Intelligent areca seed marinating machine

A technology for placing brine and betel nut, applied in the field of intelligent betel nut brine machine, can solve the problems of unfavorable market competition, high labor intensity, low work efficiency, etc., and achieve the effects of improving market competitiveness, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

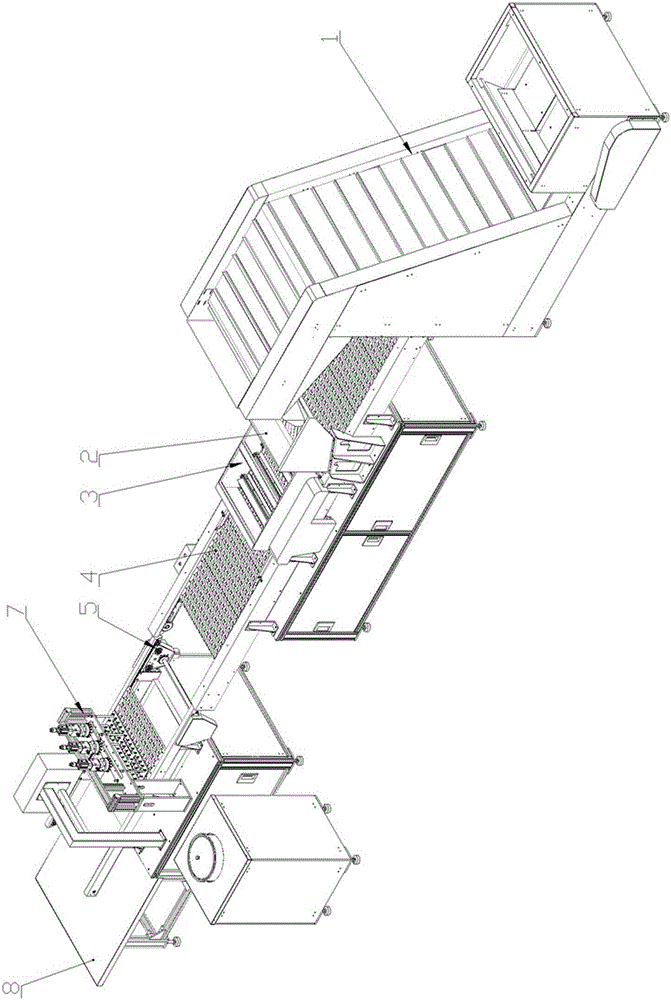

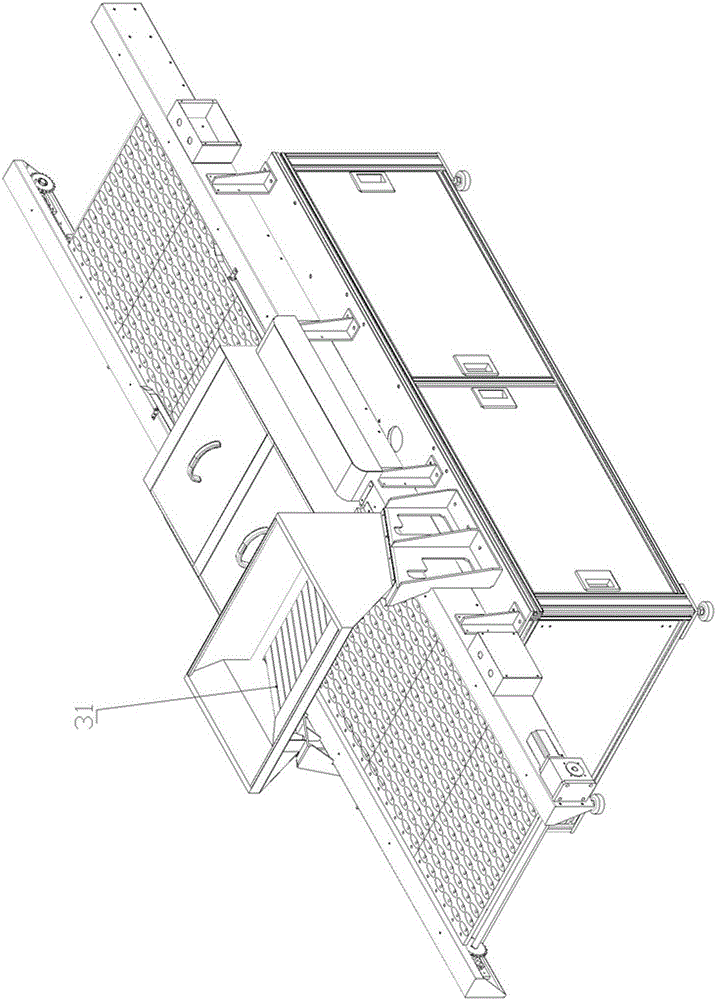

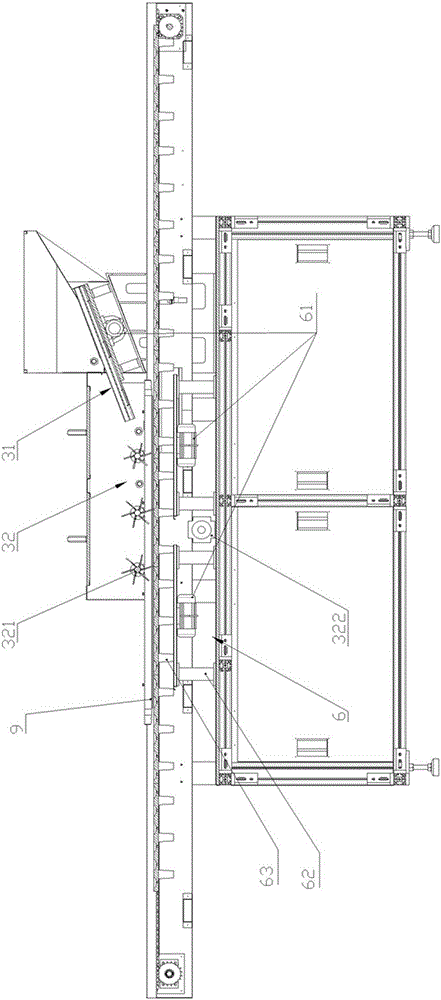

[0023] Such as Figure 1-6 As shown, the present invention discloses an intelligent betel nut pointing machine, which includes a bucket elevator 1, a hopper 2, a sorting device 3, a discharge tray 4, a transmission device 5, a vibration device 6, a pointing device 7, and a placement platform 8 and the disc plate 9, wherein the sorting device 3 includes a guide member 31 and a scraper device 32; the guide member 31 includes a rectangular plate and a partition arranged on it along the moving direction of the discharge tray, between two adjacent partitions Form guide grooves, the number of guide grooves matches the number of columns of betel nut accommodation grooves on the discharge tray 4, the distance between two adjacent guide grooves matches the distance between two adjacent rows of betel nut accommodation grooves, the guide member 31 is arranged obliquely, and the high end is aligned with the hopper. The rear side walls of 2 are connected, and the lower end passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com