Patents

Literature

184results about How to "Tackle splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand casting die assembly

ActiveCN107876709AAvoid disassembly and replacementEasy to disassemble and replaceMoulding machinesCompression moldingSand casting

The invention discloses a sand casting die assembly comprising a shell which is of a hollow structure. One side wall of the shell is further provided with a feed port of which the opening position isrotatably connected to a cover plate, and the inner wall of the upper side of the shell is fixedly connected to a cylinder; the output end of the cylinder is connected to a piston rod, and the end, far away from the cylinder, of the piston rod is connected to a mounting plate of which the lower end is further provided with a die; the upper end of the die is provided with a mounting block, and thelower side wall of the mounting plate is provided with a mounting groove matched with the mounting block; the mounting plate is internally provide with two cavities arranged symmetrically, and the cavities are internally provided with first slide bars arranged vertically; the opposite side walls of the two first slide bars are both provided with first clamping blocks which penetrate the cavities;and the side wall of the mounting block is provided with a first slot matched with the first clamping blocks. According to the sand casting die assembly disclosed by the invention, a clamping sand mould is simple and firm, and the die for compression molding is easy to remove and displace; and the die assembly is wide in application scope.

Owner:马鞍山市海华金属制品有限公司

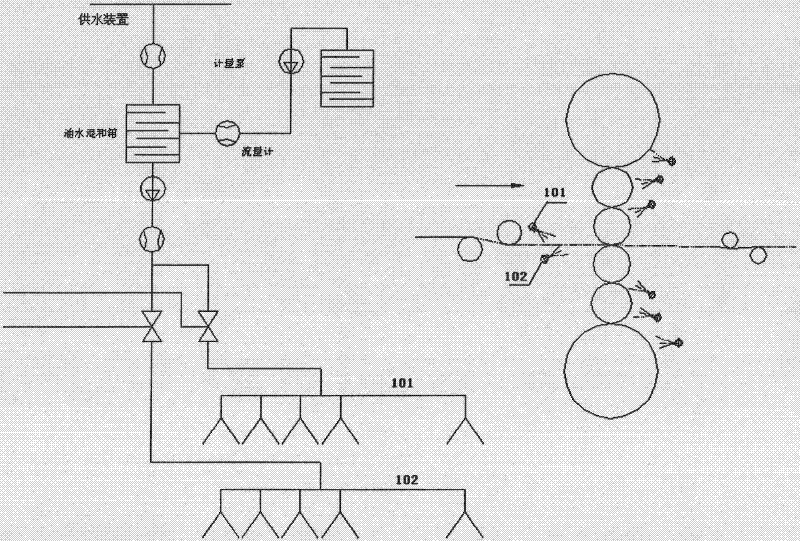

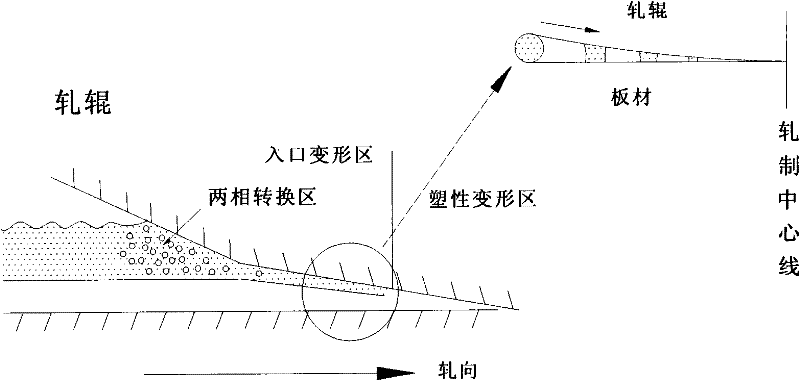

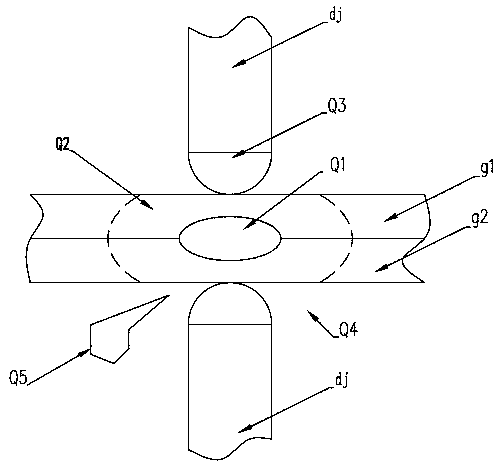

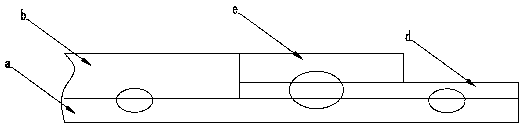

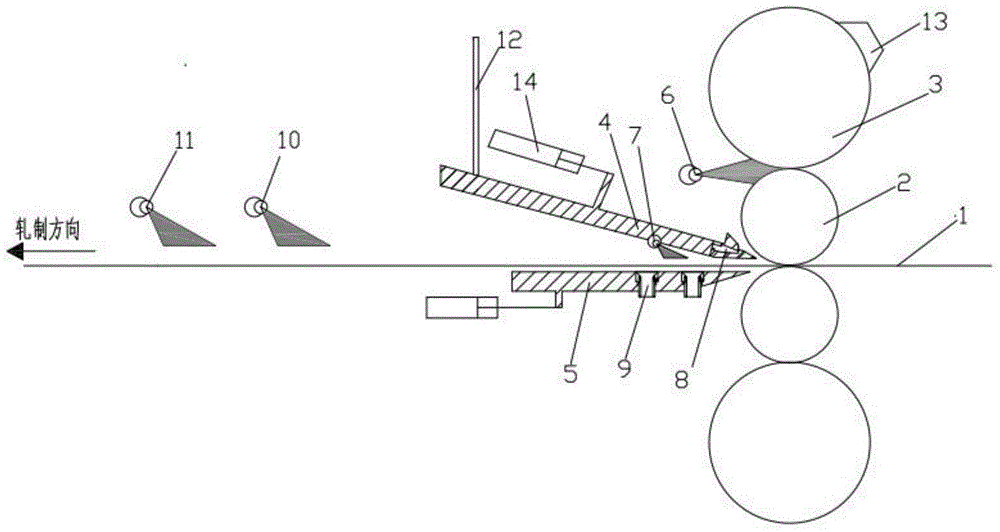

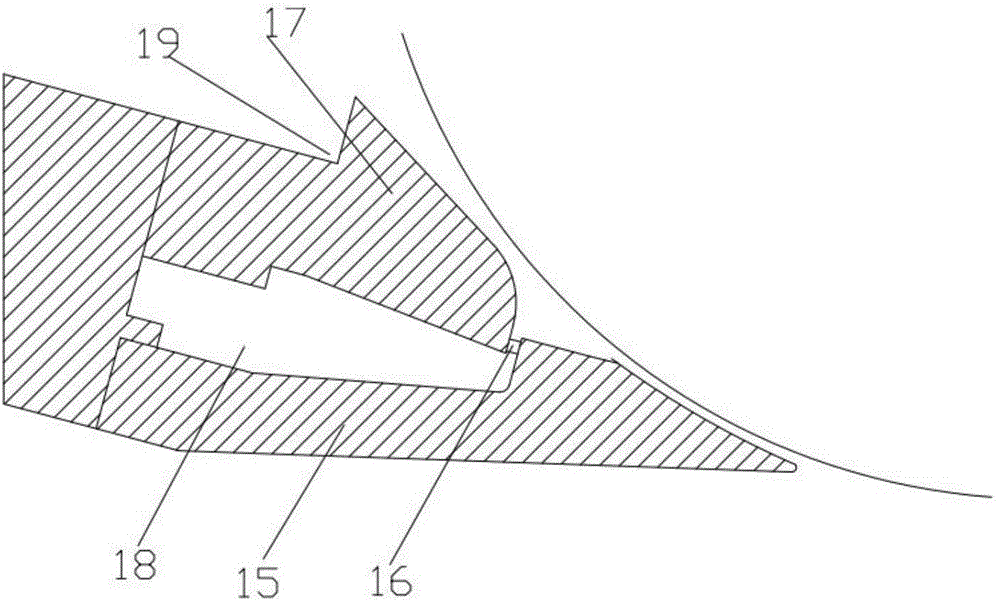

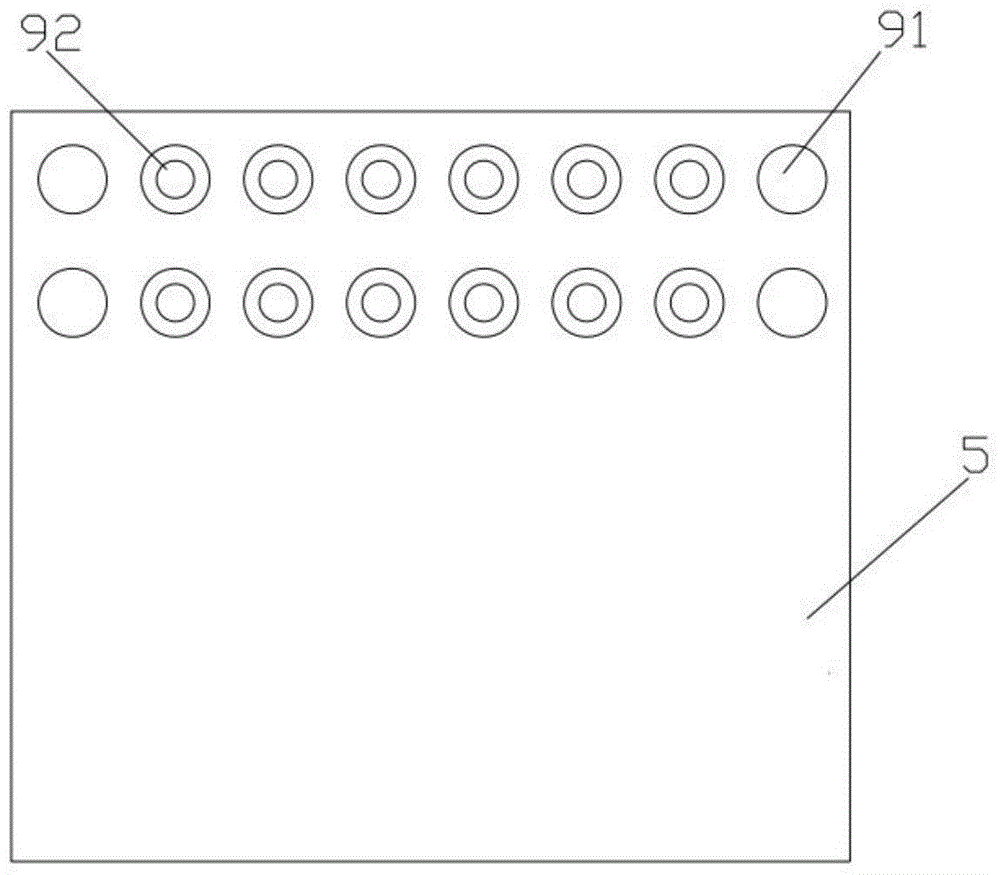

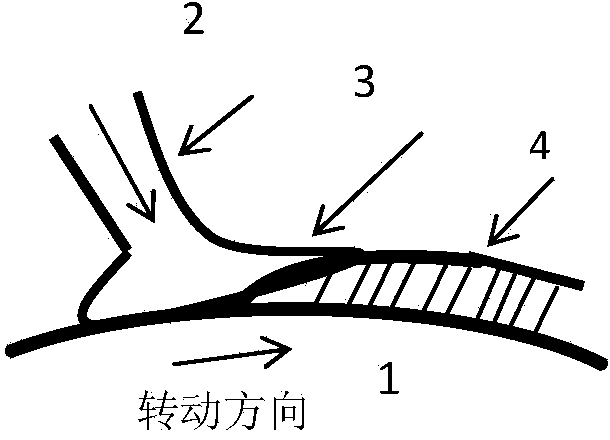

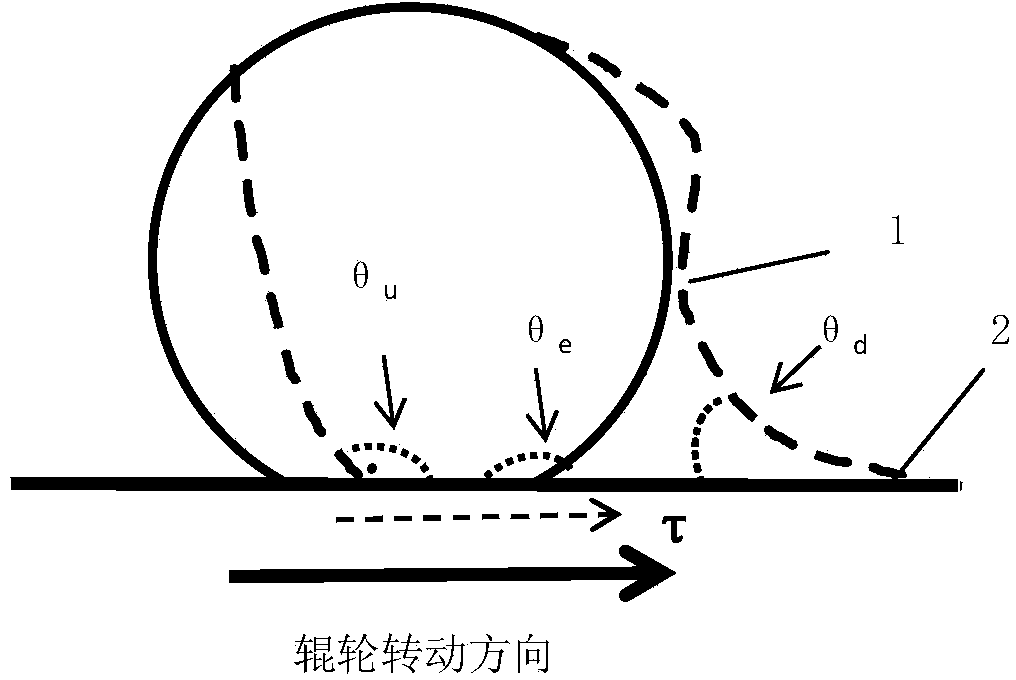

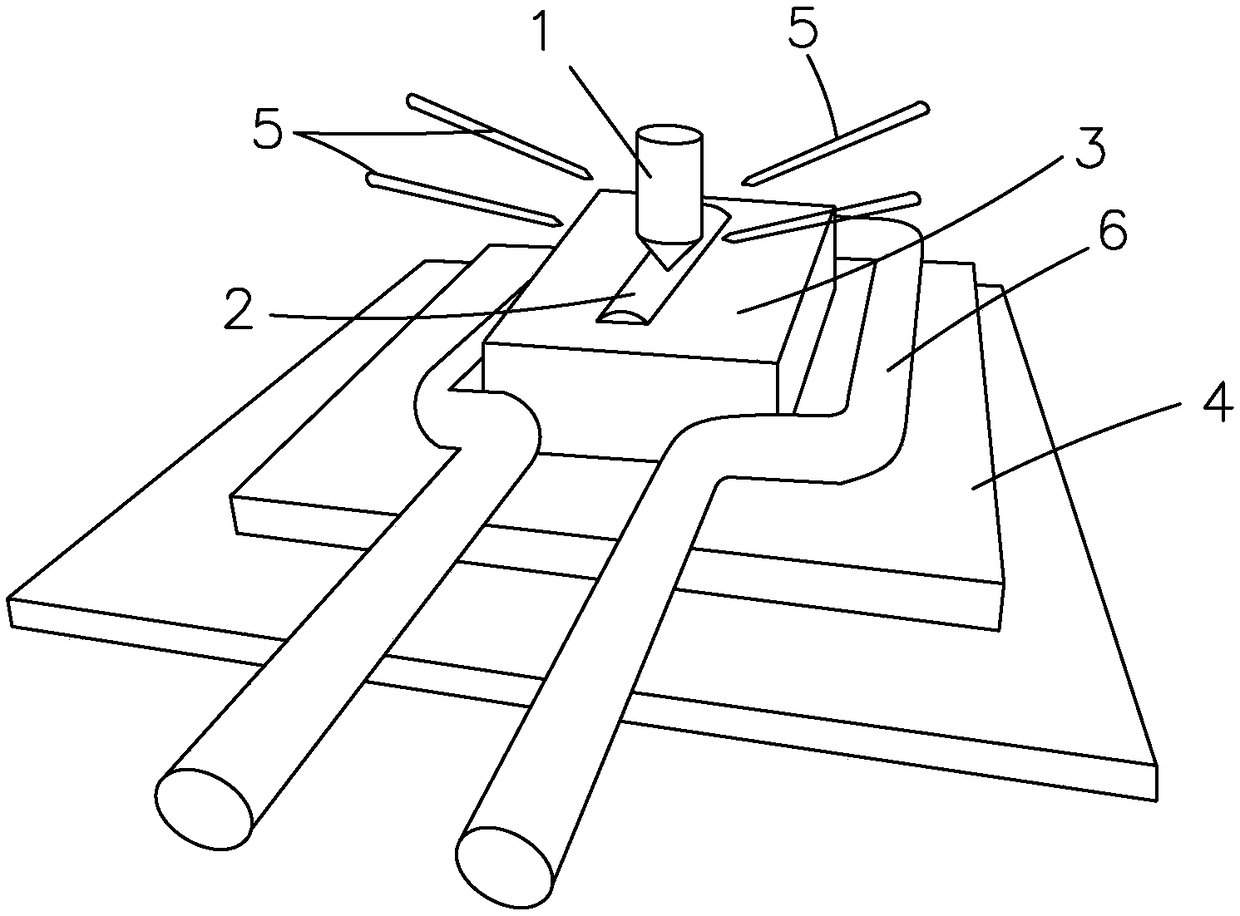

Injection device and method for uniformly lubricating roll gap of rolling mill

ActiveCN102189126ATackle splashGive full play to lubricityWork treatment devicesRollsSpray nozzleInjection emulsion

The invention discloses an injection device for uniformly lubricating a roll gap of a rolling mill. The injection device comprises a direct injection emulsion spraying rack (101) arranged on the upper surface of strip steel (104) and at an inlet of a rolling mill rack, a direct injection emulsion spraying rack (102) arranged on the lower surface of the strip steel and at the inlet of the rolling mill rack and a direct injection emulsion spraying rack (103) arranged on the lower surface of the strip steel (104) and at the inlet of the rolling rack. The invention also discloses an injection method comprising the following steps of: 1, determining the distance from a nozzle in the spraying rack (103) to a centerline of a roller (105) and the distance from the nozzle in the spraying rack (103) to a rolling centerline; 2, determining the angle dimension between the nozzle and the horizontal plane; and 3, determining the injection flow of each spraying rack. By adopting the injection deviceand the injection method, the problem of easily dripping and splashing when the emulsion flow is excessive is solved; ample lubrication in a lower roll gap and sufficient oil film thickness are also realized; and the uniformity of lubricating oil film thicknesses of the upper and the lower roll gaps are simultaneously guaranteed.

Owner:BAOSHAN IRON & STEEL CO LTD

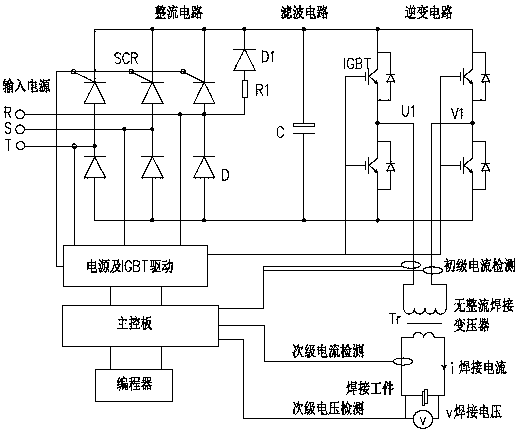

Non-splashing dynamically heating self-adaptive resistance welding method for automobile metal sheets

ActiveCN103394801AShort welding timeNo thermal equilibriumWelding electric supplyTransformerMetallic materials

The invention relates to a non-splashing dynamically heating self-adaptive resistance welding method for automobile metal sheets, which comprises the following implementation steps: firstly, a nugget formation process is enabled to be kept in the state of non-splashing power-on heating fusion and cooling crystallization heat balance in the way that a non-secondary rectification welding transformer and a pulse width adjustable alternate current contravariant power supply are utilized and different metallic materials thermal balance factors are called; the nugget size is controlled through detecting the change rate of dynamic resistances at the two ends of electrodes. According to the invention, as a non-splashing thermal balance factor, namely t+t0, is adopted in the method, the splashing problem in the welding is effectively solved, and the welding quality is improved; the change rate of dynamic resistances at the two ends of the welding electrodes during the welding can be detected to quickly judge the nugget formation process, so that the interference in the measuring is reduced, and the reliability of the detection is improved; besides, the difficult problem that a plenty of splashes are generated in the welding of automobile metal sheets for a long time is effectively solved, the welding quality and the production efficiency are greatly improved, and the production and processing cost is greatly reduced.

Owner:TIANJIN SUNKE DIGITAL CONTROL TECH CO LTD

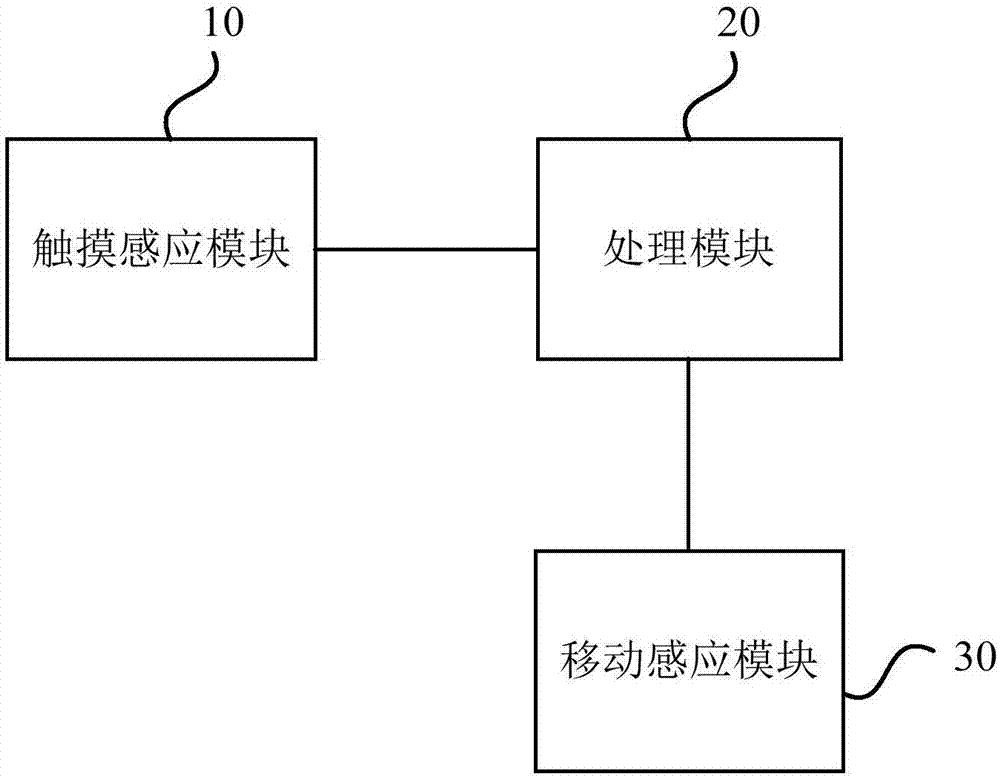

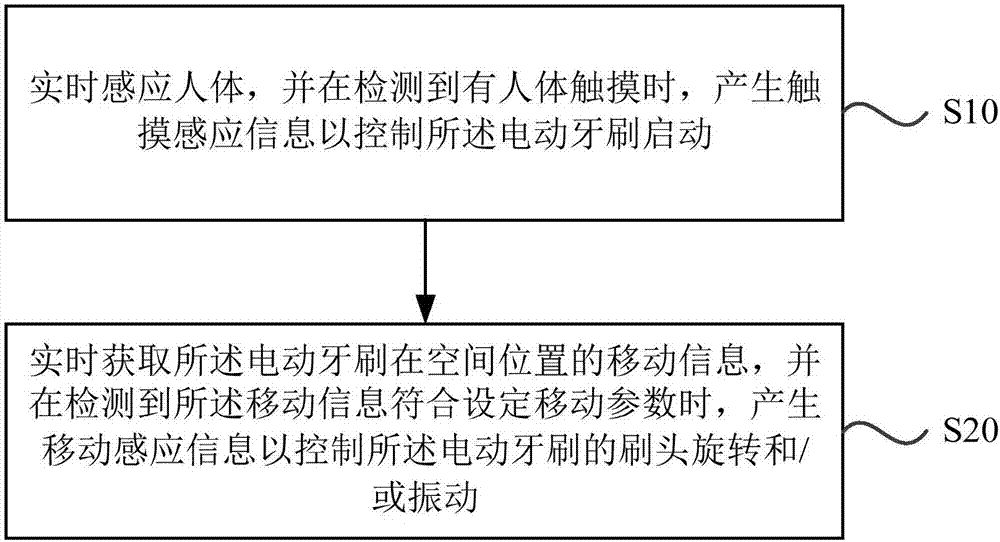

Electric toothbrush as well as control device and method thereof

PendingCN107334555AAvoid water leakage hazardsRealize integrationTooth cleaningWater leakageTouch Senses

The invention discloses an electric toothbrush as well as a control device and method thereof. The control device of the electric toothbrush comprises a touch sensing module and a mobile sensing module, wherein the touch sensing module is used for sensing the human body in real time and generating touch sensing information when detecting that the human body touches the touch sensing module to allow a processing module to control the electric toothbrush to start; the mobile sensing module is used for acquiring mobile information of the electric toothbrush in the space position in real time and generating mobile sensing information when detecting that the mobile information conforms to set mobile parameters to allow the processing module to control a brush head of the electric toothbrush to rotate and / or vibrate. With the adoption of the technical scheme, the problems that electric toothbrushes have potential water leakage risks and are complex and tedious to operate and toothpaste water stains splash during starting are solved, and integration, operation simplicity and intelligence of the electric toothbrush are realized.

Owner:深圳市科思飞科技有限公司

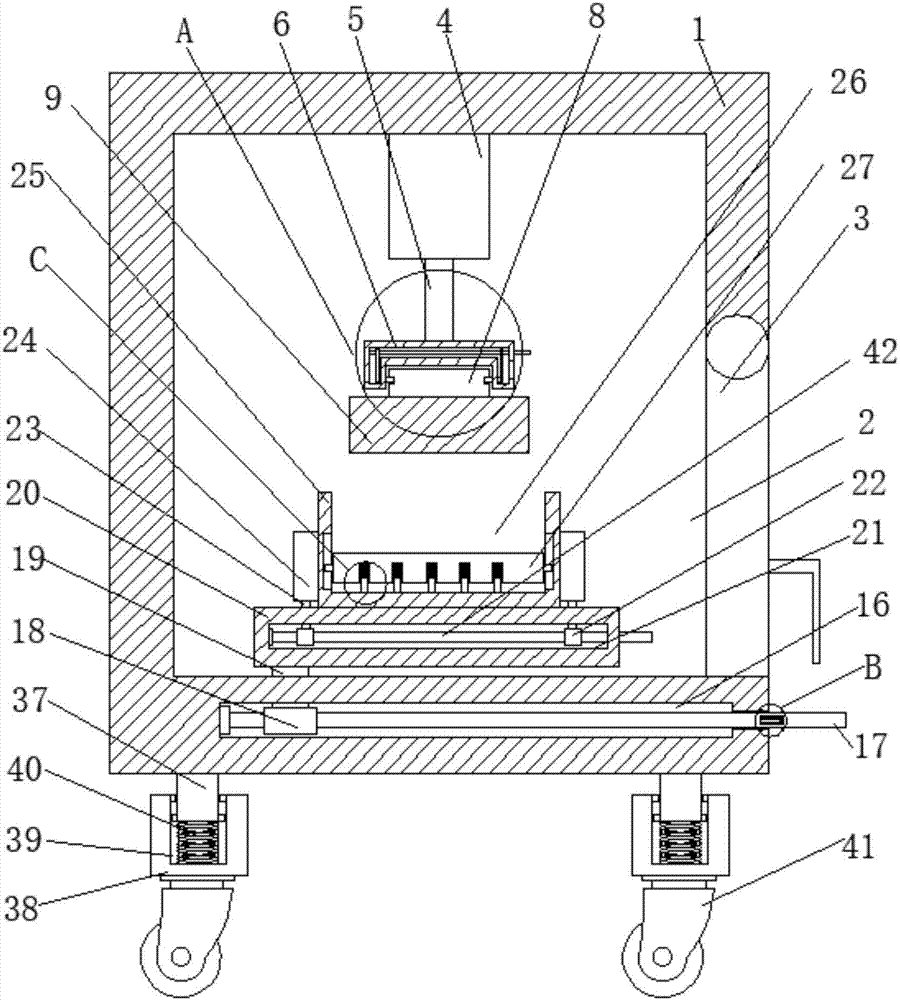

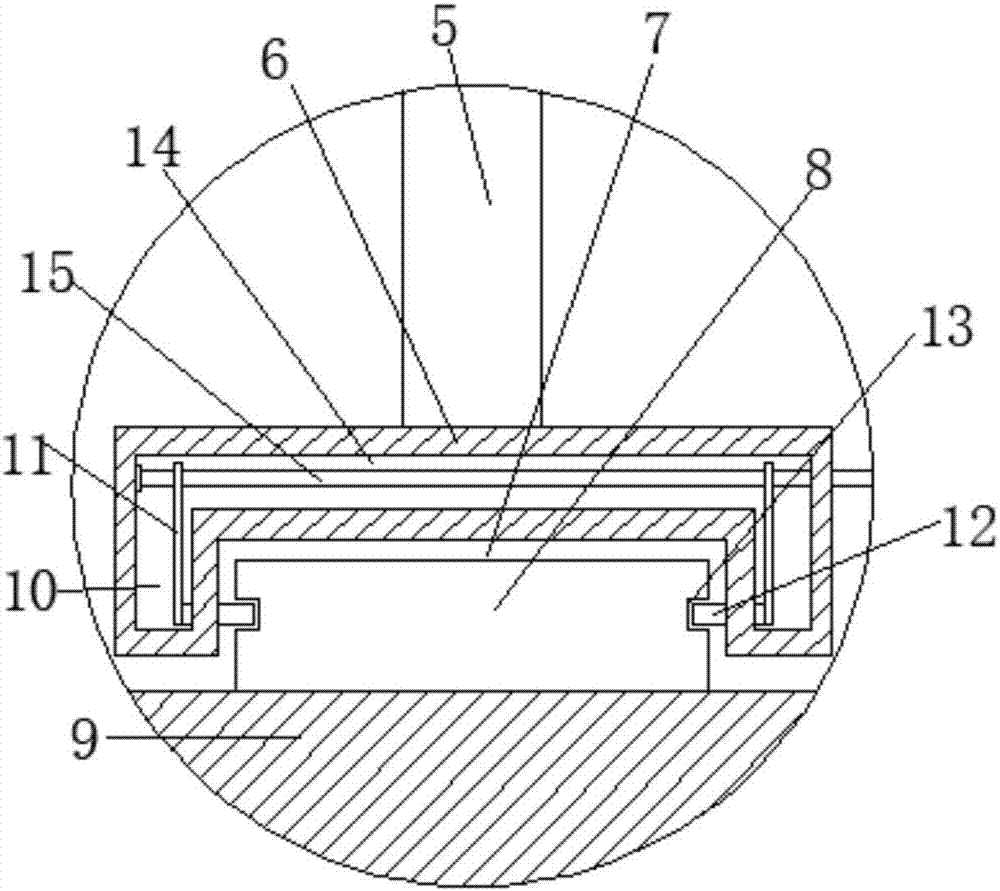

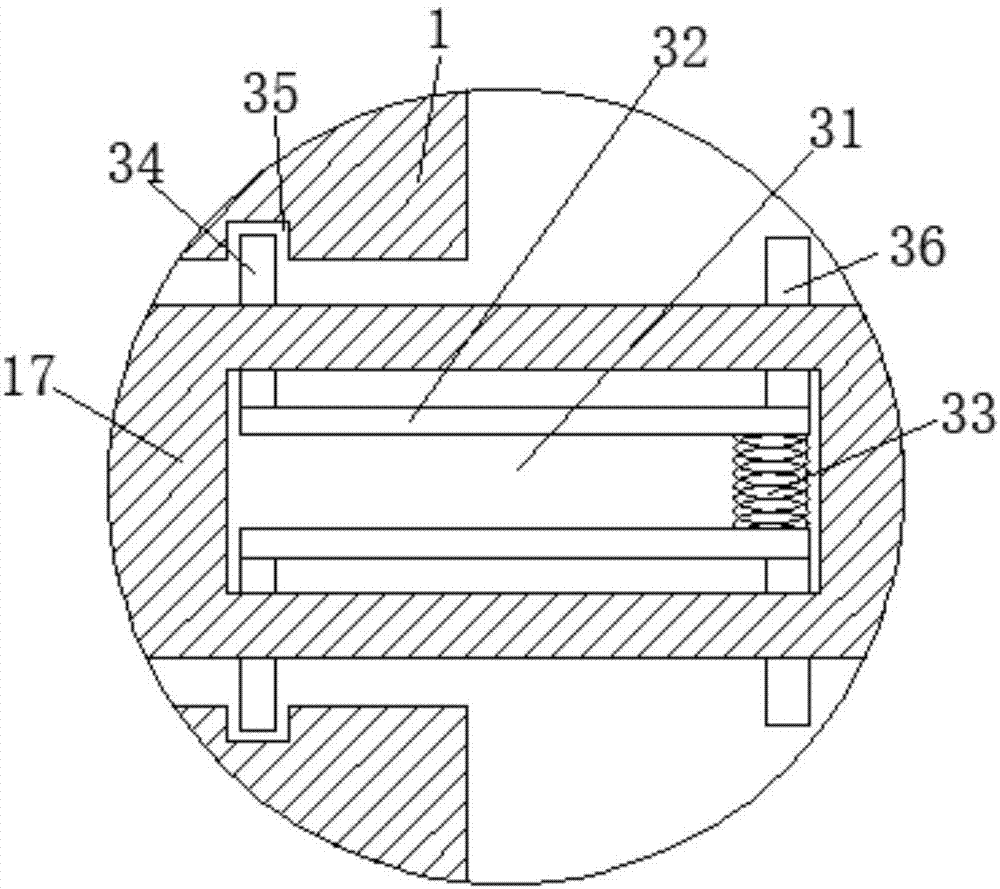

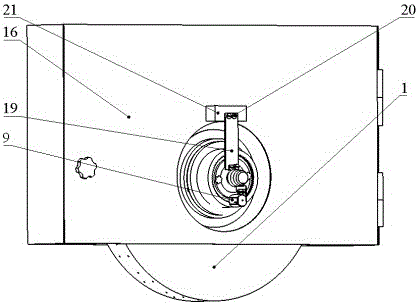

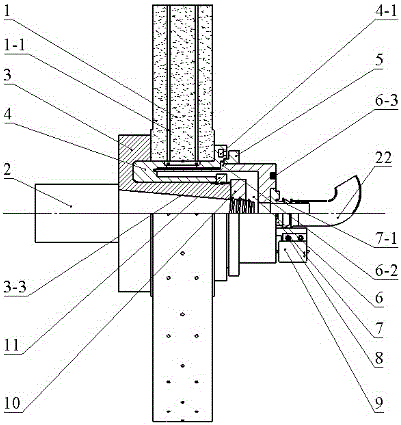

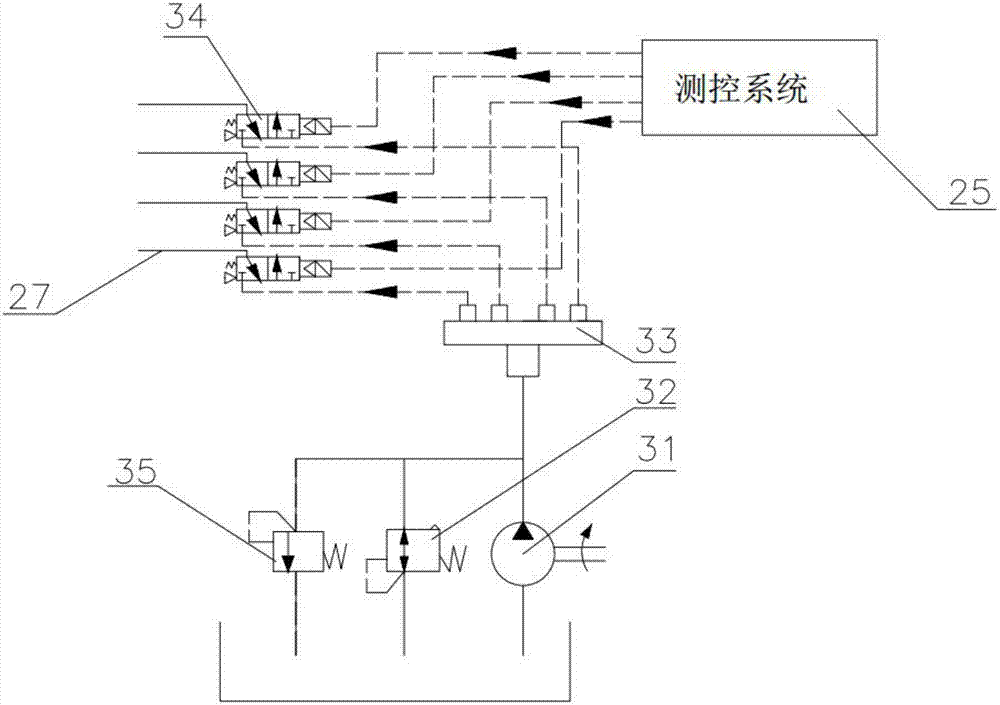

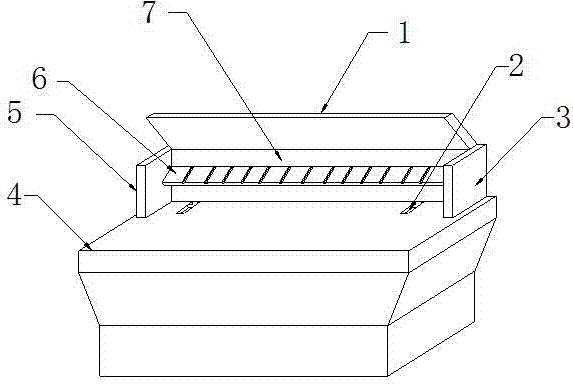

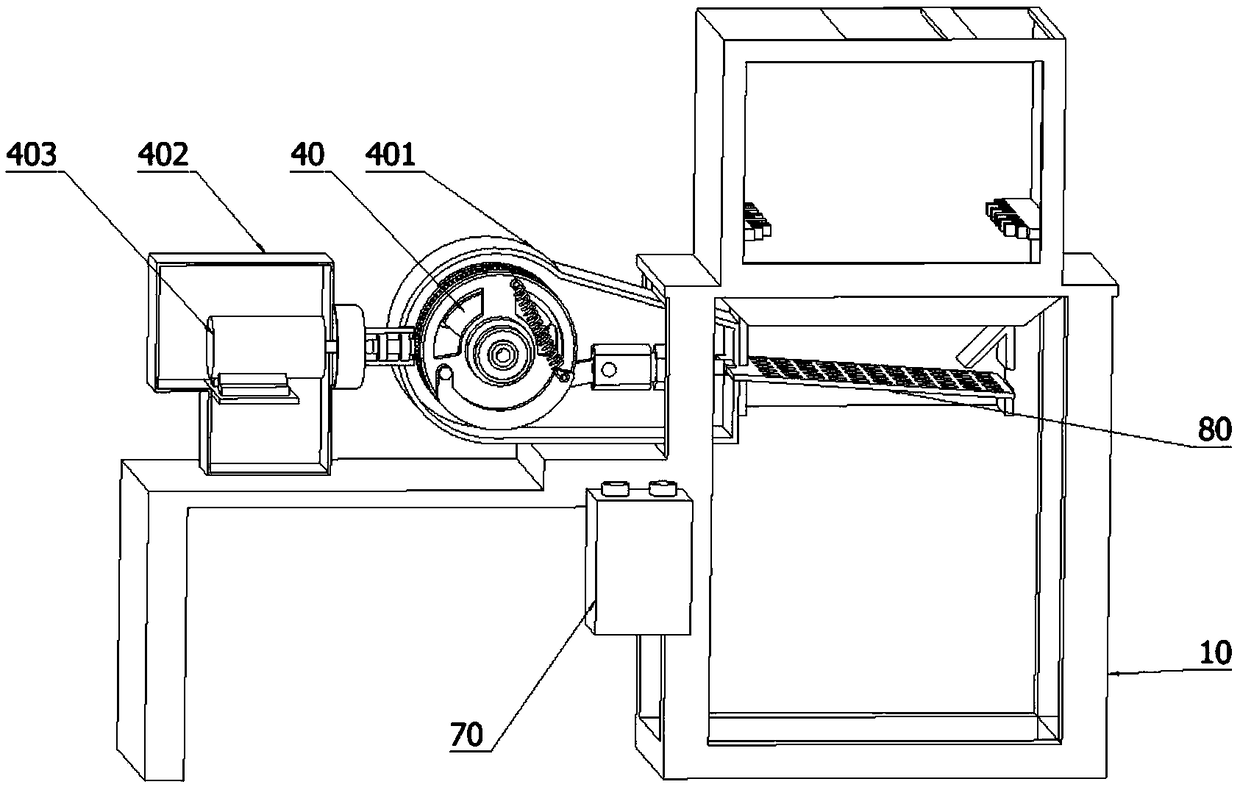

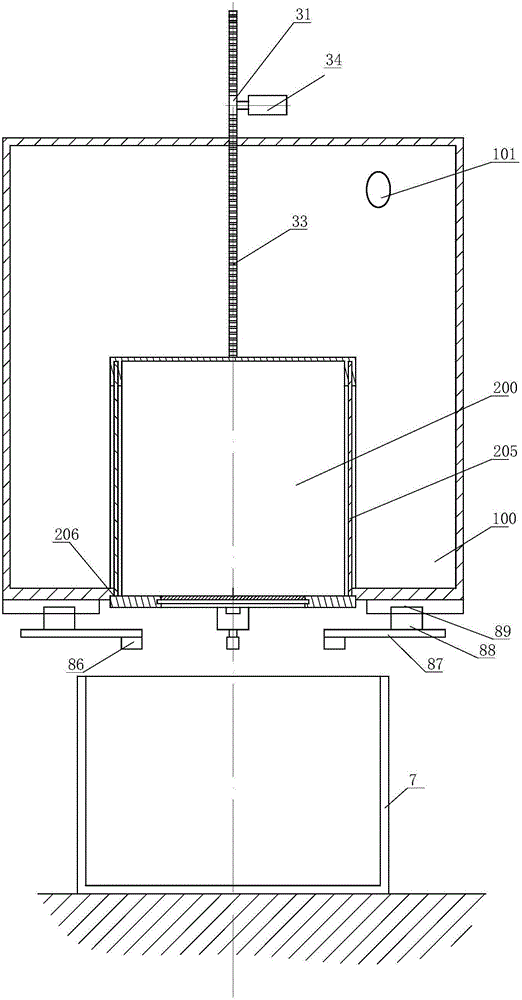

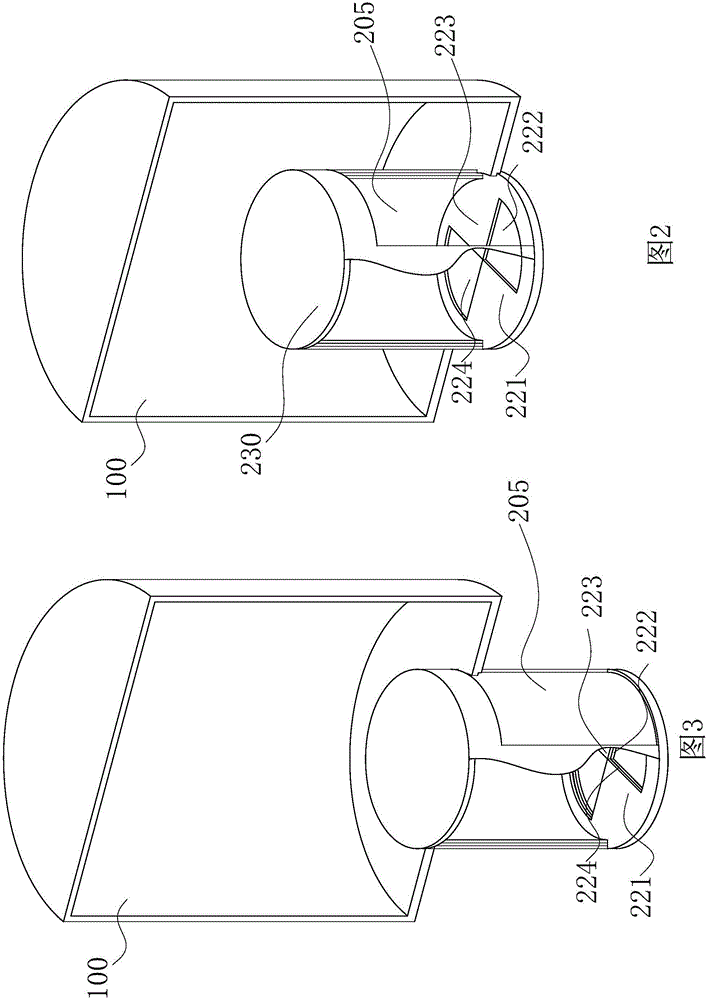

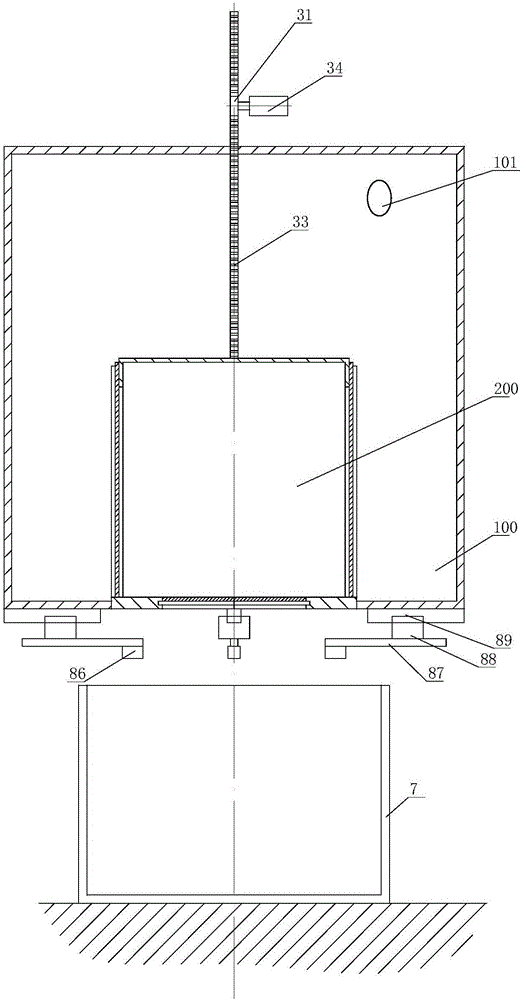

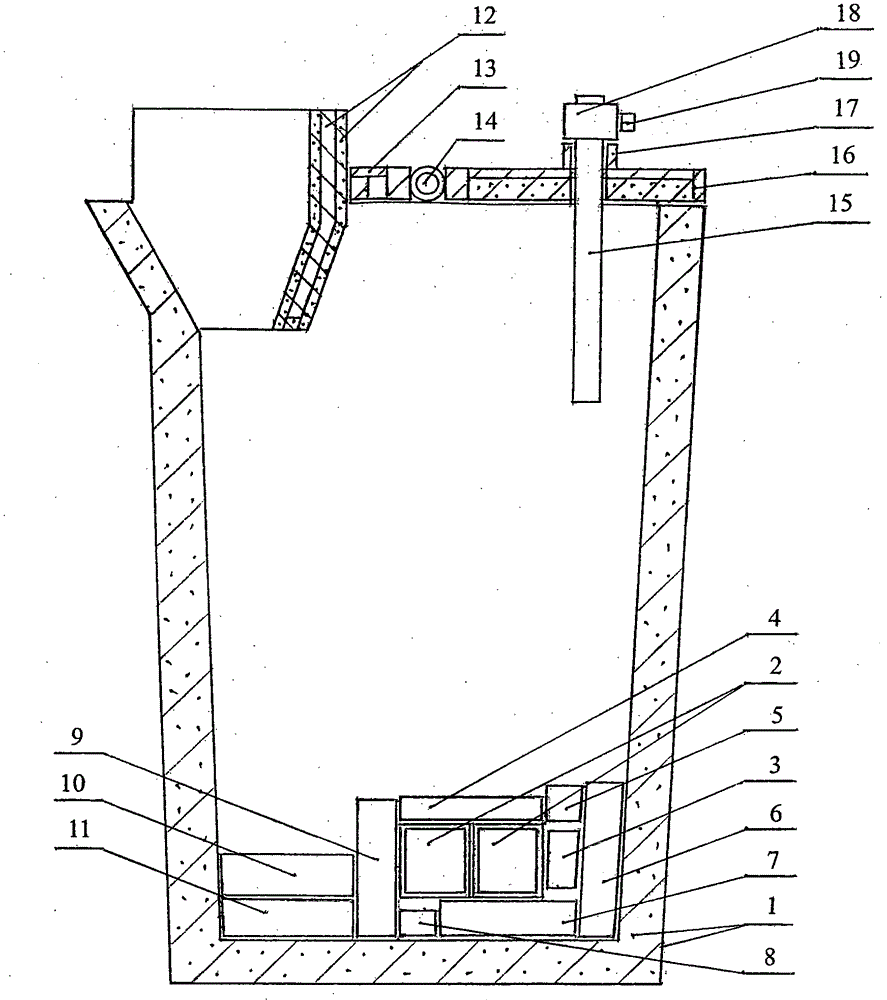

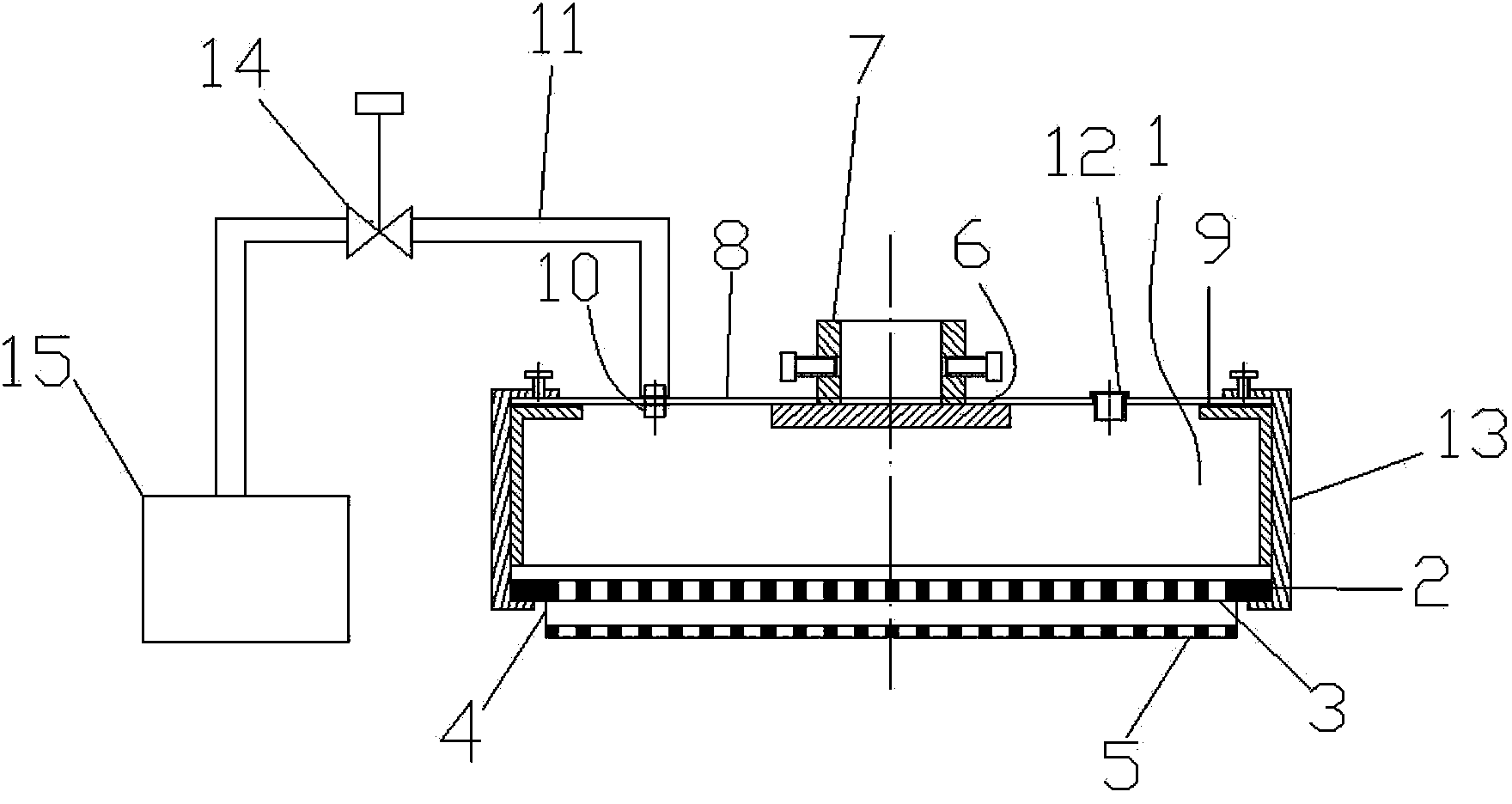

Grinding internal cooling system capable of automatically calibrating liquid supply position

ActiveCN106272083AImprove efficiencyLow costGrinding/polishing safety devicesEngineeringMachine control

The invention discloses a grinding internal cooling system capable of automatically calibrating the liquid supply position. The system comprises a grinding wheel device and a liquid supply position automatic calibrating mechanism. The grinding wheel device comprises an internal-cooling grinding wheel, a liquid guide gate, a flange plate and a second nut. The liquid guide gate penetrates through a center hole of the internal-cooling grinding wheel; the second nut and the flange plate clamp the liquid guide gate and the internal-cooling grinding wheel to form the grinding wheel device; and the grinding wheel device is mounted on a grinding machine spindle through a first nut. The liquid supply position automatic calibrating mechanism comprises a joint, a motor, an adjusting sleeve and a gear. When the rotating speed of the grinding wheel changes, the motor can drive the adjusting sleeve to rotate by a proper angle through the gear according to a feedback signal of a grinding machine control system, so that when grinding liquid flows through a rectangular opening of the adjusting sleeve, elliptical holes of the liquid guide gate and small radial holes of the internal-cooling grinding wheel and then reaches the working face of the grinding wheel, the grinding liquid is exactly injected into a grinding area, and automatic calibration of the liquid supply position is achieved. The grinding internal cooling system capable of automatically calibrating the liquid supply position has the characteristics that the utilization ratio of the grinding liquid is increased, the grinding quality is improved, the cost is reduced, and the environment is protected.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

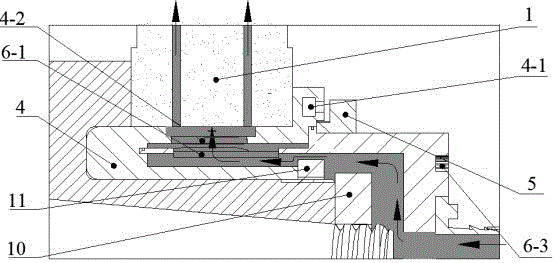

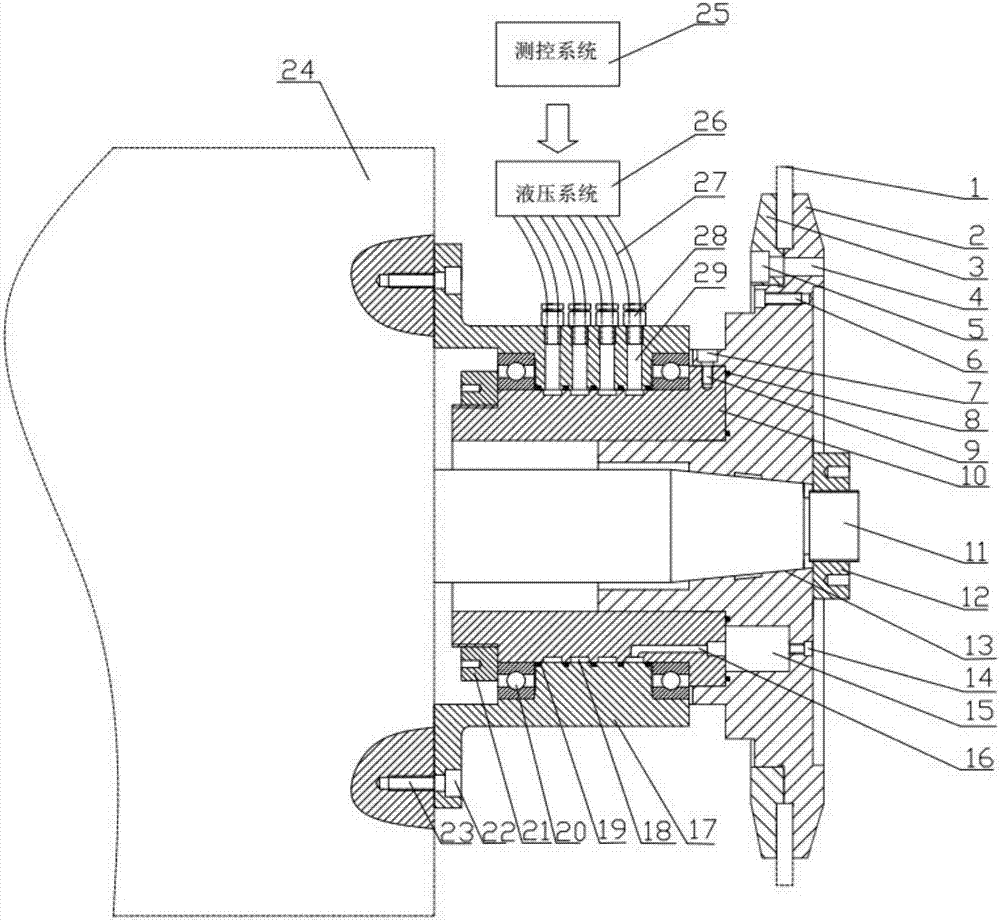

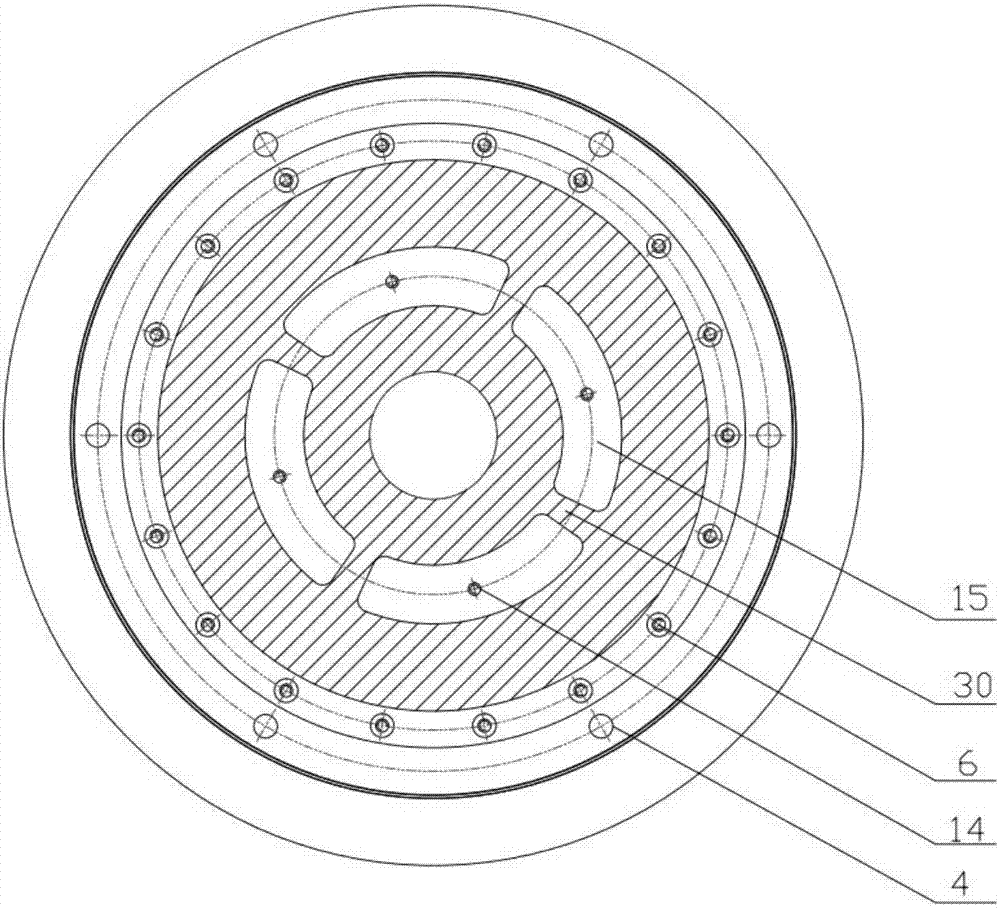

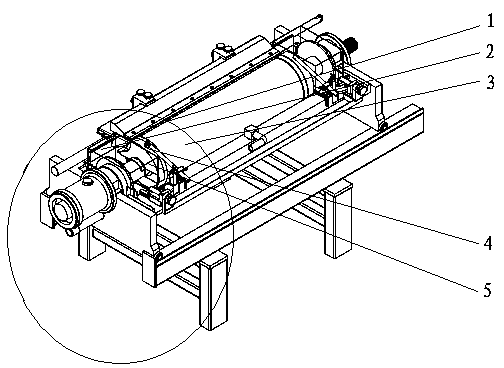

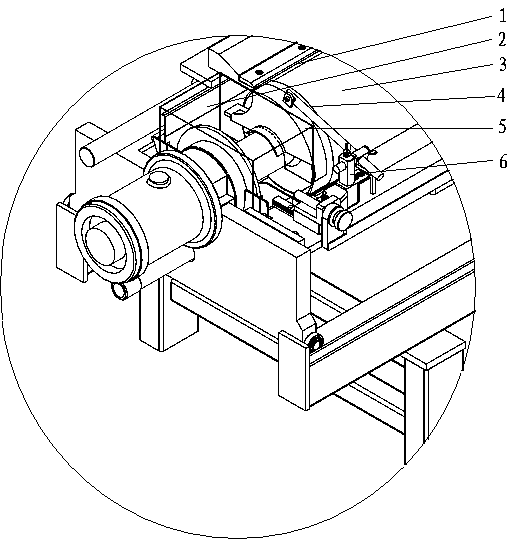

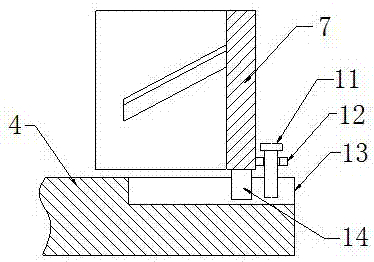

Liquid injection type online dynamic balance terminal suitable for large-external-diameter external thread grinder spindle

ActiveCN107363720AEliminate static imbalanceOffset imbalanceGrinding machine componentsThread cutting machinesDynamic balanceCoupling

A liquid injection type online dynamic balance terminal suitable for a large-external-diameter external thread grinder spindle comprises a grinding wheel base plate connected with the spindle. The grinding wheel base plate and a grinding wheel end cover are connected with a tightening grinding wheel. The grinding wheel base plate is connected with a rotary connector rotor. The rotary connector rotor is in clearance fit with a rotary connector stator. The rotary connector stator is fixed to a case. Second liquid guide holes are formed in the rotary connector stator. Annular liquid guide grooves are formed in the external diameter of the rotary connector rotor. First liquid guide holes are evenly distributed in the rotary connector rotor in the circumferential direction. The two ends of the first liquid guide holes communicate with the annular liquid guide grooves and liquid containing cavities which are evenly distributed in the grinding wheel base plate in the circumferential direction correspondingly. A sealed liquid channel is formed from a hydraulic system to the liquid containing cavities through PVC pipes, quick couplings, the second liquid guide holes, the annular liquid guide grooves and the first liquid guide holes. According to the liquid injection type online dynamic balance terminal, automatic online dynamic balance compensation of the large-external-diameter external thread grinder spindle in the grinding machining process is achieved, the sealed runner is formed, liquid splash is avoided, and the quality and efficiency of grinding machining are effectively improved.

Owner:无锡超通智能制造技术研究院有限公司

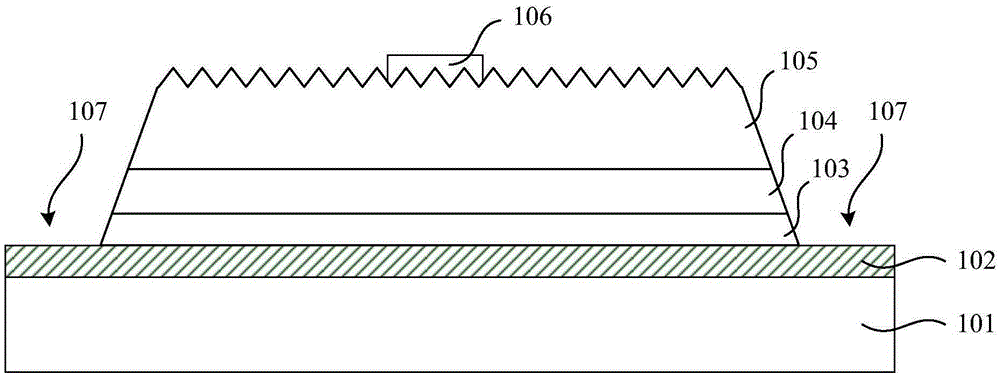

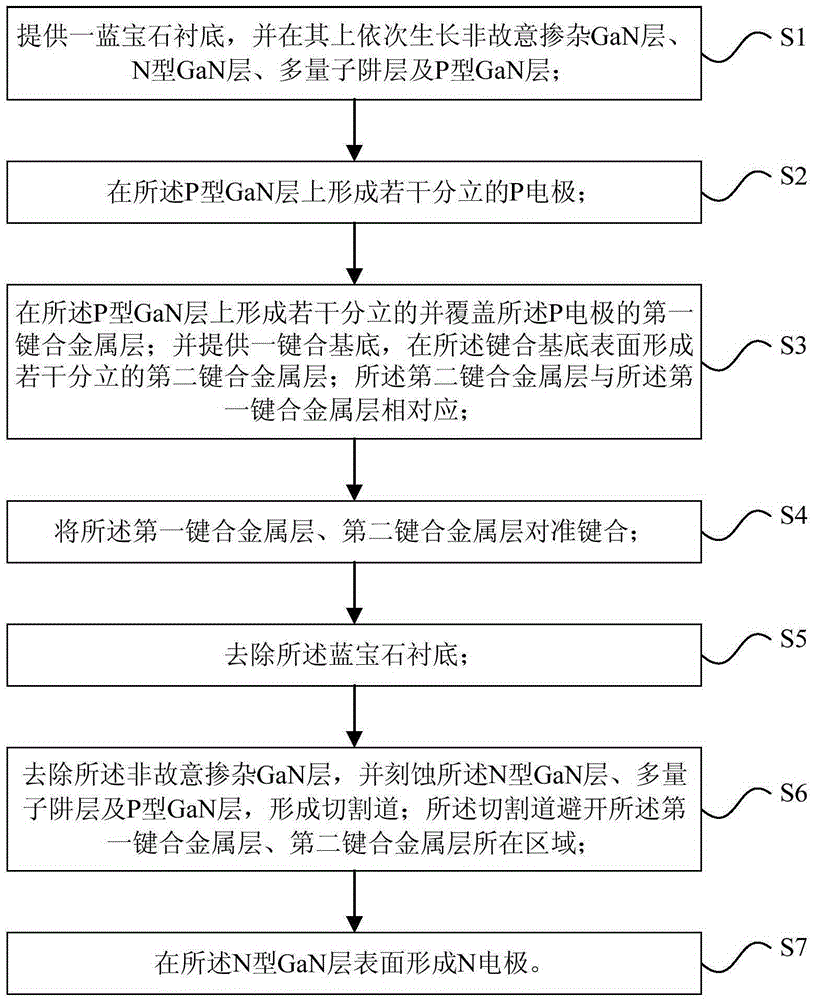

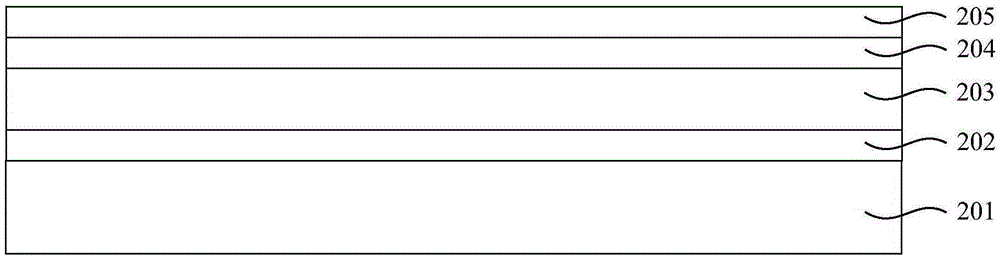

LED vertical chip structure and manufacturing method thereof

ActiveCN106711291APrevent metal splashReduce the risk of electric leakageSemiconductor devicesEngineeringQuantum well

The invention provides an LED vertical chip structure and a manufacturing method thereof. The method comprises the following steps of S1, providing a sapphire substrate and growing an unintentionally-doped GaN layer, an N-type GaN layer, a multi-quantum well layer and a P-type GaN layer successively on the substrate; S2, forming several discrete P electrodes; S3, forming several discrete first bonding metal layers which cover the P electrodes; and providing a bonding substrate and forming several discrete second bonding metal layers on a surface of the bonding substrate; S4, carrying out alignment bonding on the first bonding metal layers and the second bonding metal layers; S5, removing the sapphire substrate; S6, removing the unintentionally-doped GaN layer, and using a dry method etching technology to form a cutting channel, wherein the cutting channel avoids an area where the bonding metal layers are located; and S7, forming an N electrode. In the invention, a graphical bonding structure (formed by several discrete bonding metal layers) is adopted so that a metal splashing problem generated when ICP etches the cutting channel is effectively avoided; and a chip electric leakage risk is reduced so that chip reliability is effectively increased.

Owner:ENRAYTEK OPTOELECTRONICS

Device and method for removing emulsion on surfaces of cold-rolled steel strips

InactiveCN104646440AImproves the effectiveness of peeling emulsionsSolve the shortcomings of suctionWork treatment devicesMetal rolling arrangementsEmulsionWhole body

The invention discloses a device and a method for removing emulsion on surfaces of cold-rolled steel strips. The device comprises an upper working roller, an upper support roller seam purging mechanism, a steel strip upper surface emulsion sealing mechanism, an upper working roller surface emulsion removing mechanism, a steel strip lower surface emulsion removing mechanism, a steel strip upper surface purging mechanism and an upper support roller surface emulsion removing mechanism. The method is mainly characterized by reasonably controlling the sequence of opening and closing an emulsion injecting system and an emulsion removing device; a plurality of removing methods synergistically cooperate to form a whole body; the effect of removing the emulsion on the surfaces of the steel strips on the outlet side of a rolling mill is further improved; meanwhile, the residues of the emulsion in special parts of heads, tails, sides and the like of the steel strips can be removed; the surface quality of the finished steel strips can be improved.

Owner:SHANDONG IRON & STEEL CO LTD

Ink splash and printing watermark preventing device of gravure printing machine

ActiveCN104228315ATackle splashSpeed up the flowRotary intaglio printing pressPrinting press partsEngineeringMechanical engineering

The invention discloses an ink splash and printing watermark preventing device of a gravure printing machine. A protection plate is arranged on one side of a scraper, the upper end of a strip-shaped protection plate is connected with a scraper fixing device, and an arc-shaped protection plate is arranged between a layer of ink box and a printing roller; a protection hood comprises an inner hood body and an outer hood body, the inner hood body is provided with an end surface scraping plate and an outer circle scraping plate, the inner hood body is fixed through a support, and the outer hood body is movably connected with the inner hood body. An ink baffle is added to reduce produced floating ink drops; the depth of an end surface notch of the layer of ink box is reduced and the height of the end surface is increased to change the flowing direction of ink, so that floating ink drops are drained out from the layer of ink box as quickly as possible. By continuously and innovatively improving an ink splash preventing system and an ink supply system, the problem of ink splash is fundamentally solved, the printing speed is improved from original 120m / min to 200m / min, and the operation and control are convenient and quick to realize. The problem of watermarks and ink drops on products is effectively controlled and the solution has very great popularization and reference significance in the printing industry.

Owner:SHANDONG TOBACCO LAIZHOU PRINTING

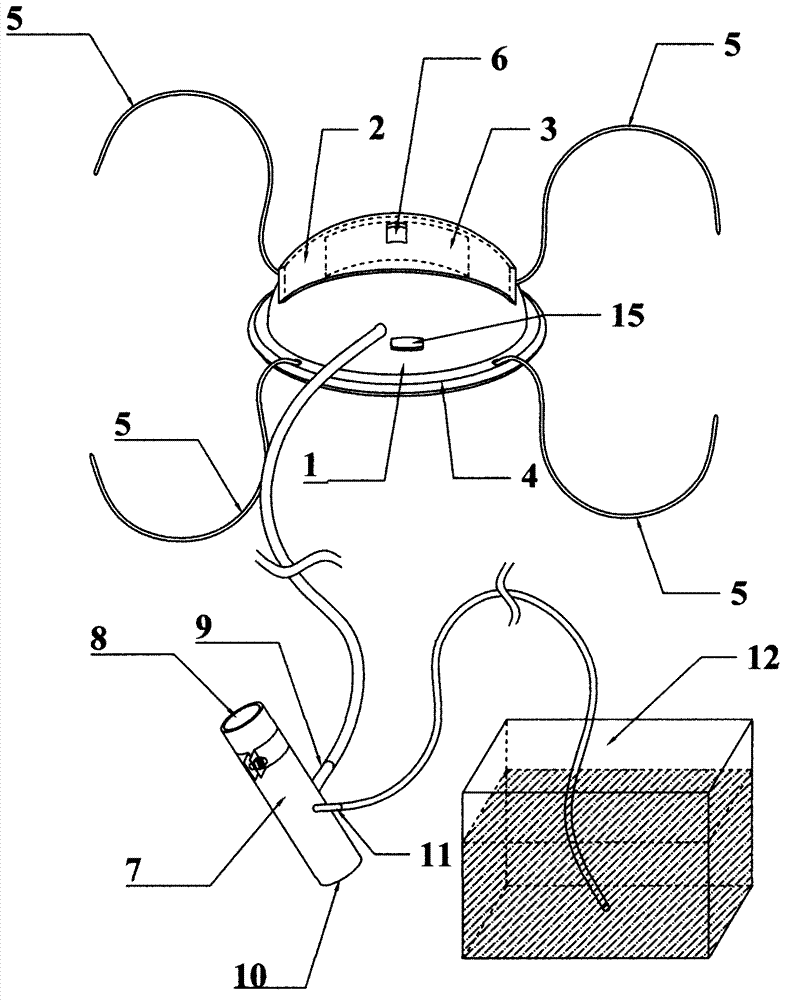

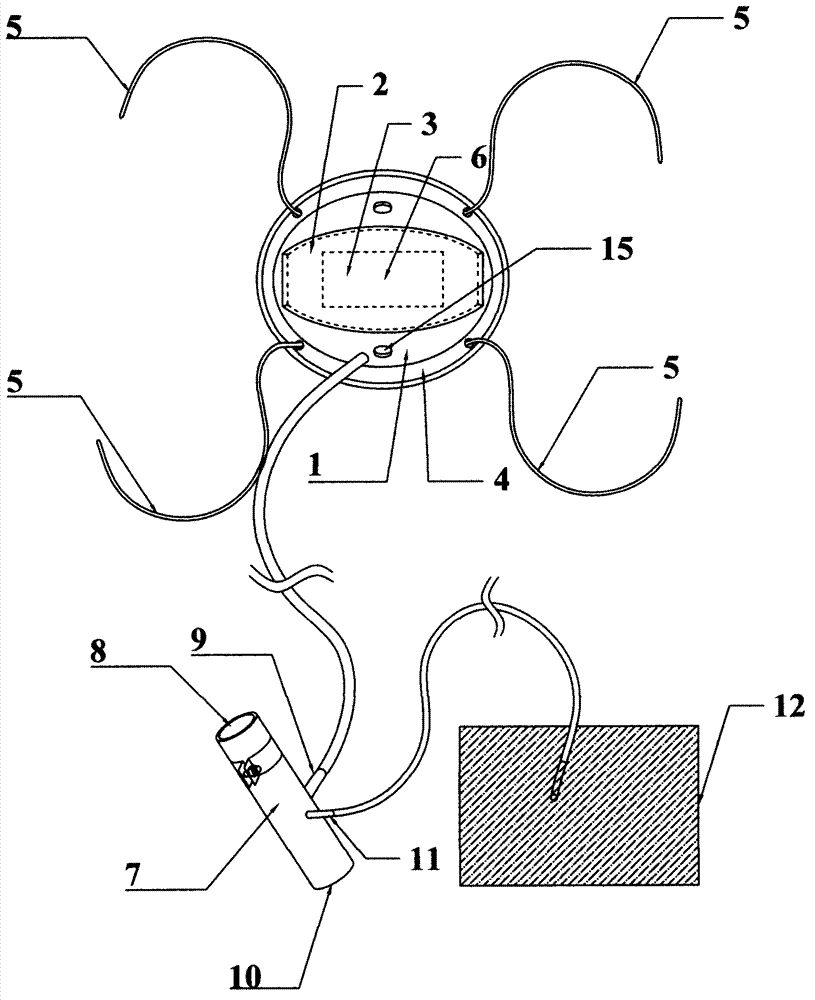

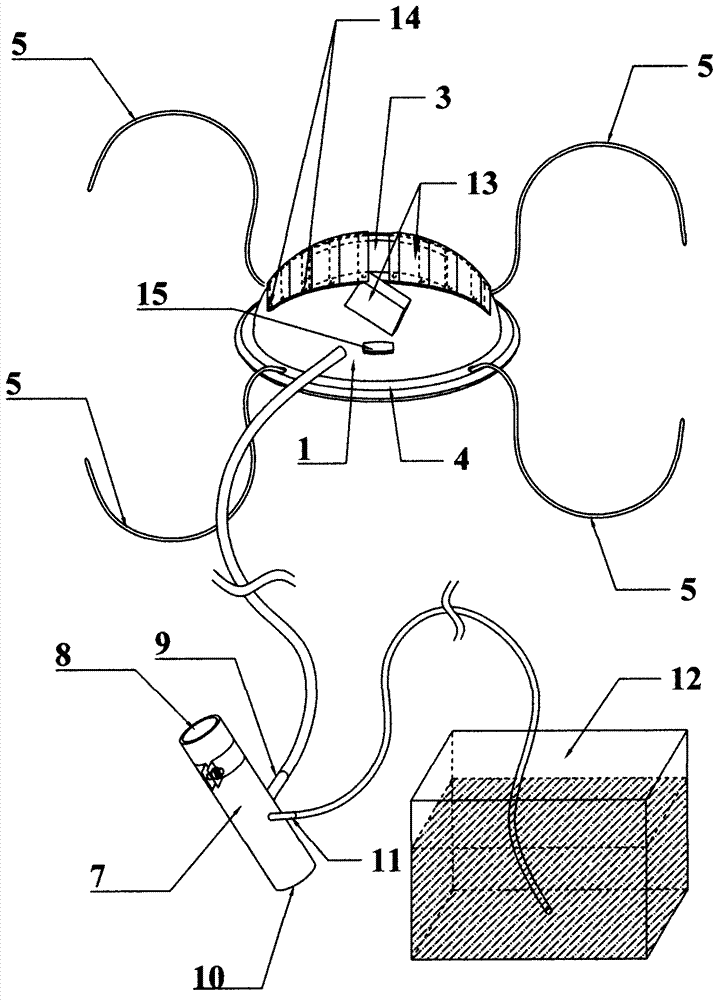

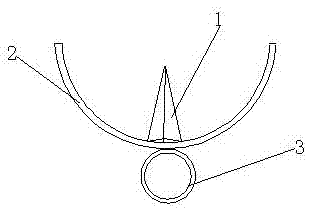

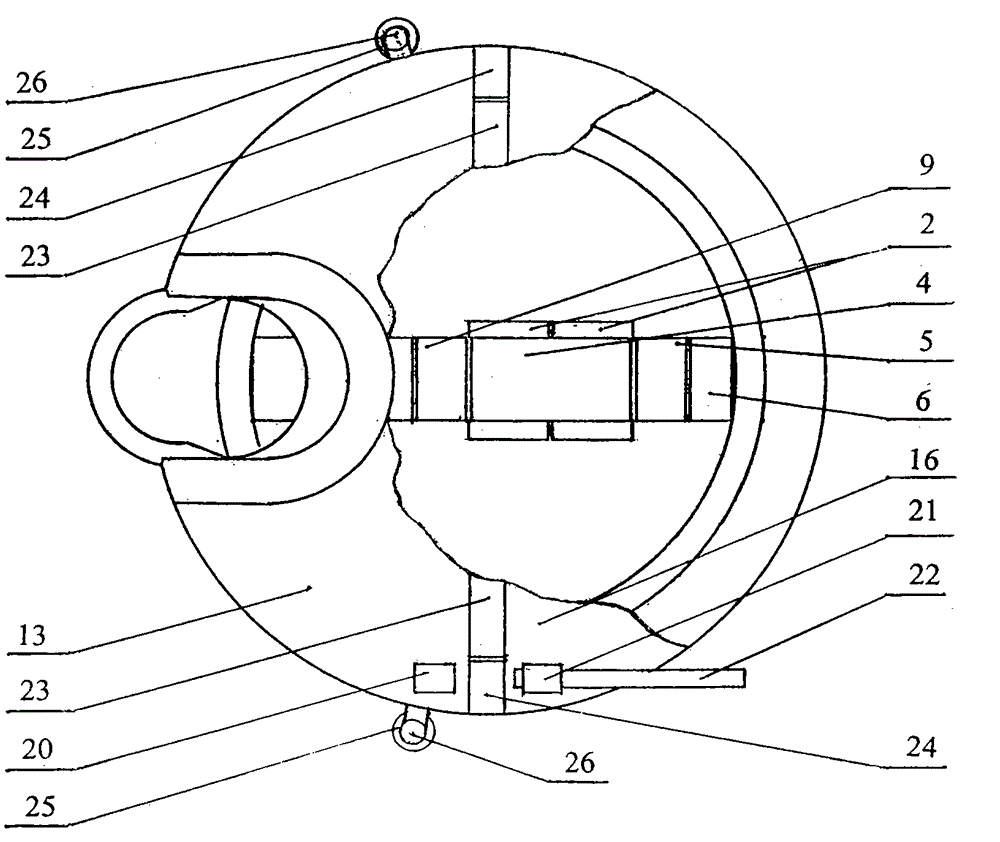

Bone residue splashing preventive device for knee osteotomy

The invention relates to a bone residue splashing preventive device for knee osteotomy. Repeated osteotomy according to a mold plate is the most important and complicated procedure in knee replacement, an electric osteotomy swing saw is high in power, and accordingly bone residues and blood can splash all around in an osteotomy procedure, stain an aseptic operating zone, cannot be cleaned easily and occasionally can splash into eyes of surgeons. The bone residue splashing preventive device for knee osteotomy comprises a shield and a movable cover plate; the shield is an elliptical shield made of transparent materials, an opening is arranged on the upper side of the shield, two through holes are arranged on two sides of the shield, and a flexible edge and straps are arranged at the edge of the shield; and the movable cover plate is a hard arc-shaped plate made of transparent materials, an operating opening is arranged on the upper side of the movable cover plate, and the movable cover plate is arranged on the opening in a sliding fit manner, can slide and can completely cover the opening. The bone residue splashing preventive device has the advantages that the bone residue splashing preventive device is simple in structure and convenient to use, is environment-friendly and pollution-free and is particularly suitable for knee osteotomy in various general hospitals or special orthopedic hospitals, and the problem of splashing of bone residues and blood in a knee osteotomy procedure is effectively solved.

Owner:李邦国 +1

Pretreatment method for oxygen blowing welded pipe before welded pipe aluminizing processing

InactiveCN106011715AExtended service lifeTackle splashHot-dipping/immersion processesCleaning using liquidsTectorial membranePretreatment method

The invention discloses a pretreatment method for an oxygen blowing welded pipe before welded pipe aluminizing processing and relates to the technical field of welded pipe processing. The pretreatment method comprises the following steps of (1) dedusting and primary deoiling; (2) primary washing; (3) secondary deoiling; (4) primary acid pickling; (5) secondary washing; (6) secondary acid pickling; (7) auxiliary plating; and (8) drying. According to the pretreatment method for the oxygen blowing welded pipe before welded pipe aluminizing processing, dust and oil stains attached to the welded pipe are effectively removed through dedusting and two times of deoiling, and the using problem of high energy consumption caused by high-temperature drying and deoiling can be solved; then, washing agents and rust spots are removed through two times of washing and two times of acid pickling; and finally a layer of protection film is formed on the surface of the welded pipe through auxiliary plating and drying so that oxidation and rustiness before aluminizing can be prevented, and molten aluminum splashing during hot aluminizing is avoided.

Owner:安徽鹏远金属制品股份有限公司

Lathe splash-proof device for industrial machine

ActiveCN107486752AEasy to operateAvoid spillingMaintainance and safety accessoriesGear wheelEngineering

The invention provides a lathe splash-proof device for an industrial machine. The lathe splash-proof device comprises a positioning bolt, a T-shaped slot, a T-shaped slide block, a rotating shaft, a connecting lug, an upper splash-proof plate, a gear I and a gear II, wherein the positioning bolt is mounted in the middle of the fixed plate, the T-shaped slot is formed in the upper end surface of a lathe body, and the T-shaped slide block is fixed on the lower end surface of a rear splash-proof plate and is assembled into the T-shaped slot. According to the design, the lathe splash-proof device can be rapidly assembled; the rotating shaft is mounted at the upper part in a cavity body, the connecting lug is fixed on the left side of the lower end surface of the splash-proof plate, the upper splash-proof plate is arranged on the upper end surface of the rear splash-proof plate, the gear I is mounted at the right part of the annular side surface of the rotating shaft and is meshed with the gear II, and the gear II is mounted at the lower part in the cavity body, so that the splash-proof range of the device is increased; and the device is simple in structure, strong in practicability, good in stability and high in reliability and has a good splash-proof effect.

Owner:徐州玉科工程机械有限公司

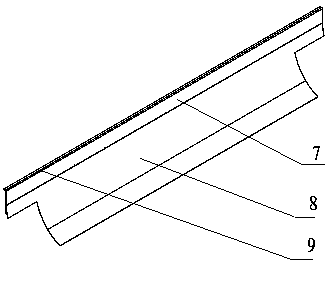

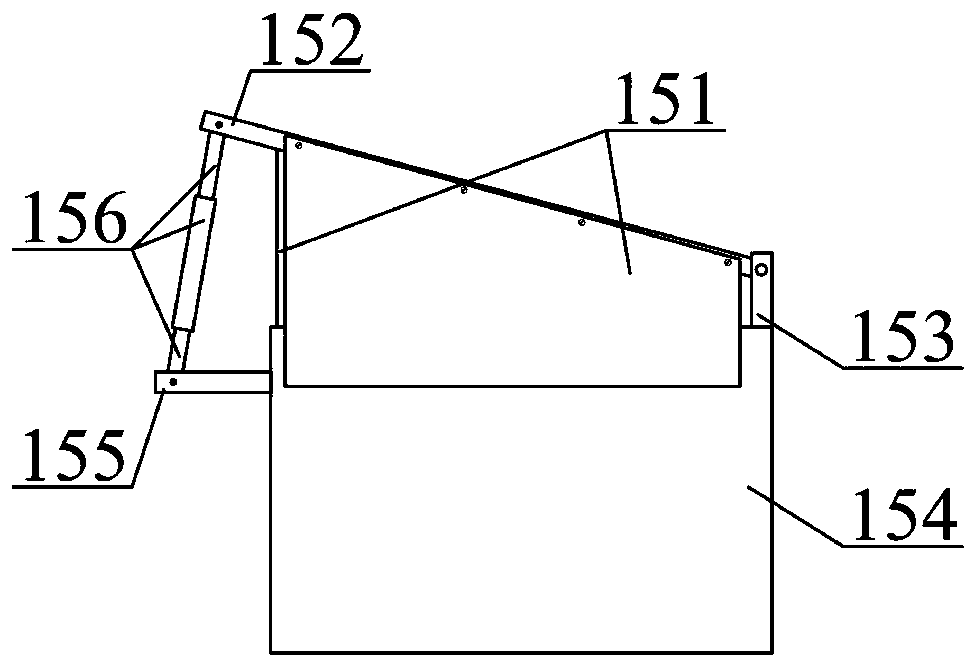

Elastic strip post-breakage splashing preventive structure for fastener system

The invention discloses an elastic strip post-breakage splashing preventive structure for a fastener system. The elastic strip post-breakage splashing preventive structure comprises an elastic strip body, and is characterized in that a flexible protective sleeve covers and wraps the annular cross section of the elastic strip body and is connected with the elastic strip body in a tight fit manner;the flexible protective sleeve is arranged along the total length of the elastic strip body or is arranged on bent sections, which are vulnerable to breakage, of the elastic strip body. The elastic strip post-breakage splashing preventive structure has the advantages that an elastic strip can be effectively prevented from splashing after the elastic strip is broken under abnormal conditions, and the insulation performance of the fastener system under normal use conditions can be improved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

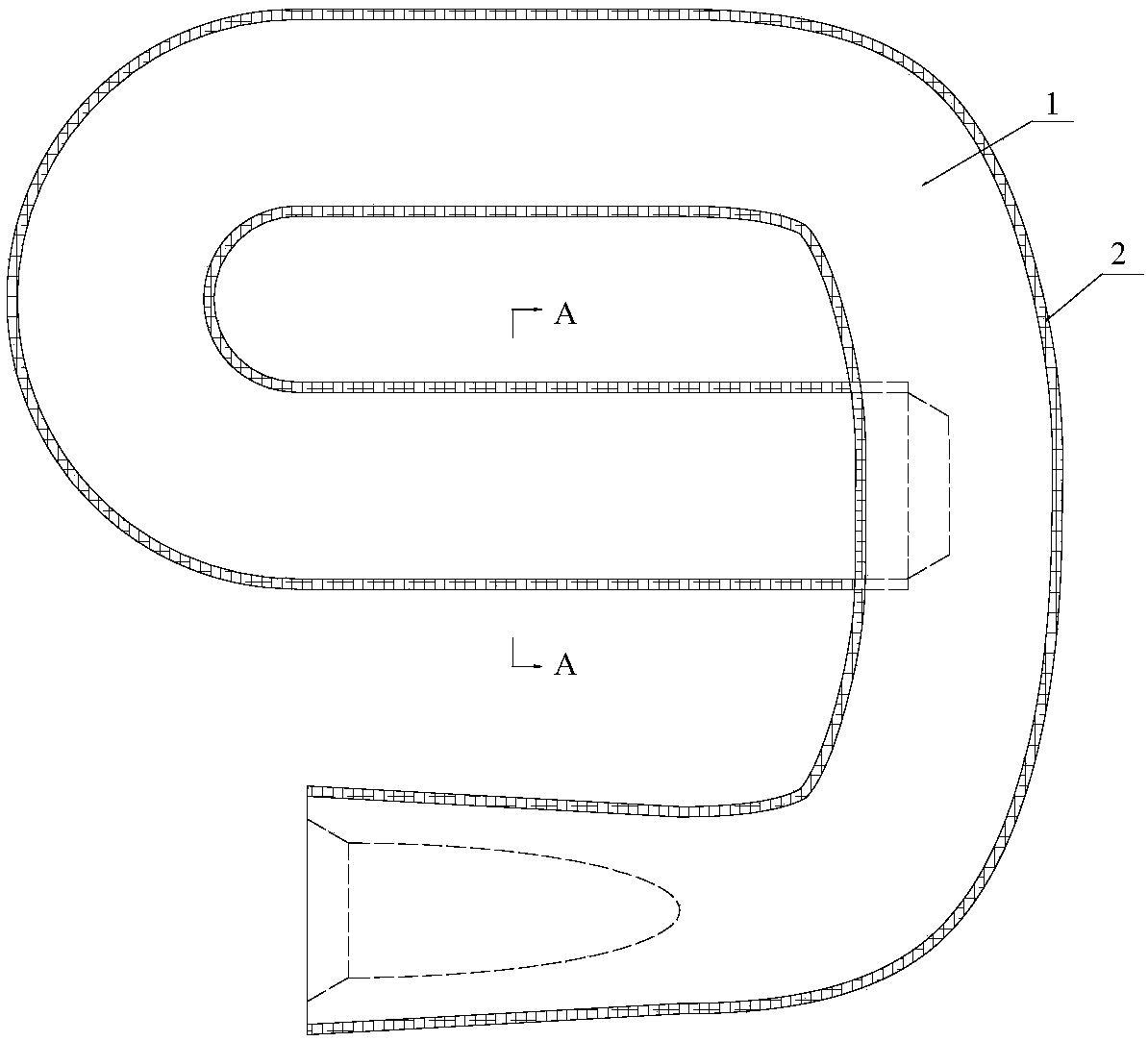

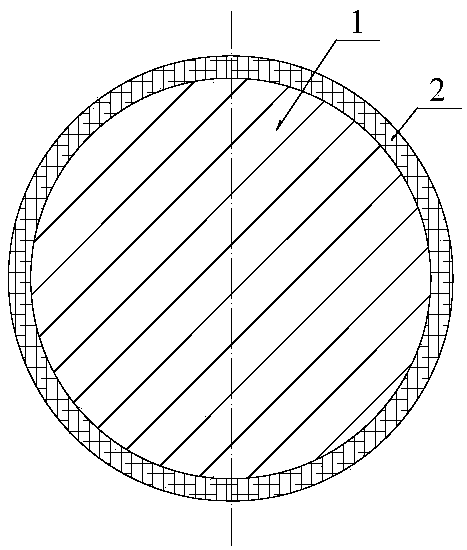

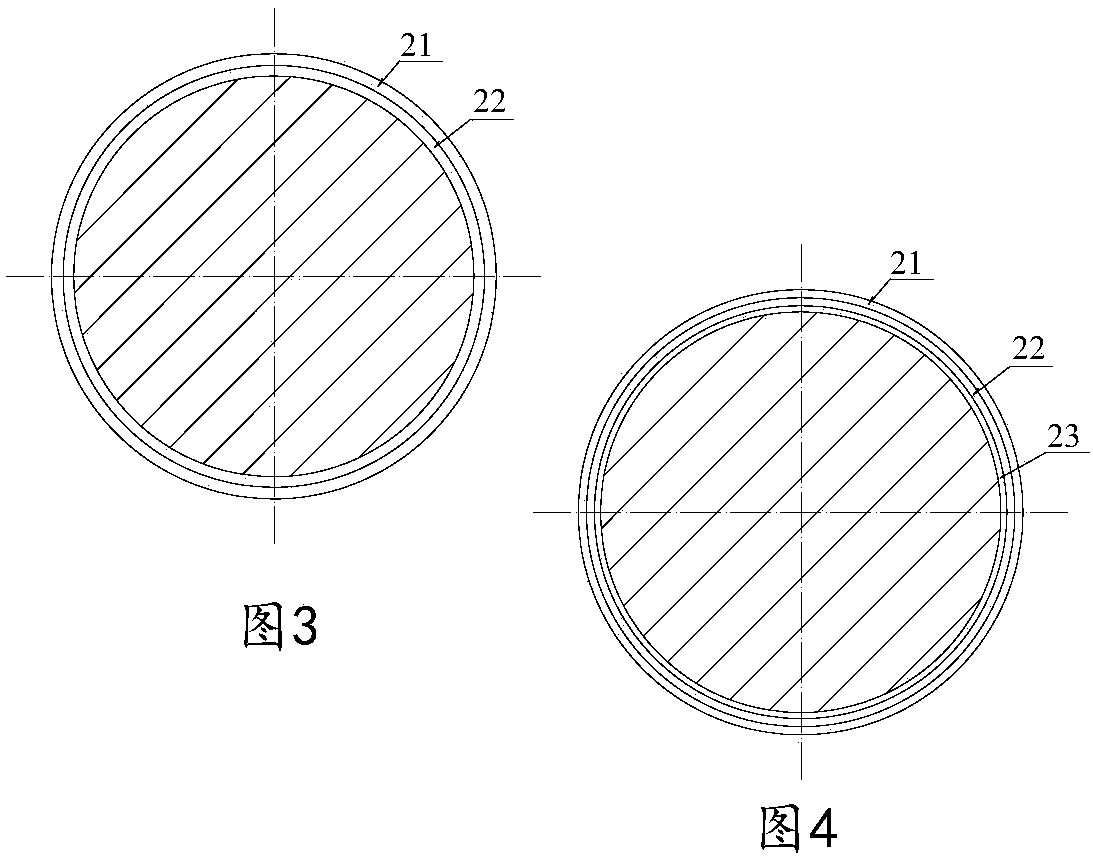

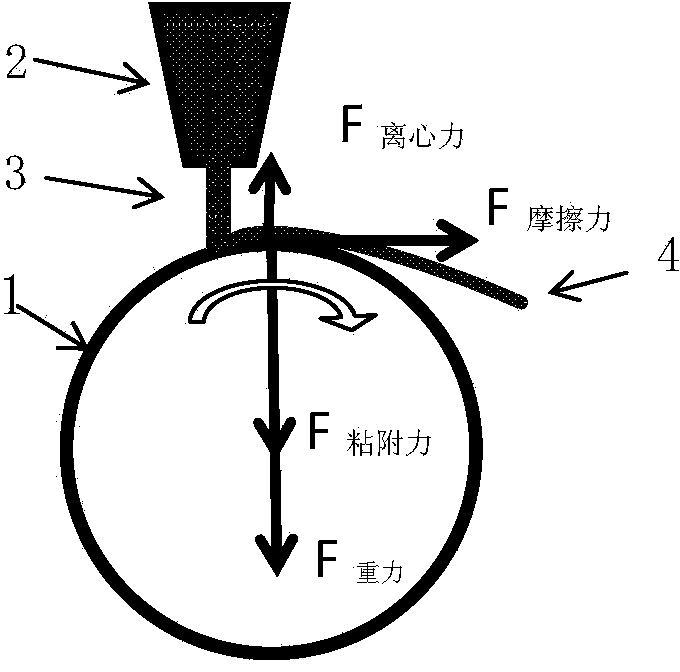

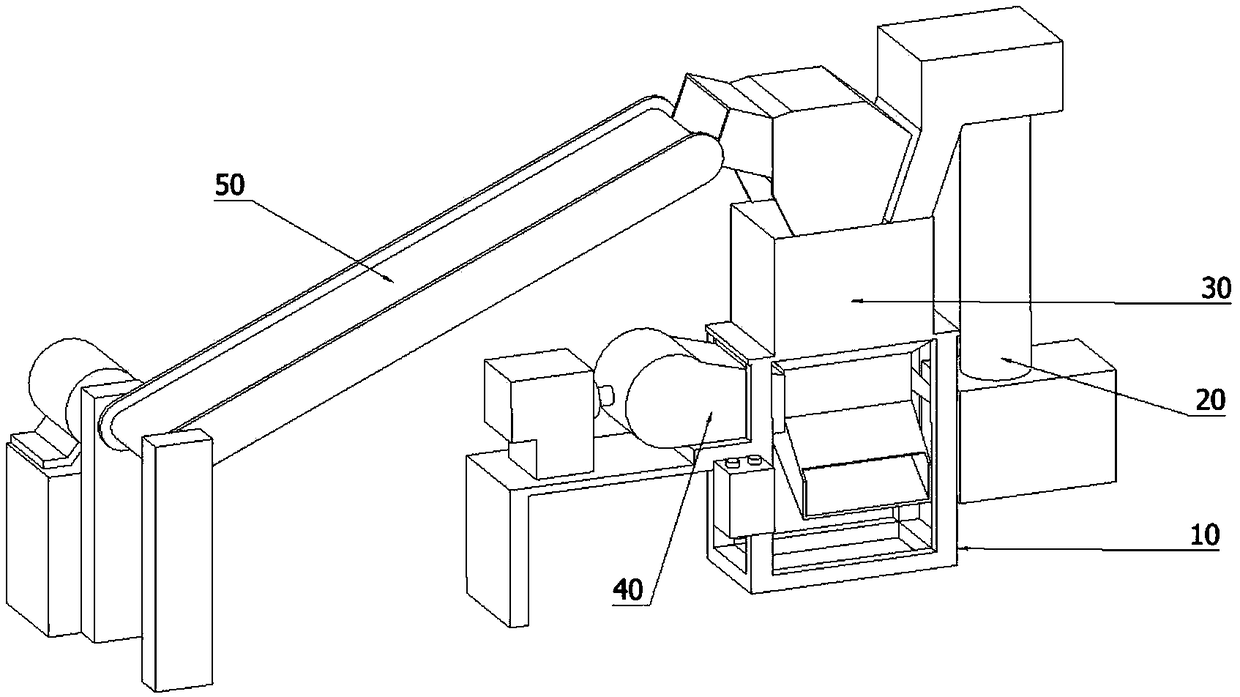

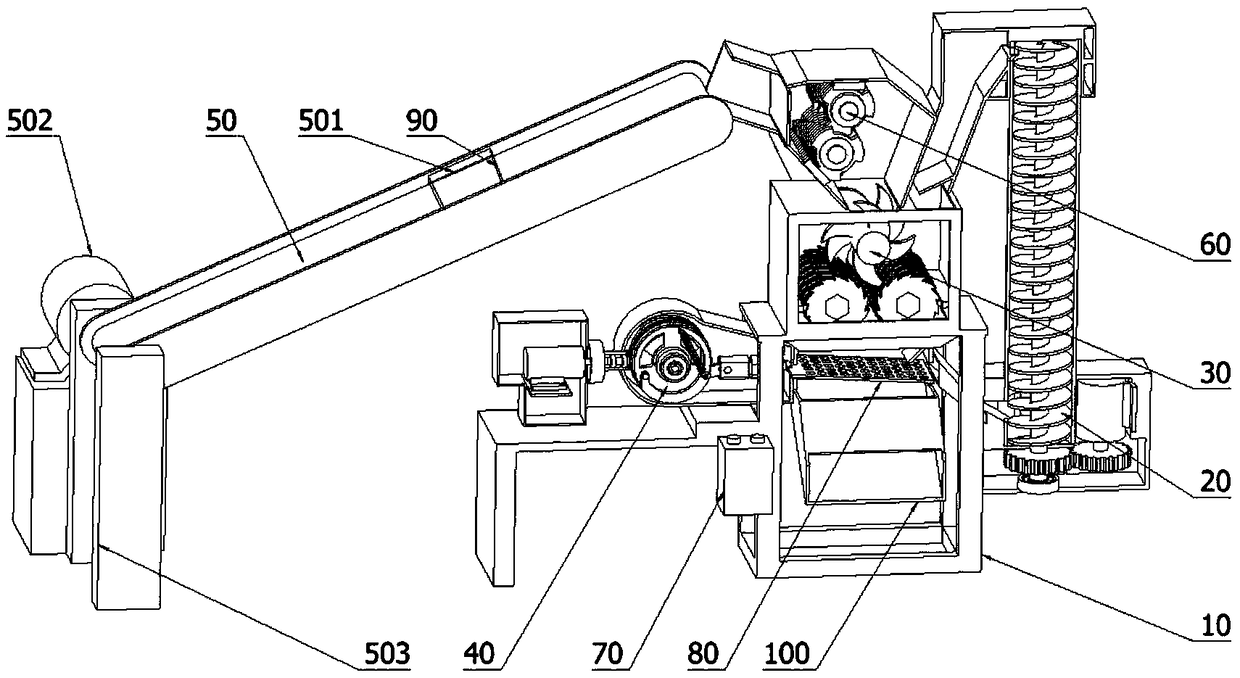

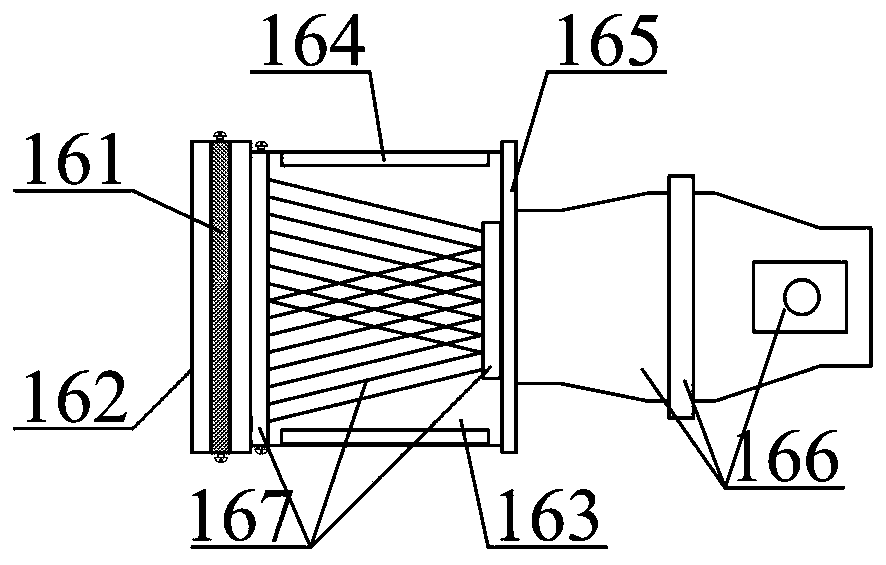

Method for adopting belt spinning of disc-type single roller to prepare amorphous alloy thin belt

ActiveCN103706770ALarge melt spreading areaGood belt forming performanceAmorphous metalSurface smoothness

The invention belongs to the technical field of alloy thin belt preparation and discloses a method for adopting belt spinning of a disc-type single roller to prepare an amorphous alloy thin belt. The method includes adopting the disc-type roller, spraying melt on the surface of a disc rotating around a disc central shaft, enabling a direction in which a centrifugal force is applied on the melt to be parallel to a contact face, namely the surface of the disc, and forming the amorphous alloy thin belt after an amorphous thin belt at the edge of the disc automatically breaks away from the roller under the action of cooling contraction and the centrifugal force. The amorphous alloy thin belt prepared by the method is thinner in size, higher in surface smoothness and better in performance.

Owner:TONGZHOU XINGCHEN MACHINERY

Crushing device for wasted circuit board

The invention discloses a crushing device for a wasted circuit board, and relates to the field of circuit board recycling devices. The crushing device for the wasted circuit board comprises a support,a discharging port which is formed in the support and is used for discharging the broken circuit board, a screening plate which is positioned at the upper part of the discharging port, a second crusher which is arranged at the upper part of the support, a first crusher which is mounted on the upper surface of the second crusher, and a feeding device which is arranged at an opening in one side ofthe first crusher and is used for conveying the wasted circuit board. According to the crushing device for the wasted circuit board, the circuit board is pre-crushed through the first crusher and is crushed for the second time through the second crusher, and thus the problem of serious splashing is caused by the wasted circuit board in rapid contact with a high-speed rotating crushing cutter during direct crushing in the prior art can be solved.

Owner:XINFENG FUCHANGFA ELECTRONICS +1

Beverage cup loading machine

ActiveCN106214002AShorten working timeReduce splashBeverage vesselsEngineeringMechanical engineering

The invention relates to a beverage cup loading machine which comprises a water conveying device and a transition container. The water conveying device is used for allowing the transition container obtain a beverage from the water conveying device. The transition container is provided with a liquid circulating opening. The liquid circulating opening is used for being controlled to be opened or closed so as to discharge liquid and transferring the beverage in the transition container into a water cup. By means of the beverage cup loading machine, the beverage cup loading speed can be increased, and the beverage can not be easily splashed out when poured.

Owner:李永刚

An eel belly cutting device

InactiveCN104770454ASimple structureEasy to usePoultry/fish slaughtering/stunningSlaughtering tools/knivesAnguilliformesBiomedical engineering

The present invention discloses an eel belly cutting device, and comprises a hand-holding part and a cutter edge part. The device is characterized in that: a tapered cutter body is arranged within a half-circular bead flange; the hand-holding part is a finger fixing ring; and the finger fixing ring is arranged at the apex angle outside the bead flange part. Specifically, the cutter edge part is the tapered cutter body. Beneficial effects of the device are that the device is simple in structure, convenient to use and suitable for dissecting eels in various sizes.

Owner:方小玲

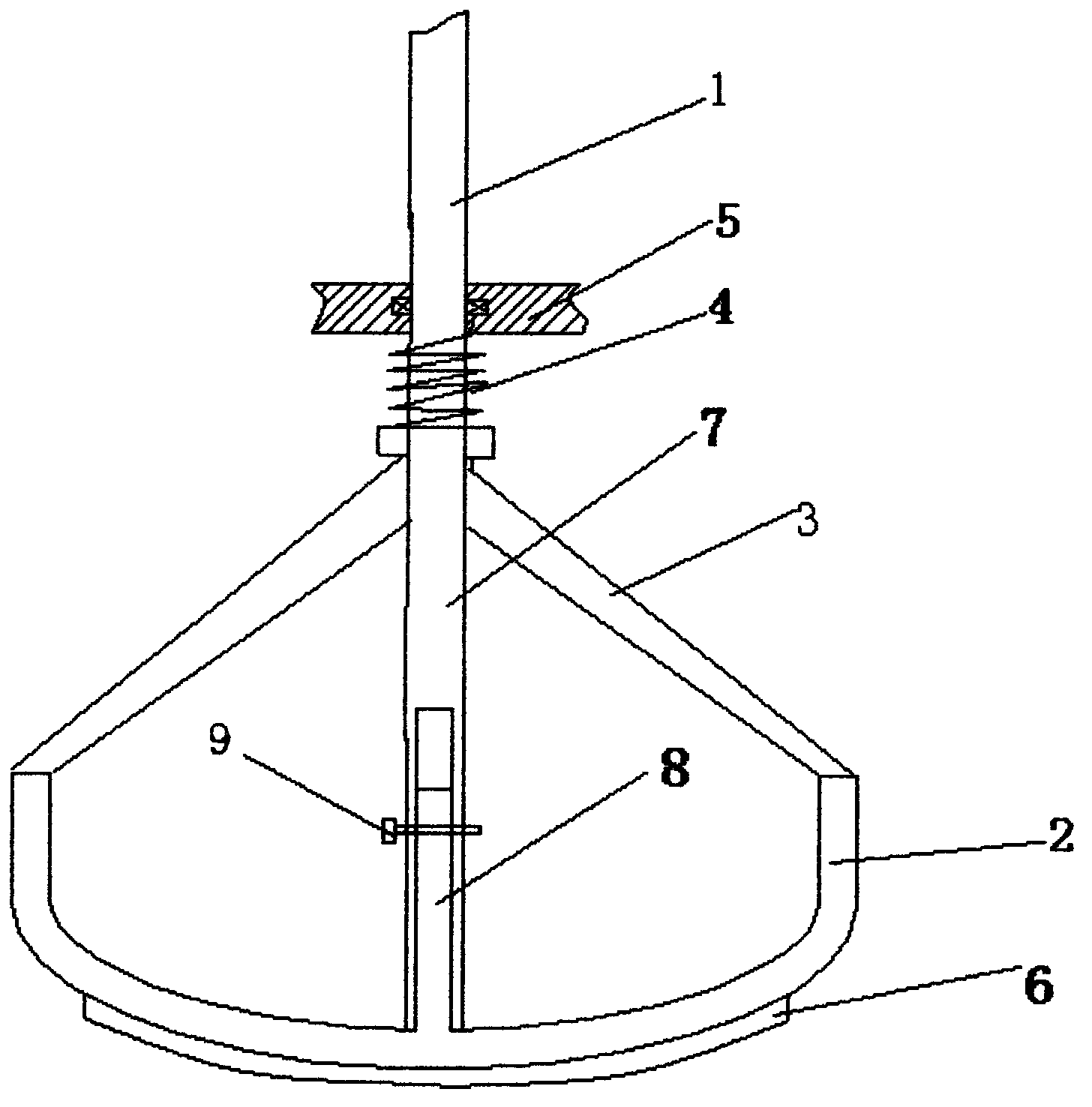

Height-adjustable wear-resistant anchor type stirring paddle

InactiveCN104001447APrevent material from splashingPromote stirringMixer accessoriesWear resistantPulp and paper industry

The invention discloses a height-adjustable wear-resistant anchor type stirring paddle comprising a stirring shaft pivotally mounted on a support, the lower end of the stirring shaft is an anchor type paddle, the anchor type paddle and the side wall of the stirring shaft are directly connected with inclined stirring blades, the stirring shaft is sleeved with a damping spring, the stirring spring is arranged between the stirring shaft and the support, a wear-resistant layer is arranged on the lower surface of the anchor type paddle, the stirring shaft comprises an upper half shaft and a lower half shaft which are slidably cooperated, and the upper half shaft and the lower half shaft are arranged by a positioning pin roll. The height-adjustable wear-resistant anchor type stirring paddle can effectively prevent material splashing problem, and an upper material is simultaneously pressed, the stirring is even, and the mixing time can be correspondingly shortened.

Owner:周鹏

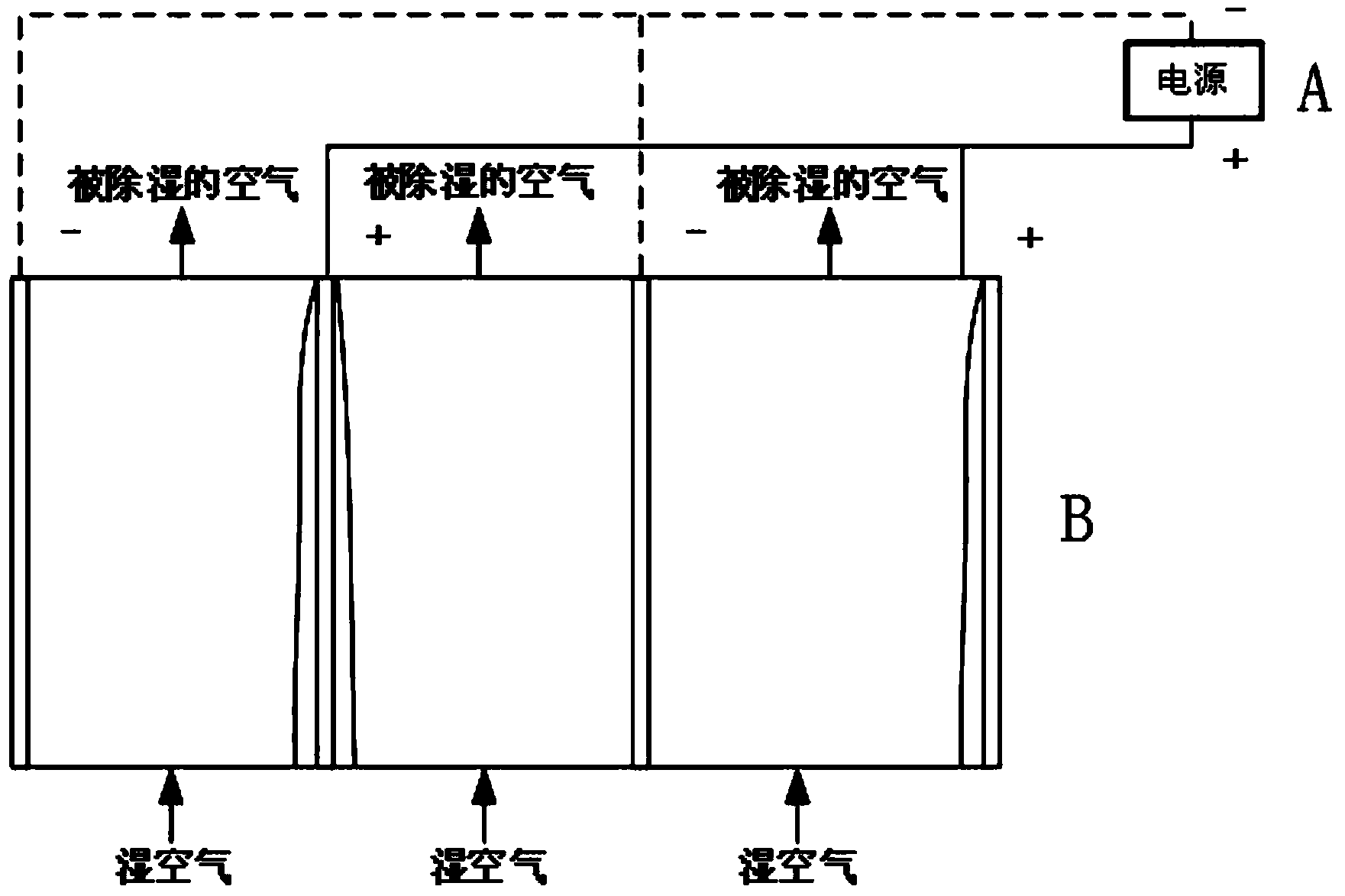

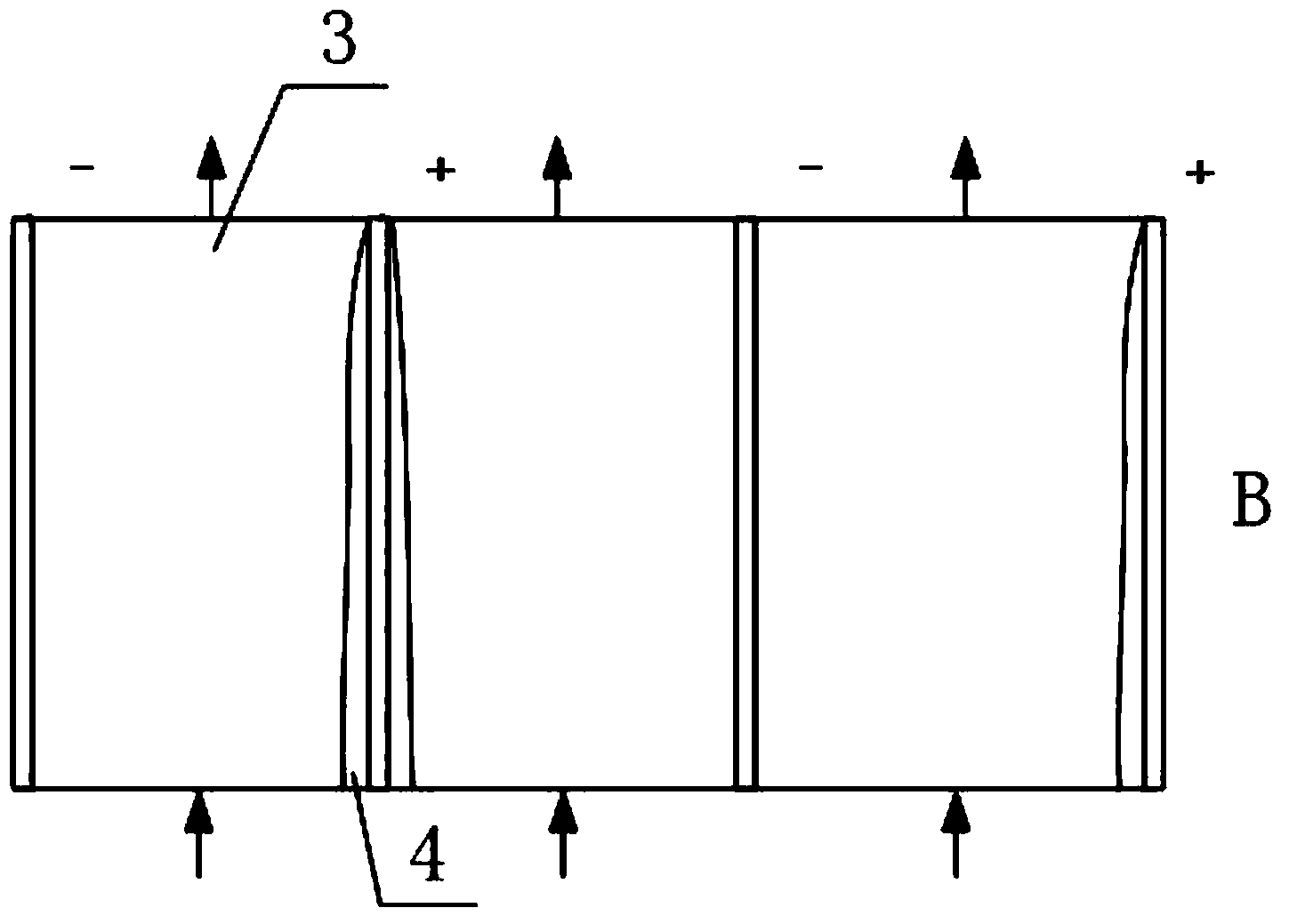

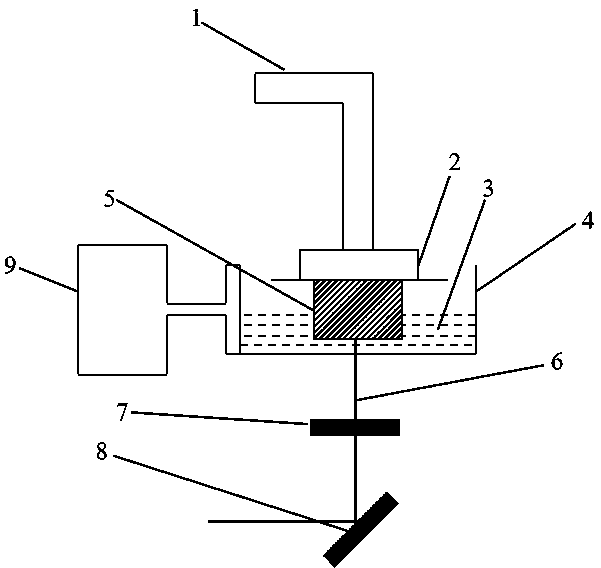

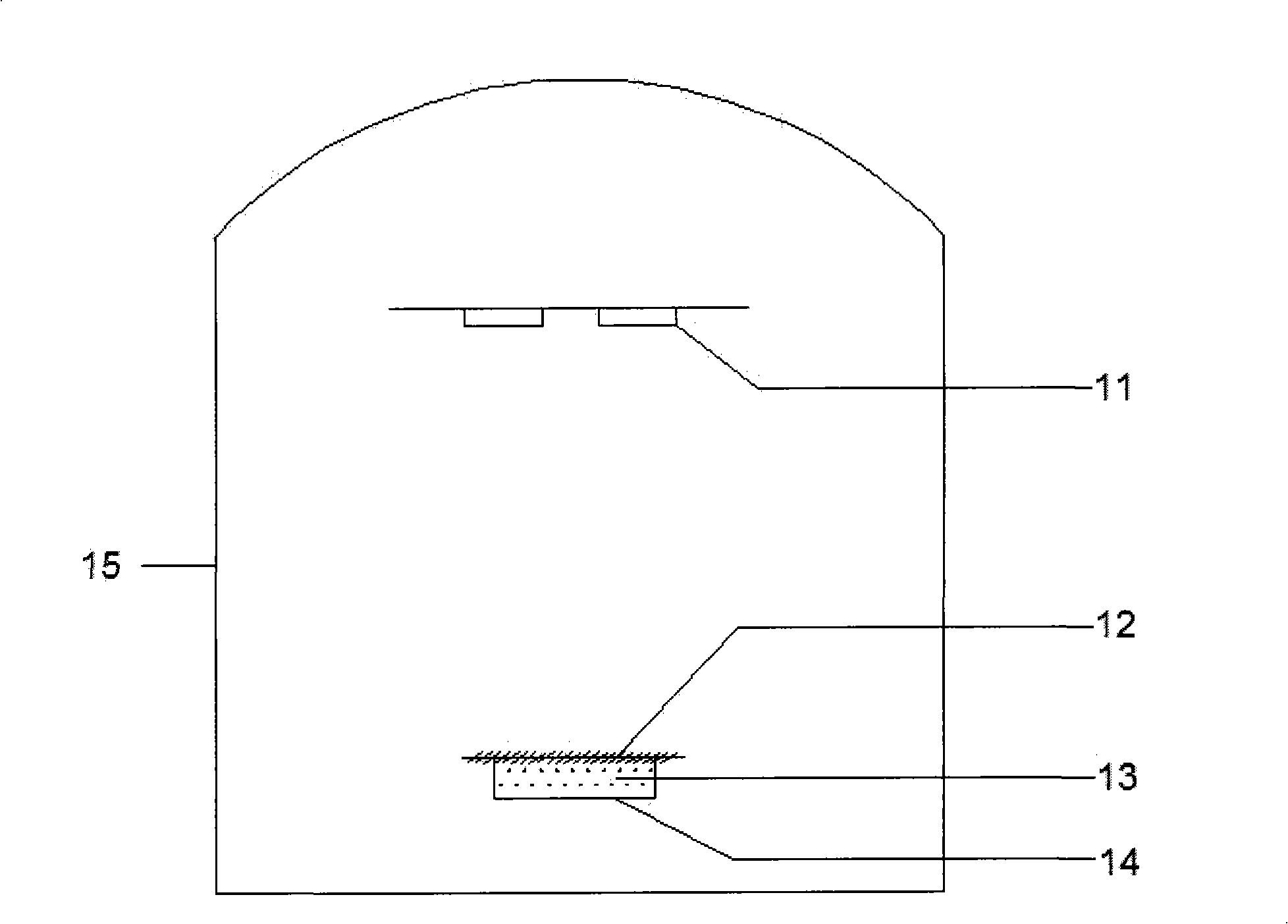

High-voltage electric field auxiliary solution dehumidifying device

InactiveCN104296273AEnhanced Migration MomentumPromote absorptionLighting and heating apparatusAir conditioning systemsElectric fieldEngineering

The invention discloses a high-voltage electric field auxiliary solution dehumidifying device which comprises a direct-current power supply unit and a dehumidifying unit. The direct-current power supply unit is connected with a positive electrode plate and a negative electrode plate of the dehumidifying unit to form a high-voltage electric field, a solution liquid film is attached to the surface of the inner side of the positive electrode plate of the dehumidifying unit, and steam in air to be dehumidified moves to the solution liquid film under the action of the high-voltage electric field. According to the device, solution absorbing and dehumidifying are enhanced by means of directional moving of the steam in a direct-current electric field, liquid drops, splashing in the air, on the liquid film are removed by means of directional moving of charged liquid drops, molecule migration of the steam is enhanced, and meanwhile the problem that liquid exists during solution dehumidifying is solved.

Owner:SOUTHEAST UNIV

Coating filtering device with alarm function

InactiveCN101579591ALarge filter areaLarge accumulation of impuritiesFiltration separationSteel platesSheet steel

The invention relates to a coating filtering device with alarm function. A cylindrical shell with an inner ring welded at the lower part of the inner wall is in threaded connection with a groove-shaped end cover, a filter screen support with a filter screen is welded on an underpan of the end cover, the filter screen is tightly compressed at the lower part of the inner ring of the shell by a circular elastomer mounted between the shell and the end cover, and a pressure sensor connected with an external alarm is mounted on the shell. The height of the shell and the diameter size of a cylinder are changed to adjust an effective filter area and suit the requirements for the production of coating steel plates; the internally arranged filter screen has a large surface area so that the upper part can still filter coatings even if impurities are piled at sides; and the pressure sensor drives the alarm to act when pressure increases so as to solve the problem in time, avoid a coating flying phenomenon because of the crack of the filter screen, overcome a flooding phenomenon generated in lacquer trays in the production process of the coating steel plates and improve the surface quality of coating plates.

Owner:ANGANG STEEL CO LTD

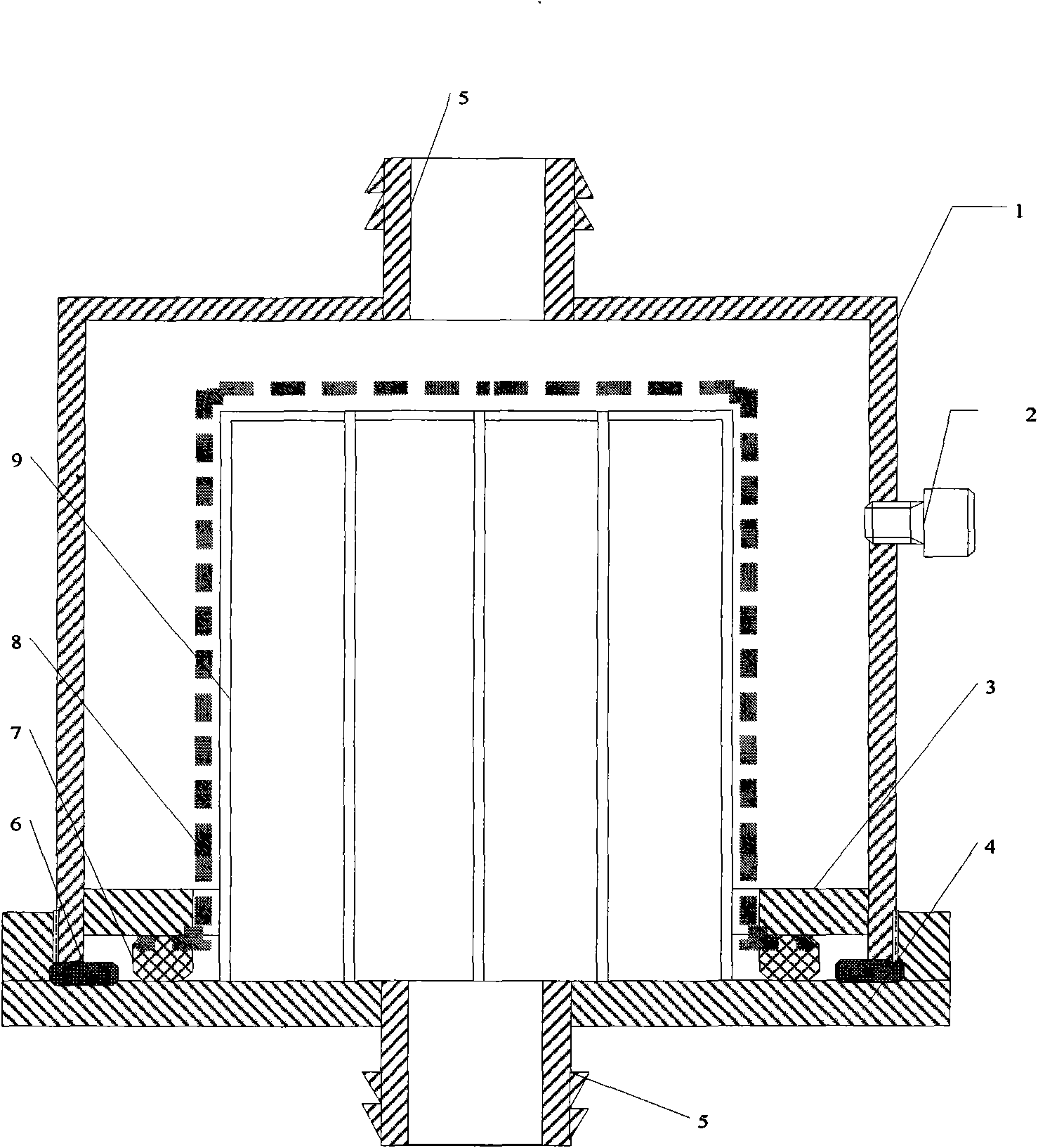

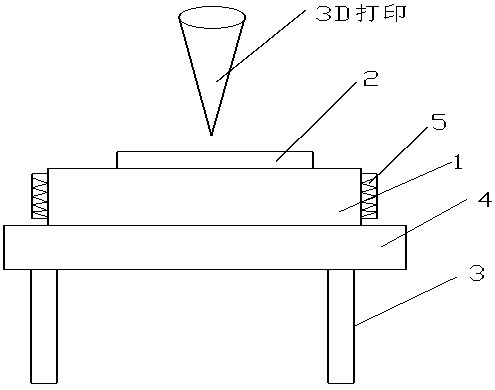

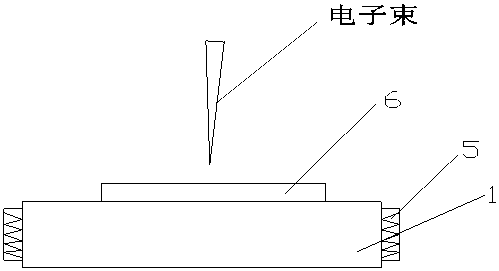

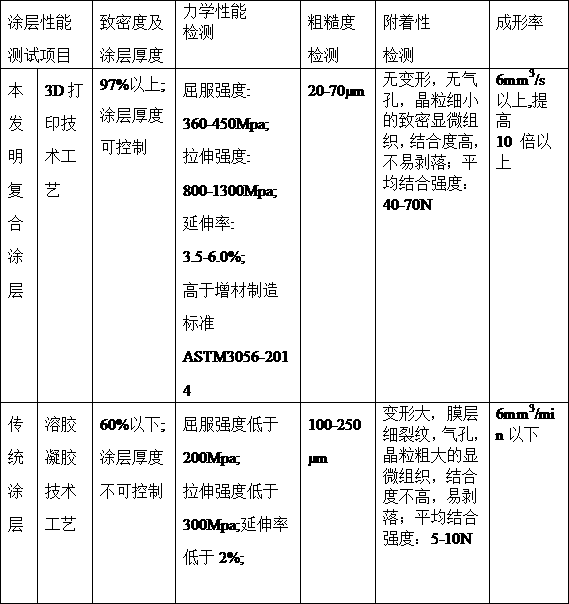

Method for preparing coating by 3D printing overlapping electron beam

InactiveCN110714199AGood molding precisionAvoid low powder utilizationAdditive manufacturing apparatusIncreasing energy efficiencyCermetCeramic composite

The invention relates to a method for preparing a coating by 3D printing overlapping an electron beam. Metal or ceramic powder and metal / ceramic powder are printed on the surface of a base material layer by layer through 3D printing, layer-by-layer printing is carried out by a three-dimensional model according to the set layer thickness, and then the metal or ceramic powder and metal / ceramic powder on the surface of the base material are preheated to form a fusion layer. A heating device used for the preheating includes a high-frequency vibrator and an induction heating coil which are placed on a workbench, the high-frequency vibrator acts on the bottoms of the fusion layer and the base material, the induction heating coil is arranged around the base material for preheating, after preheating is carried out, the fusion layer is melted with the electron beam to form a metal / ceramic. composite coating, and finally the metal / ceramic composite coating is subjected to post-heat treatment through the induction heating coil. The product development cycle is greatly shortened, production rate is improved, and the production cost is reduced.

Owner:FUJIAN UNIV OF TECH

Method for recycling waste lithium ion battery electrolyte by using supercritical CO2 fluid

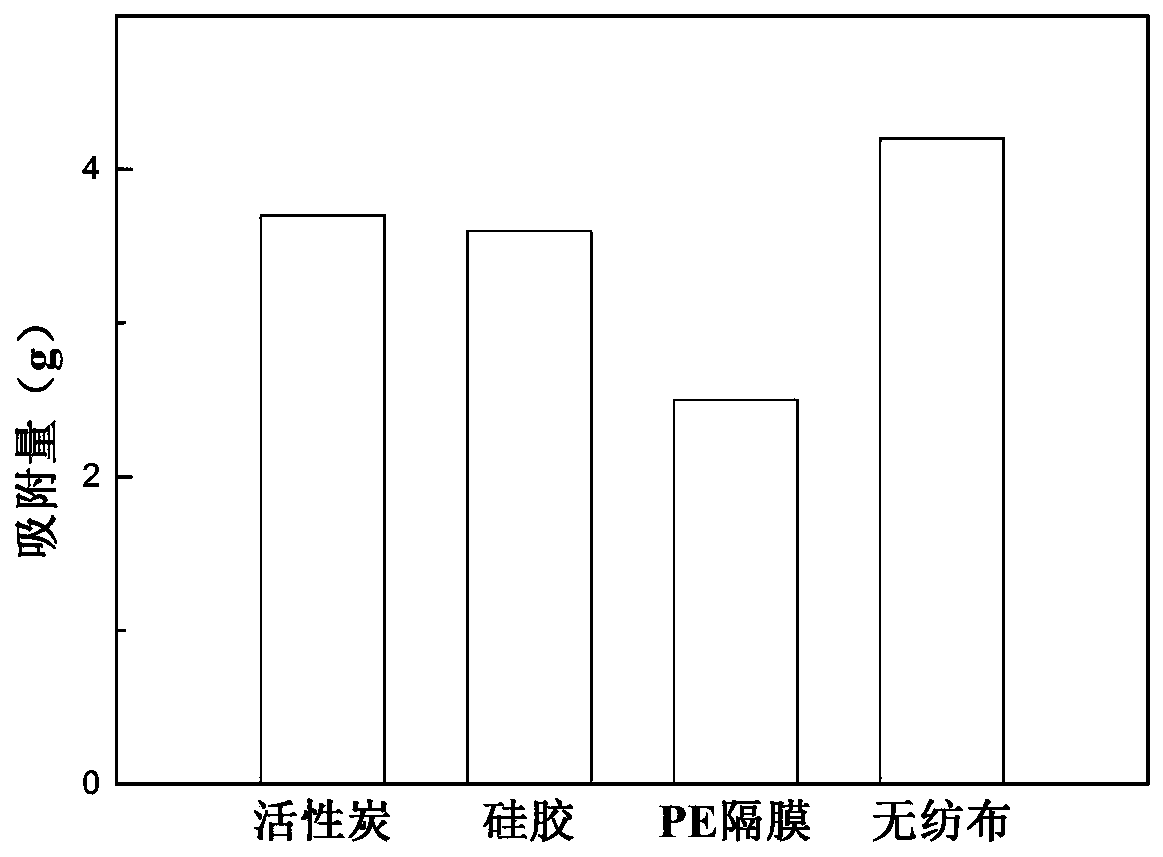

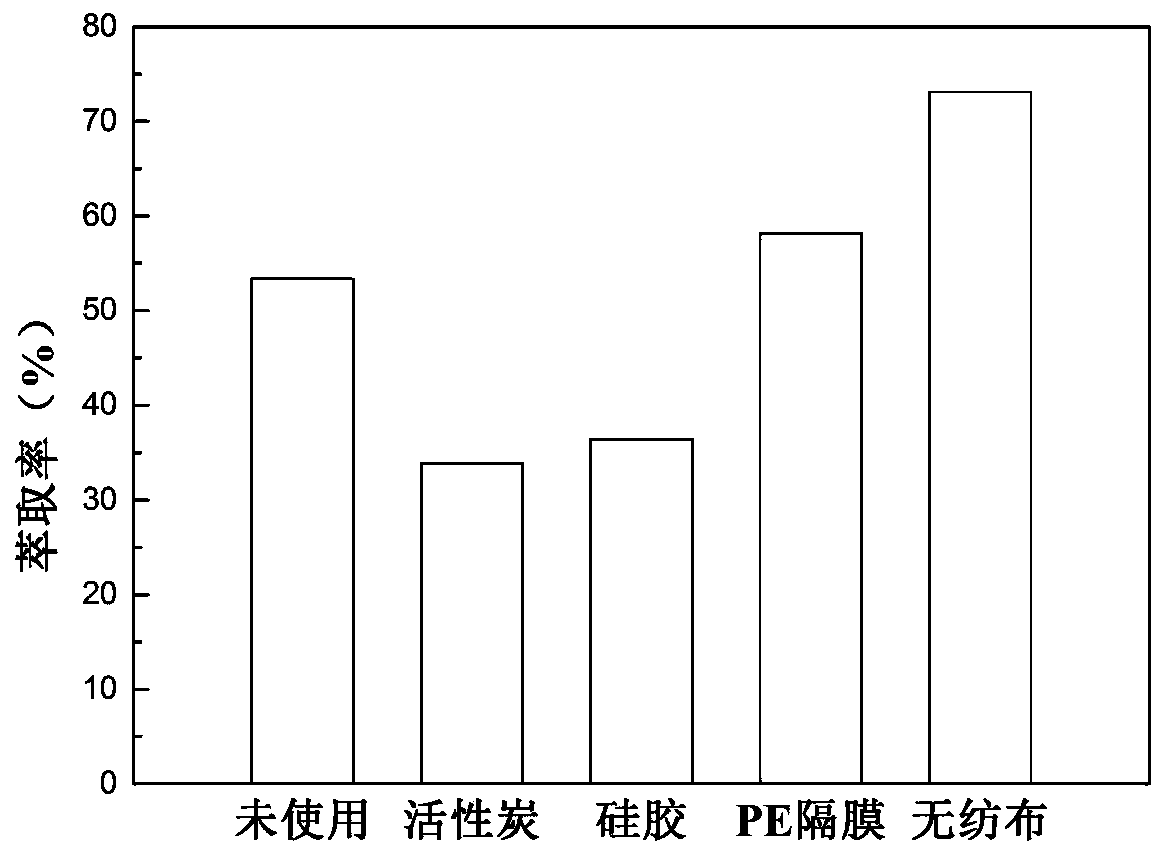

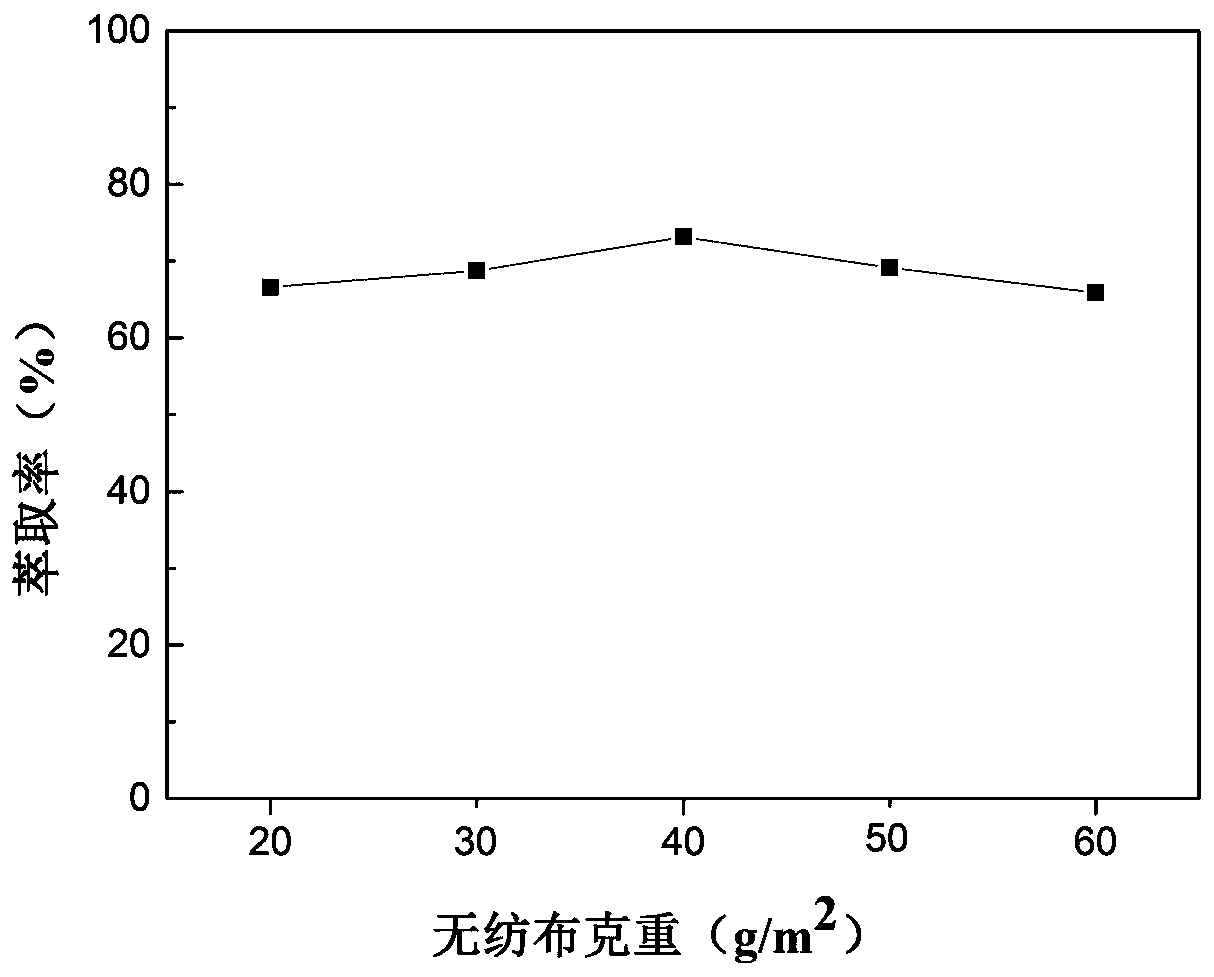

ActiveCN110534835AMulti-layer bigIncrease the areaIon-exchange process apparatusIon-exchanger regenerationOrganic solventPhysical chemistry

The invention provides a method for recycling waste lithium ion battery electrolyte by using supercritical CO2 fluid. The extraction method mainly comprises the steps that (1) a waste lithium ion battery is fully discharged and disassembled, and a casing, positive and negative electrode materials and a cover plate are removed; (2) under the protection of inert gas, a free electrolyte is adsorbed by an adsorption material and completely transferred to a supercritical extraction apparatus; (3) the pressure, temperature, extraction time and flow rate of the supercritical CO2 fluid are set to extract an organic solvent; and (4) exhaust gas is absorbed by an exhaust gas absorption device, and the extract is collected by a cryogenic device. The lithium ion battery electrolyte recycling process provided by the invention has the advantages of simple operation, high recycling rate and fast extraction and recycling speed, and omits subsequent complicated processing procedures.

Owner:CHANGZHOU UNIV +1

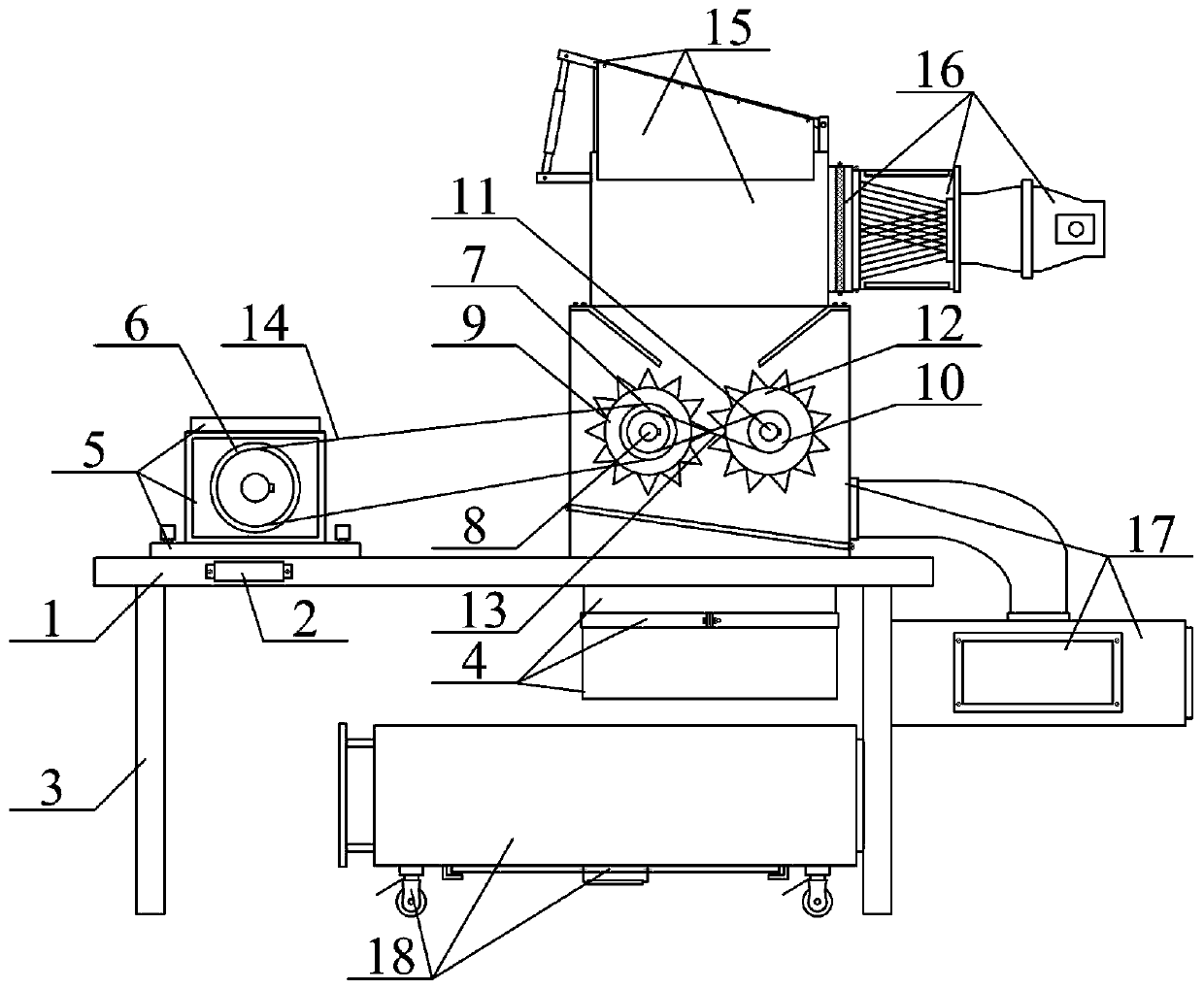

Intelligent environmental protection construction crusher

InactiveCN111389497AEnsure personal safetyAvoid splashing stonesCombination devicesGrain treatmentsElectric machinerySmart control

The invention provides an intelligent environmental protection construction crusher. The intelligent environmental protection construction crusher includes a crusher frame, an intelligent control switch, supporting legs, a crushing powder diversion pipe, a crushing motor, a driving belt wheel, a double groove plane belt wheel, a driving wheel shaft, a driving broken sawtooth gear, a single grooveplane belt wheel, a driven wheel shaft, a driven crushing sawtooth gear, a V-shaped transmission belt, a V belt and a stone anti-splash inlet adjusting baffle structure. According to the intelligent environmental protection construction crusher, through the arrangement of a stone anti-splash baffle, an inlet adjustable plate, a fixed seat, a stone to be crushed guide pipe, a connecting seat and aninlet size adjusting rod, avoiding the problem of stone splashing when crushing is facilitated, the personal safety of operators is ensured, by stretching and adjusting the inlet size adjusting rod,the inlet adjustable plate can act inside the fixed seat, and the inlet size can be changed; and the stone anti-splash baffle plays a side protection role to avoid stone splashing, and the stone diversion can be carried out through the stone to be crushed guide pipe so as to facilitate the work of crushing stones

Owner:丁金旺

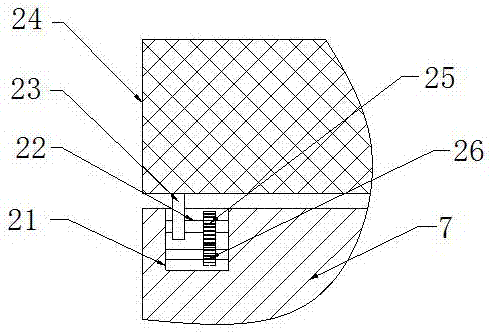

Ultrasonic and induction heating-assisted laser cladding method of composite nanometer coating

ActiveCN108588708ASolve the problem that it is easy to generate tensile stress and greatly increase the crack sensitivitySolve the problem of greatly increased crack susceptibilityMetallic material coating processesUltrasonic assistedOptoelectronics

The invention provides an ultrasonic and induction heating-assisted laser cladding method of a composite nanometer coating. A laser, a precoated layer, a base body, a working table, an ultrasonic vibrator and an induction heating coil are arranged. The ultrasonic and induction heating-assisted laser cladding method of the composite nanometer coating comprises the following concrete steps of (10) after preprocessing the base body, placing the precoated layer on the base body, placing the base body with the precoated layer onto the working table, and moving a laser head of the laser to a position to be cladded of the base body; (20) starting the induction heating coil, and using the induction heating coil for heating the base body and the precoated layer to 200 to 400 DEG C; (30) switching on the laser and the ultrasonic vibrator, wherein the laser is used for laser-cladding the base body through the laser head, and the ultrasonic vibrator is used for ultrasonic-assisting the laser cladding process; (40) after finishing laser cladding, switching off the ultrasonic vibrator and the laser; (50) switching off the induction heating coil; and (60) taking out the base body subjected to laser cladding.

Owner:FUJIAN UNIV OF TECH

3D printing method for metal material

ActiveCN110756804AAvoid powder splashReduced spreading processAdditive manufacturing apparatusIncreasing energy efficiencyLaser lightLight source

The invention belongs to the field of metal 3D printing and discloses a 3D printing (additive manufacturing) method for a metal material. By taking stable metal powder slurry prepared by metal powder,an organic solvent, a bonder, a dispersant, a suspending agent and a degassing agent or a solid-liquid mixture such as a suspension liquid, a dispersion liquid, a complex and a colloid as a forming material, a metal product which is fine in structure is prepared simply and rapidly by adopting a novel selective laser melting mode. The 3D printing method comprises the following steps of uniformly mixing metal or alloy powder, the organic solvent, the bonder, the dispersant, the suspending agent and the degassing agent to prepare the metal powder slurry which is stable and good in flowability, wherein a storage tank is connected to a base, a printing platform is connected to a lifting structure and is located right above the storage tank, and a laser light source system is placed below the storage tank; and establishing a printing model by three-dimensional software, and setting laser process parameters for SLM printing. According to the 3D printing method, the powder paving process is reduced, the device is simplified, the printing efficiency is improved, and the metal powder splashing and oxidizing problems are solved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

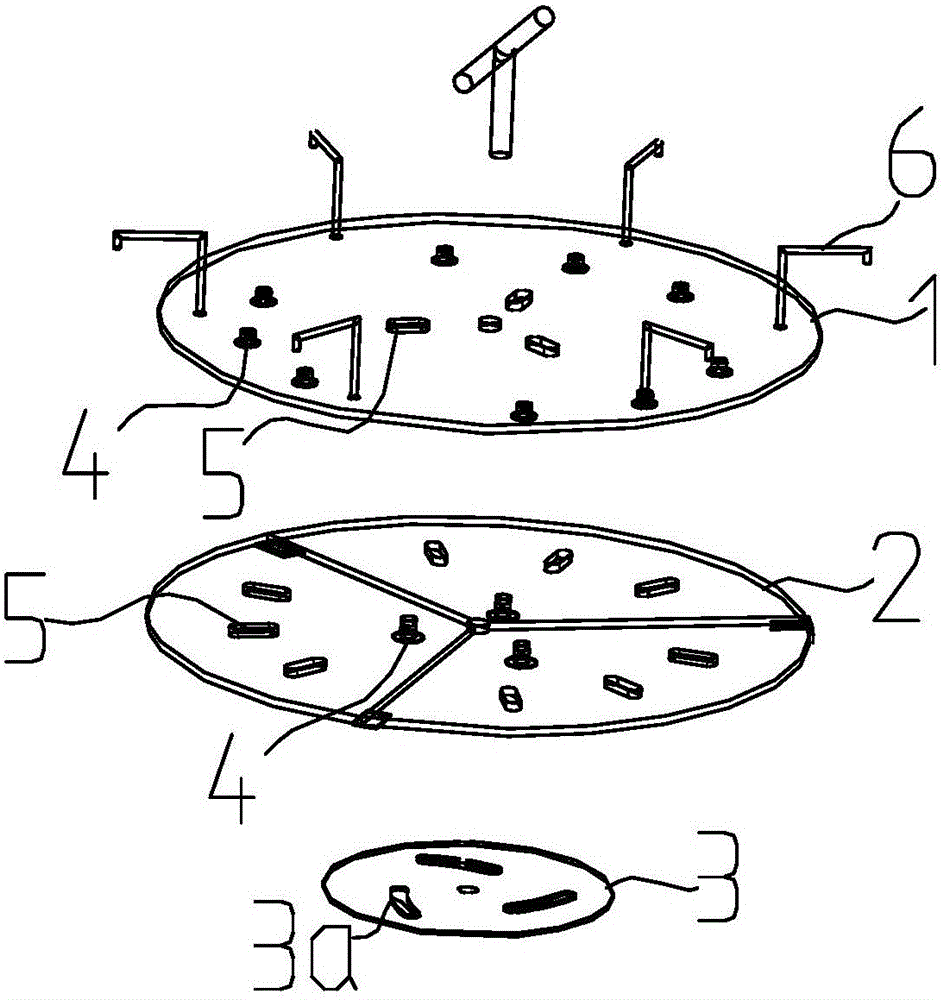

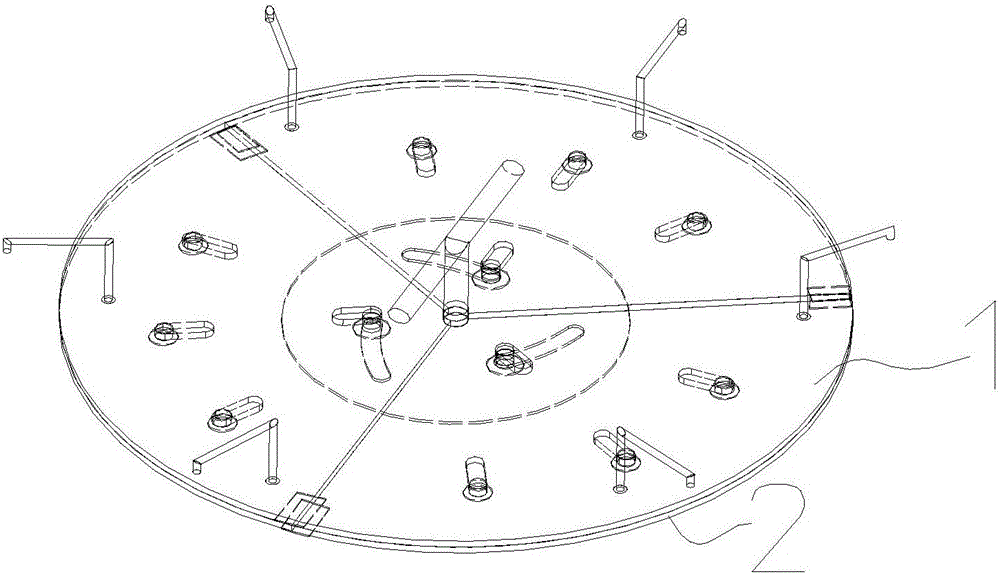

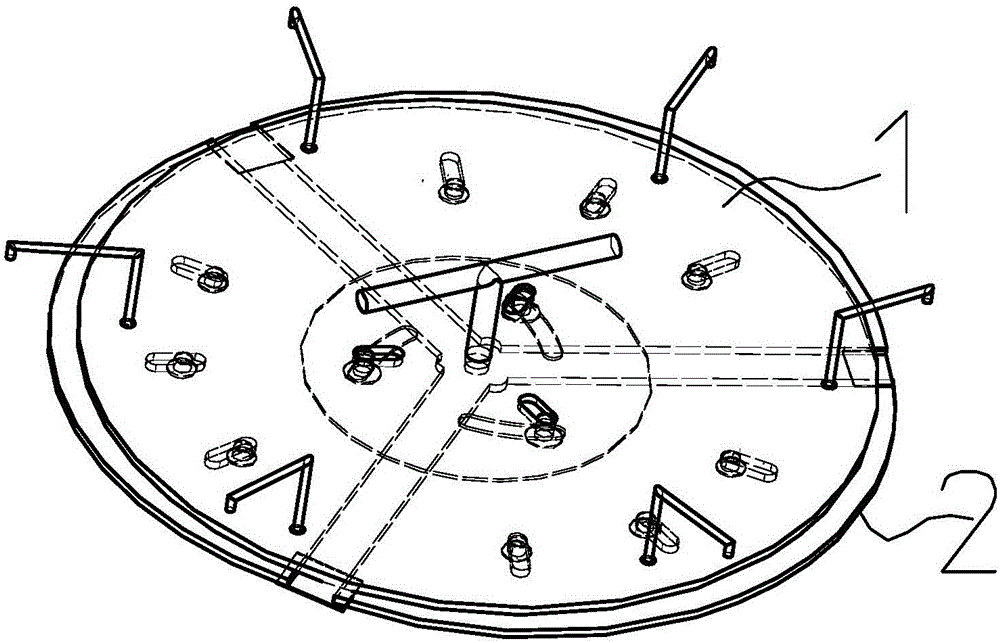

Self-expanding protection disc

The invention discloses a self-expanding protection disc. The self-expanding protection disc comprises an upper-layer fixing disc, a middle-layer expanding disc and a lower-layer cam disc which are sequentially stacked from top to bottom. The middle-layer expanding disc is formed by combining and splicing the side faces of a plurality of fan-shaped plates, and a screw serving as a sliding block penetrates each fan-shaped plate and is located on the symmetric axis of the corresponding fan-shaped plate. A plurality of guiding strip holes are formed in the positions, corresponding to the screws, of the upper-layer fixing disc and extend outwards along the radius of the upper-layer fixing disc, and the top ends of the screws are inserted in the guiding strip holes. A plurality of rotary pushing strip holes are formed in the positions, corresponding to the screws, on the lower-layer cam disc, the rotary pushing strip holes are strip-shaped openings with one ends opposite to the screws and the other ends obliquely extending towards the edge of the lower-layer cam disc, and the bottom ends of the screws are inserted in the rotary pushing strip holes. By means of the three-layer structure, the upper-layer fixing disc serves as a sliding way and also has a function of protecting the structures at the lower portion, and after the self-expanding protection disc is placed in a crucible, the diameter can be changed at will, and the coating work is greatly facilitated.

Owner:曲靖晶澳光伏科技有限公司

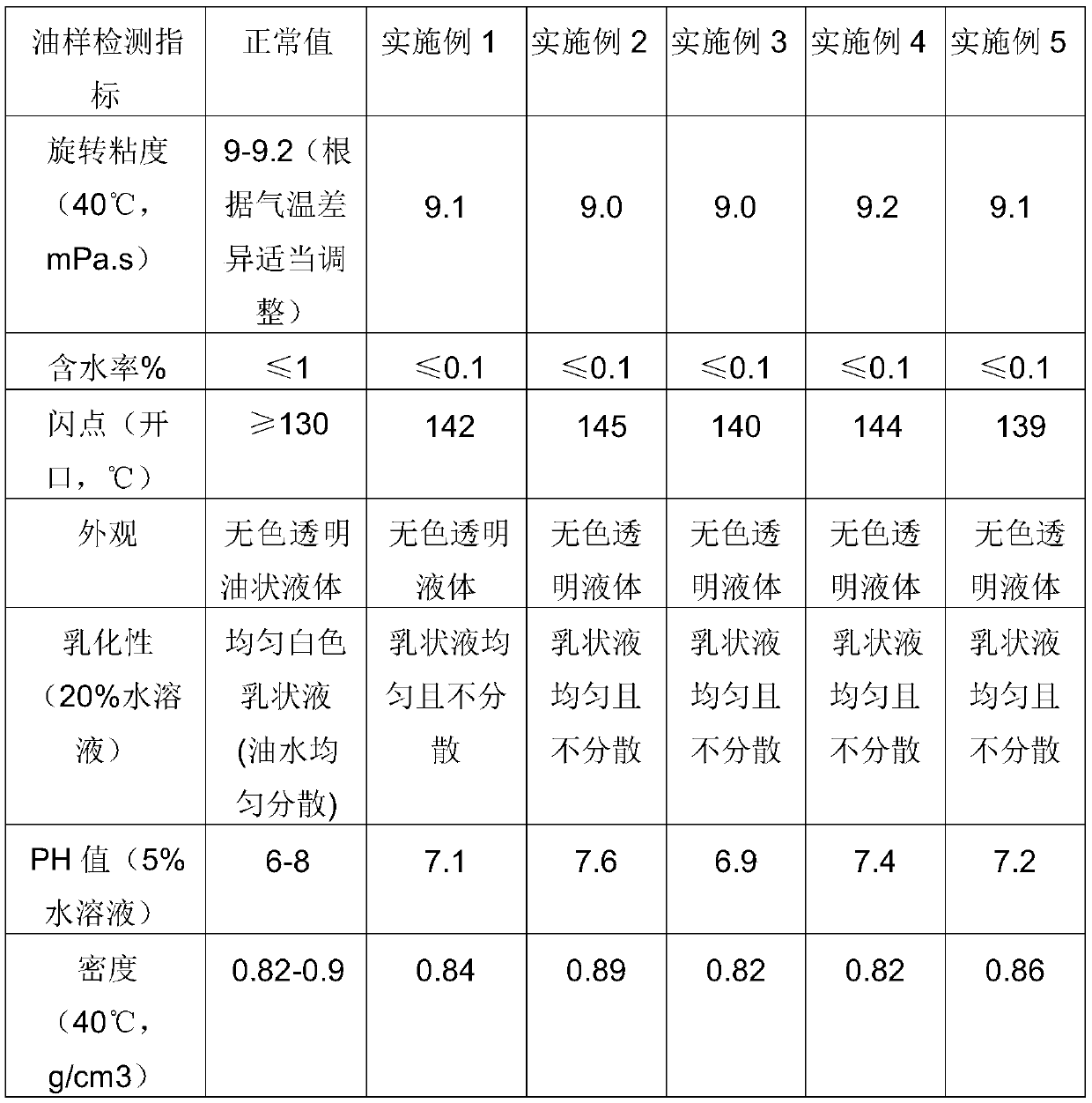

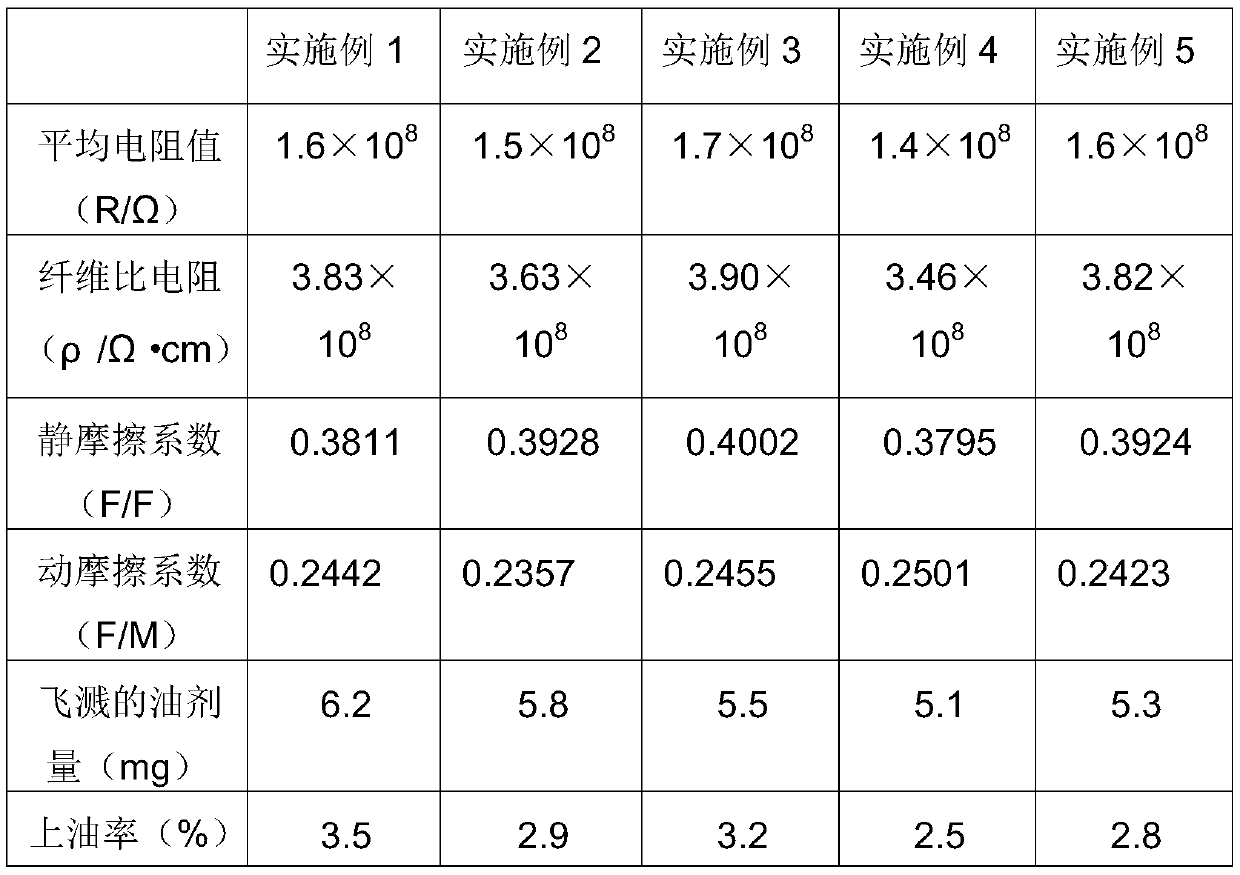

Efficient manufacturing technology of DTY elasticity enhancement addition agent composite material

ActiveCN111501338AImprove washabilitySimple processFibre treatmentManufacturing technologyEngineering

The invention discloses an efficient manufacturing technology of a DTY elasticity enhancement addition agent composite material. The efficient manufacturing technology of the DTY elasticity enhancement addition agent composite material comprises the following steps that mineral oil A and mineral oil B are added and mixed in proportion to obtain mixed mineral oil with the viscosity of being 20Pa.s,and then the mixed mineral oil is stirred for 30 minutes under the conditions of normal temperature and normal pressure; a splashing resistant agent, a penetrating agent and a composite material areadded to the stirred mixed mineral oil in sequence, the materials are mixed and stirred, the materials are stirred for 30 minutes under the conditions of normal temperature and normal pressure, and amixed oil agent is obtained; the mixed oil agent is transferred to an intermediate tank and statically placed for 24 hours, and the DTY elasticity enhancement addition agent composite material is obtained; and the DTY elasticity enhancement addition agent composite material is canned, and the canned DTY elasticity enhancement addition agent composite material leaves a factory after the DTY elasticity enhancement addition agent composite material is detected and qualified. The efficient manufacturing technology of the DTY elasticity enhancement addition agent composite material is simple and efficient in technology and reasonable in formula, the manufactured DTY elasticity enhancement addition agent composite material is safe and environmentally friendly and has good smoothness, good antistatic property, good washability and stable storage performance, the splashing problem is solved, the DTY elasticity enhancement addition agent composite material has good usage performance, and the requirement of production can be met.

Owner:江苏悦孚油品有限公司

Organic metal film preparation enhancing ultraviolet response of silicon based image device

InactiveCN101339920ATackle splashImproved ability to respond to UV lightFinal product manufactureSemiconductor/solid-state device manufacturingCooking & bakingFrequency conversion

The invention relates to an organic metal film preparation method for enhancing the ultraviolet response of a silicon-based imaging device. The preparation method is characterized in that a pre-baked organic metal valency substance Alq3 fine power is taken as coating material; UV frequency conversion materials are coated by vaporization into the film by adopting vacuum deposition on the surface of photosensitive units of the silicon-based imaging device. The baking time of the pre-baked organic metal valency substance Alq3 fine power is six to twelve hours, the temperature is 300 DEG C. The vapor deposition conditions of the vacuum deposition preparing a frequency conversion film are that: the vacuum degree is 2*10<-3>Pa; the optical monitoring wavelength is 500nm, the thickness of the film is 125 nm, the thickness of the optical is 125nm, the evaporation current is 20A.; the baking temperature is 200 DEG C. The film not only effectively improves the Ultraviolet response capability of the silicon-based imaging device, but also overcomes the problem that the organic frequency conversion film weakens and ages with time.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Spheroidizing method

The invention relates to a spheroidizing method for producing spheroidal graphite cast iron, and the method comprises the following steps: injecting melted rare earth magnesium silicon iron nodulizer alloy fluid containing less than or equal to 20% of Mg, less than or equal to 65% of Si and less than or equal to 3% of RE into a square steel pipe for cooling and solidification; fixing the whole rare earth magnesium silicon iron nodulizer of the outer lining square steel pipe in a spheroidizing bag by using refractory bricks and wedge-type chocks at the bottom of the spheroidizing bag covered, and then carrying out spheroidizing by utilizing a bag injecting method. The time for controlling spheroidizing is accurate, the molten iron cooling is less in the spheroidizing and casting process, the absorption rate of Mg, RE and Si after the spheroidizing is high, degradated spheroidization is prevented 15min after spheroidizing, the environment for producing and using a nodulizer is improved, the production cost is remarkably reduced and the quality of the product is improved. Compared with the conventional rare earth magnesium silicon iron nodulizer containing the rare-earth element RE of 2-8%, the spheroidizing method can be used for reducing the use amount of the rare-earth element RE by 50-75%.

Owner:深圳市嘉能新型环保建材有限公司

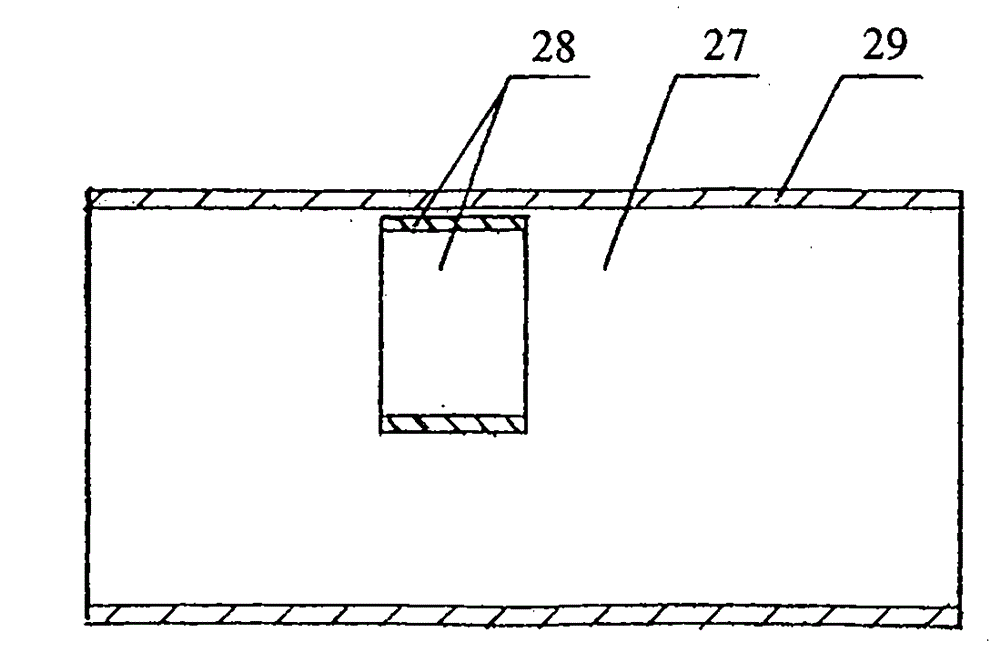

Air pressure type window patching glue box

InactiveCN103640262ATackle splashSimple structureContainer making machineryEngineeringMechanical engineering

The invention provides an air pressure type window patching glue box which comprises a glue box body (1). A bottom plate (2) is arranged at the bottom of the glue box body (1), glue discharge holes (3) are formed in the bottom plate (2), a rubber strip (4) is arranged at the bottom of the bottom plate (2), gluing holes (5) are formed in the bottom of the rubber strip (4), a connecting plate (6) is arranged on the upper portion of the glue box body (1), a connector (7) is arranged on the connecting plate (6), a cover plate (8) is arranged on the glue box body (1), and sealing strips (9) are arranged between the cover plate (8) and the glue box body (1). The air pressure type window patching glue box is characterized in that an air tap (10) is formed in the cover plate (8), and a vent pipe (11) is connected to the air tap (10). The air pressure type window patching glue box is characterized in that the structure is simple, manufacturing is convenient, and the problem that glue in the box is splashed is solved on the basis of not changing the appearance structure of an original window patching box.

Owner:徐晟伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com