Textile concrete externally-hung curtain wall and preparation method thereof

A fiber woven mesh, concrete technology, applied in the direction of walls, building materials, building components, etc., to achieve the effect of low maintenance cost, good durability, and strong self-healing ability of micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following describes the examples of the present invention in detail in conjunction with the technical scheme and the accompanying drawings, and further describes the present invention in detail. It should be understood that the specific examples described here are only used to explain the present invention, not to limit the present invention.

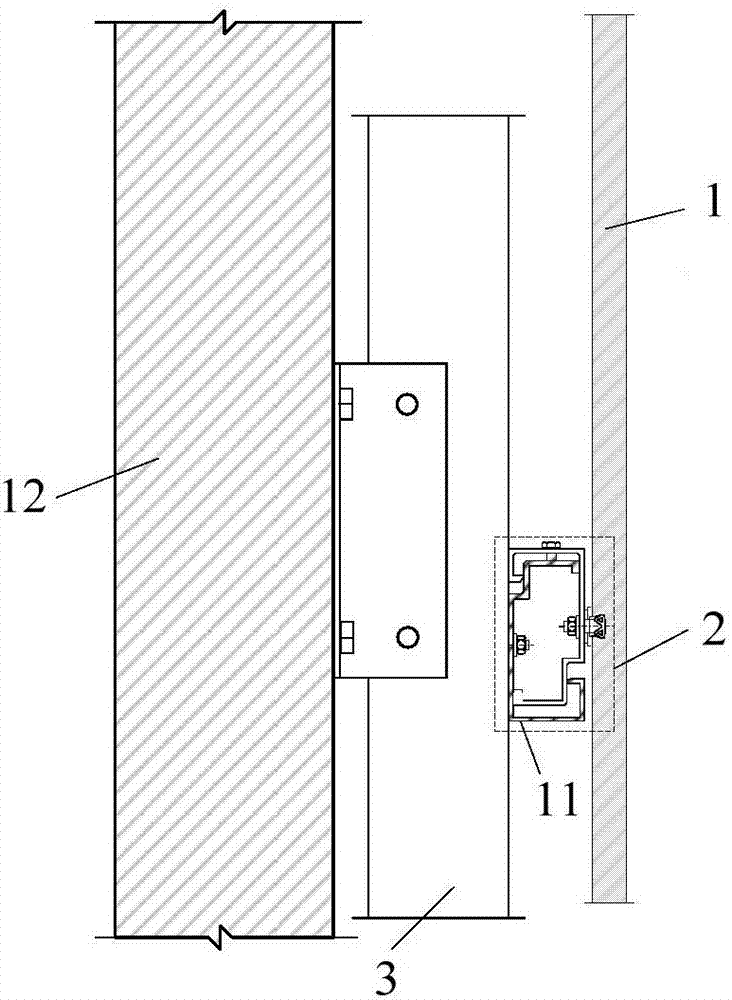

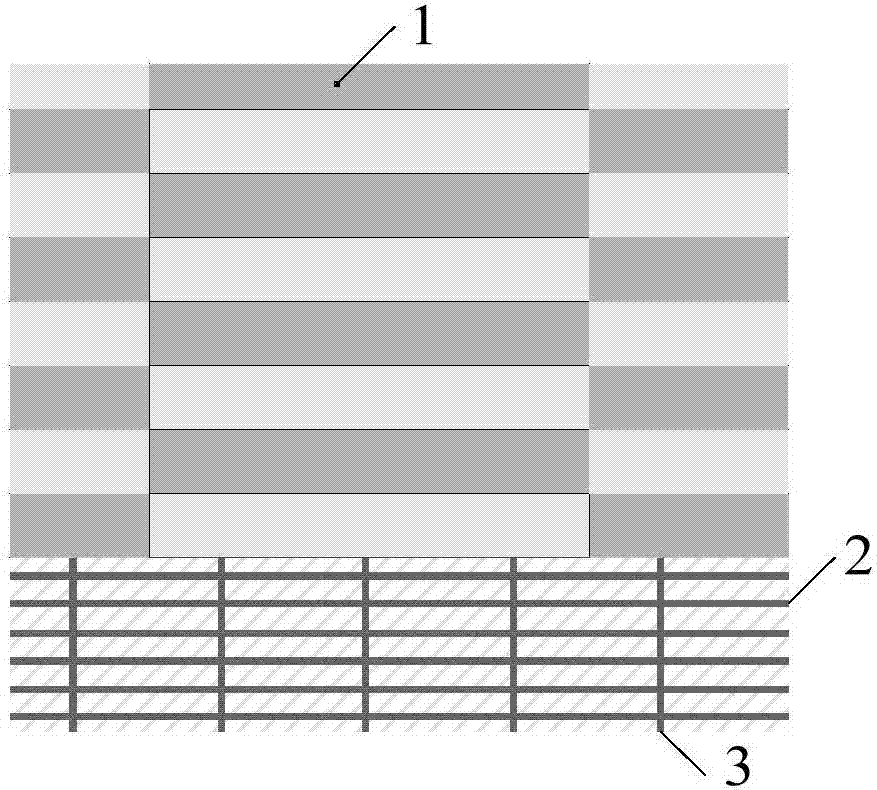

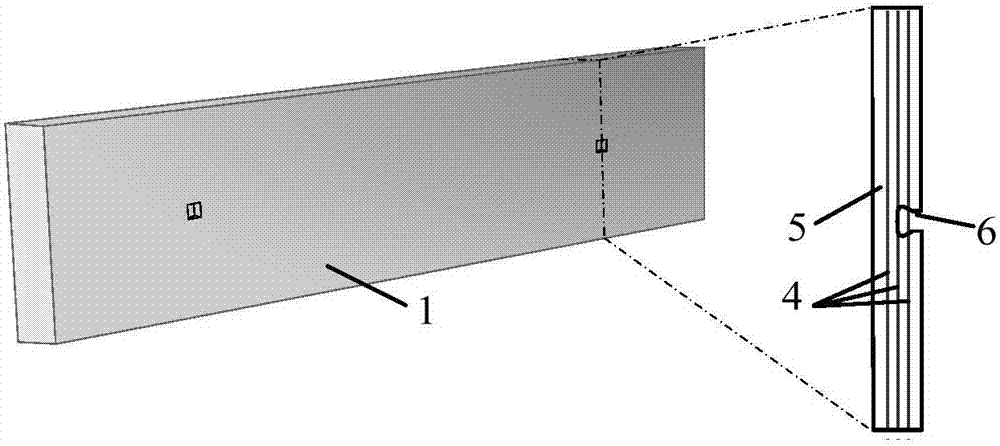

[0036] attached figure 1 The fiber woven mesh concrete external curtain wall 1 described in the present invention is given, and the external curtain wall 1 is connected with the main structure 12 through the beam 2 and the column 3, as shown in Figure 5 and Figure 6 shown. The manufacturing process of the curtain wall is shown in Figures 3(a) to 3(f). The external hanging curtain wall 1 is made of fiber woven mesh 4 and fine concrete 5 mixed with chopped fibers, and the non-metallic fiber woven mesh is located on the external hanging Inside the curtain wall 1, the number of layers of the fiber woven mesh 4 laid out shall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com