A device and method for treating emulsion wastewater in fully mechanized coal mining face

A technology for fully mechanized mining face and wastewater treatment, applied in mining wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Coagulation and sedimentation and other problems, to achieve the effect of saving investment and operating costs, significant economic benefits, and good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

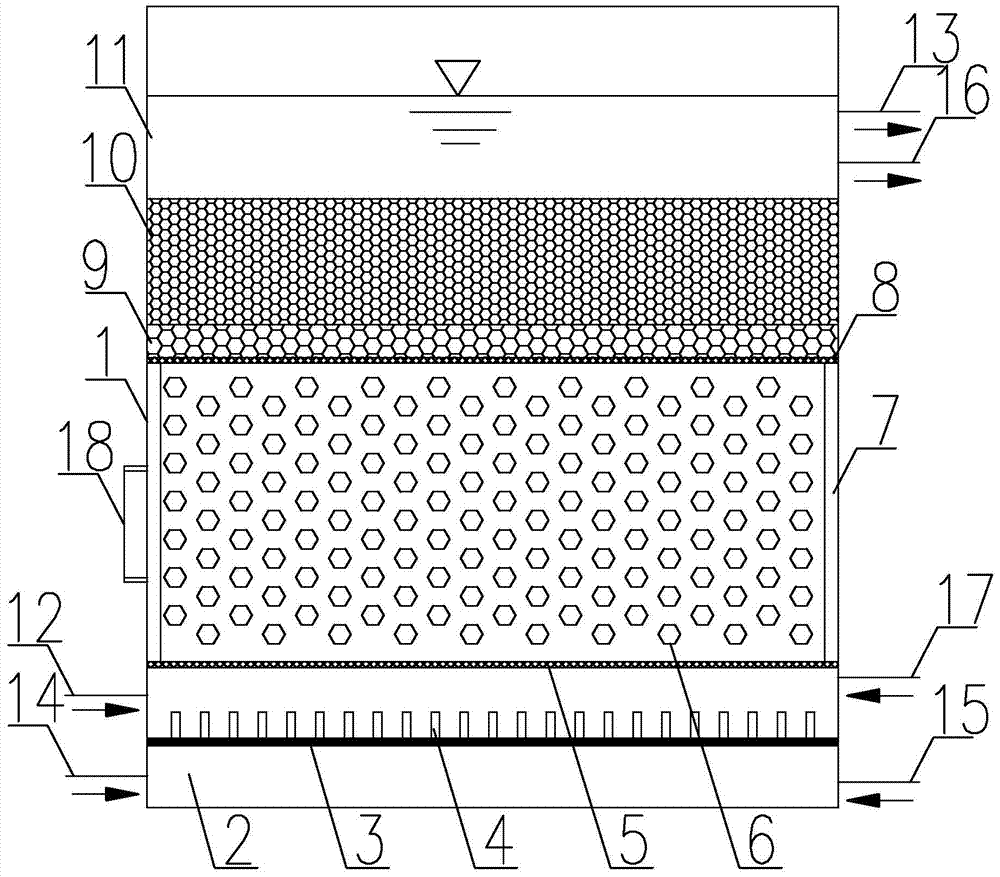

[0024] An emulsion wastewater treatment device for fully mechanized mining face in coal mine, such as figure 1 As shown, the device includes a cylinder body 1, and inside the cylinder body, a bottom water flow channel 2, a bottom support plate 3, a filter head 4, a bottom grid plate 5, a bottom filter material layer 6, and a two-way air flushing tube are sequentially arranged inside the cylinder body. 7. The middle grid plate 8, the middle filter material layer 9, the upper filter material layer 10 and the upper clear water area 11, the bottom of the side of the cylinder 1 is provided with a water inlet 12, a water flushing port 14, an air flushing port 15 and an inlet Air port 17, water outlet 13 and drain port 16 are provided on the top side of cylinder 1, and inspection hole 18 is provided on the outer wall corresponding to filter material layer 7 at the bottom of cylinder 1, through which filter material is regularly added. The liquid in the bottom water flow channel 2 ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com