Patents

Literature

128results about How to "Improve seeding accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

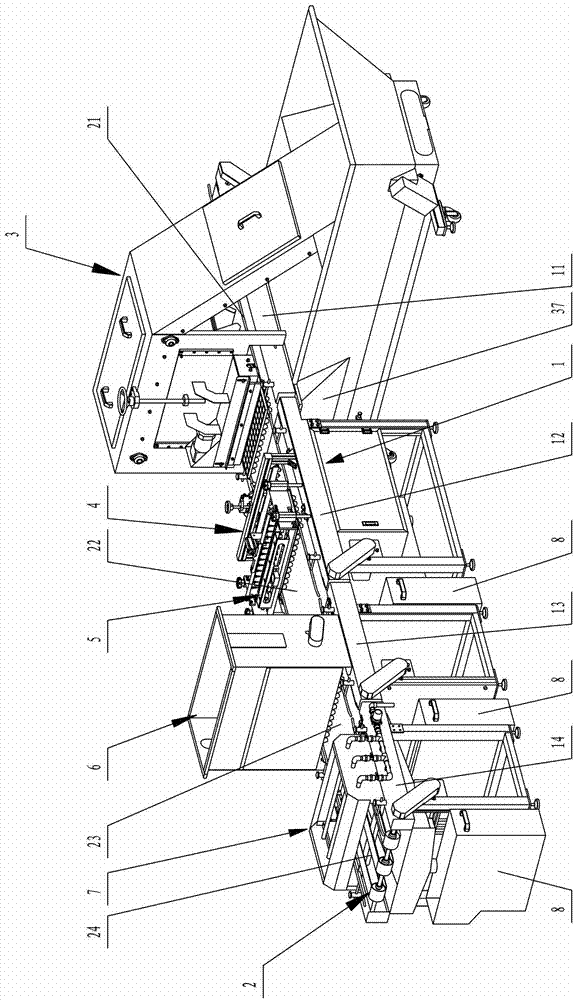

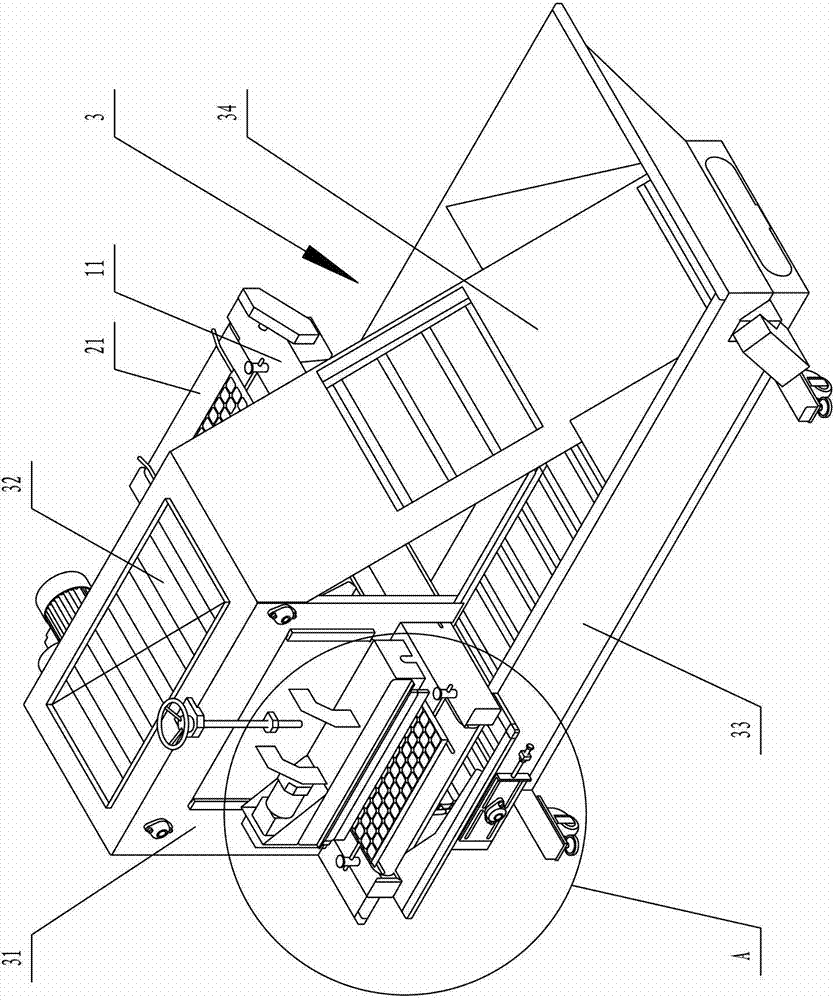

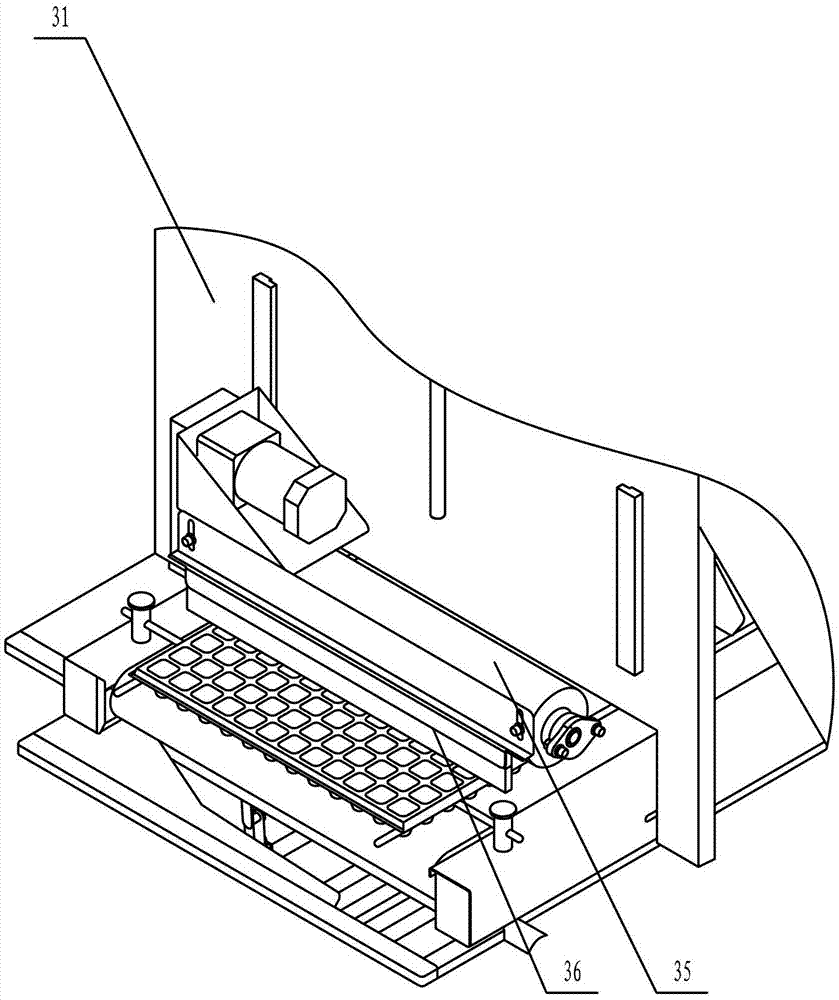

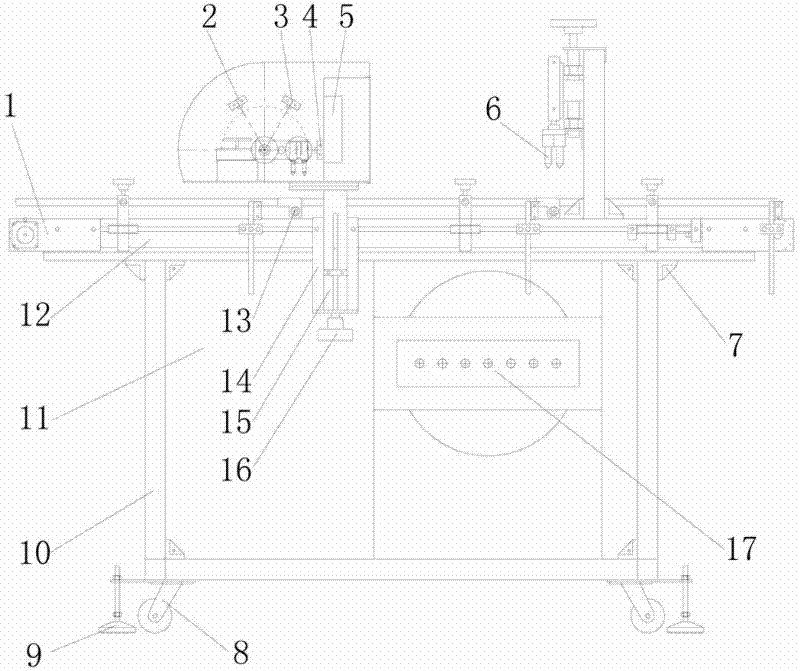

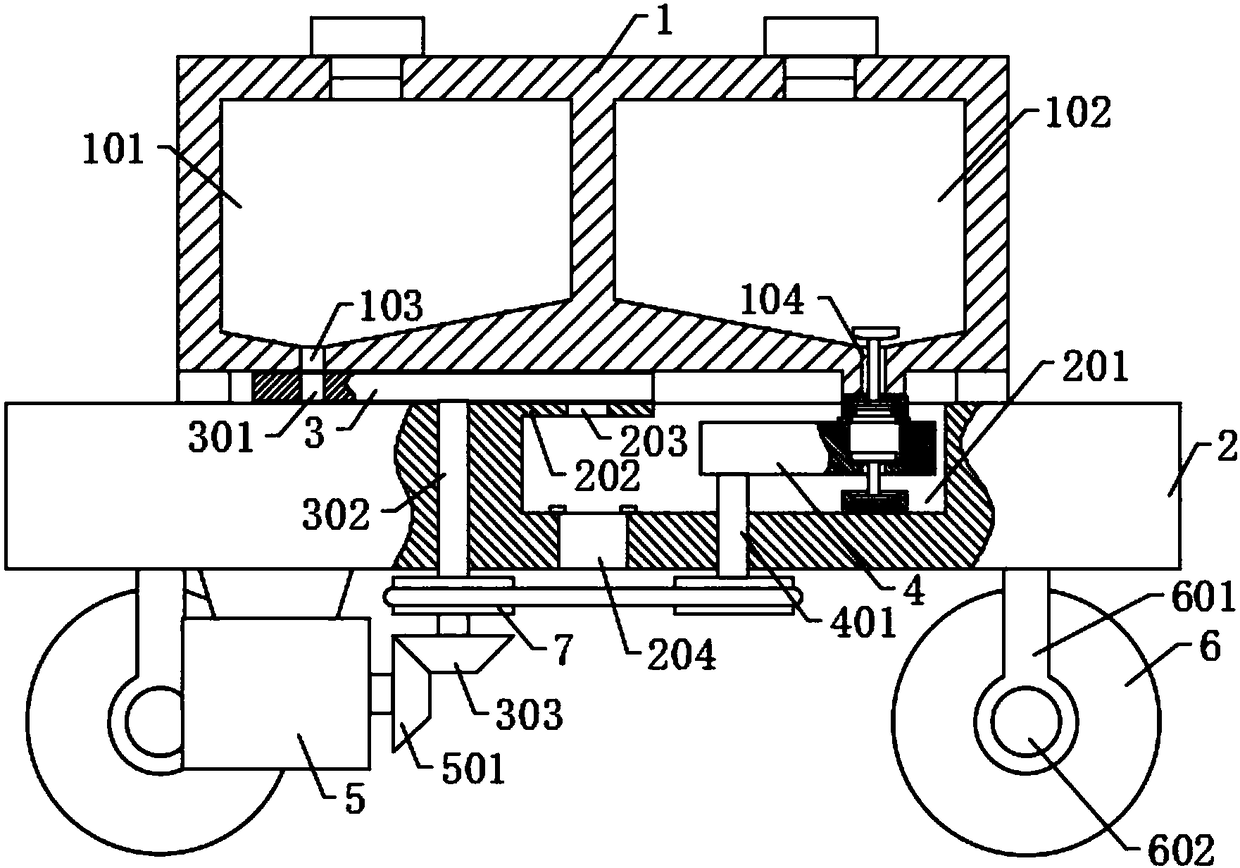

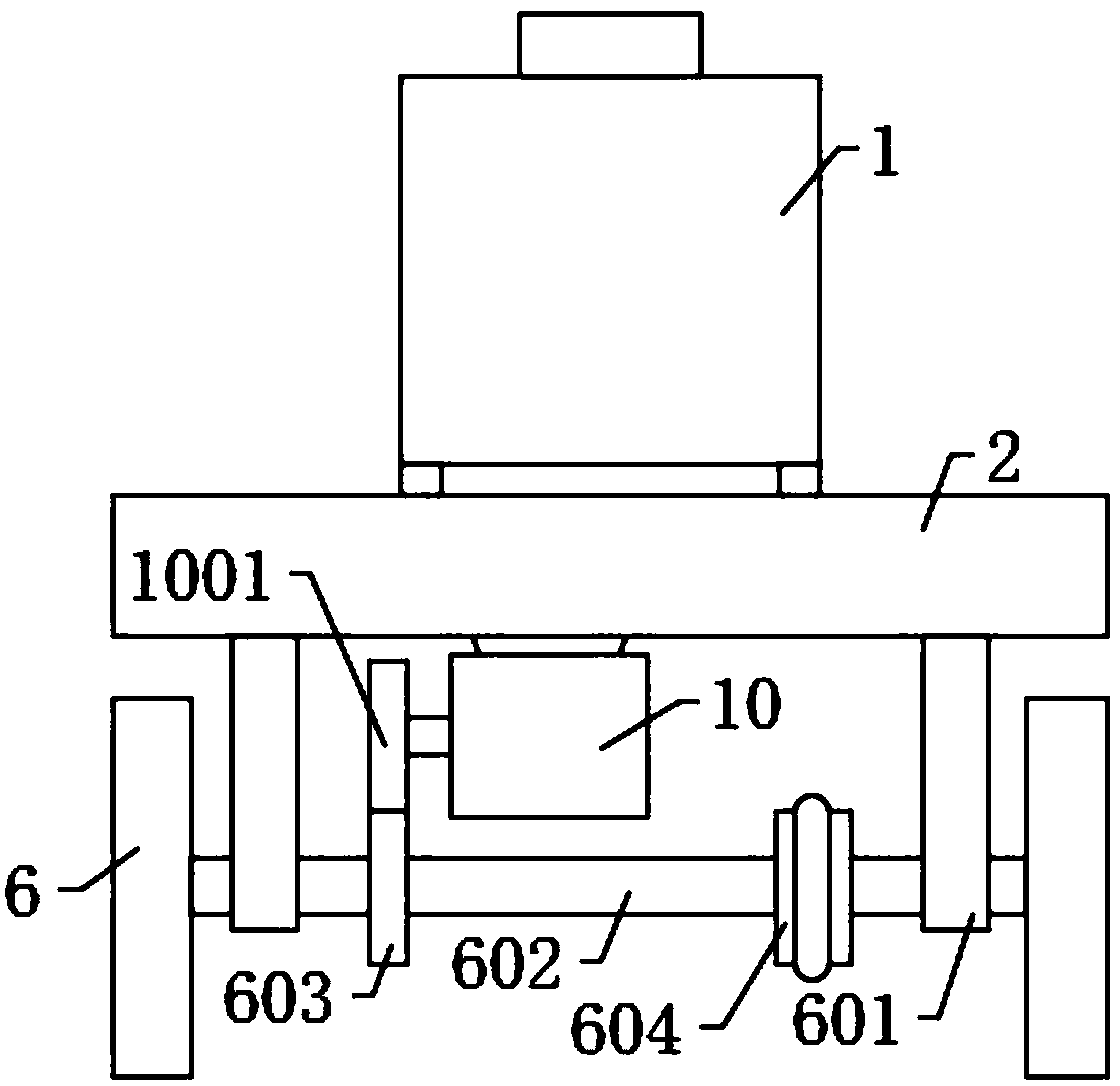

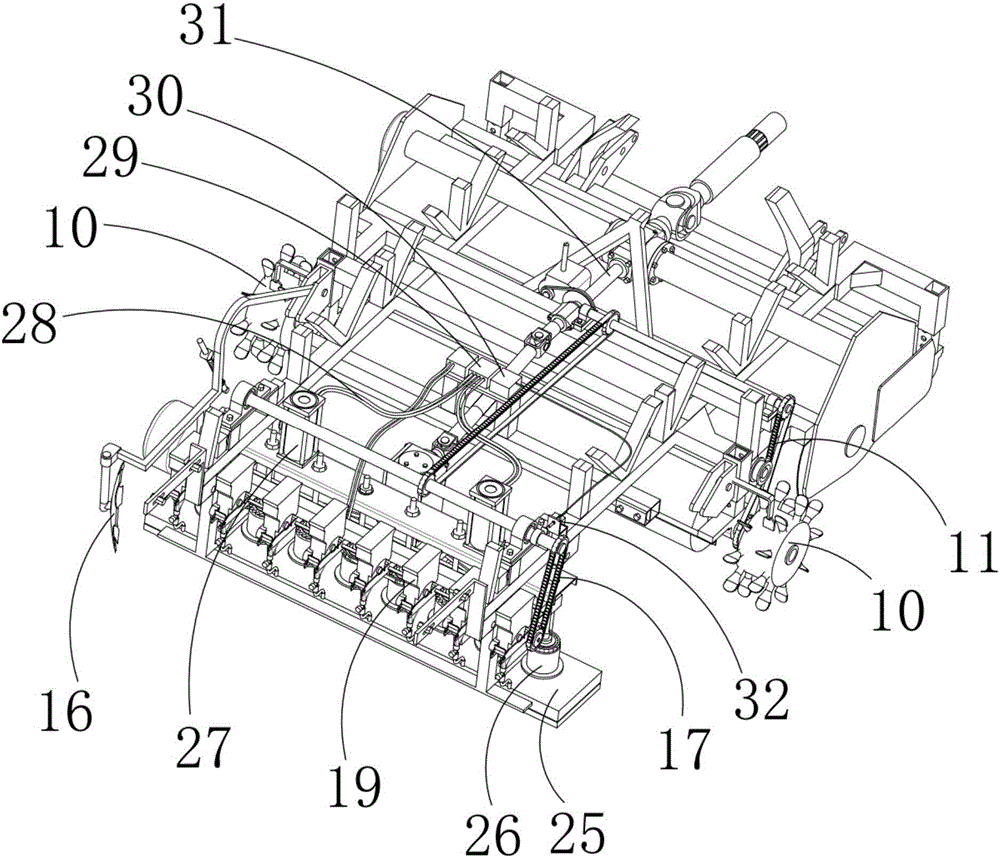

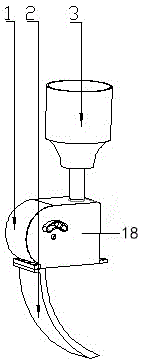

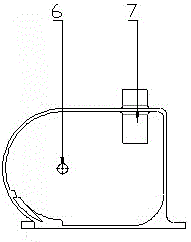

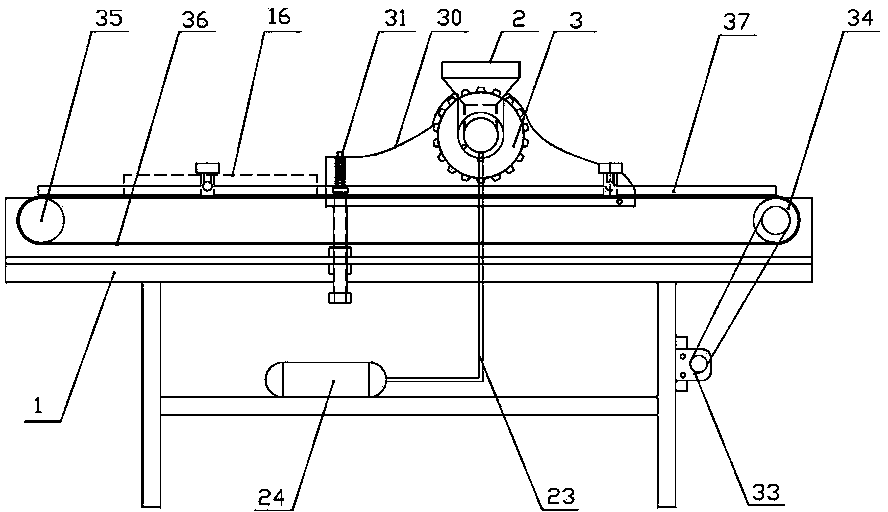

Seedling and seeding machine and seedling and seeding method

ActiveCN102960101AImprove work efficiencyRealize automatic controlCultivating equipmentsSeed depositing seeder partsProduction linePunching

The invention provides a seedling and seeding machine. The seedling and seeding machine comprises a rack, and a conveying device at the top of the rack, wherein a subsoil filling device, a punching device, a needle type tray seeding device, a soil covering device and a watering device are sequentially arranged on the conveying device along the conveying direction of the conveying device. According to the seedling and seeding machine provided by the invention, the subsoil filling device, the punching device, the needle type tray seeding device, the soil covering device and the watering device which are sequentially arranged on the conveying device are used for conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering, so that the whole work of seedling and seeding can be carried out on one production line, and as a result, the working efficiency in seedling and seeding can be effectively improved. The invention also provides a seedling and seeding method. The seedling and seeding method comprises the following steps in sequence: conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering; and by adopting the method, the working efficiency in seedling and seeding can be effectively improved.

Owner:四川川龙拖拉机制造有限公司

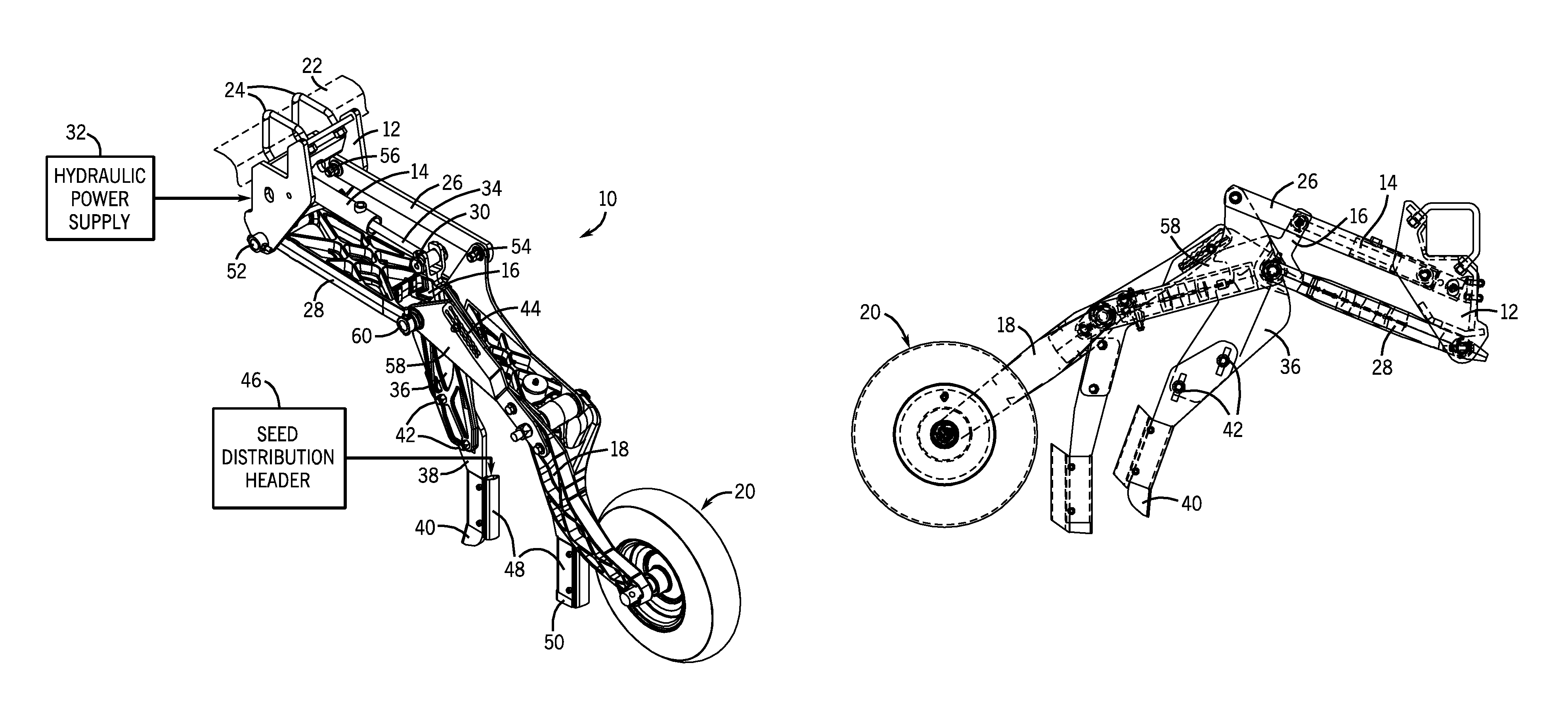

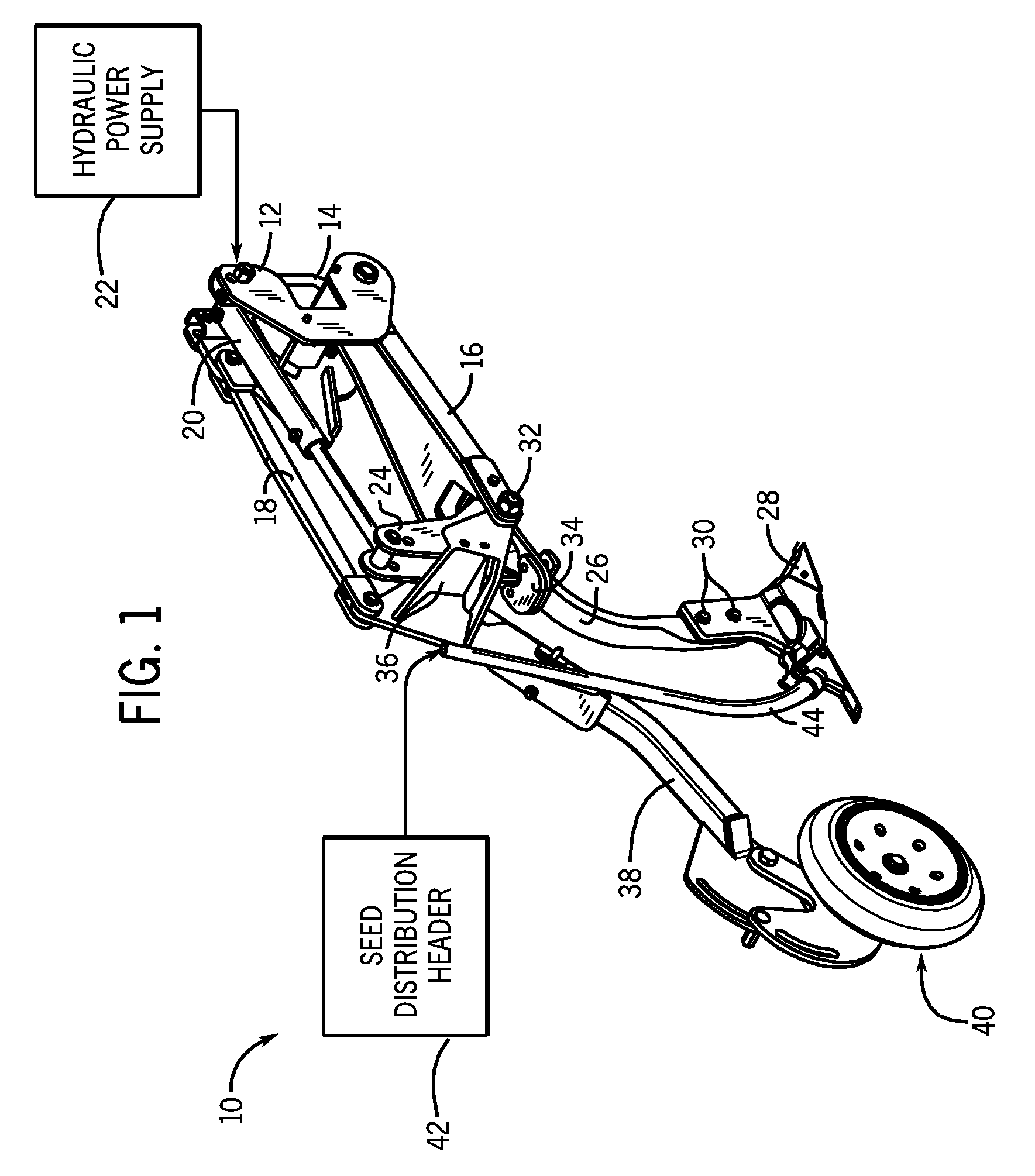

Precision hoe opener with draft force compensation

InactiveUS7578246B2Increase relative motionConstant pressureSpadesPlantingMechanical engineeringTerrain elevation

A precision hoe opener assembly is provided with improved accuracy of seeding as well as improved control over the opener and packer wheel assemblies. The opener assembly includes a hydraulically-driven parallel linkage assembly, a swing link, a ground engaging tool, and a packer wheel. The design provides improved seeding accuracy, by compensating for changes in draft force caused by changes in terrain elevation. The swing link allows the cylinder to compensate for the forces applied to the ground engaging tool, thereby providing a substantially constant packing force to the soil beneath the packing wheel.

Owner:CNH IND CANADA

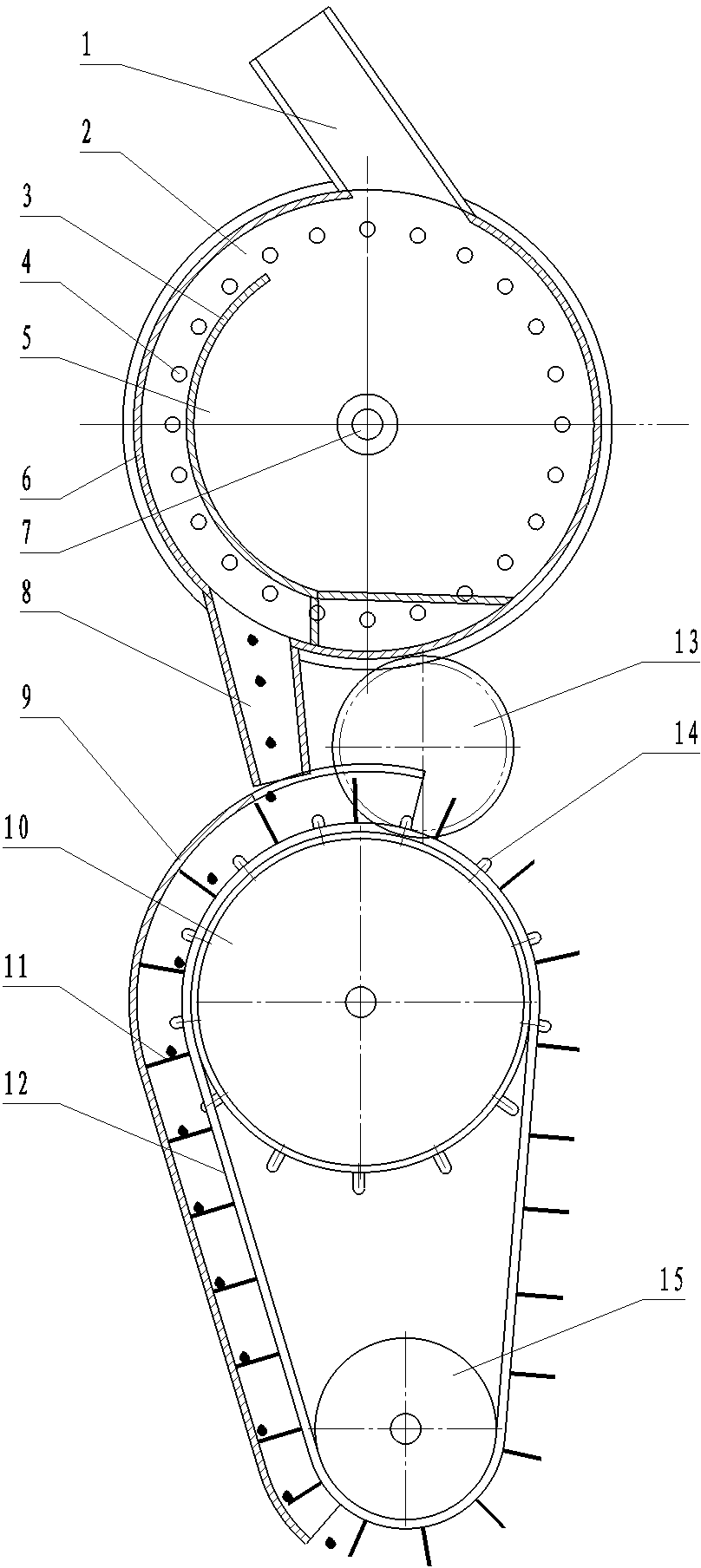

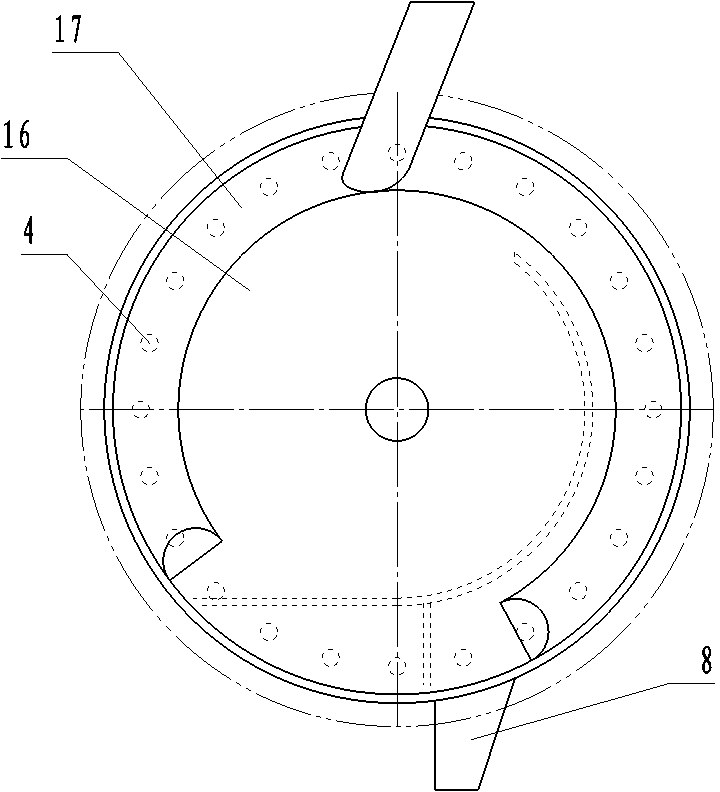

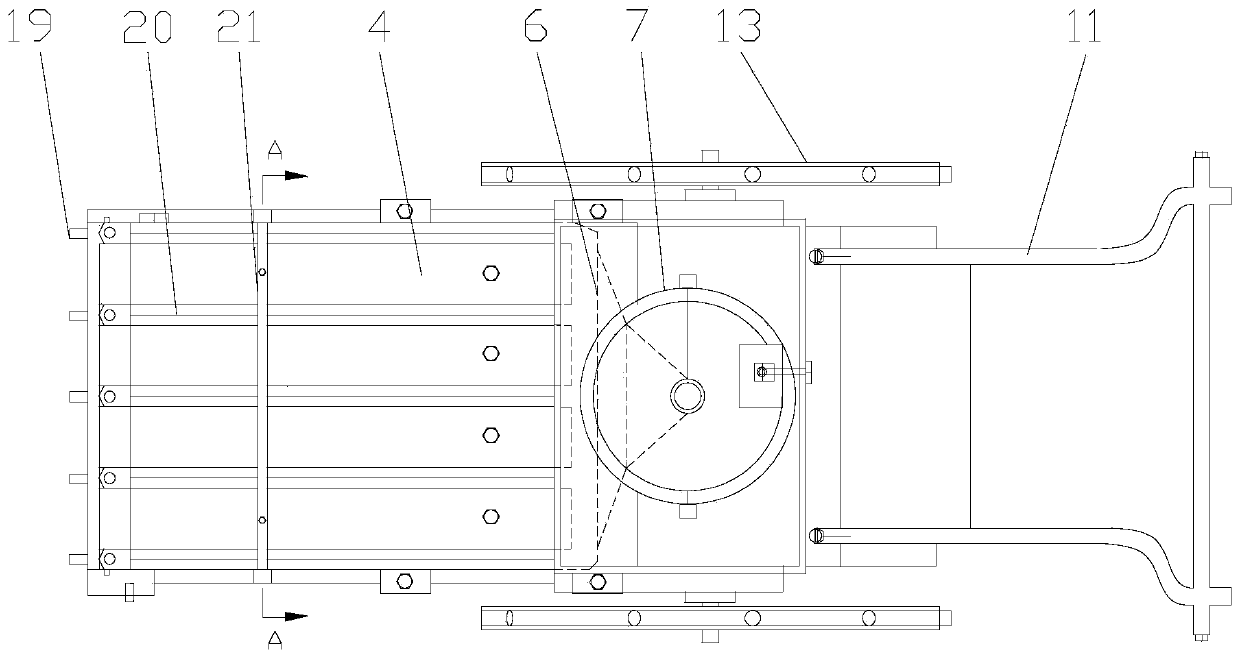

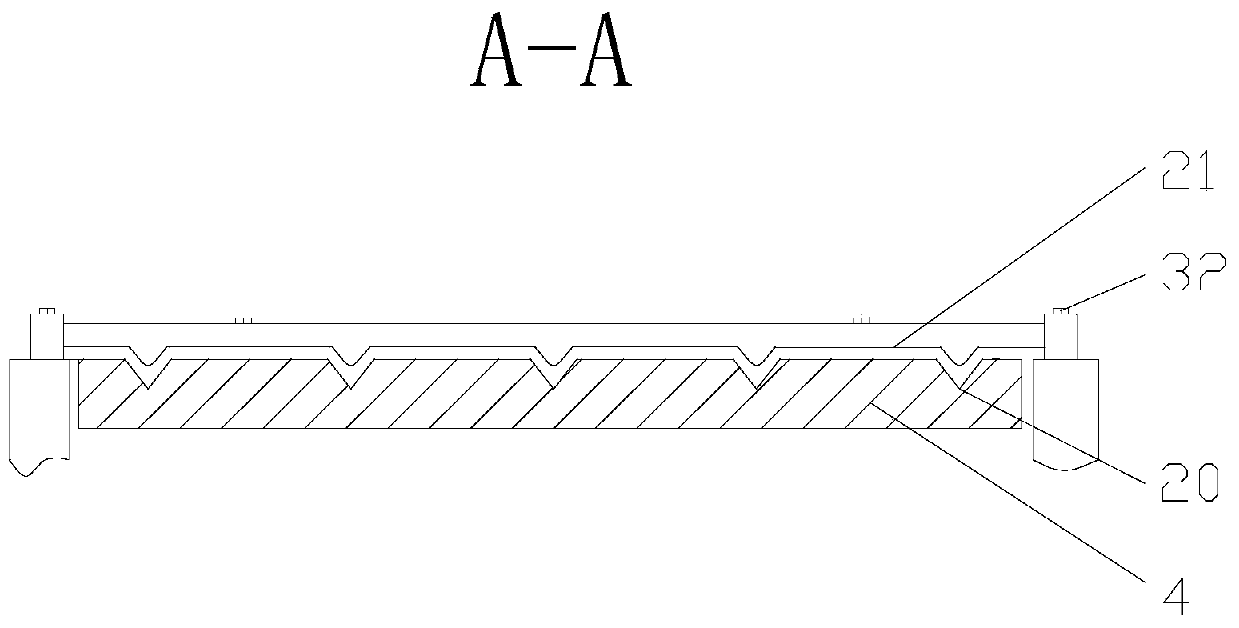

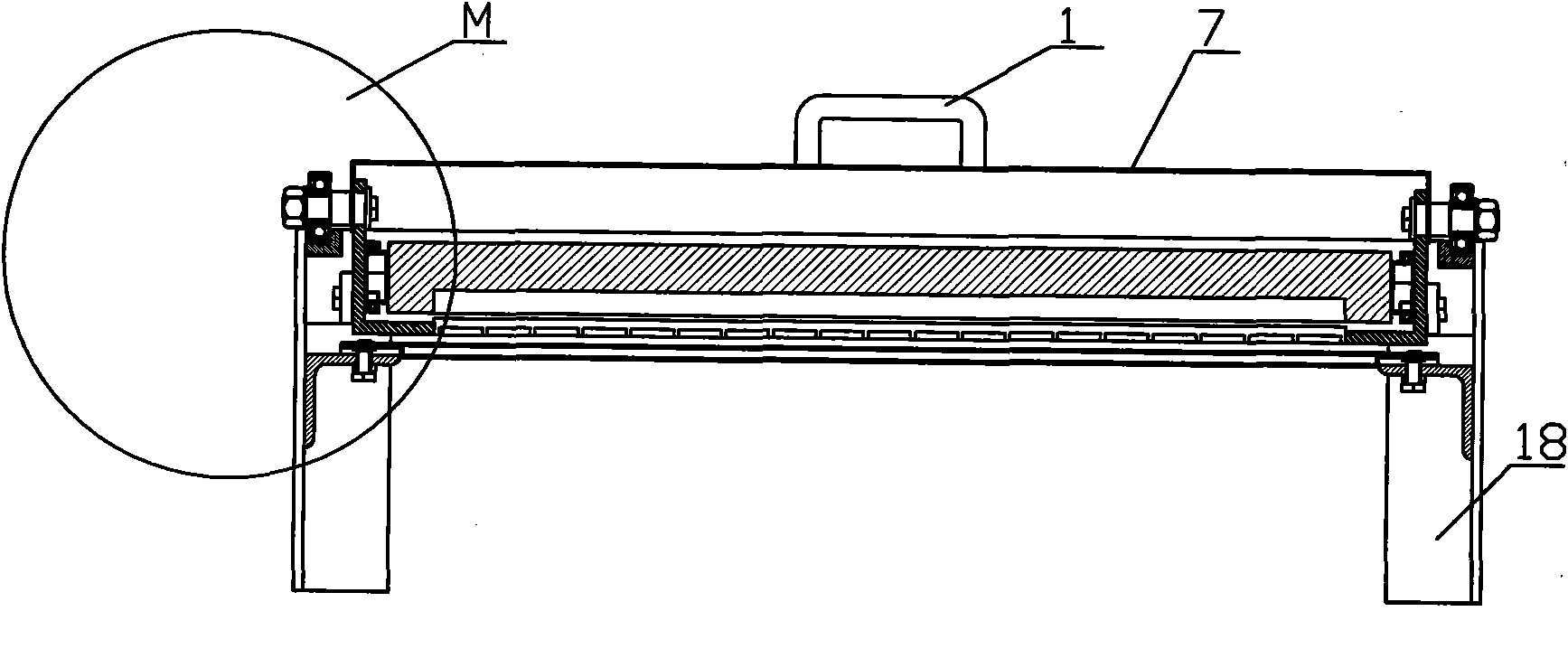

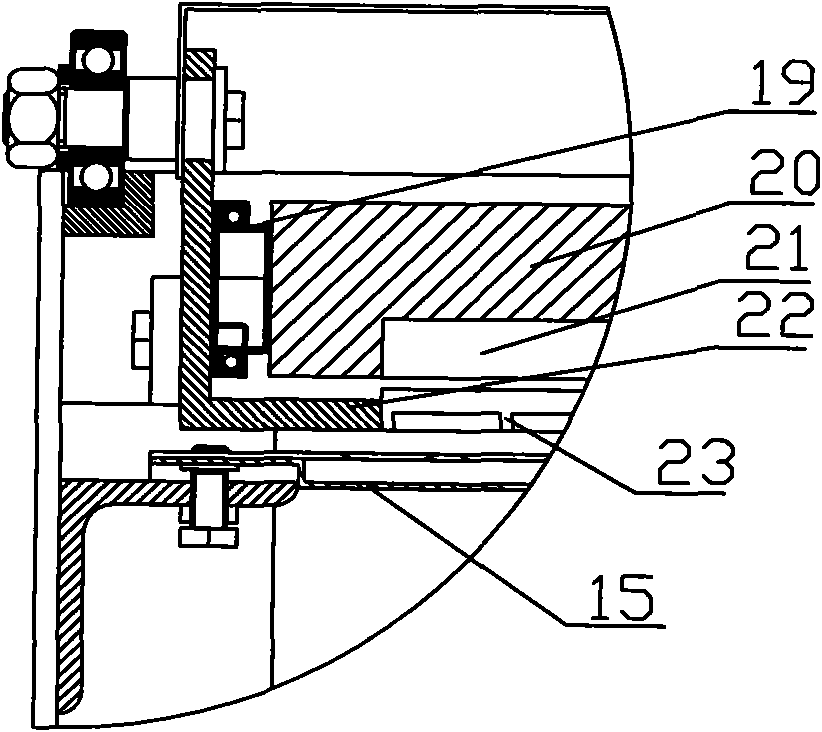

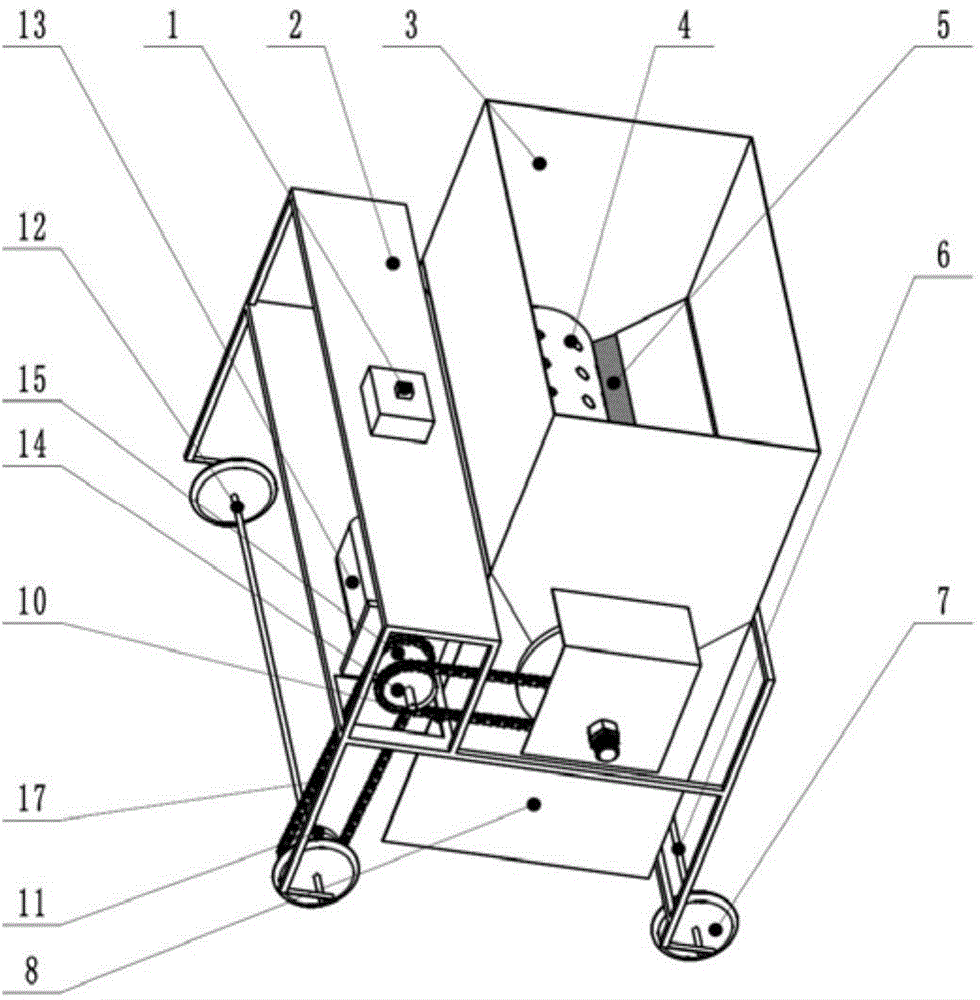

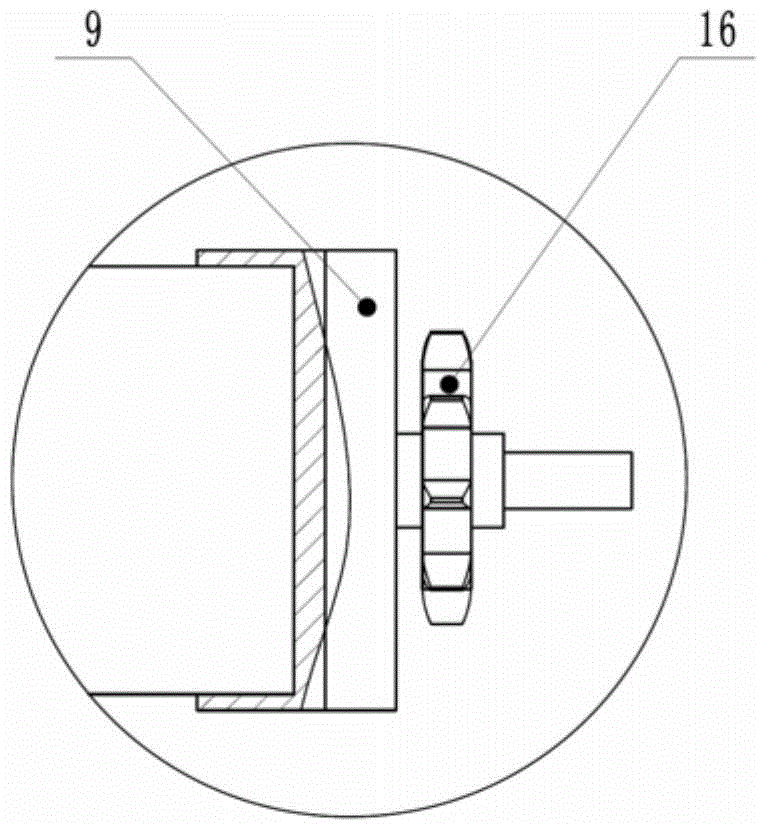

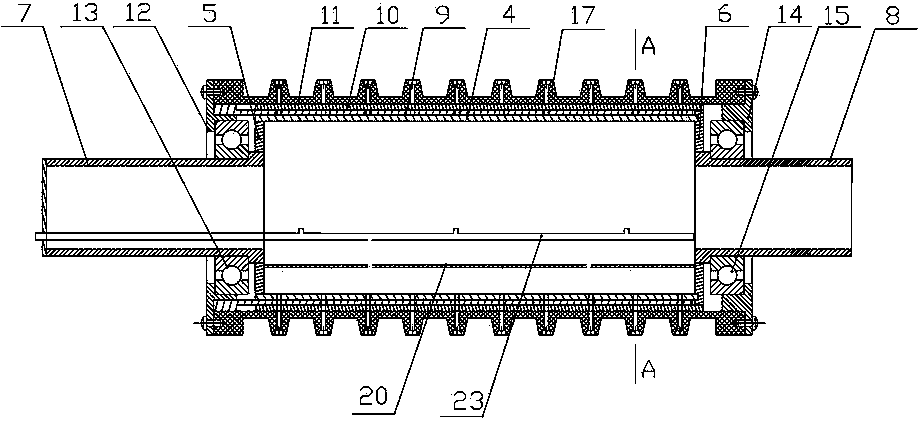

Seed metering and distributing device for precision drill

InactiveCN102763507AImprove seeding accuracyImprove performanceSeed depositing seeder partsSingle grain seedersSprocketConveyor belt

The invention discloses a seed metering and distributing device for a precision drill, which comprises a seed taking mechanism and a conveying mechanism. The seed taking mechanism is provided with a seed room (5) consisting of a movable disk (2) and a fixed disk (6) and a seed discharge pipe (8); and the conveying mechanism is a conveyor belt type conveying mechanism and comprises a driving roller (10), a driven roller (15), a conveyor belt (12), a seed retaining plate (11) and a seed protection groove (9). The seed metering and distributing device is characterized in that both the movable disk (2) of the seed taking mechanism and the driving roller (10) of the conveying mechanism are provided with driving gears (16, 18); and a middle transmission gear (13) is arranged between the driving gears (16, 18). Compared with the prior art, the gears or chain wheels are adopted to carry out forced synchronization, so that the seed metering and distributing device not only has high seed taking accuracy and stable performance and can be suitable for various different soil conditions, but also has very stable seeding intervals and is particularly suitable for carrying out precision drilling in the harsh environment such as the no-tillage stubble field.

Owner:XINJIANG KESHEN AGRI EQUIP SCI&TECH DEV

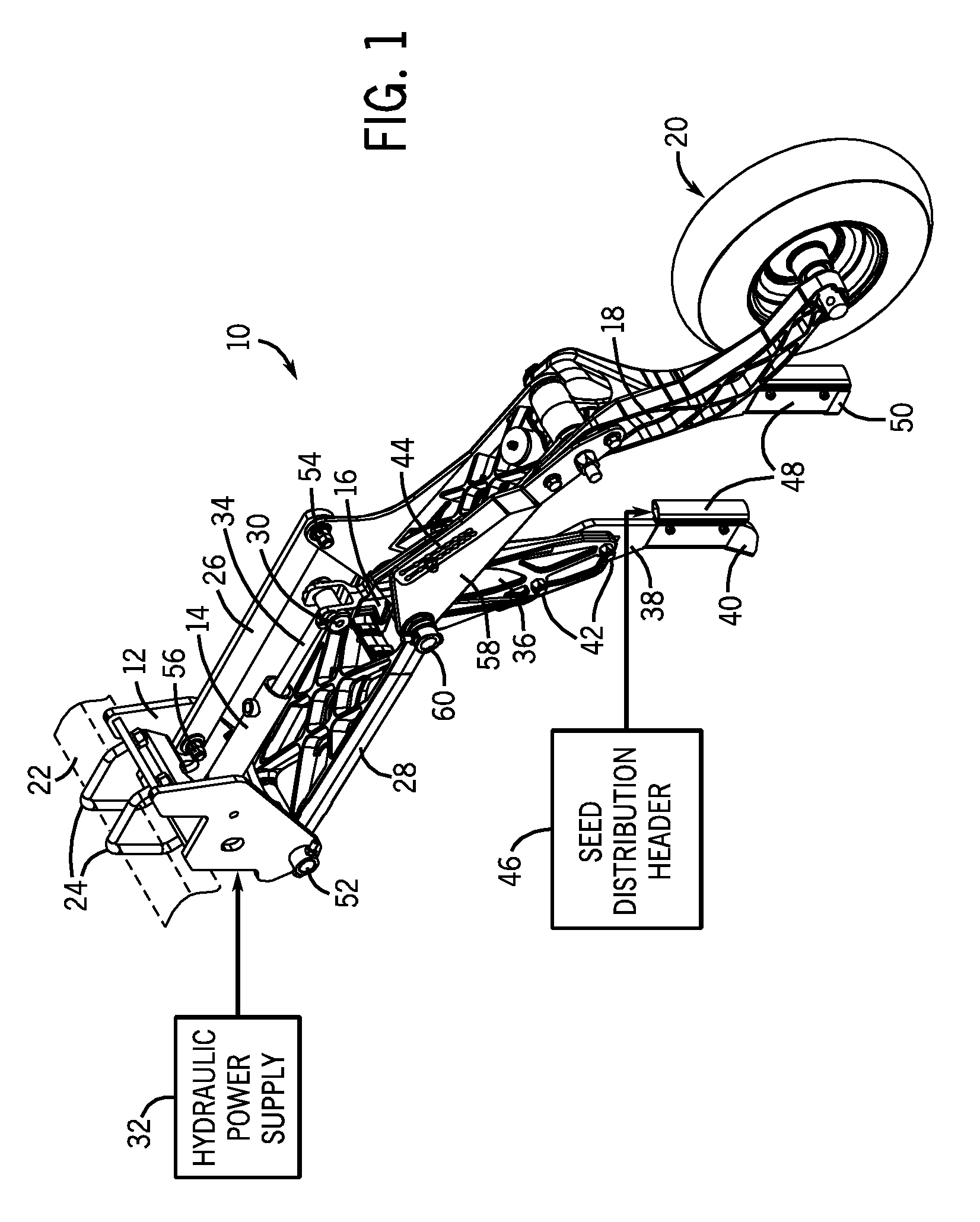

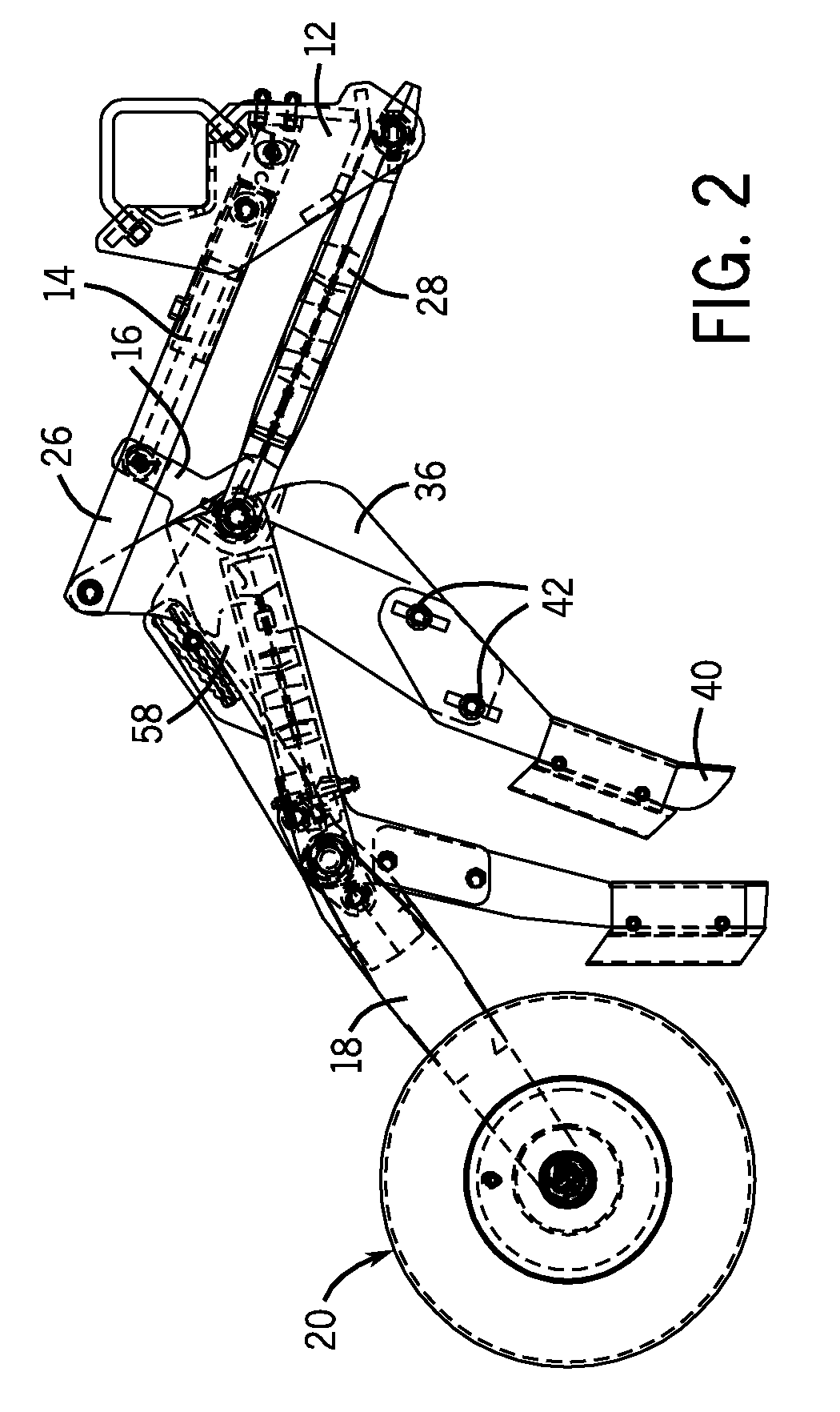

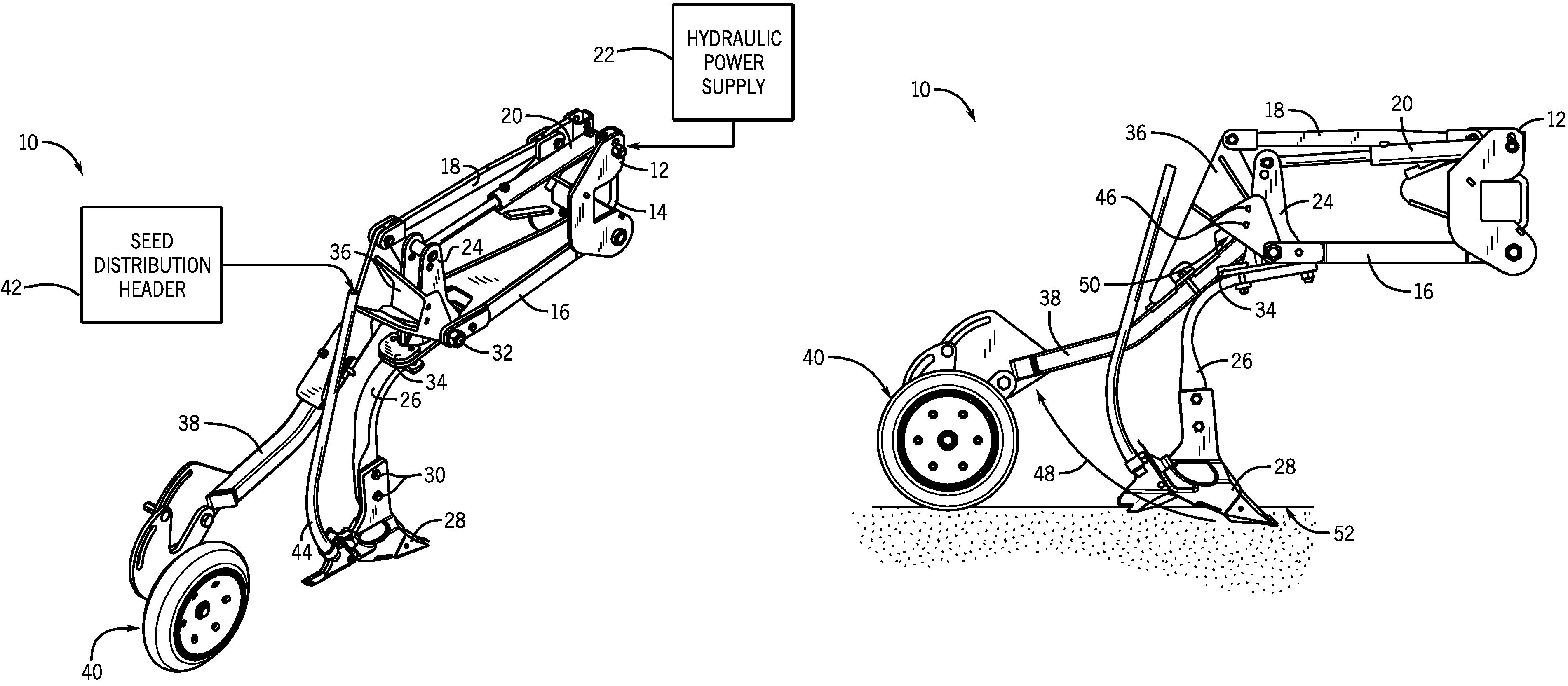

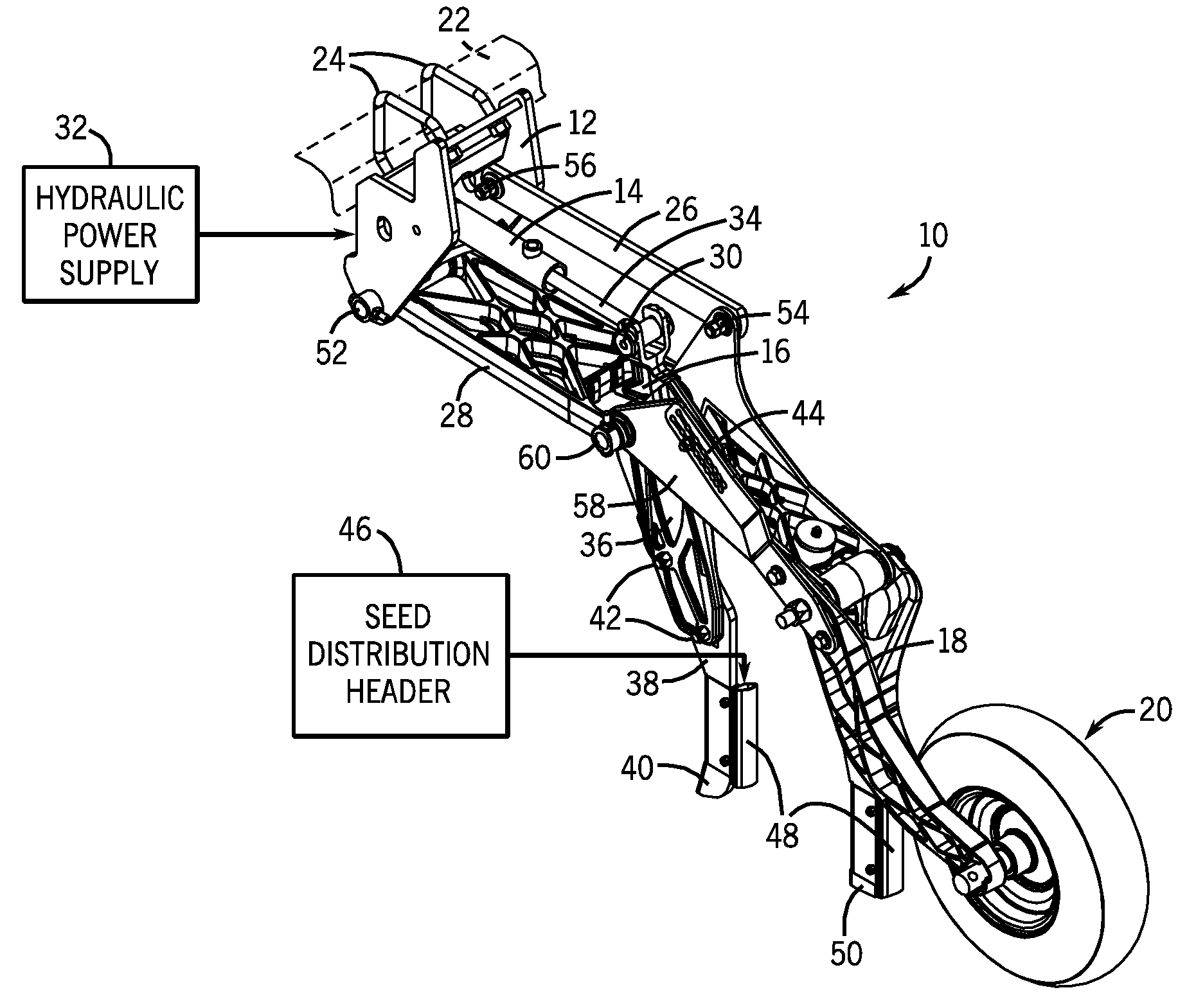

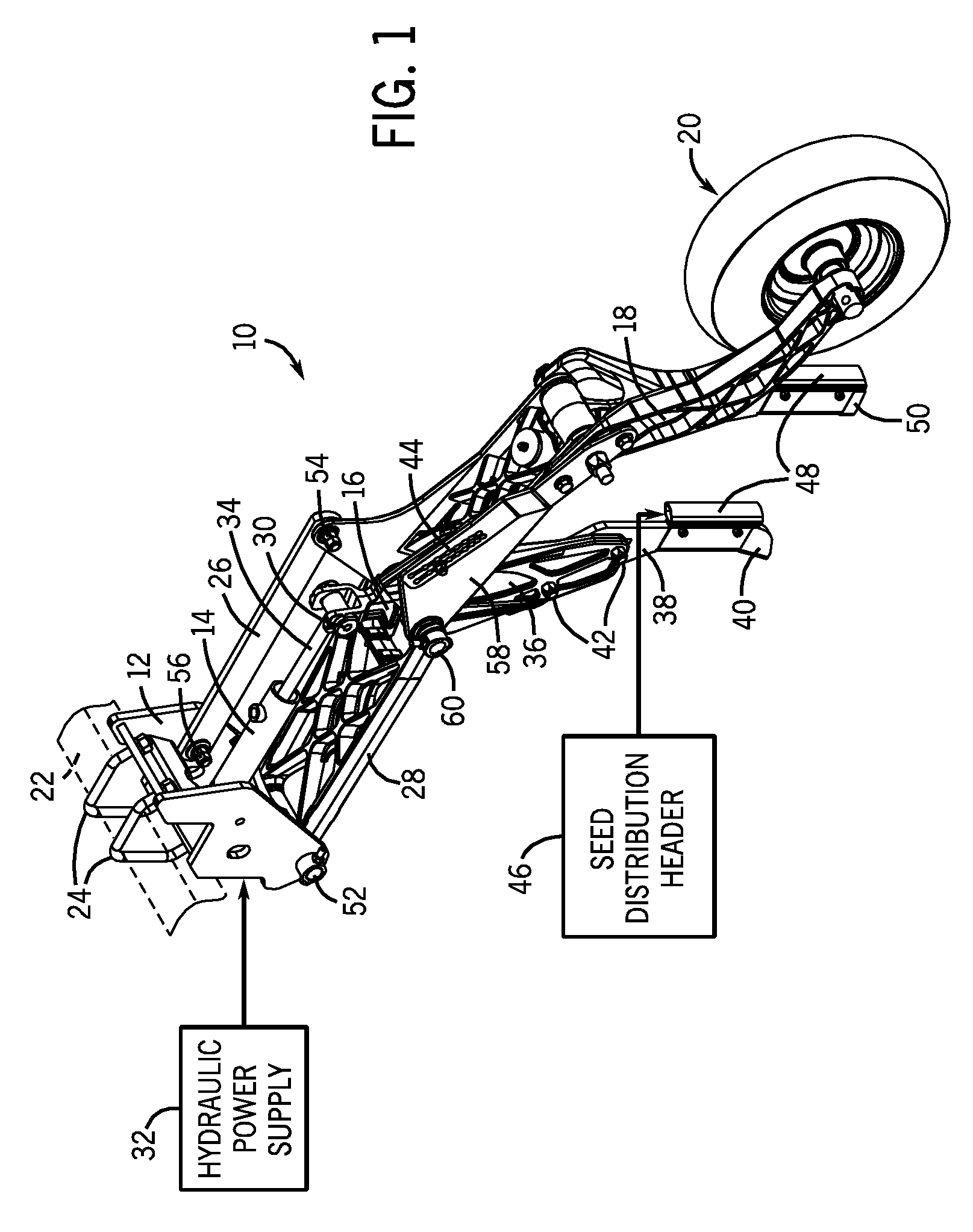

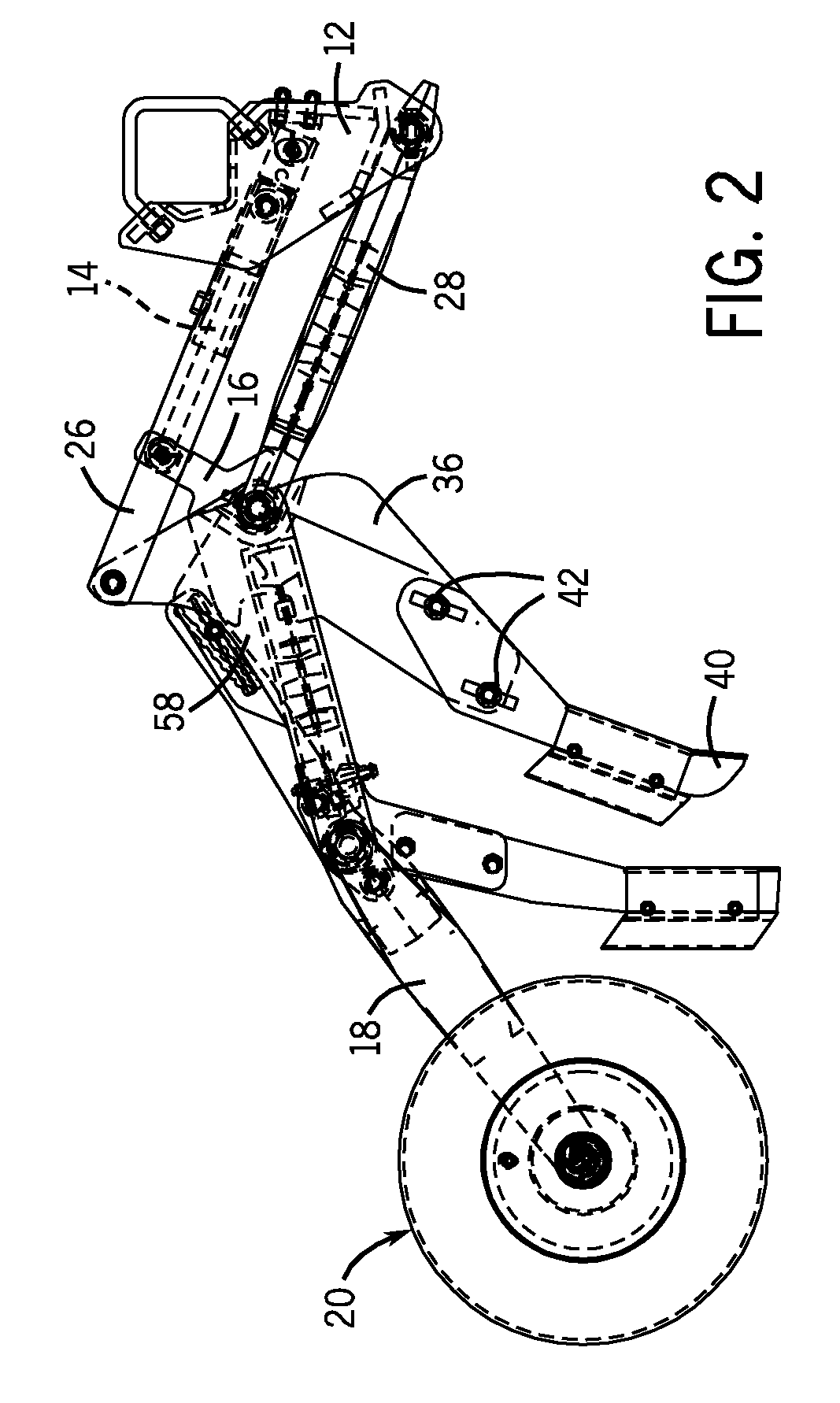

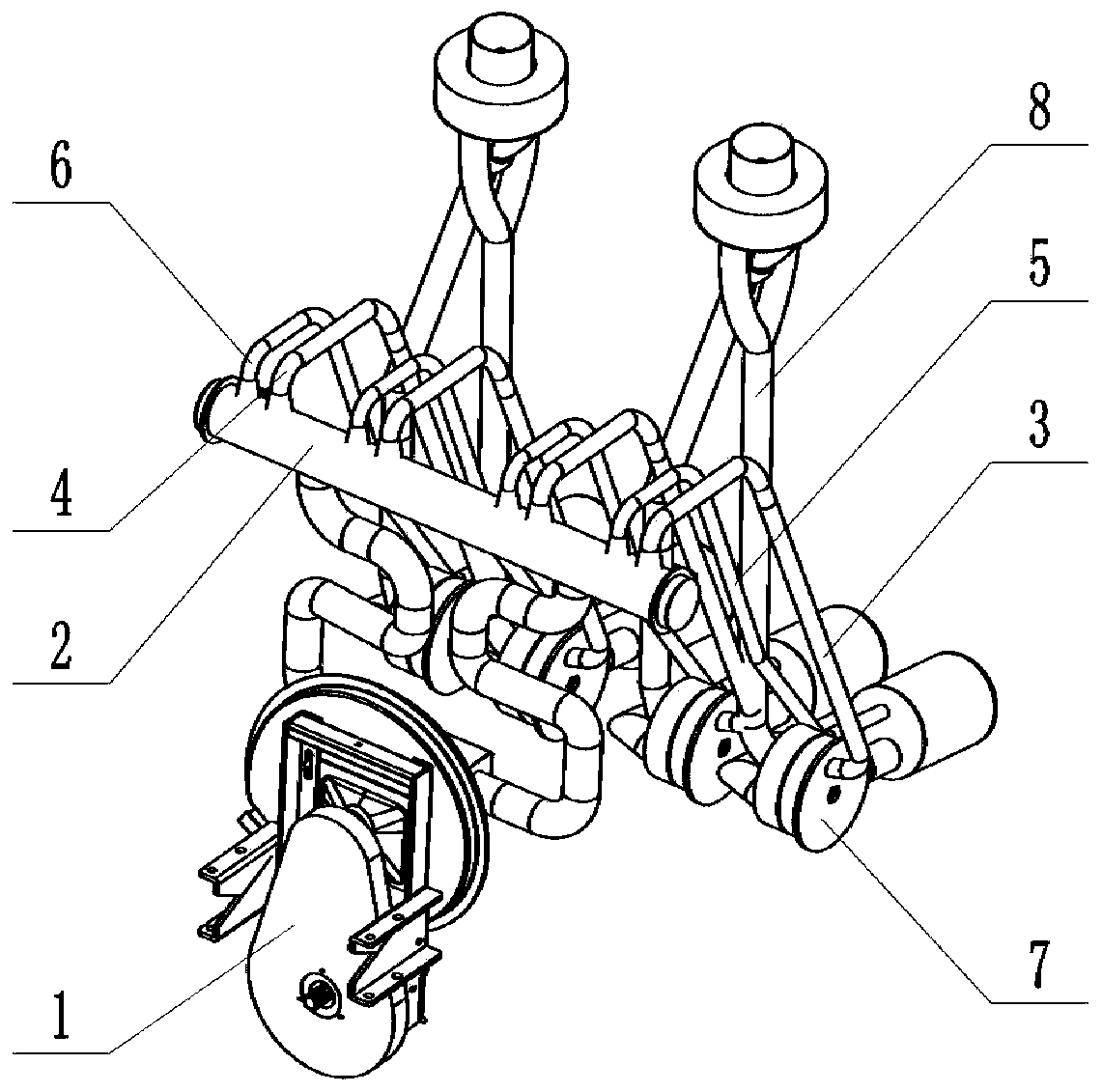

Precision hoe opener and packer wheel assembly

ActiveUS7574969B1Improve seeding accuracyEasy to assemblePlantingSoil-working equipmentsEngineeringMechanical engineering

A precision hoe opener assembly is provided with improved accuracy of seeding as well as improved control over the opener and packer wheel assemblies. The opener assembly includes a hydraulically-driven parallel linkage assembly, hoe opener, and a packer wheel. The design provides improved seeding accuracy, especially during changes in terrain elevation.

Owner:CNH IND CANADA

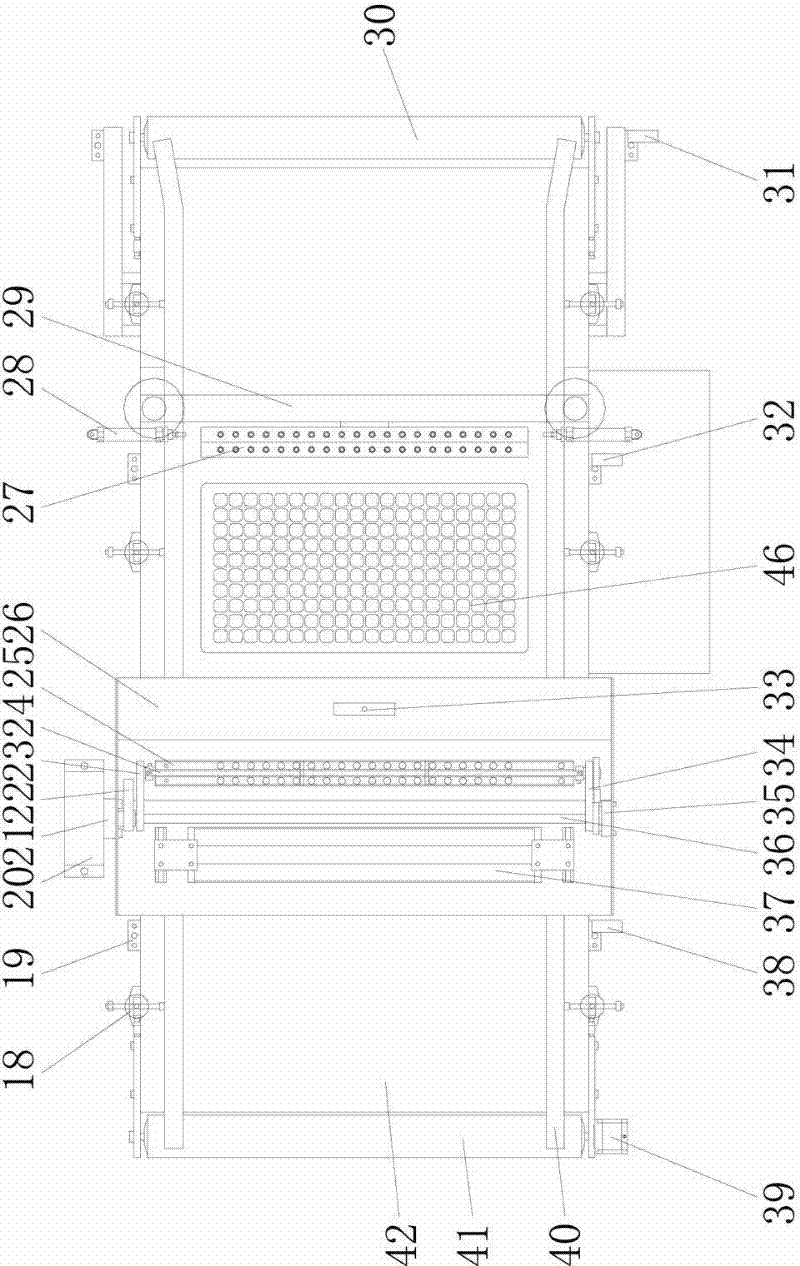

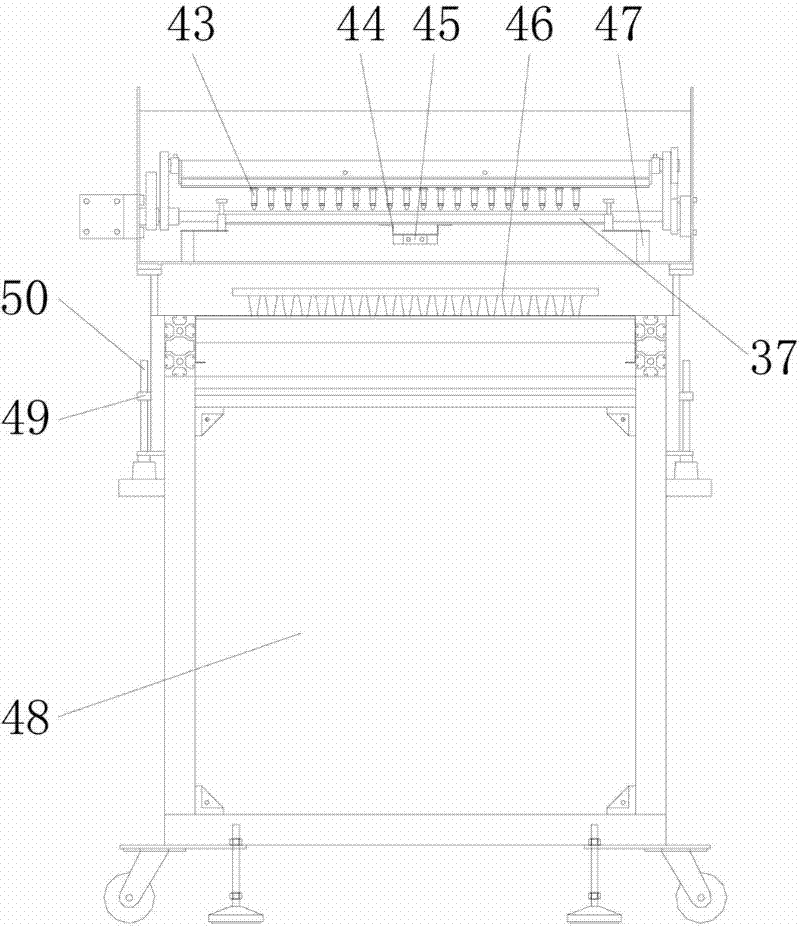

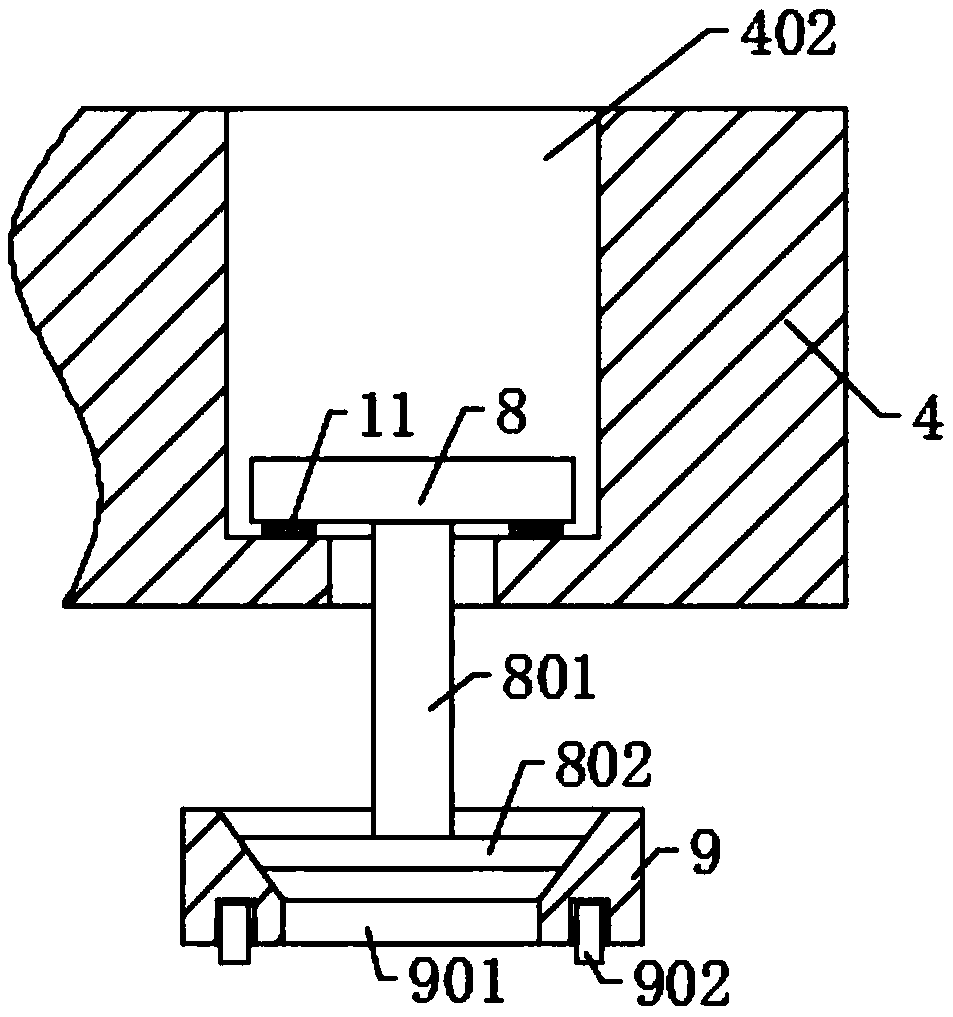

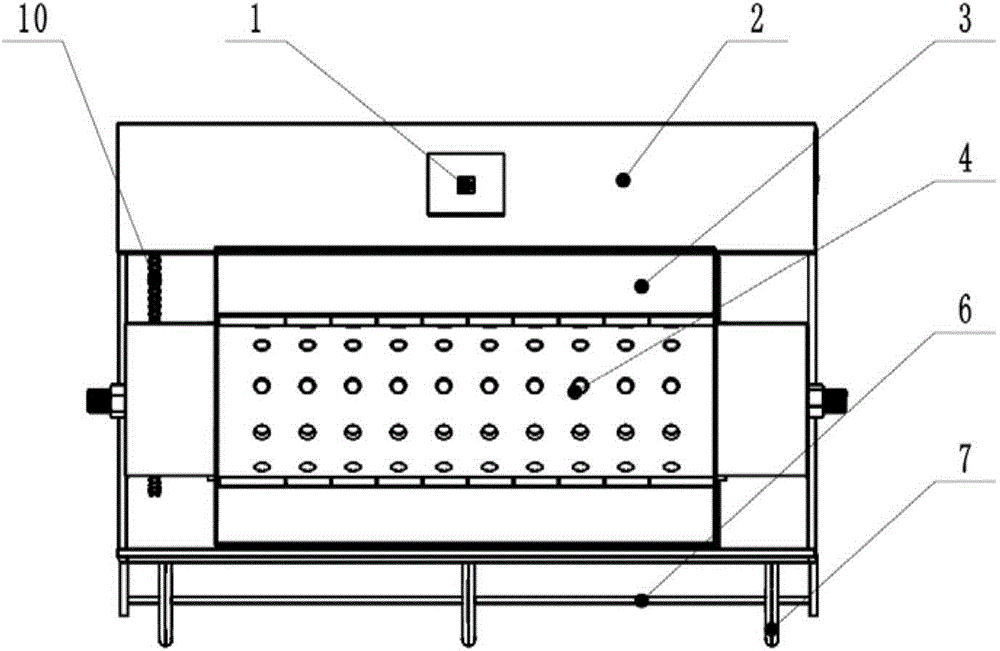

Tray seeder with self-cleaning suction nozzles

ActiveCN102550174AImprove adaptabilityPromote high yield and high qualitySeed depositing seeder partsSingle grain seedersControl systemSolenoid valve

The invention discloses a tray seeder with self-cleaning suction nozzles. The tray seeder comprises a frame unit, a holing system unit, a seeding system unit and a control system unit, wherein a conveyer belt transmission device pulled by a stepping motor is arranged on an upper end face of the frame unit; the holing system unit is provided with a holing supporting beam which stretches across frame main girders; a group of holing heads are arranged on each row of holing beam; a seeding beam connecting rod is fixed between a pair of swing arms of a swing mechanism of the seeding system unit; at least one row of seeding beams are fixed on the seeding beam connecting rod; a row of self-cleaning suction nozzles are arranged on the lower side of each row of seeding beam; a vibrating seed tray for accommodating seeds is arranged below the self-cleaning suction nozzles; the control system unit comprises a control box, a group of air-operated solenoid valve components, a group of photoelectric sensors, photoelectric sensor reflectors matched with the photoelectric sensors, and a sensor contact block fixed on a swing shaft of the seeding system unit; and the control system unit controls the start / stop of electric parts of each unit. By the tray seeder, the seeding efficiency and seeding precision can be improved, and high quality and high yield of seedlings are guaranteed.

Owner:BEIJING KINGPENG INT HI TECH CORP

Vibrating type paddy planter

InactiveCN103733778ANo mechanical damageNo cloggingSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringBud

The invention discloses a vibrating type paddy planter which mainly comprises a rack with a walking device, wherein a seeding device is arranged on the rack; the seeding device comprises a seed box, a horizontal seed guide plate and an intermittent seeding mechanism; the horizontal seed guide plate is fixed on the rack through a vibrator; multiple seed guide slots are formed in the horizontal seed guide plate; one end of the seed guide slot is connected with the seed box through a falling hopper, and the other end is connected with the intermittent seeding mechanism; the intermittent seeding mechanism comprises a seed guide pipe and a seeding stop tongue which can be intermittently opened; the seed guide pipes and the seed guide slots are in para-position connection to realize discharge of paddy seed buds; the seeding stop tongue is arranged in each seed guide slot; the seed guide slot is started or stopped through the intermittent mechanism. The vibrating type paddy planter disclosed by the invention has the advantages of relatively small overall volume and high sowing precision, is flexible and convenient to use, avoids mechanical damage to the buds and effectively improves the sowing efficiency.

Owner:HUNAN AGRICULTURAL UNIV

Retaining type precise seed metering device

InactiveCN101326873AExtended service lifeGrain number adjustableSeed depositing seeder partsRegular seed deposition machinesEngineeringMechanical engineering

Owner:SHIHEZI UNIVERSITY

Seeding device

ActiveCN106922258AEasy to operateImprove seeding accuracySeed depositing seeder partsHand sowing implementsGear wheelAgricultural engineering

The invention discloses a seeding device, which comprises a shell, a first partition plate, a pressure bar, a spring, a sowing nozzle, a soil poking block, first connecting rods, gears, a rack and a seed metering mechanism. The first partition plate is disposed in the shell, and divides the inner cavity of the shell into an installation cavity and a seed metering cavity, the sowing nozzle is fixed on a discharge port, the soil poking block is hinged to a discharge port side wall, the two gears are rotatably disposed in the seed metering cavity and are engaged with each other, the upper ends of the two first connecting rods are respectively hinged to the two gears, the lower ends are respectively hinged to the sowing nozzle and the soil poking block correspondingly, the pressure bar is movably inserted into the installation cavity, and the upper end and lower end of the pressure bar both pass through the side wall of the shell and extend out of the shell, the spring sleeves the pressure bar, and the upper end and lower end of the spring respectively abut against the inner wall of the installation cavity and the pressure bar correspondingly, the rack is fixed on the pressure bar, and is engaged with one of the gears, the seed metering mechanism is disposed in the seed metering cavity, and one end of the seed metering mechanism is connected to the pressure bar. The seeding device provided by the invention has the advantages of wide applicability and good stability.

Owner:临沂罗开建设工程有限公司

Sowing apparatus for vegetable plantation

ActiveCN108156906AEven numberHigh precisionWatering devicesCultivating equipmentsEngineeringVegetable farming

The invention discloses a sowing apparatus for vegetable plantation, and belongs to the technical field of vegetable plantation. The sowing apparatus comprises a box, a fixed plate, a rotation disc, and a rotation rod. Through a seed box, seeds fall in the placing hole of the rotation disc; the size of the placing hole determines the number of filled seeds; the water amount of a water tank is thesame for each watering, the seed number for each sowing is uniform, and the water amount is uniform. When the placing hole of the rotation disc rotates to a top hole, seeds fall into soil through thetop hole and a bottom hole, sowing is finished, then a water storing tank in the rotation rod rotates to the bottom hole later, through a raised block, a moving plate is jacked up, water moves along awater guiding disc and is sprayed on the seeds through the bottom hole, and watering is finished. Sowing and watering are finished continuously, and the work efficiency is improved. An axle is connected to a second motor through a grooved wheel and a drive plate so as to rotate a moving wheel intermittently; during the stop period, sowing and watering are performed, seeds and water are accuratelyadded into a hole, and the sowing precision is further improved.

Owner:HEXIAN LVYUAN VEGETABLE PLANTATION CO LTD

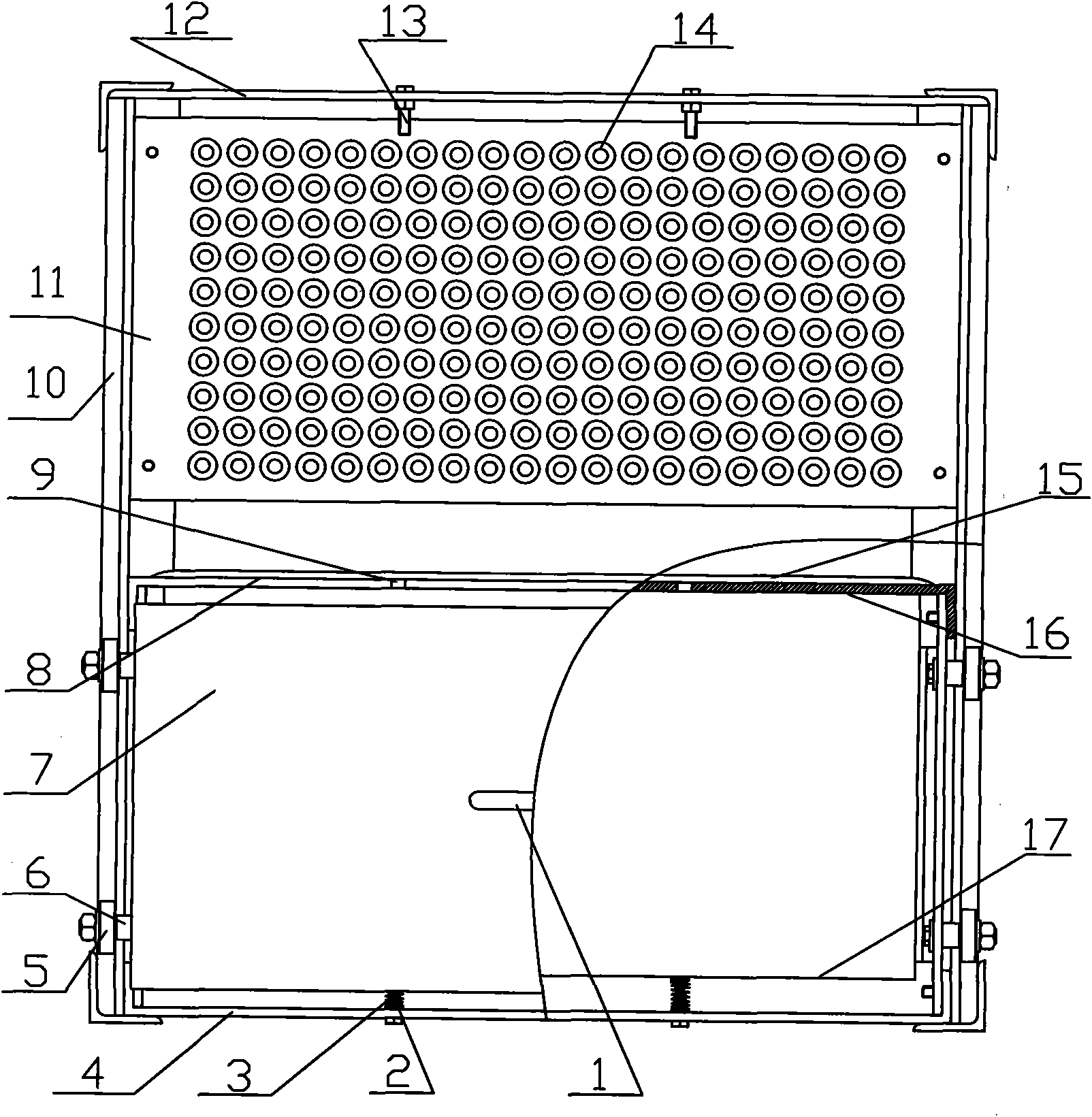

Magnetic plate-type plug precision planter

The invention relates to a magnetic plate-type plug precision planter, comprising a rack, a magnetic disc, a nail plate, a seed plate, a seed guiding plate and a top cover, wherein one end of the rack is provided with the seed plate, an electromagnetic or pneumatic vibrating device can be arranged below the seed plate, the seed guiding plate is placed at the other end of the rack, the seed guiding plate is provided with seed guiding holes, the geed guiding plate is movably connected with the rack, the two sides of the magnetic disc are connected with the nail plate by virtue of slide rails and are arranged above the nail plate, the nail plate is provided with the top cover, and the top cover is provided with a push handle. The magnetic plate-type plug precision planter combines a seed pelleting process with a mechanical sowing technology, magnetic precision sowing is realized, sowing precision is higher and adaptability to seeds is good, overall structure is simple, and manufacturing cost is low, thus the magnetic plate-type plug precision planter is more beneficial to popularization of precision sowing technology and is applicable to production of seedlings in large-scale centralized sowing manner.

Owner:HENAN AGRICULTURAL UNIVERSITY

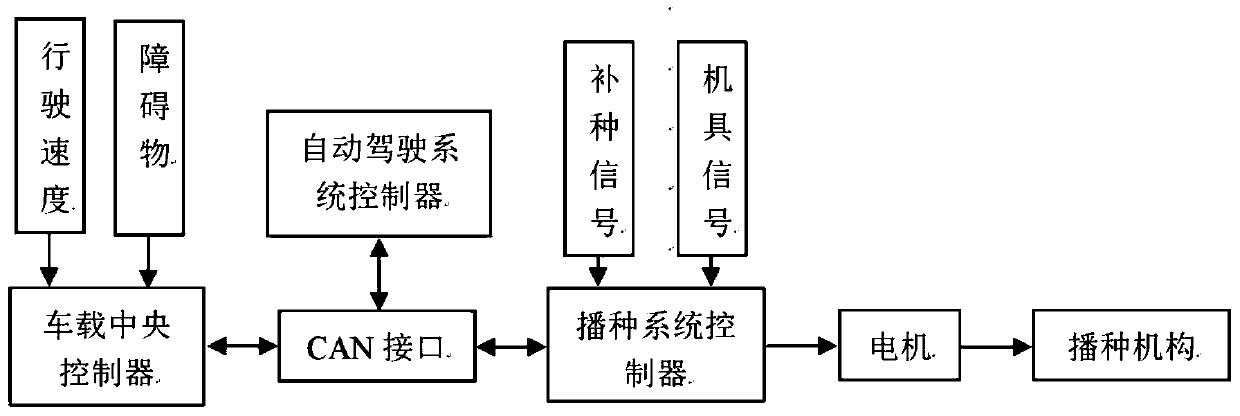

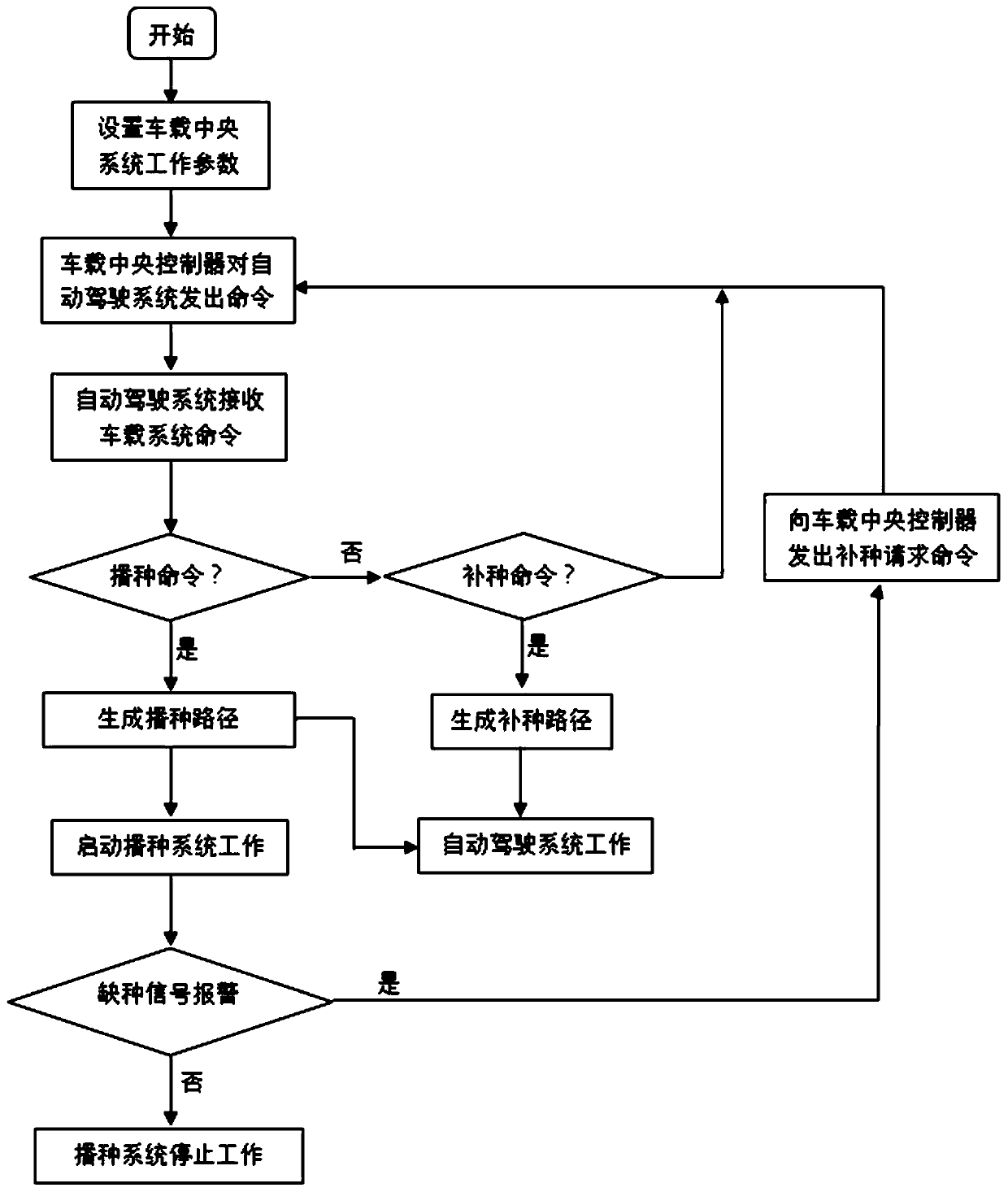

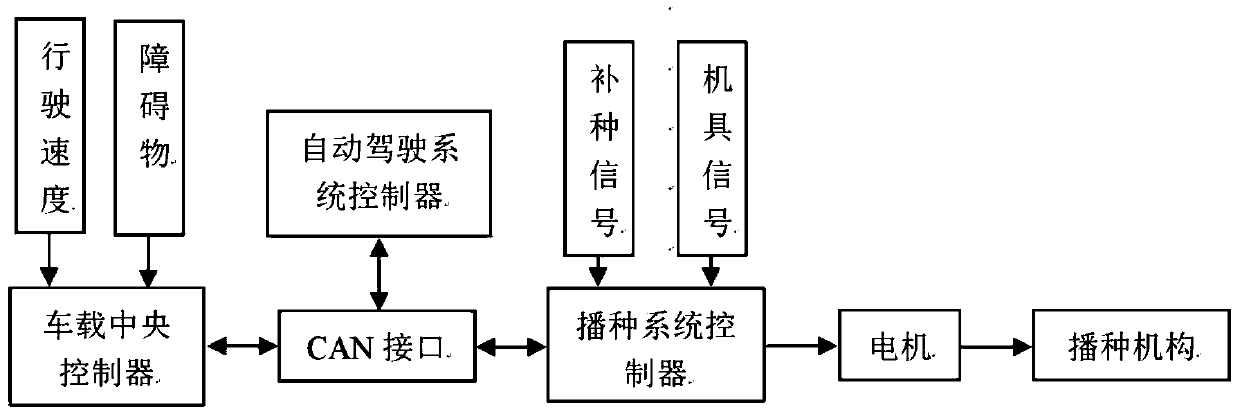

Self-adaptive seeding control system based on unmanned driving technology and control method thereof

ActiveCN111142518ARealize a high degree of automationEasy to tracePosition/course control in two dimensionsVehiclesControl signalIn vehicle

The invention discloses a self-adaptive seeding control system based on an unmanned driving technology. The self-adaptive seeding control system comprises a vehicle-mounted central controller, an automatic driving system controller, a seeding system controller, a driving state monitoring device and an agricultural machine state monitoring device, the vehicle-mounted central controller responds tothe agricultural machine and moves to the seeding path, and drives the seeding system controller to adjust the rotating speed of the motor according to preset seeding parameters so as to execute seeding operation; the agricultural machinery state monitoring is used for monitoring agricultural machinery seeding state parameters in real time, generating a reseeding control signal if the abnormal type is seed shortage, and calculating a reseeding navigation planning path. According to the invention, the automatic driving system and the seeding system in a completely independent state can be effectively coordinated, and the seeding operation task can be efficiently and adaptively completed; the abnormal state in the seeding operation task process is processed in time, particularly, seed shortage abnormity is processed in time, and route adjustment and reseeding operation are completed in a self-adaptive mode on the premise that seeding efficiency is not affected.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +2

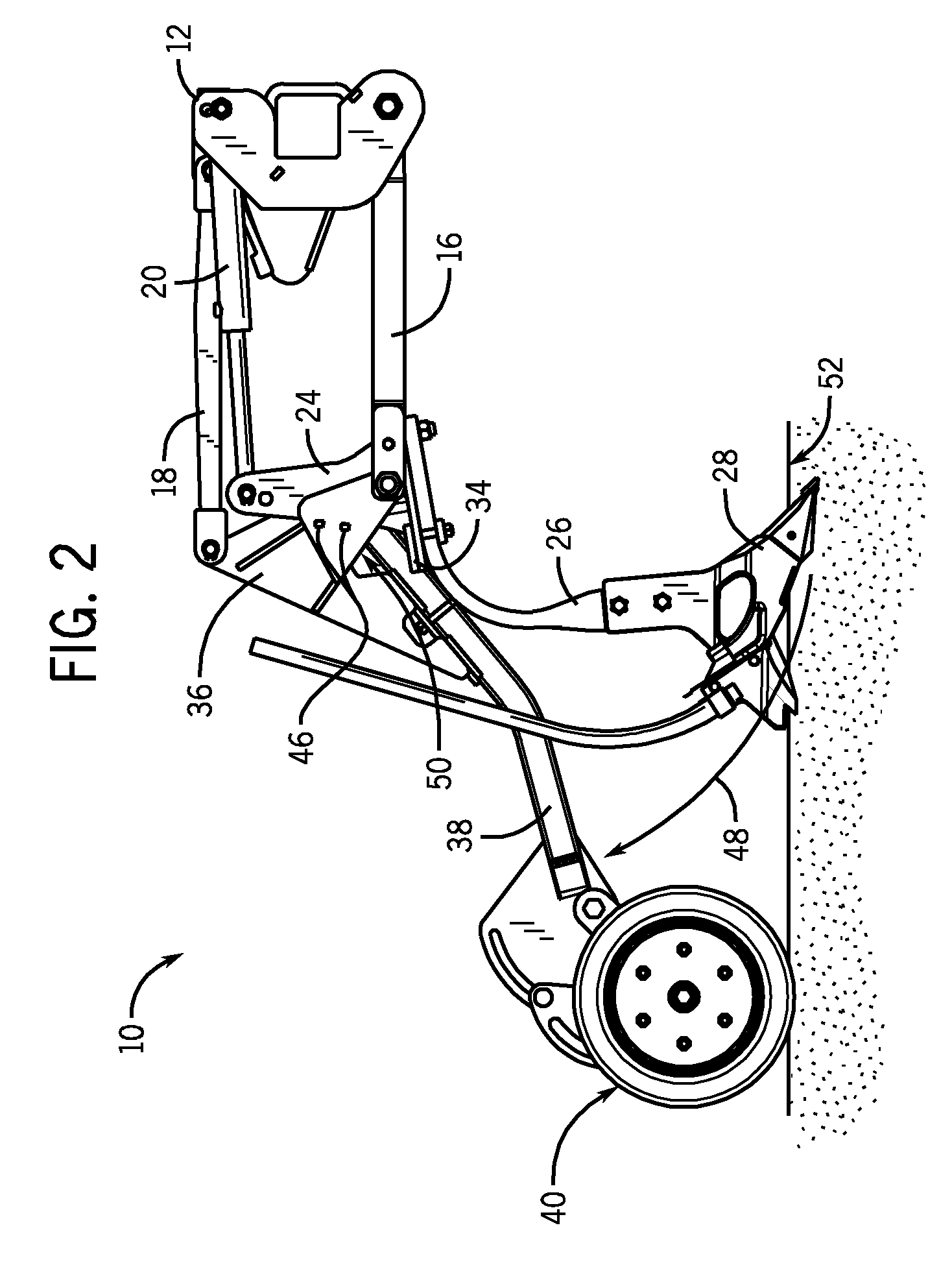

Precision hoe opener assembly with adjustable packer wheel location

ActiveUS20080308022A1Improve seeding accuracyOptimize locationAgricultural machinesPlantingEngineeringMechanical engineering

A precision hoe opener assembly is provided with improved accuracy of seeding as well as improved control over the opener and packer wheel assemblies. The opener assembly features a hydraulically-driven parallel linkage assembly, a ground engaging tool, and an adjustable packer wheel assembly. The design provides improved seeding accuracy by providing a variable distance between the ground engaging tool and the packer wheel. Specifically, embodiments of the present invention allow for adjustment of the distance between the ground engaging tool and wheel elements.

Owner:CNH IND CANADA

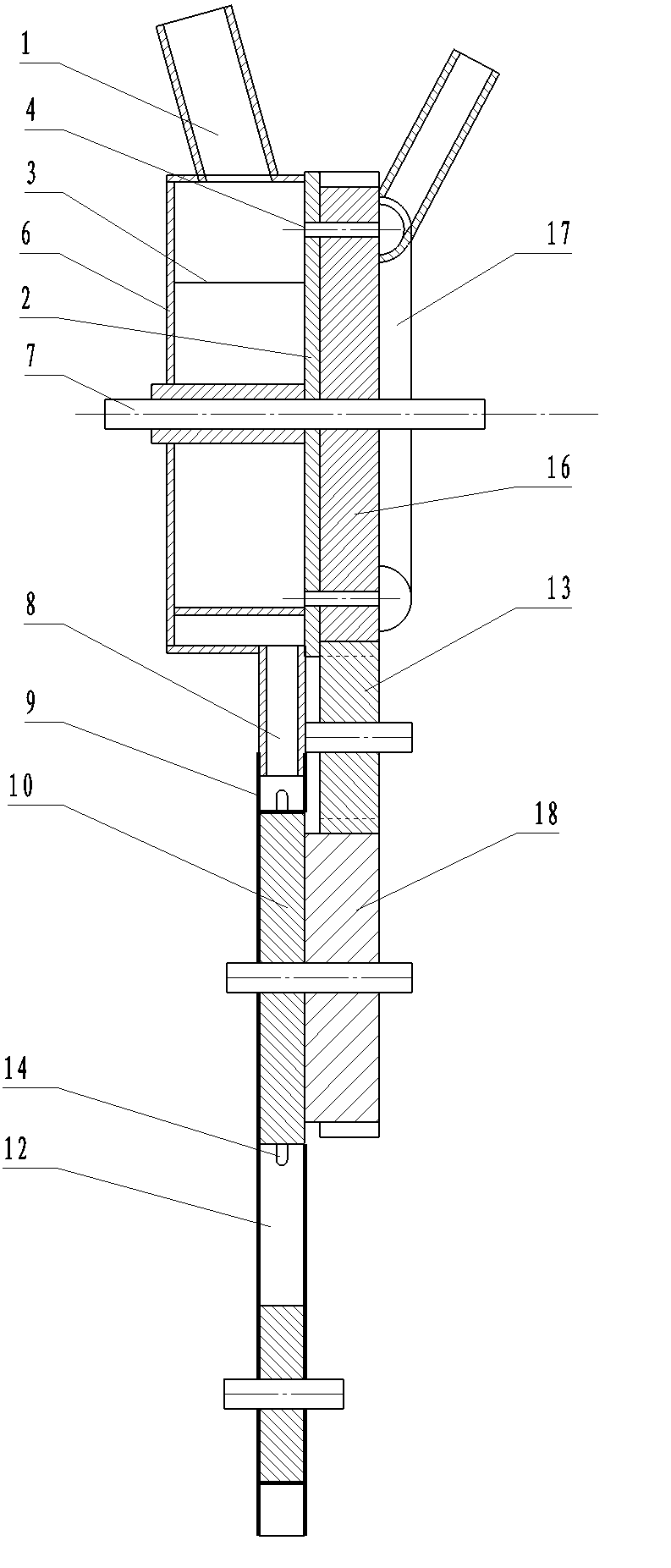

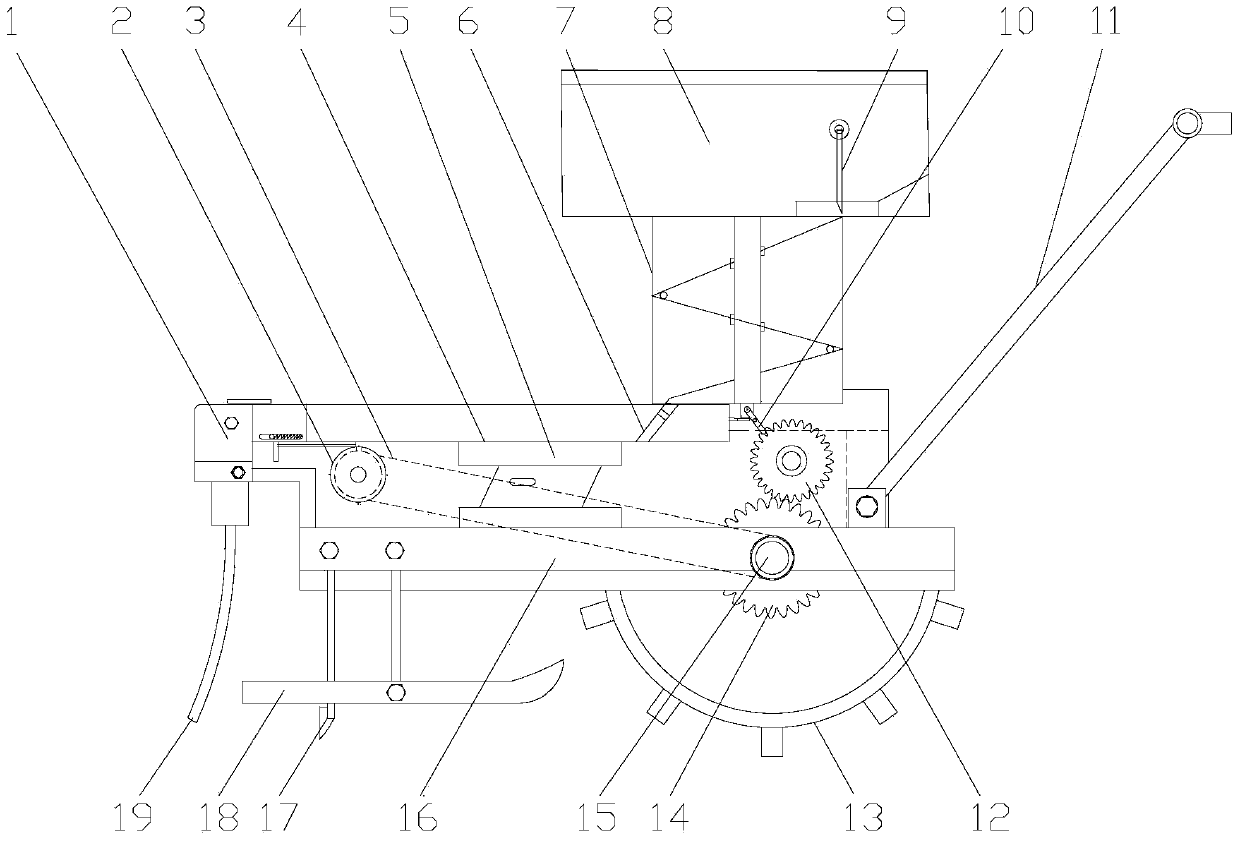

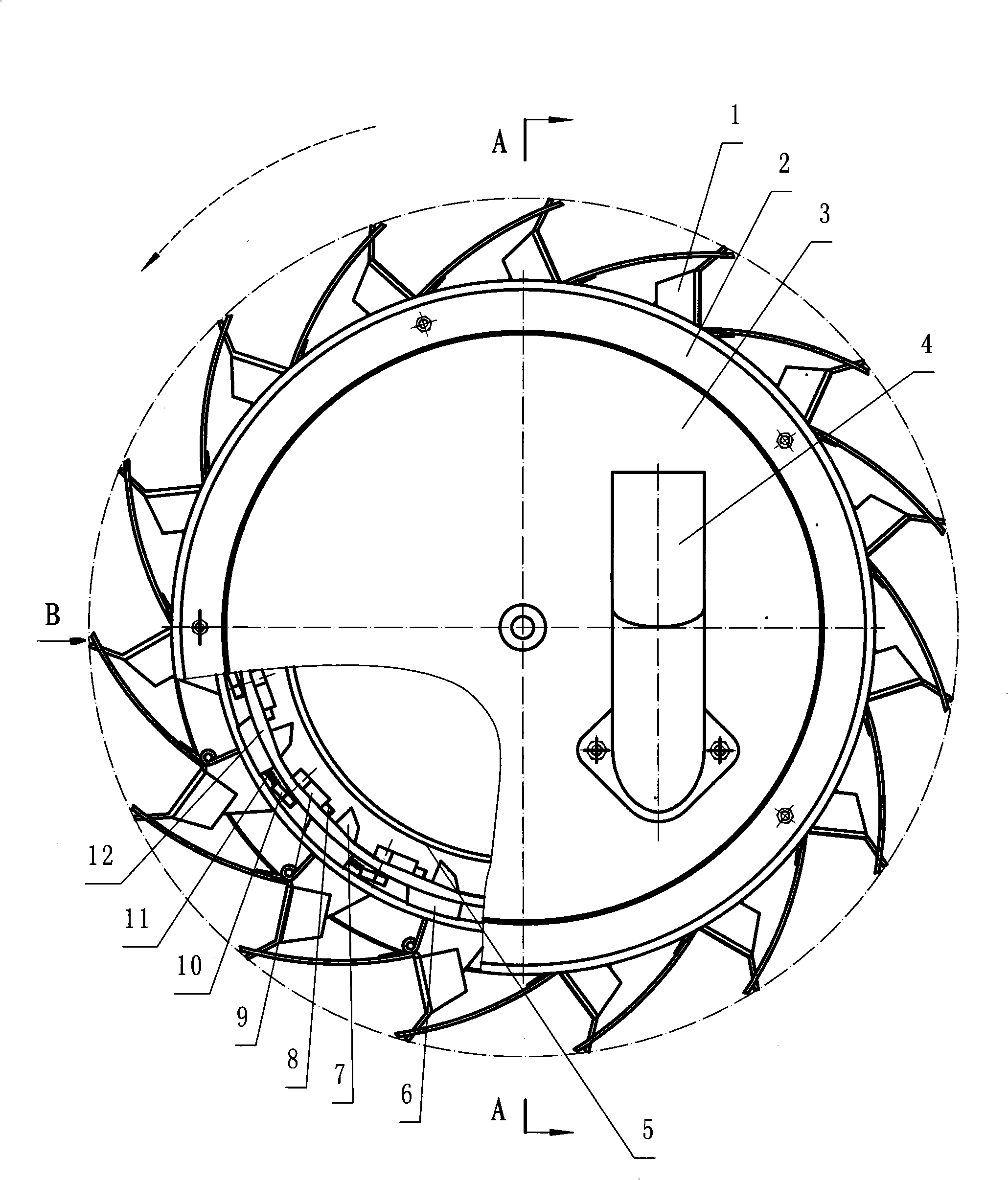

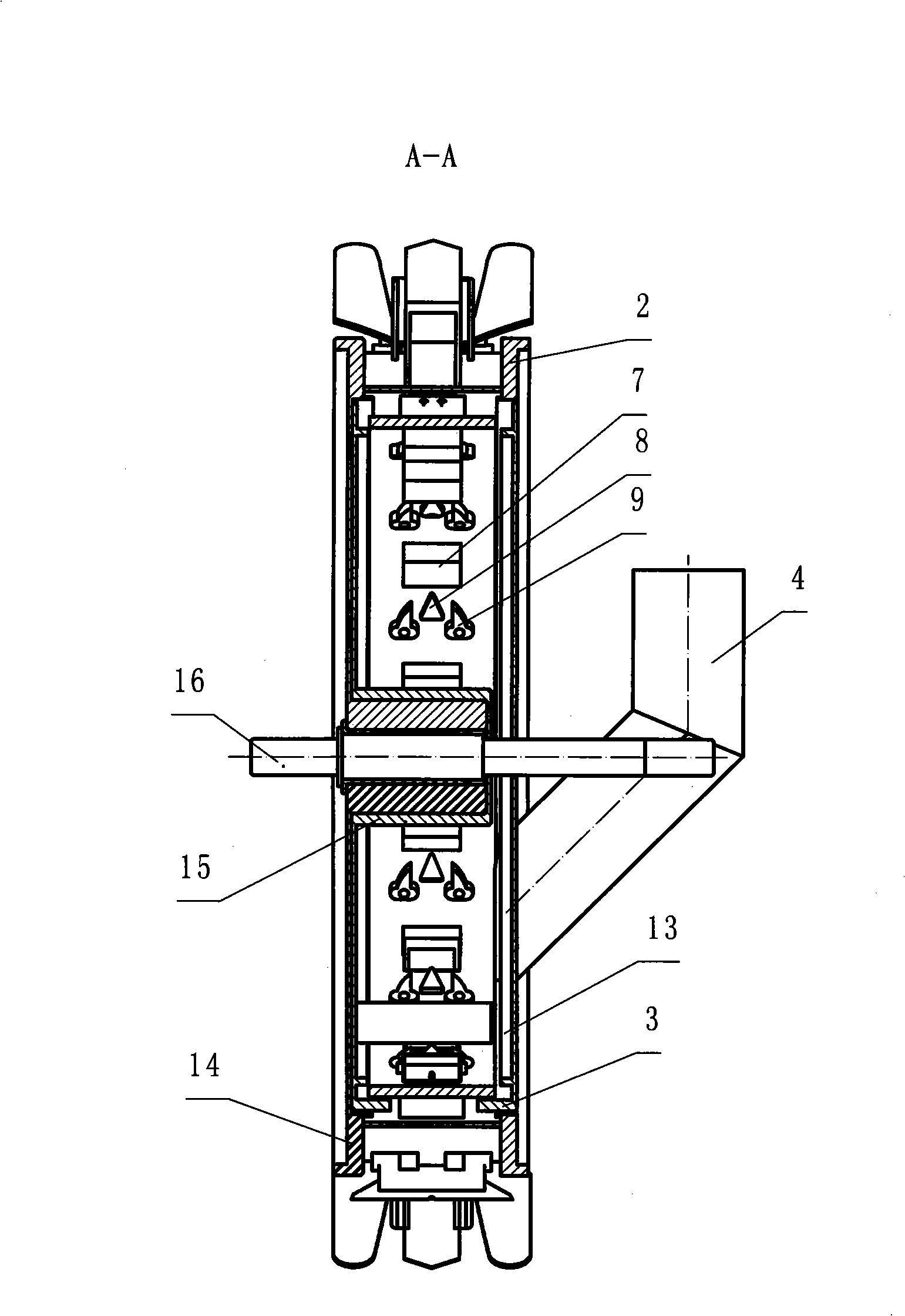

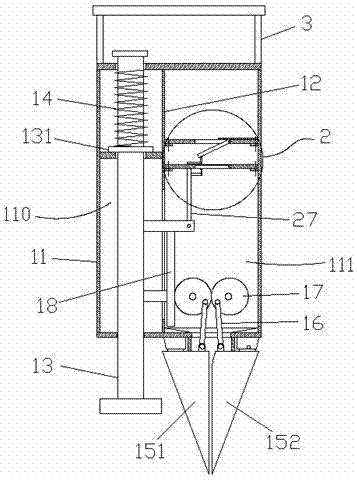

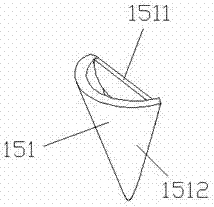

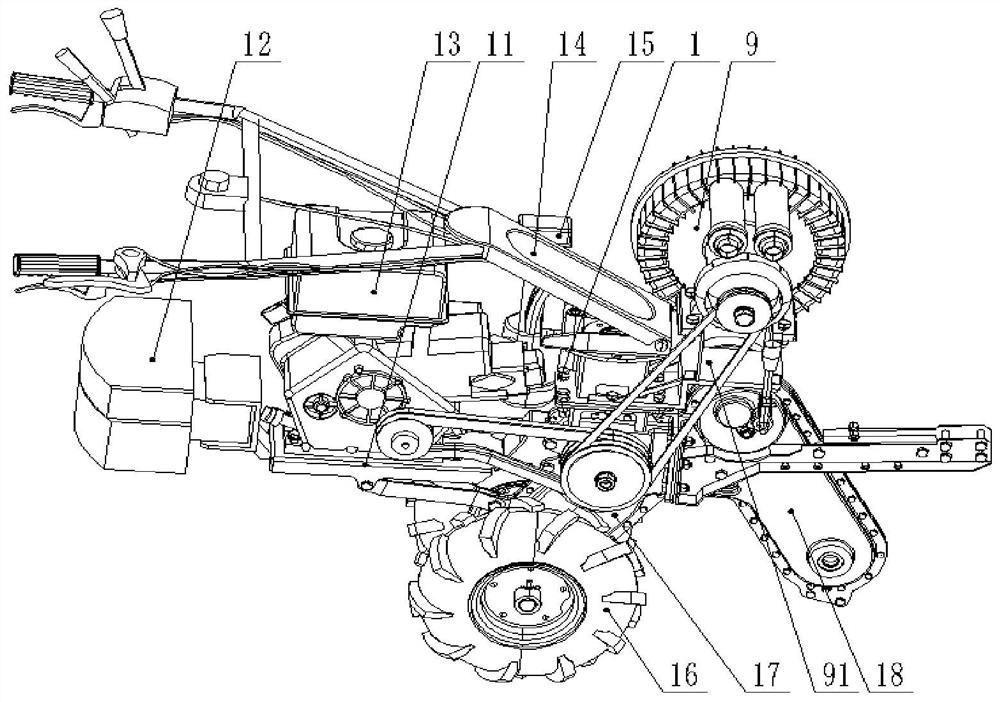

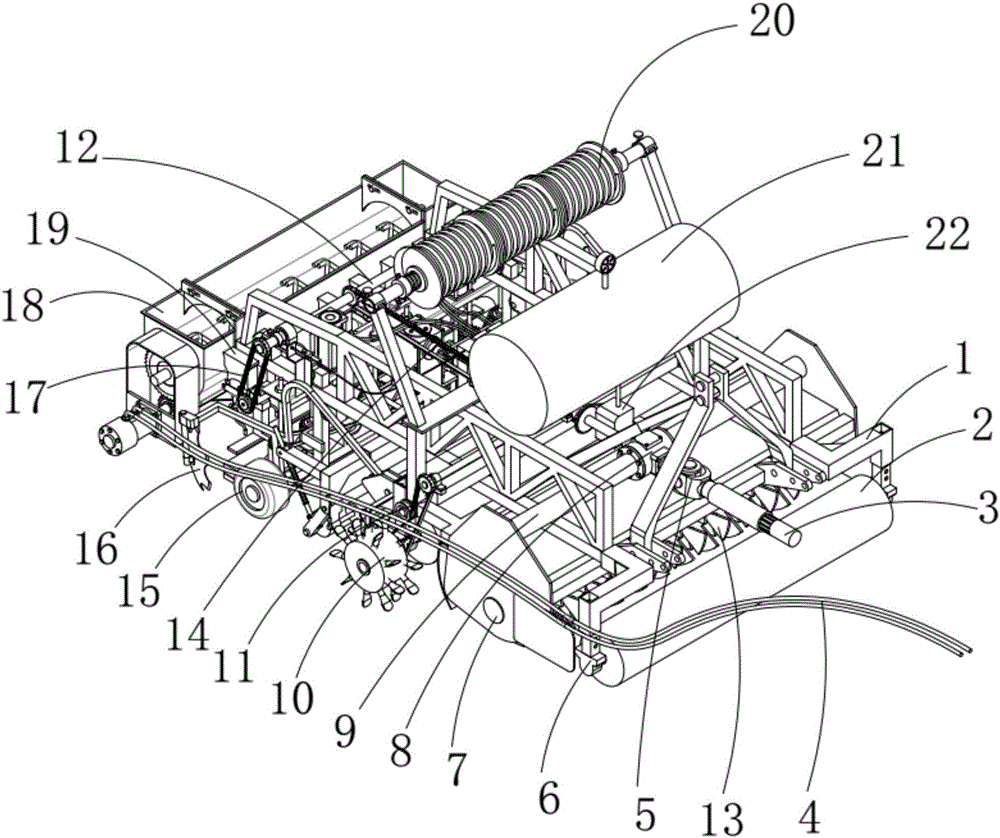

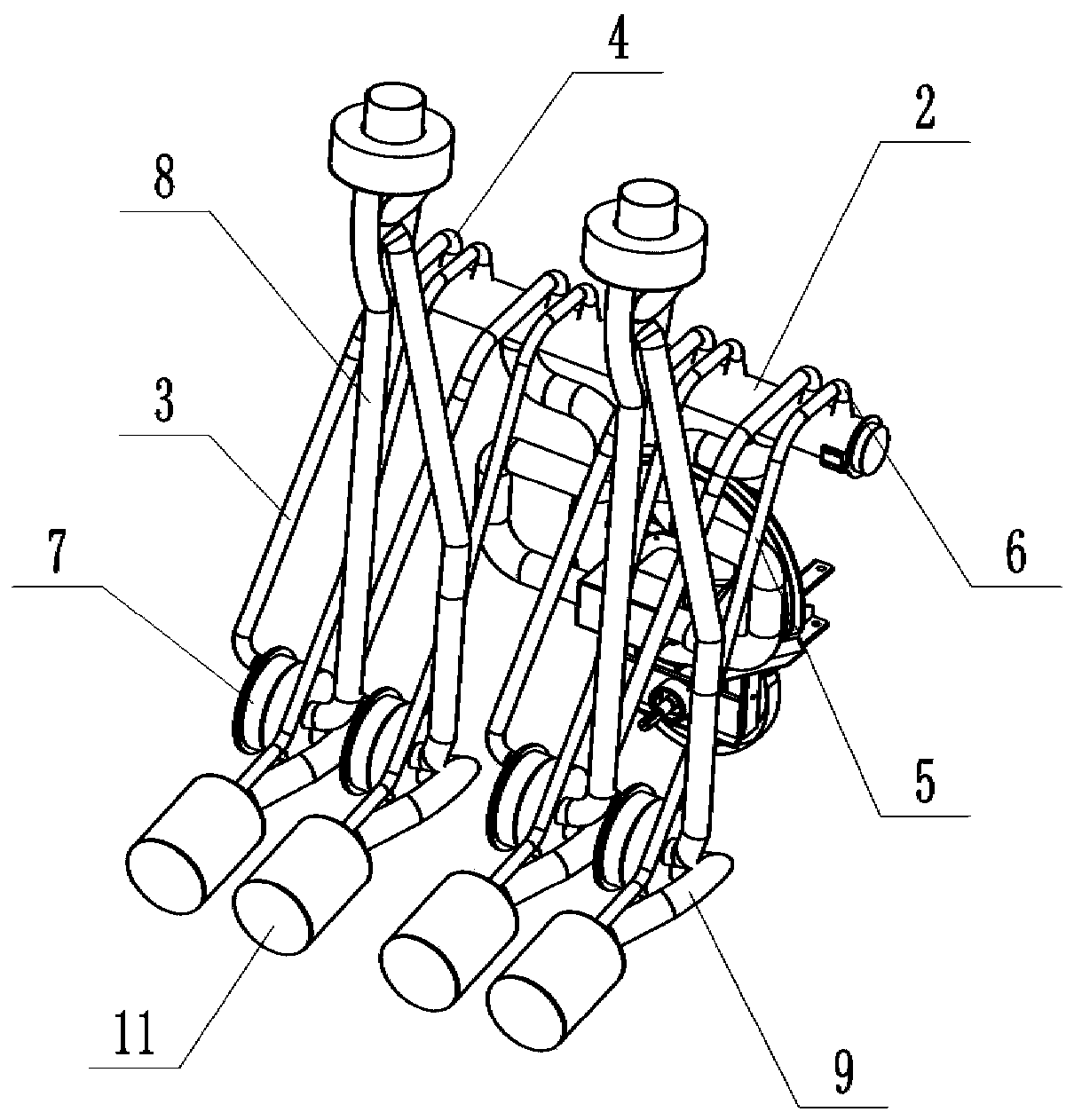

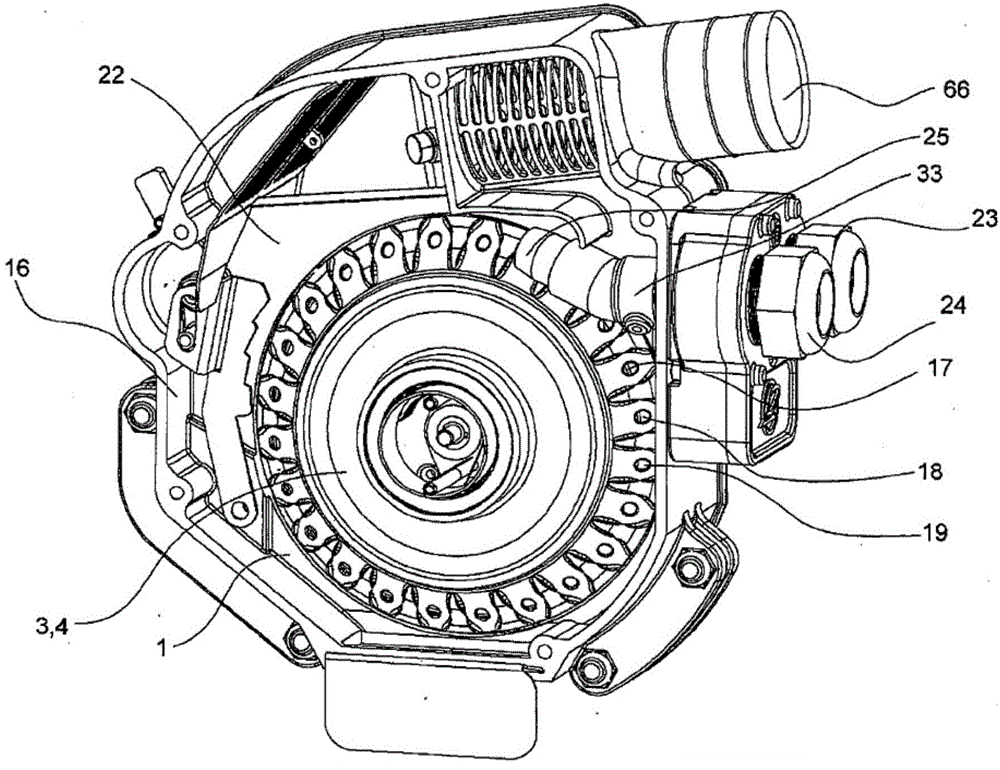

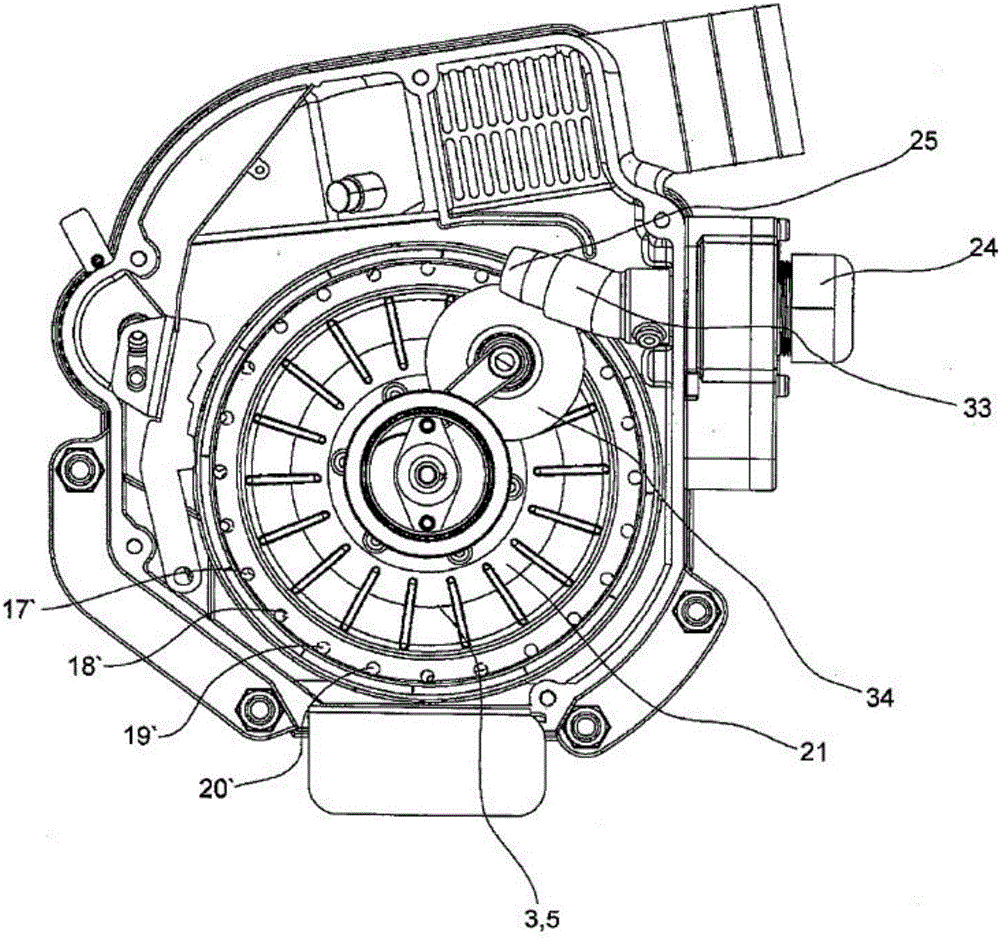

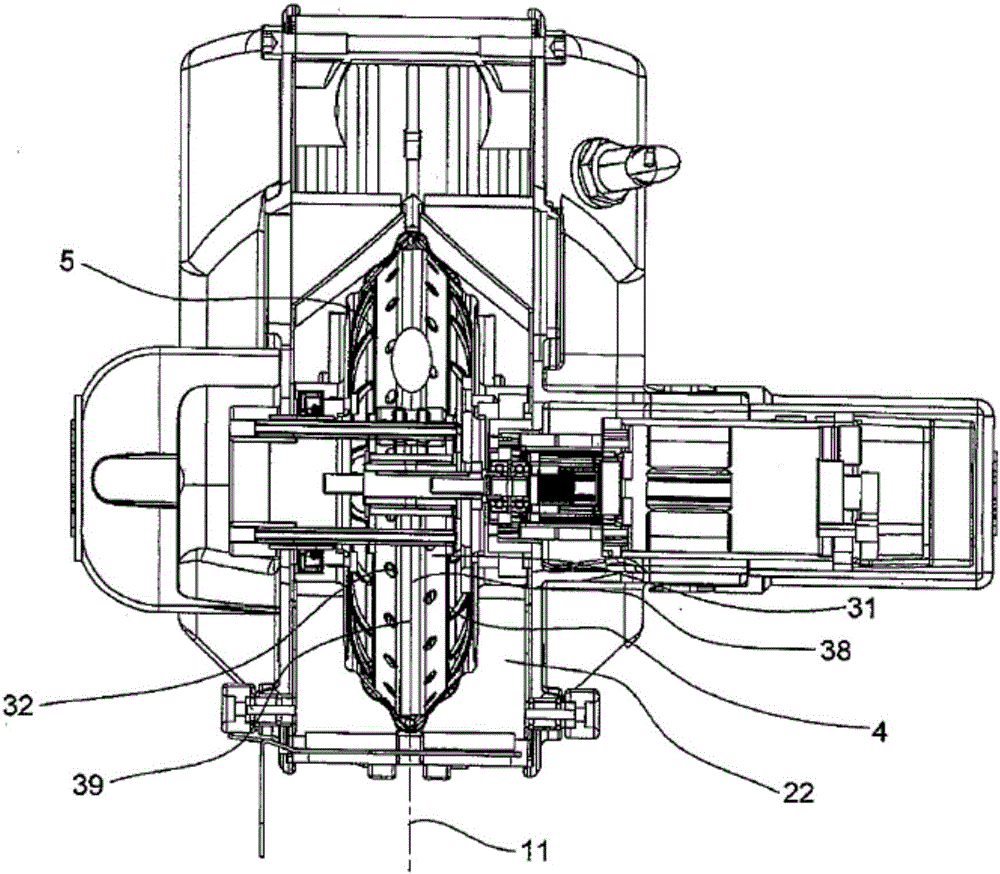

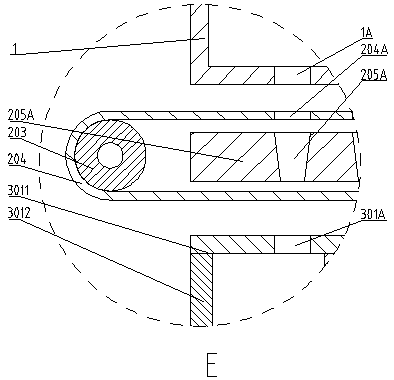

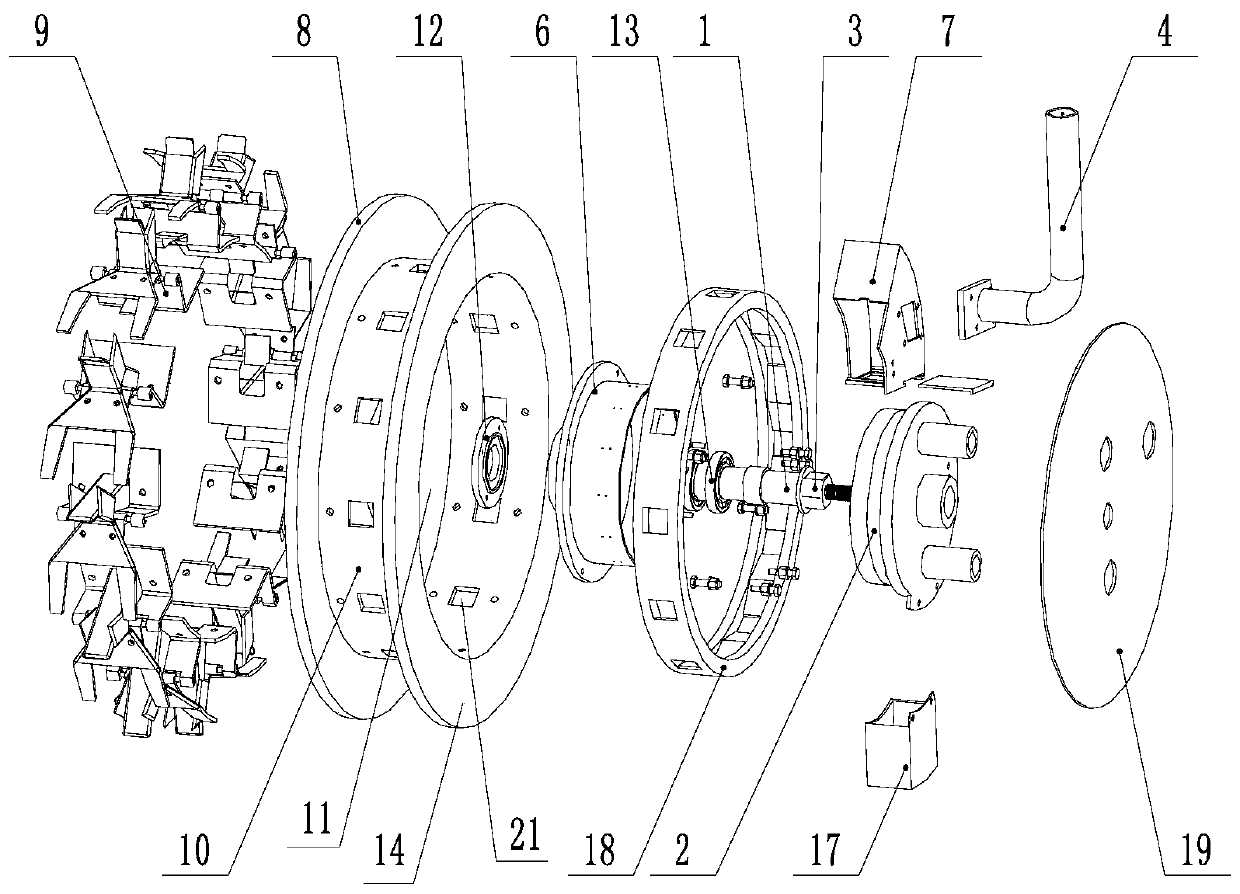

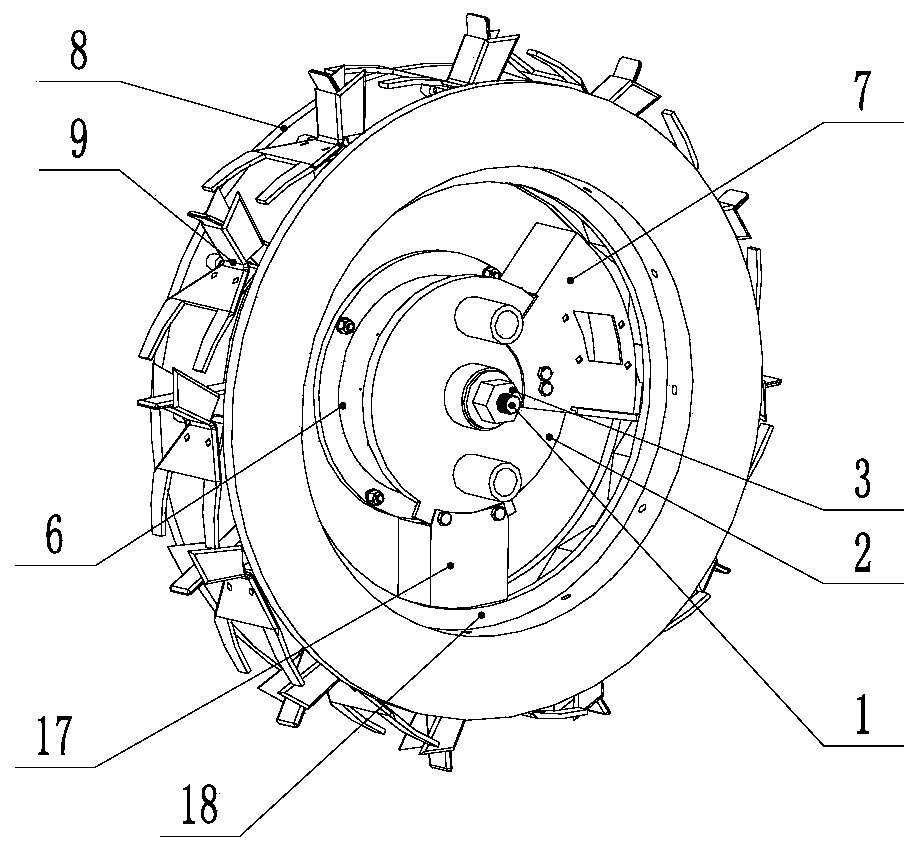

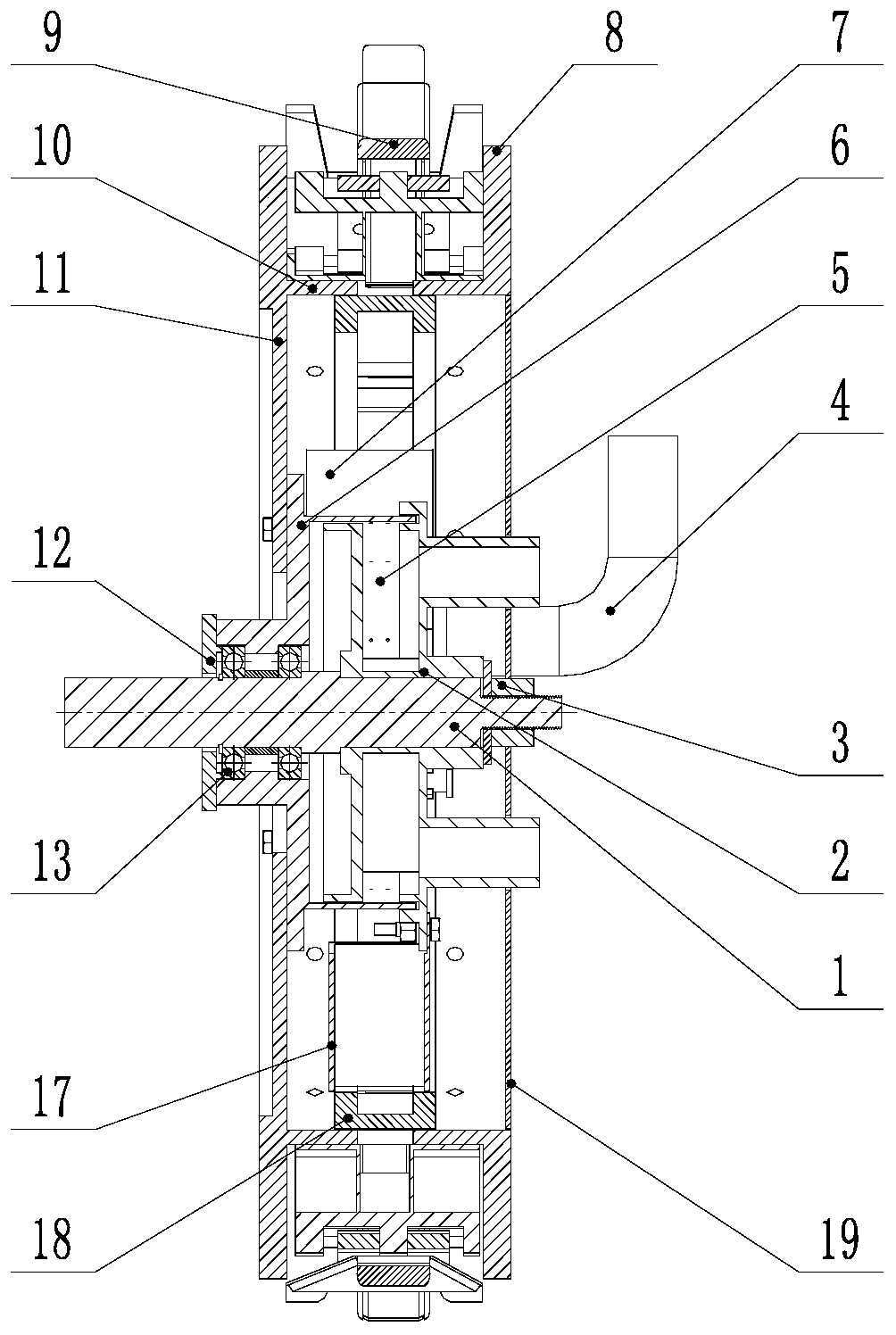

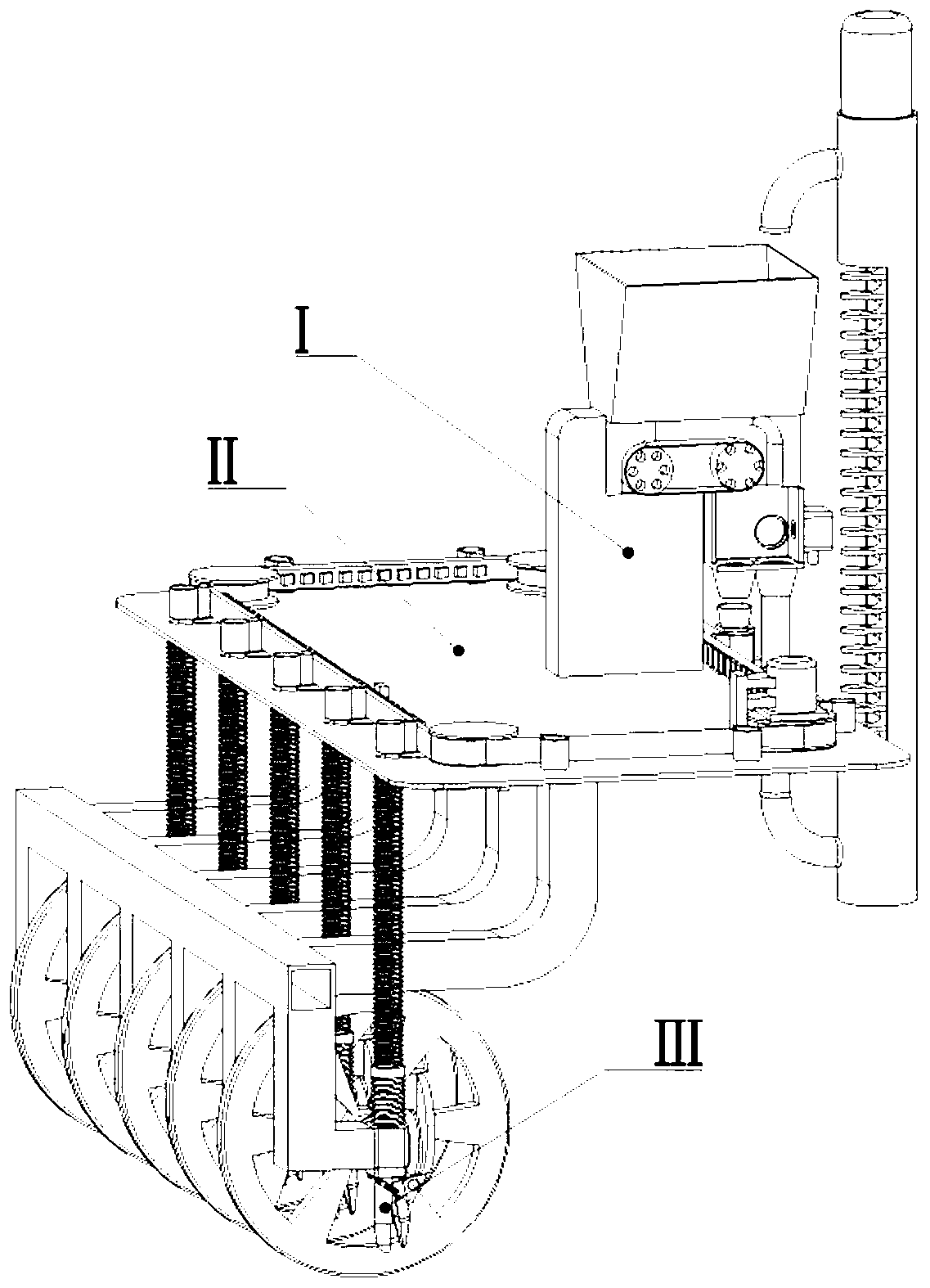

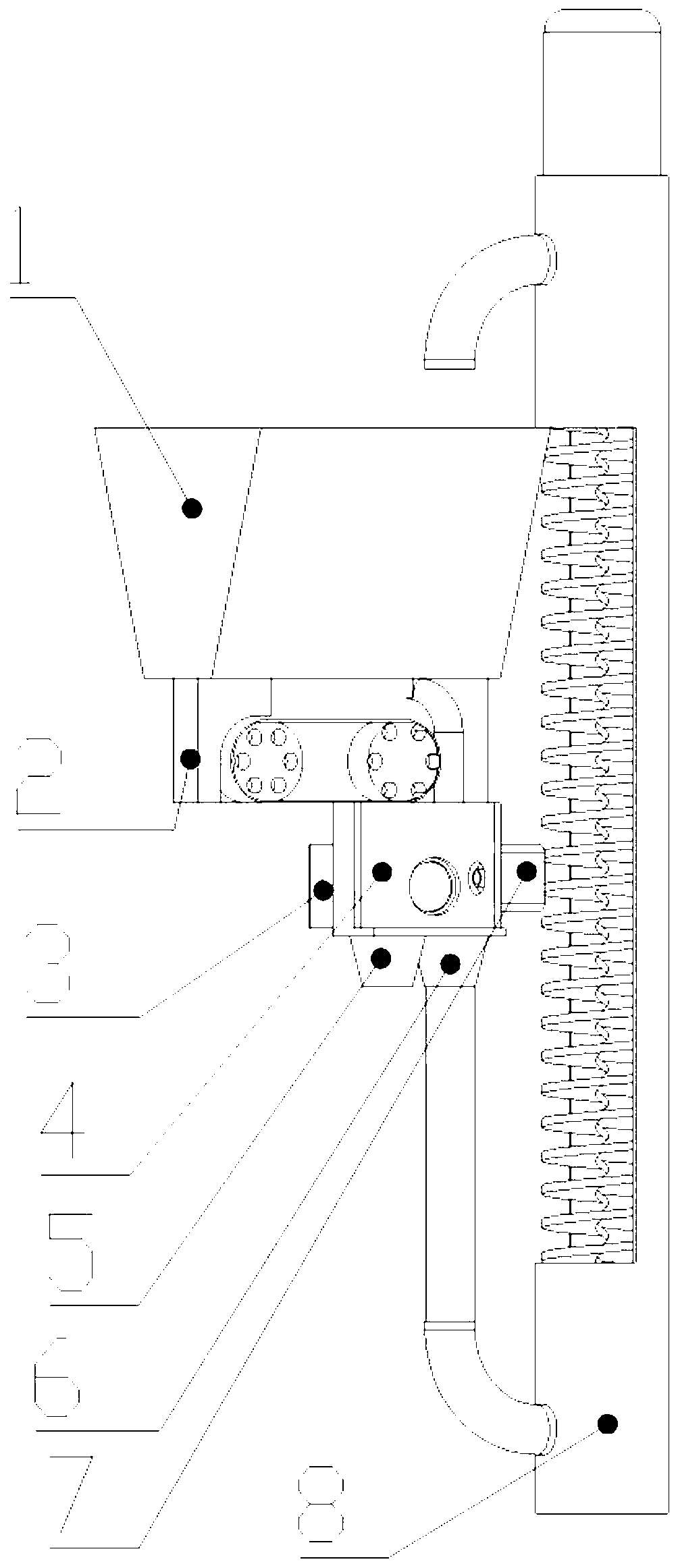

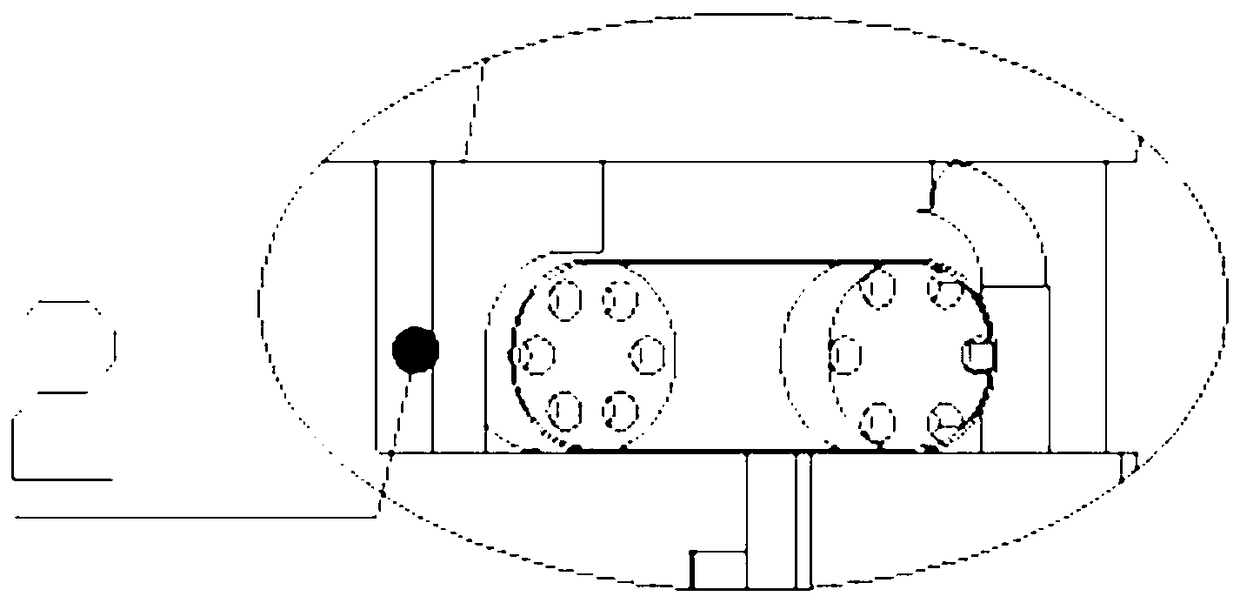

Pneumatic needle type single-grain precision seeder

The invention discloses a pneumatic needle type single-grain precision seeder which comprises a walking power device, a spiral ridging device, a main rack, a driving device, a seed metering device, aseed guide device, a soil covering device, a pair of land wheels and a fan; the seed guide device comprises a pair of star wheel discs, a seed guide shaft, a middle wheel shaft, hanging basket shafts,a double-row seed guide chain wheel and control cams; each star wheel disc comprises a disc end cover, a planetary wheel disc and a planetary gear train; the pair of double-row seed guide chain wheels are respectively fixed on the disc end covers to drive the star wheel discs to rotate; a plurality of hanging baskets are uniformly distributed on each hanging basket shaft in the axial direction, the opening and closing ends of the hanging baskets are always kept in a vertically downward state while the hanging baskets rotate around a central shaft, and the control cams with the same number asthe hanging baskets are uniformly distributed on the seed guide shaft in the axial direction; and by adopting the planet wheel dibbling type full-constraint seed guide principle, the full constraint with the local freedom degree can be realized in the process from the time when seeds leave a seed suction needle to the time when the seeds fall into seedbed soil for seed guide and transportation, the bounce and slippage of the seeds and the seedbed soil are reduced, the seed feeding precision is high, and the seeding quality is good.

Owner:HUAZHONG AGRI UNIV

Double-suction ring broad-width precision sowing apparatus

ActiveCN105052315ASlow down the landing speedImprove seeding accuracySeed depositing seeder partsRegular seed deposition machinesSowingEngineering

The invention provides a double-suction ring broad-width precision sowing apparatus. The apparatus comprises a seed containing box, a seed discharging device and a seed discharging tube, the seed discharging device comprises a shell, a sealing cover and an inner core, the seed discharging device is a double-suction ring air suction type seed discharging device, the bottom of the seed discharging device is fixedly provided with a hollow baffle block, the seed discharging tube is arc-shaped, and the arc angle theta is not smaller than 40DEG and not greater than 50DEG. When the apparatus works, seeds fall into the seed discharging device from the seed containing box, the inner wall rotates with a driving shaft, the seed discharging device adopts a double-suction ring structure to increase the suction force, the seed containing box is divided into two parts, a negative pressure is generated in the seed discharging device through a high speed fan, seeds adsorbed in recessed round pits rotate with the inner core, the suction force to the seeds decreases and even disappears when the seeds rotate to the fixed hollow baffle block under the seed discharging device, the seeds fall into a seed outlet under the action of a seed scraper and enter the seed discharging tube, and the seed discharging tube is arc-shaped, has a certain angle to the ground and is not vertical to the ground, so the falling speed of the seeds is reduced, deviation from sowing points due to bouncing after seed falling to the ground is avoided, and the sowing precision is improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

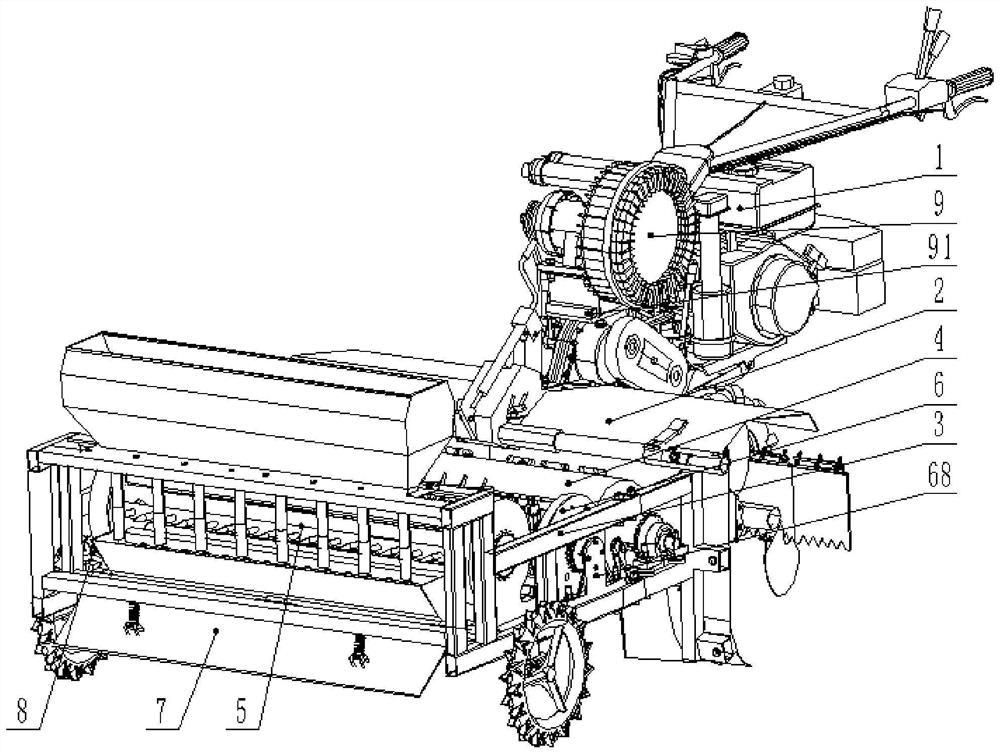

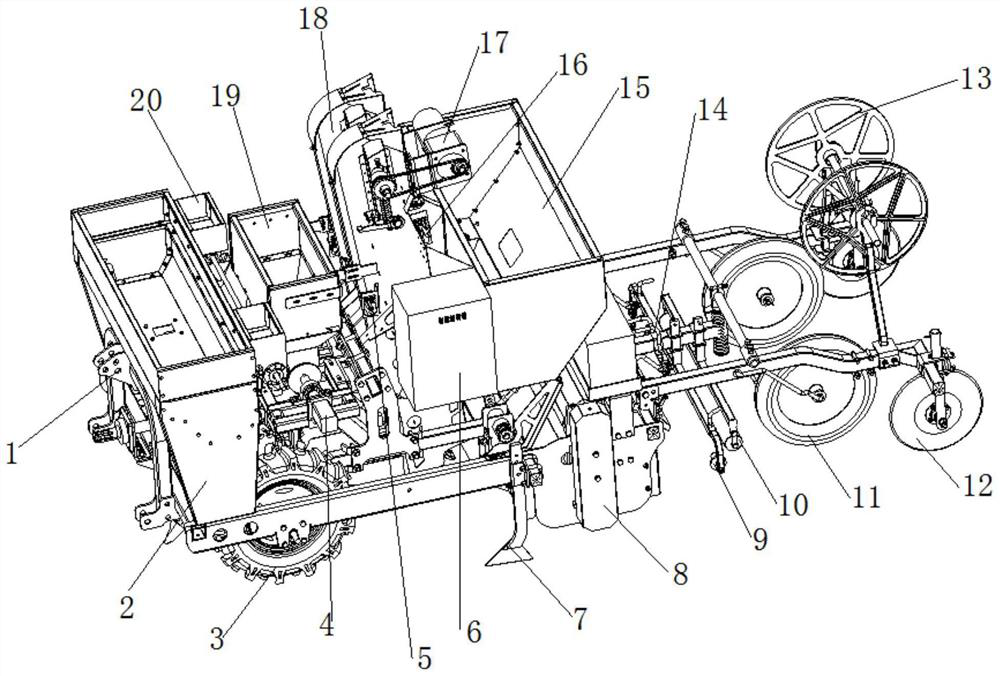

Multifunctional celery seeding all-in-one machine

InactiveCN106489325AGuarantee the quality of sowingKeep moistureSpadesPloughsSeederProduction effect

The invention discloses a multifunctional celery seeding all-in-one machine, and belongs to the field of agricultural machinery. The multifunctional celery seeding all-in-one machine comprises a rack, a pressing roller, a rotary tillage ridging device, a ground wheel device, a film laminating device, a sand pressing device and a seeder, wherein the pressing roller, the rotary tillage ridging device, the ground wheel device, the film laminating device and the seeder are fixedly mounted on the rack from front to back. The machine advances under the traction of a tractor or other agricultural machinery; rotation of ground wheels of the machine is realized through a first-stage chain in a transmission manner; and rotation of a film laminating shaft in the film laminating device and transmission of an output shaft of a speed change box of a perforation device are realized through second-stage and third-stage chains in a transmission manner. According to the multifunctional celery seeding all-in-one machine, the sand pressing device and the ground wheel device are improved, and a drop irrigation device is additionally arranged, so that the sand stirring and production effect is enhanced, the advancing resistance of the all-in-one machine is reduced, and the seeding precision is improved.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI +1

Air tube equipment suitable for corn plot precision seeding

PendingCN111010933AImprove seeding accuracyHigh precisionSeed depositing seeder partsSeederAgricultural engineering

The invention discloses air tube equipment suitable for corn plot precision seeding, and relates to the technical field of plot corn seeding. An air pipe is connected to a fan through a pipe; one endof each seed metering pipe is arranged on the air pipe; one end of each seed removing pipe is arranged on the air pipe; a hollow cavity is arranged in each seed metering device, and a seeding hole isarranged in the bottom end of each seed metering device; seed suction pipes and seed drop pipes are located on the same side of the seed metering devices; each seed removing box communicates with theother end of one corresponding seed removing pipe for collecting seeds; a rotating disk is arranged in a hollow cavity of each seed metering device, and each rotating disk is provided with a circle ofseed holes for adsorbing seeds; and each scraping plate is used to scrape down the seeds on one corresponding rotating disk and make the seeds move along the scraping plate to slide out from the seeding hole in the bottom of one corresponding seed metering device. The equipment has the beneficial effects of improving the seed metering precision and seed removing precision of a corn plot precisionseeder, reducing the seed mixing rate of the corn plot precision seeder, reducing the affect on seed metering and seed removing due to different wind power and wind directions, and improving the accuracy of corn plot seeding tests through the structural design.

Owner:QINGDAO AGRI UNIV

Drum-type precise sowing device for hole sowing of vegetable seeds

ActiveCN104620735AAvoid damageSame distanceSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringSprocket

The invention discloses a drum-type precise sowing device for hole sowing of vegetable seeds. The device comprises a switch, a stander, a feed hopper, a seed metering device, a brush, a rear walking wheel axle, wheels, a blanking hopper, an overrun clutch, a plurality of chains, a plurality of chain wheels, a front walking wheel axle and a motor, wherein the motor, the front walking wheel axle and the wheels are arranged at the front end of the stander; the rear walking wheel axle and the wheels are arranged at the rear end of the stander; the feed hopper, the seed metering device, the brush and the blanking hopper are arranged in the middle of the stander; the motor can be used for controlling the front walking wheel axle, the rear walking wheel axle and the seed-metering device by chain transmission. The drum-type precise sowing device has the characteristics of being simple in structure, convenient to operate and the like, and can be used for precisely and evenly sowing seeds at equal intervals.

Owner:ZHEJIANG UNIV

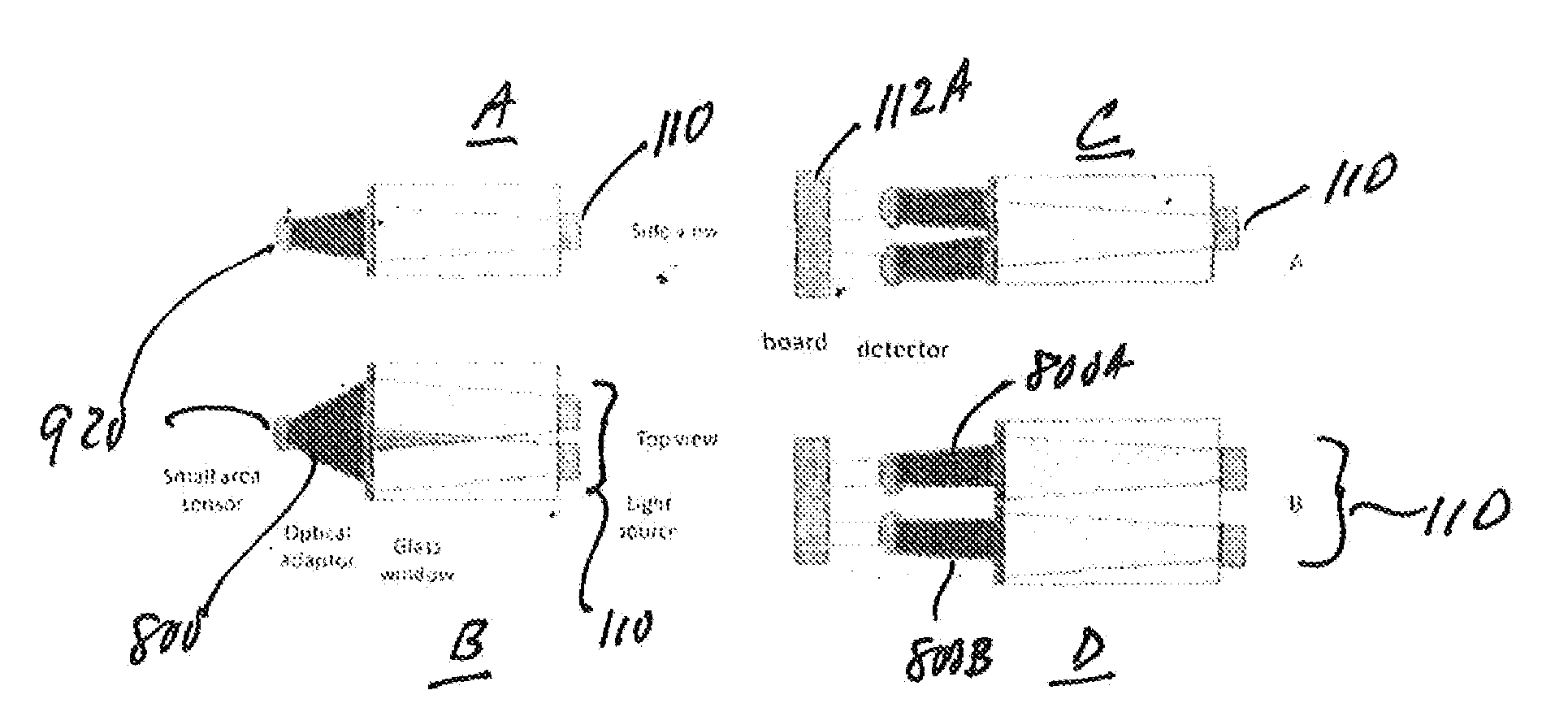

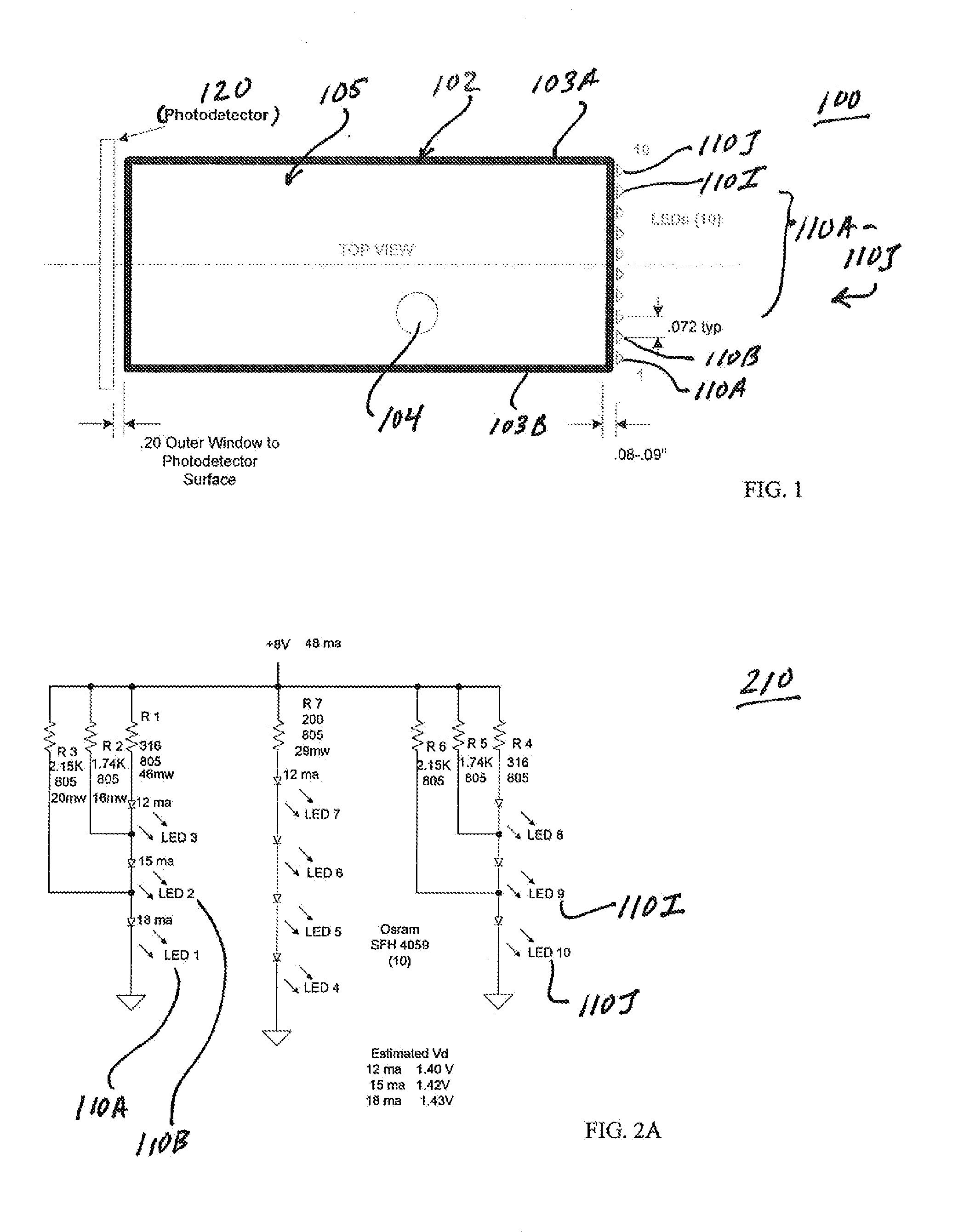

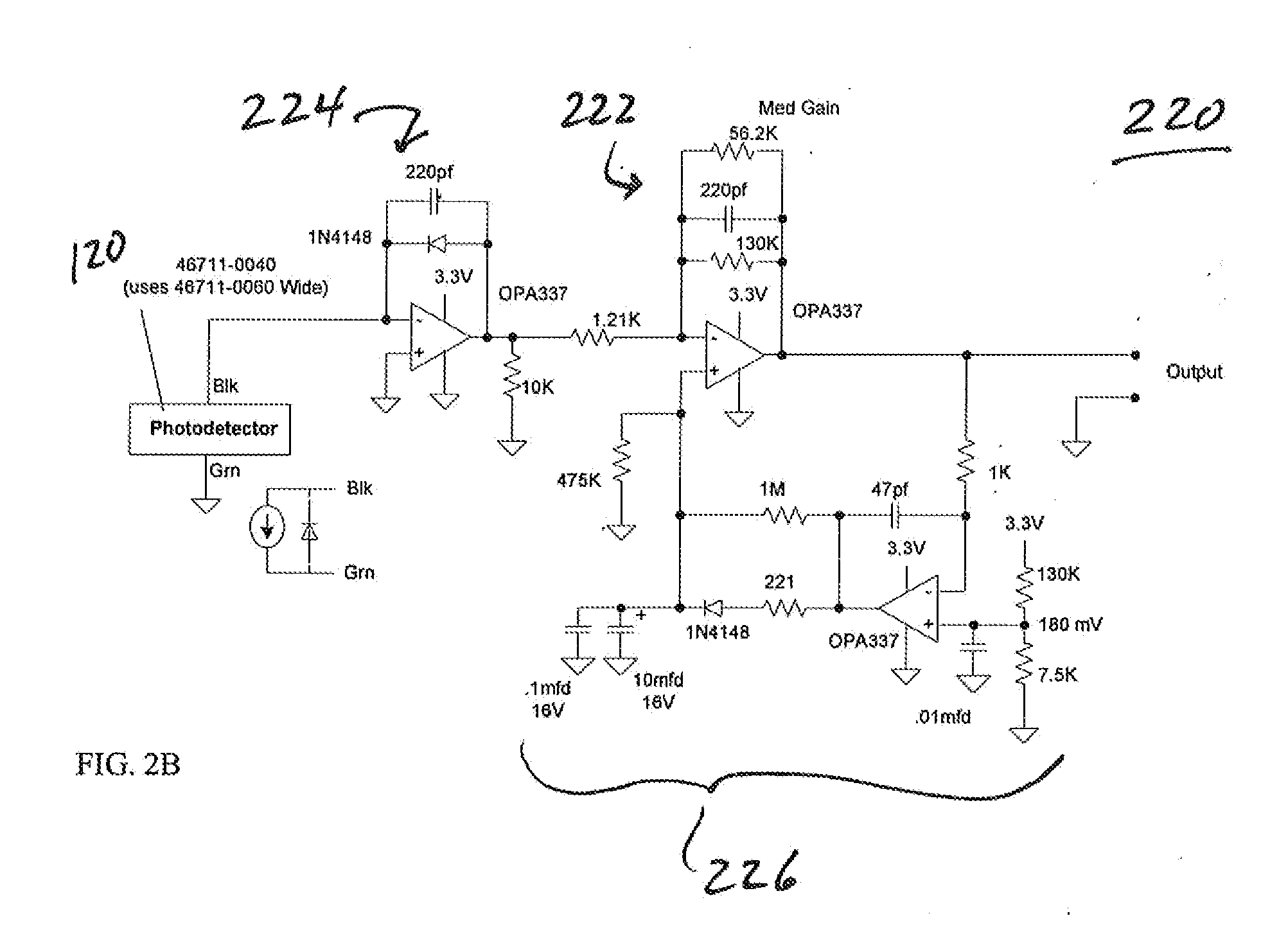

Seed sensor with lightpipe photodetect assembly

ActiveUS20160374263A1Improve performanceReduce spatial variabilityUsing optical meansSeed depositing seeder partsPhotovoltaic detectorsPhotodetector

In one example embodiment, a seed sensor is disclosed adapted to fit a conventional mounting location in existing seed tubes that provides improved performance by providing a wide light source (more LEDS), a wide photodetector and a current profiling scheme for the LEDs that provides more light at the opposite ends of the LED array. A result of such an arrangement is to improve seed resolution and to reduce seed spatial variability within the seed tube.

Owner:TSI INC

Suction wheel type broad-width precious speed distribution apparatus

ActiveCN105052316ASlow down the landing speedAvoid elasticSeed depositing seeder partsRegular seed deposition machinesMechanical engineeringHorticulture

The invention provides a suction wheel type broad-width precious speed distribution apparatus. The apparatus comprises a seed containing box, a seed discharging device and a seed discharging tube, the seed discharging device is a suction wheel type seed discharging device and comprises a box body, a sealing cover, an inner core and a seed discharging opening, the bottom of the seed discharging device is fixedly provided with a baffle block, the inner core is cylindrical in shape, a driving shaft traverses through the inner core, recessed round pits are uniformly distributed on the external surface of the inner core, the recessed round pits are distributed in a five-in-line and six-in-line interval manner, the seed discharging tube is arc-shaped, and the arc angle is not smaller than 40DEG and not greater than 50DEG. When the apparatus works, a negative pressure is generated in the seed discharging device through a high speed fan, seeds are adsorbed in recessed round pits under the action of below air suction holes and rotate with the inner core, the suction force to the seeds decreases and even disappears when the seeds rotate to the fixed hollow baffle block under the seed discharging device, the seeds depart from the recessed round pits under the action of a seed scraper and enter the seed discharging tube, and the seed discharging tube is arc-shaped and has a certain angle to the ground, so the falling speed of the seeds is reduced, deviation from sowing points due to bouncing after seed falling to the ground is avoided, and the sowing precision is improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

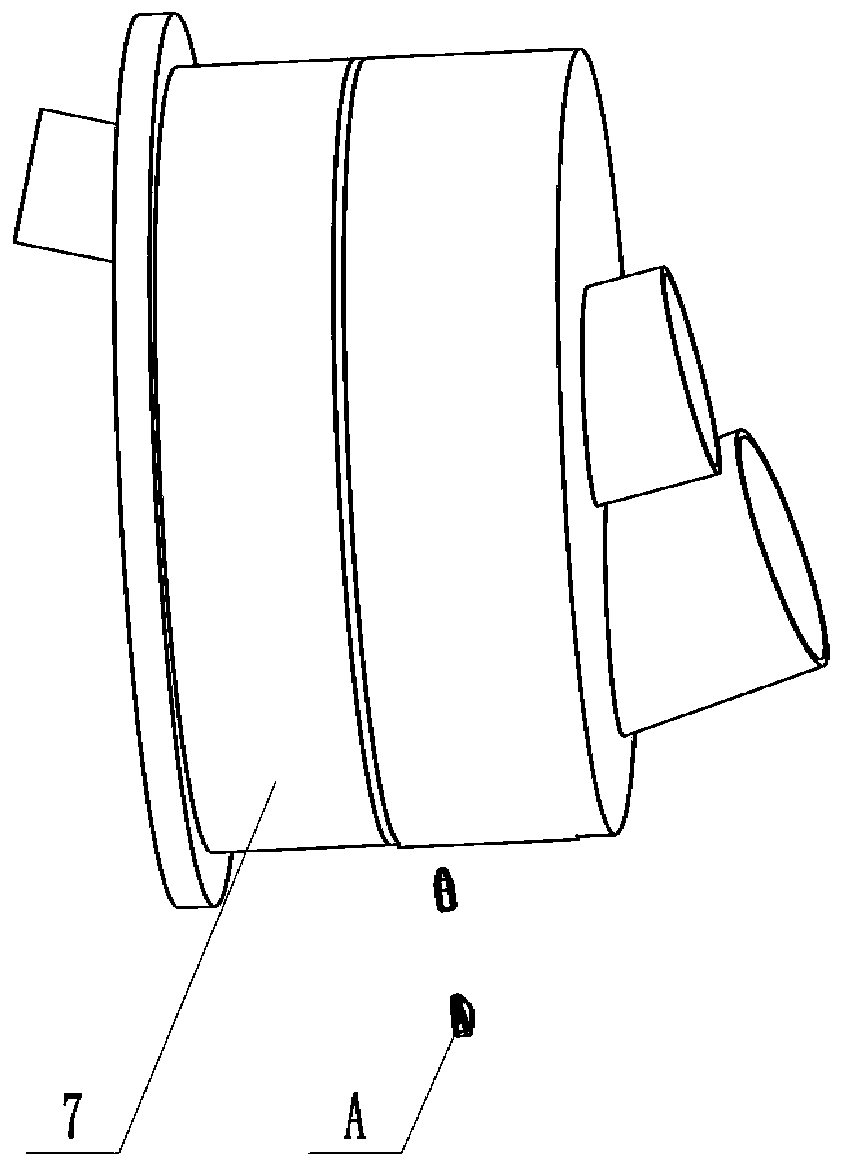

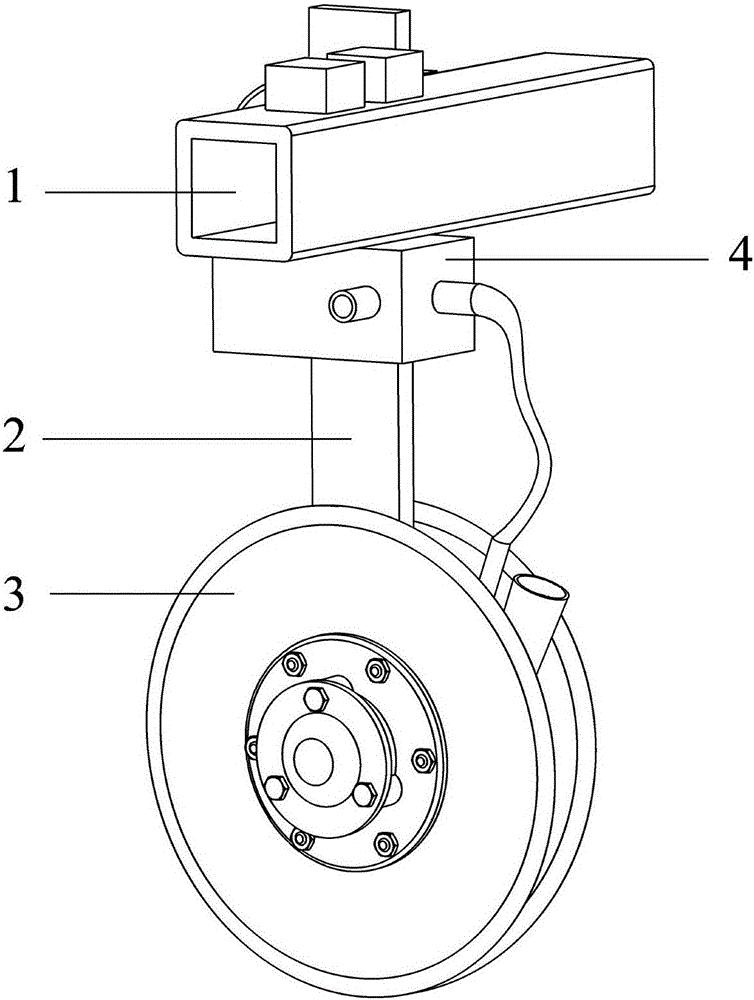

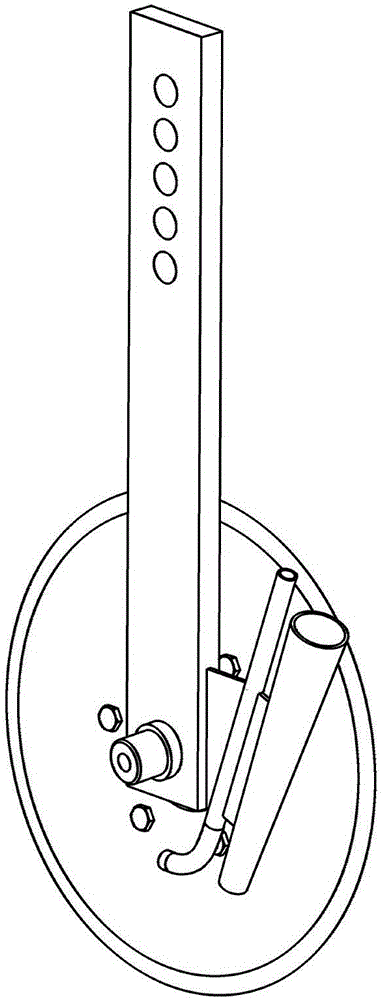

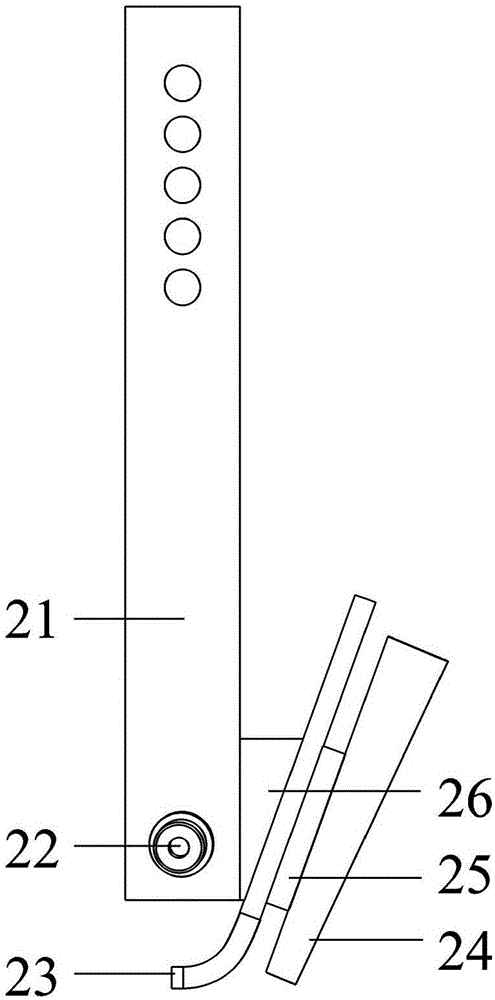

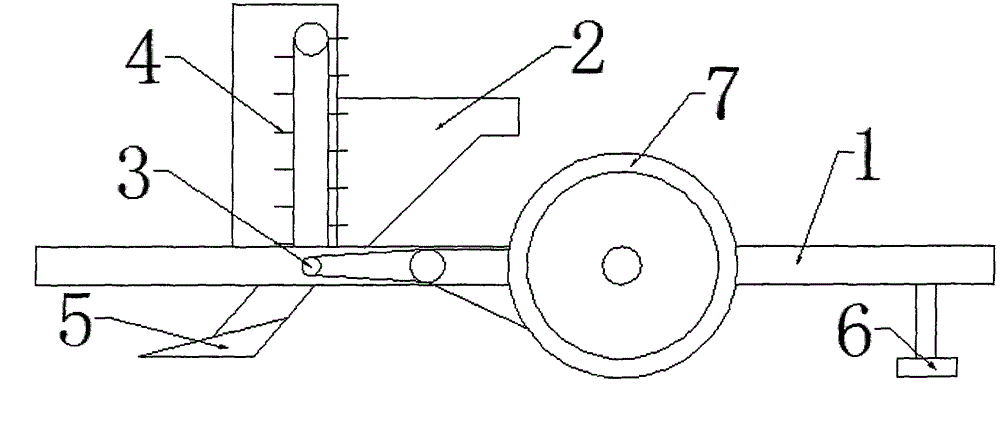

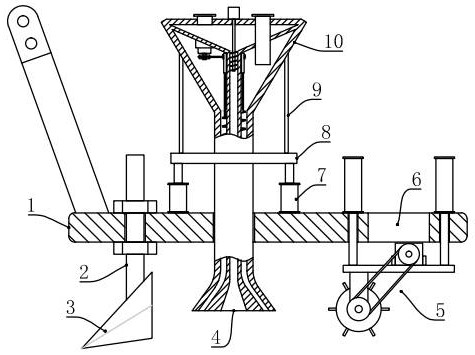

Seed furrow liquid spraying type seed anti-bouncing device

InactiveCN106612782AIntegrity guaranteedIncrease moisture contentPlantingWatering devicesEngineeringDirect current

The invention relates to a seed furrow liquid spraying type seed anti-bouncing device which comprises a frame, a handle welded part and two cutter discs, wherein the handle welded part comprises a handle, two stepped shafts and a seed guide pipe; the stepped shafts are symmetrically fixed under the two sides of the handle; the seed guide pipe is fixedly arranged on the surface of the handle along an advancing direction of the device in a bias form; the two cutter discs are respectively arranged on the two stepped shafts; the device is characterized in that a water pump is welded between the frame and the handle welded part; a water tank or a drug box is connected with a liquid inlet of the water pump; a flow guide pipe is connected with a liquid outlet of the water pump; a water outlet of the flow guide pipe is toward the advancing direction of the device; a PLC controller and a direct current power supply are arranged on the frame; a power supply input end of the PLC controller is connected with a power supply output end of the direct current power supply; the water pump is connected with the PLC controller; an inclined angle of the projections of the axis of the stepped shafts and the asymmetry axis of the handle welded part along the advancing direction is alpha; alpha is more than or equal to 2 phi / 5 but less than or equal to phi / 2; the inclined angle of the projections of the axis of the stepped shafts and the asymmetry axis of the handle welded part in a horizontal plane is beta; beta is more than or equal to 2 phi / 5 but less than or equal to phi / 2. The device can effectively control the seed falling position and can promote the seed feeding precision.

Owner:JILIN UNIV

Seed meter for a single-grain seeder

ActiveCN105828596APrevent wrong dischargeImprove seeding accuracyPlantingFurrow making/coveringSeederEngineering

Owner:LEMKEN

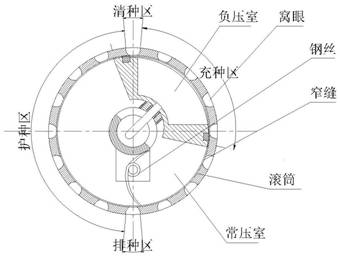

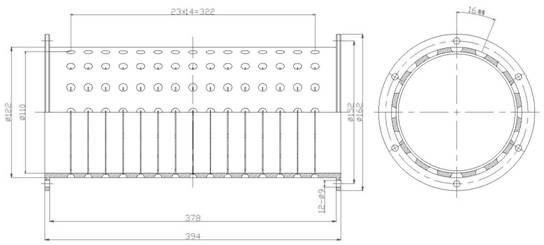

Pneumatic combined rice seed metering device

PendingCN111758343AReduce wasteAchieve cleaning effectSeed depositing seeder partsMechanical engineeringOryza sativa

The invention relates to a pneumatic combined rice seed metering device. 15 rows of 12 hemispherical indents in each row are uniformly arranged on the outer surface of a roller, the position, oppositeto the centers of the indents, of the inner surface of the roller is provided with 15 annular grooves, the indents are machined in the outer surface of the roller, the annular grooves are formed in the inner surface of the roller, the indents and the annular grooves penetrate through each other to form long and thin rectangular narrow slits, and the effect of adsorbing rice bud seeds is achievedthrough the internal and external pressure difference of the annular grooves. When the roller indents are filled with seeds, firstly, seed filling is completed under the combined action of self-filling of the gravity of the seeds and the pressure difference between the two ends of the narrow slits, and the purpose of ensuring stable seed filling is achieved; before the bud seeds are carried by theroller indents and conveyed to a seed discharging position, the pressure difference between the two ends of the narrow slits disappears, and the conveying process is completed completely with the help of the protection effect of a seed protection belt; and when the roller discharges seeds to a growing tray, the seeds can be separated from the roller and sown on the growing tray due to the gravityof bud seeds and the action of force generated by outward release of potential energy of seed bouncing steel wires, the seed bouncing steel wires penetrate through the narrow slits to complete the cleaning effect on suction holes, the seed suction capacity of the seed metering device is recovered, and the seed metering device can continuously and stably work. Therefore, the designed seed meteringdevice can adapt to the existing 15-row 25-column type rice growing soft trays to carry out high-precision operation.

Owner:CHANGCHUN AGRI MACHINERY

Planting method of tulips

InactiveCN105284336AOvercome the miss rateOvercome the disadvantage of high replay rateHorticultureUltimate tensile strengthTractor

The invention discloses a planting method of tulips, pertaining to the technical field of agriculture. The planting method of tulips comprises following five steps: selecting soil, selecting and disinfecting bulbs, mechanically sowing, applying fertilizers to soil and performing post-harvest treatment. A planting and sowing machine for tulips is utilized in the manner of matching a tractor so that operation such as trench digging, sowing, earthing and ridging is finished at one time. The planting method of tulips has following beneficial effects: the above-mentioned operation is advantaged by protecting and picking, labor-saving, seed-saving, fertilizer-saving and is uniform in depth; by utilizing mechanical sowing, sowing quality is increased and labor intensity is decreased; seeds are discharged accurately and rapidly; leakage sowing rate is considerably decreased; sowing precision and efficiency are enhanced; defects of a scoop-type sower such as high leakage sowing rate and re-seeding rate are solved; and the percentage of damaged seeds is low during work.

Owner:XINJIANG TULIP BIOTECH LTD

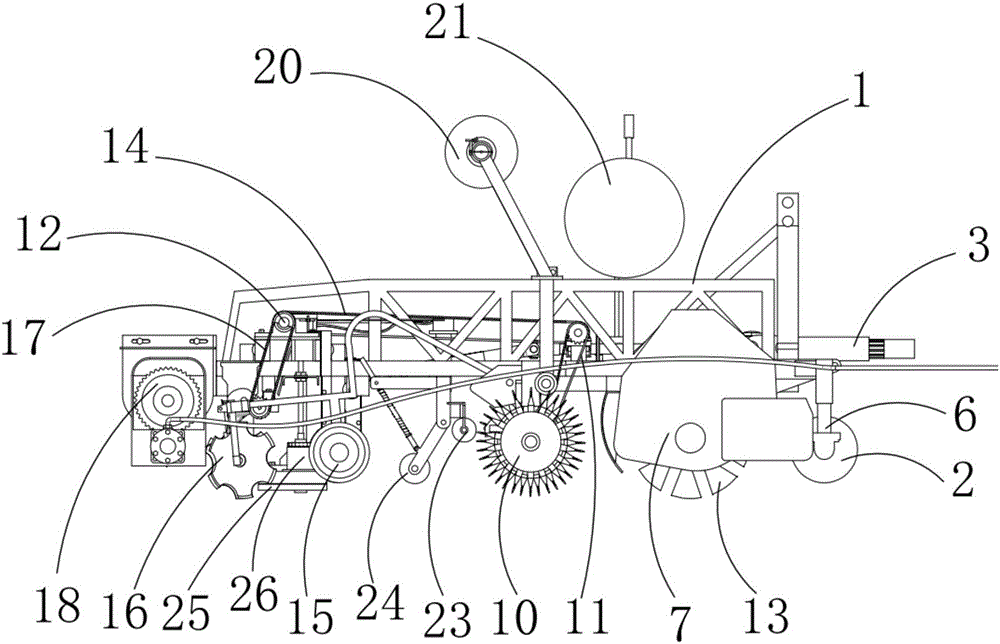

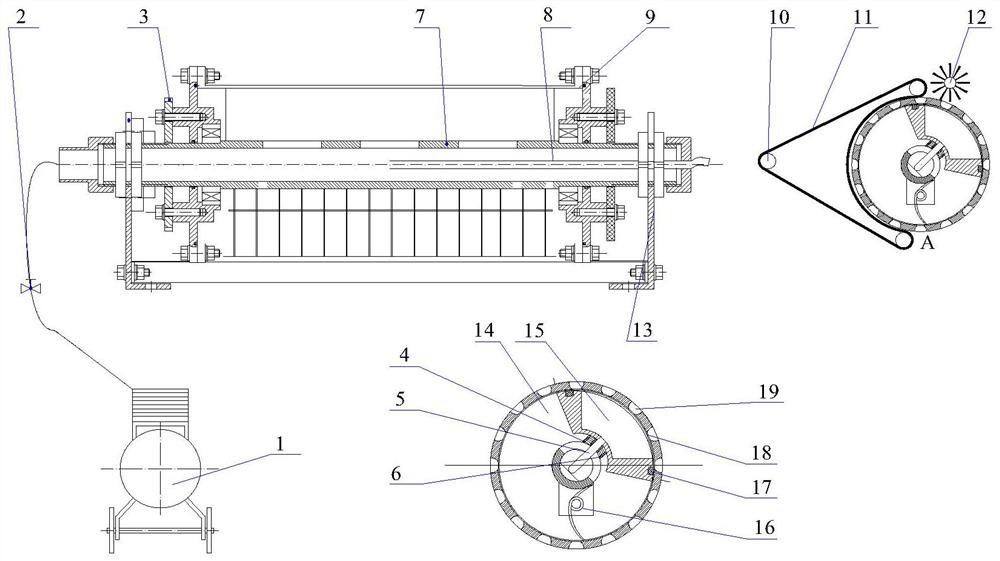

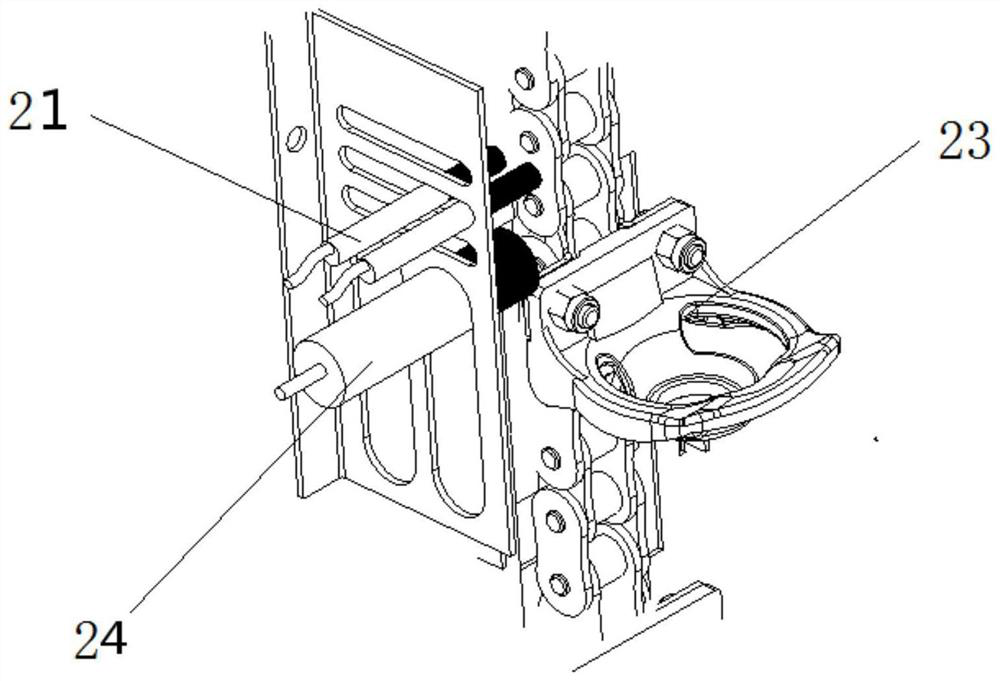

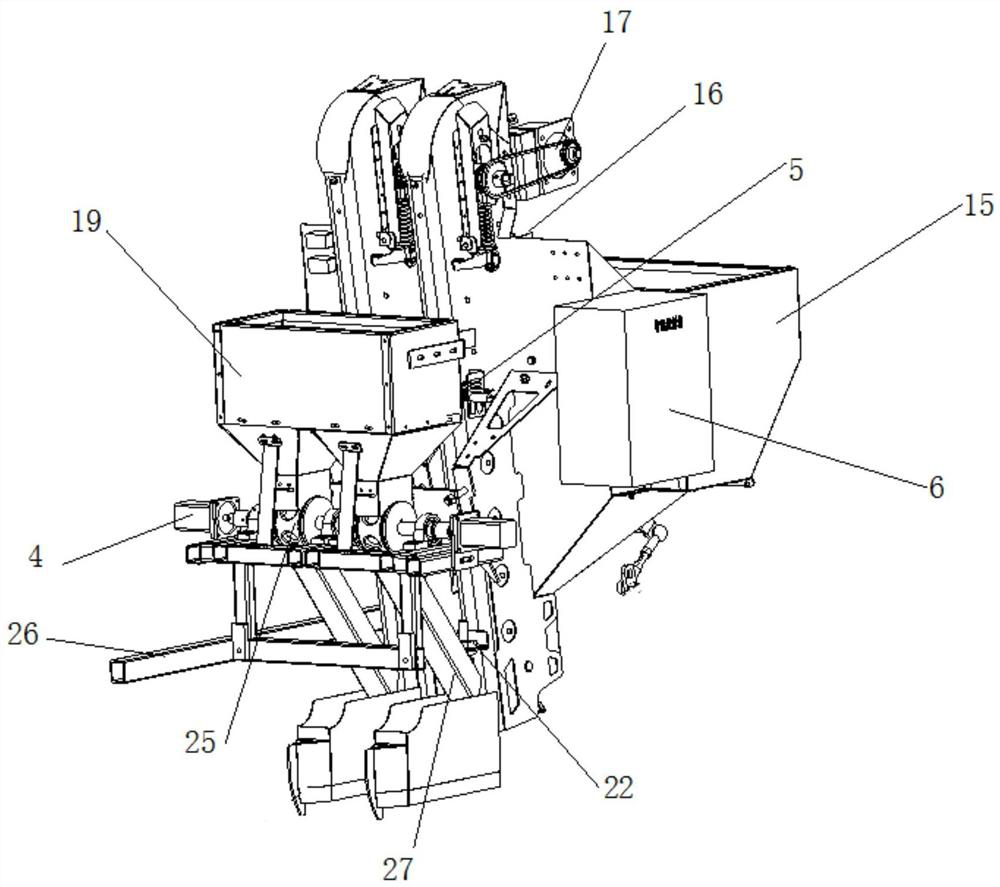

Potato miss-seeding reseeding machine capable of realizing high efficiency precision and low miss-seeding

PendingCN111771442ASolve the shortcomings of low efficiency, low seeding accuracy and high cost of artificial reseedingImprove seeding accuracySpadesFertiliser distributersAgricultural engineeringDrip irrigation

The invention belongs to the technical field of agricultural machinery, and particularly relates to a potato miss-seeding reseeding machine capable of realizing high efficiency precision and low miss-seeding. The potato miss-seeding reseeding machine comprises fixed racks, a fertilizing device, a granular pesticide seeding device, a reseeding device, a seed metering device, a miss-seeding detection device, a rotary tillage ridging device, a weeding and pesticide spraying device and a film mulching and soil covering device, wherein a cross beam is arranged in front of the two fixed racks, a suspension bracket is mounted on the cross beam, a fertilization ditching shovel is mounted in the middle of the cross beam, a traveling wheel is mounted on each of the two fixed racks, the rotary tillage ridging device is mounted behind the fixed racks, and a drip irrigation belt laying device and a film mulching and soil covering device are arranged behind the rotary tillage ridging device. The potato miss-seeding reseeding machine capable of realizing high-efficiency precision and low miss-seeding is compact in mechanical structure, simple in structure and stable in operation, and capable of realizing accurate seeding of potatoes and reducing the miss-seeding rate.

Owner:QINGDAO AGRI UNIV

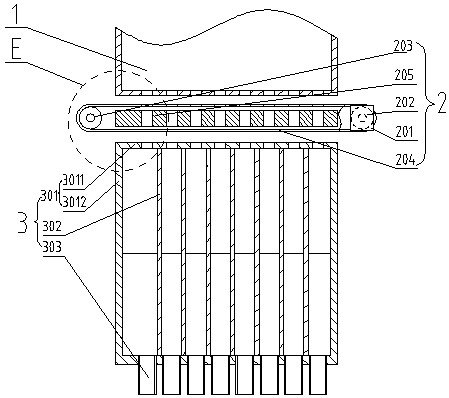

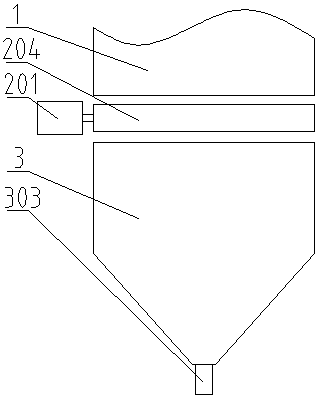

Isolation type seed-metering device and application method thereof

InactiveCN108848800ASimple structureImprove seeding accuracySeed depositing seeder partsConveyor belt

The invention provides an isolation type seed-metering device and an application method thereof, aiming at the problem in the prior art that a seed box is communicated with a seed sowing mechanism sothat the seed sowing precision is influenced. The isolation type seed-metering device comprises a vibration seed box for storing seeds, a movable seed leakage assembly arranged just below the vibration seed box and a direction dividing chamber which is arranged just below the movable seed leakage assembly and is used for discharging the seeds, wherein a plurality of leakage holes for discharging the seeds are formed in the bottom of the vibration seed box; the isolation type seed-metering device is characterized in that the movable seed leakage assembly comprises a driving part, a driving transmission roller driven by the driving part, a driven transmission roller, an isolation conveyor belt of the driving transmission roller and the driven transmission roller, and a seed discharging thickplate arranged between the driving transmission roller and the driven transmission roller. The isolation type seed-metering device provided by the invention is simple in structure; a seed sowing partand the vibration seed box are isolated through the isolation conveyor belt, so that the seed sowing precision is improved.

Owner:HENAN UNIV OF SCI & TECH

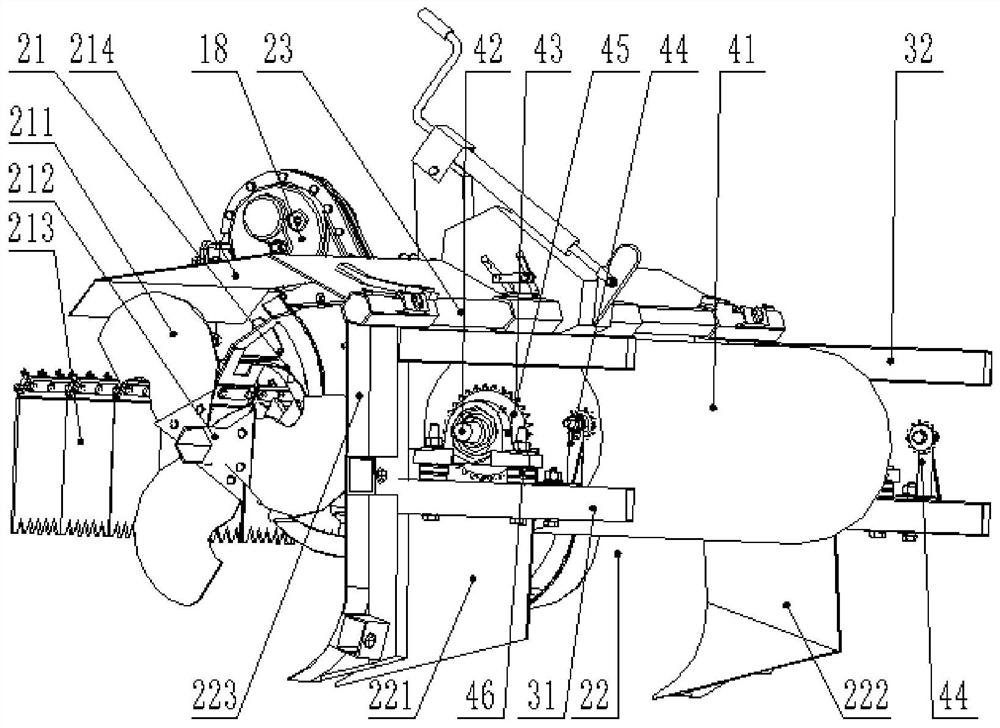

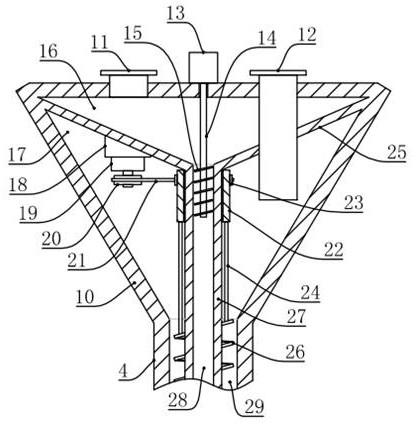

Positive-negative air pressure combined duck-billed precise hill-drop planter

The invention discloses a positive-negative air pressure combined duck-billed precise hill-drop planter. The positive-negative air pressure combined duck-billed precise hill-drop planter comprises a fixing shaft, an air chamber cavity, a seed metering wheel, a hill-drop turntable, a seed filling chamber cavity and a seed guiding groove, wherein the air chamber cavity is inserted into one end of the fixing shaft and installed on the fixing shaft, the seed metering wheel is inserted into the other end of the fixing shaft and installed on the fixing shaft, and the hill-drop turntable is connectedto the seed metering wheel; and the seed filling chamber cavity and the seed guiding groove are mounted on the circumference of the air chamber cavity. The seed metering principles of negative-pressure seed suction and positive-pressure seed blowing are combined with the principle of duck-billed hole formation, the hill-drop planter has a simple structure and reliable operation, precise hole sowing of seeds of small particle size is realized, the seeding precision is high, seed jamming and damage to seeds are reduced, little damage is caused to the seeds, the seeds are saved, and membrane punching, seed sucking and seed metering can be completed at a time; and the hill-drop planter has high sowing efficiency, low work intensity and convenient operation, and time and labor can be saved.

Owner:HUAZHONG AGRI UNIV

Multi-row seeding machine for garlic

The invention provides a multi-row seeding machine for garlic. The seeding machine comprises a garlic single-clove upright seed selecting device, a garlic seed falling device and garlic insertion seeding devices. According to the seeding machine provided by the invention, the garlic single-clove upright seed selecting device is utilized to select single-clove, upright and upward-bud-end garlic seeds, a plurality of rows of the selected seeds fall through the garlic seed falling device, and multi-row simultaneous seeding is performed by the garlic insertion seeding devices; the seeding machinerealizes single-clove, upright and upward-bud-end seeding manner of the garlic, and when a forward velocity of the seeding machine is controlled, equal-distance seeding can be realized; and meanwhile,the seeding machine has a simple structure, solves the problems existing in artificial seeding, and realizes a mechanized planting technology of the garlic.

Owner:重庆化工职业学院

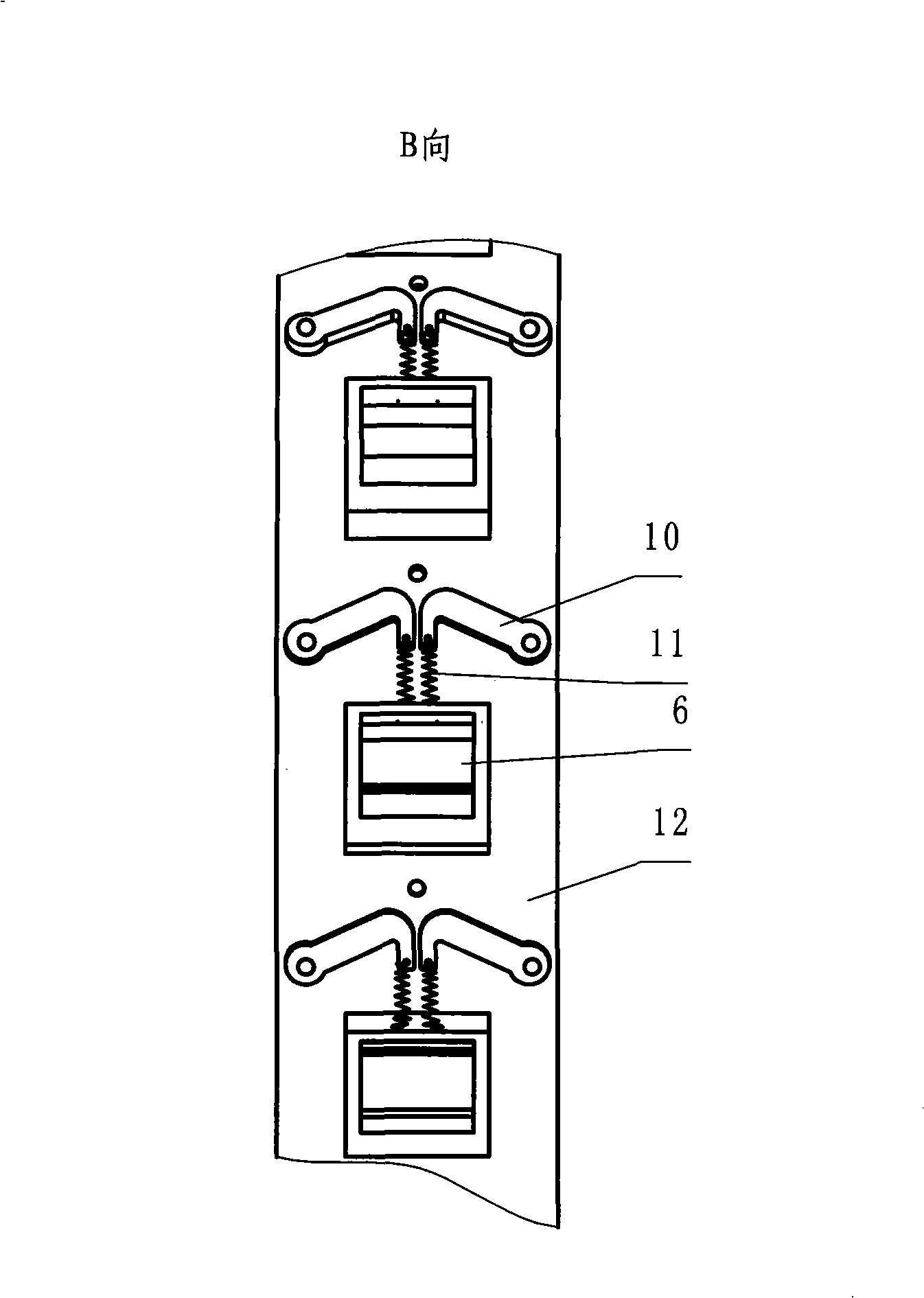

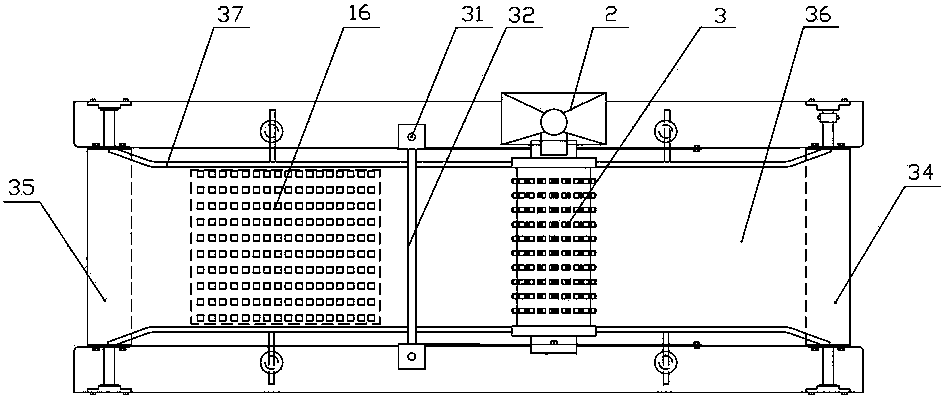

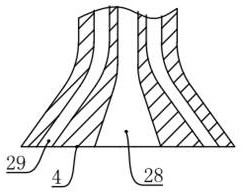

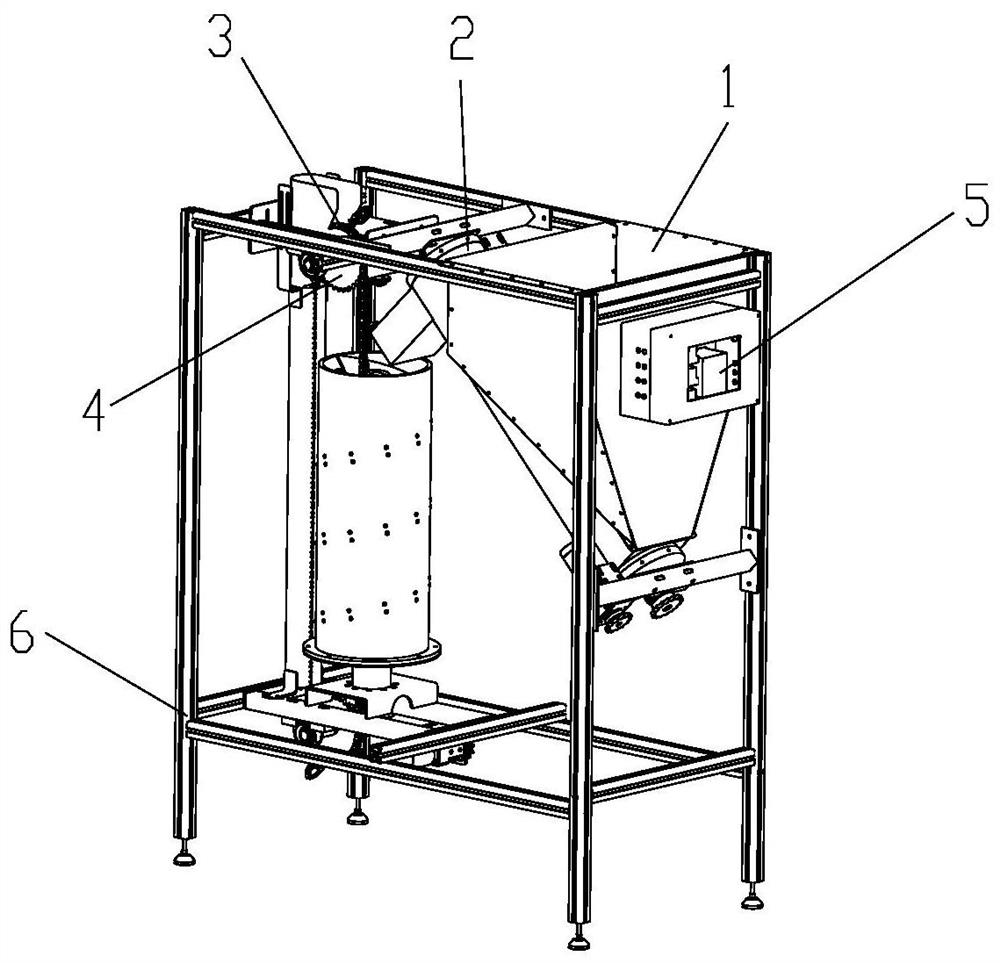

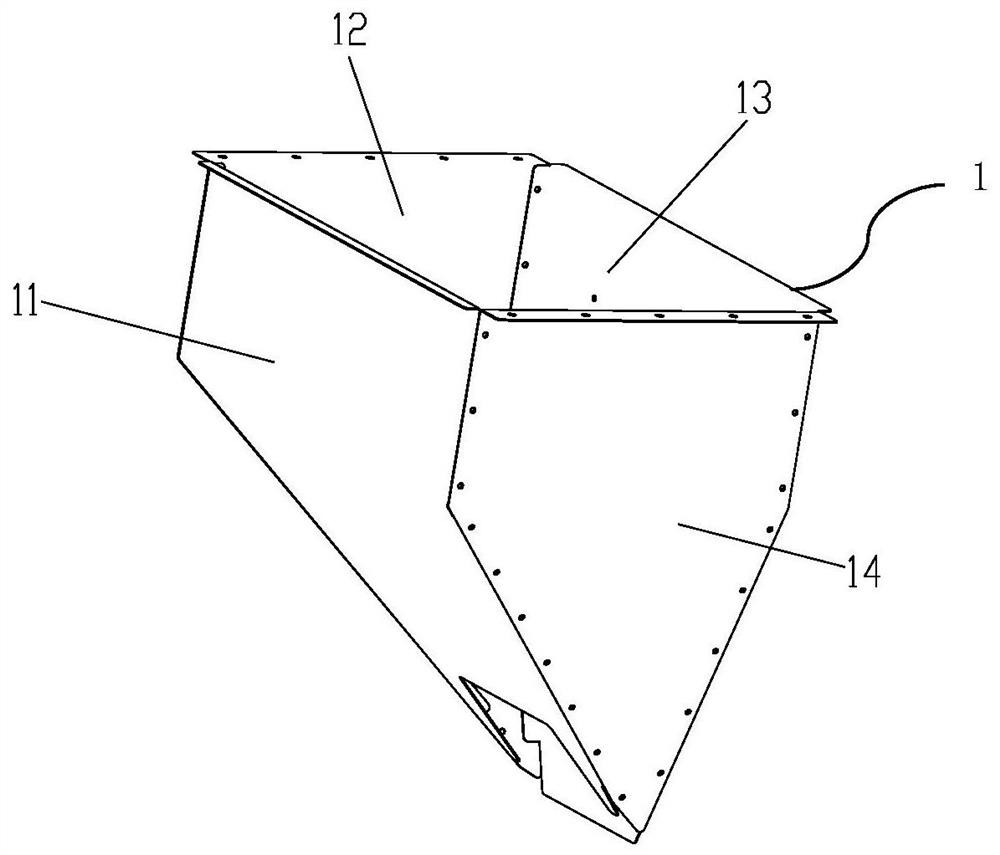

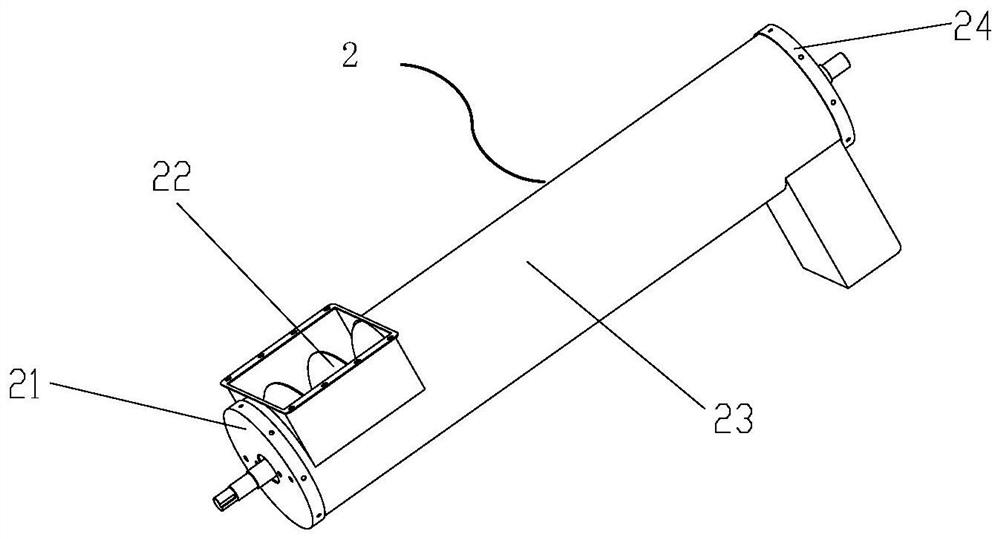

Pneumatic roller type tray seeder

InactiveCN103733775ARealize mechanized continuous productionSimple structureSeed depositing seeder partsSingle grain seedersSeederEngineering

The invention discloses a pneumatic roller type tray seeder. The pneumatic roller type tray seeder comprises a rack, wherein the rack is provided with a tray seeding device with a seed containing hopper and a tray transferring device; the tray seeding device is arranged above the tray transferring device and comprises a seed containing roller, a left joint and a right joint; the left joint and the right joint are respectively and fixedly connected to the two ends of the seed containing hopper by a left blocking ring and a right blocking ring; the seed containing roller is provided with a seed distributing roller, a seed falling roller and a hole pressing roller in a sheathing manner from inside to outside in sequence. The pneumatic roller type tray seeder disclosed by the invention has the advantages that the structure is simple, the use is convenient, the seeding accuracy is high, the seeding and the hole pressing are integrated, and the mechanical continuous production of hole discs is realized; the seed containing roller and the seed falling roller are respectively provided with a seed-containing impurity removing hole and a seed-falling impurity removing hole, and impurity removal is carried out on seed distributing holes and seed discharging holes by utilizing a seed-blowing air chamber, so that good anti-blocking effect is achieved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Precise sowing and fertilizing machine for cotton

InactiveCN113412706AImprove seeding quality and precisionGood environmental adaptabilityPlantingFurrow making/coveringFertilizerAgricultural engineering

The invention is applicable to the field of cotton planting, and provides a precise sowing and fertilizing machine for cotton. The precise sowing and fertilizing machine comprises a rack body and further comprises a seeding and fertilizing pipe, a seeding and fertilizing box and a soil covering mechanism, wherein the seeding and fertilizing pipe is slidably installed on the rack body on the rear side of a furrow plough in a matching mode, a supporting and lifting mechanism used for driving the seeding and fertilizing pipe to ascend and descend and supporting the seeding and fertilizing pipe is further installed on the rack body, the sowing and fertilizing pipe is used for conveying seeds into a groove formed by the furrow plough and conveying a fertilizer to the periphery of the seeds, the seeding and fertilizing box is installed at the upper end of the seeding and fertilizing pipe, a seed and fertilizer controlling and conveying mechanism for controlling and conveying seeds and fertilizers to the seeding and fertilizing pipe is further installed in the seeding and fertilizing box, the soil covering mechanism is installed on the rack body on the rear side of the seeding and fertilizing pipe, and the soil covering mechanism is used for covering soil on the grooves after seeding and fertilizing. According to the precise sowing and fertilizing machine, the seed quantity and the fertilizing quantity are convenient to control, the sowing and fertilizing effects are good, and the sowing and fertilizing precision and efficiency are improved.

Owner:江西农业工程职业学院

Distributed feeding type potato seed metering device

The invention discloses a distributed feeding type potato seed metering device. The device comprises a rack, a test seed box, a lifting conveying auger mechanism, a spoon type seed metering mechanism,a transmission device and a control device. The test seed box is mounted on the rack; the lifting conveying auger mechanism is installed on the rack and located below the test seed box, and an outletof the test seed box is connected with a feeding port of the lifting conveying auger mechanism and used for controlling the feeding amount of seed potatoes; the spoon type seed metering mechanism ismounted on the rack and located behind the lifting conveying auger mechanism, and an outlet of the lifting conveying auger mechanism corresponds to an inlet of the spoon type seed metering mechanism and is used for single-grain separation, seed filling and seed metering of seed potatoes; the transmission device is arranged on the rack and is respectively connected with the lifting conveying augermechanism and the spoon type seed metering mechanism; and the control device is installed on the rack, connected with the transmission device and used for adjusting the working speed of the transmission device in real time. According to the device, the problems of high seed leakage rate, low efficiency and the like of a spoon-type potato seeder are fundamentally solved.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com