Tray seeder with self-cleaning suction nozzles

A plug seeder and self-cleaning technology, applied in the field of agricultural engineering, can solve the problems of low seeding precision, unstable yield, low production efficiency, etc., and achieve the effects of improving seeding precision, improving seeding efficiency, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

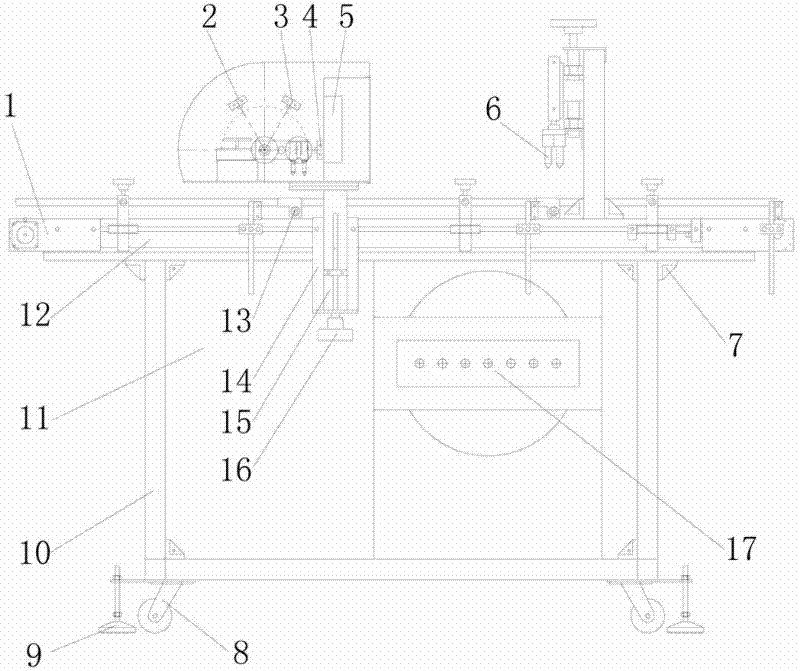

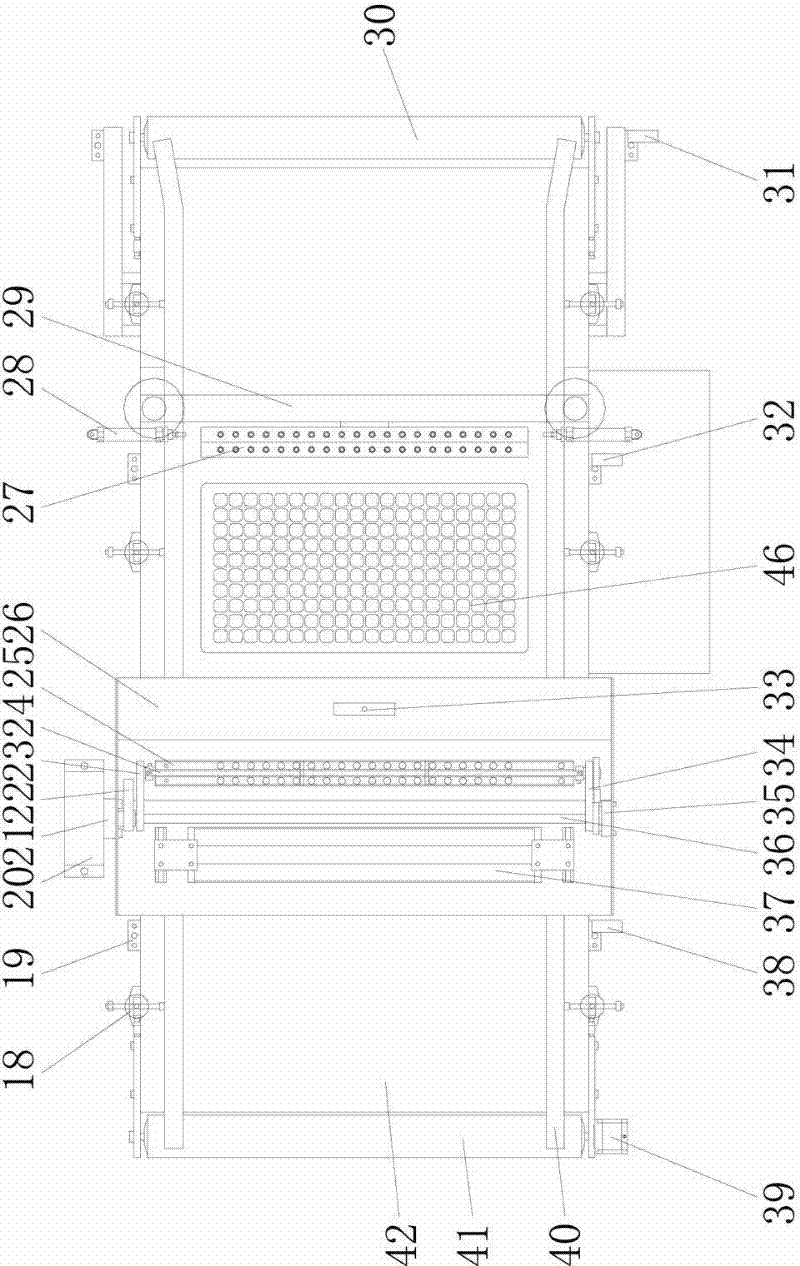

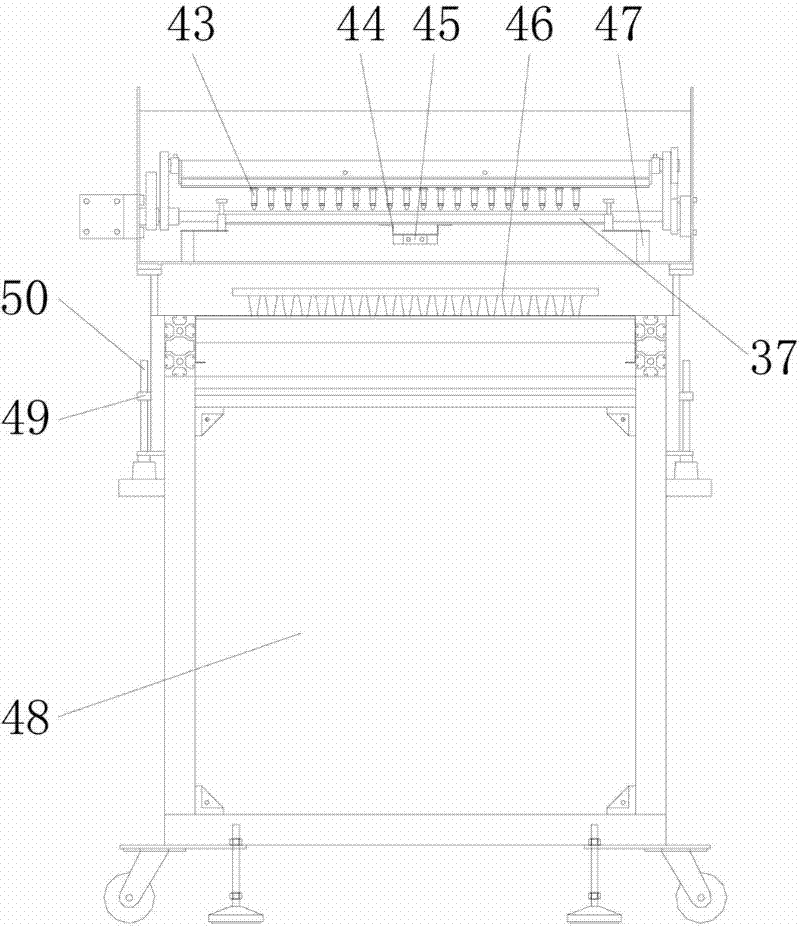

[0027] refer to Figure 1 to Figure 4 As shown, the tray seeder with self-cleaning suction nozzle of the present invention includes four major parts such as a frame system unit, a seeding system unit, a punching system unit, and a control system unit.

[0028] The rack system unit includes a tension plate 1, corner fittings 7, universal wheels 8, hoof feet 9, side columns 10, front panel 11, rack main beam 12, tray conveying guide adjustment member 18, driven Cylinder 30, tray conveying guide rod 40, driving roller 41, conveyer belt 42, side panel 48 etc. The driving roller 41 and the driven roller 30 install the conveyor belt 42 on the frame main beam 12 through the tension plate 1, the side columns 10 are installed and fixed on the frame main beam 12 through the corner fittings 7, and the front panel 11 and the side panel 48 pass through The corner fittings 7 are installed on the outside of the frame 12, and four sets of universal wheels 8 and hoofs 9 are installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com