High-pressure gas preservation method

A high-pressure gas and compressed gas technology, applied in the field of high-pressure gas storage, can solve the problems of high operating costs and large floor space, and achieve the effects of strong construction adaptability, low maintenance costs, and small chances of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

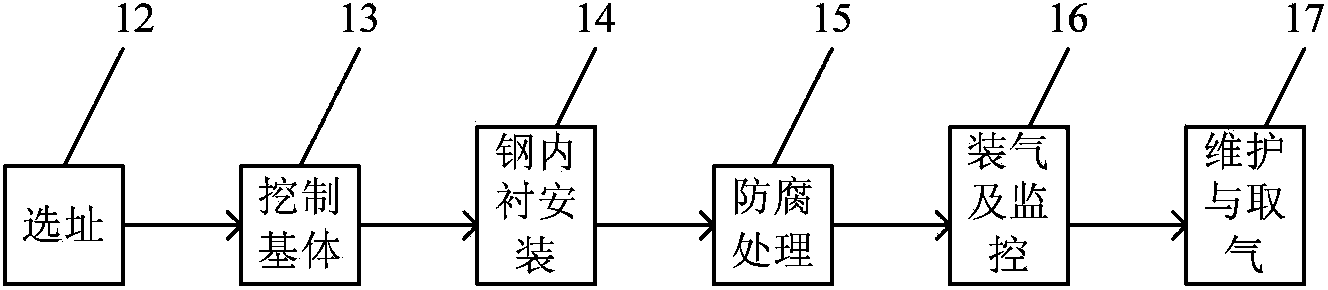

[0022] The process steps of this embodiment include site selection, excavation of substrate, installation of steel lining, anti-corrosion treatment, gas filling and monitoring, maintenance and gas extraction;

[0023] (1) Site selection: first select an area with a hard geological structure within the determined area as the gas storage site. The geographical conditions of the selected gas storage site are that the range of 10 to 150 meters below the ground level is a hard geographical environment, and the hard index Rocky and sandy soil, less groundwater;

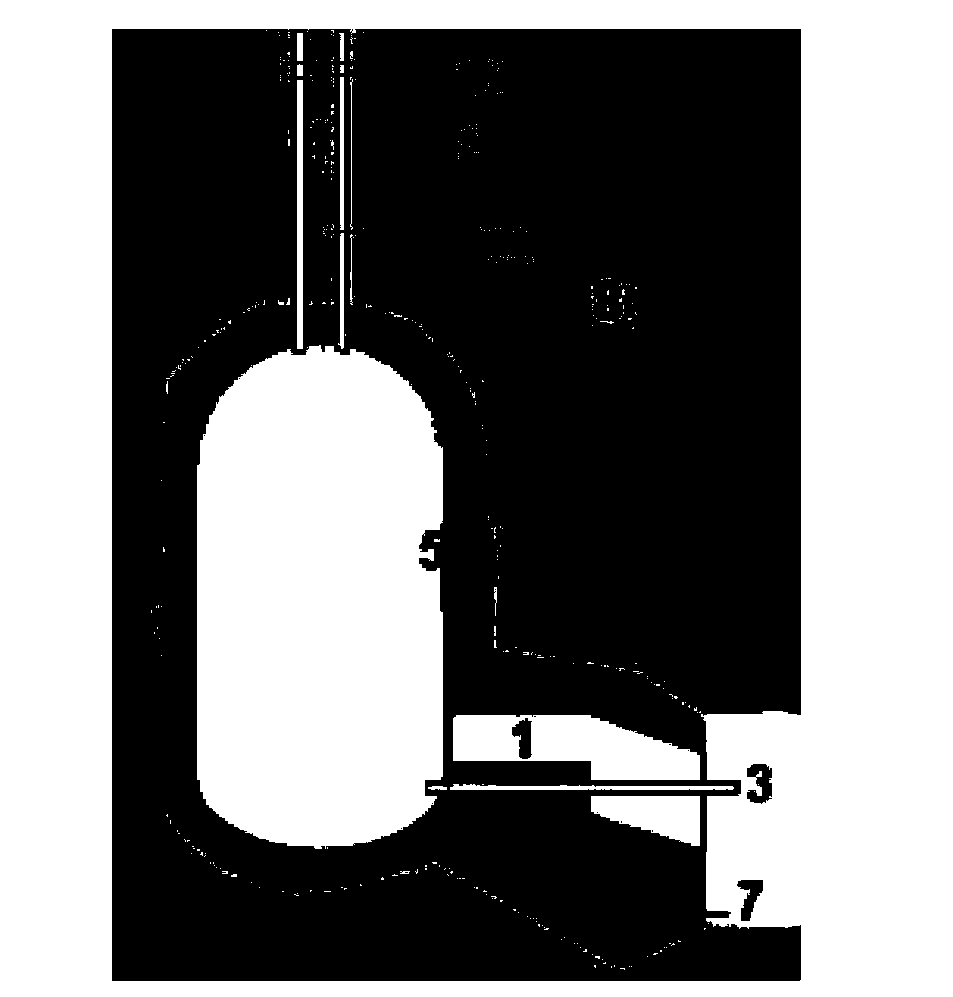

[0024] (2) Excavating the substrate: At the selected gas storage location, excavate the hollow or embedded concave substrate manually or mechanically, and the structural shape and size of the substrate are larger than the size of the steel lining; the excavation method is Open-pit excavation or tunnel drilling; construction passages or workshops are left at the bottom of the substrate to facilitate the installation of steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com