Patents

Literature

156results about How to "Same quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

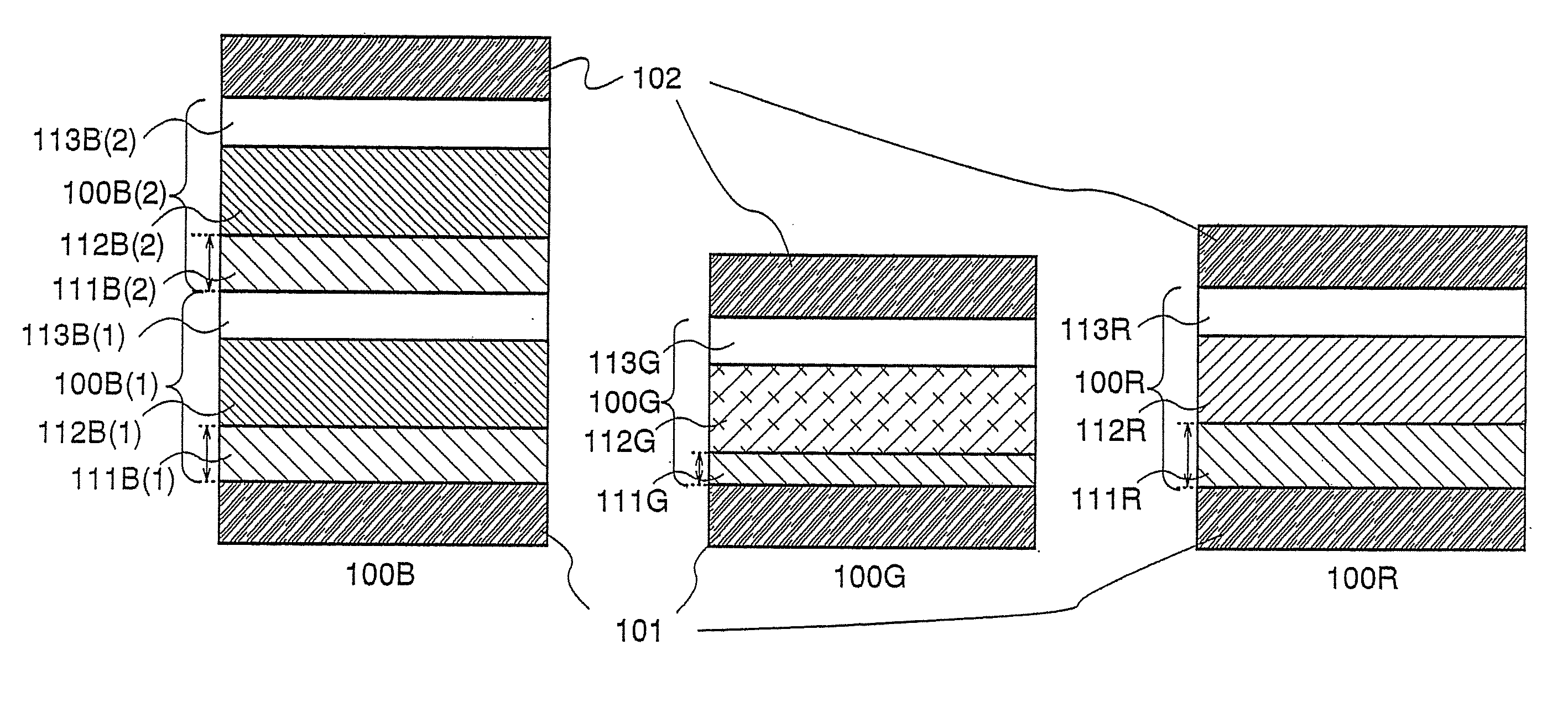

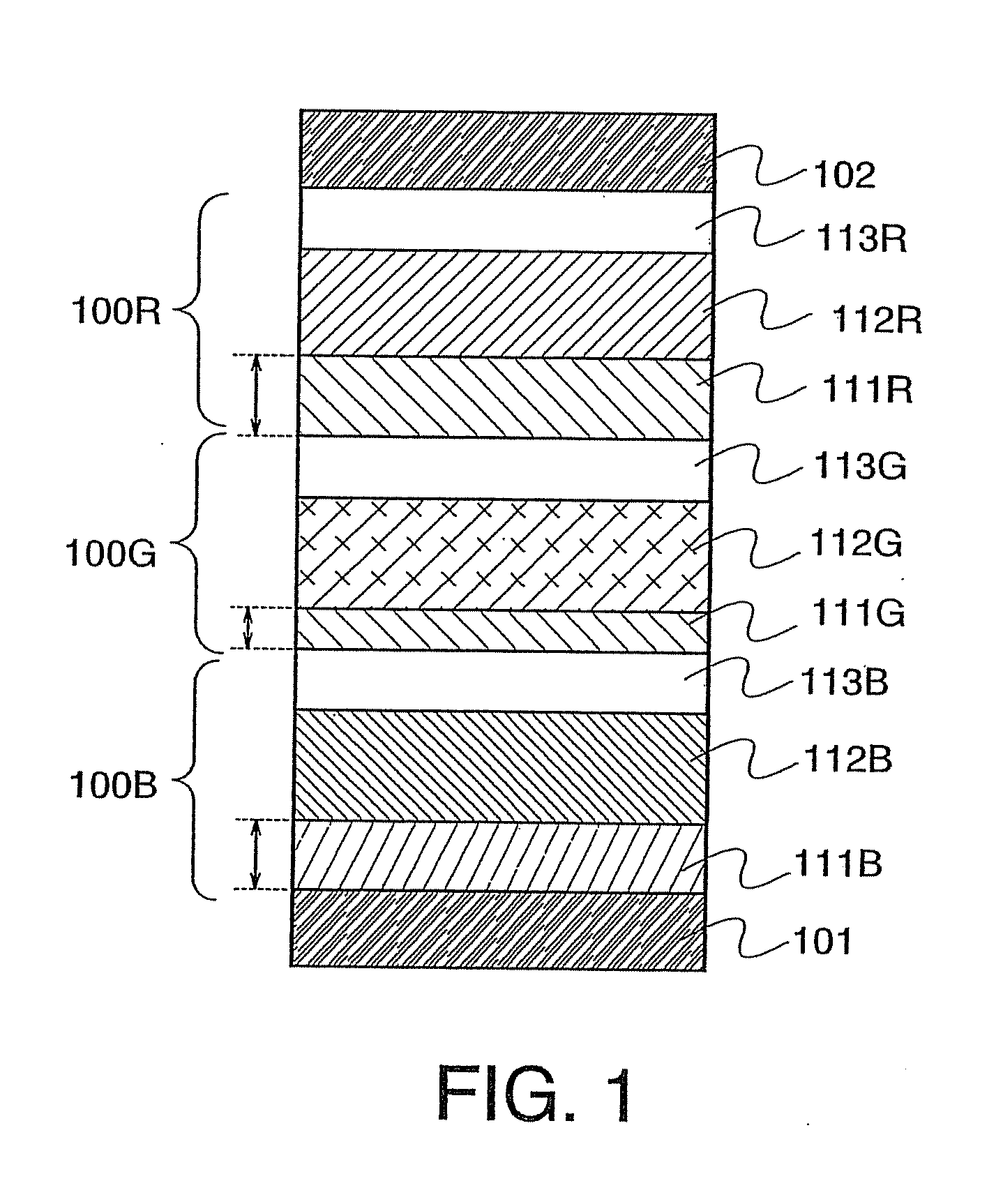

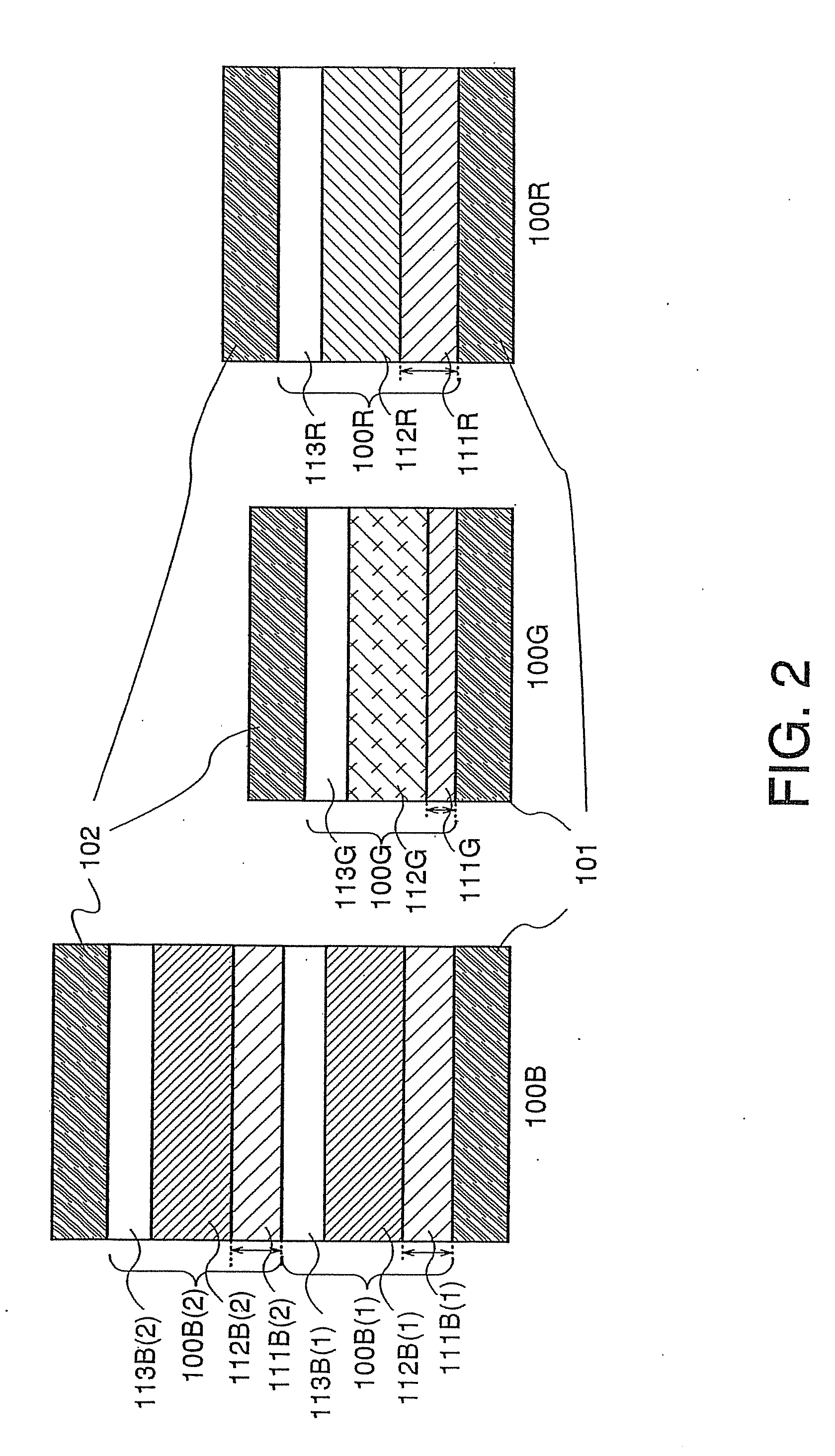

Light Emitting Device

InactiveUS20110291088A1Luminous efficiencyConvenient lightingSolid-state devicesSemiconductor/solid-state device manufacturingConductive materialsLength wave

It is an object of the invention to provide a light emitting device which can display a superior image in which luminescent color from each light emitting layer is beautifully displayed and power consumption is lowered in a light emitting element in which light emitting layers are stacked. One feature of the invention is that, in a light emitting element which comprises light emitting layers stacked between electrodes, each distance between each light emitting layer and an electrode is approximately oddly multiplied ¼ wavelength by controlling a thickness of a layer provided therebetween to enhance luminous output efficiency. Another feature of the invention is that a drive voltage is lowered using a high conductive material for the layer compared with a conventional element.

Owner:SEMICON ENERGY LAB CO LTD

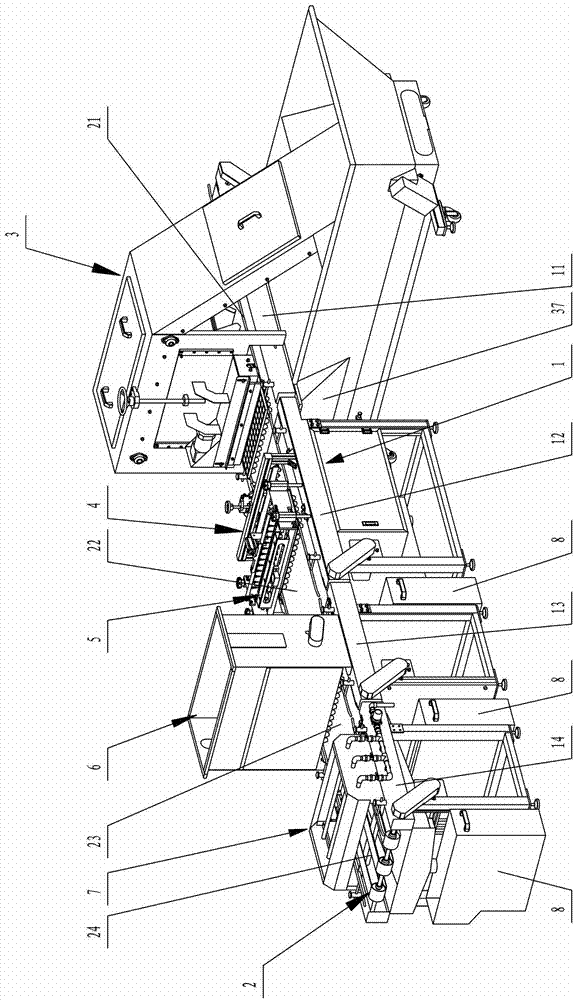

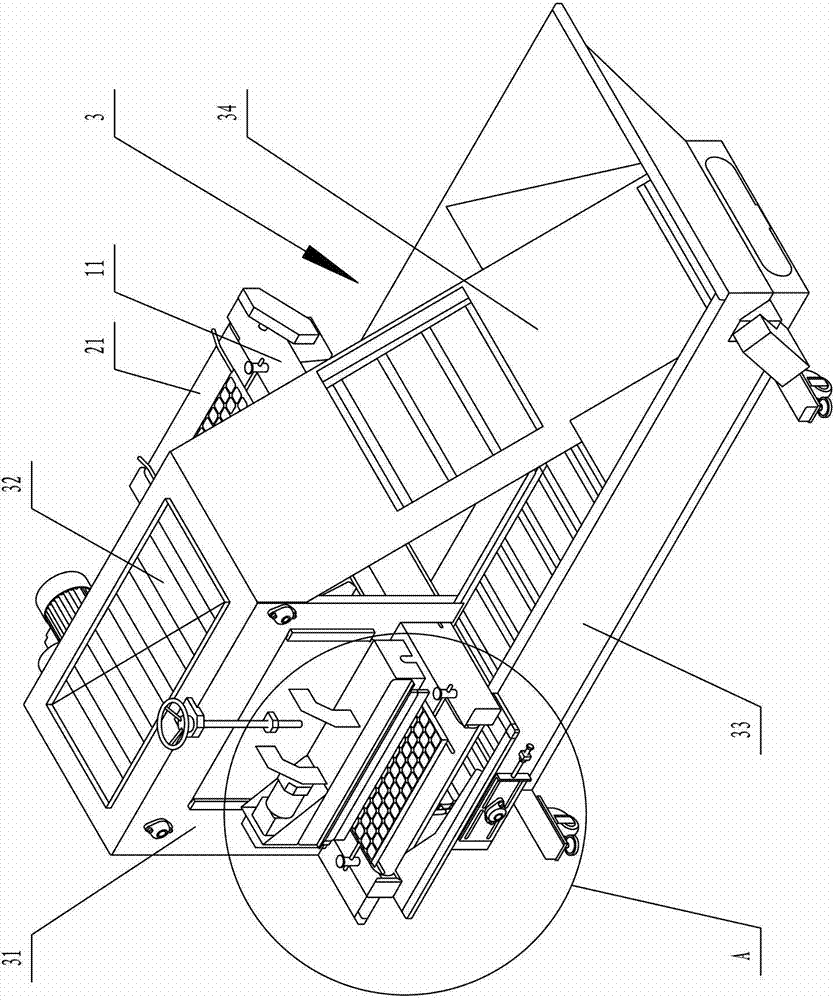

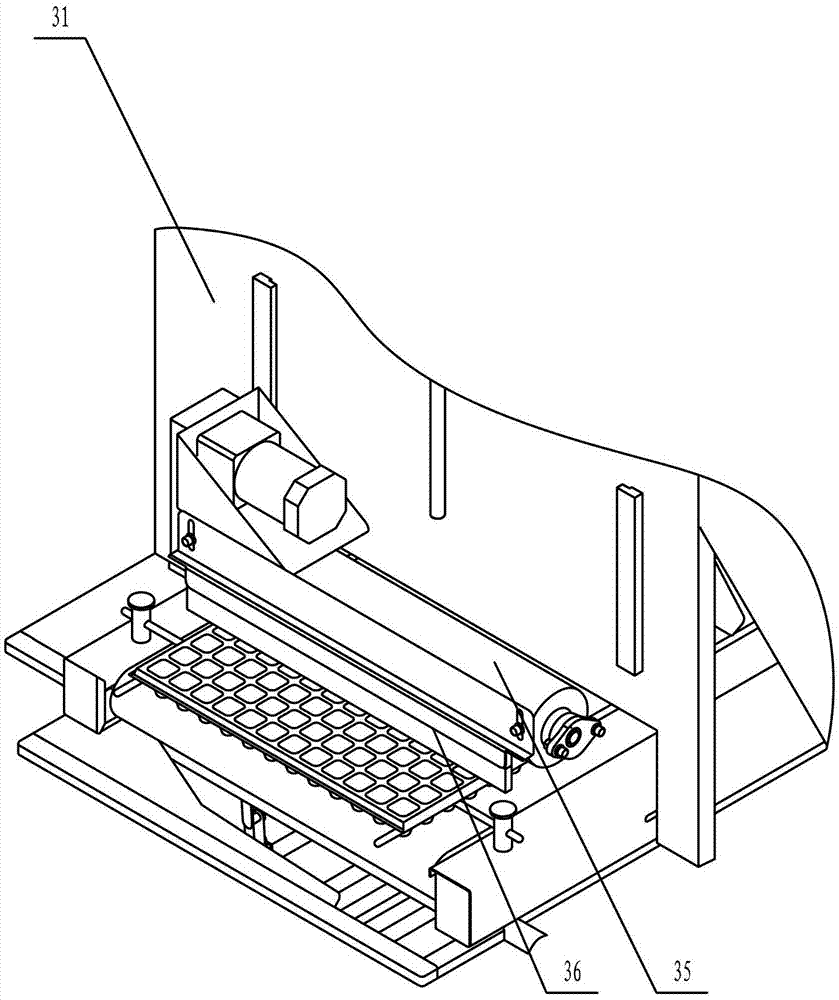

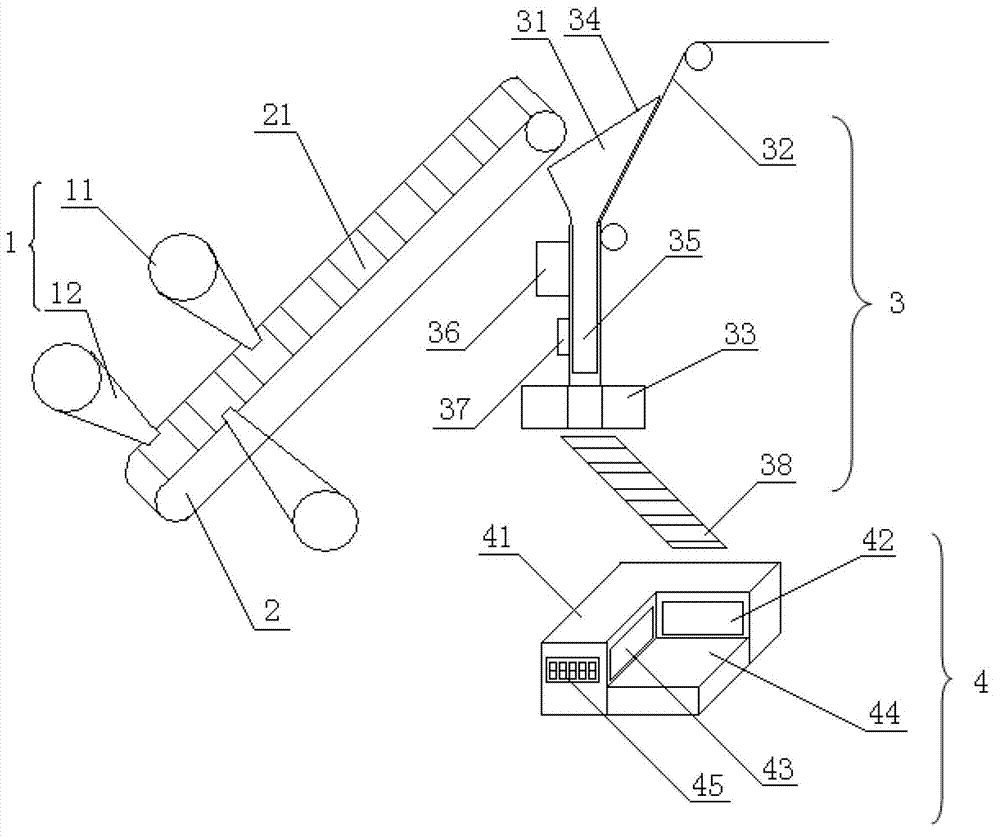

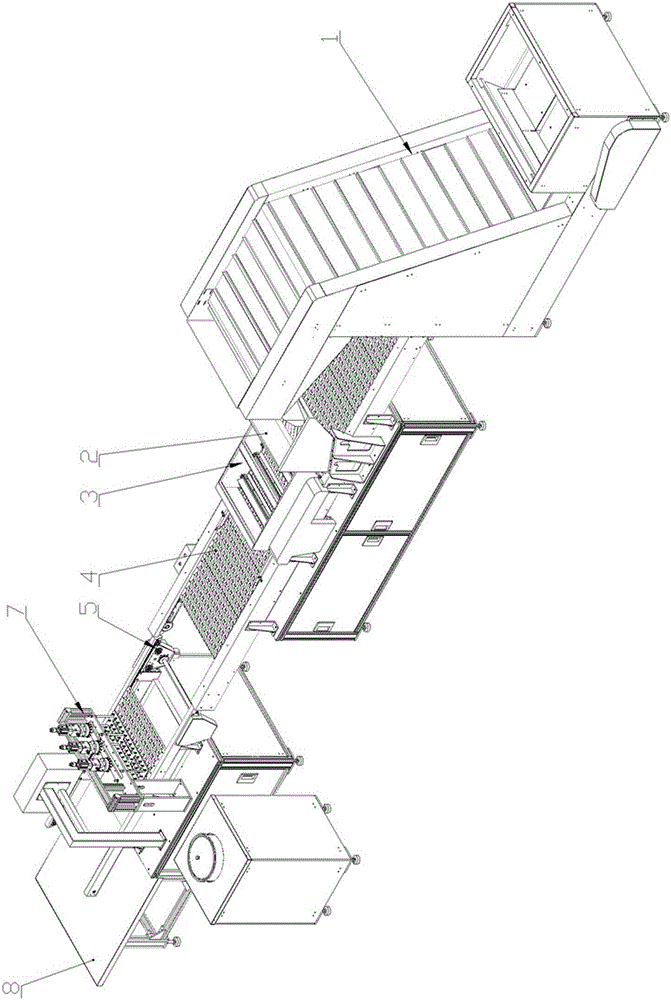

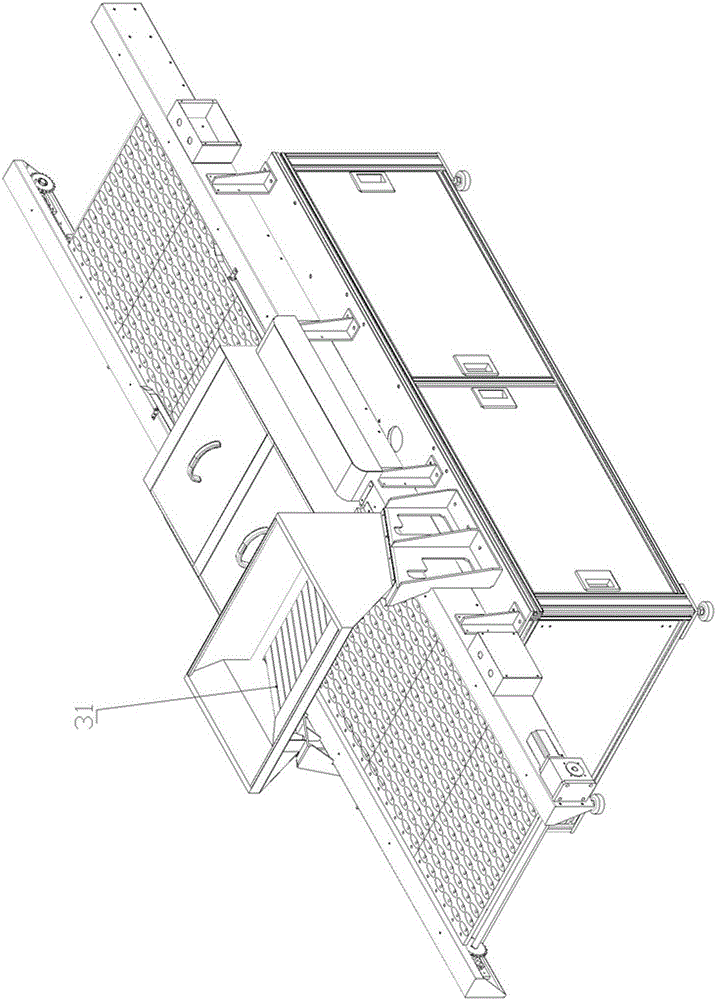

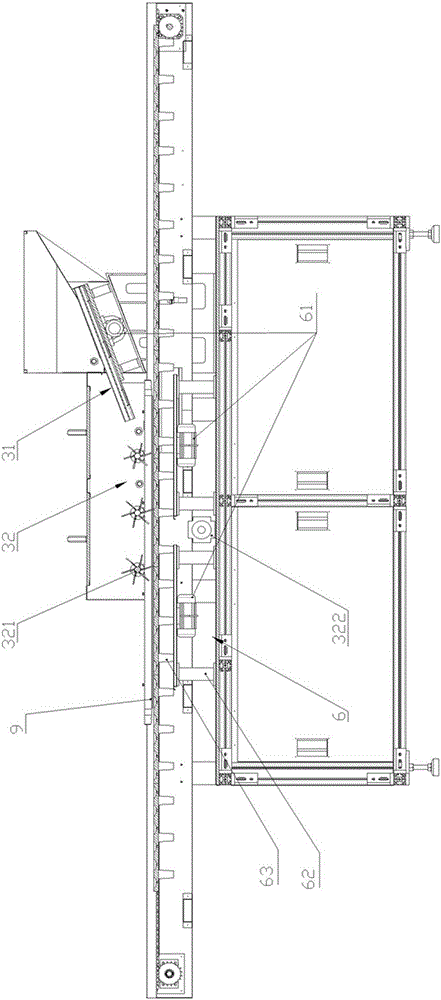

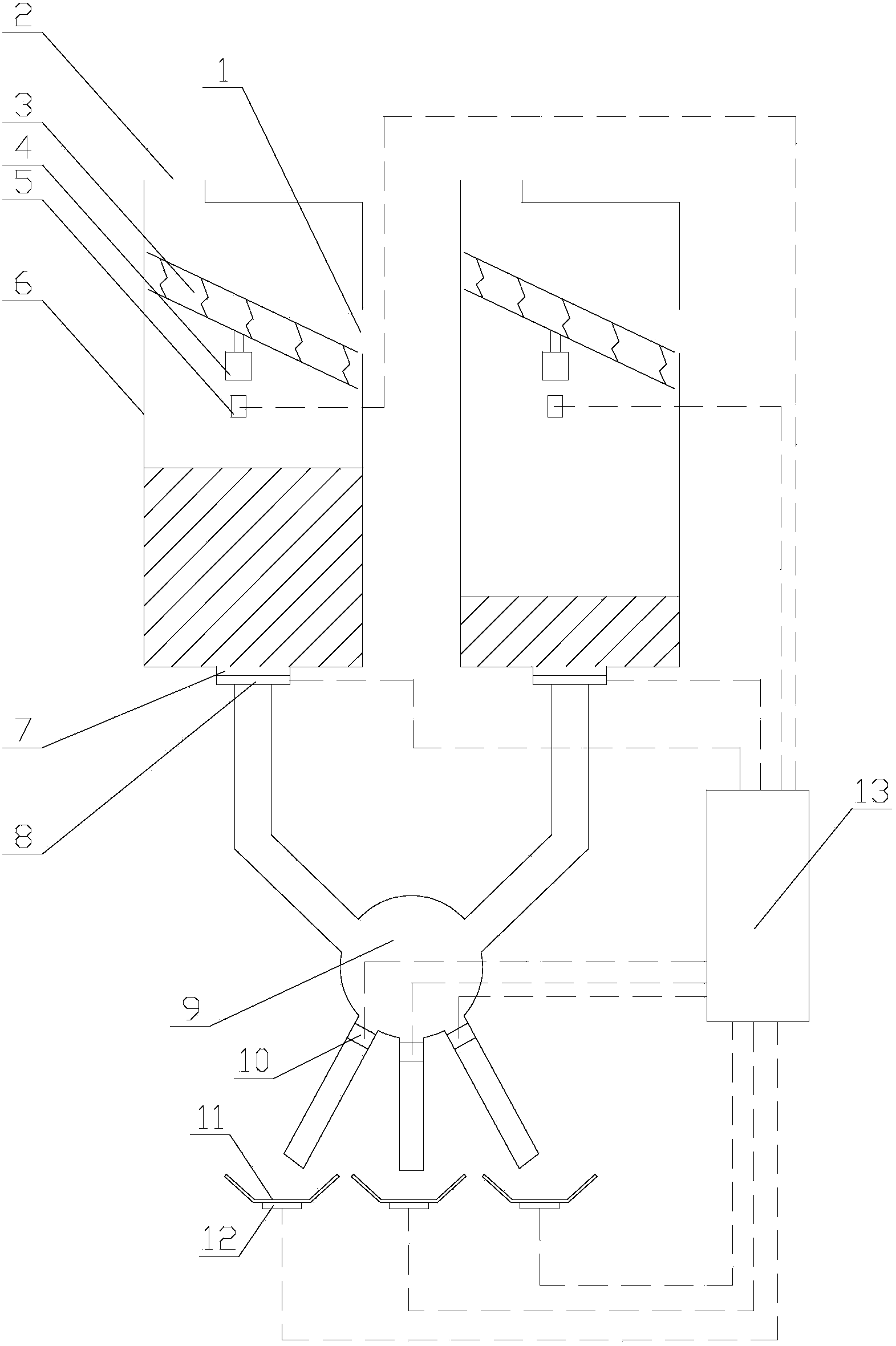

Seedling and seeding machine and seedling and seeding method

ActiveCN102960101AImprove work efficiencyRealize automatic controlCultivating equipmentsSeed depositing seeder partsProduction linePunching

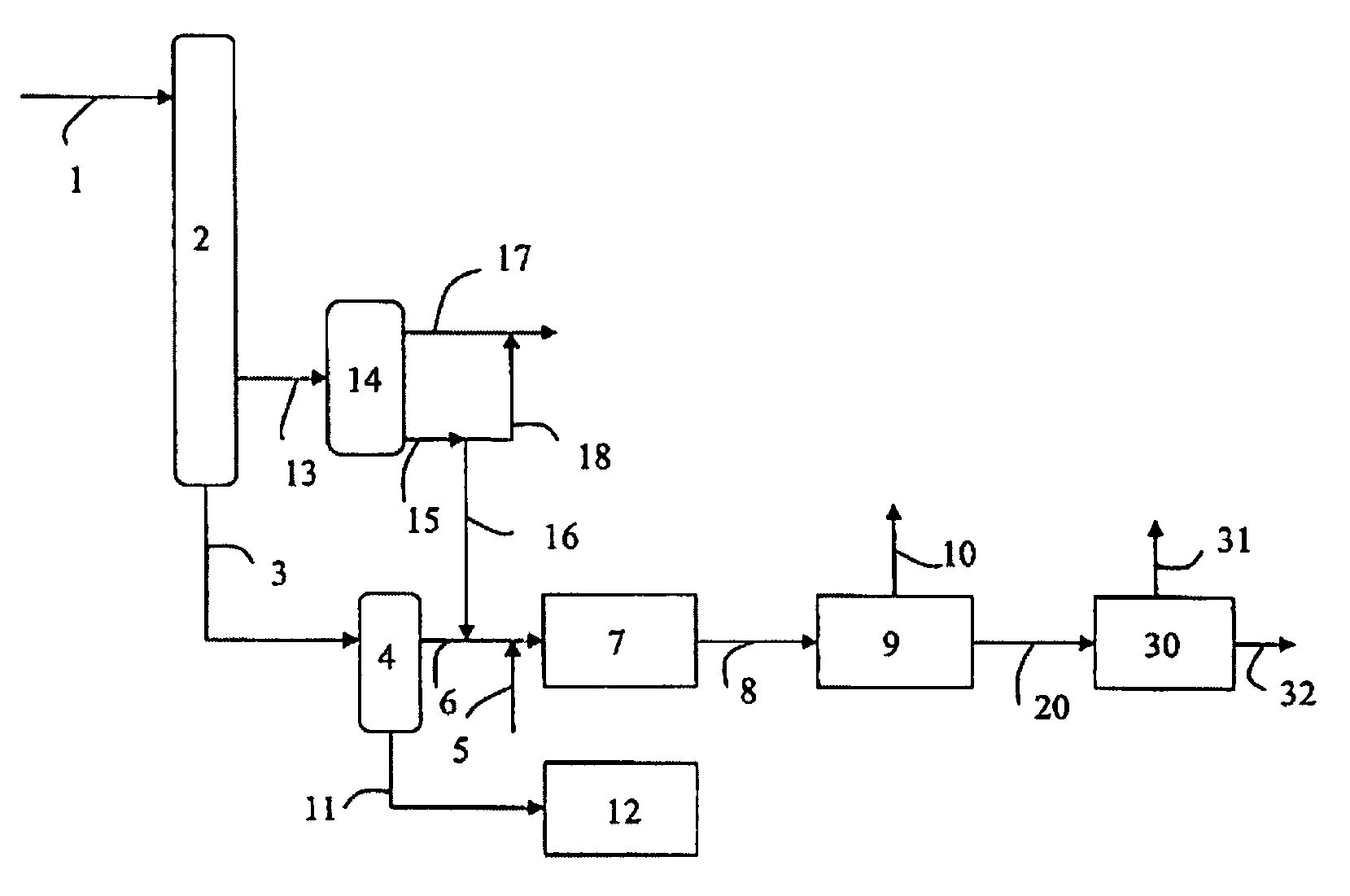

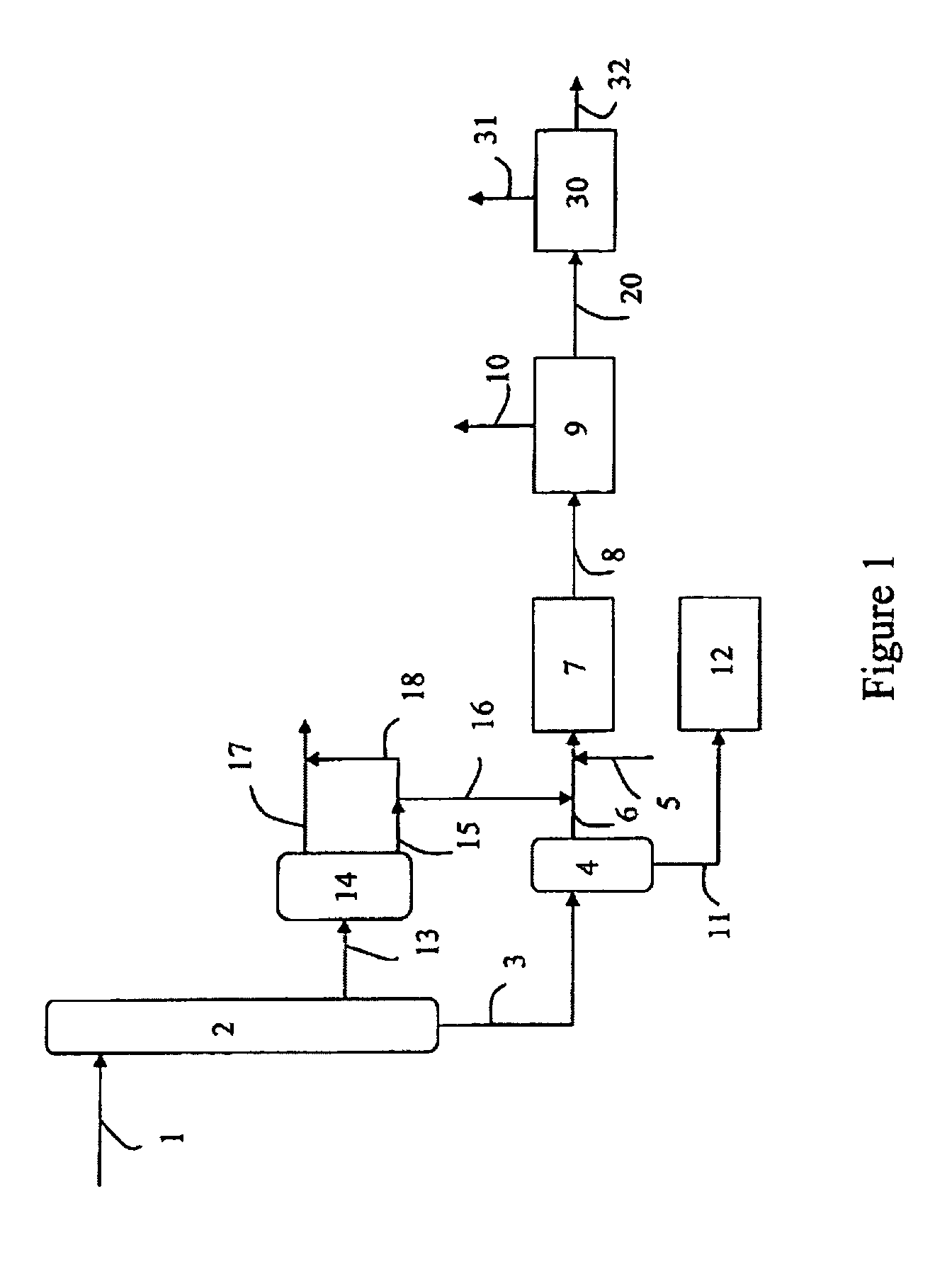

The invention provides a seedling and seeding machine. The seedling and seeding machine comprises a rack, and a conveying device at the top of the rack, wherein a subsoil filling device, a punching device, a needle type tray seeding device, a soil covering device and a watering device are sequentially arranged on the conveying device along the conveying direction of the conveying device. According to the seedling and seeding machine provided by the invention, the subsoil filling device, the punching device, the needle type tray seeding device, the soil covering device and the watering device which are sequentially arranged on the conveying device are used for conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering, so that the whole work of seedling and seeding can be carried out on one production line, and as a result, the working efficiency in seedling and seeding can be effectively improved. The invention also provides a seedling and seeding method. The seedling and seeding method comprises the following steps in sequence: conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering; and by adopting the method, the working efficiency in seedling and seeding can be effectively improved.

Owner:四川川龙拖拉机制造有限公司

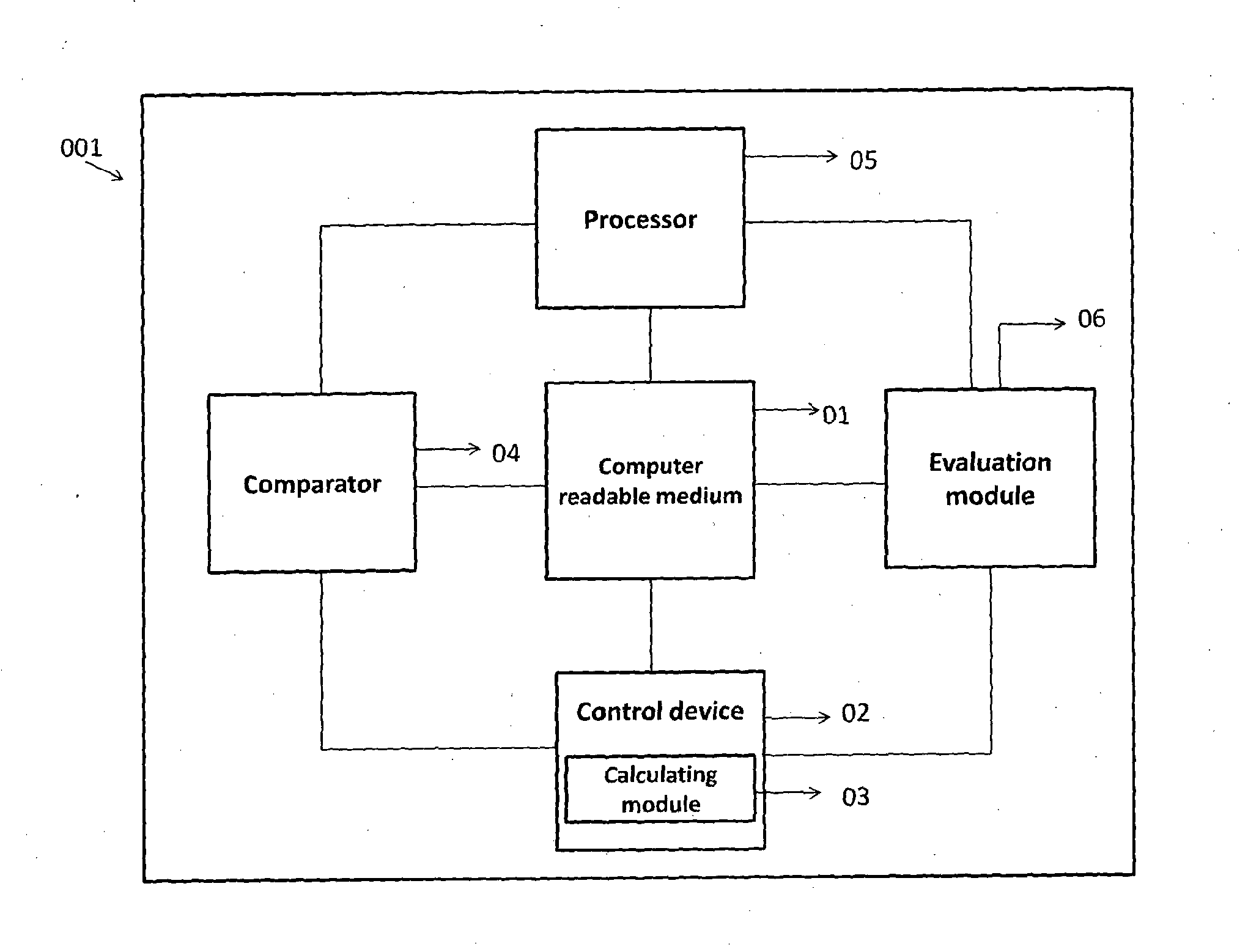

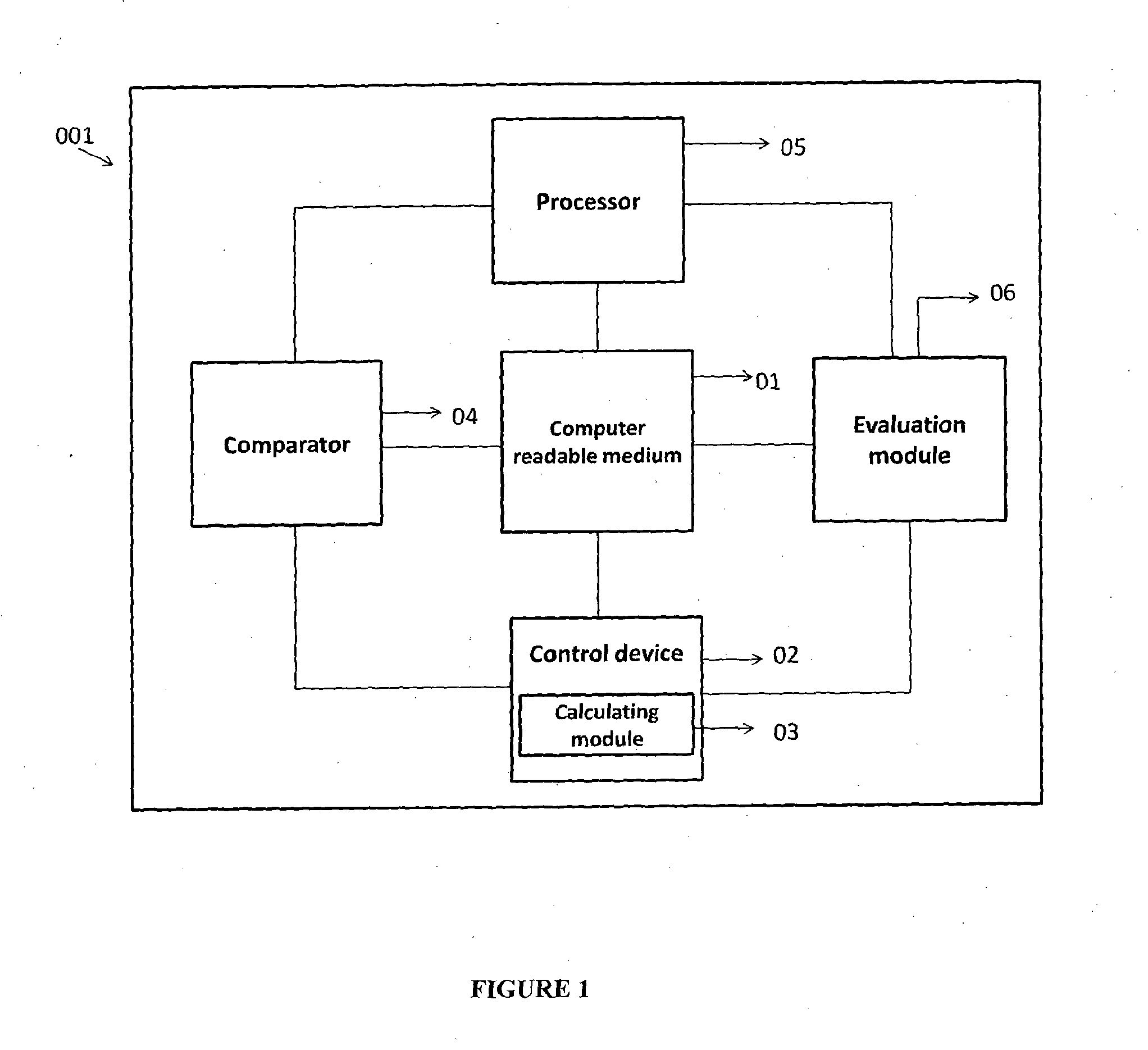

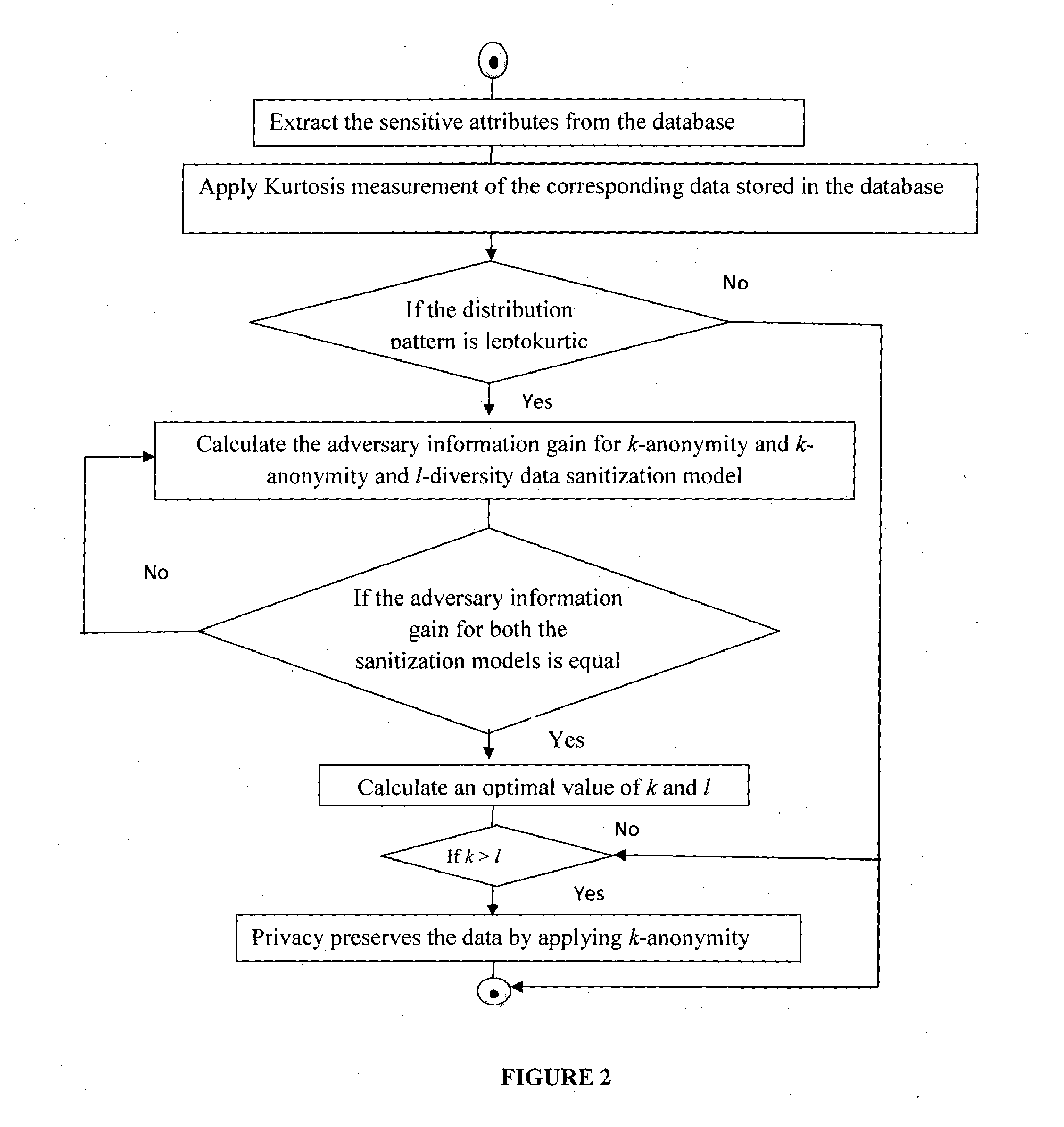

System and method for database privacy protection

ActiveUS20140237620A1Reduce complexitySame quantityDigital data processing detailsAnalogue secracy/subscription systemsK-anonymityAdversary

The invention relates to a system and a method for privacy preservation of sensitive attributes stored in a database. The invention reduces the complexity and enhances privacy preservation of the database by determining the distribution of sensitive data based on Kurtosis measurement. The invention further determines and compares the optimal value of k-sensitive attributes in k-anonymity data sanitization model with the optimal value of l sensitive attributes in l diversity data sanitization model using adversary information gain. The invention reduces the complexity of the method for preserving privacy by applying k anonymity only, when the distribution of the sensitive data is leptokurtic and optimal value of k is greater than the optimal value of l.

Owner:TATA CONSULTANCY SERVICES LTD

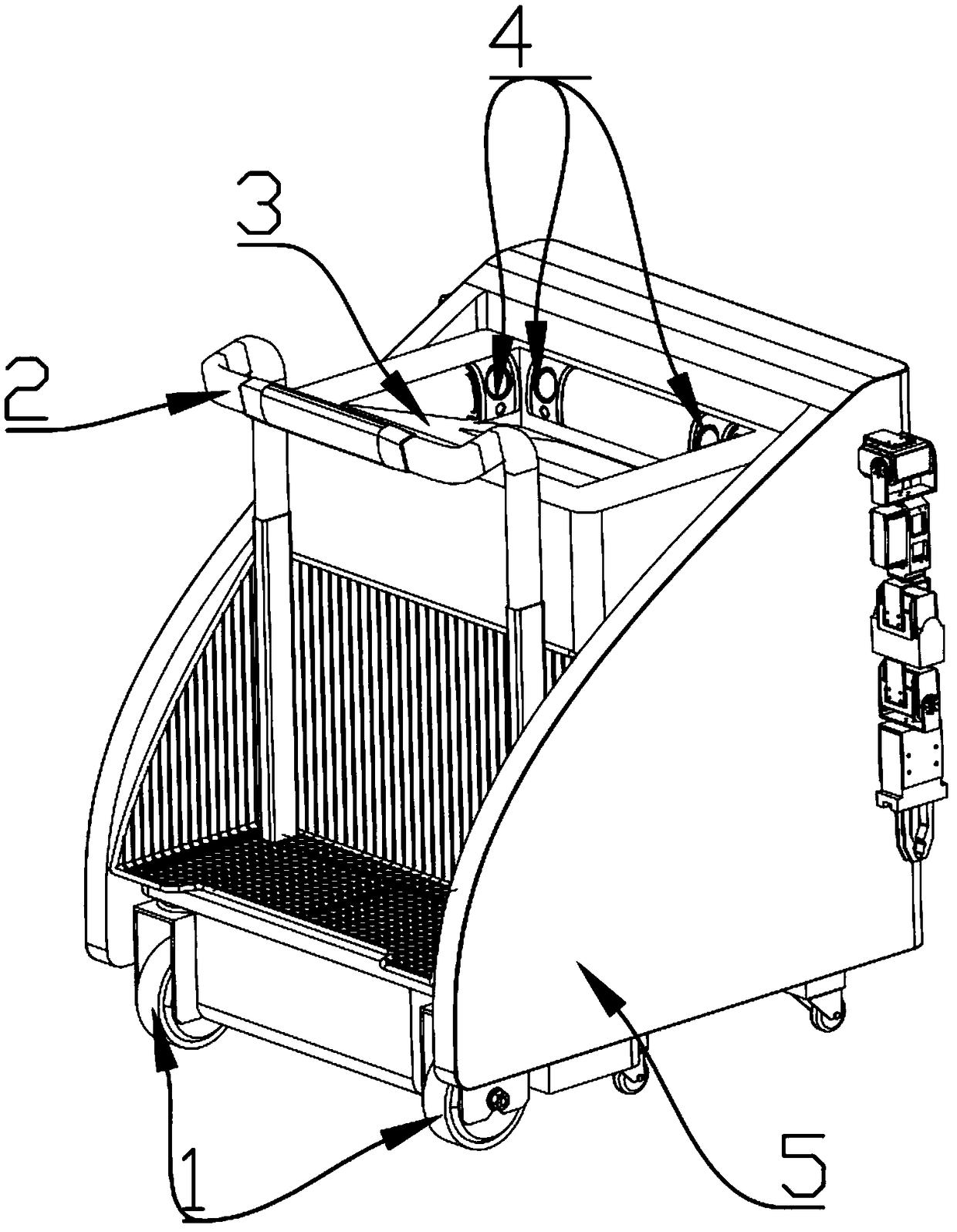

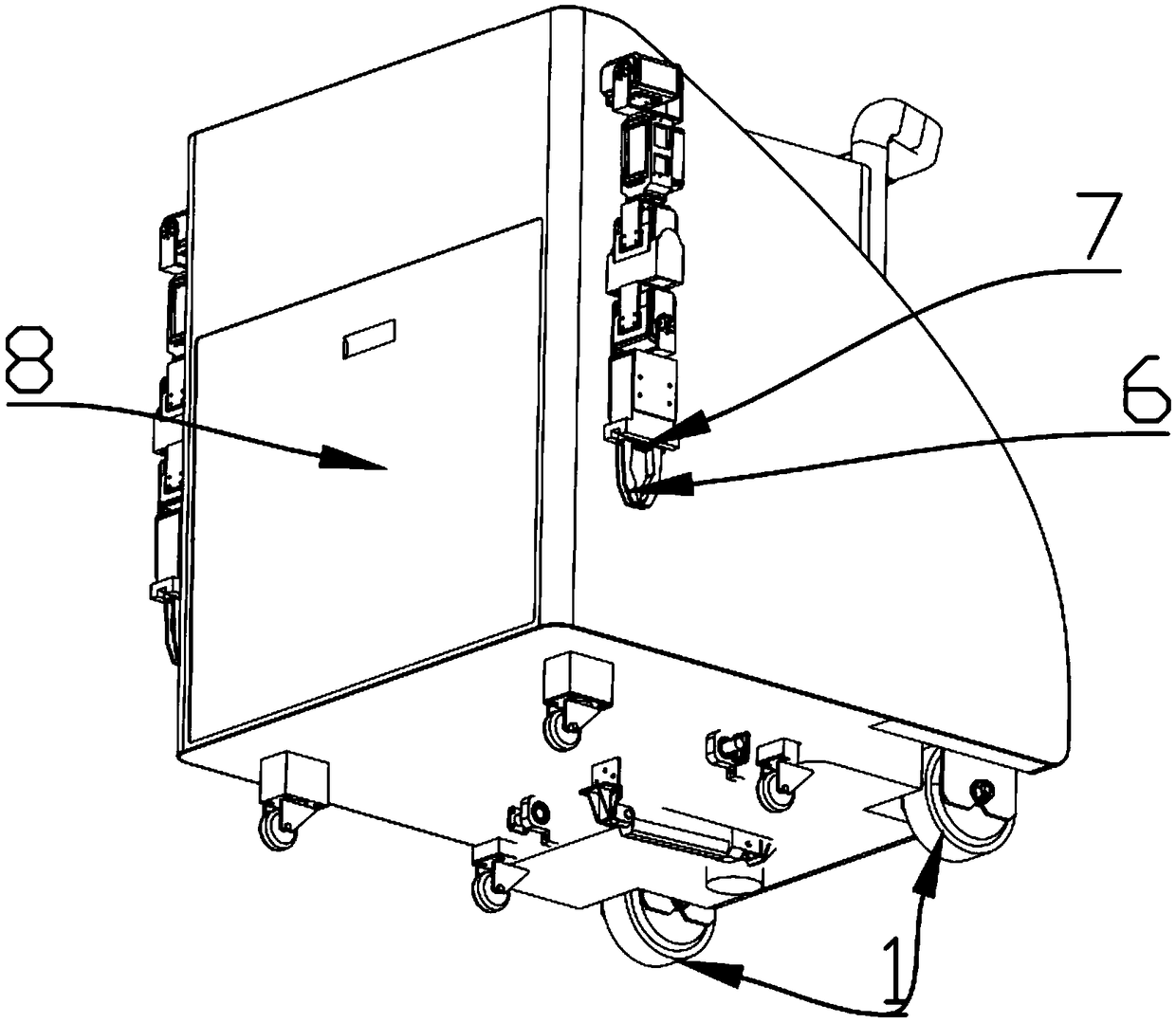

Automatic shopping trolley and business model for unmanned supermarket

PendingCN109367608AEfficient identificationSame quantityCash registersBuying/selling/leasing transactionsSupermarket shopping cartCargo container

The invention discloses an automatic shopping trolley and a business model for an unmanned supermarket. Through a perfect software backstage management system and assorted intelligent goods taking anddelivering equipment, after online purchase, goods are automatically taken and delivered to a user. According to the business model, at least one automatic shopping trolley used in the supermarket and at least one automatic delivering trolley used outside the supermarket are adopted to realize the entire automatic shopping and automatic delivering process; in the case of without the user or withthe user on site, according to the command of the user, the automatic shopping trolley automatically looks up and grabs the goods and automatically scans the bar codes of the goods to automatically weigh, meter and bill the goods so as to automatically charge the user for the goods. After finishing the steps, through point-to-point cargo container transferring, or a mechanical arm grabs the purchased goods in the shopping trolley out and puts the goods in the cargo container of the automatic delivering trolley, and the automatic delivering trolley automatically delivers the goods purchased bythe user remotely to a user appointed site. During the process in the supermarket and in the delivering process, unmanned operation is realized.

Owner:云南中商正晓农业科技有限公司

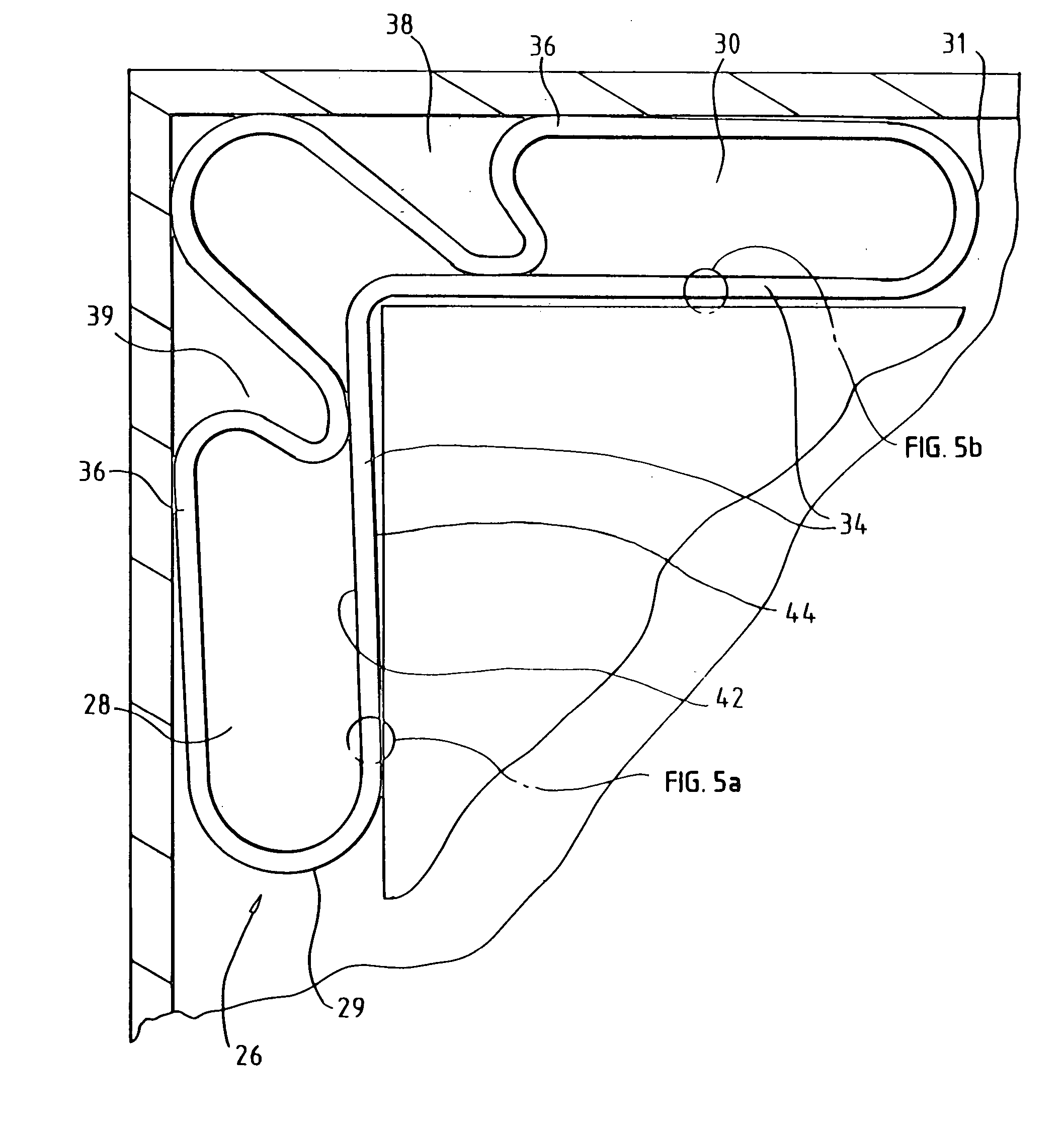

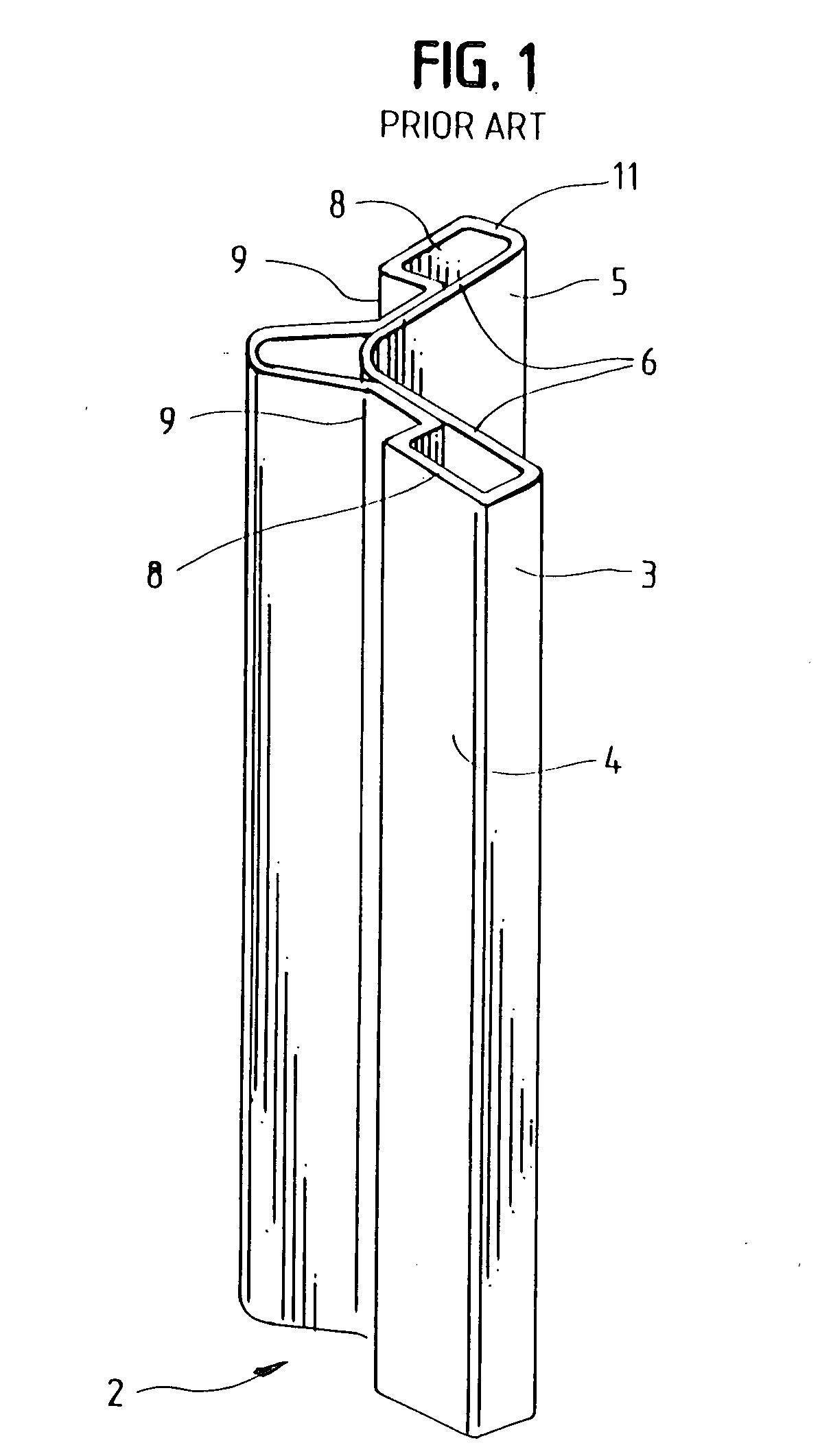

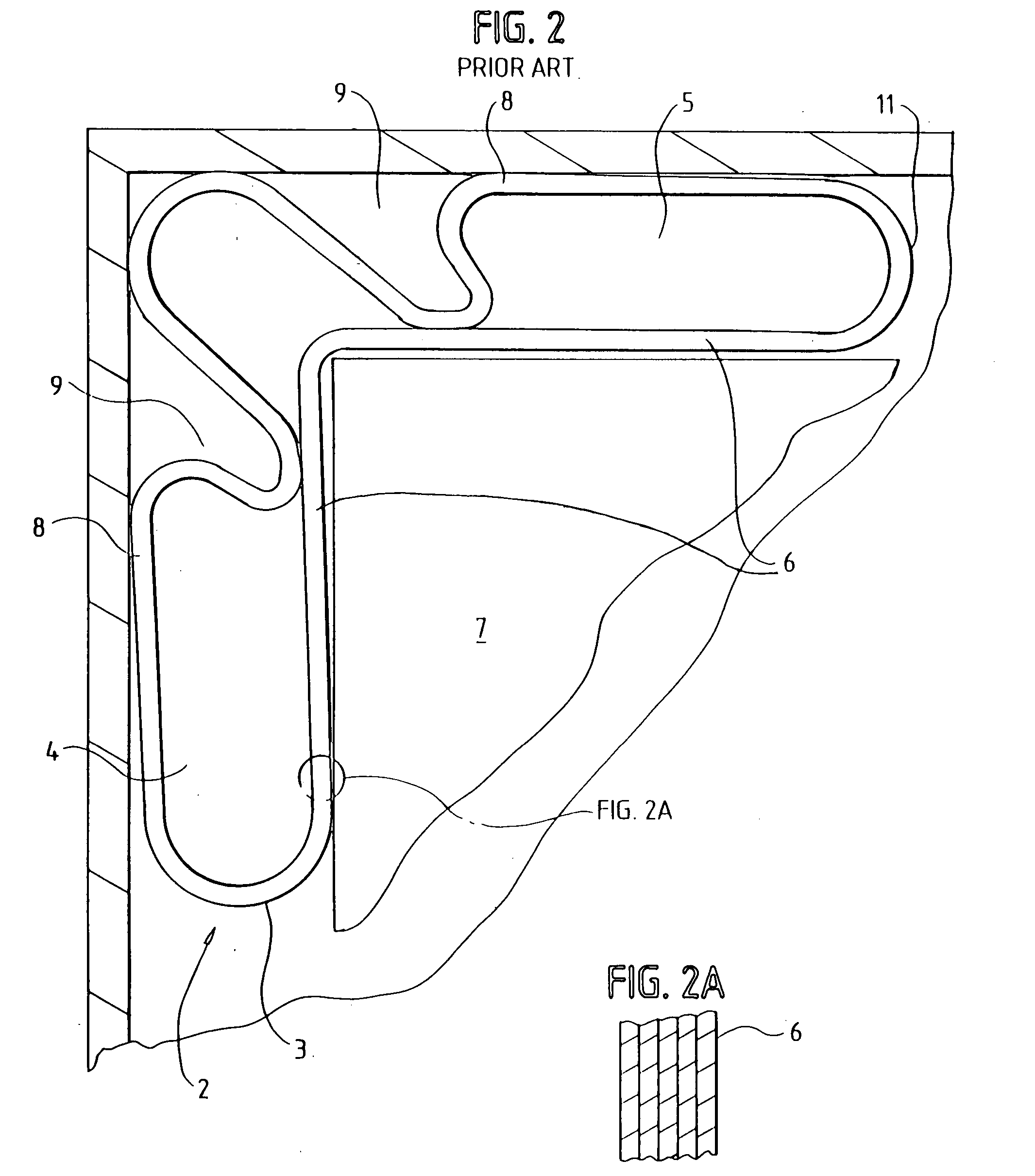

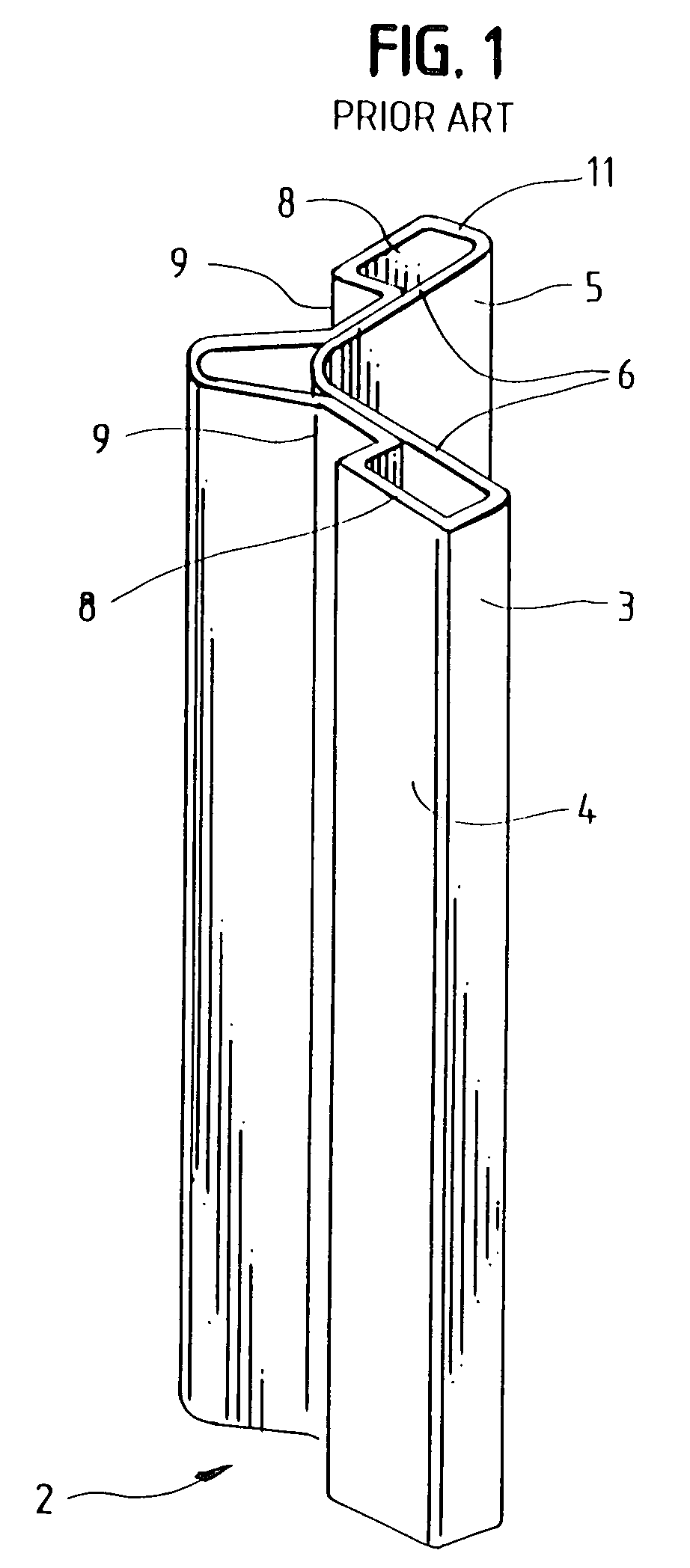

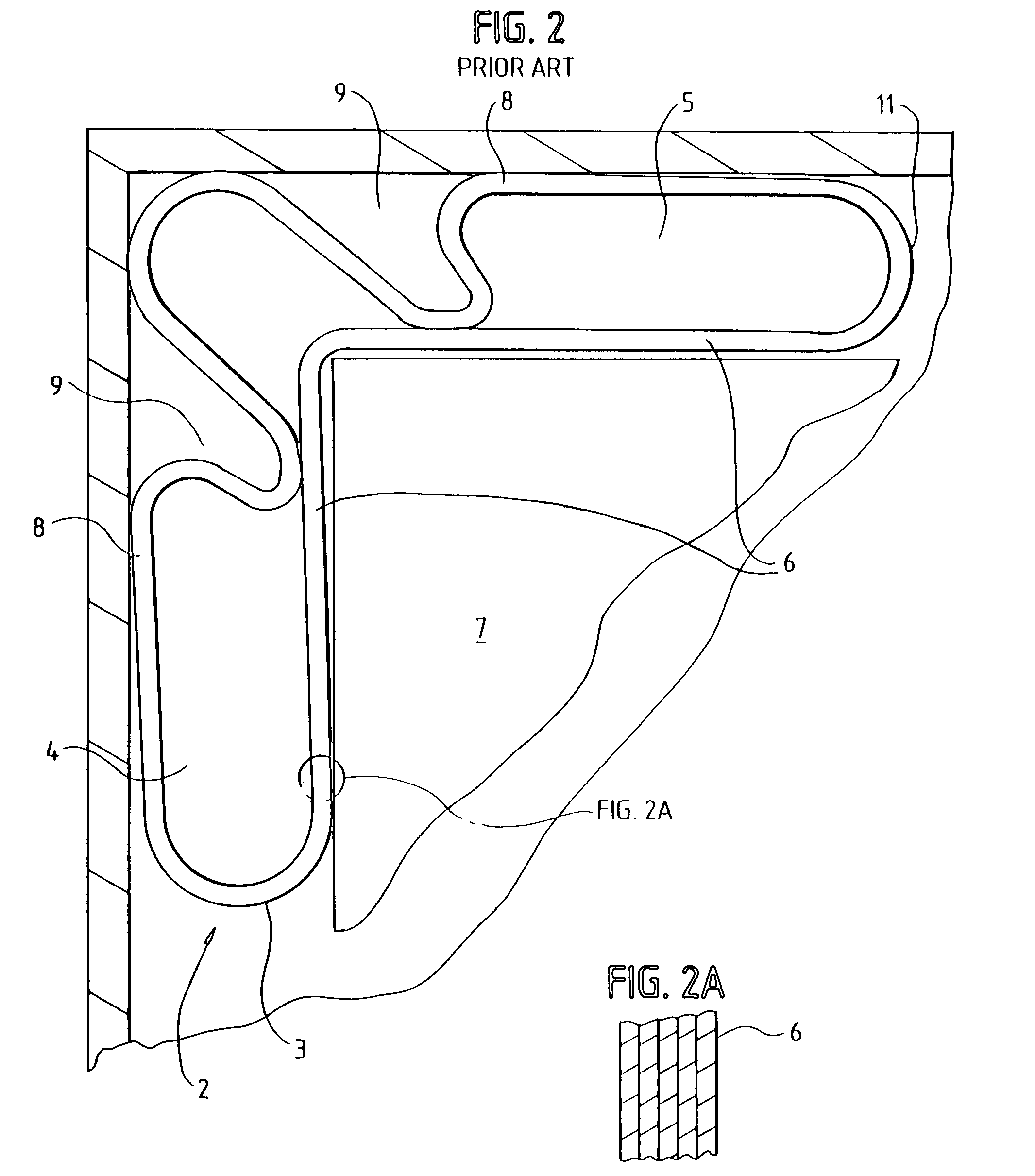

I-beam wall corner post

InactiveUS20050035257A1High strengthIncreased bending stiffnessContainer/bottle contructionStands/trestlesAxial compressionEngineering

An improved support post for cushioning and supporting large products is provided. The post is made from a sheet that is convolutely wound around a mandrel and shaped into a desired shape. The improvement comprises making the sheet from multiple thicknesses of paper so that, upon winding the sheet into a tube, the middle layer of the tube is thicker than the outer layers. The post has a higher axial compression strength than a conventional post, but the same amount (weight) of material.

Owner:SONOCO DEV INC

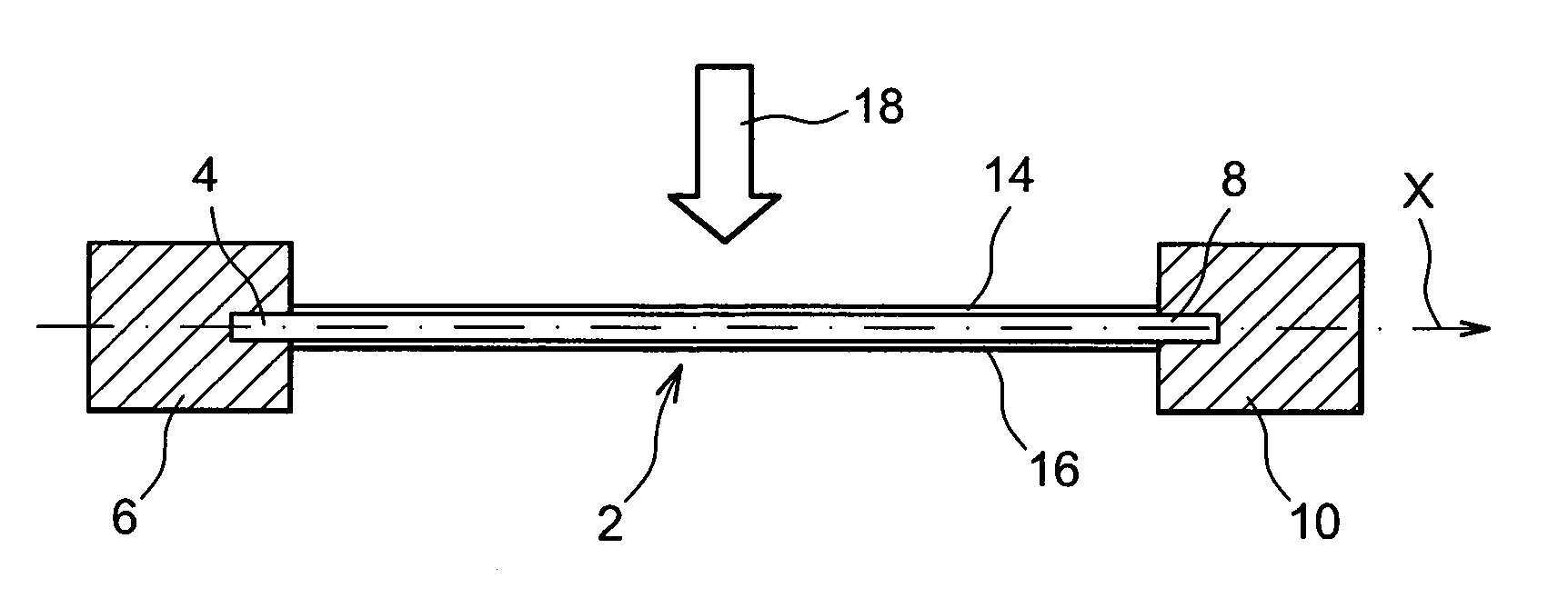

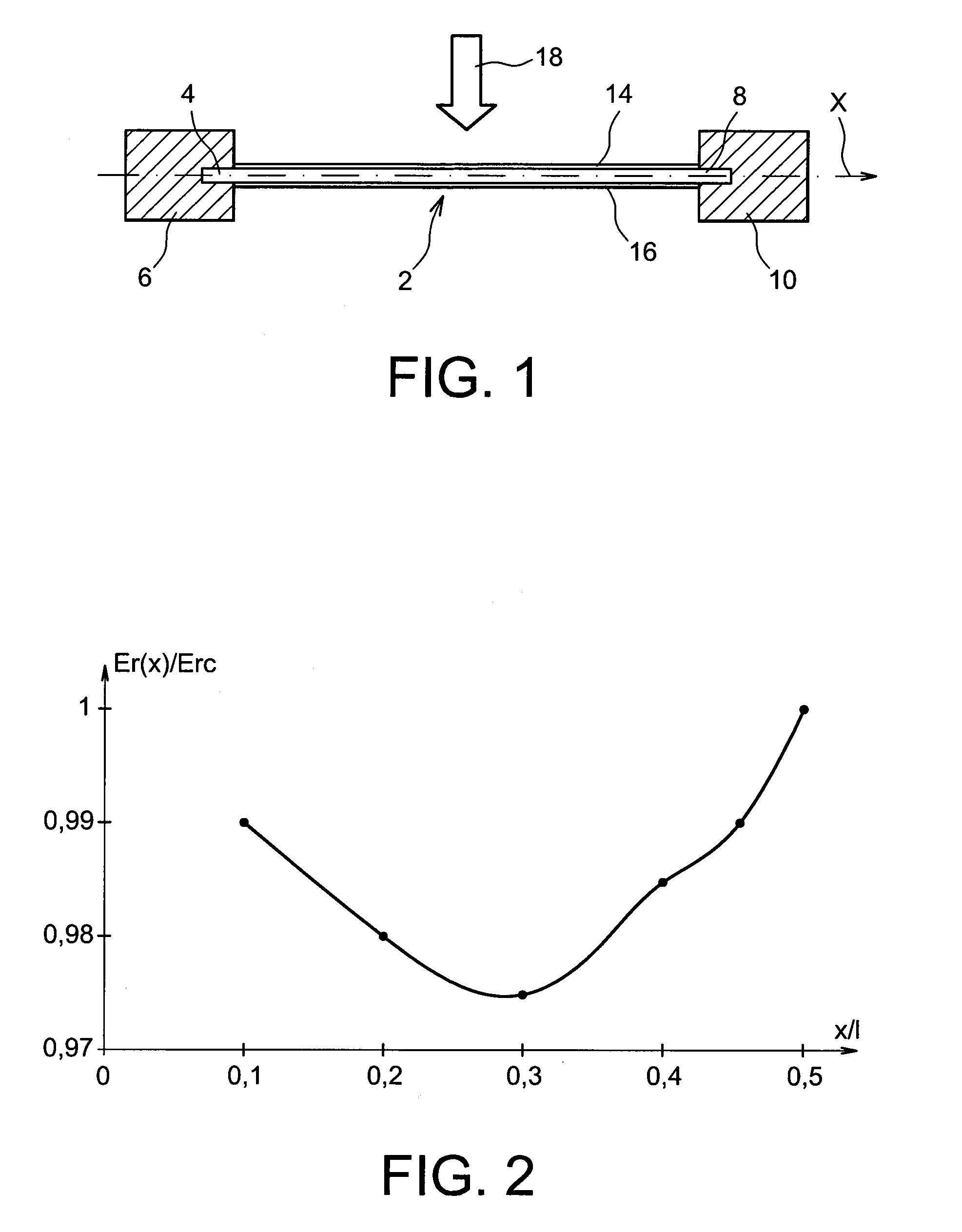

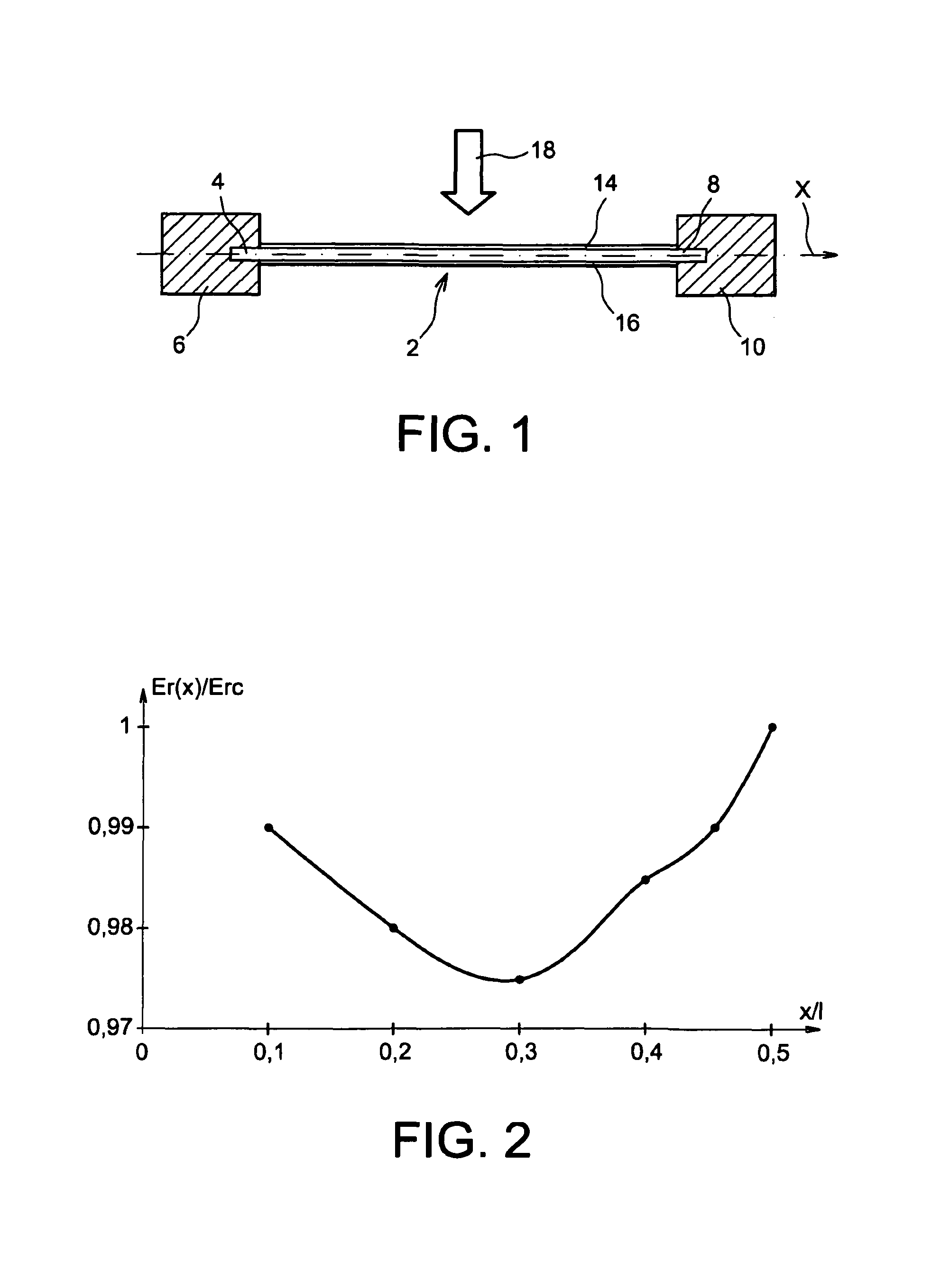

Device for converting mechanical impact energy into electrical energy with optimised efficiency

ActiveUS20100072859A1Information obtainedReduce impactRainfall/precipitation gaugesPiezoelectric/electrostriction/magnetostriction machinesMechanical energyMechanical impact

Device for converting mechanical energy from the impact of objects into electrical energy, comprising a frame, a membrane suspended on said frame by at least a first and second longitudinal end, said membrane being intended to be impacted by said objects in a direction substantially transverse to a mid-plane of the membrane, said membrane comprising a core made from material for transducing mechanical energy into electrical energy, extending from the first longitudinal end to the second longitudinal end, and at least one electrode on a first face of the core and at least one electrode on a second face of the core, said electrodes extending from the first to the second longitudinal end.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

I-beam wall corner post

InactiveUS7014046B2High strengthIncreased bending stiffnessStands/trestlesContainer/bottle contructionAxial compressionUltimate tensile strength

An improved support post for cushioning and supporting large products is provided. The post is made from a sheet that is convolutely wound around a mandrel and shaped into a desired shape. The improvement comprises making the sheet from multiple thicknesses of paper so that, upon winding the sheet into a tube, the middle layer of the tube is thicker than the outer layers. The post has a higher axial compression strength than a conventional post, but the same amount (weight) of material.

Owner:SONOCO DEV INC

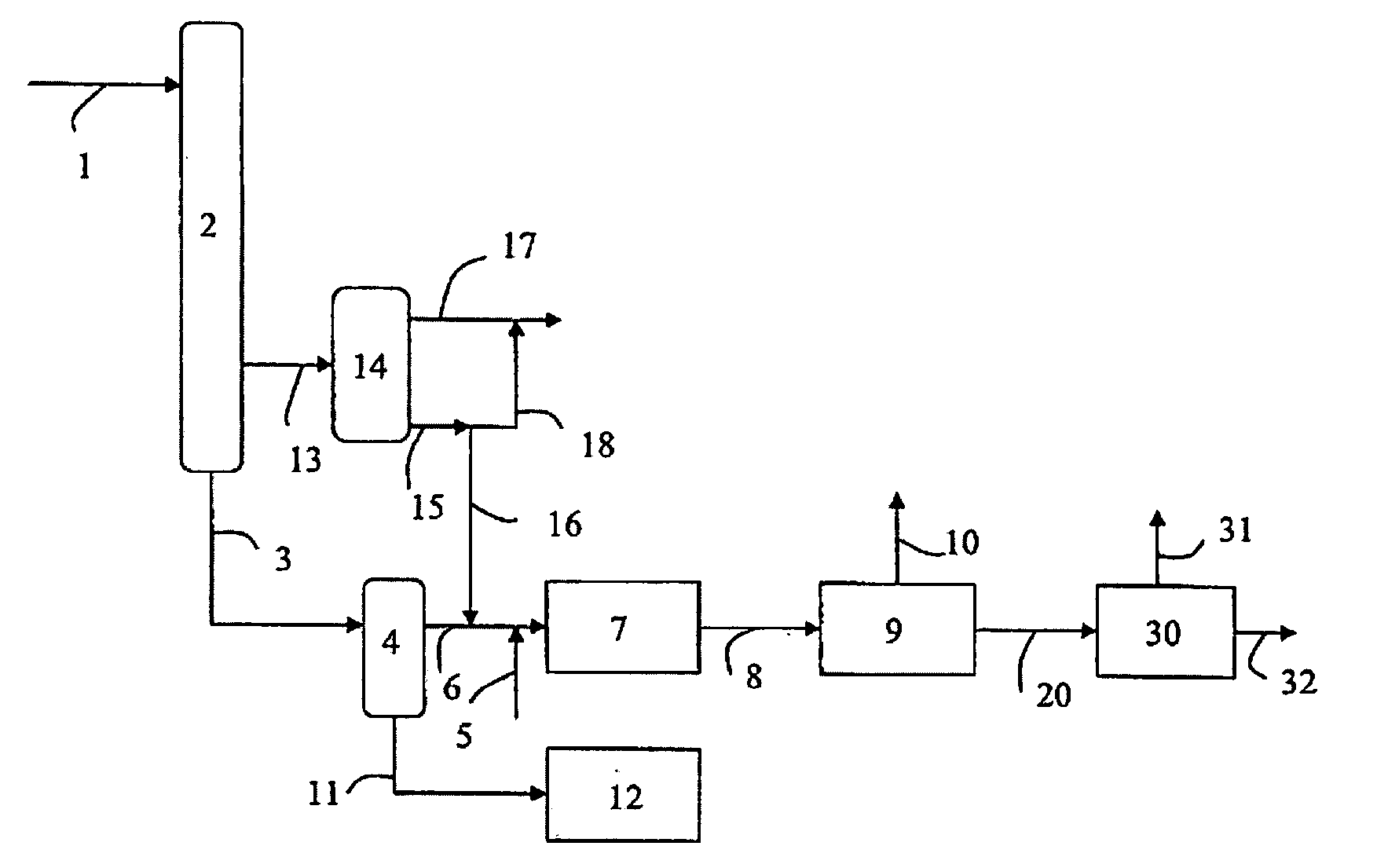

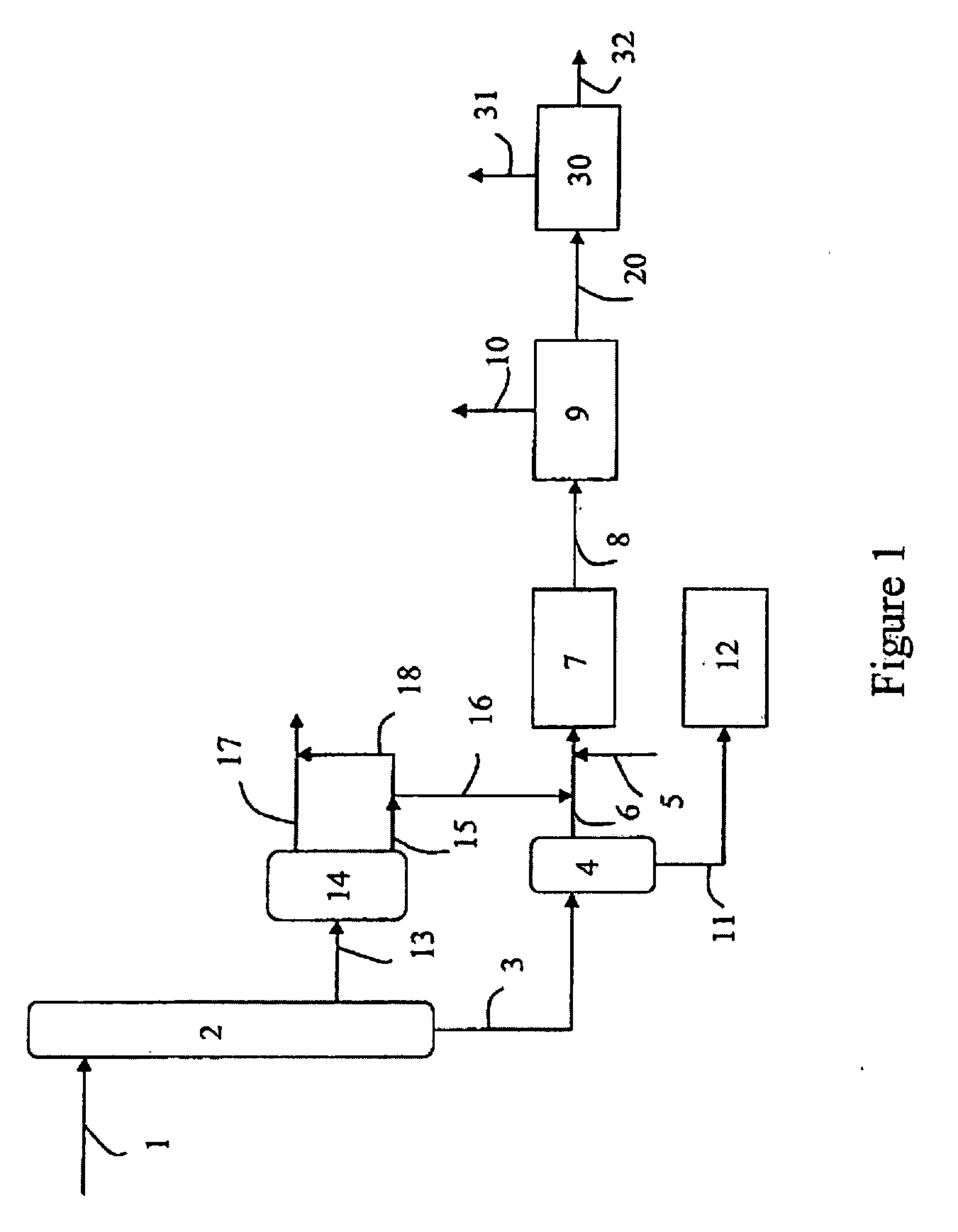

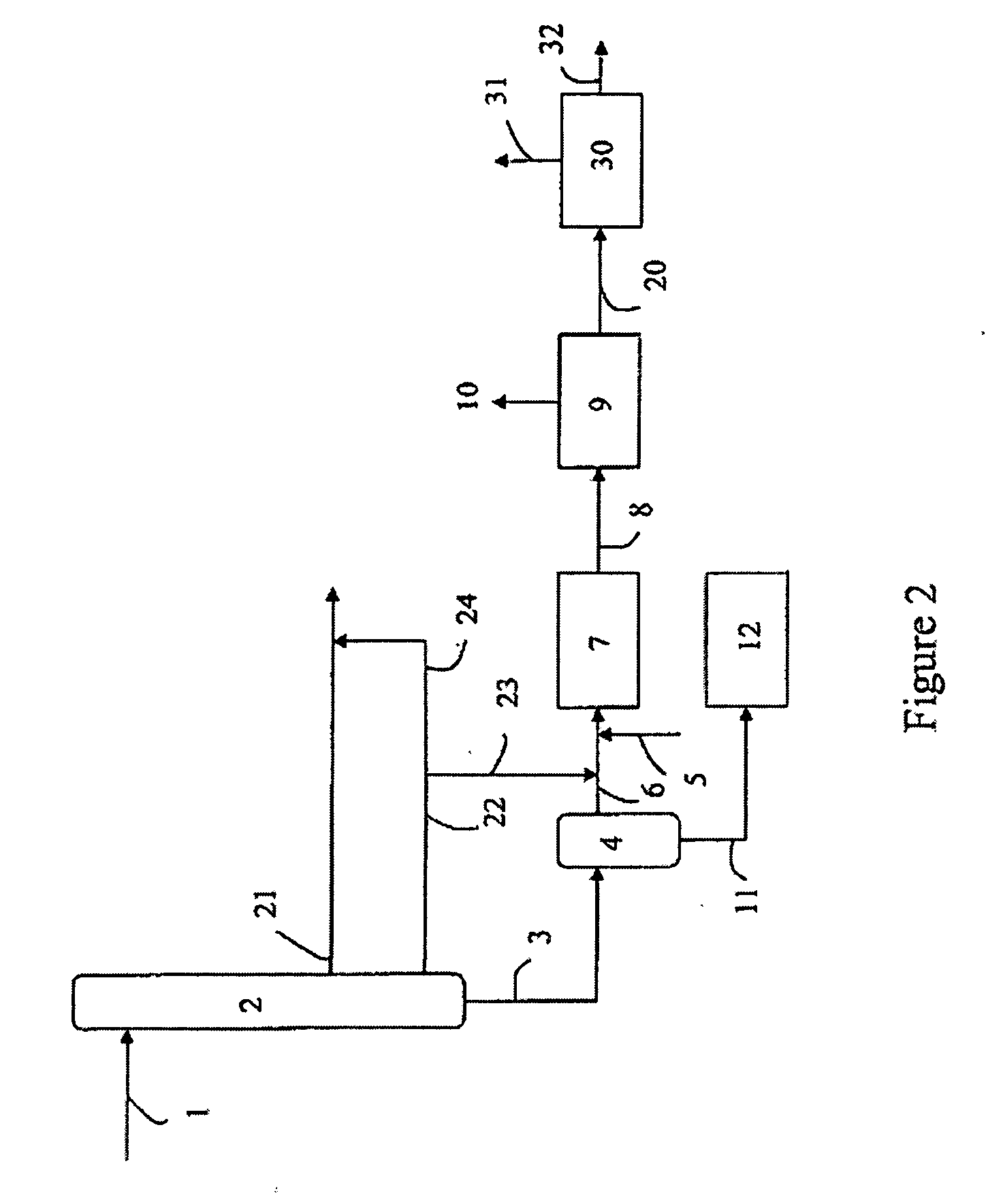

Process of mild hydrocracking including a dilution of the feedstock

InactiveUS7718050B2Increase speedImprove performanceTreatment with plural serial cracking stages onlyCatalytic crackingBoiling pointEffluent

The invention relates to a process for FCC pretreatment by mild hydrocracking of a hydrocarbon feedstock that comprises a vacuum distillate fraction or a deasphalted oil or else a mixture of these two fractions, said primary feedstock, to produce gas oil and an effluent having an initial boiling point of more than 320° C., said effluent (FCC feedstock) then being subjected to a catalytic cracking, process in which at least 85% by weight of said primary feedstock ends above 375° C. and at least 95% by weight of said primary feedstock ends below 650° C., whereby the mild hydrocracking is performed under an absolute pressure of 2 to 12 MPa and at a temperature of between 300 and 500° C., characterized in that the hydrocarbon feedstock also comprises a lighter hydrocarbon fraction, a so-called secondary feedstock, of which at least 50% by weight ends below 375° C. and at least 80% ends above 200° C.

Owner:INST FR DU PETROLE

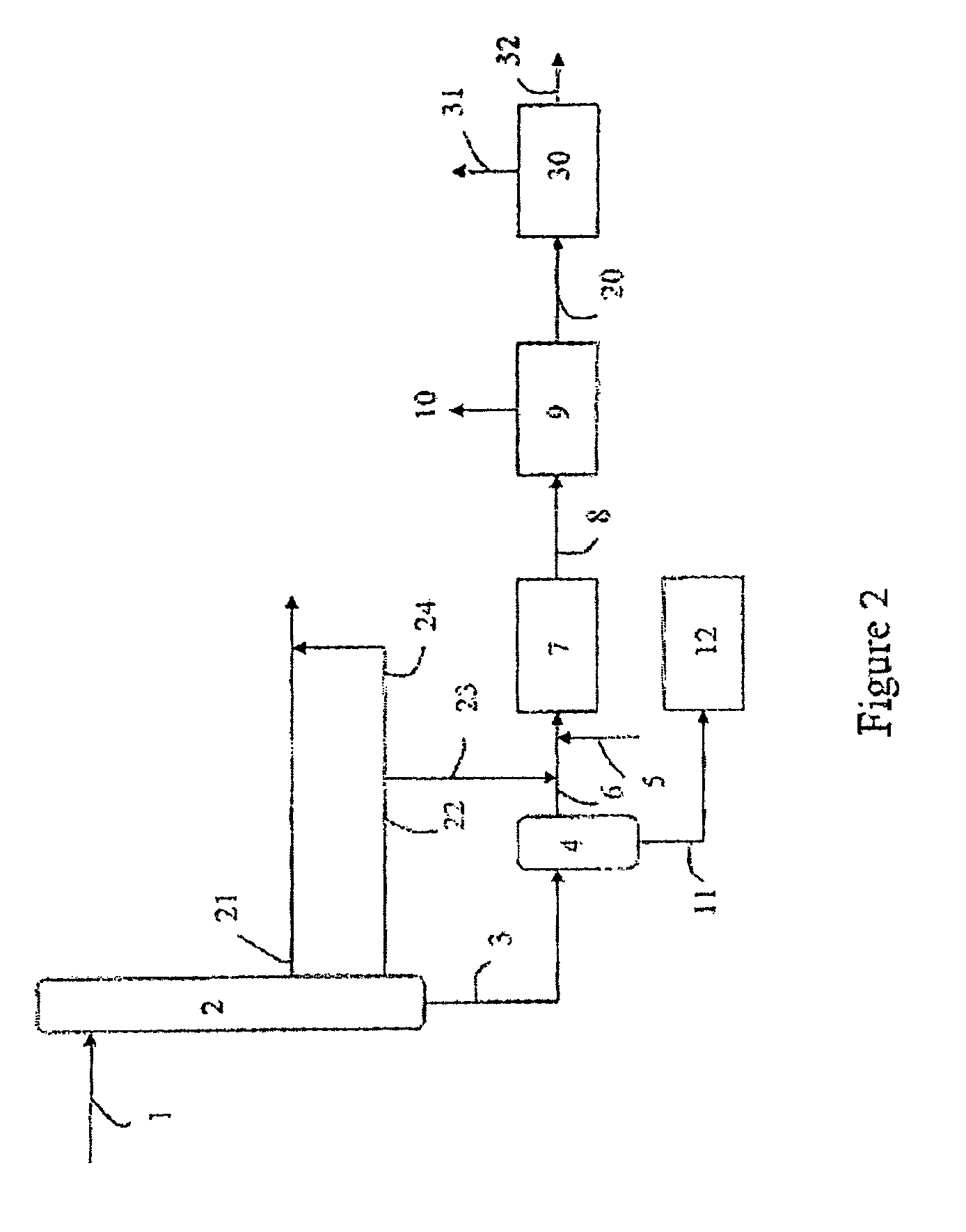

Coil mutual-supplementary magnetic pass switching biconvex permanent magnetic motor

InactiveCN101079557AImprove cooling conditionsSimple and strong structureMagnetic circuit rotating partsMagnetic circuit stationary partsHigh power densityConductor Coil

The invention discloses a motor with stronger torque output ability and higher power density, which consists of stator (1) and rotor (4), wherein the rotor (4) lies in the interior or exterior of the stator (1); the stator (1) and rotor (4) are double-salient pole structures with the gathered winding (3) and permanent magnet (2) on the stator (1); the radial of second and fourth winding coils are faced with each gathered winding coil in the U-shaped magnetic iron groove of two adjacent stators (1); four winding coils connect front head to end sequently; the permanent magnet (2) is set between two adjacent U-shaped magnetic iron core.

Owner:SOUTHEAST UNIV

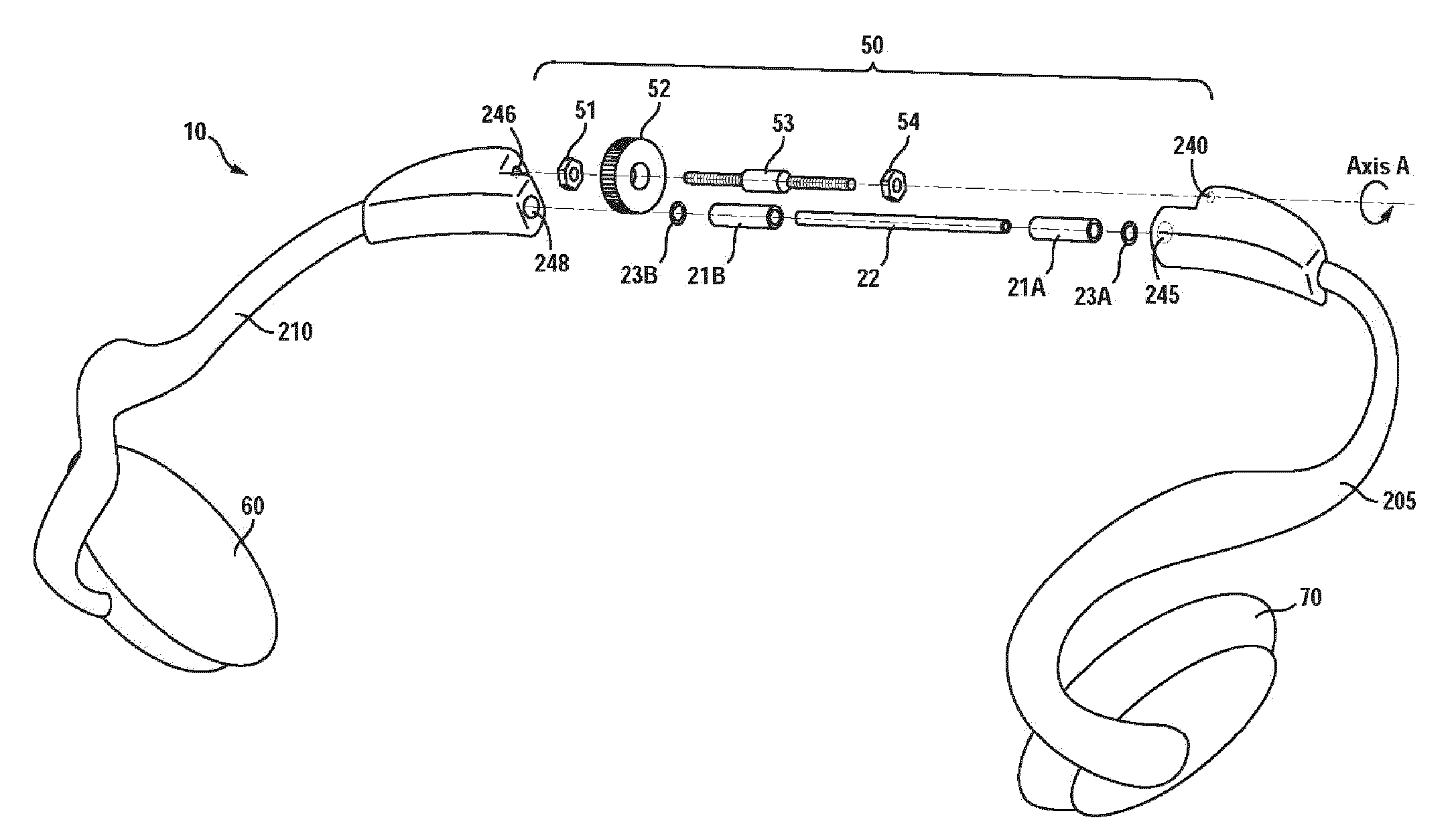

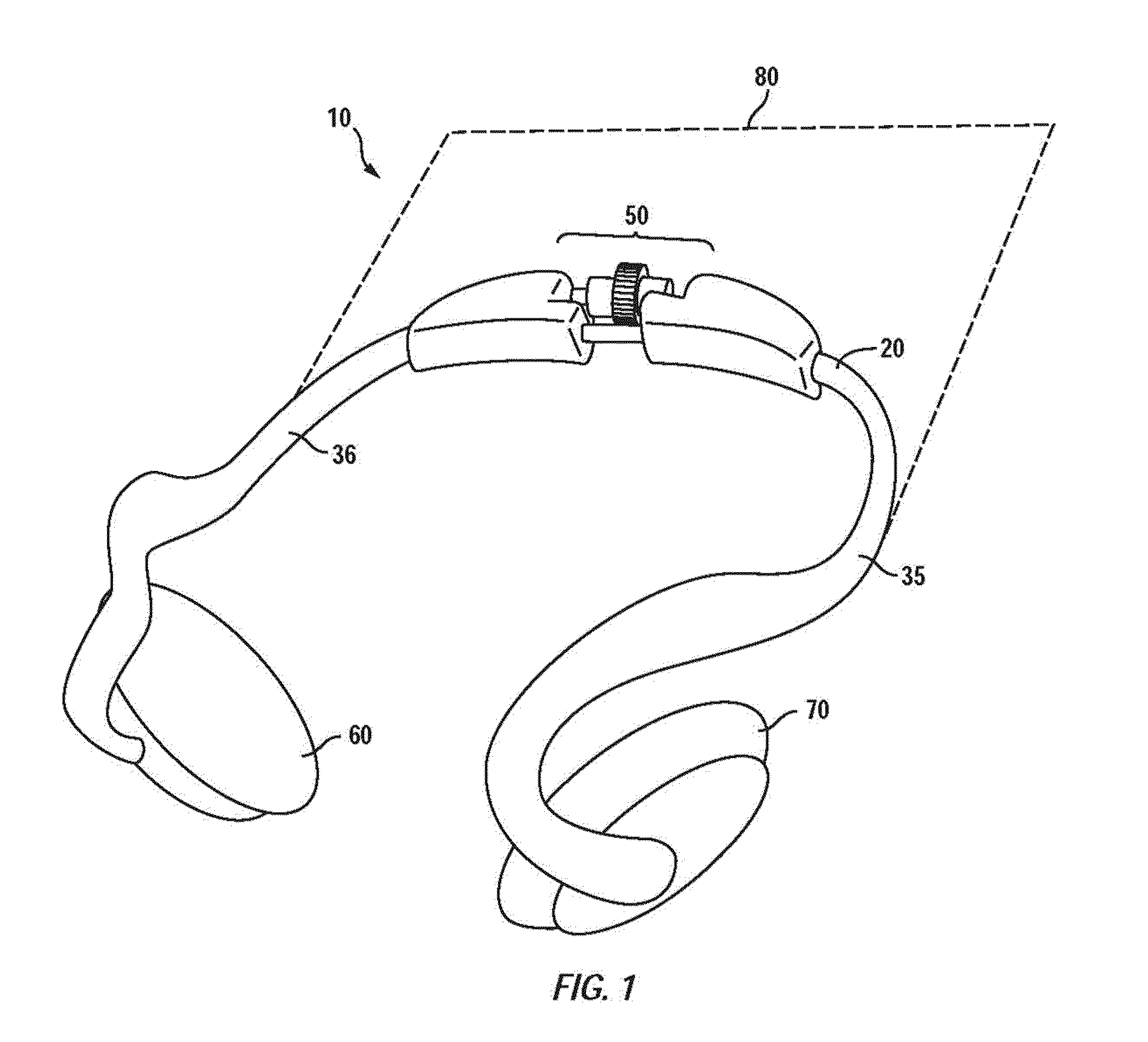

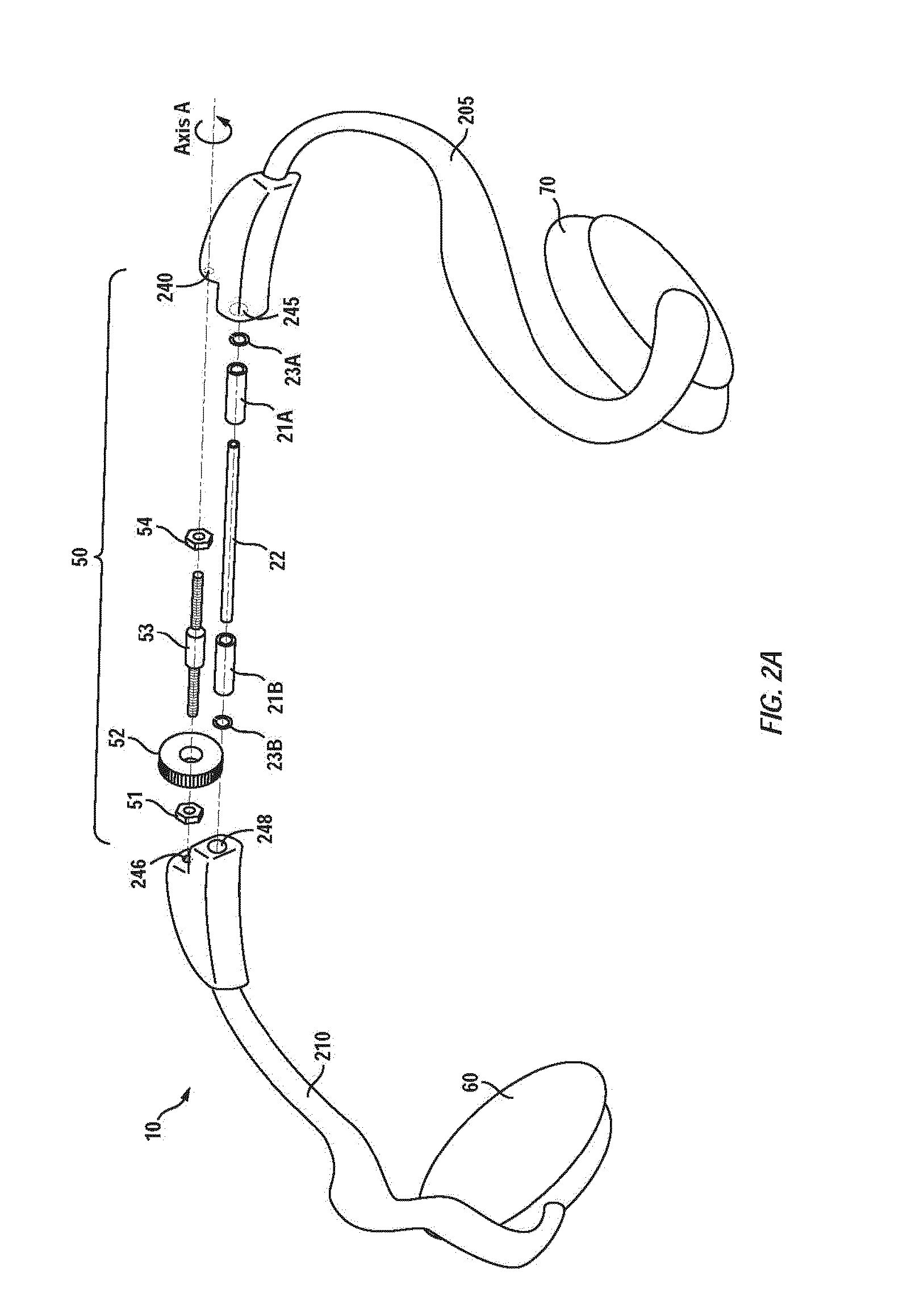

Personal Audio Set With Adjustable Force Mechanisms

ActiveUS20100189303A1More targeted controlSuppress leakage of soundHeadphones for stereophonic communicationSupra/circum aural earpiecesEngineeringHeadphones

Owner:LOGITECH EURO SA

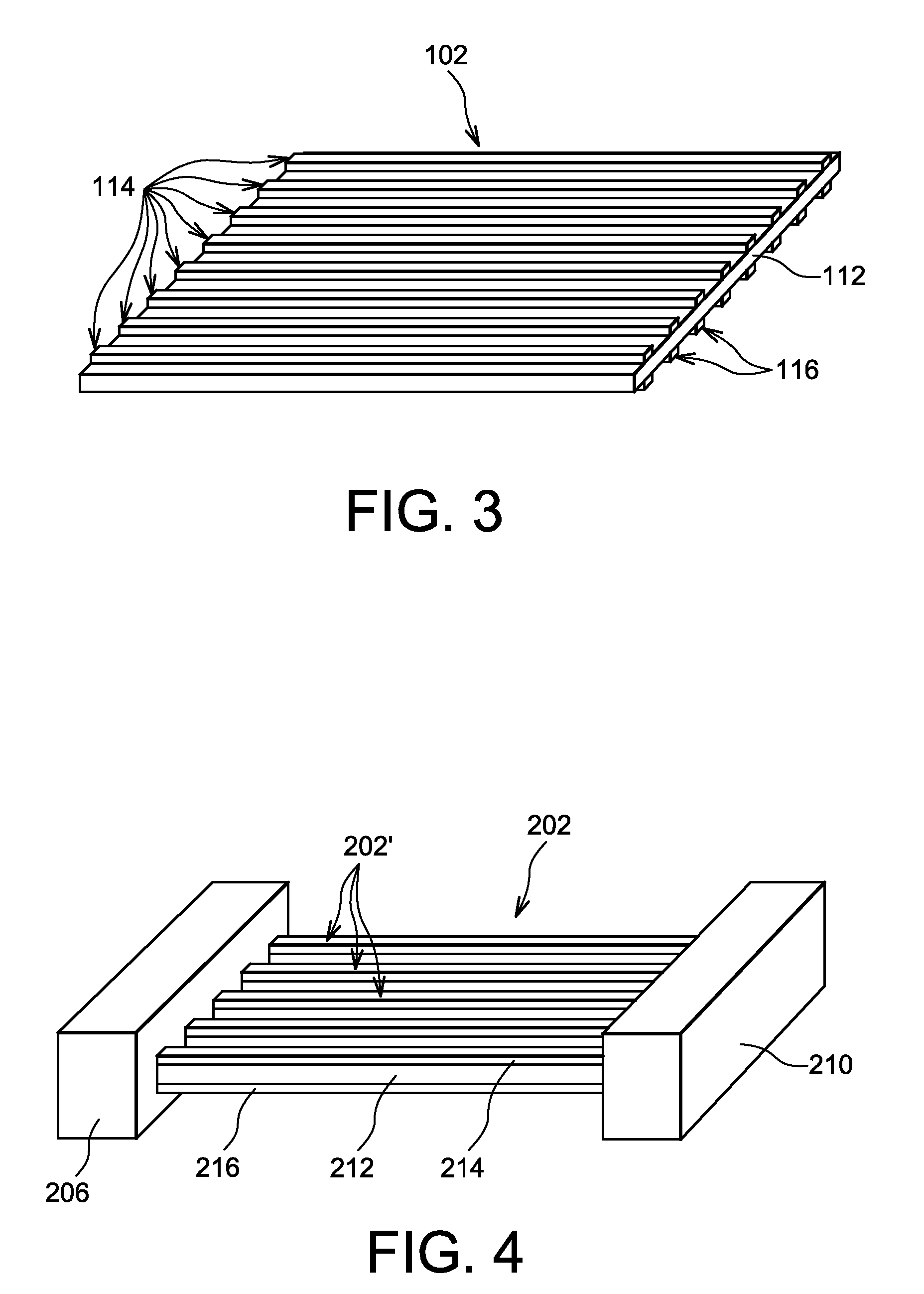

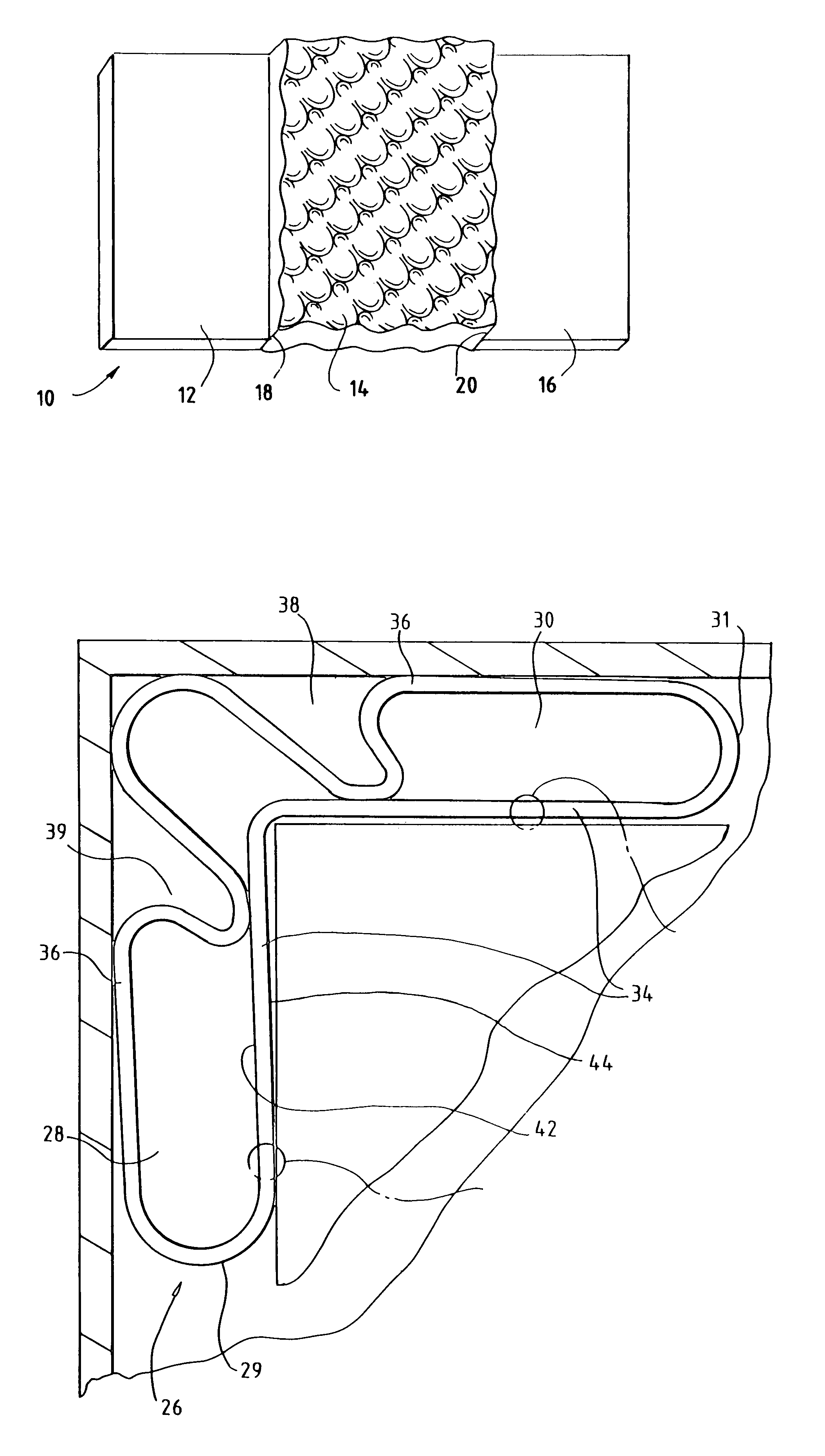

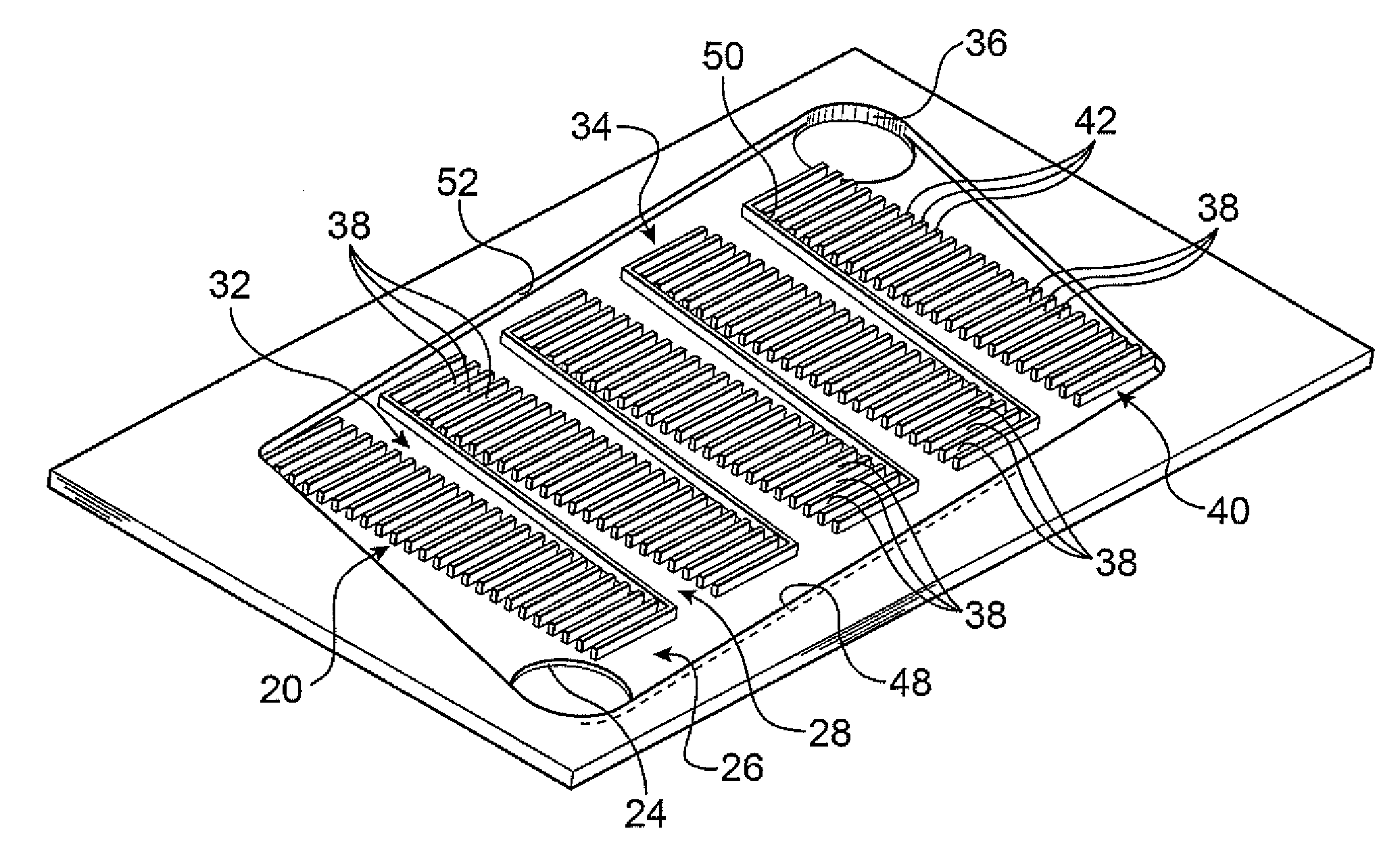

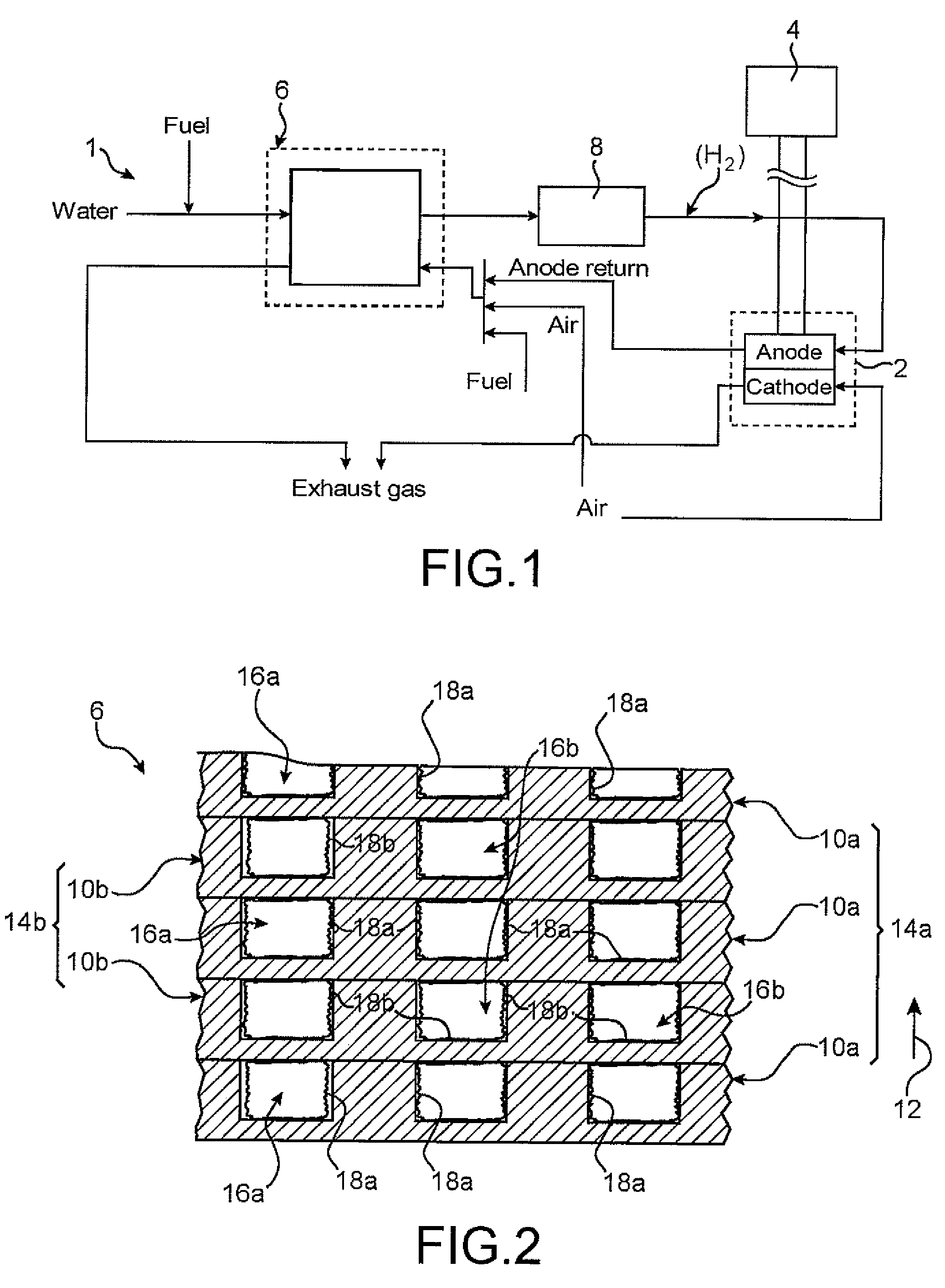

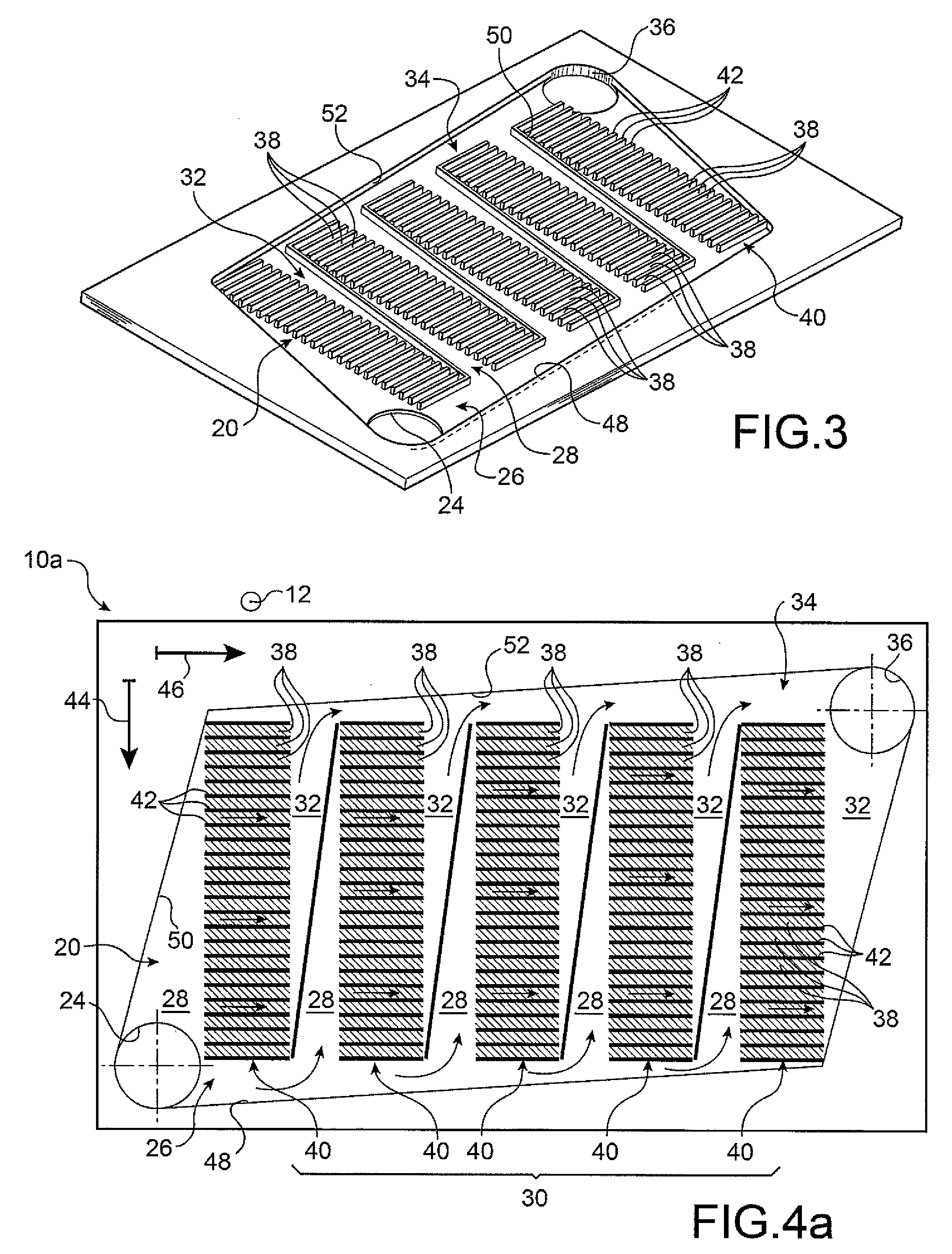

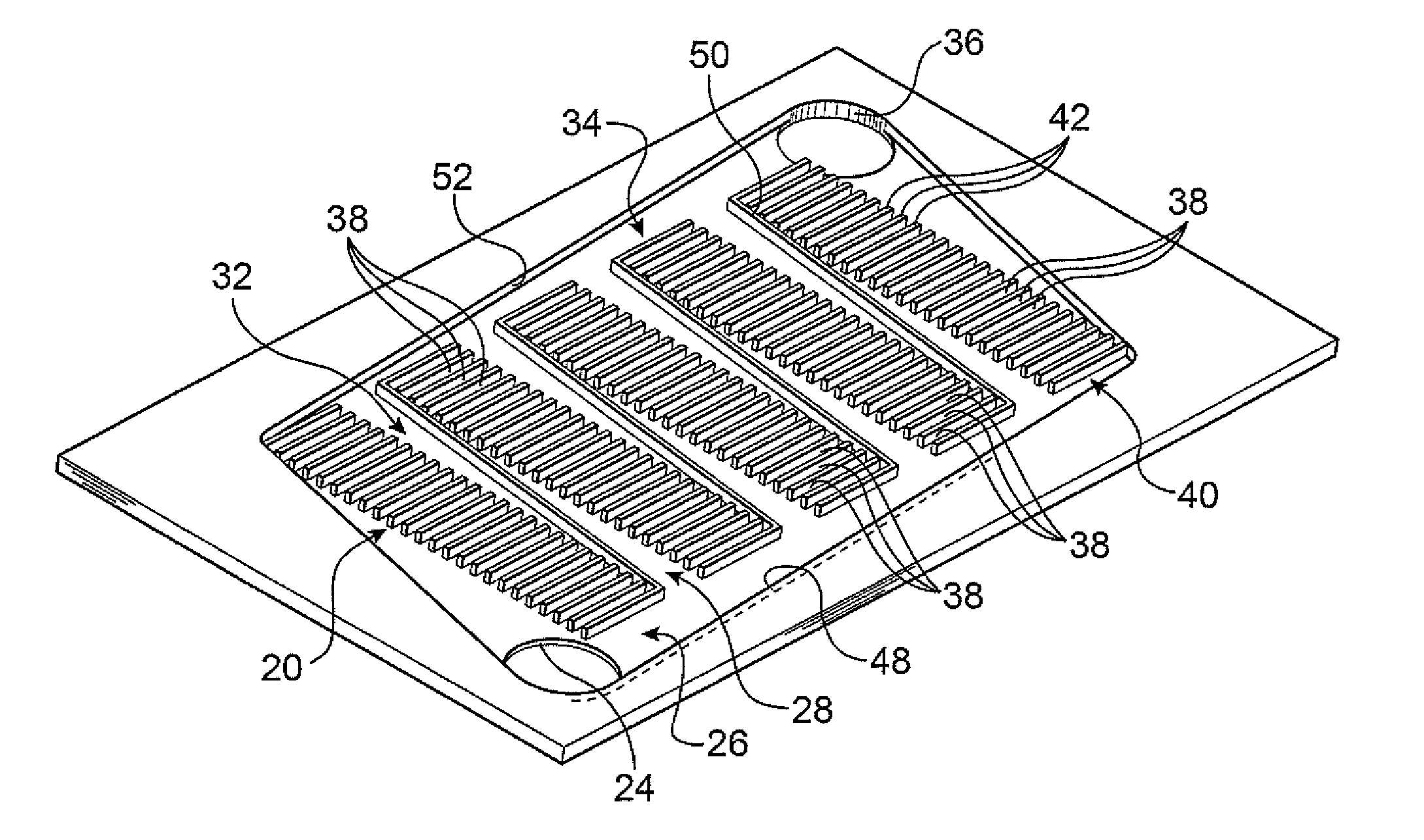

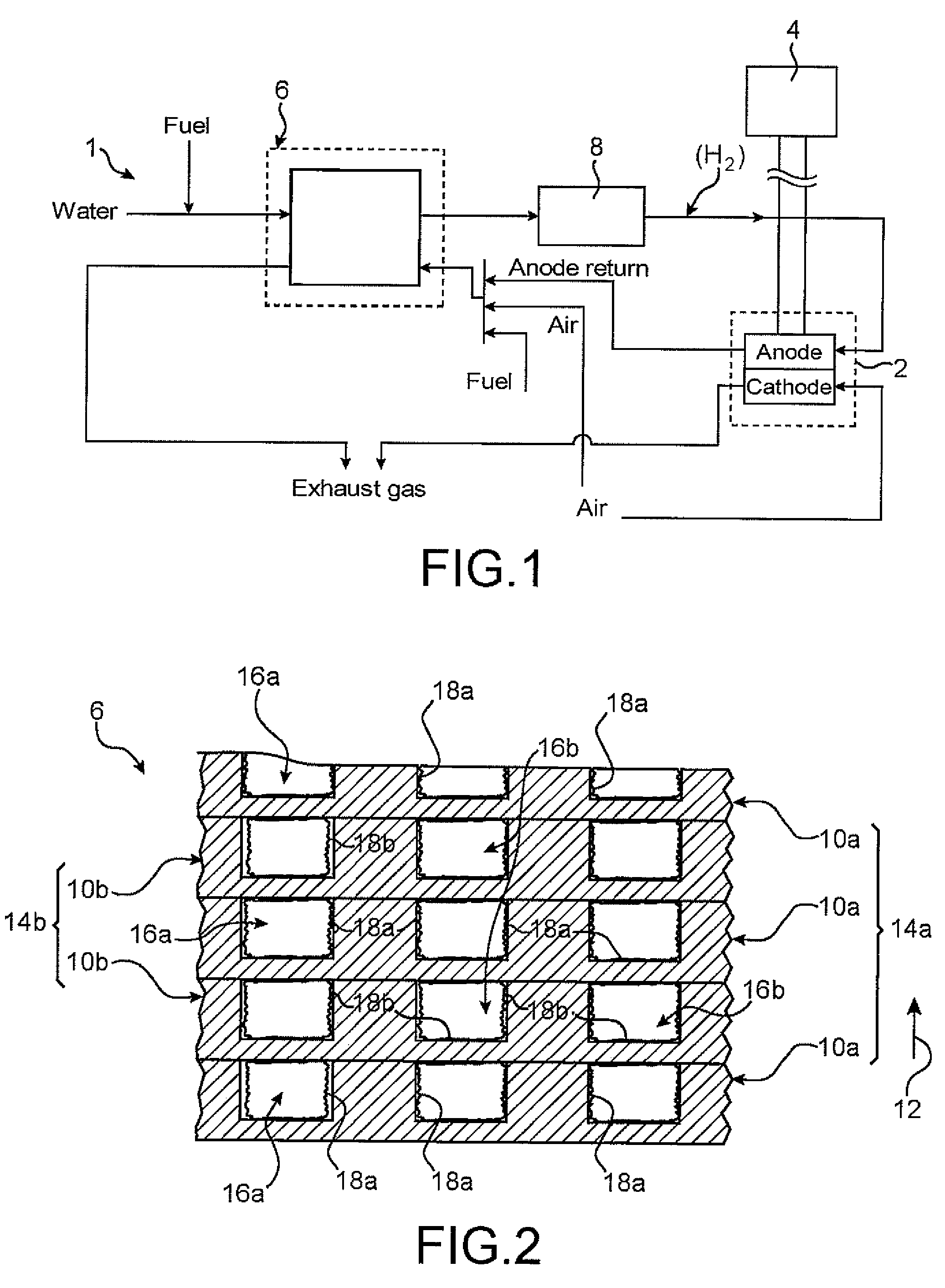

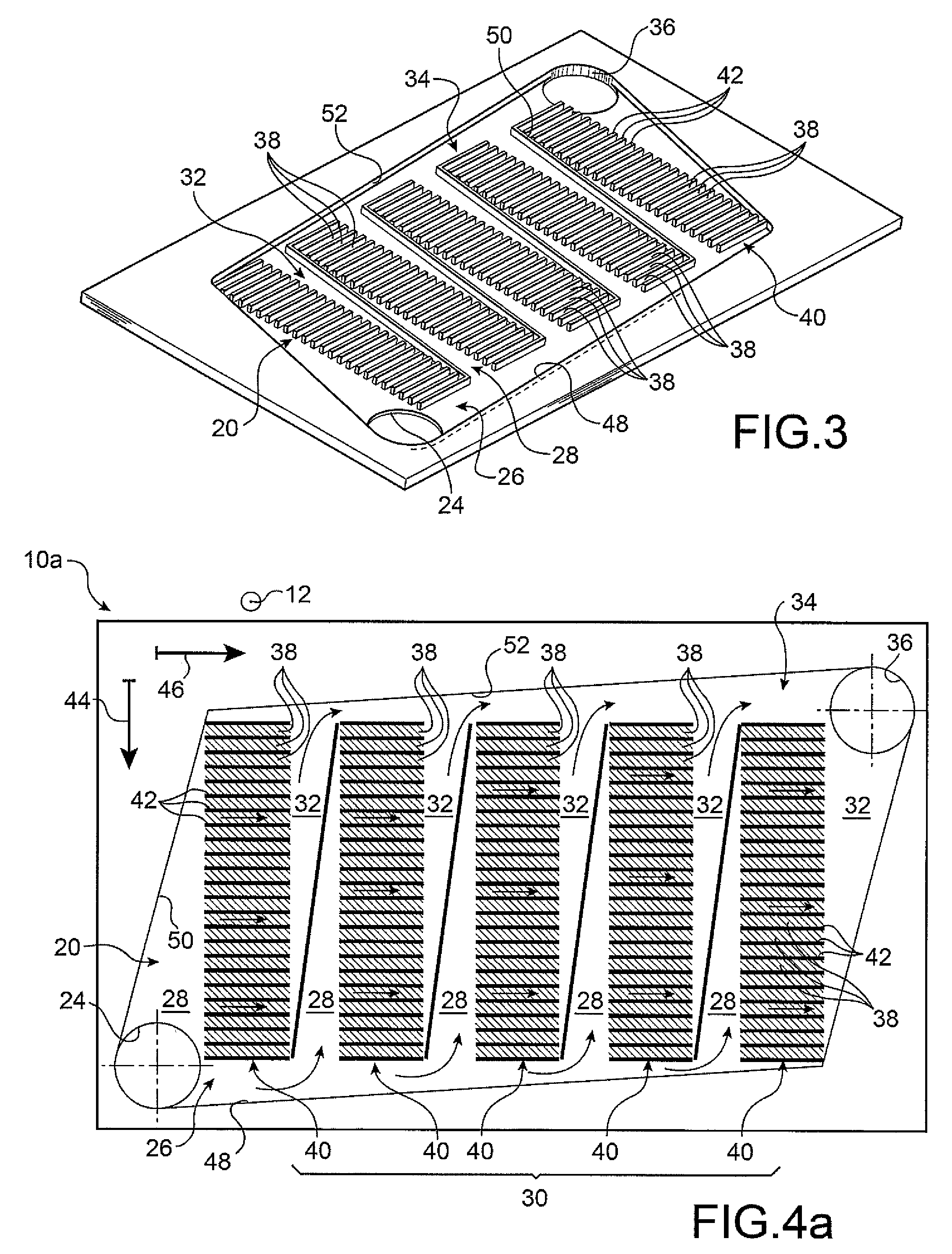

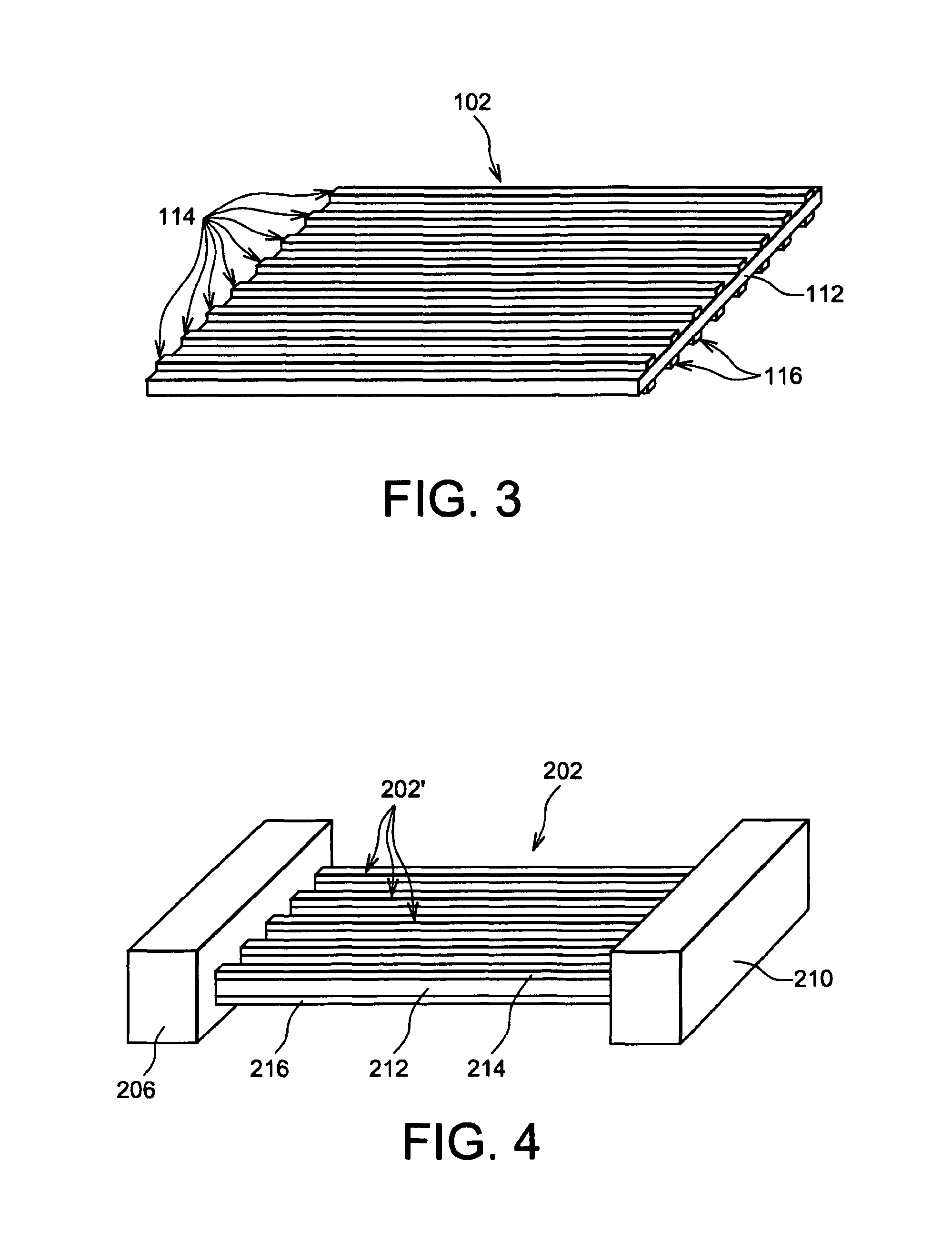

Heat Exchanger System Comprising Fluid Circulation Zones Which are Selectively Coated with a Chemical Reaction Catalyst

InactiveUS20090104488A1Improve distributionAcceptable temperatureCombination devicesExhaust apparatusChemical reactionEngineering

The invention relates to a plate (10a) intended to be integrated in a stack of plates in a heat exchanger system, the plate comprising a plurality of channels (38) distributed in rows (40), each row comprising side walls (42) arranged opposite one another and spaced apart from one another in a first direction (44), so that two directly consecutive side walls delimit one of the channels (38), the rows being arranged opposite one another and spaced apart from one another in a second direction (46) which is perpendicular to the first. Furthermore, in the fluid circulation zone (20) of the plate incorporating the channels (38), only the latter are coated with a catalyst allowing a chemical reaction.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

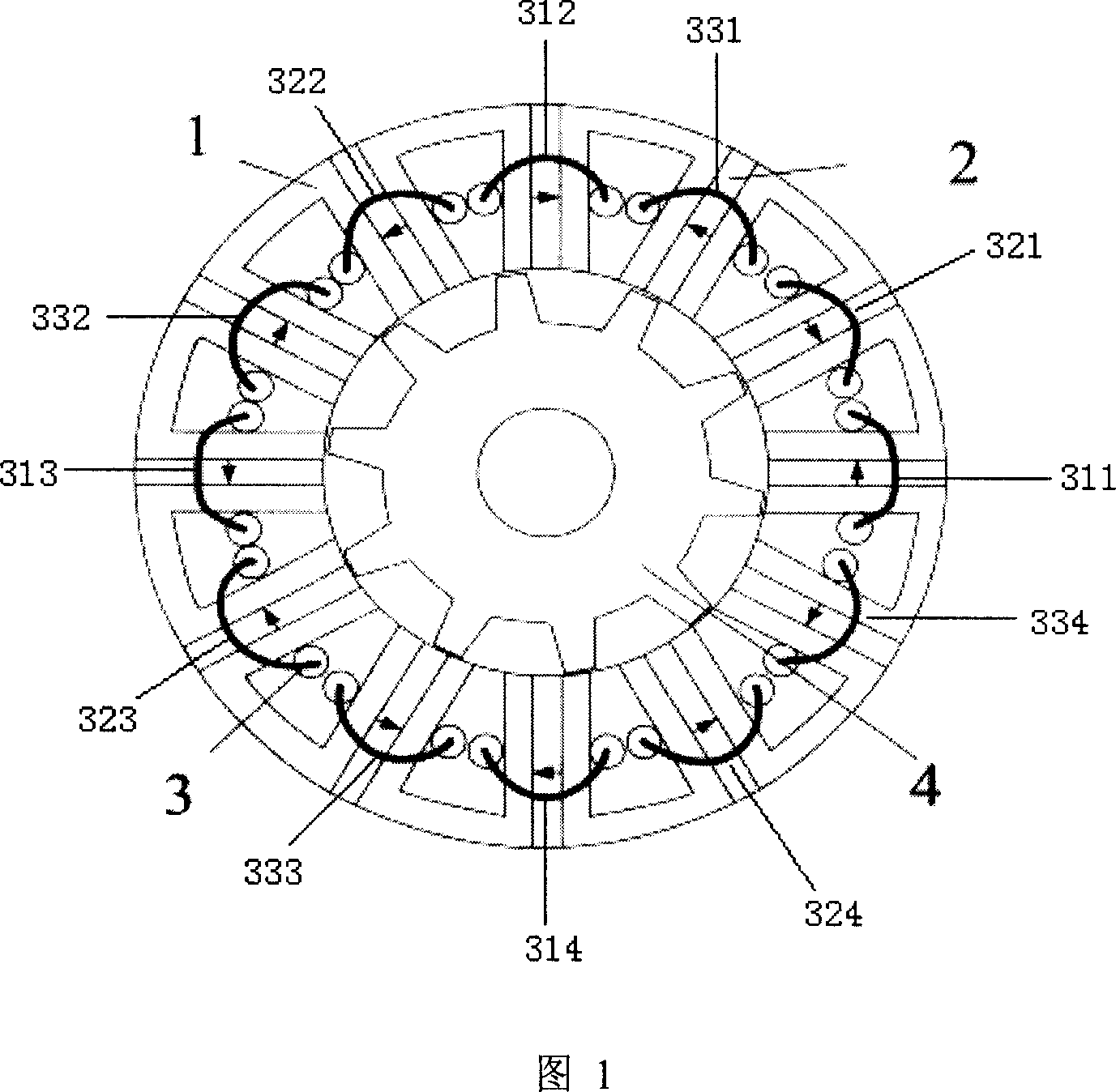

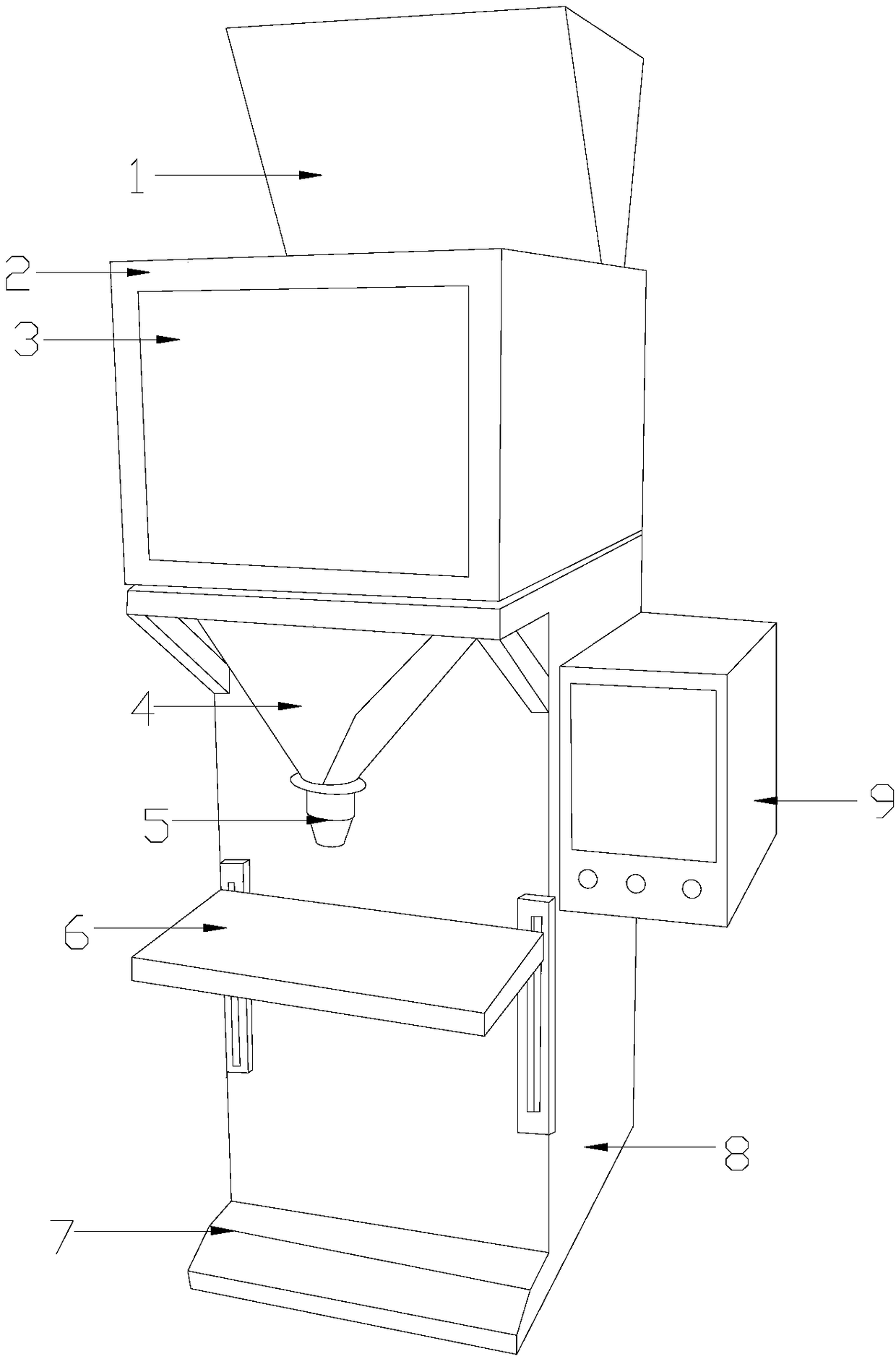

Automatic packaging machine used for materials

ActiveCN103043236ASame quantityAvoid the problem of wrong quantityWrapper twisting/gatheringPackaging automatic controlEngineeringMaterial quality

The invention discloses an automatic packaging machine used for materials. The automatic packaging machine used for materials comprises a feeding mechanism (1), a feeding track (2), packaging mechanism (3) and a weighting mechanism (4). Materials from the feeding mechanism (1) are conveyed to the packaging mechanism (3) through the feeding track (2) to be sealed and packaged, packaged materials are entered into the weighting mechanism (4) to be weighted and examined, and at last a second sliding block (34) removes packaging bags which are not in a set threshold range and delivers qualified material packaging bags to a material bucket through a first sliding block (33). The automatic packaging machine used for materials can meet the requirements of simultaneously counting and packaging of materials with more than two different material qualities, a photoelectric counting system and contact pins guarantee consistent number of materials entering material boxes each time, and the photoelectric counting system is arranged at a discharging track material outlet position and performs counting on the materials. Simultaneously, the automatic packaging machine is further provided with a weighing reexamination function, and accordingly the problem of wrong number of materials in the packaging bags caused by fault of the photoelectric counting system is solved.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

Process of mild hydrocracking including a dilution of the feedstock

InactiveUS20060289338A1Increase speedImprove performanceTreatment with plural serial cracking stages onlyCatalytic crackingBoiling pointEffluent

The invention relates to a process for FCC pretreatment by mild hydrocracking of a hydrocarbon feedstock that comprises a vacuum distillate fraction or a deasphalted oil or else a mixture of these two fractions, said primary feedstock, to produce gas oil and an effluent having an initial boiling point of more than 320° C., said effluent (FCC feedstock) then being subjected to a catalytic cracking, process in which at least 85% by weight of said primary feedstock ends above 375° C. and at least 95% by weight of said primary feedstock ends below 650° C., whereby the mild hydrocracking is performed under an absolute pressure of 2 to 12 MPa and at a temperature of between 300 and 500° C., characterized in that the hydrocarbon feedstock also comprises a lighter hydrocarbon fraction, a so-called secondary feedstock, of which at least 50% by weight ends below 375° C. and at least 80% ends above 200° C.

Owner:INST FR DU PETROLE

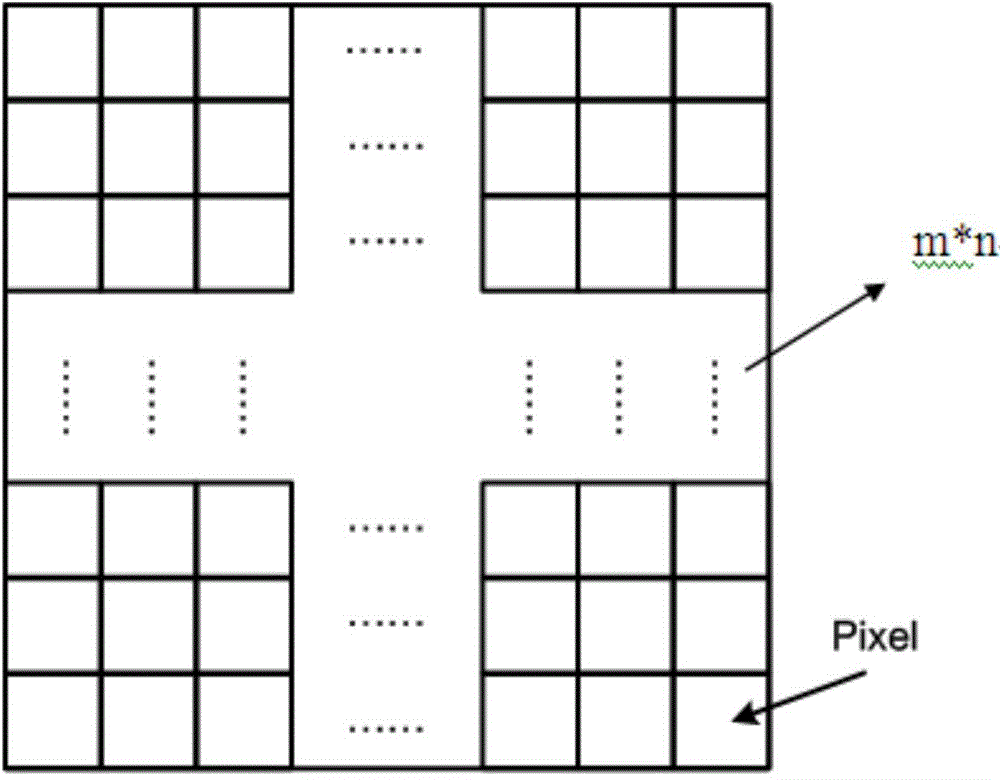

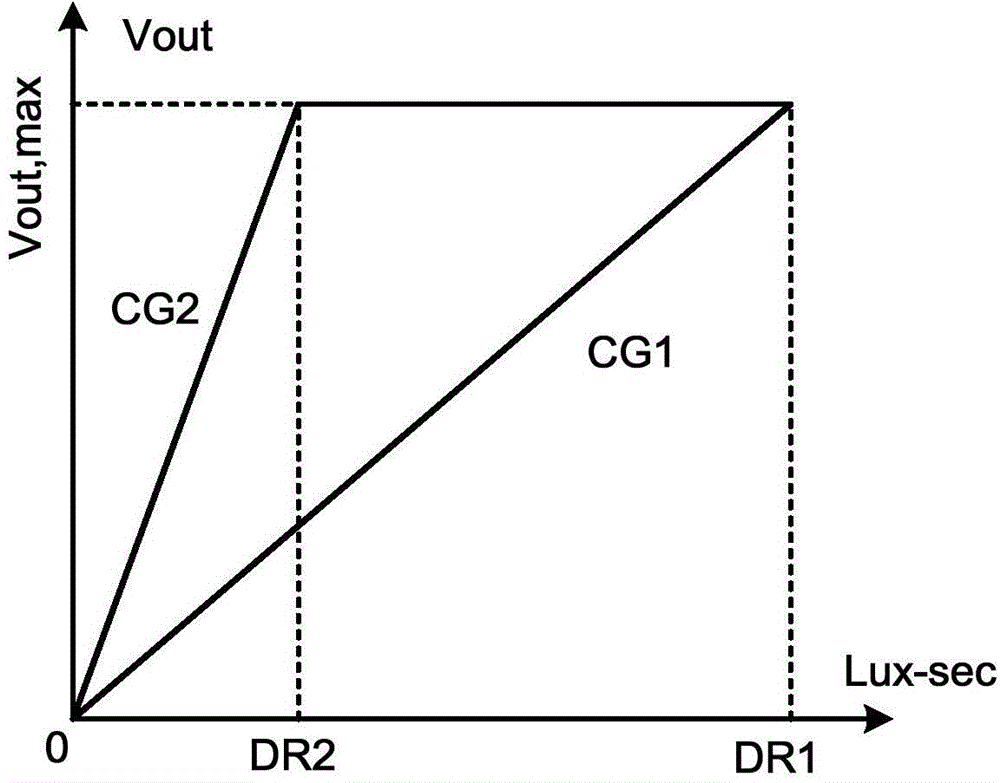

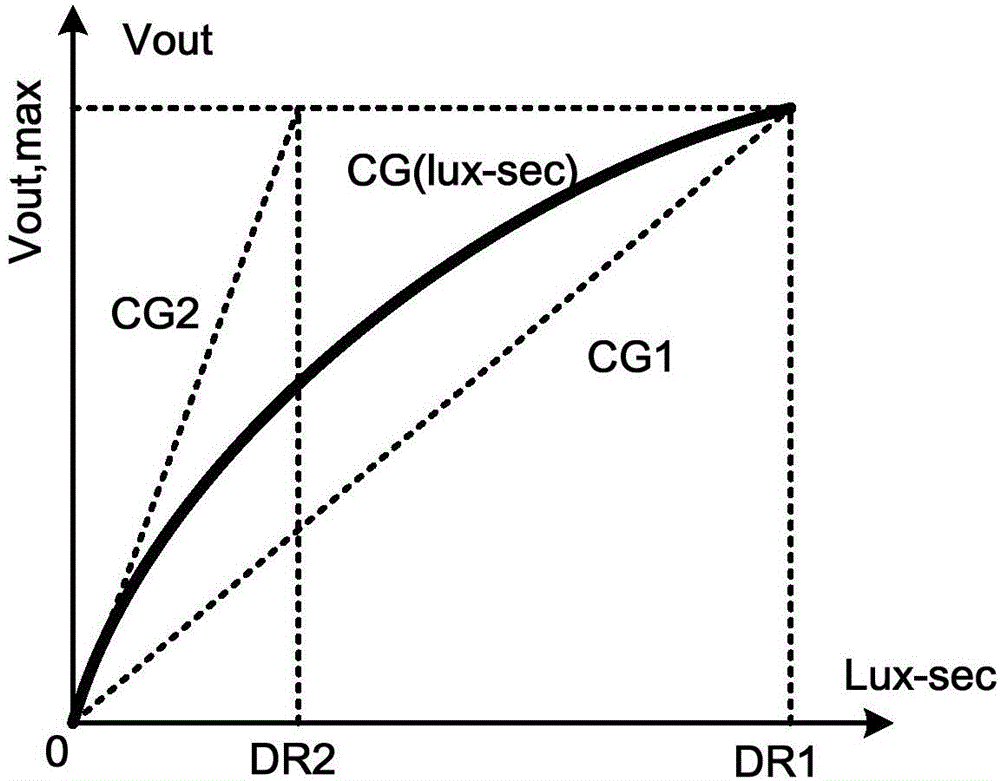

Image sensor structure and method for achieving high-dynamic-range image

ActiveCN104580945ASame quantityExpand the practicalityTelevision system detailsColor television detailsCamera lensImage resolution

The invention provides an image sensor structure for achieving a high-dynamic range and a camera formed by the sensor and a lens. The image sensor structure for achieving the high-dynamic range is composed of a pixel photosensitive unit, a control module and a peripheral circuit. The control module is in circulation connection with the pixel photosensitive unit, and thus the pixel photosensitive unit is changeable in conversion gain. The invention further provides a method for achieving a high-dynamic-range image and a video. The method comprises the steps that the pixel photosensitive unit converts external light intensity into voltage signals through certain conversion gain, outputs and forms the image and conveys the image to the control module, the control module converts the input into digital signals to conduct recognition and judgment, feeds back a result to the pixel photosensitive unit, and dynamically controls and adjusts the gain conversion of the pixel photosensitive unit; continuous adjustment is conducted according to certain frame frequency to form the video. According to the image sensor structure, the camera and the method for achieving the high-dynamic-range image and the video, under the premise that the pixel resolution ratio is not changed and multiple images do not need to be shot, the dynamic range of shooting the image can be greatly enlarged, video shooting can be easily achieved, and the practicability of the image sensor is greatly improved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

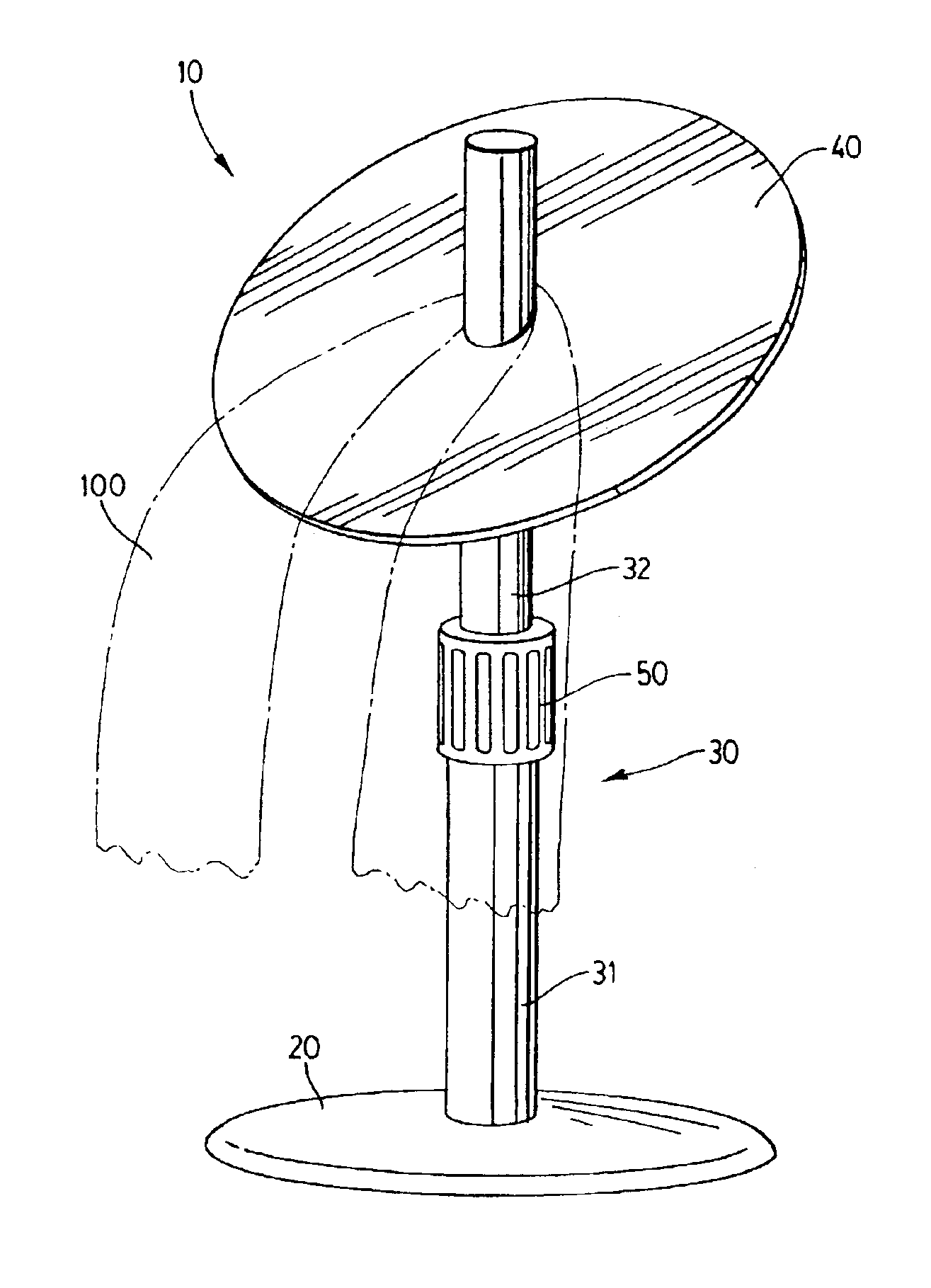

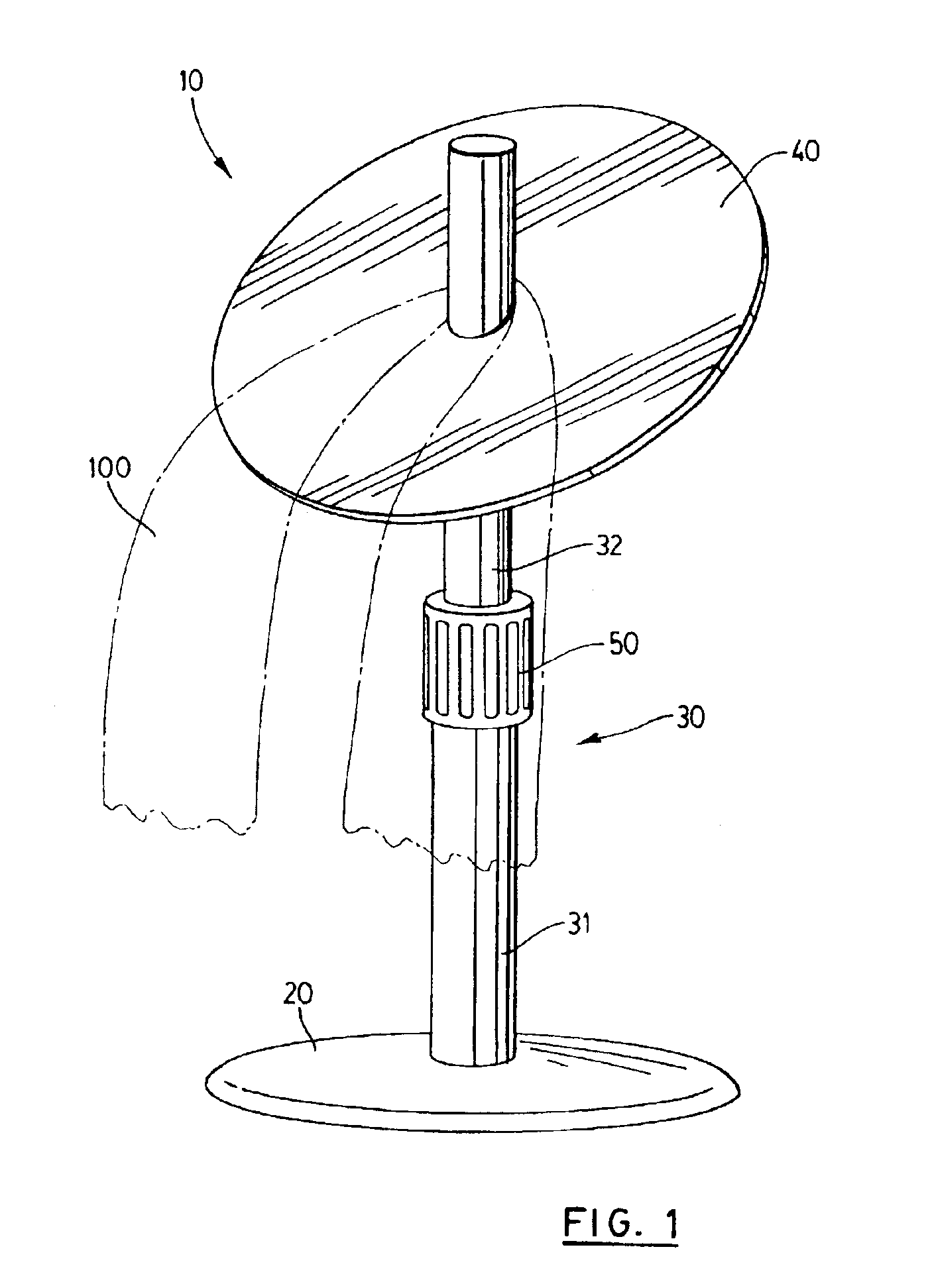

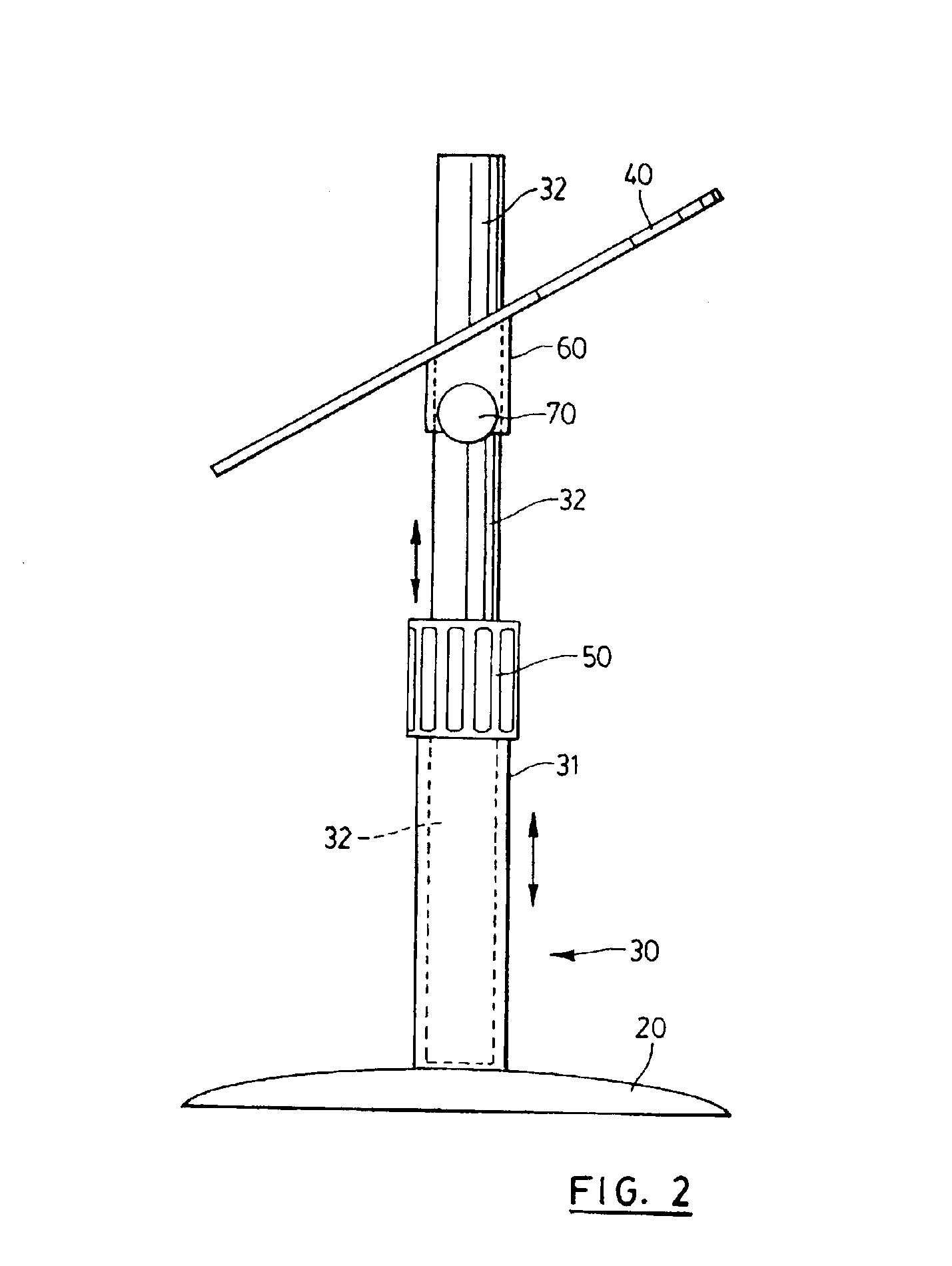

Hair braiding and weaving accessory

InactiveUS6913230B2Prevent tangling, falling or soilingSame quantityPackaging toiletriesStands/trestlesCircular discEngineering

Owner:WELLS BRENDA LEE

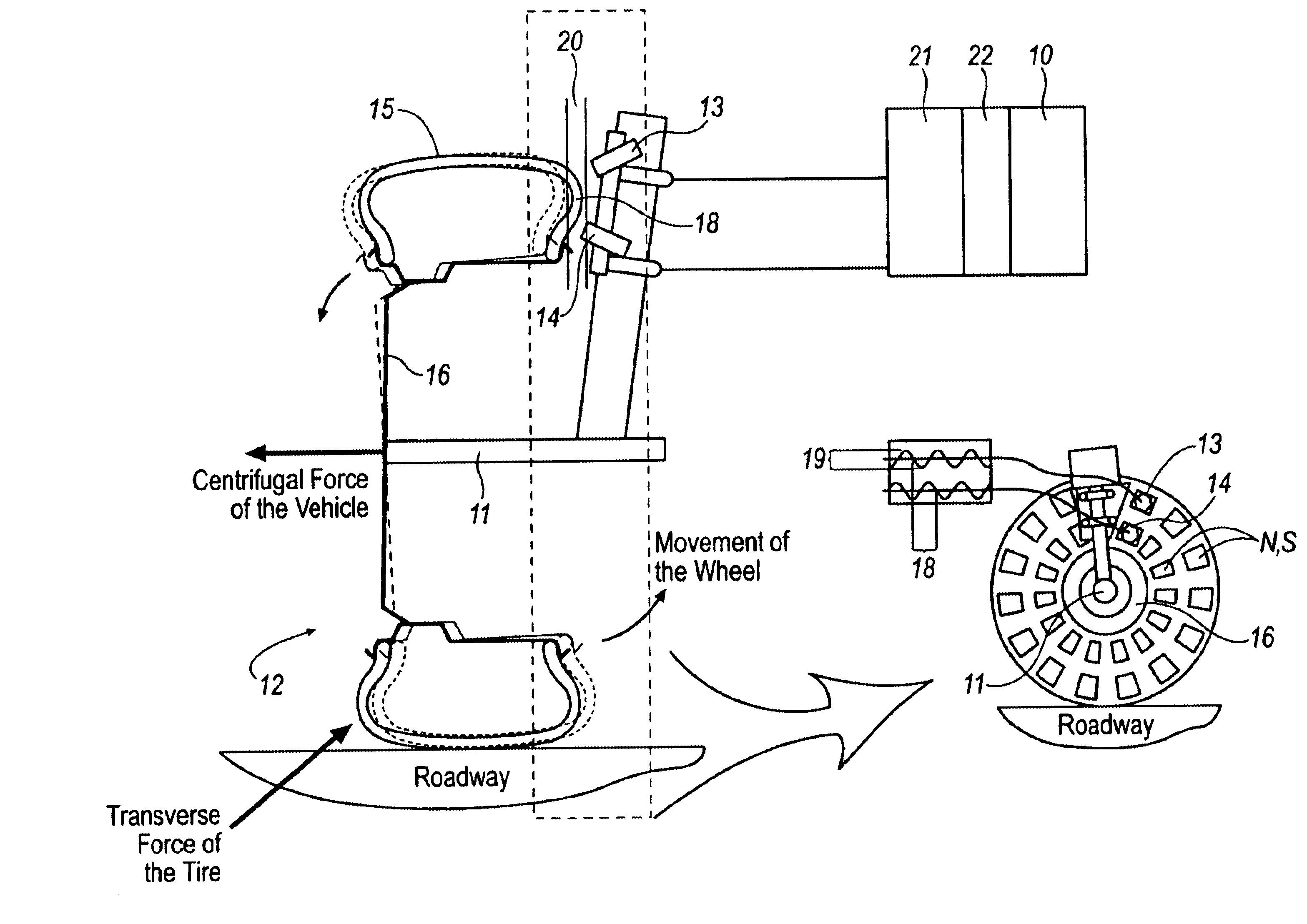

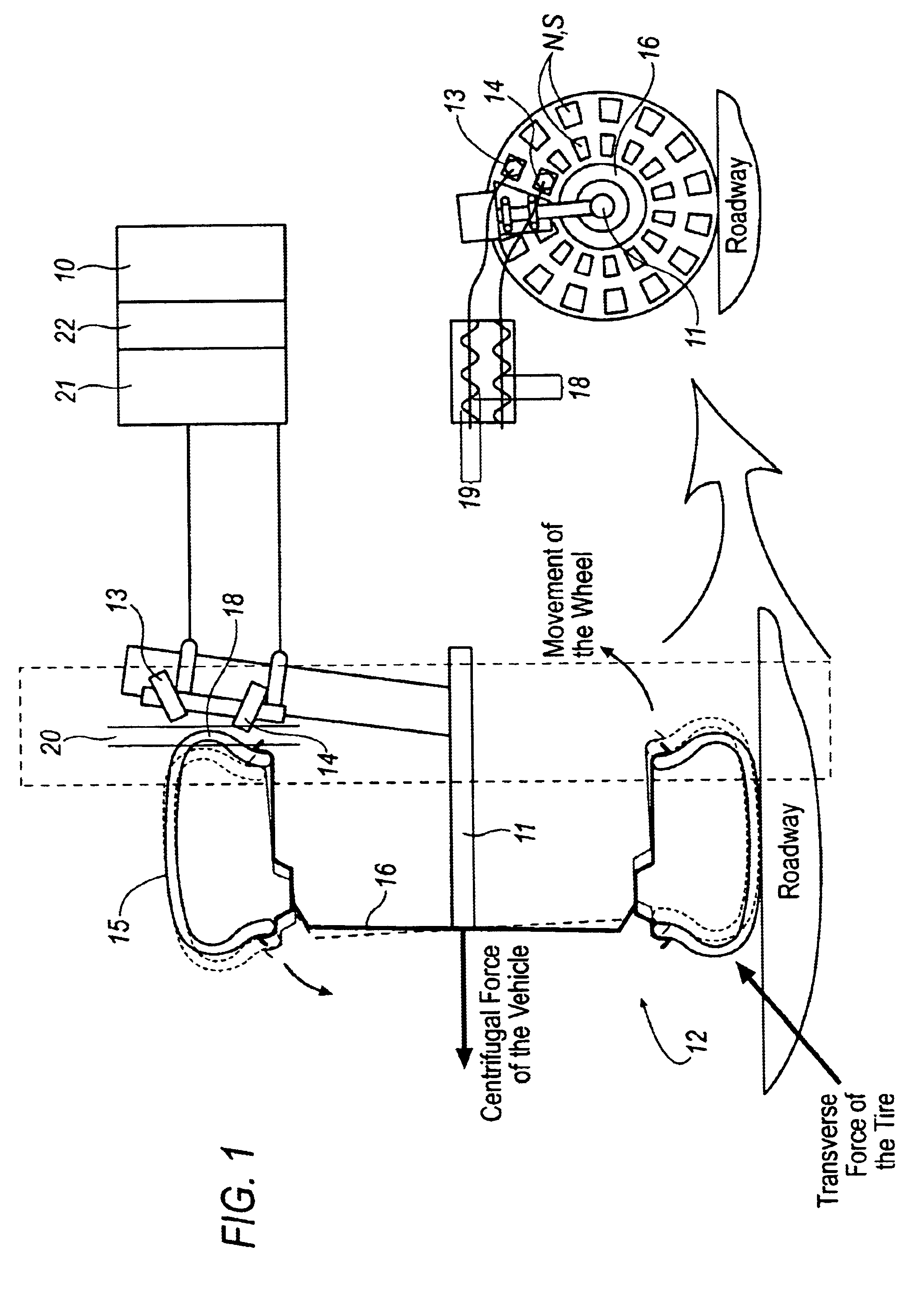

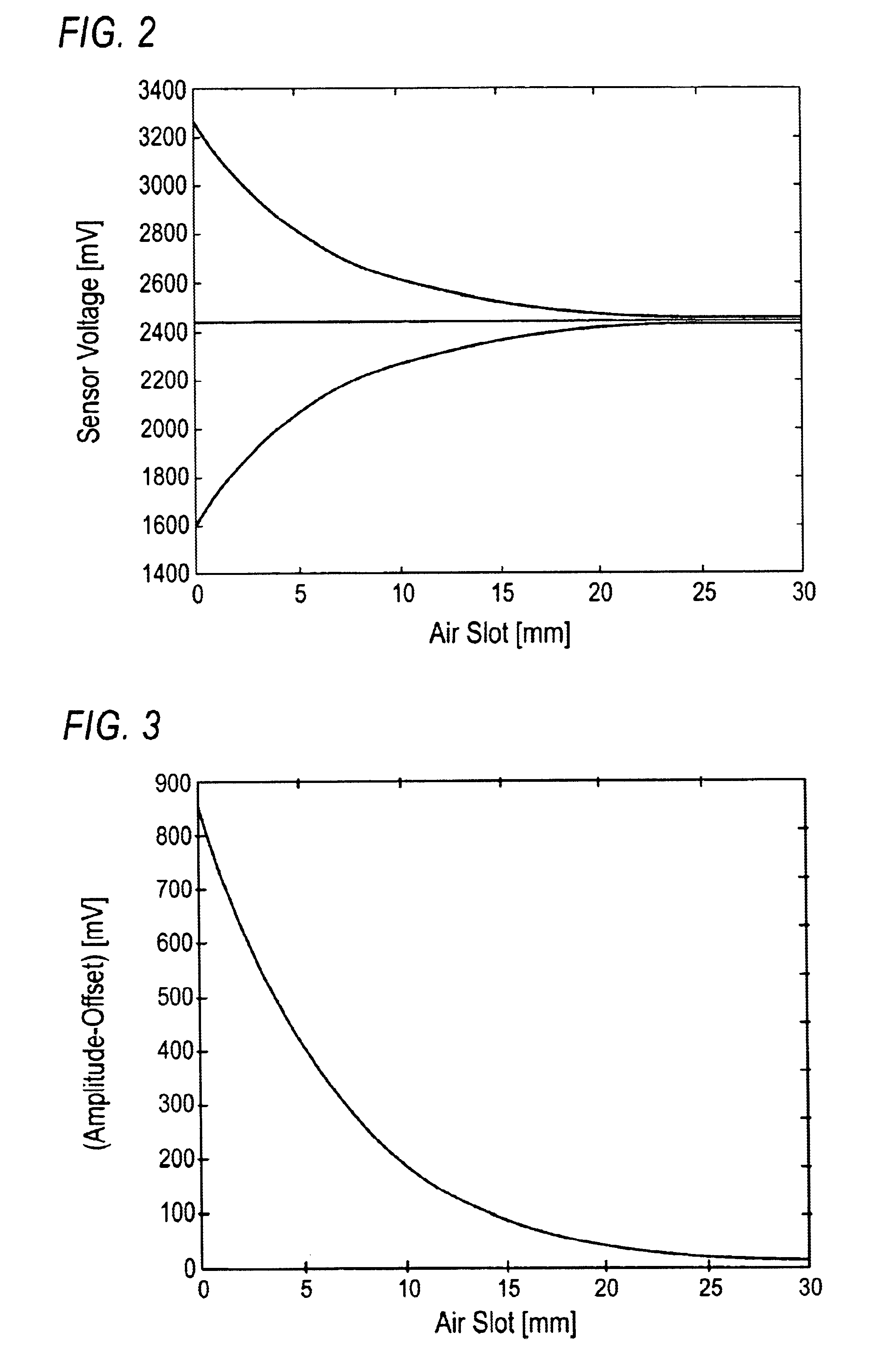

Method for detecting and evaluating the conditions of vehicle movement dynamics for a motor vehicle

InactiveUS6988395B1Reduce errorsQuality improvementEngine testingVehicle steering/rolling behaviourMobile vehicleTransverse force

The present invention relates to a method and a control circuit for detecting and evaluating the conditions of vehicle movement dynamics for a motor vehicle by means of wheel force sensors, preferably tire sensors, which take the preadjusted air slot between at least one rotating encoder and at least one pick-up for measuring data into account as a standard for the transverse forces that act on the wheel or on the tire. In order to reduce the errors in the evaluation of wheel forces, especially of deformations of the wheel rim and / or the tire detected by means of tire sensors, the air-slot-dependent operating point of the output signal of the pick-up for measuring data or a signal-conditioning device is set irrespective of the preadjustment of the said point which was made during predetermined driving behavior.

Owner:CONTINENTAL TEVES AG & CO OHG

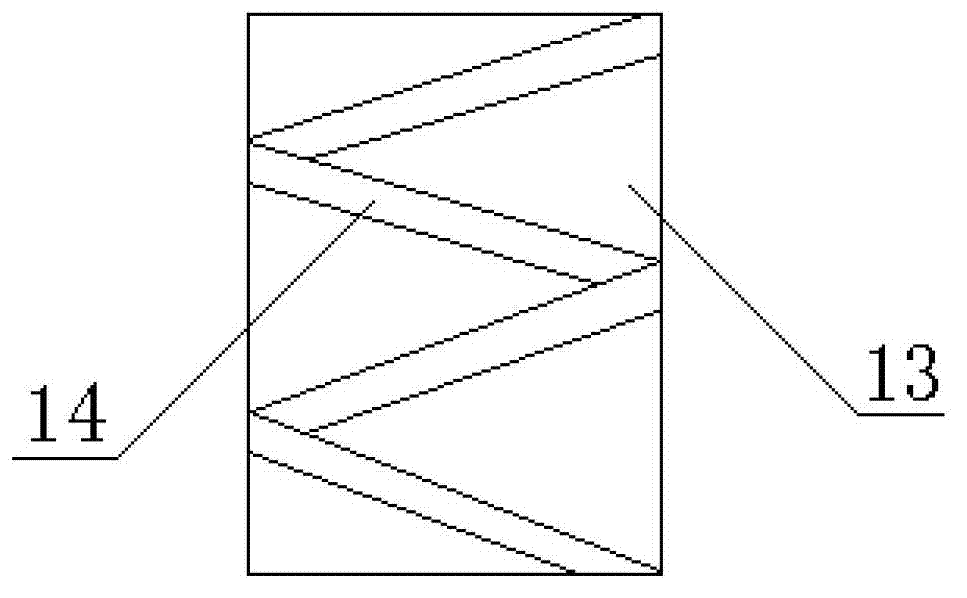

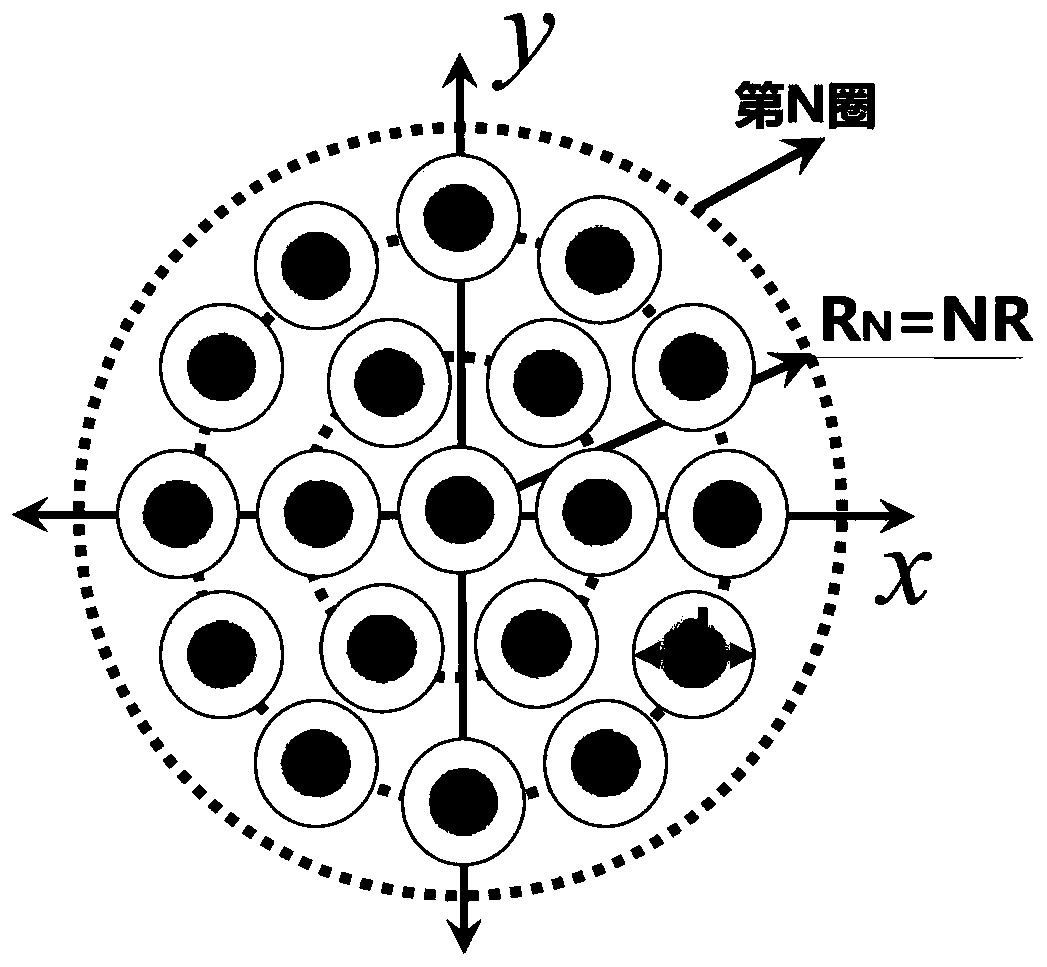

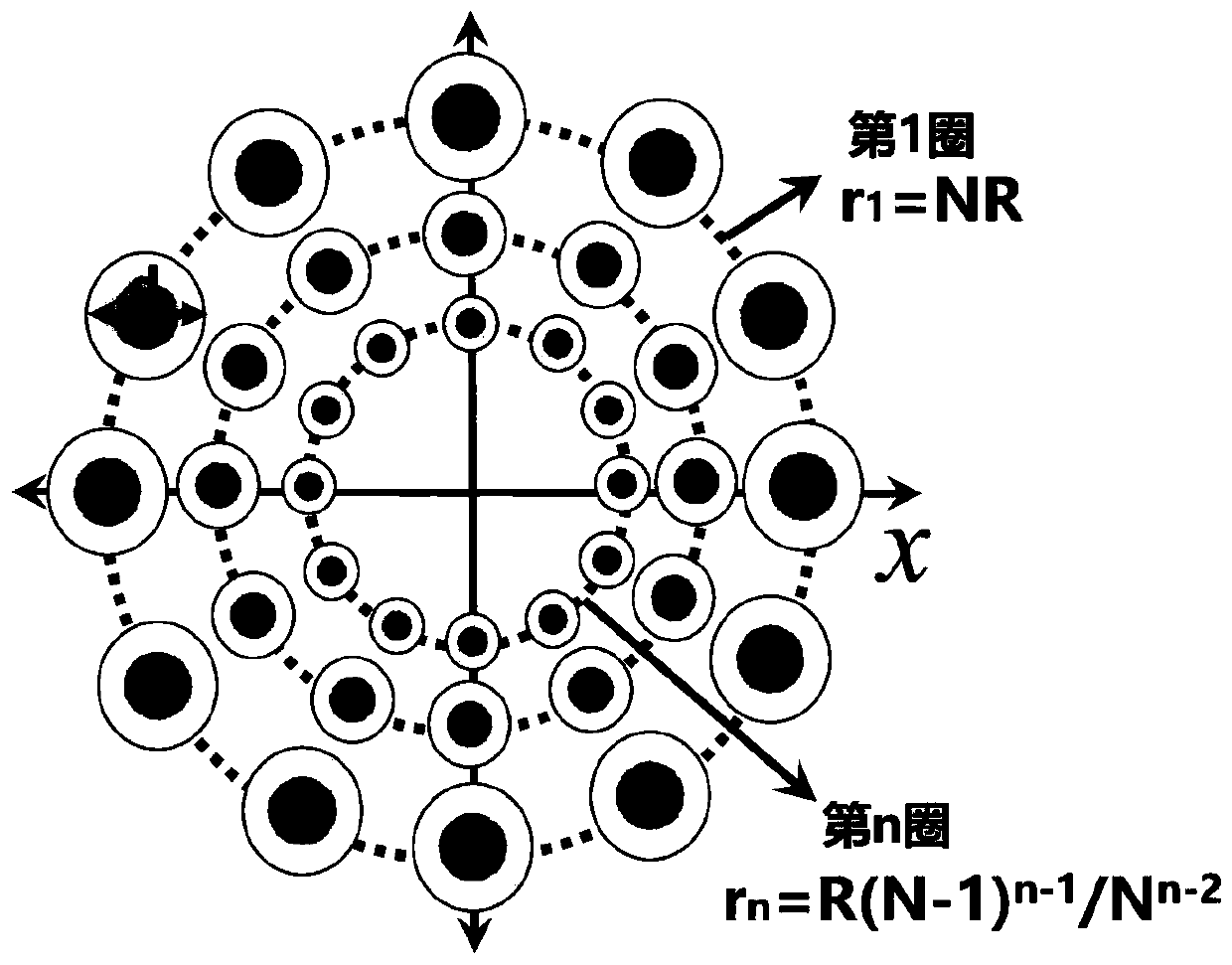

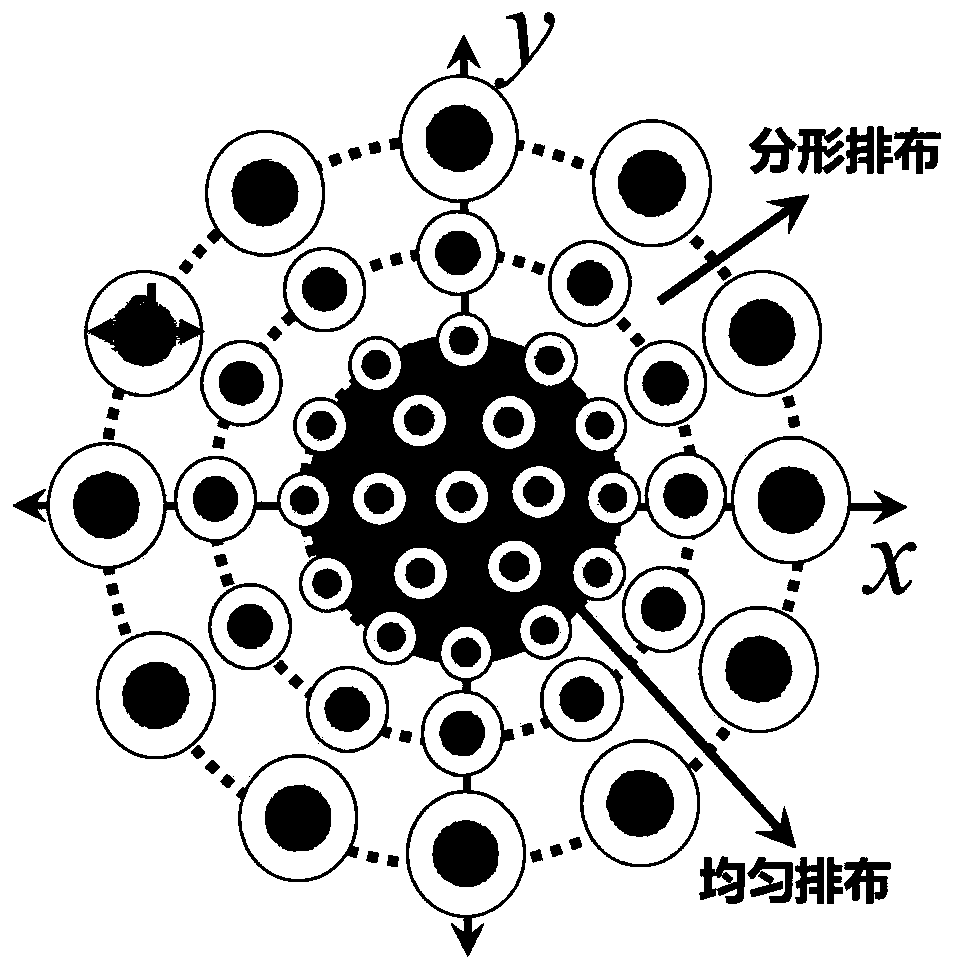

Fractal-based coherent optical fiber laser array and generation system thereof

PendingCN111193167ASame quantitySolve the problem of low purityLaser arrangementsOptical devices for laserLaser arrayLight beam

Disclosed are a fractal-based coherent optical fiber laser array and a generation system thereof. The coherent optical fiber laser array comprises N circles of light beams annularly arranged around the center of an array optical fiber from inside to outside, each circle of light beams comprises the same number of sub-light beams, and the sub-light beams in the same circle of light beams have the same optical parameters and are uniformly arranged in the angular direction. At least two or more continuous circles of light beams in the N circles of light beams form a fractal arrangement laser array; any two adjacent circles of light beams in the fractal arrangement laser array are separated from each other; and the beam waist radius, the beam caliber and the distance between the beam center and the center of the array optical fiber of each sub-beam in the circle of light beams close to the inner side are reduced in an equal ratio relative to the beam waist radius, the beam caliber and thedistance between the beam center and the center of the array optical fiber of each sub-beam in the circle of light beams close to the outer side. According to the invention, the array filling mode ofthe system can be expanded, and the optical parameter regulation and control capability of the laser array is improved, so that the synthesis efficiency and mode purity of structured light generated by the coherent optical fiber laser array are improved.

Owner:NAT UNIV OF DEFENSE TECH

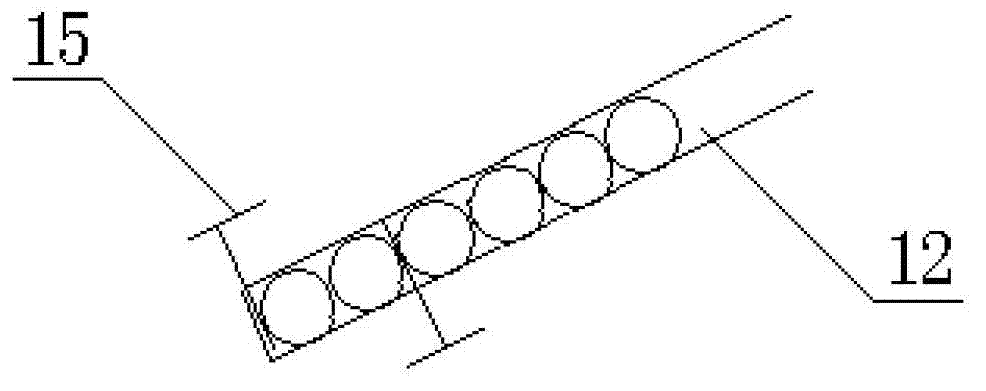

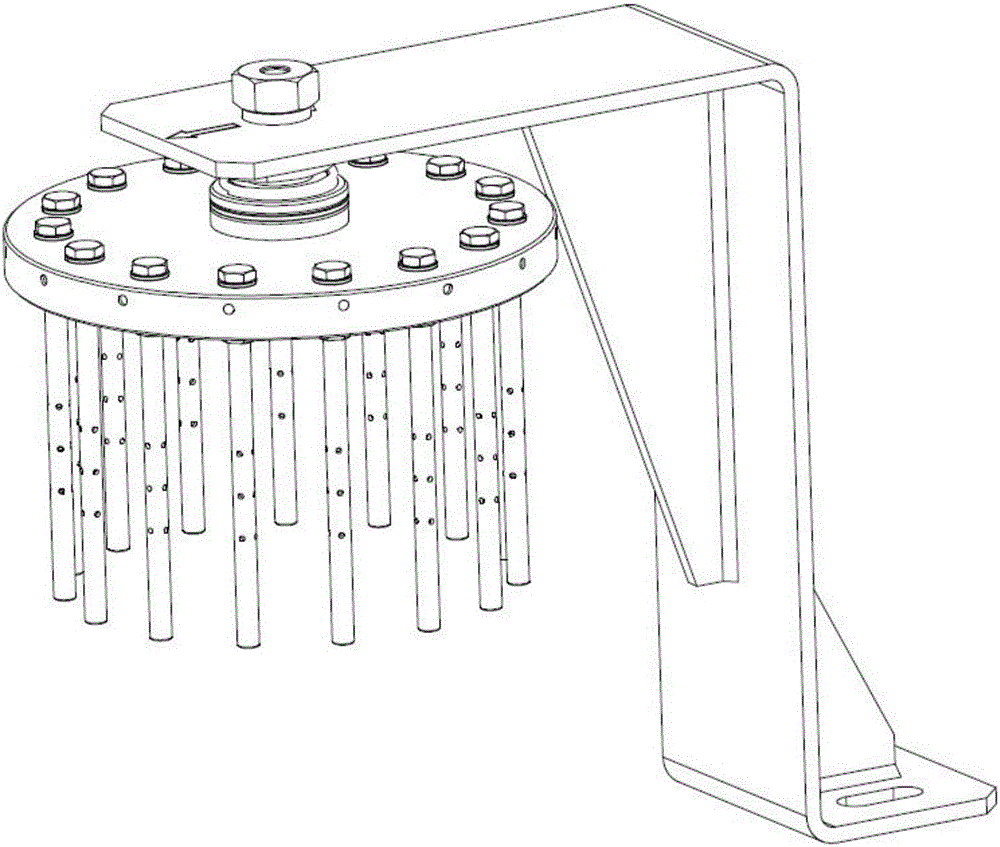

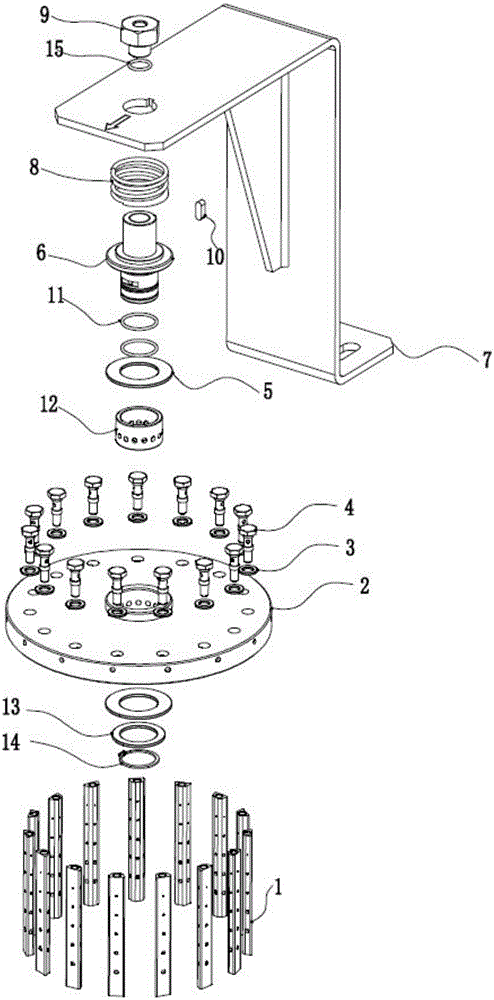

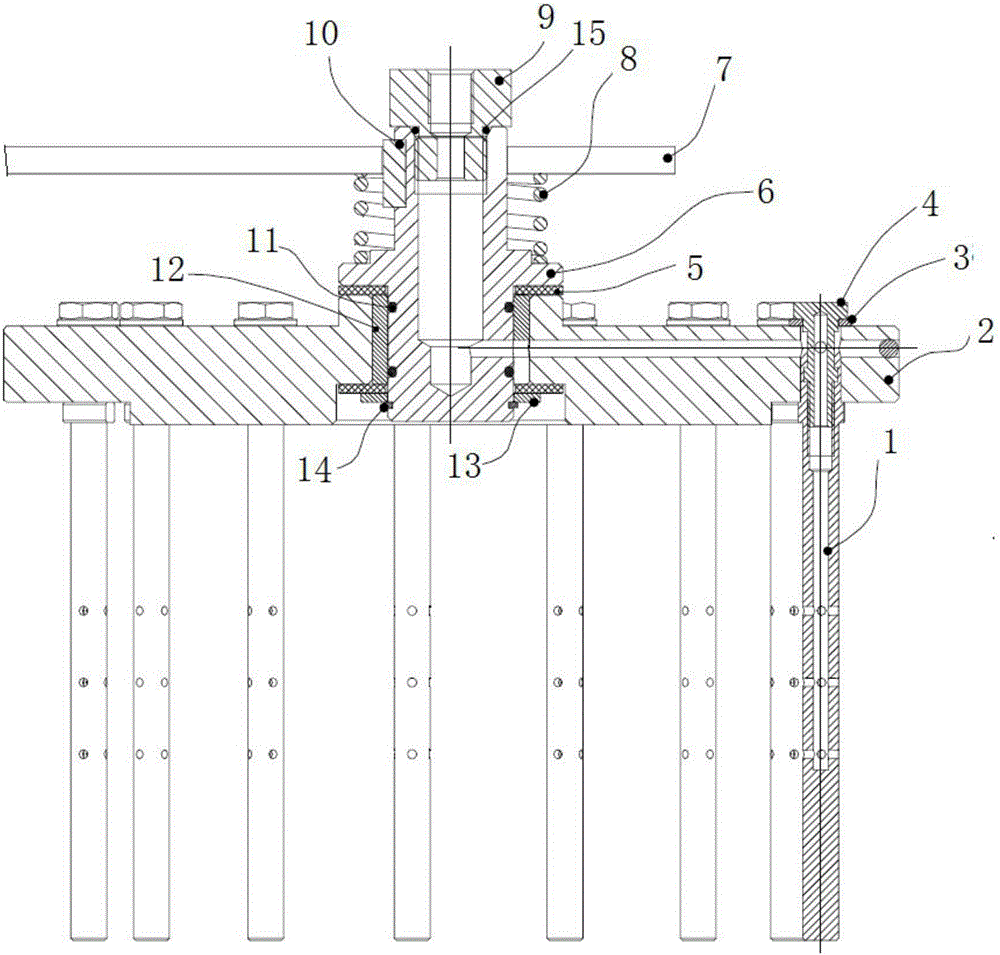

Bearing tooth surface lubricating device for wind generating set

InactiveCN106545643AIncrease frictionReduce wearGear lubrication/coolingMachines/enginesEngineeringLubrication

The invention relates to a bearing tooth surface lubricating device for a wind generating set. The bearing tooth surface lubricating device for the wind generating set is used for lubricating the engaged position of a variable paddle and a yaw gear ring, installed on a driving gear and rotates along with the driving gear. An oil distributing disk is connected to a fixed support through a shaft, the shaft is fixedly connected with the fixed support through a flat key, and a spring is installed between the boss end face of the shaft and the fixed support. The oil distributing disk can rotate around the shaft and a bronze bushing. Oil smearing sticks are evenly distributed on the lower end face of the oil distributing disk, the oil smearing sticks are fixedly connected with the oil distributing disk in a sealed mode, and the quantity of the oil smearing sticks is equal to the tooth quantity of the driving gear. The oil smearing sticks are placed at the tooth roots of the driving gear, and the lower end face of the oil distributing disk is connected with the upper end face of the driving gear in a pressed and contacting mode. A set of oil outflow holes are formed in the side of each oil smearing stick located at the engaged position of the driving gear and a bearing gear, the set of oil outflow holes are enlarged in sequence from up to down, and the oil outflow holes release oil only from the direction of the engaged position of the driving gear and the bearing gear. The set of oil outflow holes are connected with a fixed-point centralized lubrication system of the tooth surface of the variable paddle through a connecting joint.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

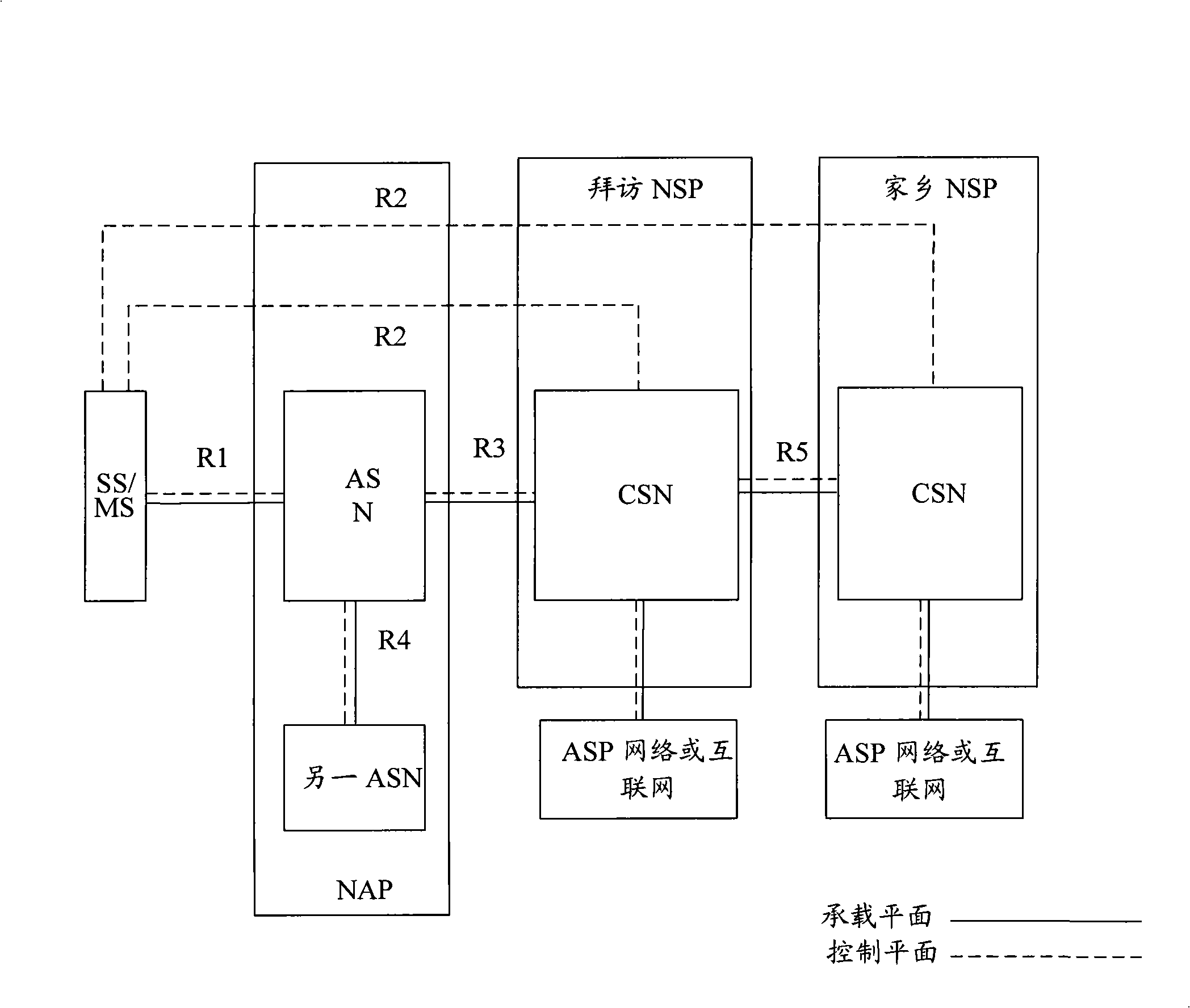

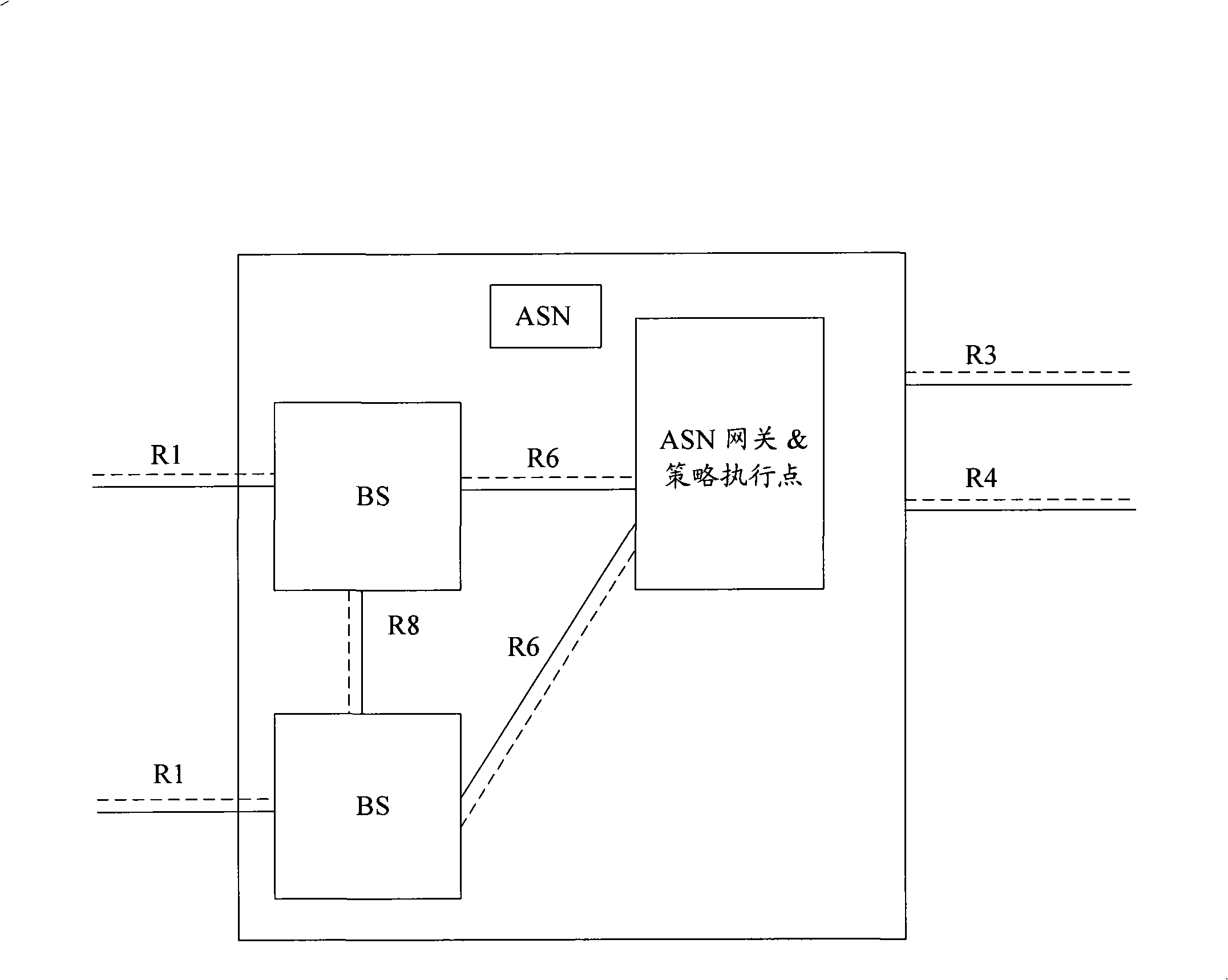

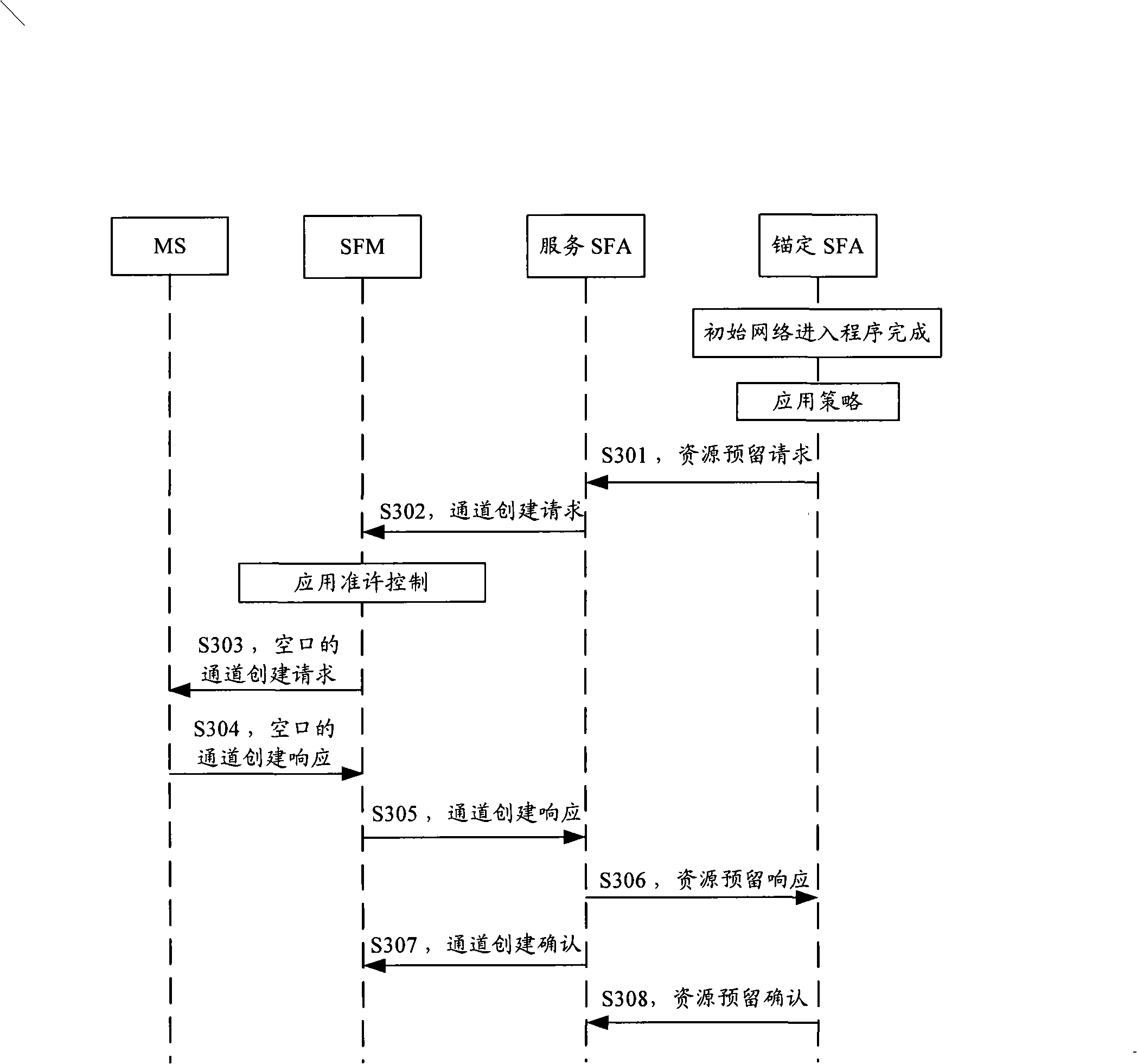

Data channel establishing method and system

InactiveCN101309223ASame quantityNormal data serviceError prevention/detection by using return channelNetwork traffic/resource managementService flowComputer science

The invention discloses a data channel establishing method and a system; wherein, the method includes that a serving service flow authorization entity receives the resource reservation request message from an anchoring service flow authorization entity; the serving service flow authorization entity sends a successful resource reservation response message to the anchoring service flow authorization entity under the situation that the resource reservation request is admitted; the serving service flow authorization entity receives the resource reservation confirm message from the anchoring service flow authorization entity and sends a channel establishment confirm message to a service flow management entity according to the result of the resource reservation confirm message. The data channel establishing method and the system can enable the number of the channels established by the BS and the AGW to be consistent.

Owner:ZTE CORP

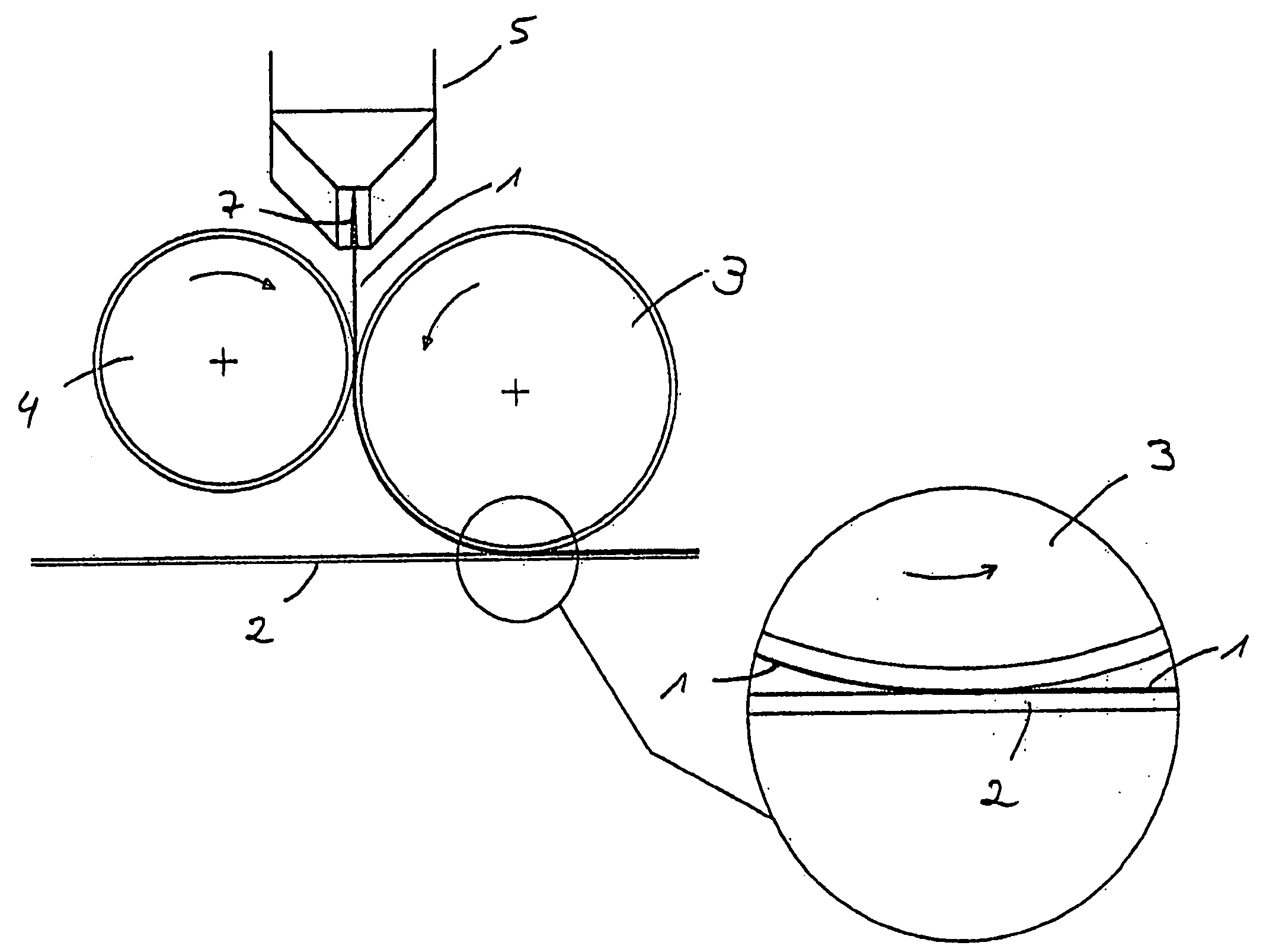

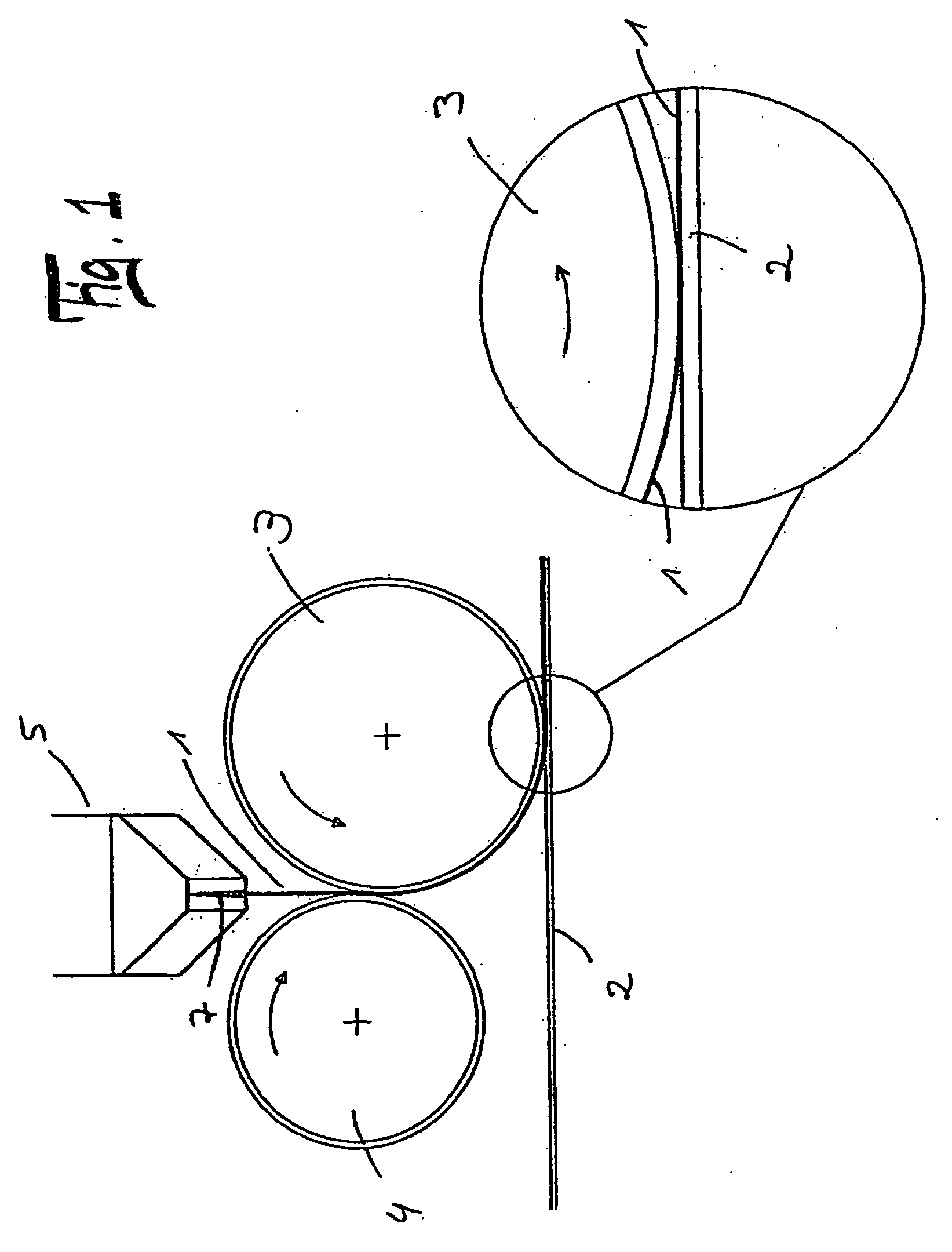

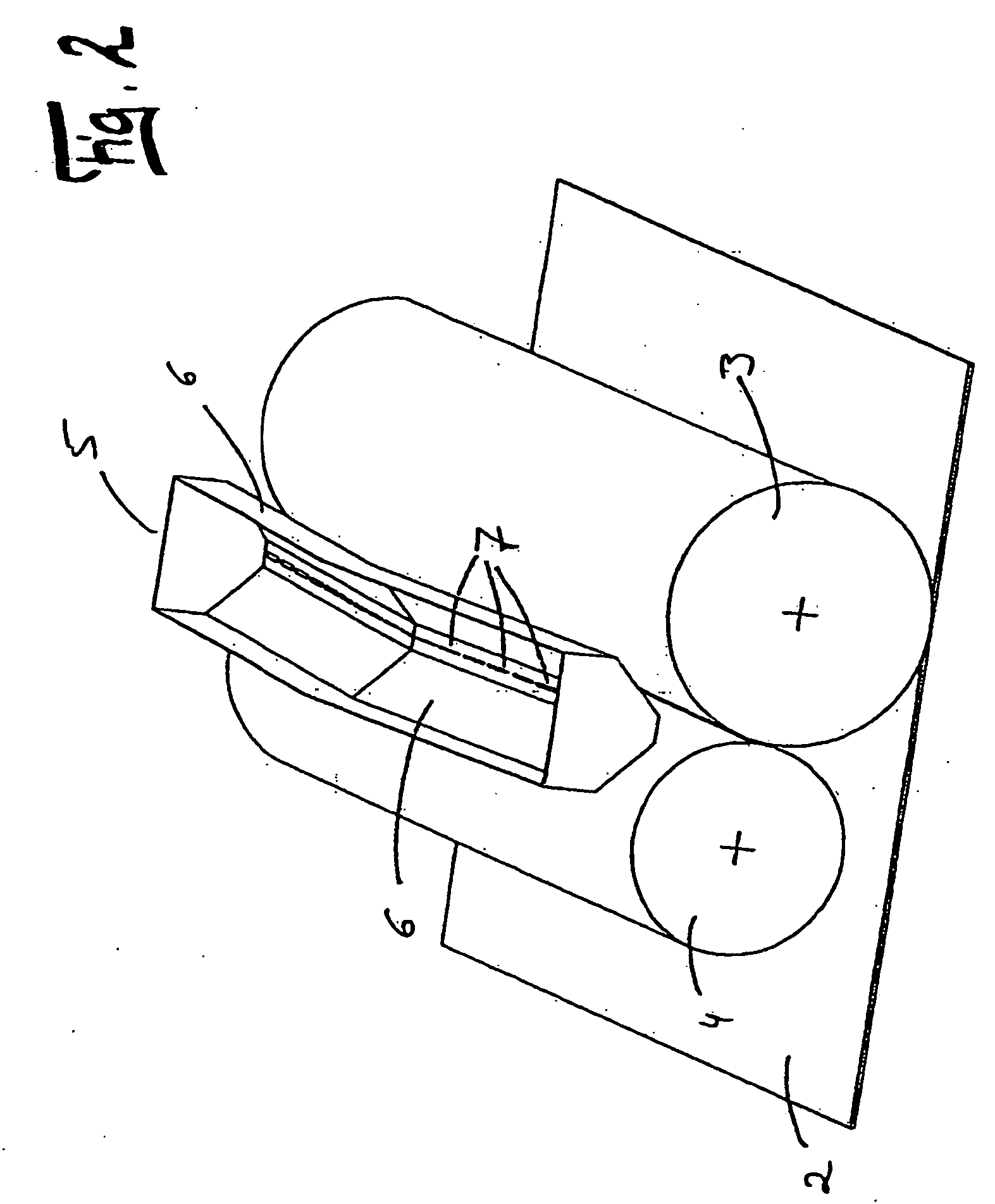

Device for applying a suspension onto a base plate

InactiveUS20090050054A1Improve accuracyUniform applicationElectrode carriers/collectorsPretreated surfacesMechanical engineeringCorundum

A device for applying a suspension to which particles, in particular corundum particles, have been added onto a base plate, with a roller mill comprising an applicator roll and a metering roll interacting with the applicator roll. An application groove with two groove halves project laterally and tilt downwards at an angle a to the horizontal with slots on the base side arranged above the roller mill.

Owner:FLOORING TECH

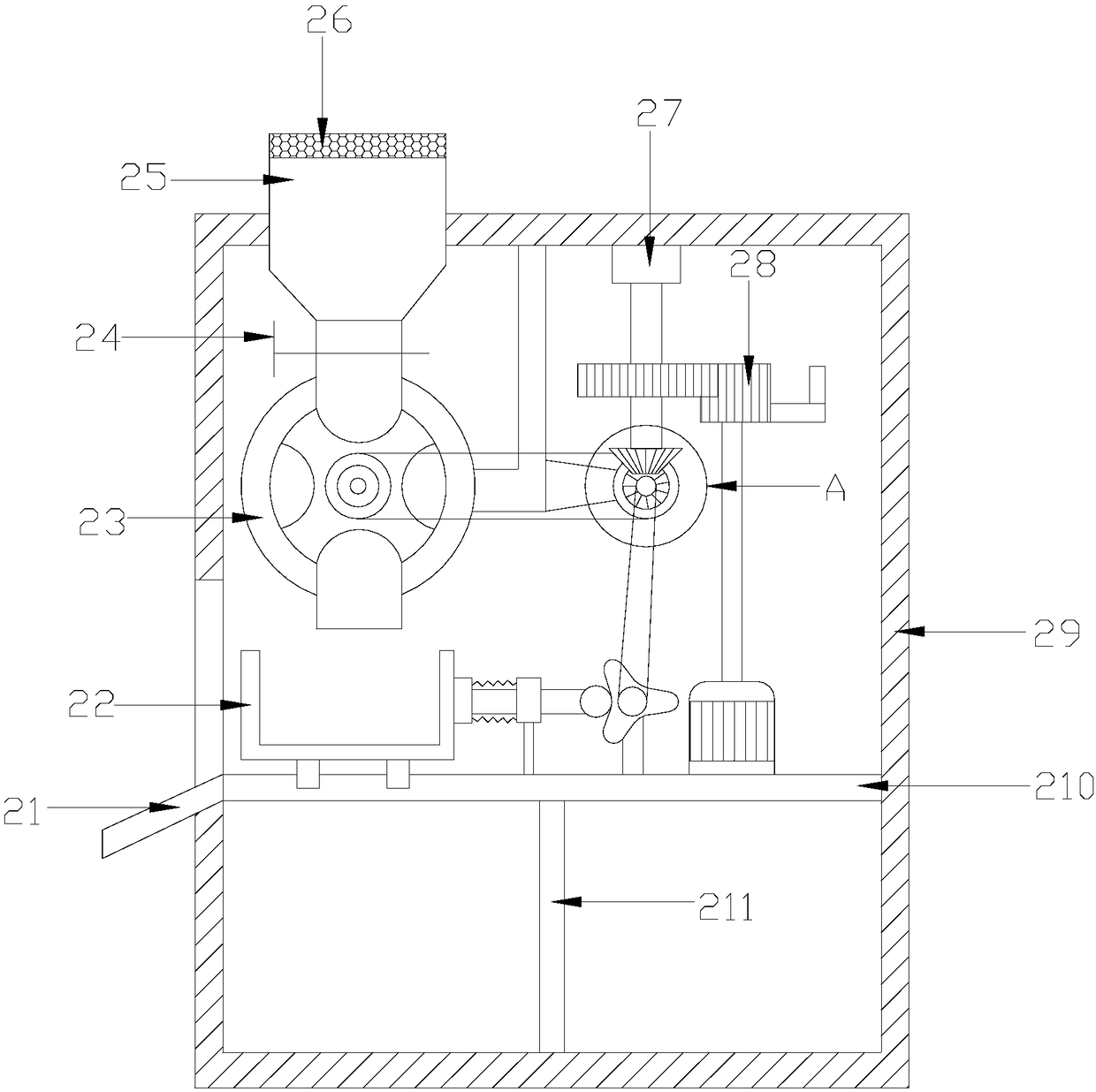

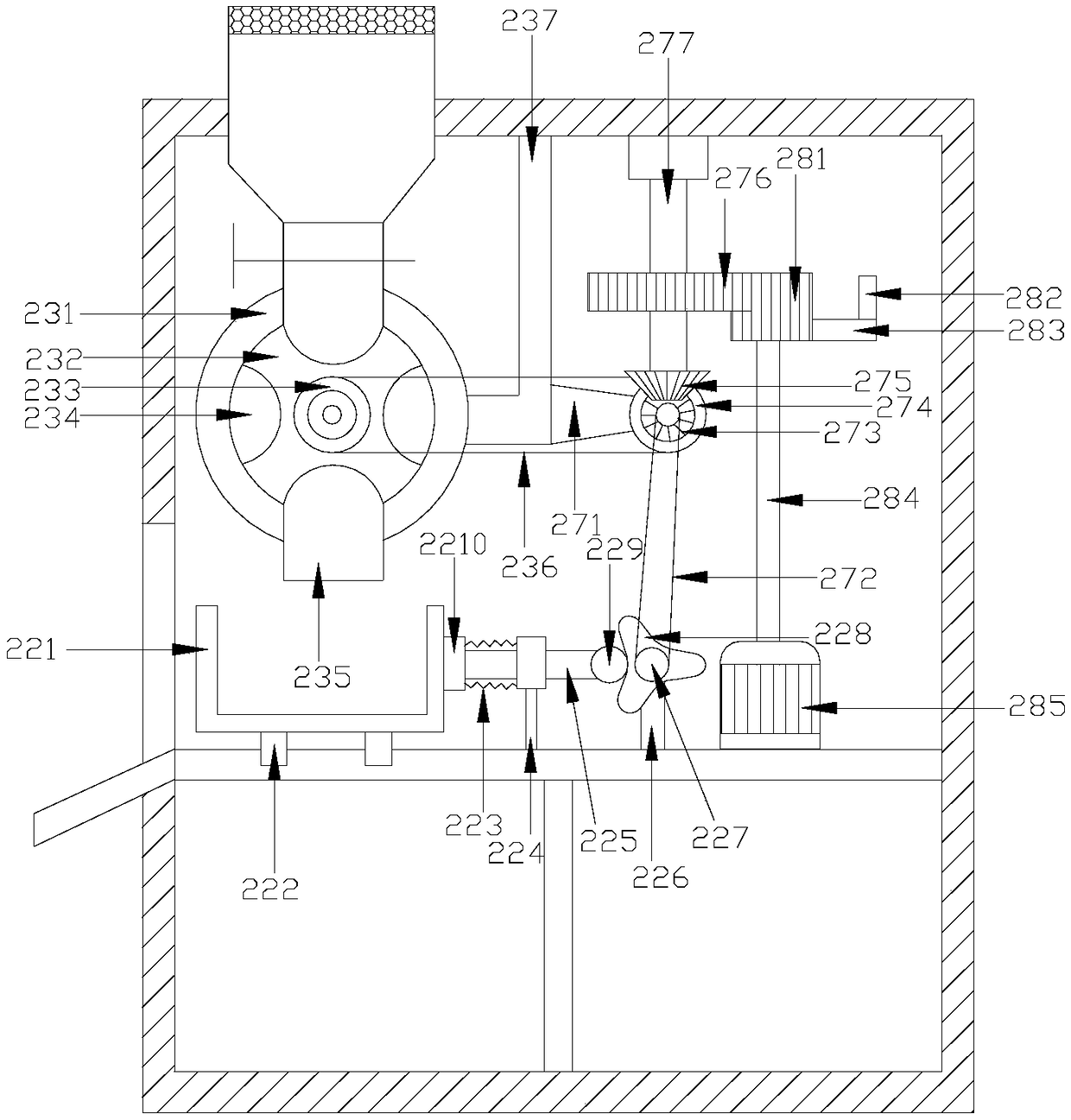

Novel feed feeding and packaging equipment

The invention discloses novel feed feeding and packaging equipment. The novel feed feeding and packaging equipment is characterized by structurally comprising a charge hopper, an automatic quantitative packaging mechanism, an observation window, a discharge hopper, a discharge pipeline, a lifting working platform, a fixed base, a working rack, and a control box body. According to the novel feed feeding and packaging equipment disclosed by the invention, a slot wheel and a pulling disc are arranged, so that the slot wheel rotates while the motor rotates one circle, and a separating wheel rotates for enabling an arc-shaped slot to intermittently move to a position below the charge hopper for collecting materials, and therefore, quantitative collecting is realized, material packaging quantitycan be controlled, weight of every pack of materials is consistent, difficult selling caused by uneven quantity of every pack is avoided, economic benefits are reduced, and daily economic benefits are guaranteed; when quantitative packaging is required, a collecting frame is placed below a discharge tube, an unloading conveying mechanism is controlled to convey from right to left; and a valve isopened for adding feed into the hopper, the feed in the charge hopper drops into the arc-shaped slot, and the motor is controlled to rotate to drive a second rotary shaft to rotate, so that a pullingdisc is driven to rotate.

Owner:HUZHOU ZHENSHUO AUTOMATION TECH CO LTD

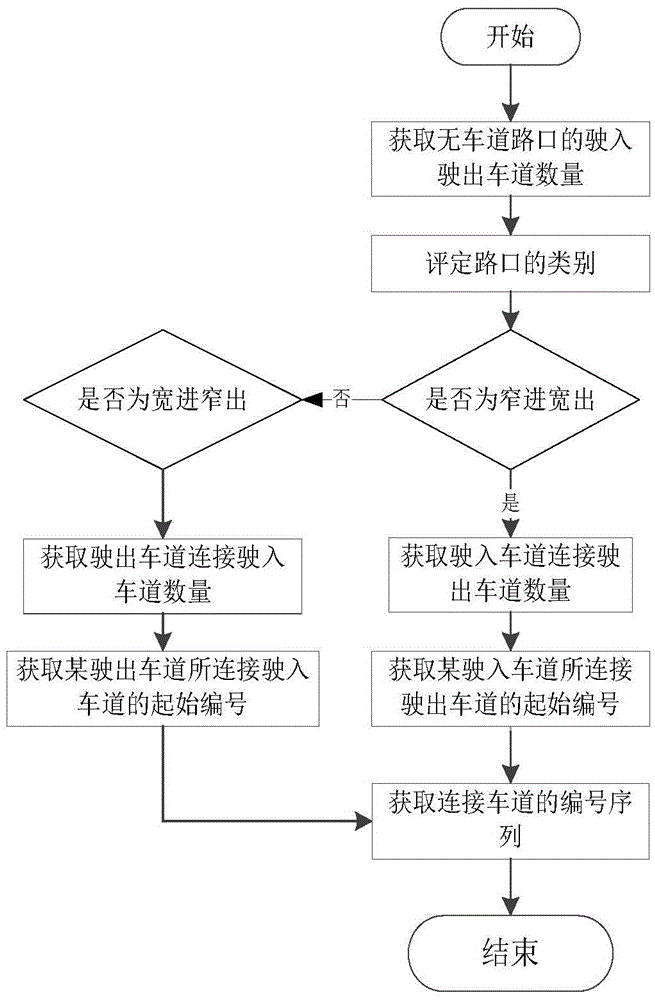

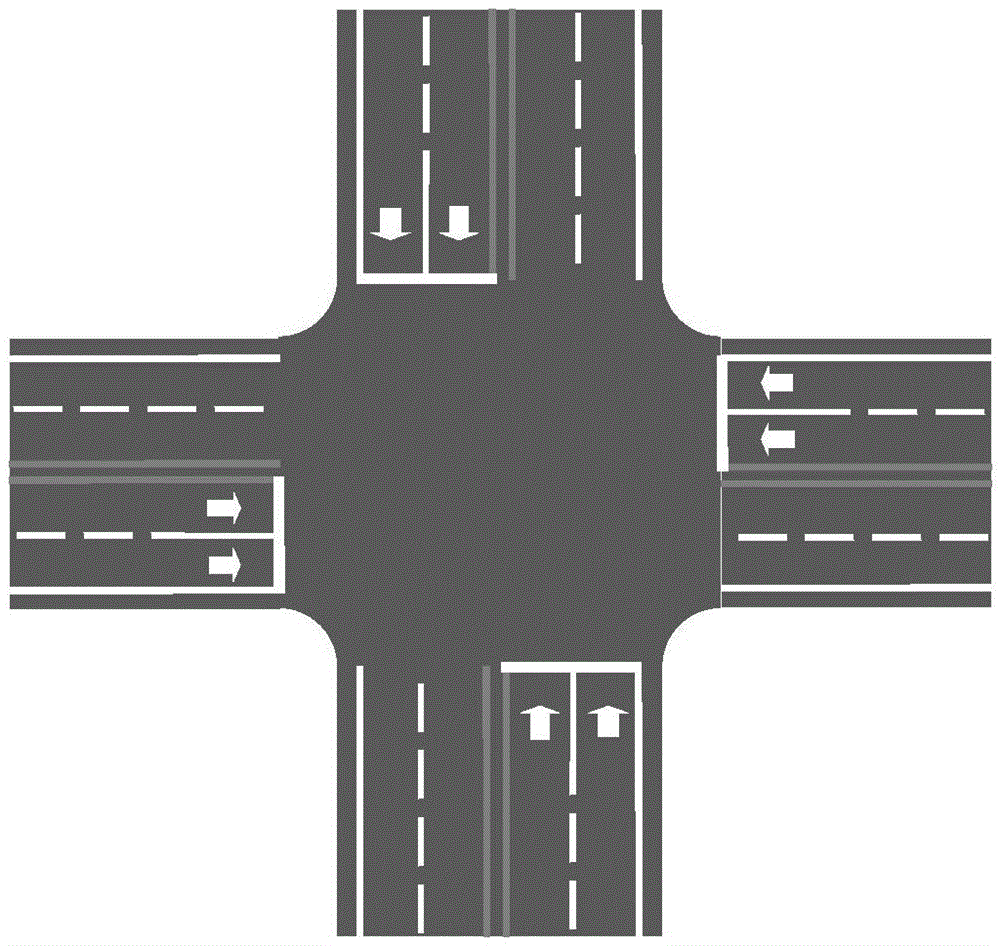

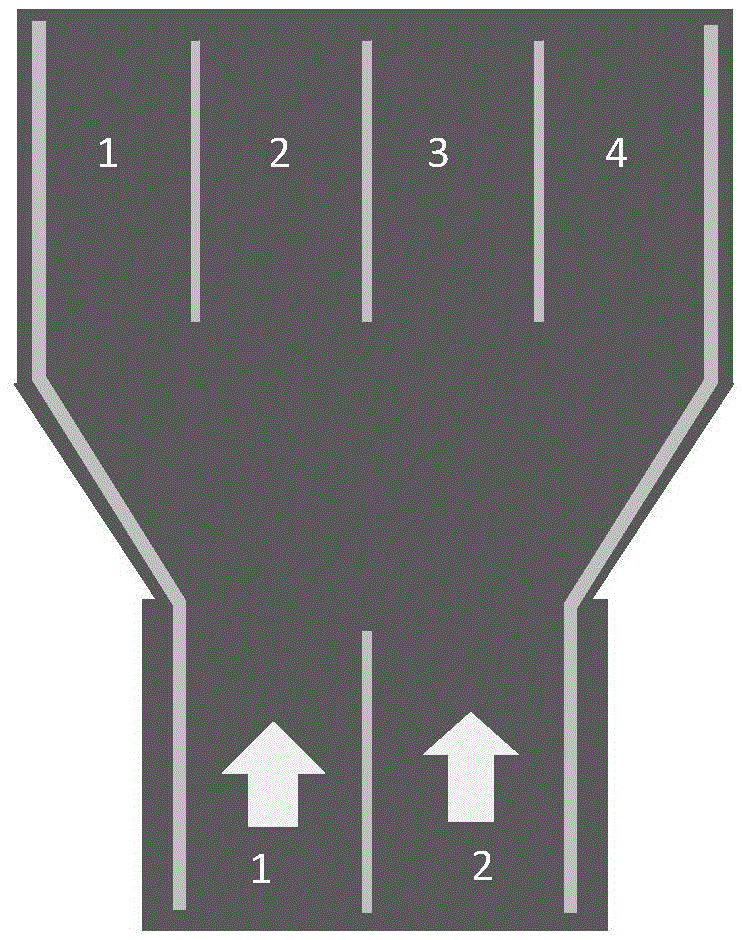

Algorithm of connection matching of entry and exit lanes of crossing without lane lines

InactiveCN105550364AGuaranteed feasibilityEnsure safetyForecastingGeographical information databasesComputer science

The invention provides an algorithm of connection matching of entry and exit lanes of crossing without lane lines. The algorithm comprises the following steps of: acquiring the number of entry and exit lanes of the crossing without lane lines; judging whether the crossing is a wide entry and narrow exit crossing or a narrow entry and wide exit crossing or an entry and exit equaled crossing; calculating the number of exit / entry lanes needed to be connected with each entry / exit lane; and calculating a start number of the exit / entry lanes connected with one entry / exit lane. With the method, establishment of a connection relation between entry and exit lanes of the crossing without lane lines can be completed by a simple and high-efficiency algorithm.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

Intelligent areca seed marinating machine

The invention discloses an intelligent areca seed marinating machine. The intelligent areca seed marinating machine comprises a rack, and a hopper, a material distribution disc, a transmission device, a vibration device, a marinating device and an arrangement platform arranged on the rack, and also comprises a sorting device which comprises a guide member and a scraper device, wherein the guide member is provided with a plurality of guide grooves which are distributed along the movement direction of the material distribution disc, the high end of the guide member is connected with the rear side wall of the hopper, and the low end of the guide member penetrates through a material outlet of the hoper to extend to the upper part of the material distribution disc; the scraper device comprises a scraping machine and a driving motor, the scraping machine is arranged above the material distribution disc and is positioned between the guide member and the marinating machine, and the marinating machine mainly comprises a marinating valve; an areca falls to the material distribution disc to be transmitted along the guide member; in the transmission process, the areca enters each areca containing groove in the material distribution disc under the combined action of the vibration device and the scraping machine; the marinating device is used for marinating to be transmitted to the arrangement platform. The automatic sorting of the areca can be realized, and the work efficiency can be improved.

Owner:CHANGSHA HERACLES INTELLIGENT EQUIP CO LTD

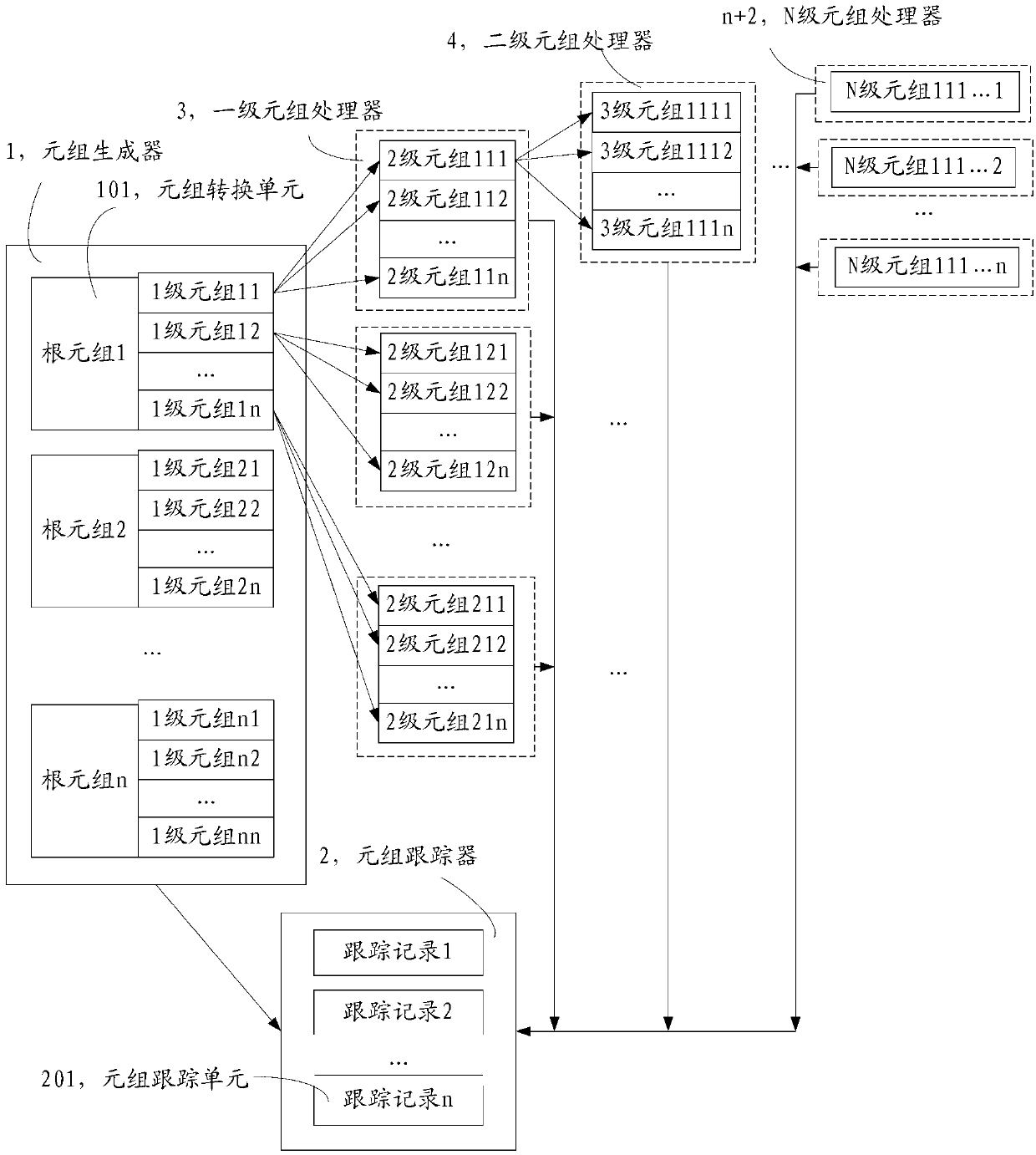

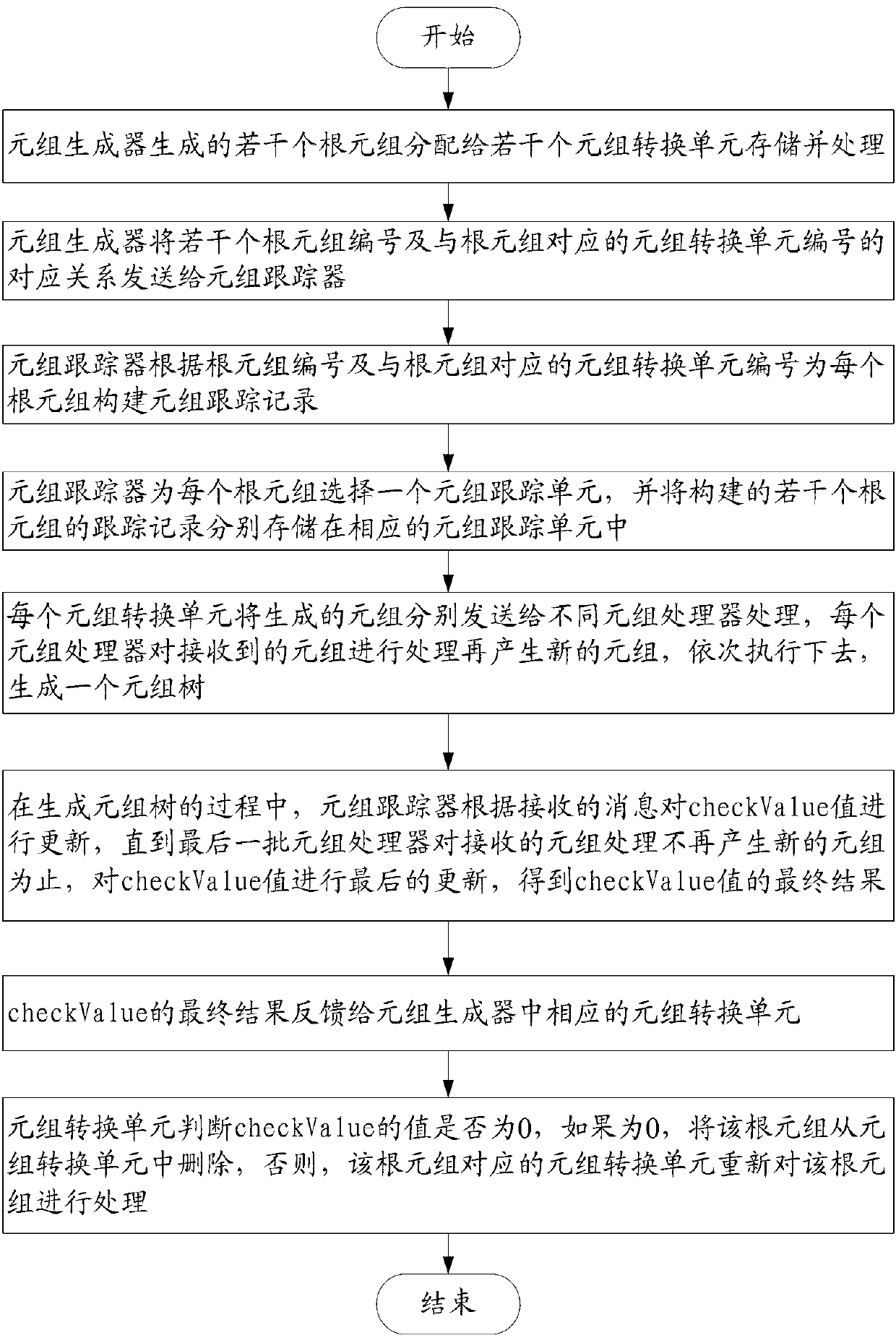

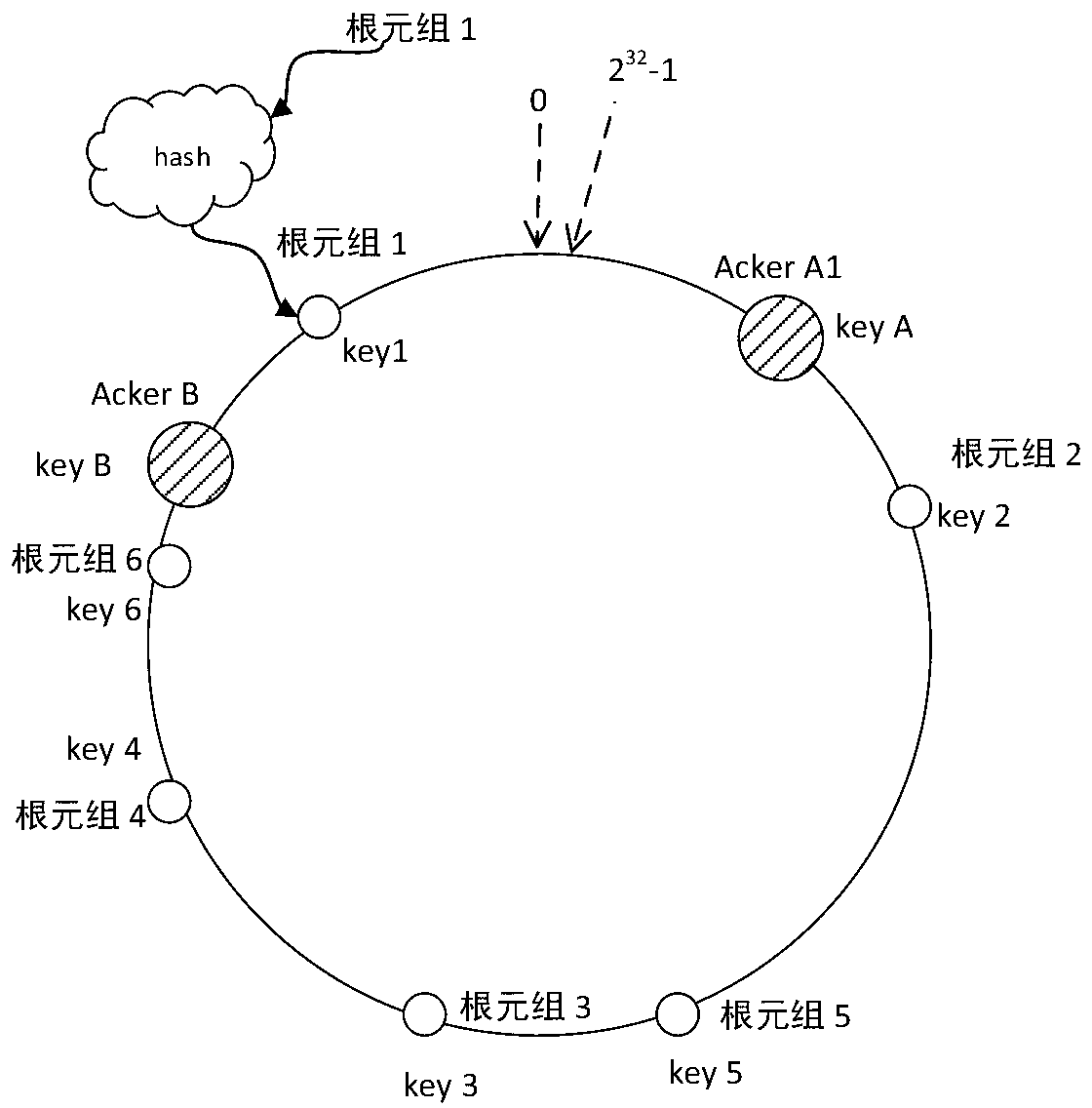

Tuple tracking method and tuple tracking system for data flow processing

ActiveCN103346901ASave memoryReduce memory overheadData switching networksSpecial data processing applicationsGeneration processRelevant information

The invention relates to a tuple tracking method and a tuple tracking system for data flow processing. The tuple tracking system comprises a tuple generator, a tupler tracker and a plurality of tuple processors. The tuple generator generates root tuples, processes the root tuples, and generates new tuples, and then transmits the new tuples to the different tuple processors. The tuple processors process the received tuples and generate new tuples. Each root tuple can generate a tuple tree after being processed, in the generation process of each tuple tree, the tuple generator transmits relevant information of the root tuple to the tuple tracker, then the tuple tracker can construct a tracking record of the root tuple, and the tuple tracker chooses one tuple tracking unit for each root tuple. When each tuple processor processes the tuple, relevant information of the tuple is sent to the tuple tracker to update identification positions of the tracking records. The tuple tracking method and the tuple tracking system for data flow processing can greatly reduce internal storage cost, achieve load balance of the tuple tracking units, and improve reliability of tuple processing.

Owner:INST OF INFORMATION ENG CAS

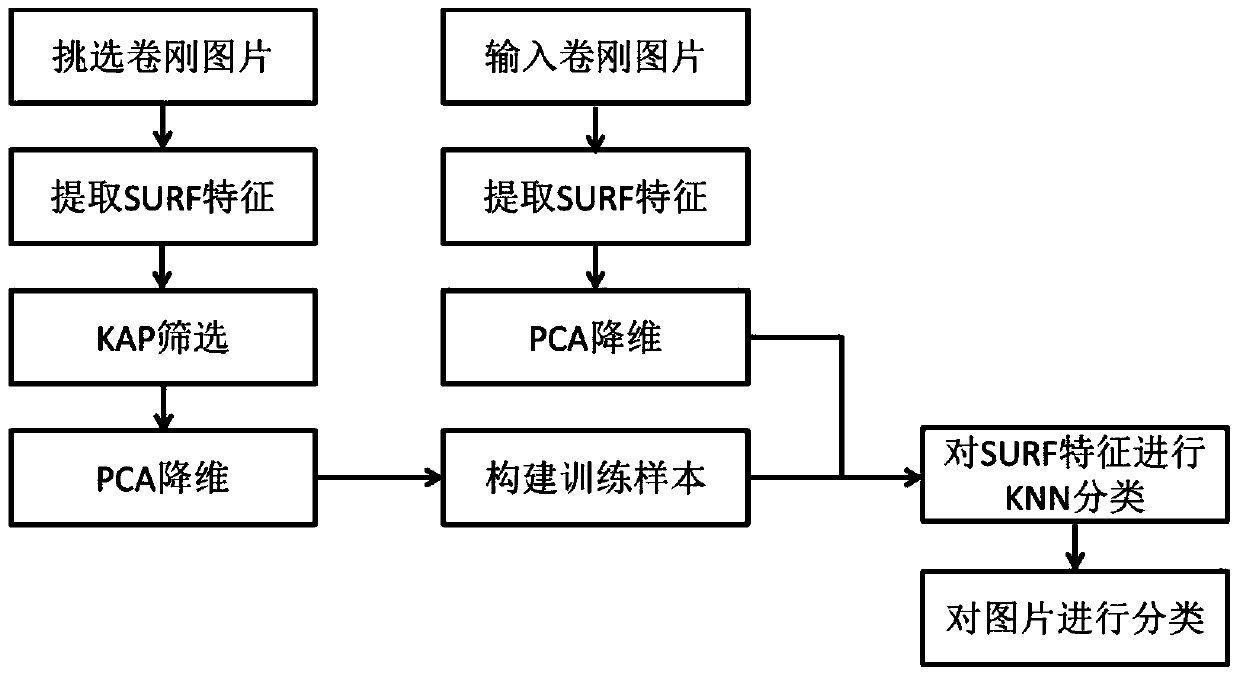

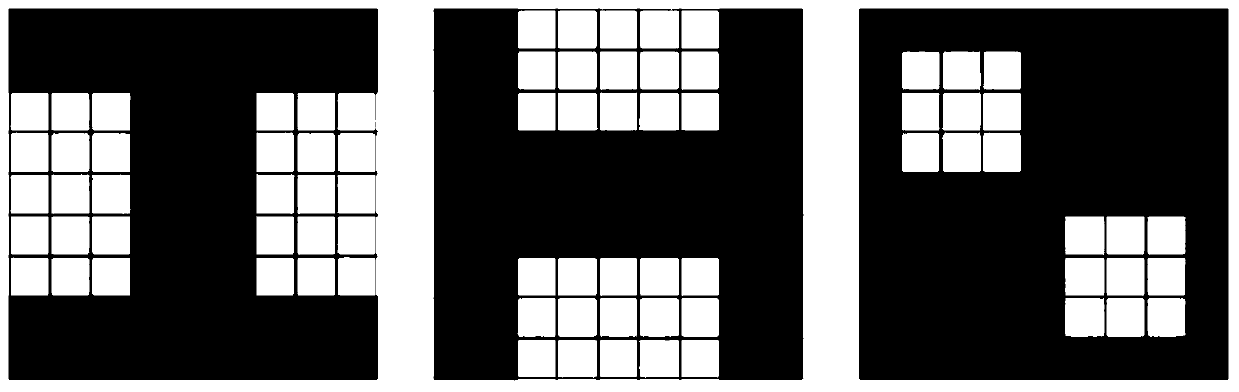

Reeling steel state identifying method based on KNN reeling steel picture data of optimized KAP sample

ActiveCN103632164AGuaranteed classification accuracyClass sample size balanceCharacter and pattern recognitionLinear arrayAlgorithm

The invention relates to a reeling steel state identifying method based on KNN reeling steel picture data of an optimized KAP sample, wherein KAP belongs to a fast efficient clustering algorithm, clustering is performed by the mutual relation among computation features, a new sample space is formed by clustering and selecting feature samples with representation in various samples, and the balance among each sample number in the new sample space is ensured by fixing the parameter K in the KAP algorithm. A PCA algorithm is utilized for performing dimension reducing on the features and the operation speed of the method is improved under the condition of ensuring the classifying precision. The classifying identification on the linear array CCD (charge couple device) picture-based reeling steel loading state under the complex natural environment is realized. The method has very high classifying precision and lower wrong classifying rate, and the actual needs are met with the faster classifying speed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Controllable discharging device system and discharge control method

ActiveCN103935741ASame quantityTimely control of overload timeControl devices for conveyorsMaterial distributionImpurity

The invention discloses a controllable discharging device system and a discharge control method. The discharge control method is characterized by comprising the steps that after materials enter material storage boxes through feed ports of the material storage boxes, impurities in the materials are filtered out through filter sieves which are arranged in the material storage boxes, the materials enter a material distribution box after flowing out of the material storage boxes, the materials are placed on a material conveying belt by the material distribution box through different material distribution ports, the levels of the materials in the material storage boxes and the fact whether the material conveying belt is overloaded or not are monitored through a comprehensive controller, and opening and closing of valves on the material distribution ports and feeders on the material storage boxes are controlled timely. The controllable discharging device system and the discharge control method have the advantages that the impurities in the materials are filtered out before loading, the overloading time of the conveying belt is controlled in time during loading, and the numbers of materials in all the material storage boxes are almost the same or the levels of materials in all the material storage boxes are almost the same.

Owner:CCCC MECHANICAL & ELECTRICAL ENG

Heat exchanger system comprising fluid circulation zones which are selectively coated with a chemical reaction catalyst

InactiveUS8187559B2Improve distributionShorten the lengthCombination devicesExhaust apparatusChemical reactionEngineering

The invention relates to a plate (10a) intended to be integrated in a stack of plates in a heat exchanger system, the plate comprising a plurality of channels (38) distributed in rows (40), each row comprising side walls (42) arranged opposite one another and spaced apart from one another in a first direction (44), so that two directly consecutive side walls delimit one of the channels (38), the rows being arranged opposite one another and spaced apart from one another in a second direction (46) which is perpendicular to the first. Furthermore, in the fluid circulation zone (20) of the plate incorporating the channels (38), only the latter are coated with a catalyst allowing a chemical reaction.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

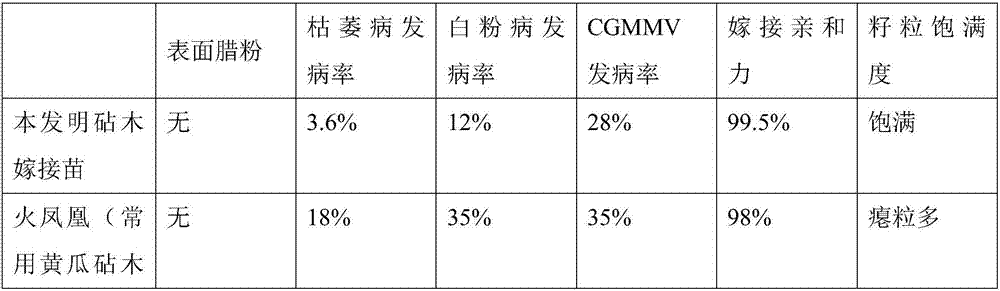

Screening method of pumpkin material for glossy disease-resistant rootstock

InactiveCN107114234AShorten the breeding periodImprove screening accuracyHorticulture methodsPlant genotype modificationPumpkin seedScreen method

The invention relates to screening method of a pumpkin material for a glossy disease-resistant rootstock. The method comprises the following steps: (1) grafting: collecting different pumpkin germplasm materials, grafting cucumber scions to pumpkin seedlings having two true leaves and an apical bud, pinching the true leaves of rootstock pumpkins before the grafting, retaining growing points, planting grafted seedlings, and retaining two vines, a cucumber vine and a pumpkin vine; (2) cucumber glossy performance screening: comparing and screening the grafted seedlings, selecting materials with the most obvious cucumber dewaxing powder and the best brightness, after bearing 2 to 3 cucumbers, removing the cucumber vines in time, only retaining the pumpkin vines to identify and screen disease resistance character or reserve seeds; (3) pumpkin rootstock disease resistance screening: screening the grated seedlings for resistance to fusarium wilt, resistance to powdery mildew, and resistance to CGMMV, selfing the materials with resistance to disease and cucumber glossy performance and retaining F1 generation pumpkin seeds. The method has short breeding time, high efficiency and standardized means, and can retain the fine properties of pumpkin seedling and rootstock at the same time.

Owner:青岛金妈妈农业科技有限公司

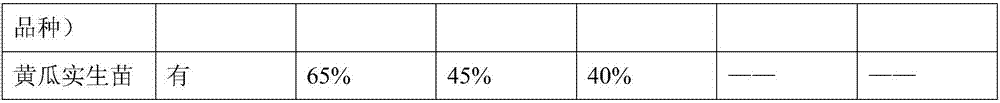

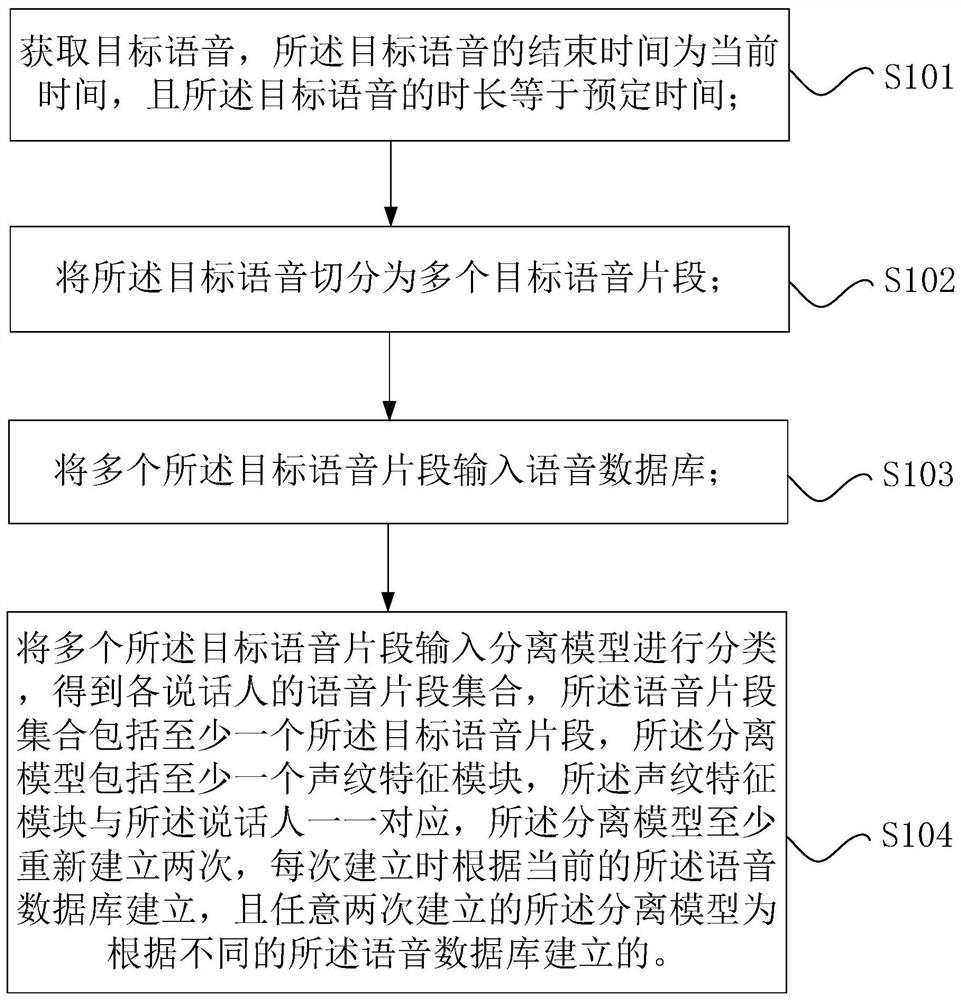

Voice separation method and voice separation device

The invention provides a voice separation method and a voice separation device, wherein the voice separation method comprises the steps: obtaining a target voice, enabling the end time of the target voice to be the current time, and enabling the duration of the target voice to be equal to the preset time; segmenting the target voice into a plurality of target voice segments; inputting the plurality of target voice segments into a voice database; inputting the plurality of target voice segments into a separation model for classification, to obtain a voice segment set of each speaker, wherein the separation model comprises at least one voiceprint feature module, the voiceprint feature modules are in one-to-one correspondence with the speakers, the separation models are re-established at least twice, the separation models are established according to the current voice database every time the separation model is established, and the separation models established at any two times are established according to different voice databases. According to the method, correction is carried out through reconstruction to ensure that the target voice segment in the voice segment set is the voice ofthe same speaker, so that the voice separation accuracy rate is improved.

Owner:BEIJING SINOVOICE TECH CO LTD

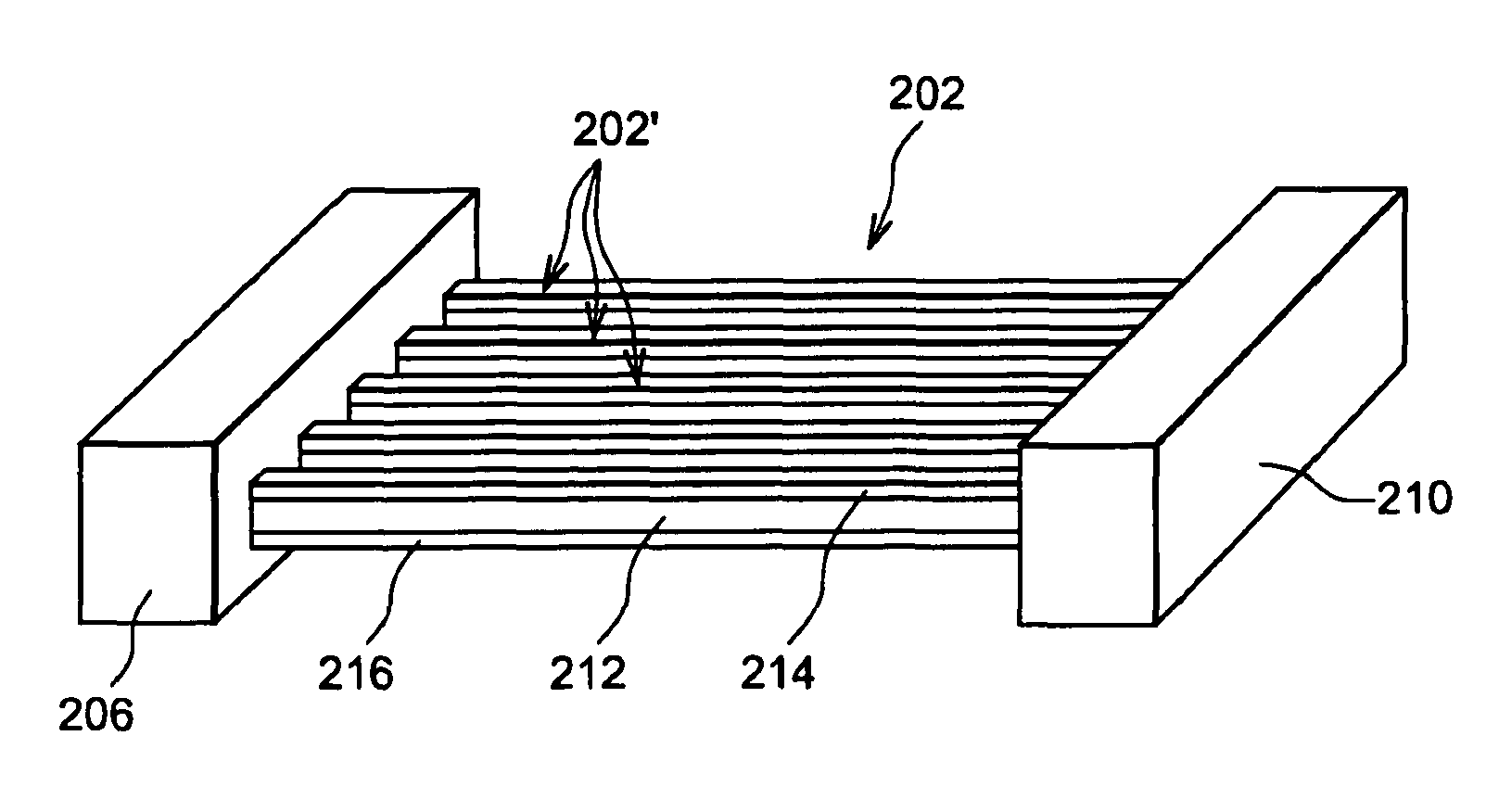

Device for converting mechanical impact energy into electrical energy with optimised efficiency

ActiveUS8456063B2Reduce impactImprove conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersMechanical energyMechanical impact

Device for converting mechanical energy from the impact of objects into electrical energy, comprising a frame, a membrane suspended on said frame by at least a first and second longitudinal end, said membrane being intended to be impacted by said objects in a direction substantially transverse to a mid-plane of the membrane, said membrane comprising a core made from material for transducing mechanical energy into electrical energy, extending from the first longitudinal end to the second longitudinal end, and at least one electrode on a first face of the core and at least one electrode on a second face of the core, said electrodes extending from the first to the second longitudinal end.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com