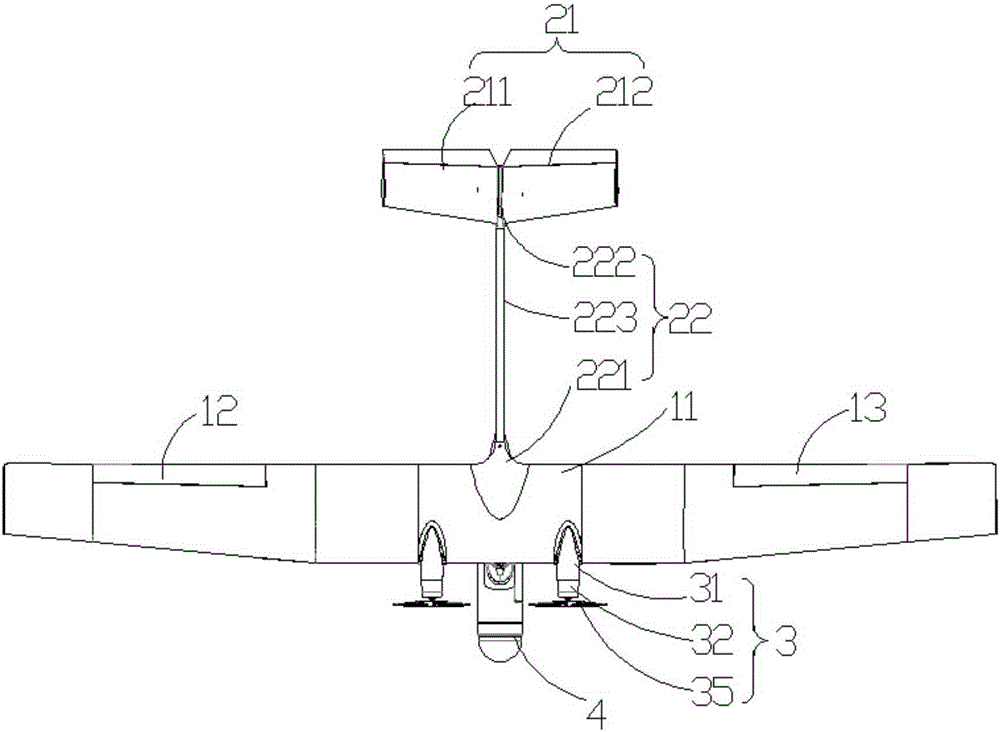

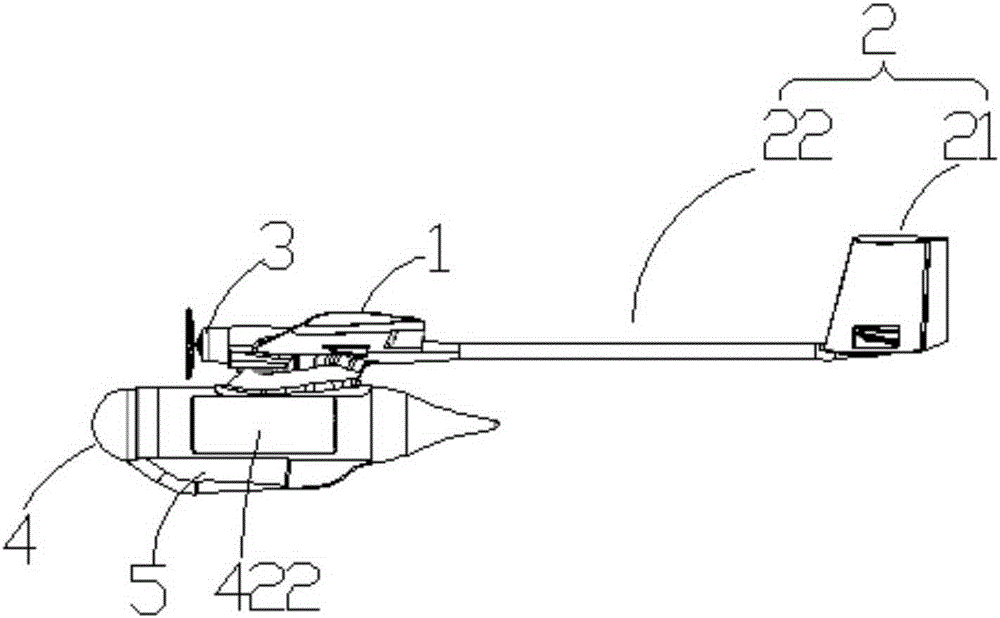

Hand-throwing unmanned aerial vehicle

InactiveCN105314085AAvoid collisionEasy to operateFuselage framesAircraft stabilisationUncrewed vehicleEngineering

The invention discloses a hand-throwing unmanned aerial vehicle, and belongs to the technical field of unmanned aerial vehicles. The hand-throwing unmanned aerial vehicle comprises a vehicle body, a tail, one or more power sources, and a lens bin, wherein the vehicle body comprises a middle section, a first lateral section and a second lateral section; two sides of the middle section are detachably connected with the first lateral section and the second lateral section correspondingly; the tail is fixed on the middle section; the power sources are fixed on the middle section; the lens bin is fixed on the middle section; a flexible buffer cushion is arranged on the lens bin. The hand throwing unmanned aerial vehicle has the advantages that the problem of high vehicle body maintenance cost of the conventional hand throwing unmanned aerial vehicle is solved; the technical defect of high damage possibility, caused by collision between the lens bin of the conventional hand throwing unmanned aerial vehicle and the ground, of the lens bin of the conventional hand throwing unmanned aerial vehicle is overcome.

Owner:EWATT TECH CO LTD

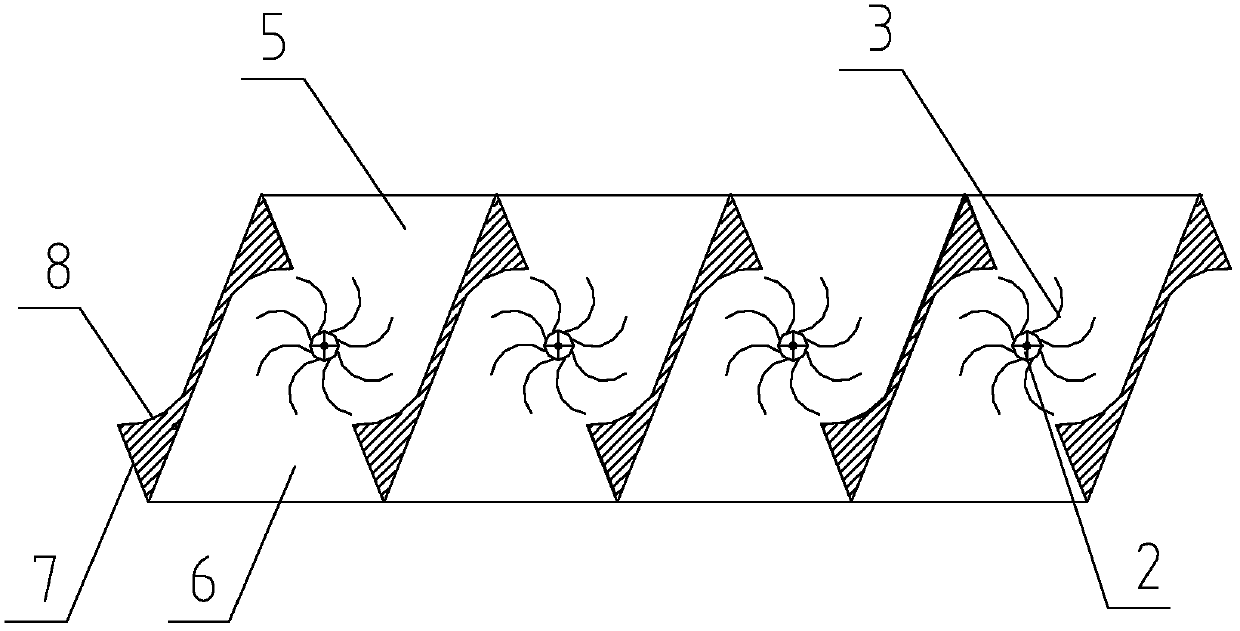

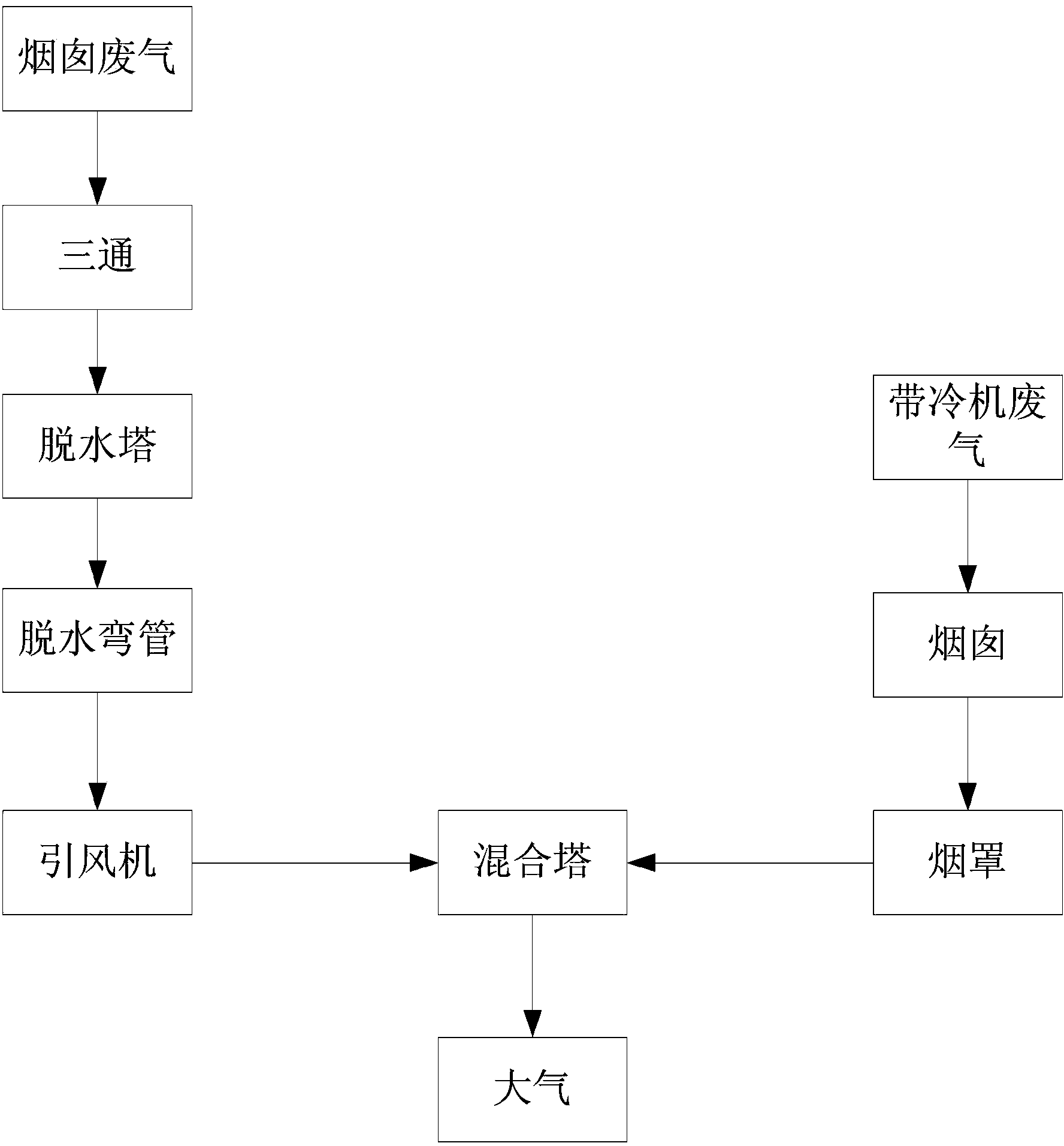

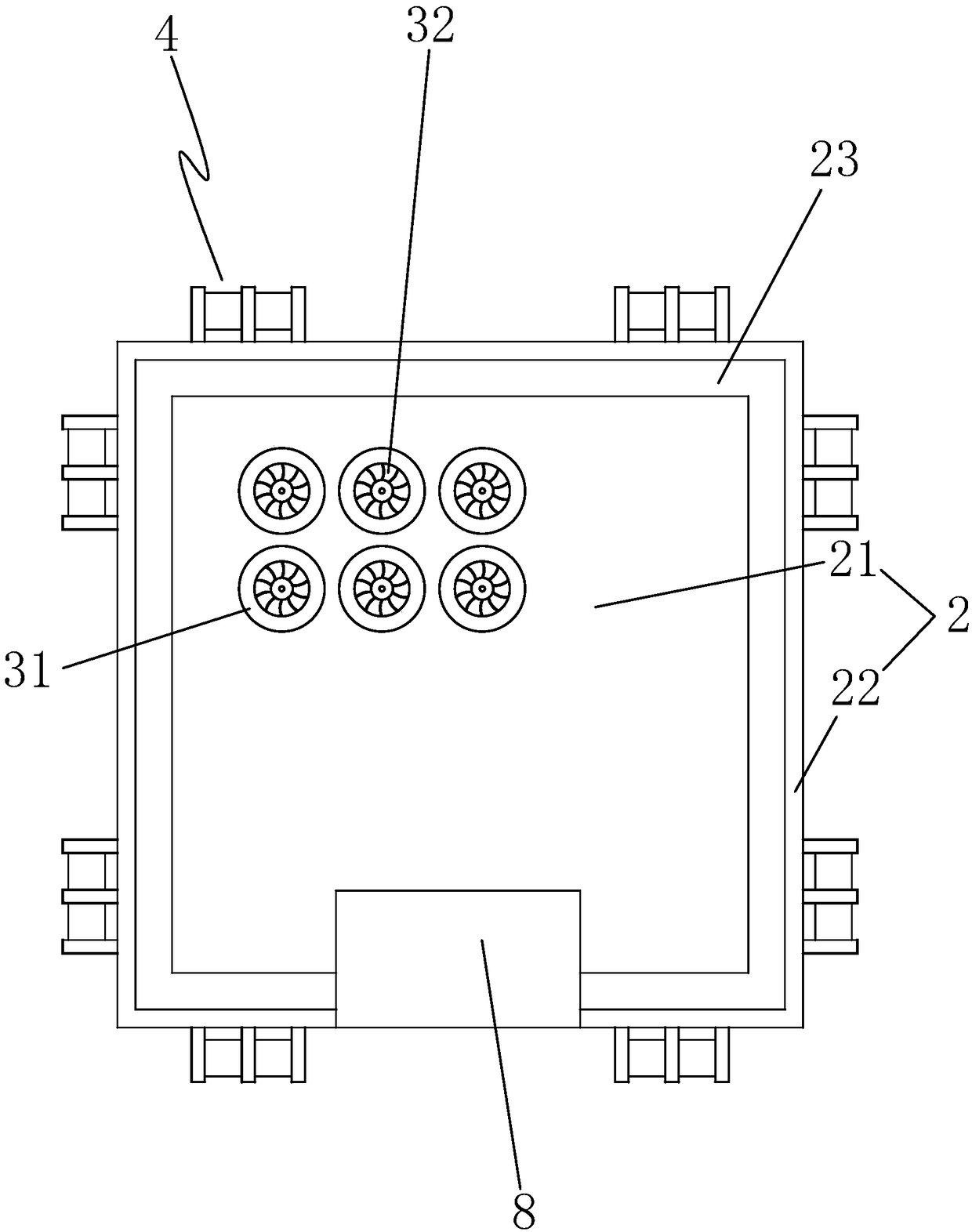

Low-energy-consumption hybrid white smoke elimination device

ActiveCN103920376AReduce moistureGood maintenance costDispersed particle separationHybrid typeTherapeutic effect

The invention discloses a low-energy-consumption hybrid white smoke elimination device, which comprises a mixing tower, wherein three openings are formed in the mixing tower; two of the openings are air inlets and are respectively connected with a multiple layered dehydration guide device of chimney exhaust gas and a belt cooler exhaust gas conveying device; the other opening is an air outlet and is directly connected with outside air; the multiple layered dehydration guide device of chimney exhaust gas comprises a T-joint and a dehydration tower, a dehydration elbow and an draught fan which are connected with the T-joint in sequence; the air outlet of the draught fan is connected on the mixing tower through a pipeline; the belt cooler exhaust gas conveying device comprises a belt cooler; a chimney is arranged on the belt cooler; a smoke hood is arranged at the top end of the chimney and is connected with the mixing tower through a pipeline. According to the low-energy-consumption hybrid white smoke elimination device, not only is the installation and maintenance cost of the device reduced, but also is the operation cost of the device reduced; the treatment effect of white smoke is greatly improved.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

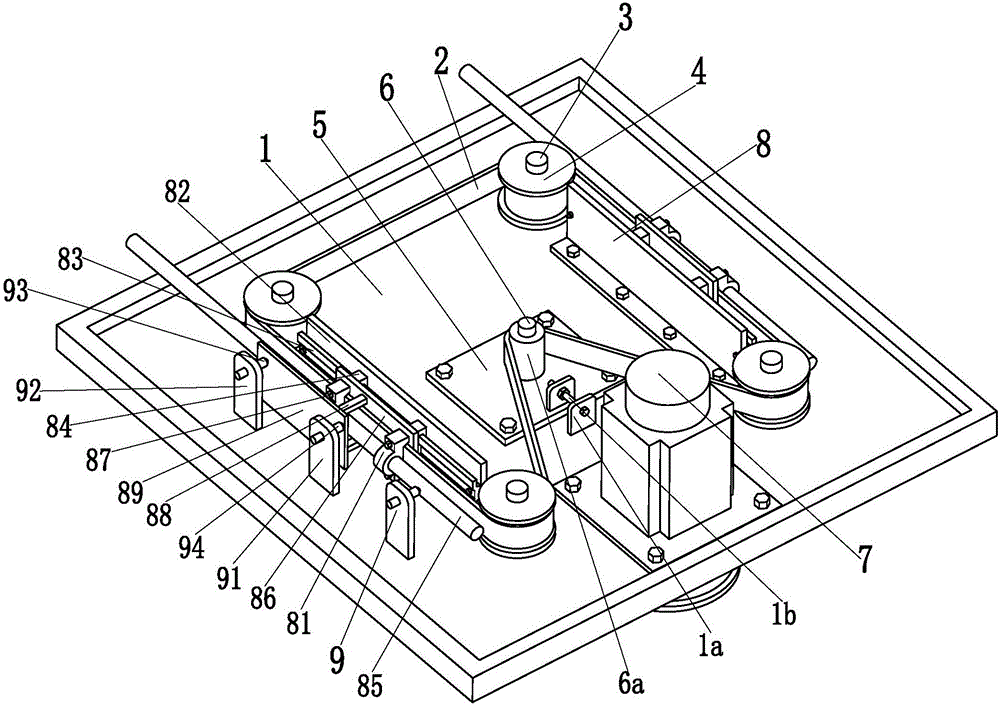

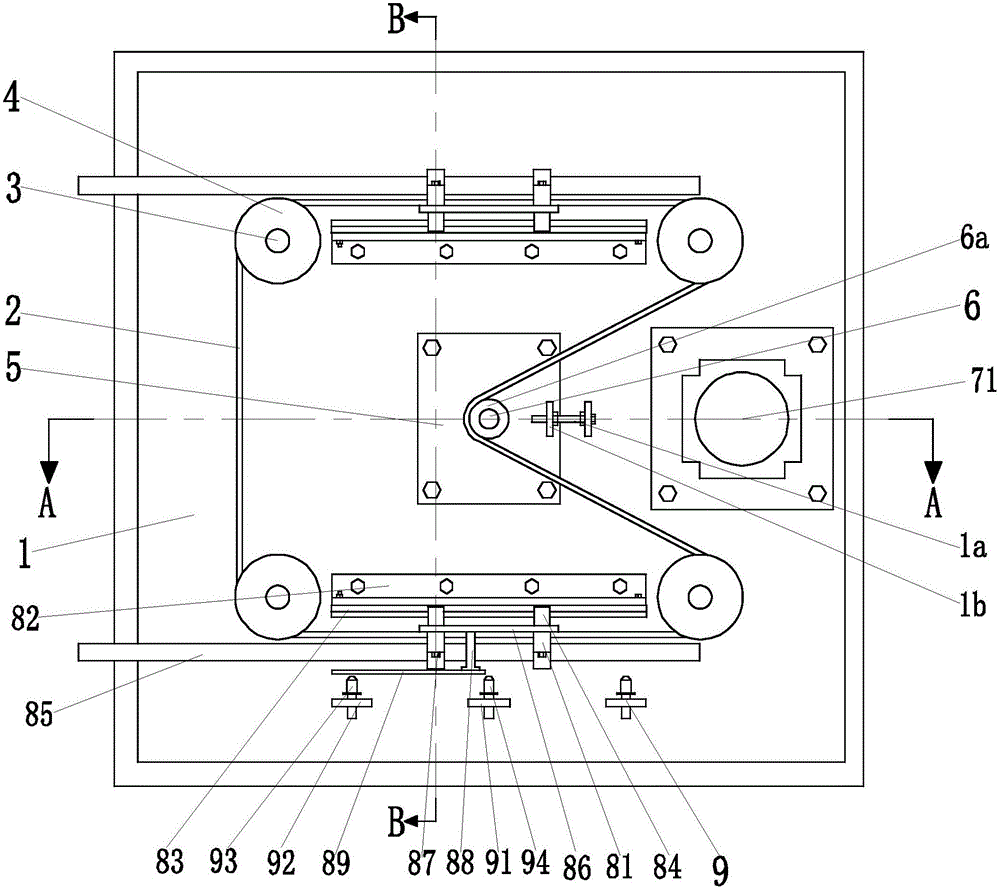

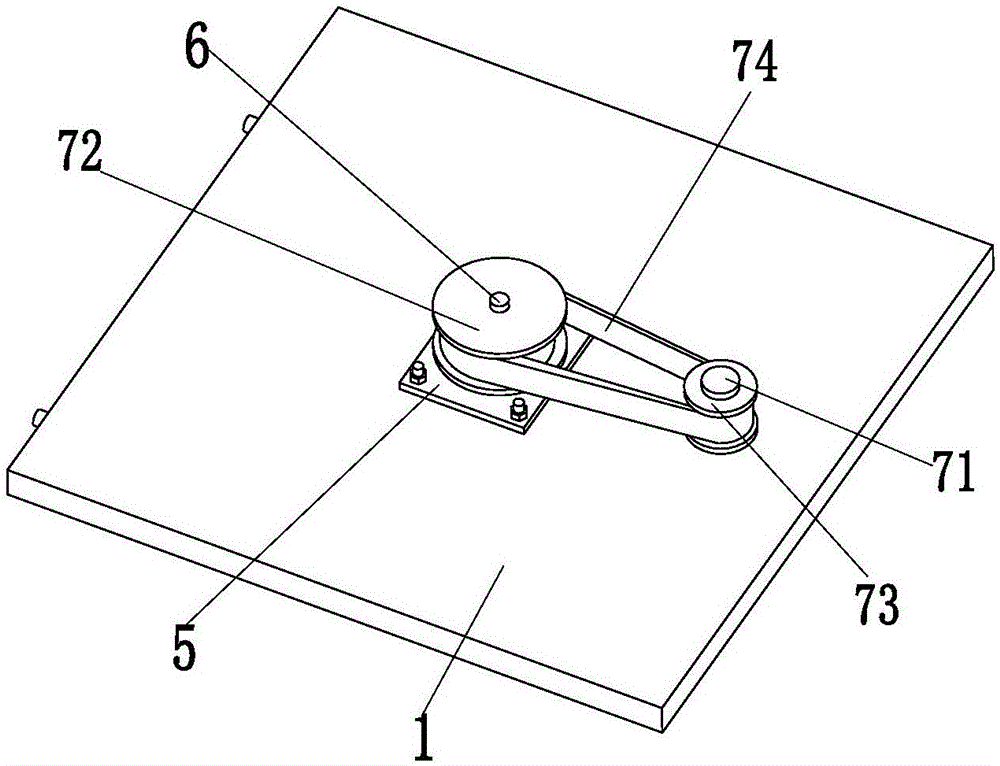

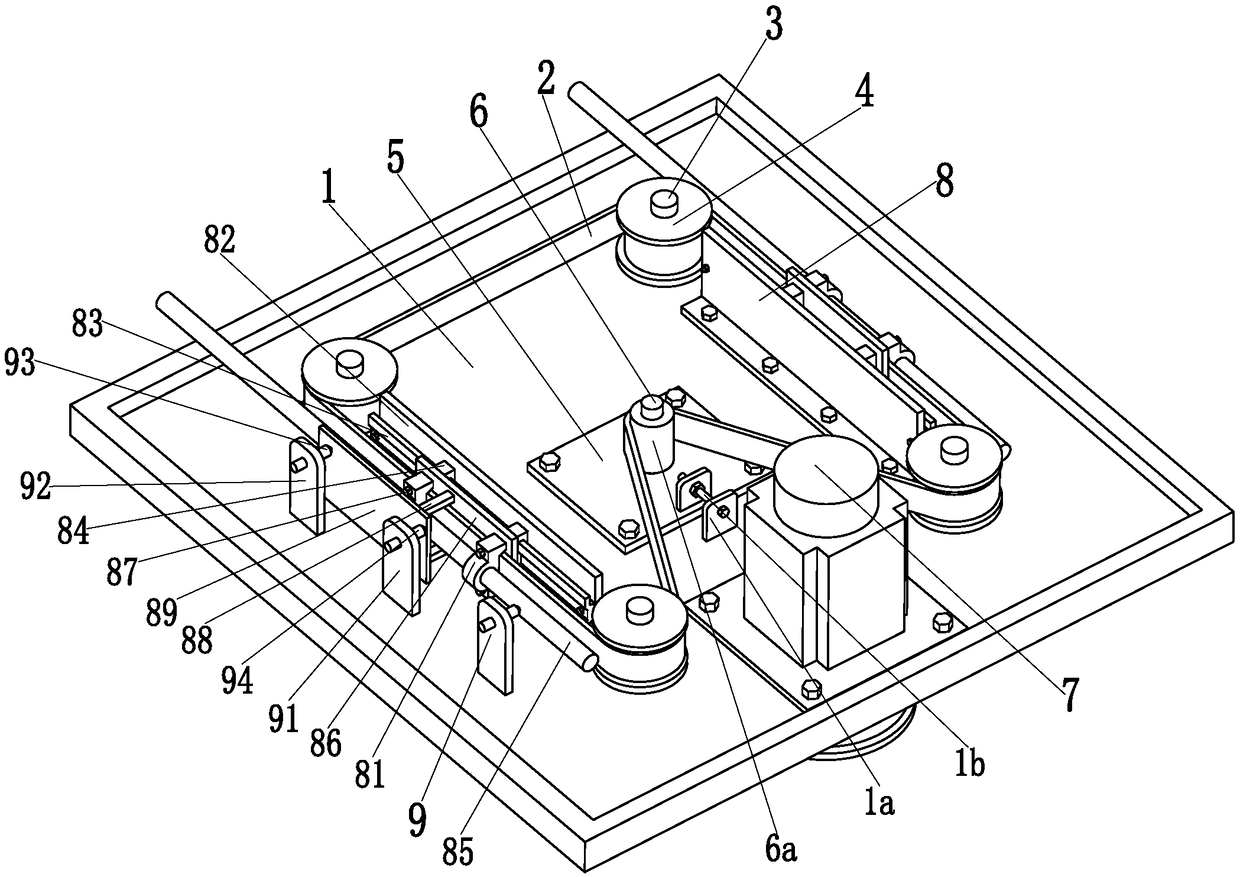

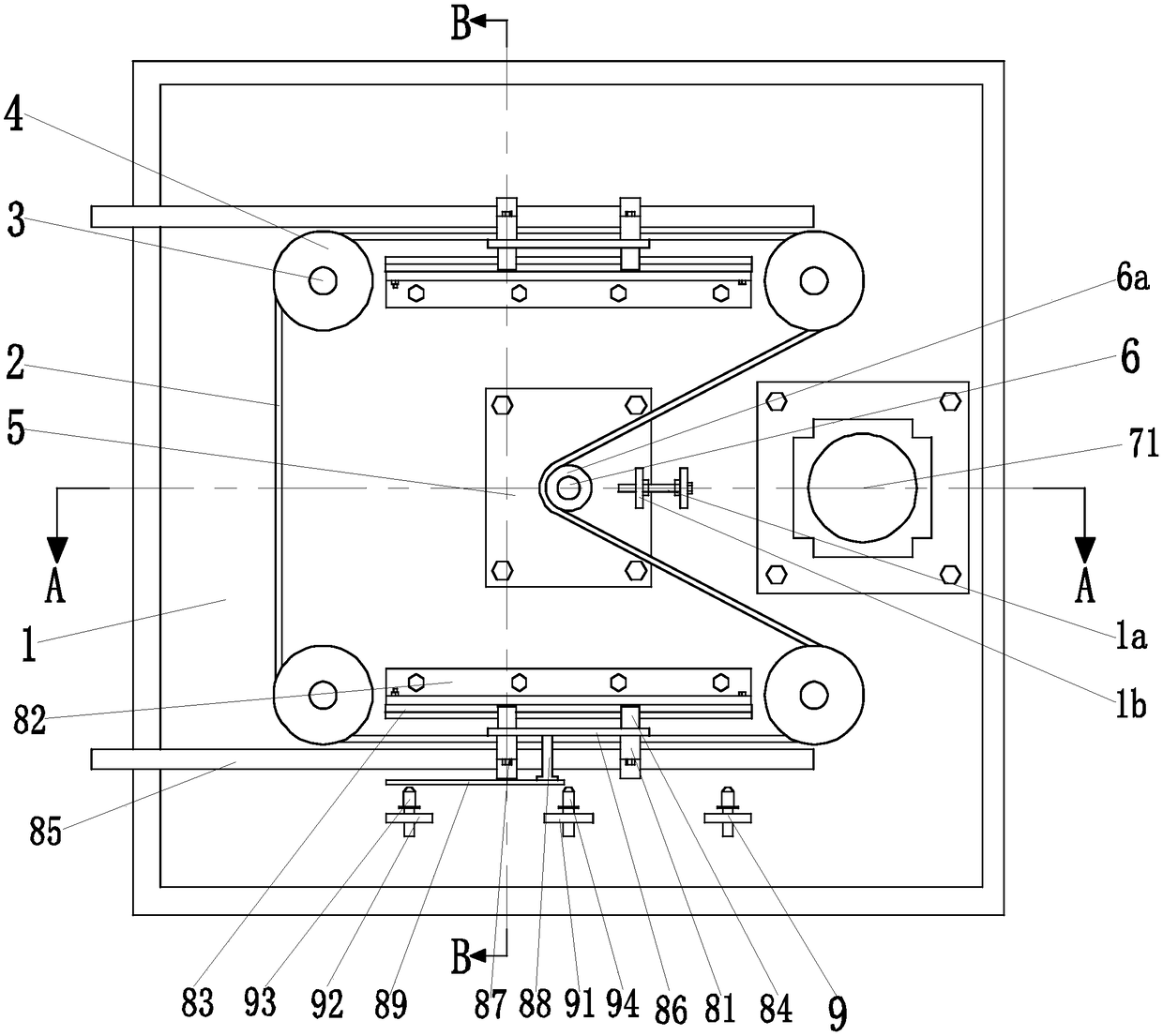

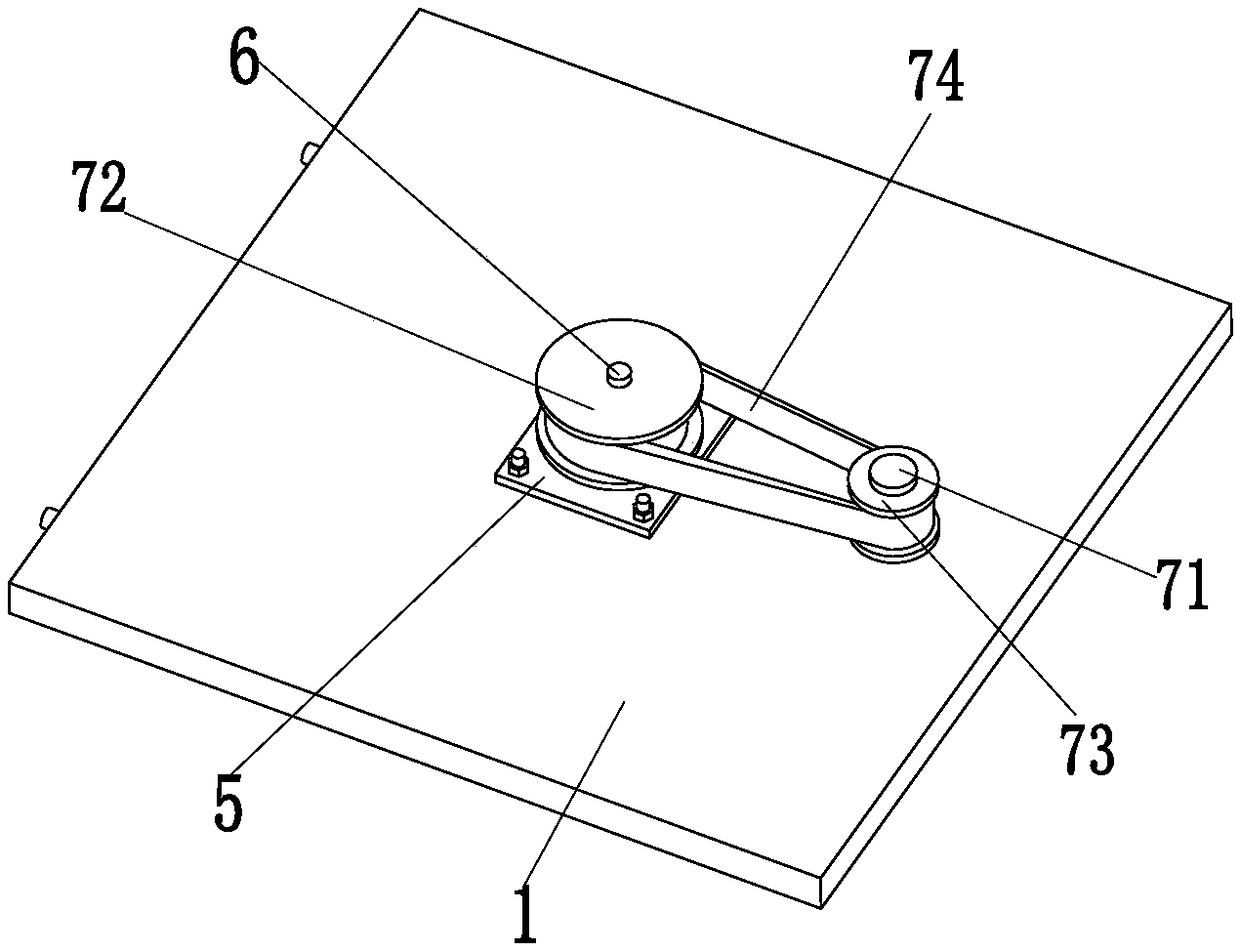

Yarn guide device having original-point positioning function

ActiveCN106012137AQuality improvementStable automatic winding functionTextiles and paperYarnInterference fit

The invention relates to a yarn guide device having an original-point positioning function. The yarn guide device comprises a base plate and a main synchronous belt, wherein four fixing shafts are symmetrically welded on the upper end face of the base plate, four driving belt wheels are respectively installed on the four fixing shafts through bearings, and the four driving belt wheels can stably rotate on the four fixing shafts. Drive holes are formed in the middle of the base plate, two installing plates are symmetrically installed at the upper end and the lower end of the middle of the base plate through bolts, driving shafts are installed in the middles of the two installing plates through bearings, and the middles of the driving shafts penetrates into the drive holes formed in the base plate. The driving belt wheels are installed at the upper ends of the driving shaft in an interference fit mode, and secondary driving branch chains are installed at the lower end of the driving shafts. Two yarn guide branch chains are symmetrically and vertically installed on the front side and the rear side of the base plate through bolts. A sensing branch chain is installed on the front side of the base plate. The yarn guide device can achieve a full-automatic, high-quality and stable yarn winding function.

Owner:ZHEJIANG JINMA AUTOMATION TECH CO LTD

Intelligent ventilation and heat dissipation-type building

ActiveCN109183976AImprove ventilationEffective ventilation and heat dissipationLighting and heating apparatusRoof drainageImpellerAir exchange

The invention discloses an intelligent ventilation and heat dissipation-type building, which comprises a building body, a roof and multiple unpowered wind balls. Each unpowered wind ball comprises a wind pipe, a wind ball base arranged on the roof, a rotating ball cap arranged on the wind ball base, and an air extraction impeller arranged in the wind pipe and coaxially connected with the rotatingball cap. The rotating ball cap is in rotary connection with the wind ball base. One end of the wind pipe is communicated with the inner part of the building and the other end of the wind pipe is communicated with the inner part of the rotating ball cap. The building body is provided with multiple air exchange ports. The building is provided with multiple heat exchange plate groups, each heat exchange plate group comprises a plurality of parallelly-arranged heat dissipation vertical plates, and the heat dissipation vertical plate passes through one side wall of the building body. The heat exchange plate group also comprises a heat dissipation transverse plate, and the heat dissipation transverse plate is located outside the building body and is connected with one side wall of the buildingbody. The intelligent ventilation and heat dissipation-type building has the beneficial effects that ventilation and heat dissipation can be effectively carried out; no electrifying device needs to beadded; the maintenance cost is low; and the safety is good.

Owner:矩阵纵横设计股份有限公司

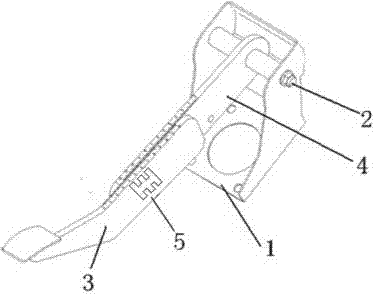

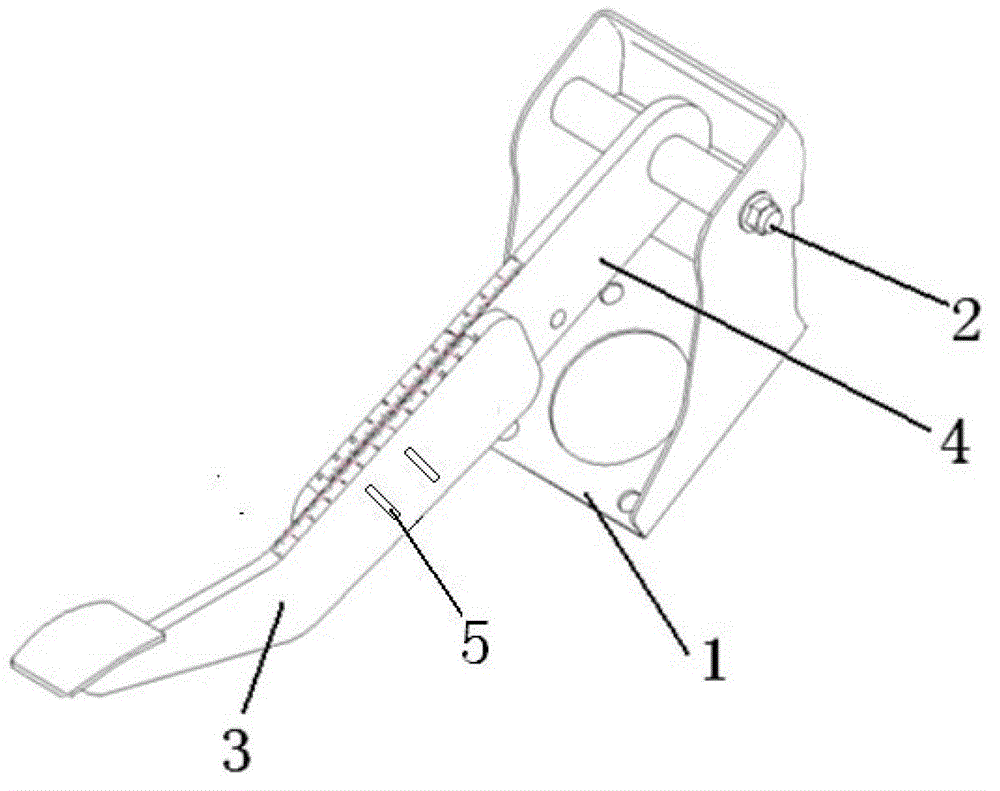

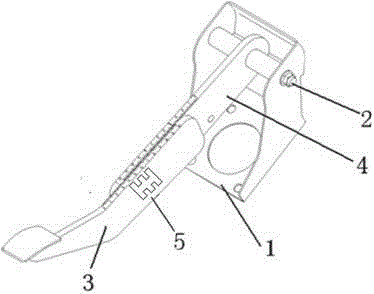

Vehicular brake pedal with adjustable lever ratio

InactiveCN103072560ASimple designConvenience Pedal ParametersFoot actuated initiationsEngineeringMachining

The invention discloses a vehicular brake pedal with an adjustable lever ratio, which comprises a pedal base, a pedal support and a pedal arm, wherein the pedal arm is arranged on the pedal support, the pedal support is arranged on the pedal base, the pedal base is connected with a vehicle body through bolts, the pedal arm consists of a pedal upper arm and a pedal lower arm, the pedal upper arm and the pedal lower arm are respectively provided with a corresponding adjustor, each adjustor consists of a longitudinal adjusting slot and a transverse adjusting slot, each adjustor at least comprises two or more longitudinal adjusting slots, and the longitudinal adjusting slots are communicated with the transverse adjusting slots. The vehicular brake pedal with the adjustable lever ratio disclosed by the invention has the lever ratio which can be automatically adjusted according to different requirements of drivers on the feeling of the pedal, and can provide more convenient pedal parameters for the performance machining of a brake system so that the brake system with good pedal feeling is designed; and the vehicular brake pedal with the adjustable lever ratio has the characteristics of low manufacturing cost, low maintenance cost, long service life and the like.

Owner:ANHUI YUFENG AUTOMOTIVE TECH

Brake pedal of adjustable lever for automobile

InactiveCN102941847ASimple designConvenience Pedal ParametersFoot actuated initiationsRelative displacementBraking system

The invention discloses a brake pedal of an adjustable lever for an automobile. The brake pedal of the adjustable lever for the automobile comprises a pedal base, a pedal support and a pedal arm, wherein the pedal arm is installed on the pedal support; the pedal support is installed on the pedal base; the pedal base is connected with an automobile body through a bolt; a longitudinal adjusting device is arranged at the middle part of the pedal arm; the pedal arm consists of an upper pedal arm and a lower pedal arm; the upper pedal arm and the lower pedal arm form relative displacement; and the pedal arm is longitudinally adjustable. The brake pedal of the adjustable lever for the automobile can adjust the pedal-lever ratio according to different requirements of drivers on pedal feeling, can further provide more convenient pedal parameters for performance matching of a braking system so as to design the braking system with better pedal feeling, and has the characteristics of low manufacturing cost, low maintenance cost, long service life and the like.

Owner:ANHUI YUFENG AUTOMOTIVE TECH

Underwater cutting system

The invention discloses an underwater cutting system. The underwater cutting system comprises a cutting water tank and an air tank communicating with the cutting water tank. A water overflow device is arranged on the outer wall of one side of the cutting water tank, the top of the air tank is provided with an air inlet and an air outlet, and an air tank water drainage hole and an air tank sludge clearing hole are formed in the outer wall of the side face of the air tank. The underwater cutting system is simple in overall structure, reasonable in design and good in stability. Under normal circumstances, the water level in the cutting water tank and the water level in the air tank are equal in height. When parts need to be cut underwater, the height of a water overflow pipe is increased along with work of an air cylinder, pressurization of the interior of the air tank is carried out through the air inlet, water in the air tank is made to quickly flow into the cutting water tank, the water level of the water tank is heightened, workpieces are immersed in the cutting water tank to be machined, after machining is completed, air in the air tank is exhausted, and water in the cutting water tank quickly flows back into the air tank. The problems of sand and water splashing and a dirty environment are solved, noise is low, maintenance cost is low, operation is convenient, and the cooling effect is good.

Owner:佛山市顺德区天擎电脑机械有限公司

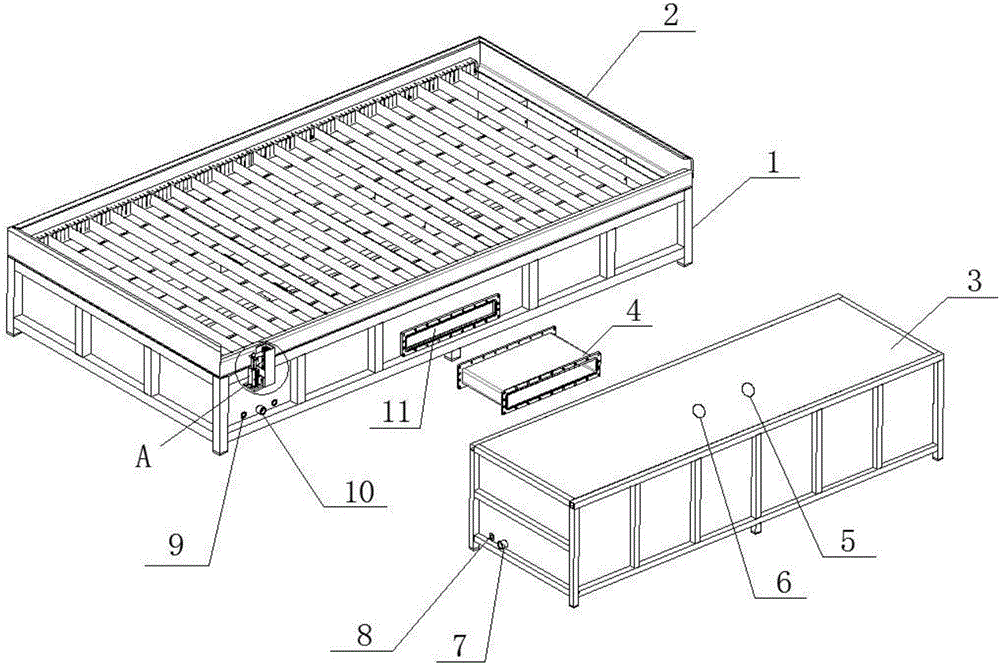

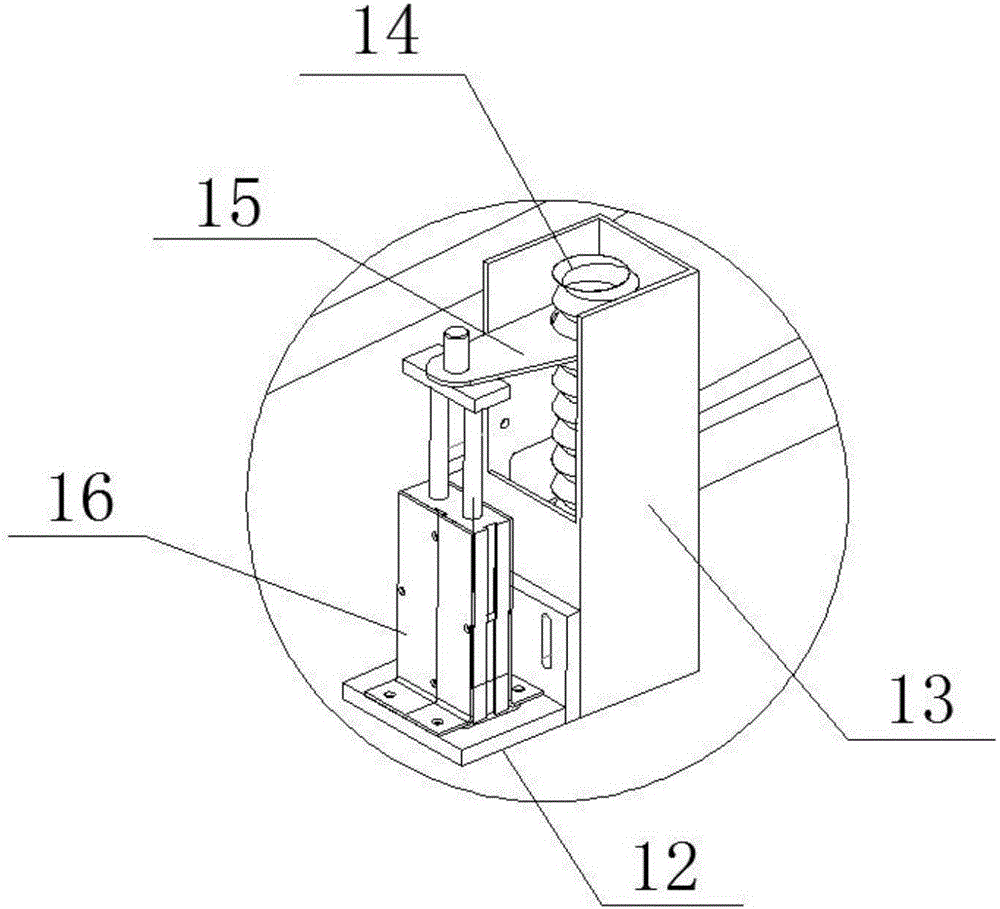

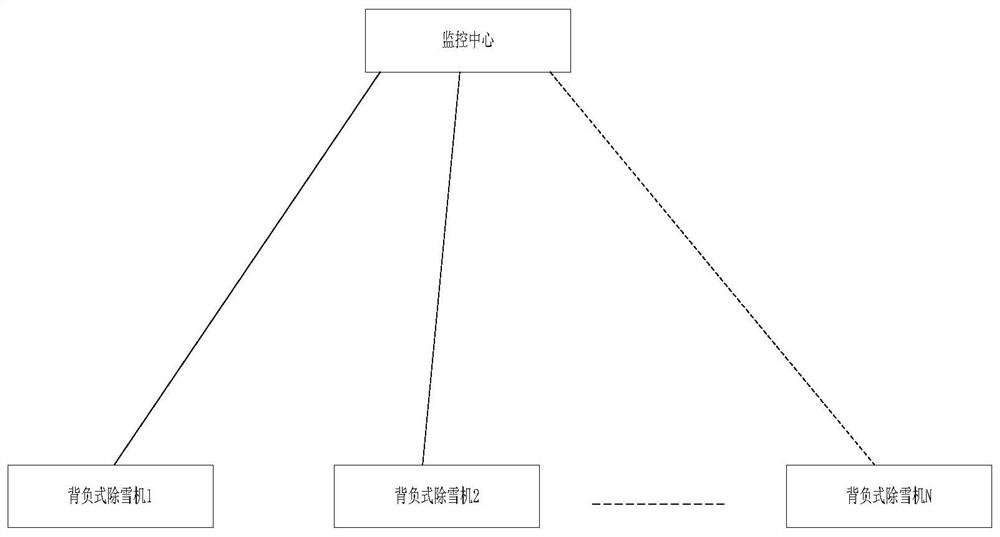

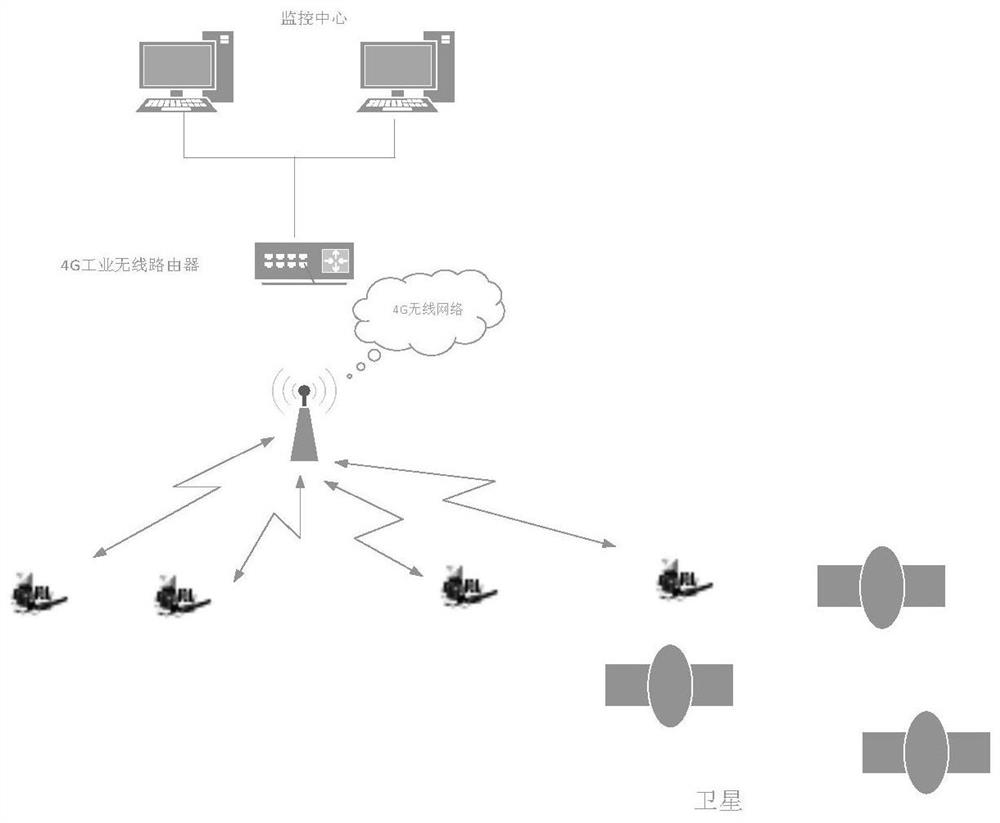

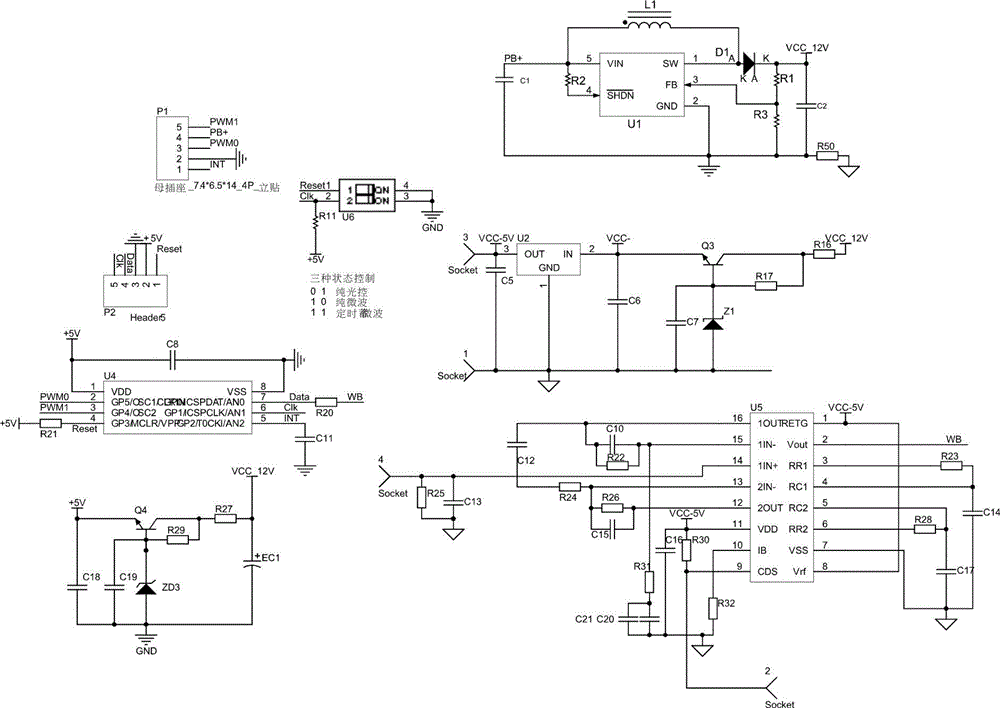

Backpack type wind power snow remover remote control system based on 4G wireless network

InactiveCN112367385ASolve potential safety hazardsLow costAlarmsRailway cleaningSnow removalRemote control

The invention discloses a backpack type wind power snow remover remote control system based on a 4G wireless network. The invention belongs to the mobile communication field. The system comprises a 4Gwireless network module, a positioning module, a remote control module, a voice communication module, an emergency alarm module and a power supply module. According to the backpack type wind power snow remover remote control system based on the 4G wireless network, when a station worker carries the snow remover on the back to remove snow on a train running track, and when a danger is found in a railway station signal building monitoring center, a station dispatching room monitoring center platform monitors the running state of each rail train through the 4G wireless network module, timely finds out hidden dangers, remotely controls and cuts off an oil way of a snow remover of snow removing personnel on site, forcibly stops the snow remover, eliminates strong noise generated by the backpack type wind power snow remover due to work, and immediately informs the snow removing personnel of being withdrawn to a safe zone. Therefore, casualty events in the working process are reduced; and the life safety of workers is ensured.

Owner:NANJING COLLEGE OF INFORMATION TECH

Automotive brake hose

InactiveCN104844920ANot easy to ageReduce maintenance costsFlexible pipesState of artAutomotive engineering

The invention discloses an automotive brake hose. After all components are matched in corresponding parts by weight, the needed hose is obtained through a rubber making process and a pressure pipe forming process. According to the automotive brake hose, the defects of likeliness in ageing, high maintenance cost, low safety and the like in the prior art can be overcome, and the advantages of non-likeliness in ageing, low maintenance cost and high safety are achieved.

Owner:WUXI YANGGONG MACHINERY MFG

Concrete side frame beam reinforcing structure with good supporting strength

InactiveCN113309375AImprove connection strengthHigh tensile strengthBuilding repairsArchitectural engineeringStructural engineering

The invention provides a concrete side frame beam reinforcing structure with good supporting strength, relates to the technical field of building structures, aims to solve the defects in the prior art of an existing reinforcing structure, and mainly aims to solve the problem of insufficient supporting strength caused by large span of an existing side frame beam. The concrete side frame beam reinforcing structure comprises a first side frame beam, a second side frame beam and a third side frame beam which are mounted on a main beam, wherein the first side frame beam is mounted at the front end of the main beam; the second side frame beam is mounted at the rear end of the main beam and is symmetrical to the first side frame beam; the third side frame beam is mounted on the side surface of the main beam; and the sections of the first side frame beam, the second side frame beam and the third side frame beam are rectangular. The concrete side frame beam reinforcing structure not only has good structural strength, but also is convenient to mount, low in construction cost, good in reliability and low in later maintenance cost.

Owner:贵州建工集团第四建筑工程有限责任公司

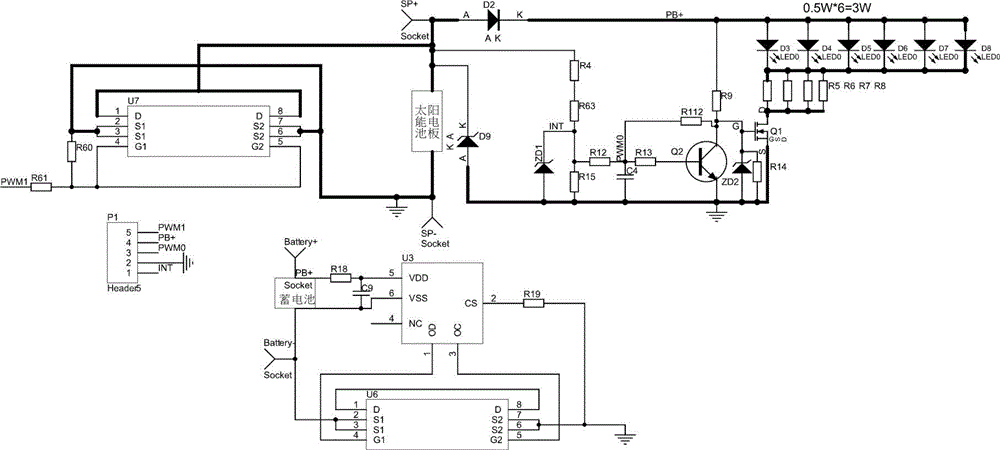

A high-efficiency intelligent solar lamp control circuit

ActiveCN104378877BReduce lossSolution to short lifeElectric light circuit arrangementSolar lightElectrical battery

The invention discloses an efficient and intelligent solar lamp control circuit. The efficient and intelligent solar lamp control circuit comprises a charging and discharging part, a sensing part and a sensing control part. The efficient and intelligent solar lamp control circuit has the following advantages that the number of external components is small, the component loss is small, charging efficiency is high, and efficient charging can be achieved; the number of the components of the system is small, the system can be directly integrated at a load end, the cable loss is reduced, and maintenance cost is low; the service life of a battery is made optimal by over-charging, over-discharging and over-current protection of the battery; intelligent power regulation is achieved, when the battery capacity is lowered, the output current can be lowered automatically by the system, traditional PWM regulation is replaced, the output ripple is extremely small, and an LED lamp is not stroboscopic; output is made more reasonable through sensing control, the output current can be lowered when nobody is around, total-power working can be achieved when somebody is in, and the battery capacity can be made smaller under the same configuration.

Owner:深圳源码智能照明有限公司

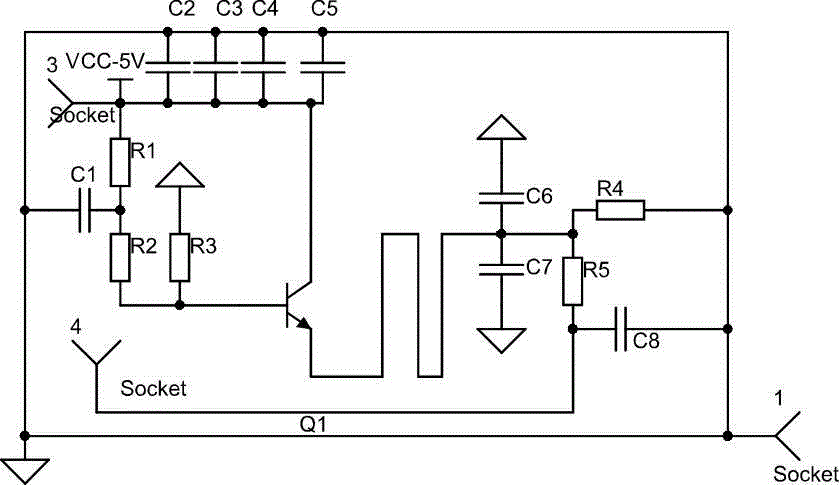

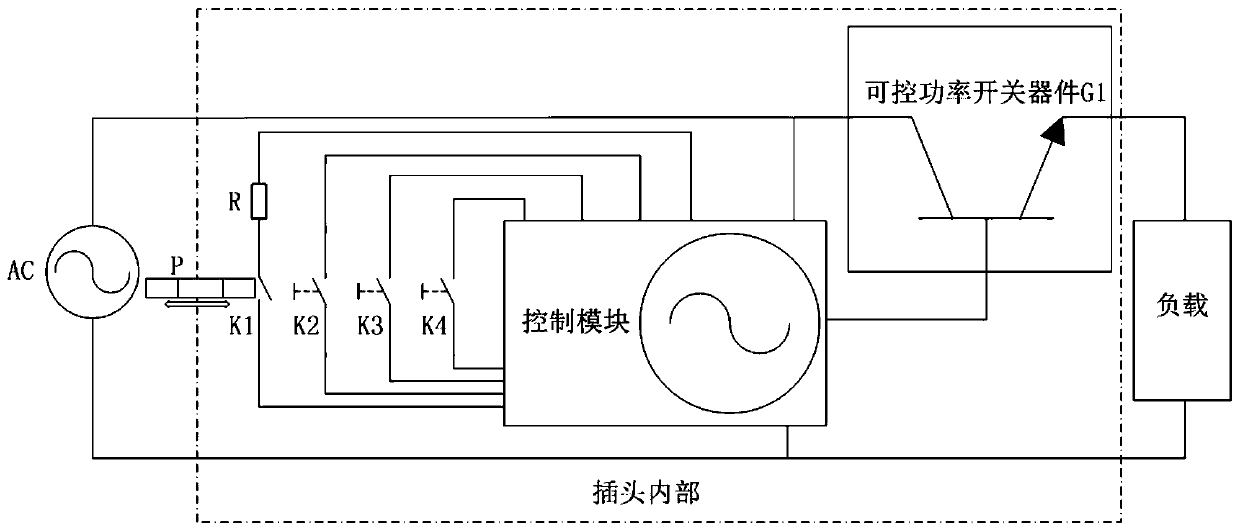

Plug control device, electronic equipment and plug control method thereof

ActiveCN109787598BLarge inrush currentImprove securityElectronic switchingPower diodeCurrent voltage

The invention discloses a plug-pull control device, electronic equipment and a plug-pull control method of the electronic equipment. The device comprises a plug assembly. The plug assembly is used fordetecting whether the current voltage is within a set range of a zero crossing point in the plugging process with the socket; If the current voltage is within the set range of the zero crossing point, controlling the current state of the device to be controlled to change; Or, if the current voltage is not in the set range of the zero crossing point, controlling the to-be-controlled device to keepthe current state, and controlling the current state of the to-be-controlled device to change until the current voltage returns to the set range of the zero crossing point again. According to the scheme provided by the invention, the problem that the power electronic device is easily damaged when the on-off operations such as hot plug, startup and shutdown of the power electronic device such as an IGBT and a power diode occur near the peak value of the voltage can be solved, and the effect that the power electronic device is not easily damaged is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Dynamic sealing device for inner side of bottom of cooling bed trolley and sealing method of dynamic sealing device

ActiveCN106403607AImprove wear resistanceGood maintenance costFurnace componentsFurnace typesEngineeringMechanical engineering

The invention discloses a dynamic sealing device for the inner side of the bottom of a cooling bed trolley and a sealing method of the dynamic sealing device and relates to a sealing device of a cooling bed trolley on a sintering machine. The dynamic sealing device for the inner side of the bottom of the cooling bed trolley and the sealing method of the dynamic sealing device aim at overcoming the defect that the sealing effect between an existing cooling bed trolley and a bottom static beam is poor. The dynamic sealing device comprises the cooling bed trolley, upper connecting parts, lower connecting parts and sealing parts. The cooling bed trolley slides relative to a lower static beam through wheels on the cooling bed trolley; the upper connecting parts are arranged on the two sides of the bottom of the cooling bed trolley correspondingly, and the lower connecting parts are arranged at the positions, corresponding to the lower portions of the upper connecting parts, on the static beam. The inner side walls of the upper connecting parts are provided with the sealing parts with the lower ends abutting against the lower connecting parts. Each sealing part comprises at least one layer of steel brush. The dynamic sealing device for the inner side of the bottom of the cooling bed trolley and the sealing method of the dynamic sealing device well solve the problem that the sealing effect between the cooling bed trolley and the bottom static beam is poor.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Automatic backlash-eliminating scale-dividing device used for numeral control helical deep hole broacher

InactiveCN101716736BLow costImprove securityPrecision positioning equipmentBroaching accessoriesDrive wheelGrating

The invention belongs to the technical field of broacher devices, in particular to an automatic backlash-eliminating dividing device used for a numeral control helical deep hole broacher. The device comprises a box body, an alternating current servo motor, an input-output mechanism, and a circular grating detection mechanism. In the device, scale division is controlled directly through the alternating current servo motor; and through pushing a driving axle to glide axially by an adjusting washer and a disc spring, the driving axle and a double-tooth backlash-eliminating mechanism consisting of driven wheels can automatically compensate to eliminate backlashes after a gear is worn. The driving device of the invention has the advantages of low cost and maintenance cost, high safety, and good reliability.

Owner:MIANYANG WEIBO ELECTRONICS

Brake pedal with adjustable lever ratio for vehicle

InactiveCN103072560BSimple designConvenience Pedal ParametersFoot actuated initiationsEngineeringMachining

Owner:ANHUI YUFENG AUTOMOTIVE TECH

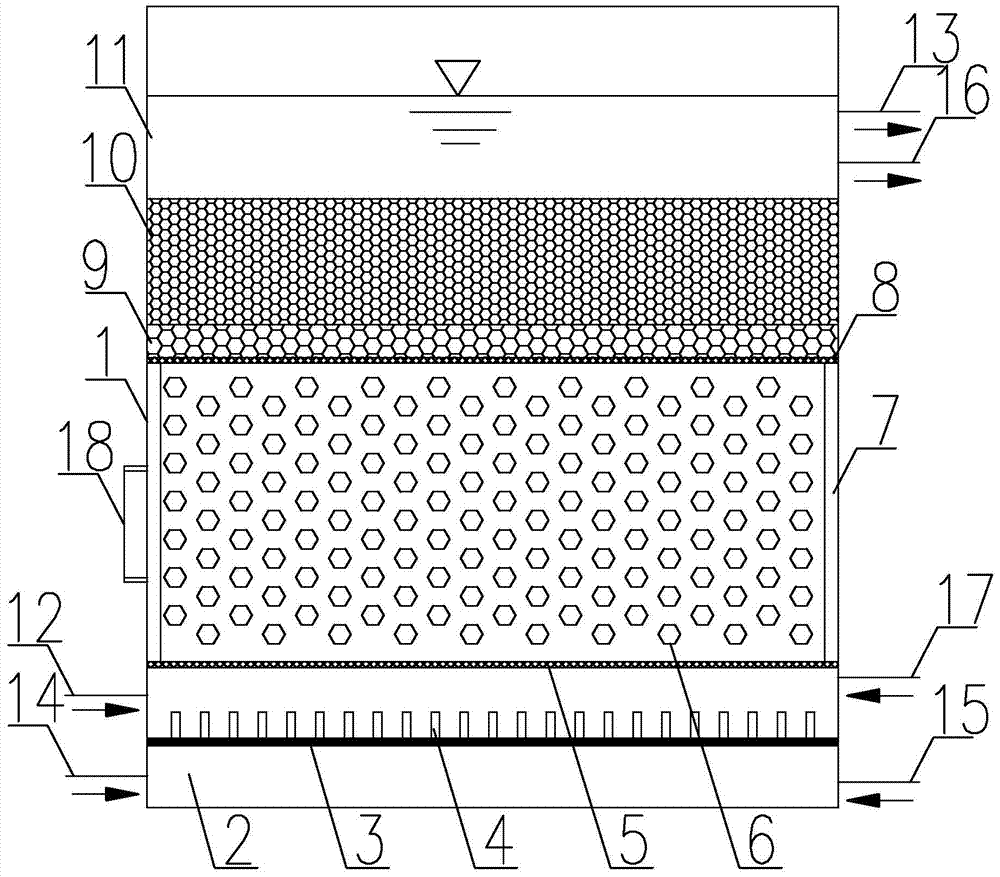

A device and method for treating emulsion wastewater in fully mechanized coal mining face

ActiveCN105254080BReduce processing difficultyReduce compactionWaste water treatment from quariesFluid removalEmulsionWater channel

The invention relates to a device and a method for treating emulsion wastewater of fully mechanized mining face in a coal mine. The device includes a cylinder, and the interior of the cylinder is sequentially provided with a bottom water flow channel, a bottom support plate, a filter head, a bottom grid plate, a bottom filter material layer, a two-way air flushing pipe, a middle grid plate, and a middle filter material from bottom to top. layer, the upper filter material layer and the upper clean water area, a plurality of filter heads are installed on the bottom support plate, the bottom of the side of the cylinder is provided with a water flushing port, an air flushing port, a water inlet and an air inlet, and the top of the cylinder is provided with A water outlet and a water outlet are arranged on one side, and an inspection hole is arranged on the outer wall corresponding to the filter material layer at the bottom of the cylinder. The device can collect and treat emulsion wastewater on the underground working face. The device adopts the technical principle of multi-stage adsorption, combined with two-way air flushing, which effectively removes macromolecular and refractory organic pollutants in the emulsion wastewater, and avoids the porous in the device. The compaction of the filler.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

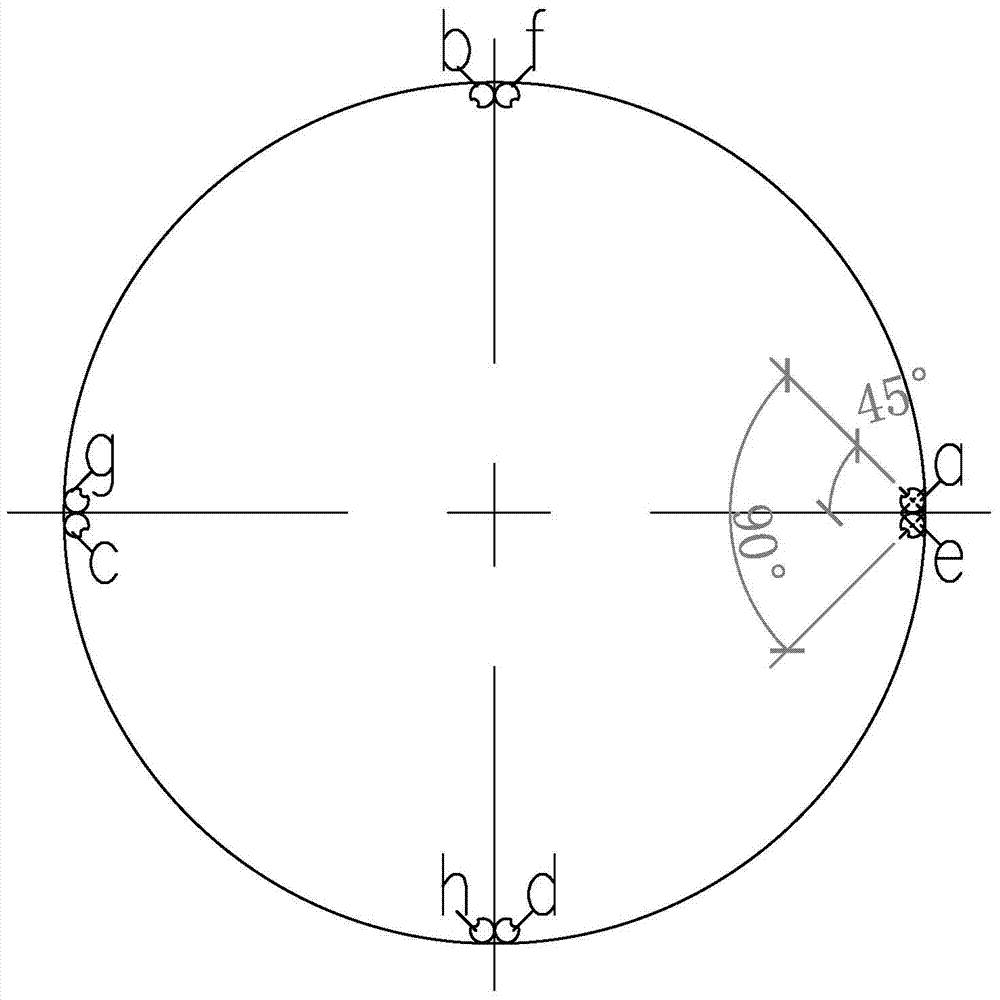

A yarn guiding device with origin positioning function

Owner:ZHEJIANG JINMA AUTOMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com