Coiled material waterproof laying equipment and coiled material waterproof laying method

A coil and equipment technology, which is applied in the direction of coil coil, bridge construction, building insulation materials, etc., can solve the problems of lack of synchronous device, fold of membrane waterproof layer, slow unwinding speed, etc., and achieve the effect of ensuring smooth laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

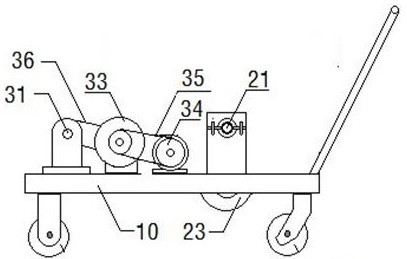

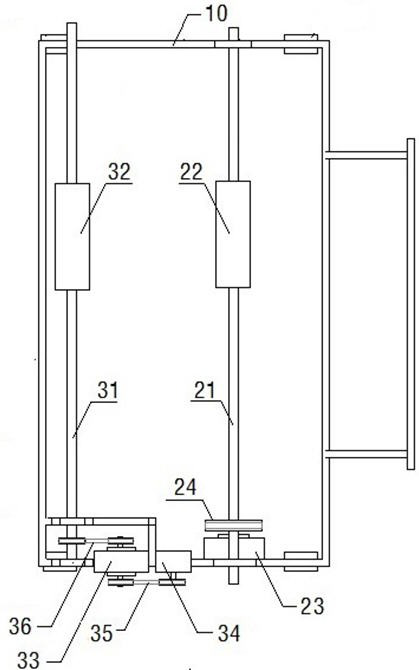

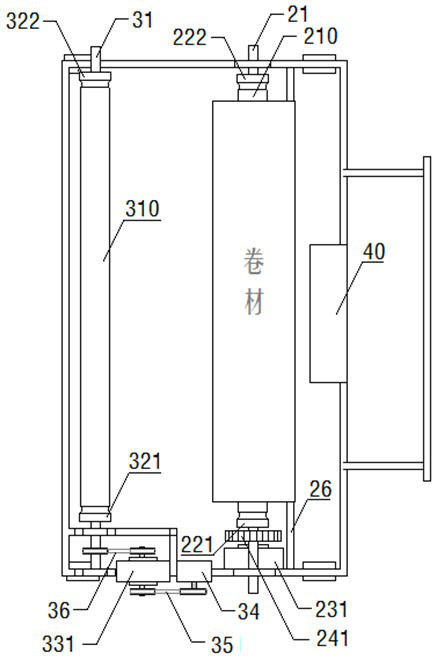

[0056] Such as Figure 4 , Figure 5 , Figure 6 As shown, this embodiment discloses a coiled material waterproof laying equipment, including equipment support 10, traveling mechanism, first semicircular bearing 201, second semicircular bearing 202, unwinding shaft 21, first coiled material mandrel tube locking chuck 221, the second coil mandrel tube locking chuck 222, the first gear 241, the second gear 242, the magnetic powder brake 231, the coil guide roller 26, the first bearing 301, the second bearing 302, the film receiving shaft 31, The first film-winding mandrel tube lock chuck 321, the second film-winding mandrel tube lock chuck 322, the magnetic powder clutch 331, the film-winding motor 34, the second transmission device 35, the third transmission device 36, the film-winding guide The roller 38 and the electric control device 40 constitute.

[0057] The running mechanism of this embodiment is made up of four wheels 11, which are installed at the four corners below...

Embodiment 2

[0082] Such as Figure 7 , Figure 8 As shown, this embodiment discloses a coiled material waterproof laying equipment, including equipment support 10, third bearing 203, fourth bearing 204, unwinding shaft 21, unrolling expansion shaft 220, unwinding expansion shaft locking knob 2201 and unwinding Mechanical torque limiter 232, the first transmission device 24, the first gear 241, the second gear 242, the coil guide roller 26, the first bearing 301, the second bearing 302, the film receiving shaft 31, the film expanding shaft 320, Film winding shaft locking knob 3201, film winding mechanical torque limiter 332, film winding motor 34, second transmission device 35, third transmission device 36, electric control device 40, meter sensor 51, meter reading display screen 52. Coil material cutting device 60, film cutting motor 61, cutting knife 62, and knife-feeding slot 63 constitute.

[0083] The third bearing 203 and the fourth bearing 204 are fixedly installed on one side of ...

Embodiment 3

[0093] Such as Figure 9 , Figure 10 , Figure 11 As shown, this embodiment discloses a coiled material waterproof laying equipment, including an equipment support 10, a traveling mechanism, a first bearing device 205, a second bearing device 206, a first unwinding shaft 211, a second unwinding shaft 212, a third roll Material mandrel tube locking chuck 223, fourth coiled material mandrel tube locking chuck 224, magnetic powder brake 231, first transmission device 24, first propulsion device 25, first nut 251, first threaded propelling rod 252 , the first handle 253, the third bearing device 303, the fourth bearing device 304, the first film receiving shaft 311, the second film receiving shaft 312, the third film receiving mandrel tube locking chuck 323, the fourth film receiving core Shaft tube locking chuck 324, magnetic powder clutch 331, film winding motor 34, second transmission device 35, third transmission device 36, second propulsion device 37, second nut 371, secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com