Suction wheel type broad-width precious speed distribution apparatus

A precision seeding, wide-width technology, applied in the direction of interval-type quantitative seeding machinery, planter parts, etc., can solve the problems of deviation from the seeding point, seed bouncing, affecting the sowing accuracy, etc., to improve the sowing accuracy and slow down the landing speed effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

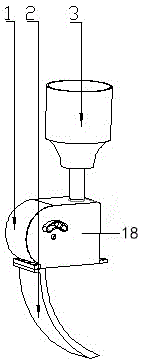

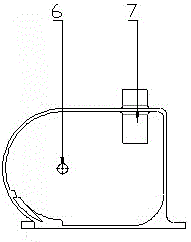

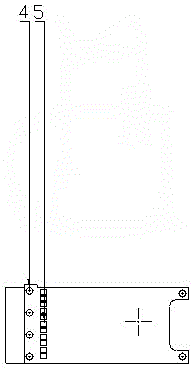

[0026] as attached figure 1 To attach Figure 10 As shown, this embodiment provides a suction wheel type wide-width precision seed distribution device, including a seed box 3, a seed meter and a seed pipe 2, and the seed meter includes a box body 1, an inner core 17 and a seed metering device. port 5, the inner core 17 is located inside the box body 1, the seed discharge port 5 is located at the bottom of the box body 1, the inner core 17 is cylindrical, and one side of the inner core 17 is a head , the drive shaft passes through the inner core 17 through the inner mandrel shaft hole 11 on the head, the outer surface of the inner core 17 is evenly distributed with concave round dimples 12, and the bottom of the concave round dimples 12 is provided with air suction holes 13, The box body 1 includes a box body and a cover 18 positioned on one side of the box body. There is an air suction barrier 14 inside the inner core, and the air suction barrier 14 is fixedly connected to th...

Embodiment 2

[0032] as attached figure 1 To attach Figure 10 As shown, this embodiment provides a suction wheel type wide-width precision seed distribution device, including a seed box 3, a seed meter and a seed pipe 2, and the seed meter includes a box body 1, an inner core 17 and a seed metering device. port 5, the inner core 17 is located inside the box body 1, the seed discharge port 5 is located at the bottom of the box body 1, the inner core 17 is cylindrical, and one side of the inner core 17 is a head , the drive shaft passes through the inner core 17 through the inner mandrel shaft hole 11 on the head, the outer surface of the inner core 17 is evenly distributed with concave round dimples 12, and the bottom of the concave round dimples 12 is provided with air suction holes 13, The box body 1 includes a box body and a cover 18 positioned on one side of the box body. There is an air suction barrier 14 inside the inner core, and the air suction barrier 14 is fixedly connected to th...

Embodiment 3

[0035] as attached figure 1 To attach Figure 10 As shown, this embodiment provides a suction wheel type wide-width precision seed distribution device, including a seed box 3, a seed meter and a seed pipe 2, and the seed meter includes a box body 1, an inner core 17 and a seed metering device. port 5, the inner core 17 is located inside the box body 1, the seed discharge port 5 is located at the bottom of the box body 1, the inner core 17 is cylindrical, and one side of the inner core 17 is a head , the drive shaft passes through the inner core 17 through the inner mandrel shaft hole 11 on the head, the outer surface of the inner core 17 is evenly distributed with concave round dimples 12, and the bottom of the concave round dimples 12 is provided with air suction holes 13, The box body 1 includes a box body and a cover 18 positioned on one side of the box body. There is an air suction barrier 14 inside the inner core, and the air suction barrier 14 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com