Crushing device for wasted circuit board

A technology for waste circuit boards and crushing devices, which is applied in the direction of solid separation, screens, grills, etc., can solve problems such as splashing, achieve high efficiency of material return, prevent blockage of screening plates, and facilitate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

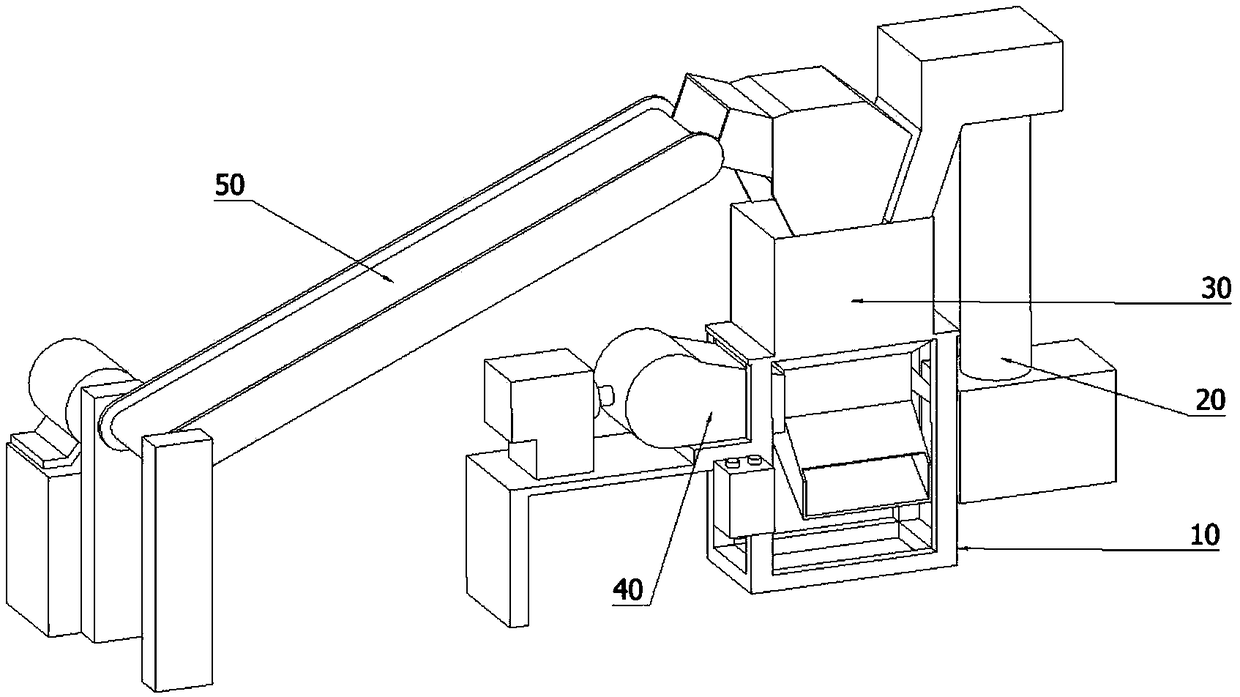

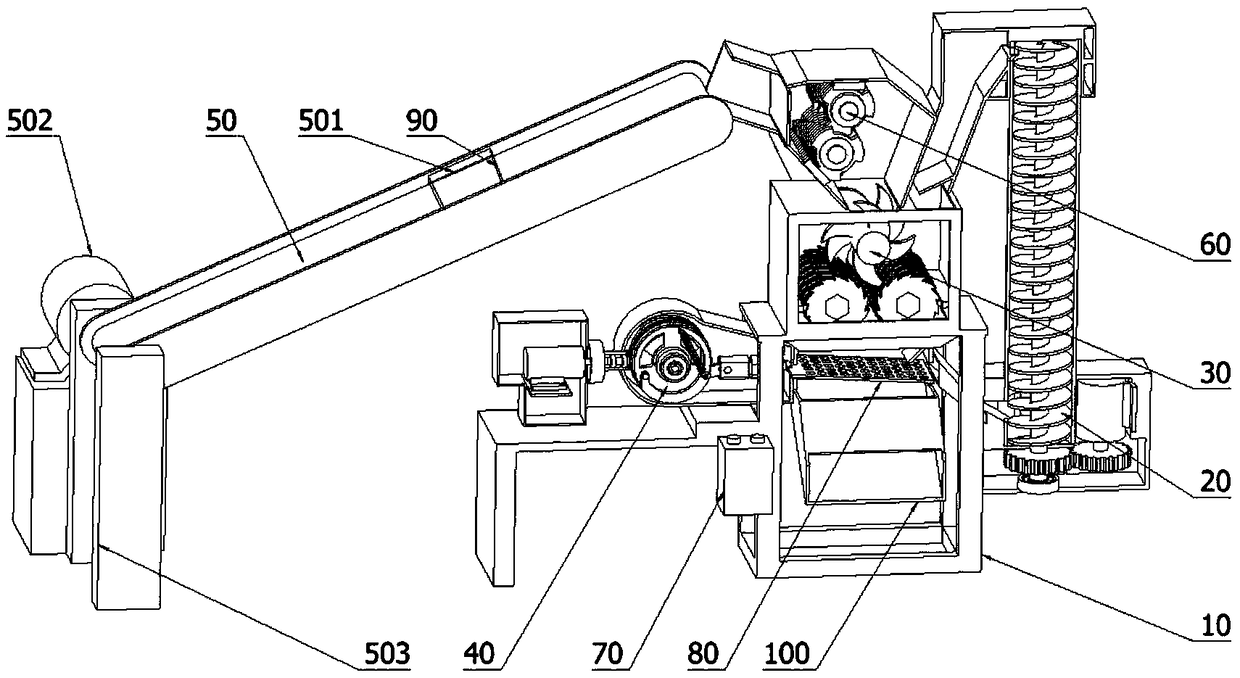

[0071] like figure 1 , 2 , 7, the embodiment of the present application discloses a crushing device for waste circuit boards, comprising: a support 10, the support 10 is arranged as a rectangle as a whole, and the four sides of the support 10 are in the shape of through holes; Port 100, the discharge port 100 is arranged in the support 10, it is suitable for the discharge of broken circuit boards; a screening plate 80, the screening plate 80 is located above the discharge port 100; a crushing device Two 30, the crushing device two 30 is arranged above the support 10, the crushing device two 30 includes a first crushing knife 301, a second crushing knife 302, a third crushing knife 303, a crushing shell 304, the crushing shell 304 has openings above and below, the upper opening communicates with the first crushing device 60, the lower opening corresponds to the screening plate 80, the first crushing knife 301 is arranged directly below the upper opening of the crushing shell 3...

Embodiment 2

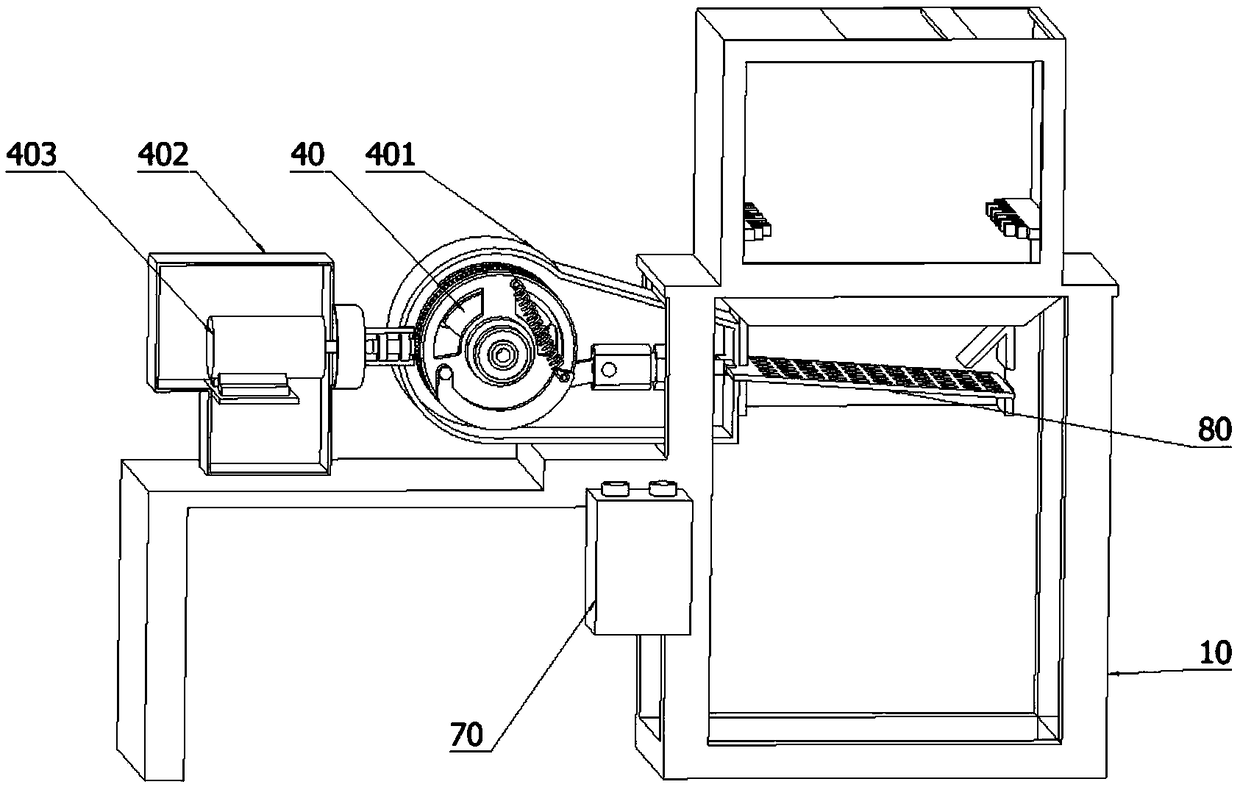

[0074] like figure 2 As shown, a crushing device for waste circuit boards, on the basis of Embodiment 1, also includes: a swinging device 40, the swinging device 40 is connected to one side of the screening plate 80;

[0075] Specifically, such as image 3 , 4 Said, the swing device 40 includes a fixed head 418, the rectangular groove on the right side of the fixed head 418 clamps the upper and lower surfaces of the left side of the screening plate 80, so that it stably clamps the screening plate 80, the fixed head 418 is connected to the outer surface of the right circular column of the fixed shell 419 through the circular threaded hole on the left. The through hole, the circular through hole is connected with the swing pin 421, and the inner circle of the circular through hole of the fixed shell 419 is provided with a card slot corresponding to the swing pin 421, and the card slot is installed with a first The circlip 422 and the second circlip 423, the swing pin 421 pas...

Embodiment 3

[0077] like figure 2 As shown, a crushing device for waste circuit boards, on the basis of Embodiment 2, further includes: a return device 20, the return device 20 is connected to the other side of the screening plate 80;

[0078] Specifically, such as Figure 5 , 6 As shown, the feeding device 20 includes a feeding motor 201, a motor housing 202, and a feeding opening 208. The motor housing 202 is installed on the right side of the bracket 10, and the motor housing 202 is installed on the right side The material motor 201, the left circular hole of the motor housing 202 is equipped with a rotating shaft cylinder 204, and the hollow interior of the rotating shaft cylinder 204 is equipped with a return material rotating shaft 203, and the bottom of the return material rotating shaft 203 has a gear and a material return motor 201. The gears are meshed, and the lower bottom of the return shaft 203 is installed in a circular hole on the bottom surface of the motor housing 202 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com