Gas-water joint assembly

A technology of air-water joints and components, applied in the direction of pipe components, etc., can solve the problems of inability to realize water-air synchronous work, unreasonable design, unreachable, etc., and achieve the effect of simple structure, reasonable design, and low cost and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

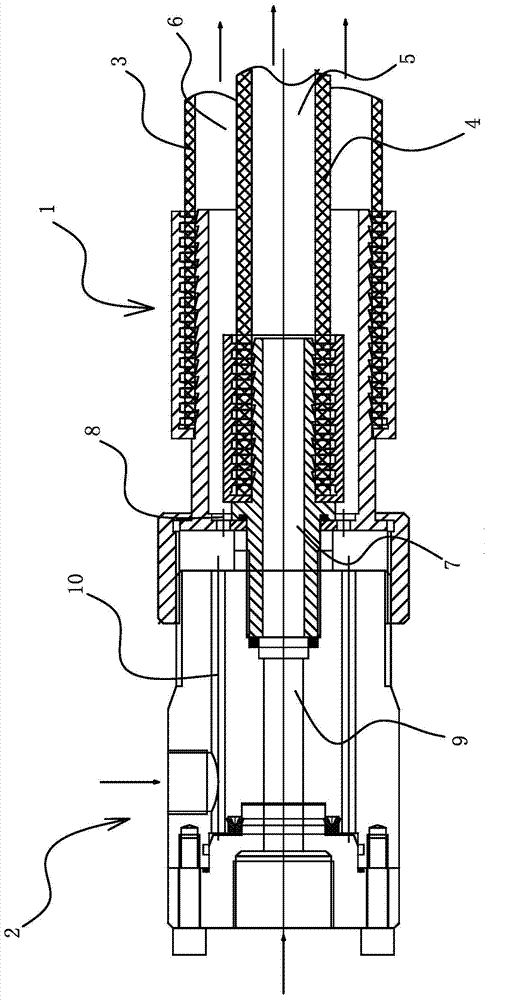

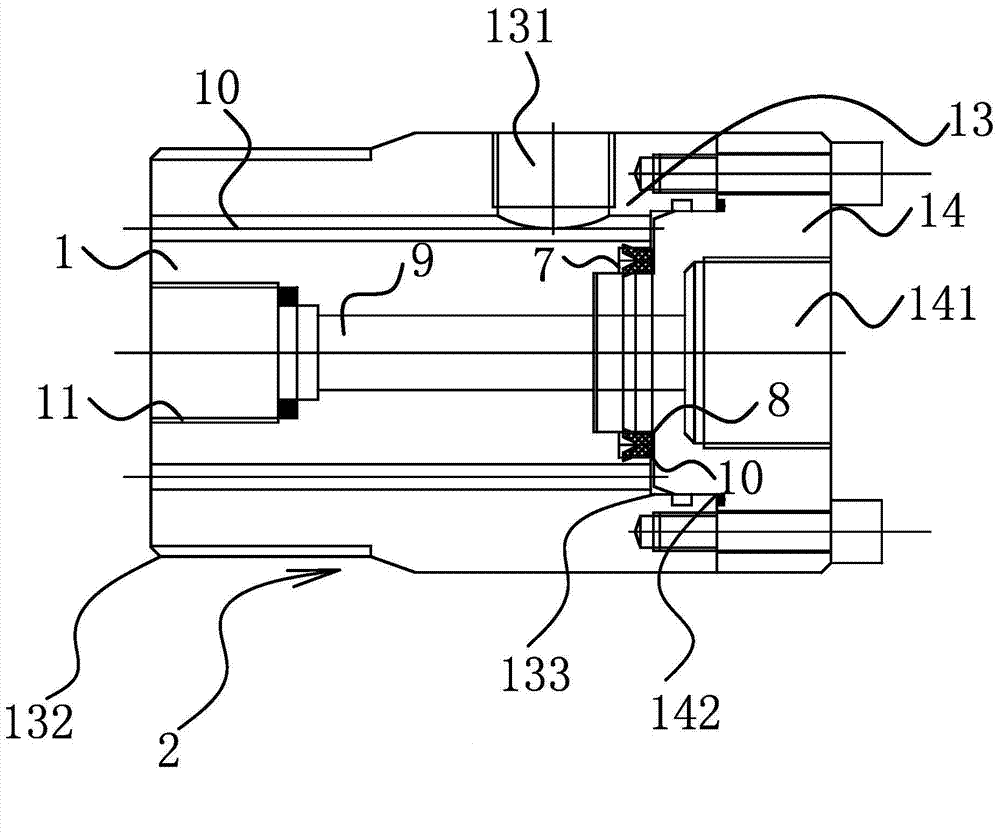

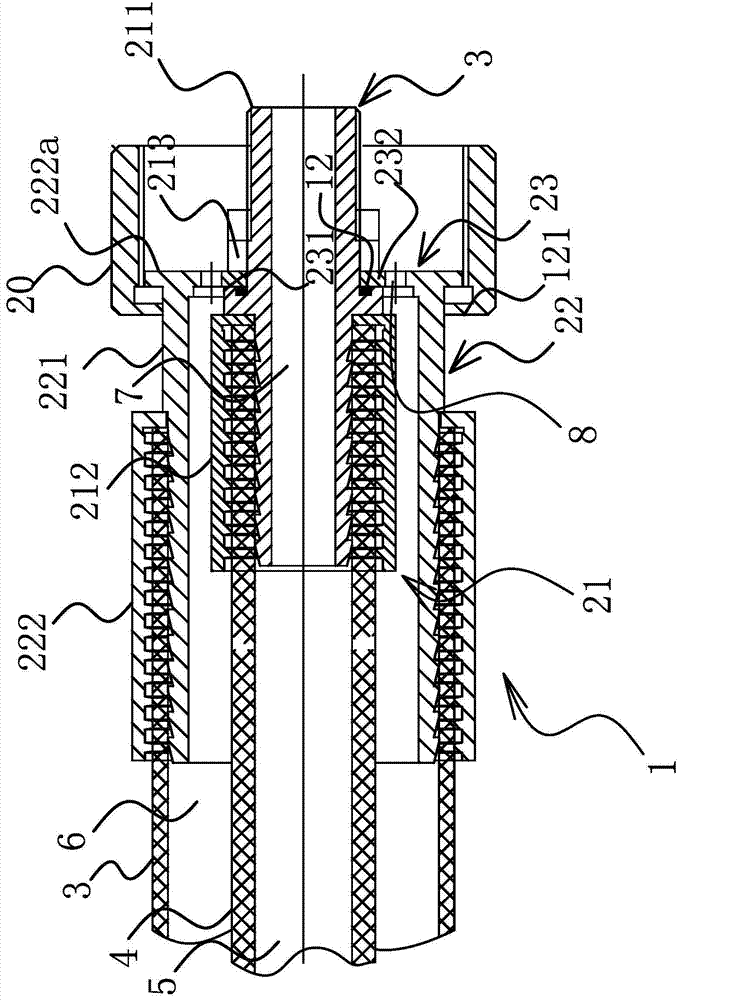

[0020] Such as Figure 1-3 As shown, the air-water joint assembly includes an outer joint 1 and a pipe end joint 2 connected to each other. An outer hose 3 and an inner hose 4 passing through the outer hose 3 are connected to the pipe end joint 2. The inner soft The pipe 4 has a water flow channel 5, an air flow channel 6 is formed between the outer hose 3 and the inner hose 4, the pipe end joint 2 has a water passage 7 and an air passage 8 isolated from each other, and the water flow channel 5 is connected to the water passage The channel 7 is connected, and the air flow channel 6 is connected with the air passage 8. The outer joint 1 has a mutually isolated water inlet / outlet channel 9 and an air inlet / outlet channel 10. The outer joint 1 and the pipe end joint 2 are fixed by a positioning structure 11 Connected, and the water passage 7 communicates with the water inlet / outlet passage 9, and the air passage 8 communicates with the air inlet / outlet passage 10.

[0021] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com