Patents

Literature

96results about How to "Controlled descent speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

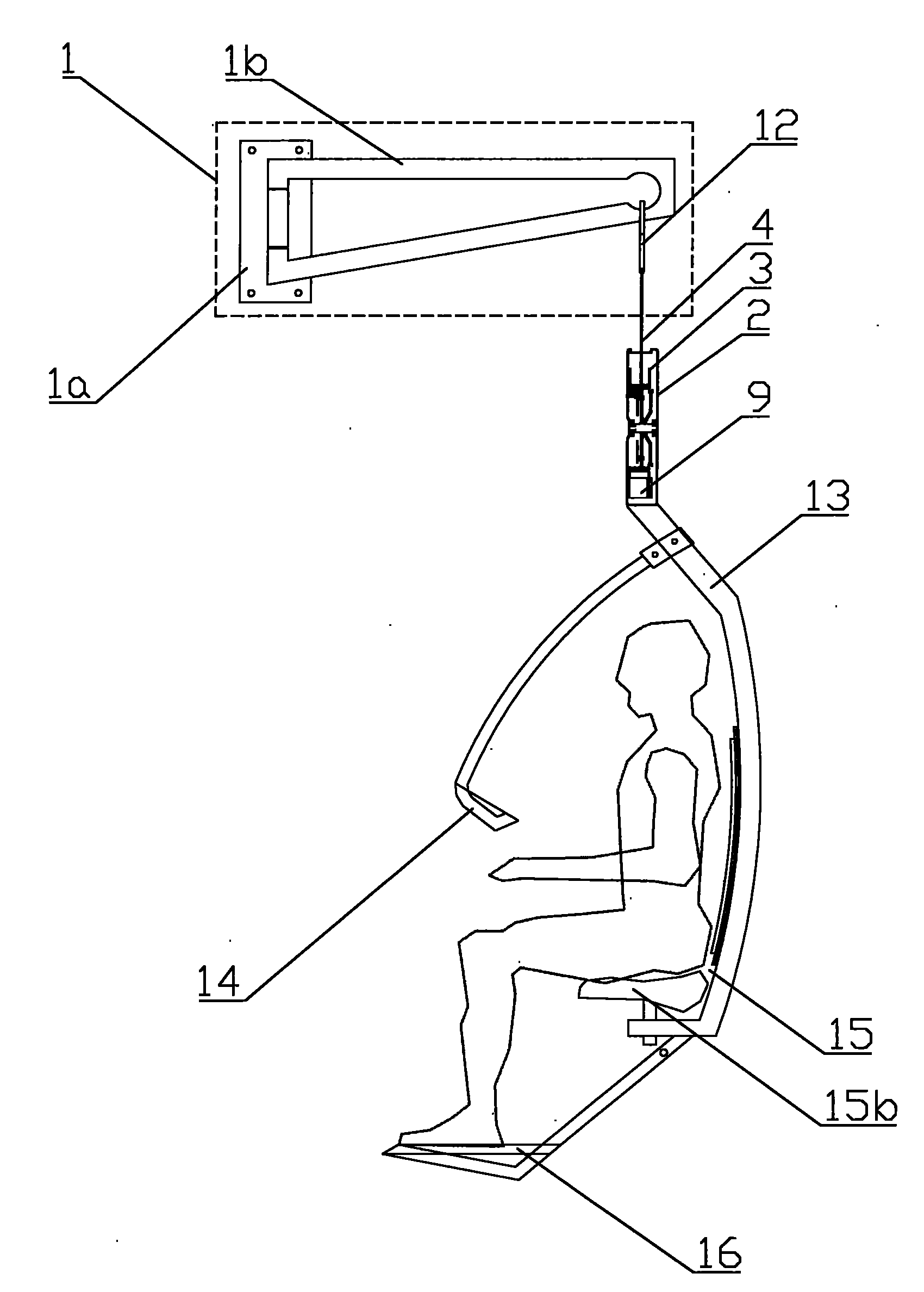

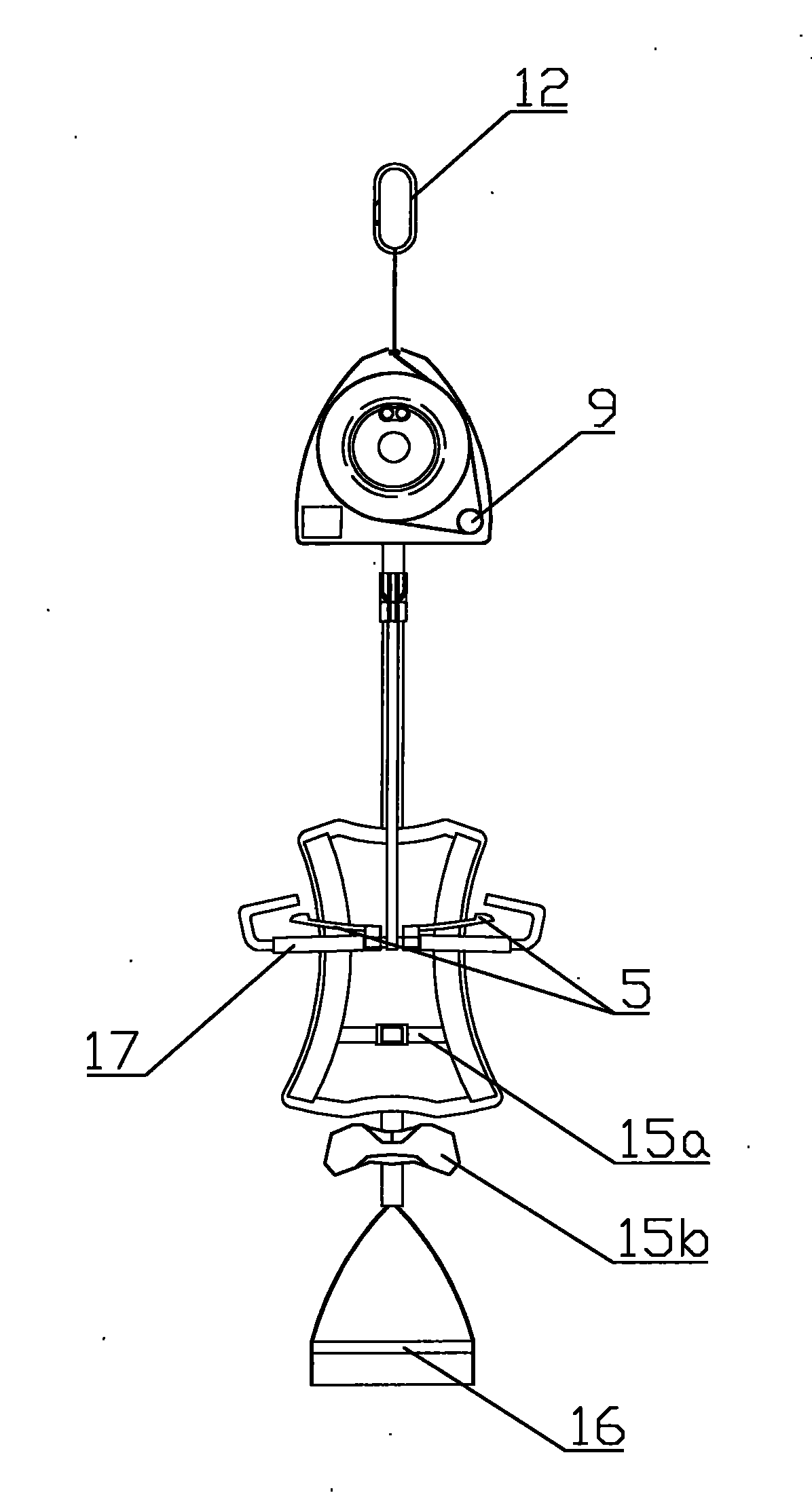

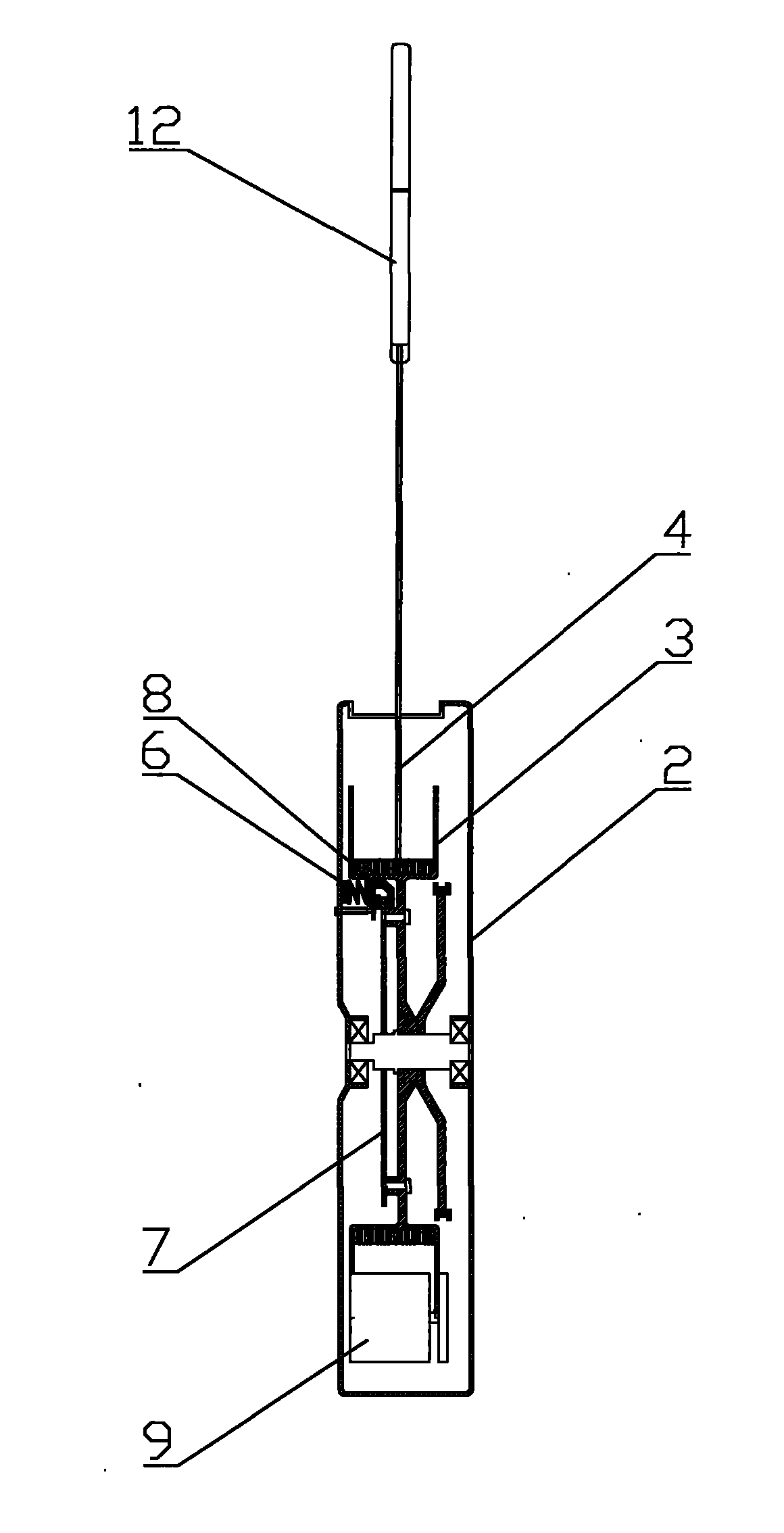

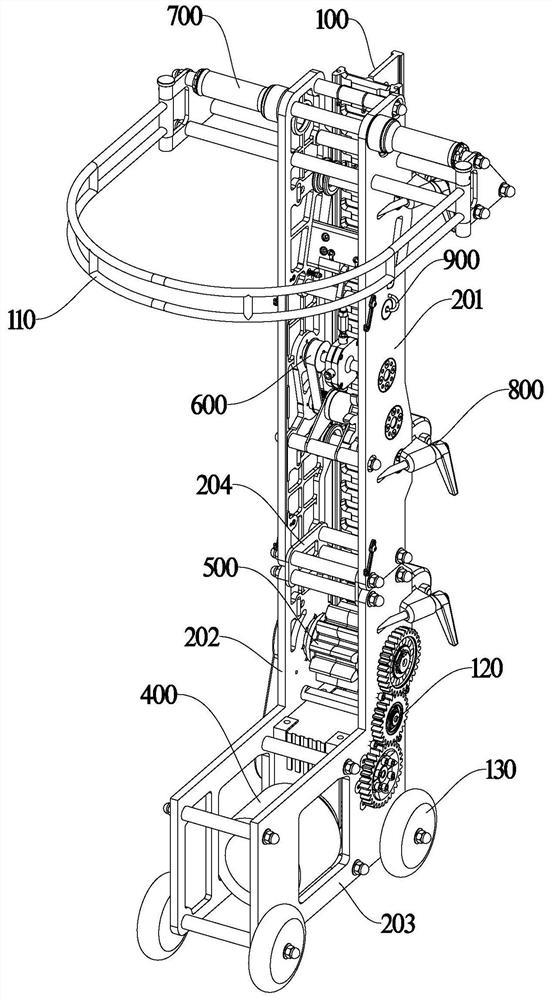

Tower escape apparatus

The invention discloses a tower escaper apparatus which comprises a bearing fixing support, a rope winding device, a riding accommodation device and a descending control device. The coiling device comprises a shell and a winding roll, the winding roll is wound with a bearing rope, and the rope winding device is suspended on the bearing fixing support through a free end of the bearing rope; the riding accommodation device is fixedly connected below the shell; and the descending control device comprises a friction brake and a descending operation handle which are tightly clasped to the winding roll in a normal state, and the descending operation handle is in transmission fit with the friction brake. When in use, the bearing fixing support is arranged on a window or a balcony or other places, a person can control the friction braking force of the friction brake to the winding roll through the descending operation handle so as to control the descending speed of the riding accommodation device to be in a safety range, and meanwhile, ground staff can unlock the winding roll through a reset unlocking mechanism and remotely control a motor through a remote controller to drive the winding roll to rotate so as to ensure that the riding accommodation device returns to a high place and can be used by other people for escape. In addition, the invention is comfortable in use and suitable for various people.

Owner:CHONGQING JIAOTONG UNIVERSITY

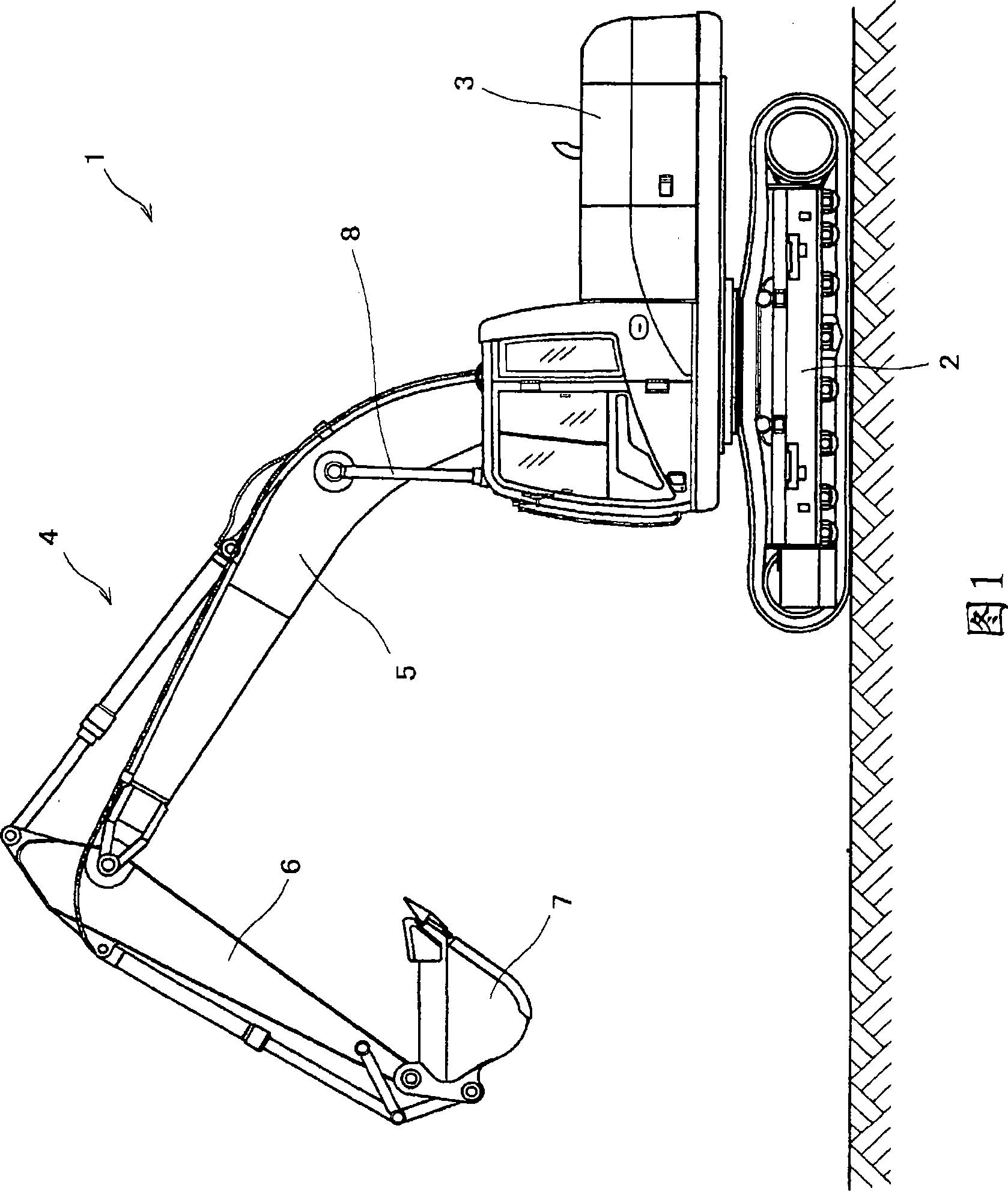

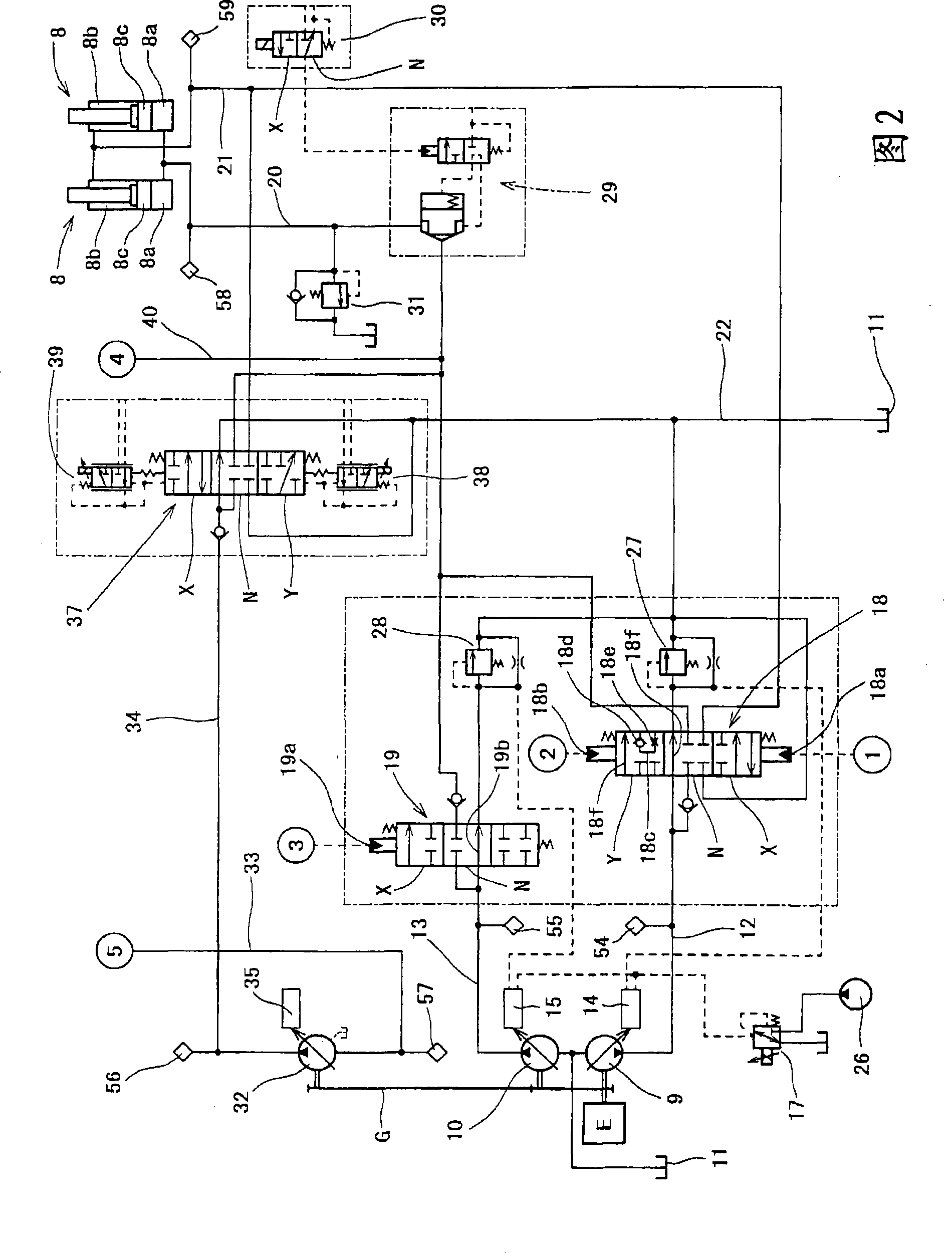

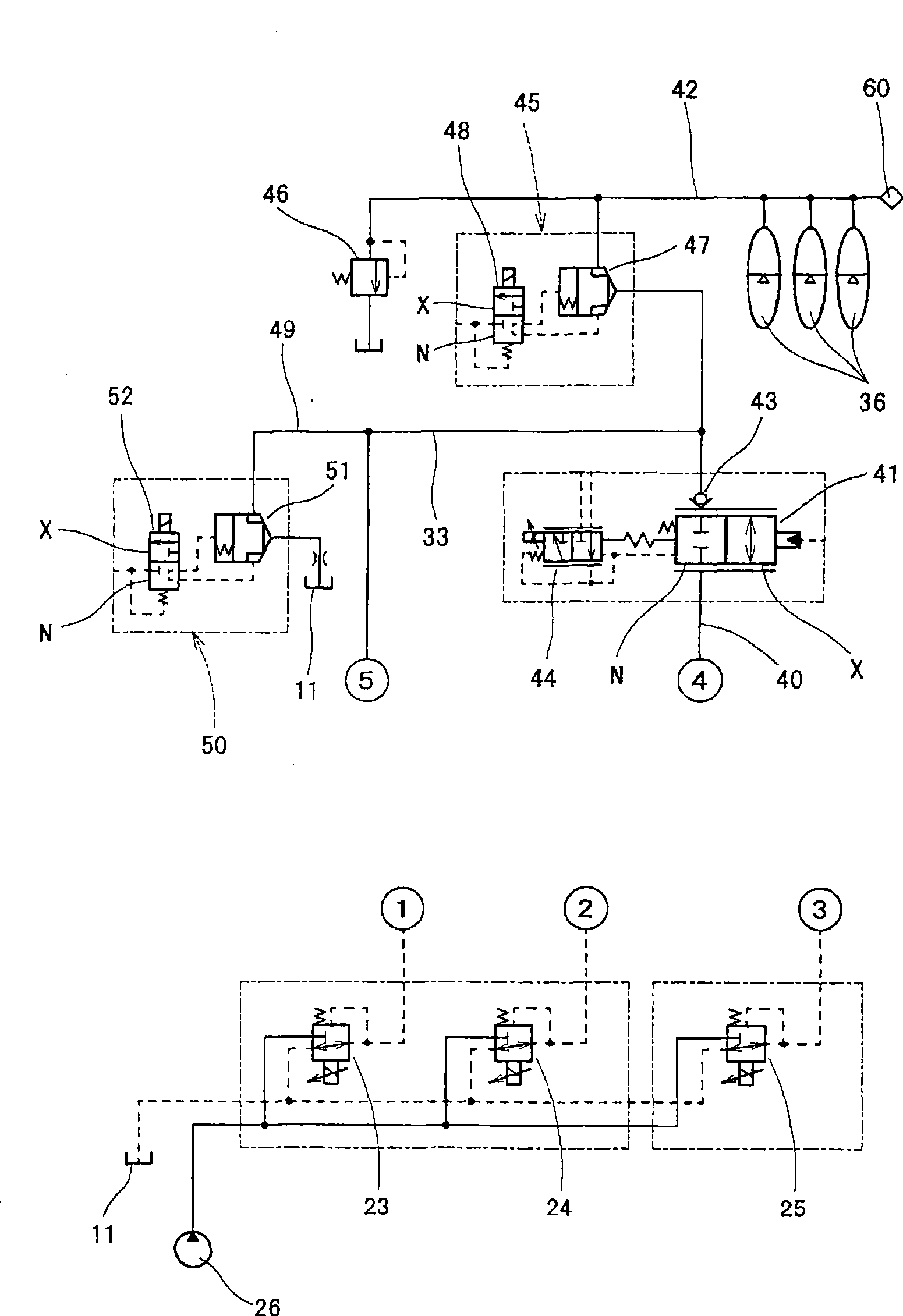

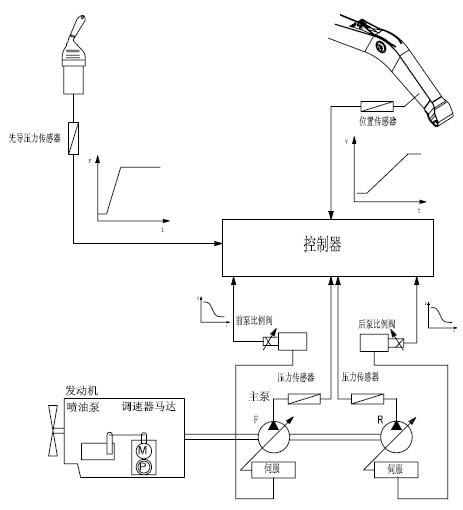

Hydraulic control system for working machine

InactiveCN101438064AControlled descent speedEasy to operateServometer circuitsSoil-shifting machines/dredgersControl systemFuel tank

A hydraulic control system for a working machine, where potential energy of a working section that vertically moves is reliably recovered and reused and where an inconvenience such as reduction in the speed of the working section is avoided in reuse of the recovered potential energy. The hydraulic control system has a first main pump (9) for drawing oil from an oil tank (11) and discharging it, an accumulator for accumulating under pressure the oil discharged from a head side oil chamber (8a) of a boom cylinder (8) when the working section is lowered; and a hybrid pump (32) for drawing the oil accumulated under pressure in the accumulator. The hydraulic control system is constructed such that, when the a boom is lifted, oil discharged from the hybrid pump (32) is supplied to the head side oil chamber (8a) and, when the supply flow rate from the hybrid pump (32) is insufficient, the deficiency is supplied to the head side oil chamber (8a) from the first main pump (9).

Owner:CATEPILLAR SARL

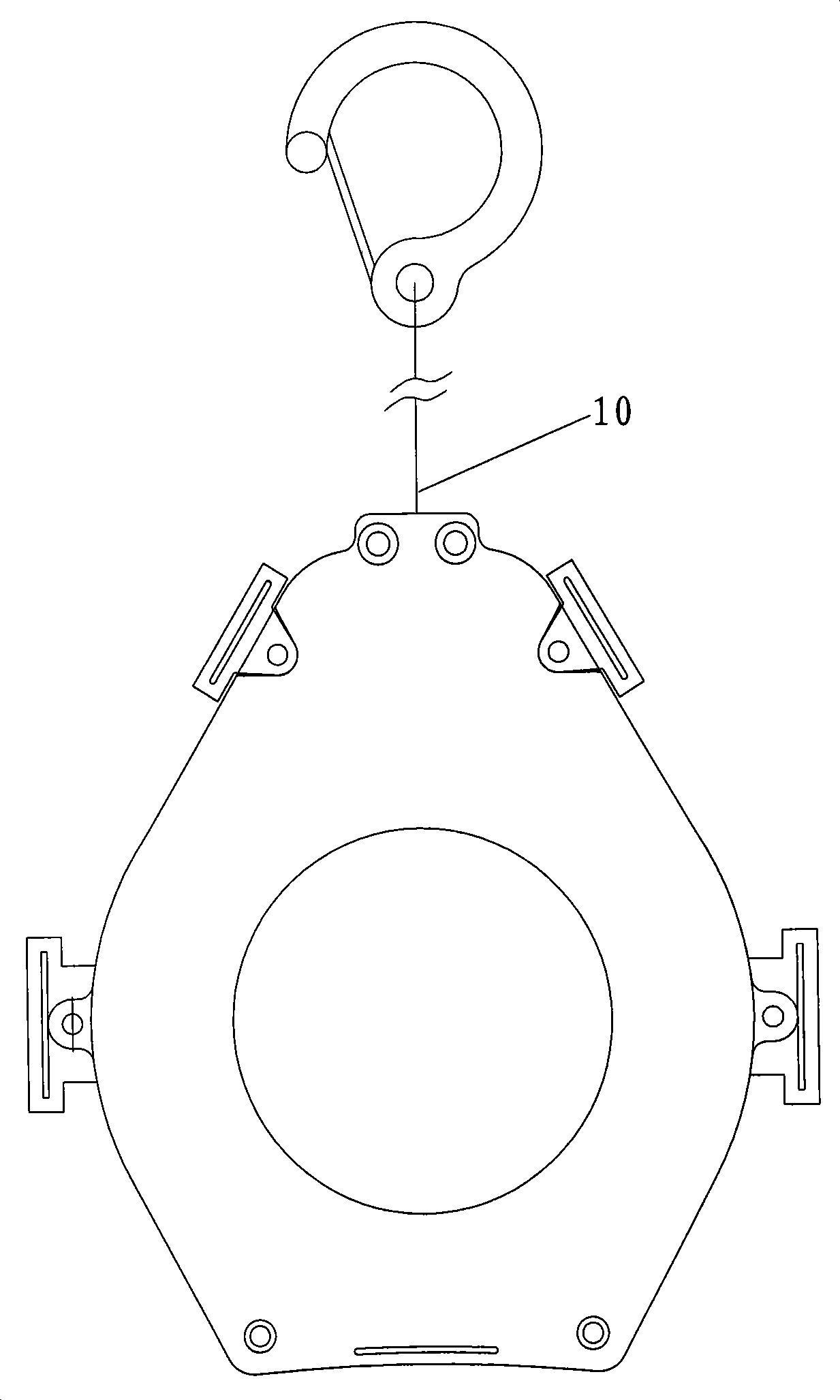

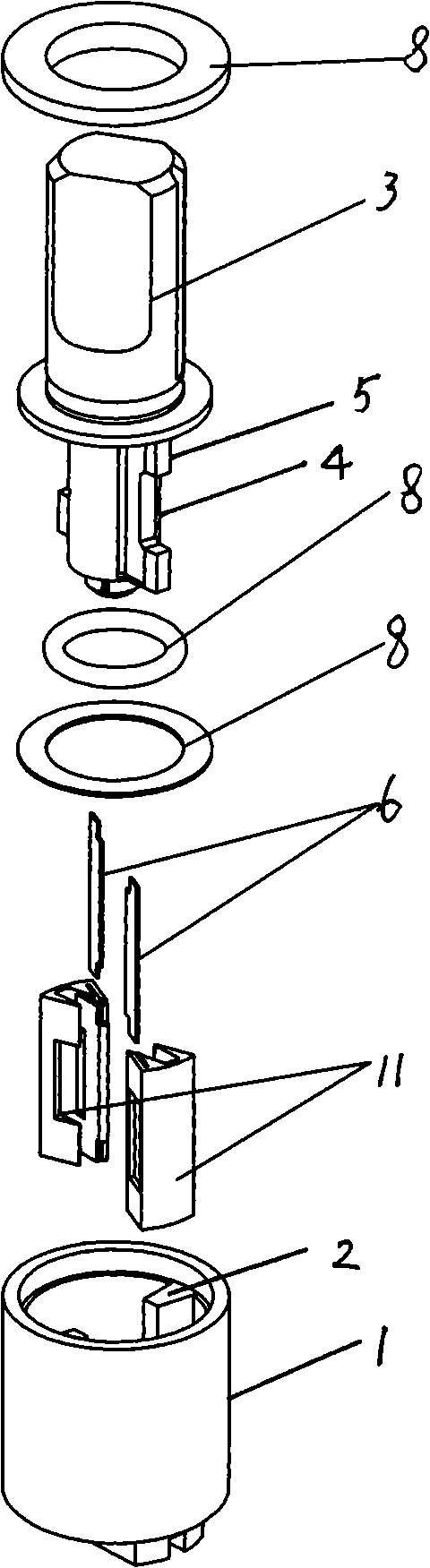

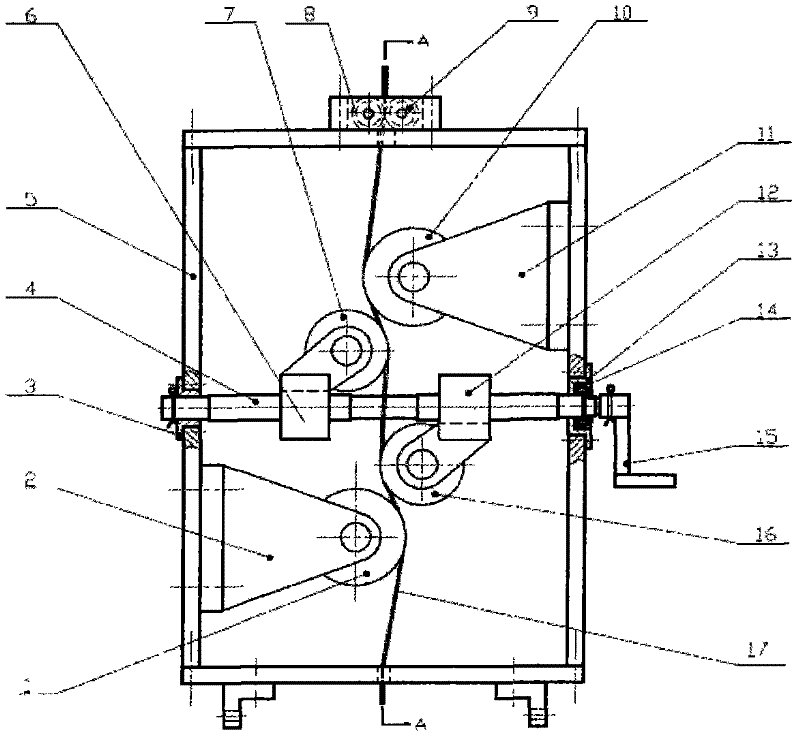

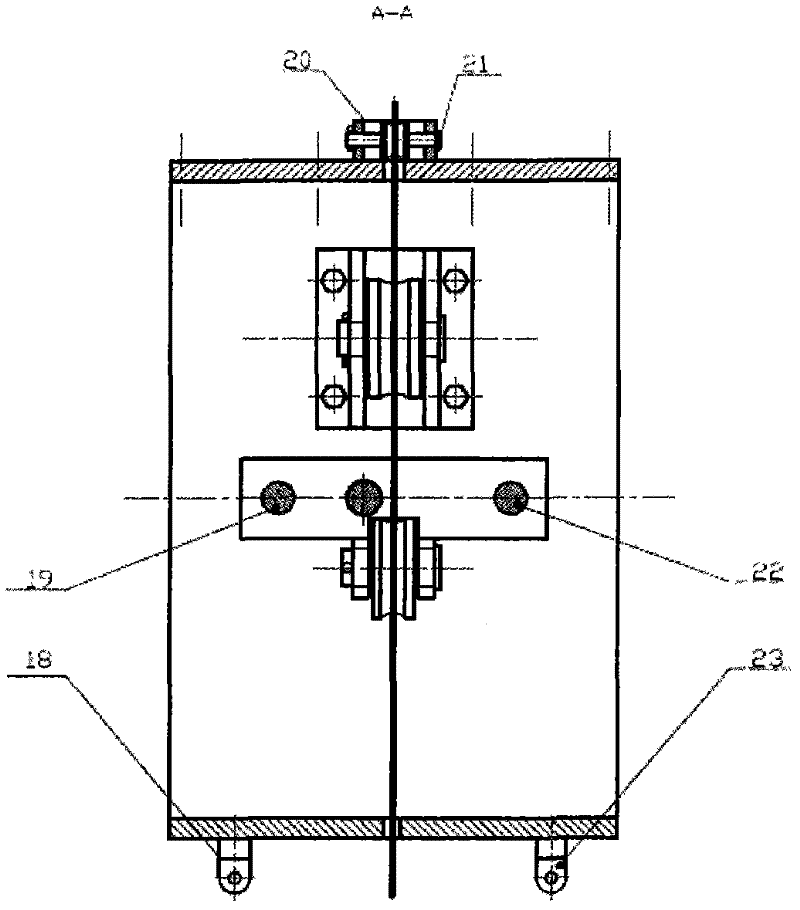

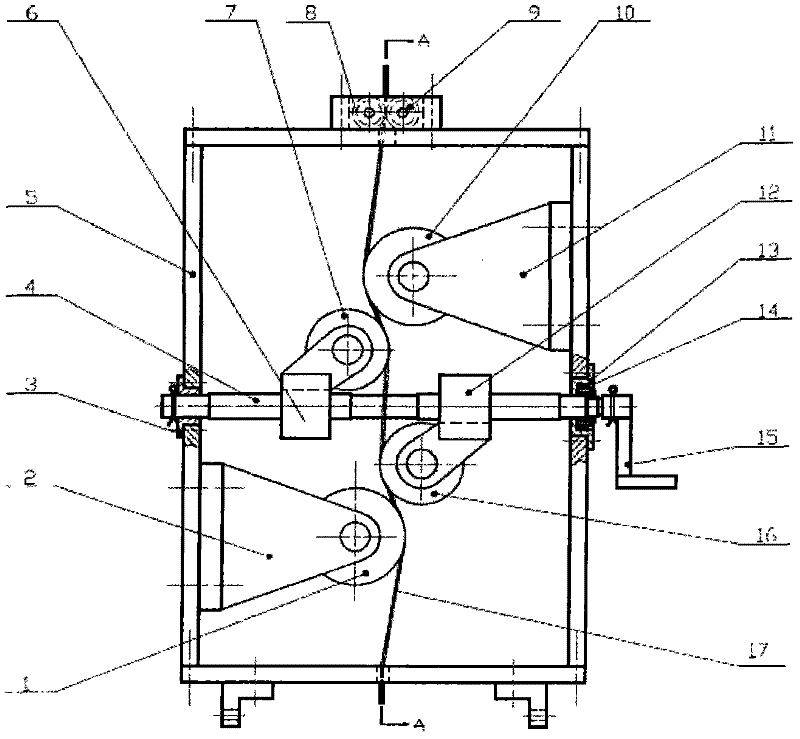

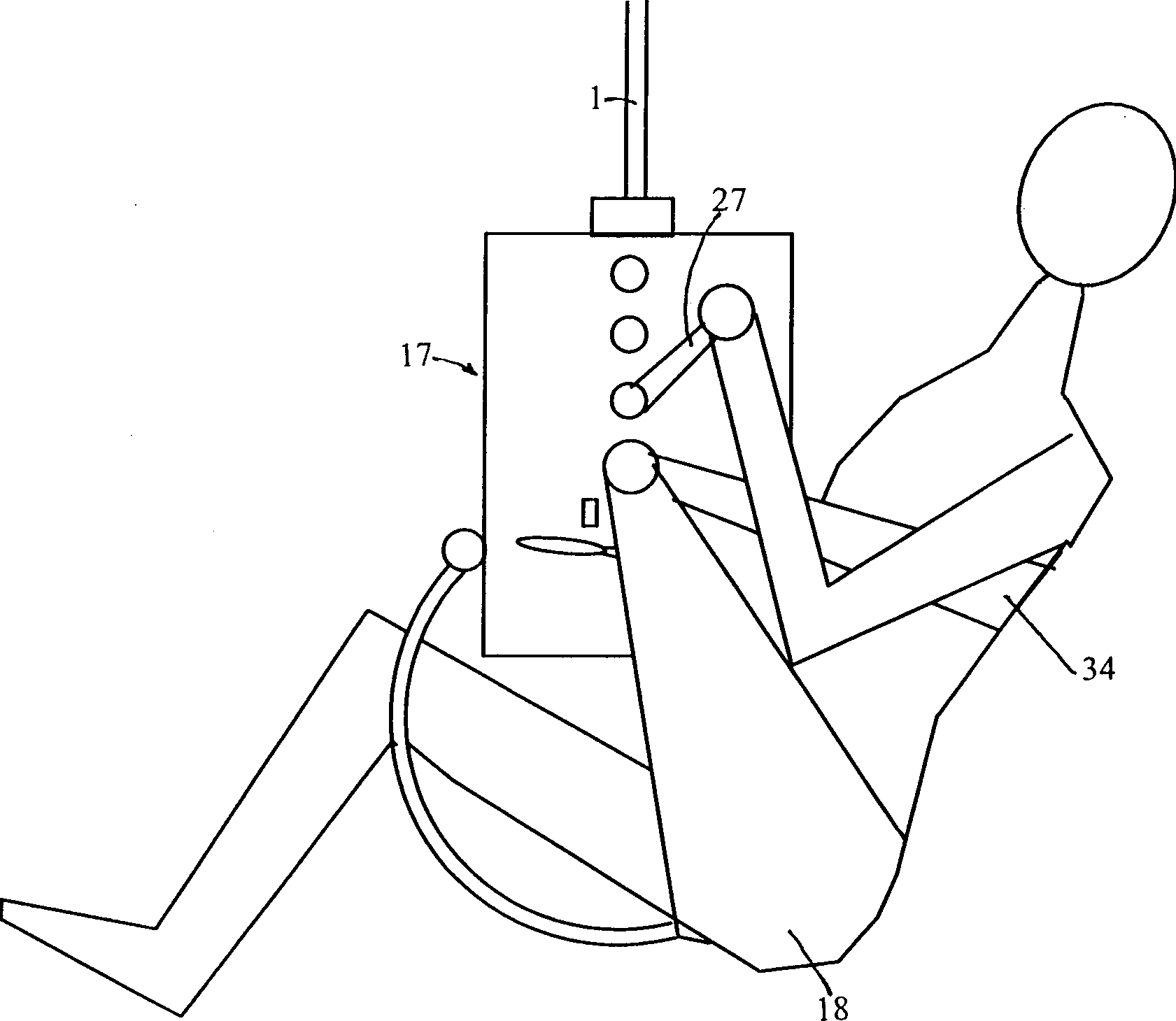

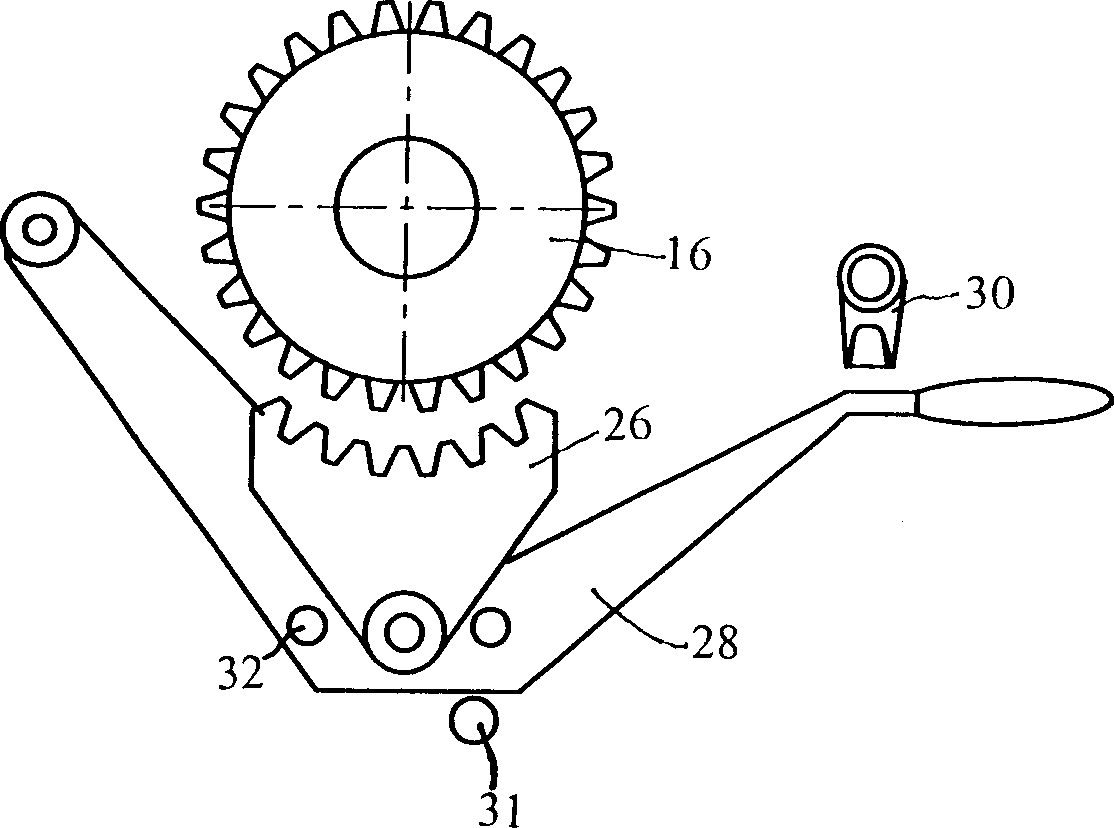

Portable high-building self-help instrument

The invention discloses a portable high-rise self rescue apparatus which mainly consists of a shell as well as a cable wire, a wire wheel that is provided with an internal wheel, a gear increaser, a centrifugal wheel, a lever type centrifugal block and a centrifugal sleeve that are assembled in the shell; the cable wire is wound on the wire wheel, one end of the cable wire extends out of the shell and is fixed on a steel hook, the internal wheel of the wire wheel transmits the gear increaser, a final stage gear of the gear increaser and the centrifugal wheel are fixed on a centrifugal wheel axle, the lever type centrifugal block is fixed on the centrifugal wheel by a shaft pin, and the centrifugal sleeve which generates centrifugal acting force and reaction force together with the lever type centrifugal block is fixed on the shell. The structure is convenient and safe for use, and can automatically control the descent speed.

Owner:许志龙

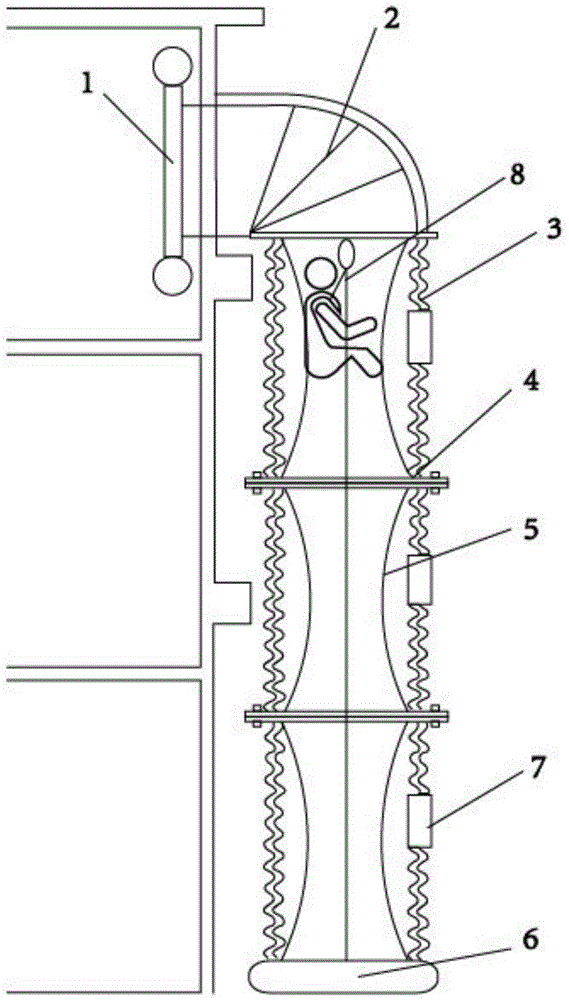

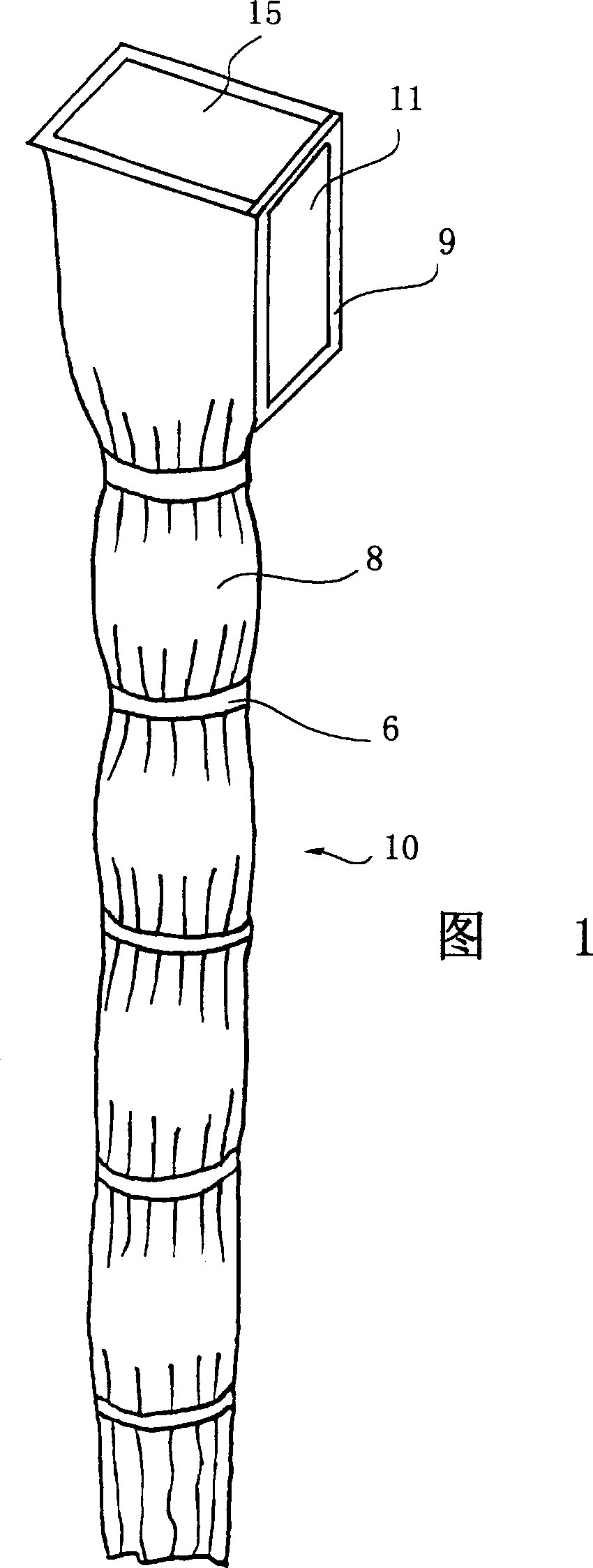

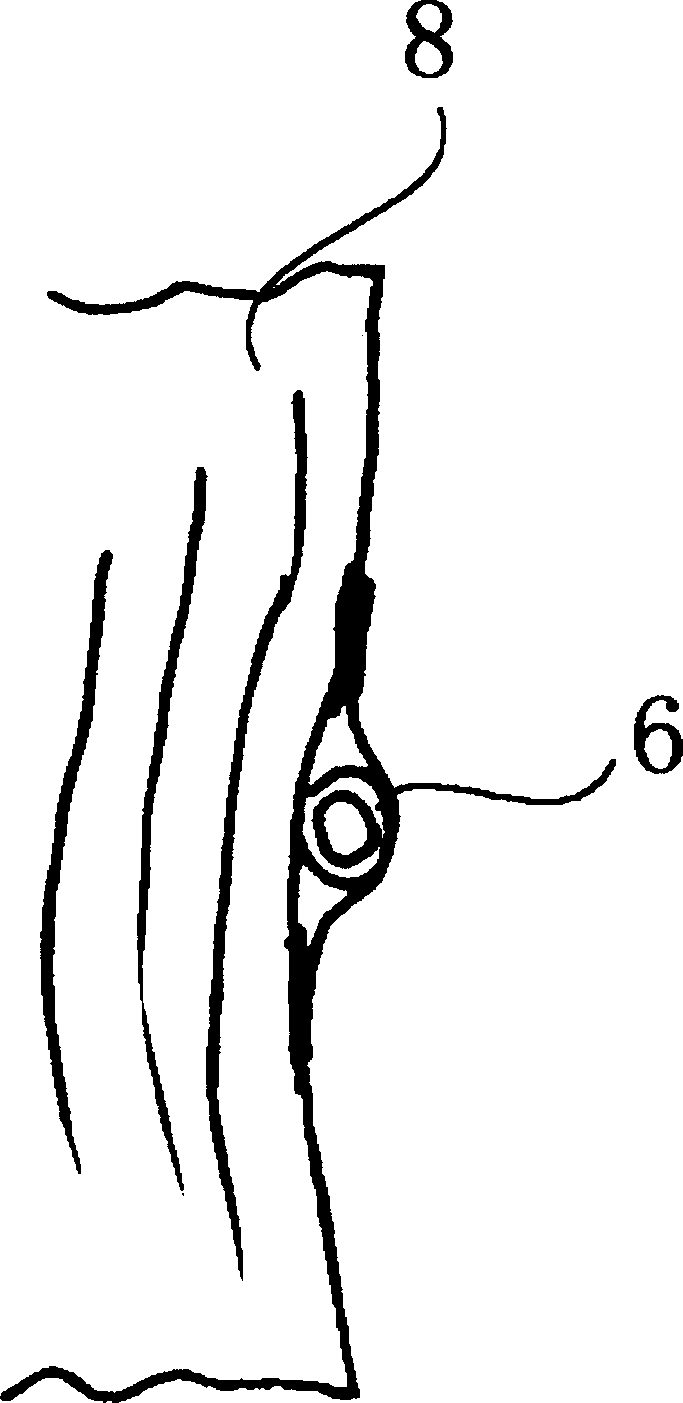

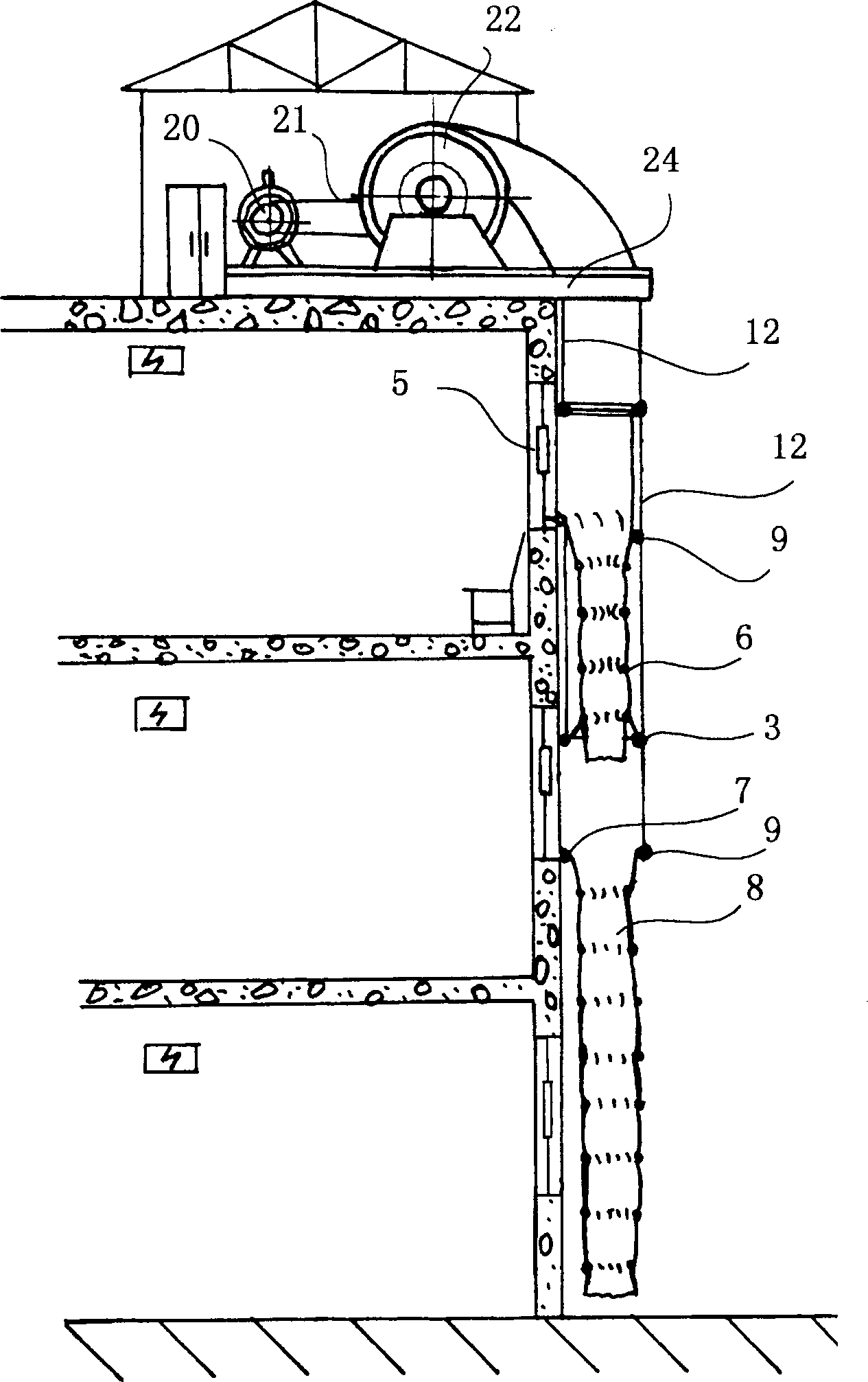

Escaping pipe

The invention discloses an escaping pipe. The escaping pipe comprises an indoor fixing frame (1), a bend (2) and a straight pipe (3); the indoor fixing frame (1) is fixed to the wall of a building and connected with the bend (2), the lower end of the bend (2) is connected with the straight pipe (3), and the straight pipe (3) is composed of a plurality of sections of double-wall corrugated pipes; two corrugated pipe sleeving structures are adopted in each double-wall corrugated pipe, the position between each outer-wall corrugated pipe body and the corresponding inner-wall corrugated pipe body is filled with a heat-resisting material, and crests of the outer-wall corrugated pipe bodies correspond to troughs of the inner-wall corrugated pipe bodies in parallel; flanges (4) are welded to the two ends of each double-wall corrugated pipe, every two adjacent double-wall corrugated pipes are connected through bolts by means of the flanges (4), and a buffer layer (5) is arranged on the inner wall of each double-wall corrugated pipe; and a safety hook is arranged at the top of the straight pipe, a descent control device is fixedly connected to the safety hook, and a buffer air cushion (6) is arranged at the bottom of the straight pipe (3). When the escaping pipe is used, the escaping efficiency is high, the flame retardant property is good, and the safety of a person during escaping is guaranteed.

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

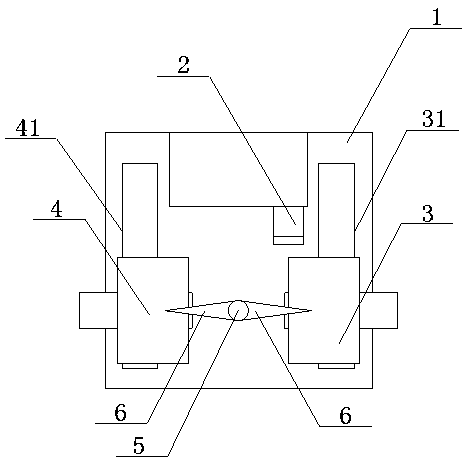

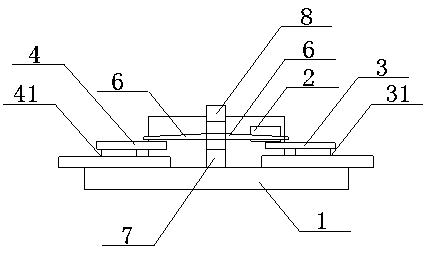

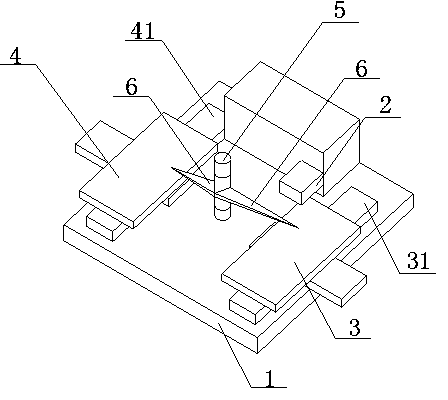

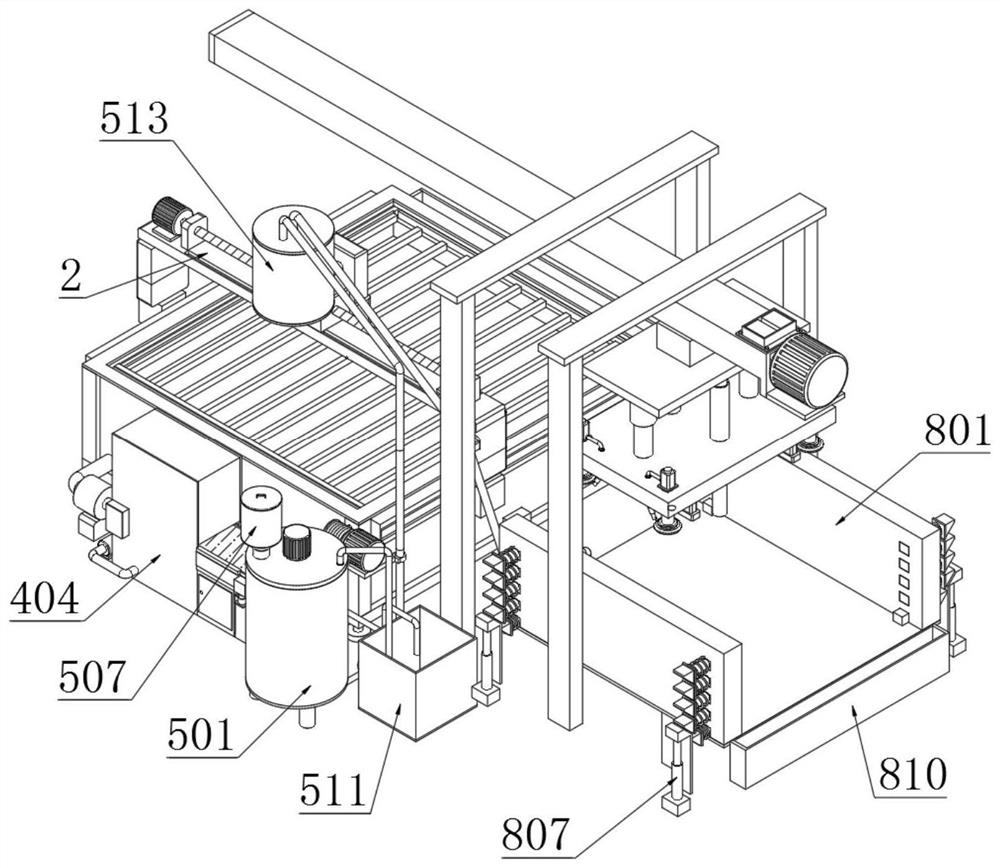

Multipurpose encapsulating equipment

ActiveCN103400784AEasy to operateAchieving the purpose of hybrid circuit packaging operationsSemiconductor/solid-state device manufacturingEngineeringElectronic component

The invention discloses multipurpose encapsulating equipment, which comprises a base, a dispensing mechanism, an encapsulating table, a movement mechanism, a sheet carrying table, a main shaft, at least two sheet loading swinging arms, a first driving device and a second driving device, wherein the movement mechanism is used for driving the encapsulating table to move; the sheet carrying table is arranged on the base, is positioned on one side of the encapsulating table, and is used for accommodating a prepared bare chip and an electronic element; the main shaft is arranged between the encapsulating table and the sheet carrying table; the sheet loading swinging arms are arranged on the main shaft, and are arranged uniformly along the circumferential direction of the main shaft; suction nozzles of different specifications are arranged on the sheet loading swinging arms; the first driving device is connected with the main shaft, and is used for driving the main shaft to rotate along the circumferential direction so as to drive the sheet loading swinging arms to switch between the encapsulating table and the sheet carrying table serving as two points; the second driving device is connected with the sheet loading swinging arms, and is used for driving the sheet loading swinging arms to move along the axial direction of the main shaft. According to the multipurpose encapsulating equipment, the aim of finishing encapsulation operation of hybrid circuits on one piece of equipment is fulfilled.

Owner:SUZHOU ACCURACY ASSEMBLY AUTOMATION CO LTD

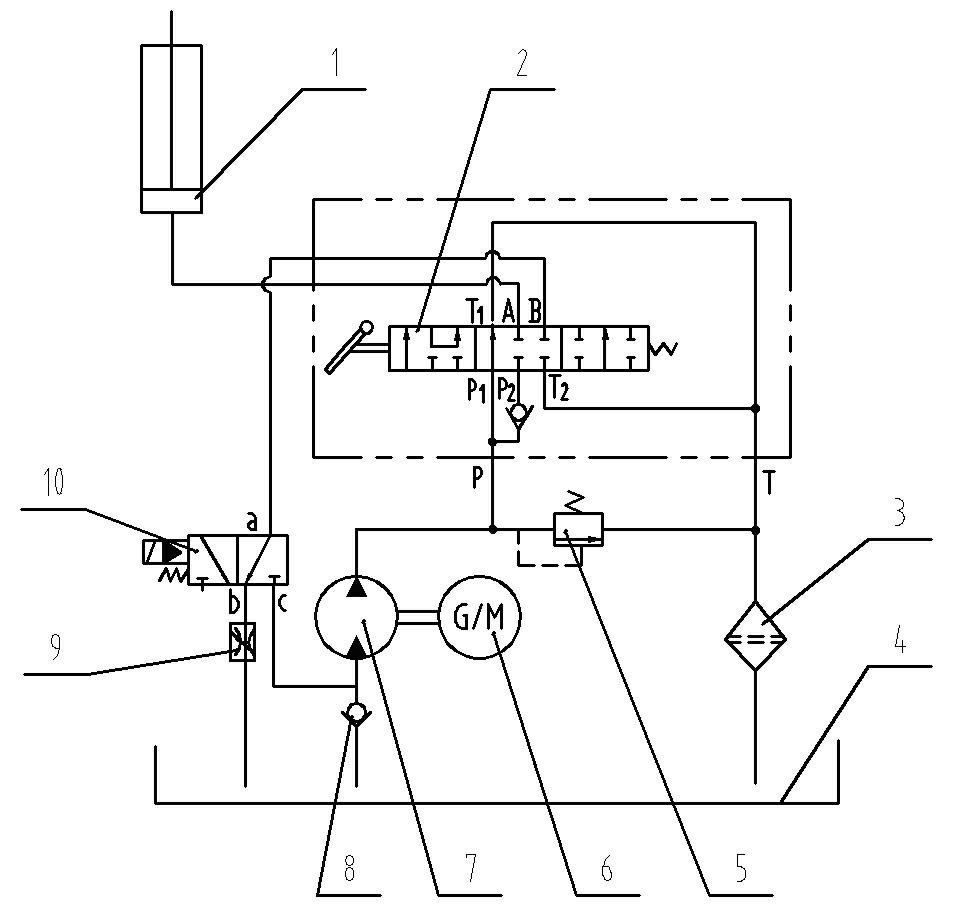

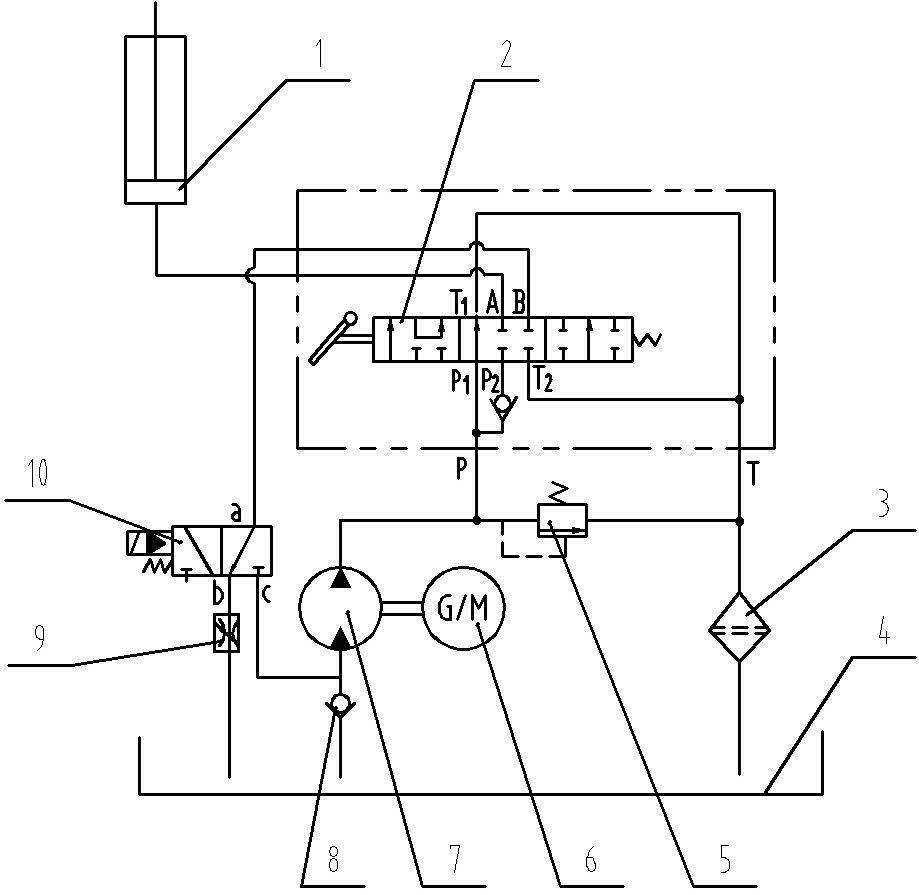

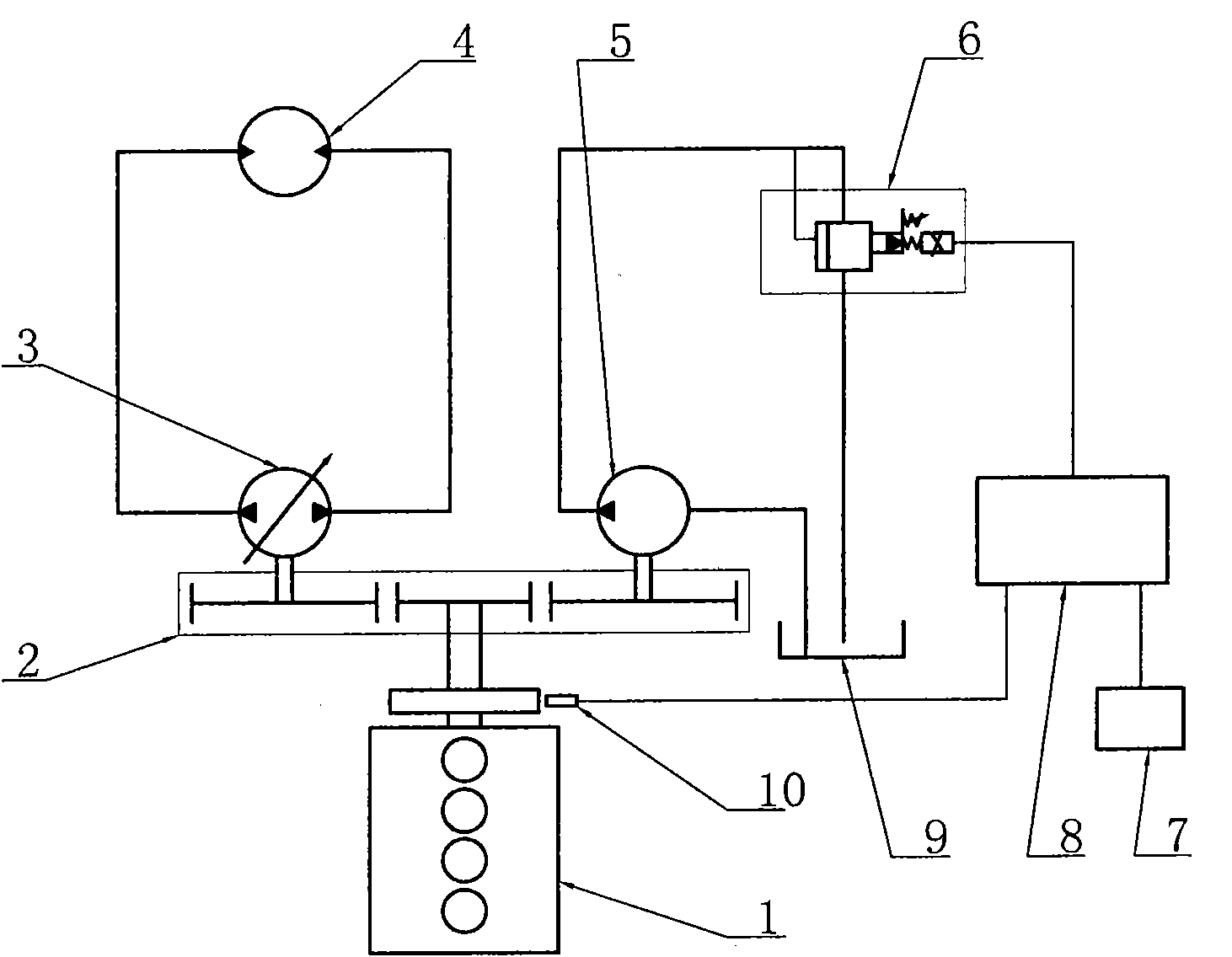

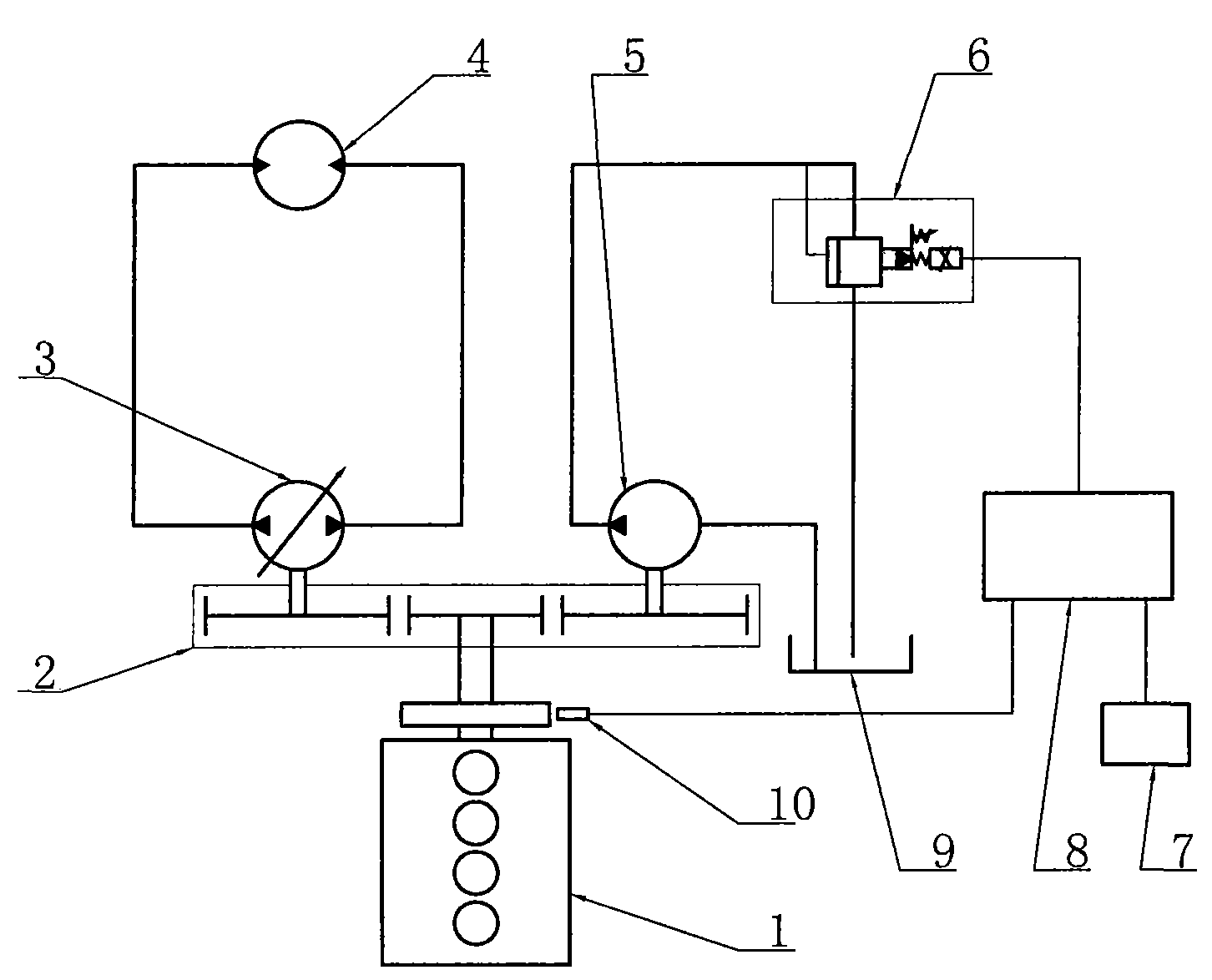

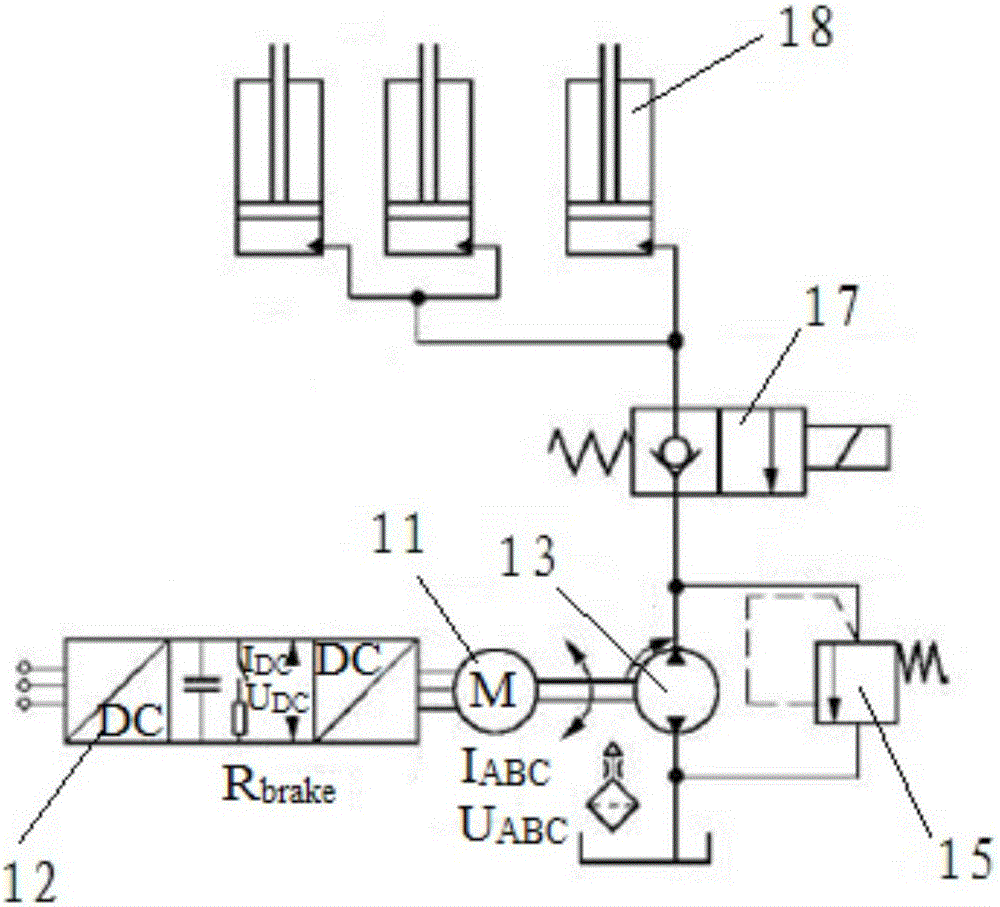

Energy recovery type lifting hydraulic system for hoisting and conveying machine

InactiveCN102628465ASimple structureEasy to operateLifting devicesFluid-pressure actuator componentsFuel tankElectro hydraulic

The invention relates to an energy recovery type lifting hydraulic system for a hoisting and conveying machine. A lifting reversing valve of the energy recovery type lifting hydraulic system is a three-position and six-way reversing valve, wherein an oil inlet P is communicated to a first oil inlet P1 and a second oil inlet P2 of the lifting reversing valve through a three-way pipe; an oil return port T is communicated to a first oil outlet T1 and a second oil outlet T2 of the lifting reversing valve through a three-way pipe; a lifting oil cylinder is communicated to a first work oil port A; an oil inlet a of a direction control valve is communicated to a second work oil port B; the direction control valve is a two-position and three-way electromagnetic reversing valve or a two-position and three-way electro-hydraulic reversing valve; the oil inlet P and an inlet of a safety valve are communicated to an oil outlet of the oil pump through a three-way pipe; a hydraulic oil tank is communicated to an oil suction port of the oil pump through a one-way valve; the oil return port T is communicated to an outlet of the safety valve; the oil tank is communicated to a first oil outlet b of the direction control valve through a speed limiting valve; the oil suction port of the oil pump is communicated to a second oil outlet c of the direction control valve; and the one-way valve is arranged on the oil suction port of the oil pump. According to the energy recovery type lifting hydraulic system disclosed by the invention, the recovery efficiency of potential energy is 65 to 75 percent.

Owner:ANHUI HELI CO LTD

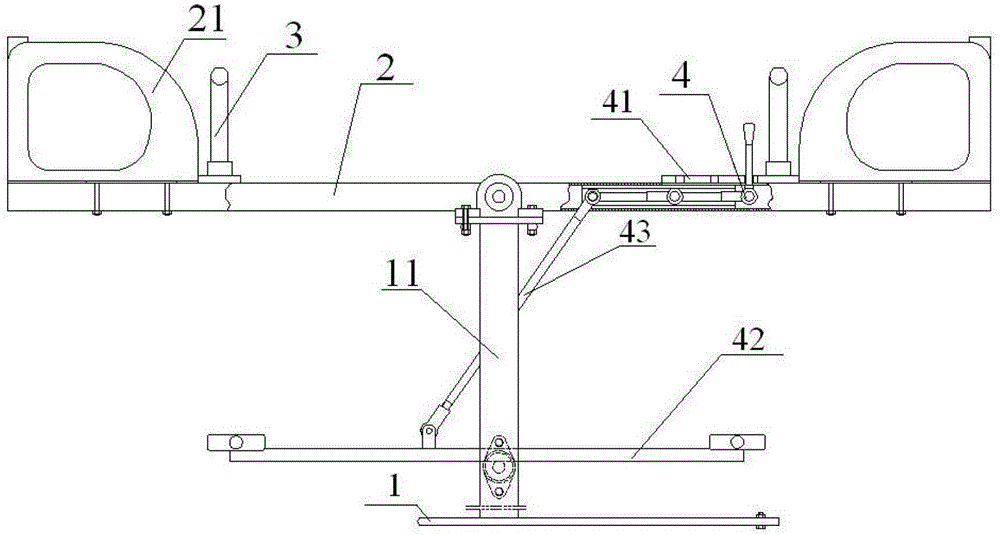

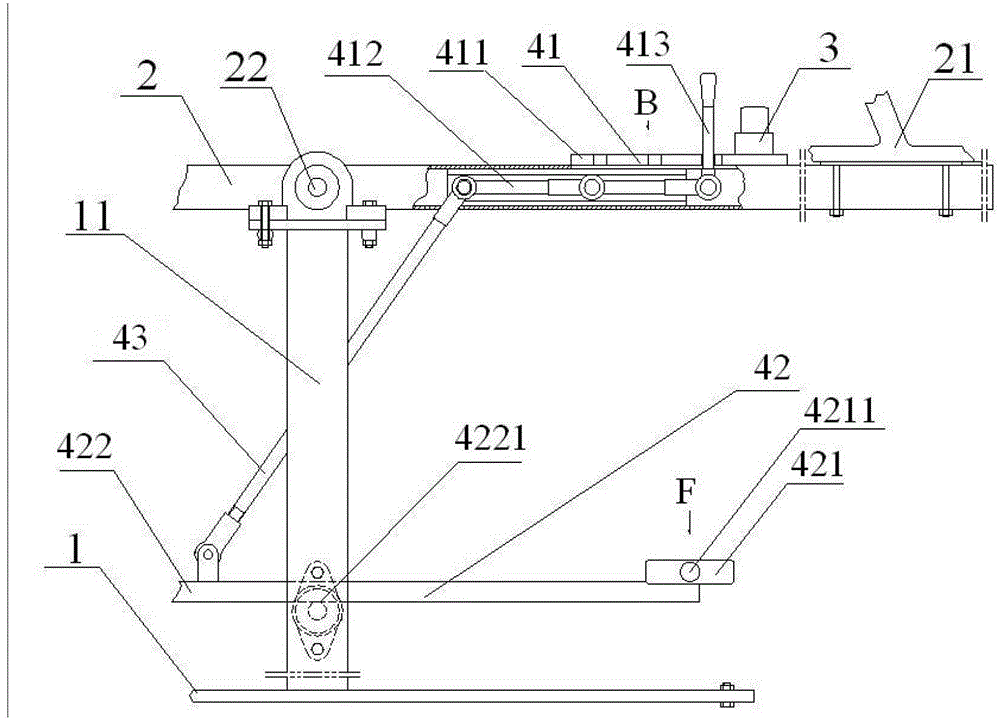

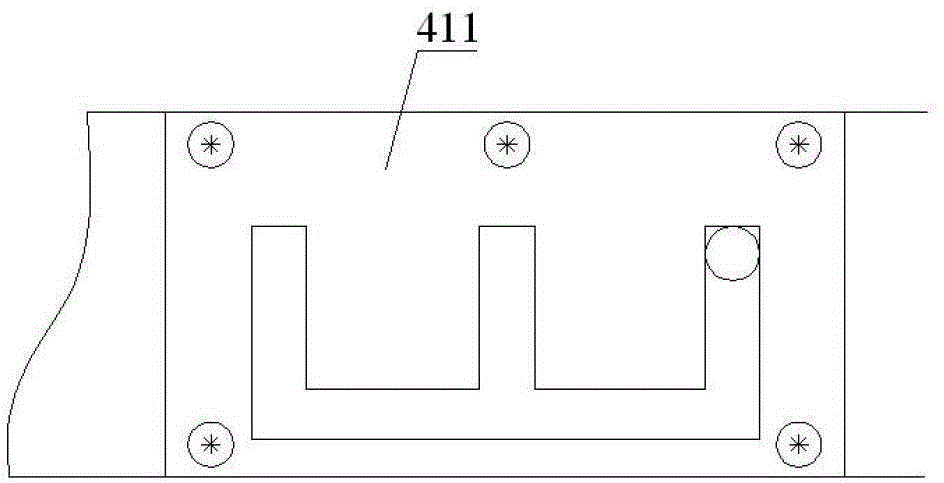

Seesaw

ActiveCN103055509AEntertainment fulfillmentControlled descent speedSee-sawsEngineeringAmusement park

A seesaw comprises a base which is provided with right and left vertical columns, a seesaw body, a hand rail which is fixedly arranged on the seesaw body and a force transmission device, wherein two ends of the seesaw body are provided with chairs and the seesaw body is arranged at the upper end of vertical columns through a rotating shaft; the force transmission device comprises a gear device, a pedaling device and a force transmission connecting rod; the gear device comprises a gear board which is provided with a sliding groove, a connecting shaft and a gear handle; the pedaling device comprises a pedal and a pedal connecting rod, the pedal is arranged at two ends of the pedal connecting rod through a pedal fulcrum shaft, and the pedal connecting rod is arranged in the middle of the vertical columns through a second rotating shaft; and the pedal connecting rod is connected with the other end of the second rotating shaft through the force transmission connecting rod. The seesaw has the advantages of achieving the function of solo entertainment, achieving the entertainment of two persons with big weight difference, being capable of entertaining and exercising simultaneously, achieving a fitness purpose, being simple in structure, safe and reliable, low in economy cost and applicable to community and amusement parks.

Owner:ZHEJIANG UNIV OF TECH

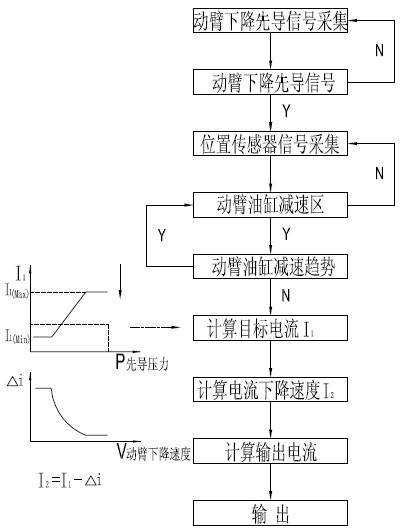

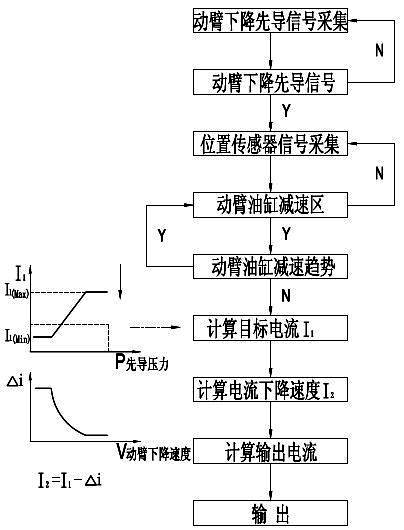

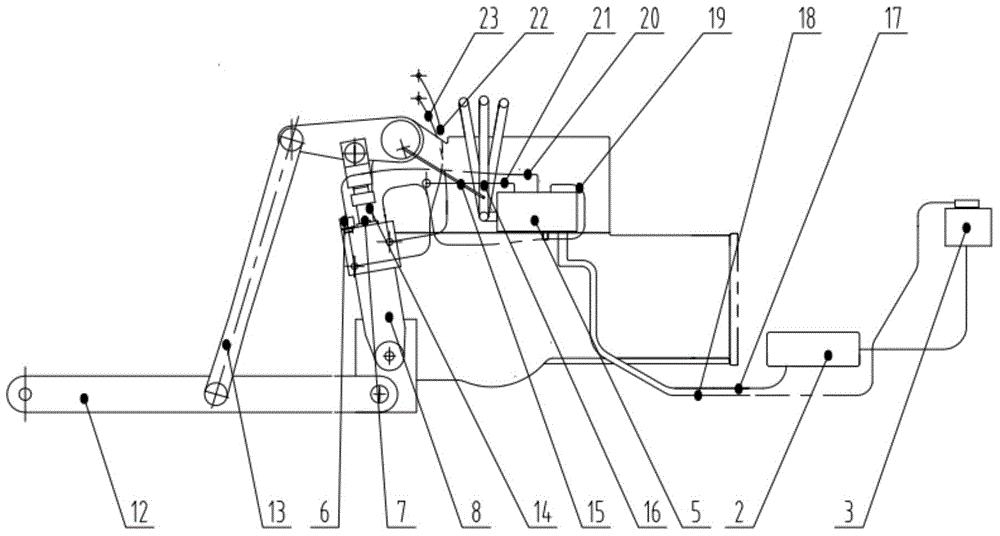

Control method for descending movable arm of excavator

InactiveCN102061714ADescent speed controlAvoid shockMechanical machines/dredgersLogical operationsExcavator

The invention discloses a control method for descending a movable arm of an excavator, which is characterized by comprising the following steps of: detecting the actions of an operating handle through a pilot pressure sensor arranged in a hydraulic control loop; when the operating handle controls the movable arm to descend, detecting the position of a movable arm cylinder through a position sensor installed on the movable arm; carrying out logical operation according to the position of the movable arm cylinder to obtain the speed of the movable arm at the moment; and controlling the oil supply of the movable arm cylinder and the descending speed of the movable arm. In the invention, the actions of the operating handle are detected through the pilot pressure sensor, the position of the movable arm cylinder is detected through the position sensor, and the descending speed of the movable arm is obtained, thereby the oil supply of the movable arm cylinder is controlled and the descending speed of the movable arm is controlled to further avoid impact generation due to too rapid descending of the movable arm.

Owner:SANY HEAVY MACHINERY

Non-Newtonian fluid speed limiter and speed limiting belt thereof

InactiveCN109371868ALimit descent speedAct as a speed limiterTraffic signalsRoad signsEngineeringLimiter

The invention relates to a non-Newtonian fluid speed limiter. The non-Newtonian fluid speed limiter comprises multiple non-Newtonian fluid speed limiter bodies arranged in a groove, a pressing rod inseries connection with bottom ends of multiple pressure pushing rods and two cover plates buckled on an opening of the groove; one sides of the cover plates are hinged to the top edge of the groove, hook tongue plates are arranged on the other sides of the cover plates at intervals, the hook tongue plates of the two cover plates are embedded in a staggered manner, the hook tongue plates of the twocover plates extend reversely to form a pressure groove hole in a defined manner, and a pressing rod is embedded in the pressure groove hole. According to the speed limiter, through limiting of the descending speed of the cover plates, barrier of wheels can be achieved, the action that the wheels press the cover plates downwards can be transmitted by the pressure push rods, once the flow speed ofnon-Newtonian fluid is too fast, a resistance plate can be stopped, the flow speed and the flow of the non-Newtonian fluid are limited, descending of a thrust plug is limited, the descending speed ofthe cover plates can be limited, and the speed limiting effect is achieved. When the vehicle speed is not fast, the non-Newtonian fluid smoothly passes through the resistance plate, the cover platesare perpendicular to the road face, and a car can smoothly pass through a speed reduction belt.

Owner:河北科创商务信息咨询有限公司

Closed hydraulic circuit of hoisting winding engine

InactiveCN101850937AControlled descent speedReduce consumptionWinding mechanismsFuel tankHydraulic pump

The invention relates to a closed hydraulic circuit of a hoisting winding engine. In the invention, a braking hydraulic pump is additionally arranged on the mechanical connection link of a diesel engine and a two-way hydraulic pump; the main shaft of the braking hydraulic pump, the main shaft of the two-way hydraulic pump and the main shaft of the diesel engine are connected in a mechanical transmission mode; the oil inlet of the braking hydraulic pump is connected with the oil outlet of a hydraulic oil tank so as to pump hydraulic oil from the hydraulic oil tank; and the oil extraction of the braking hydraulic pump is connected to the hydraulic oil tank through an overflow valve. By measuring the revolution increment of the diesel engine dragged by the driving torque of the two-way hydraulic pump and controlling the throttling actions of the braking hydraulic pump and the overflow valve, the invention ensures that the driven torque produced by the braking hydraulic pump is balanced with the driving torque produced by the two-way hydraulic pump, stabilizes the incontrollable overspeeding of the hoisting winding engine in the descending process and has a certain energy conservation effect.

Owner:CHINA FIRST METALLURGICAL GROUP

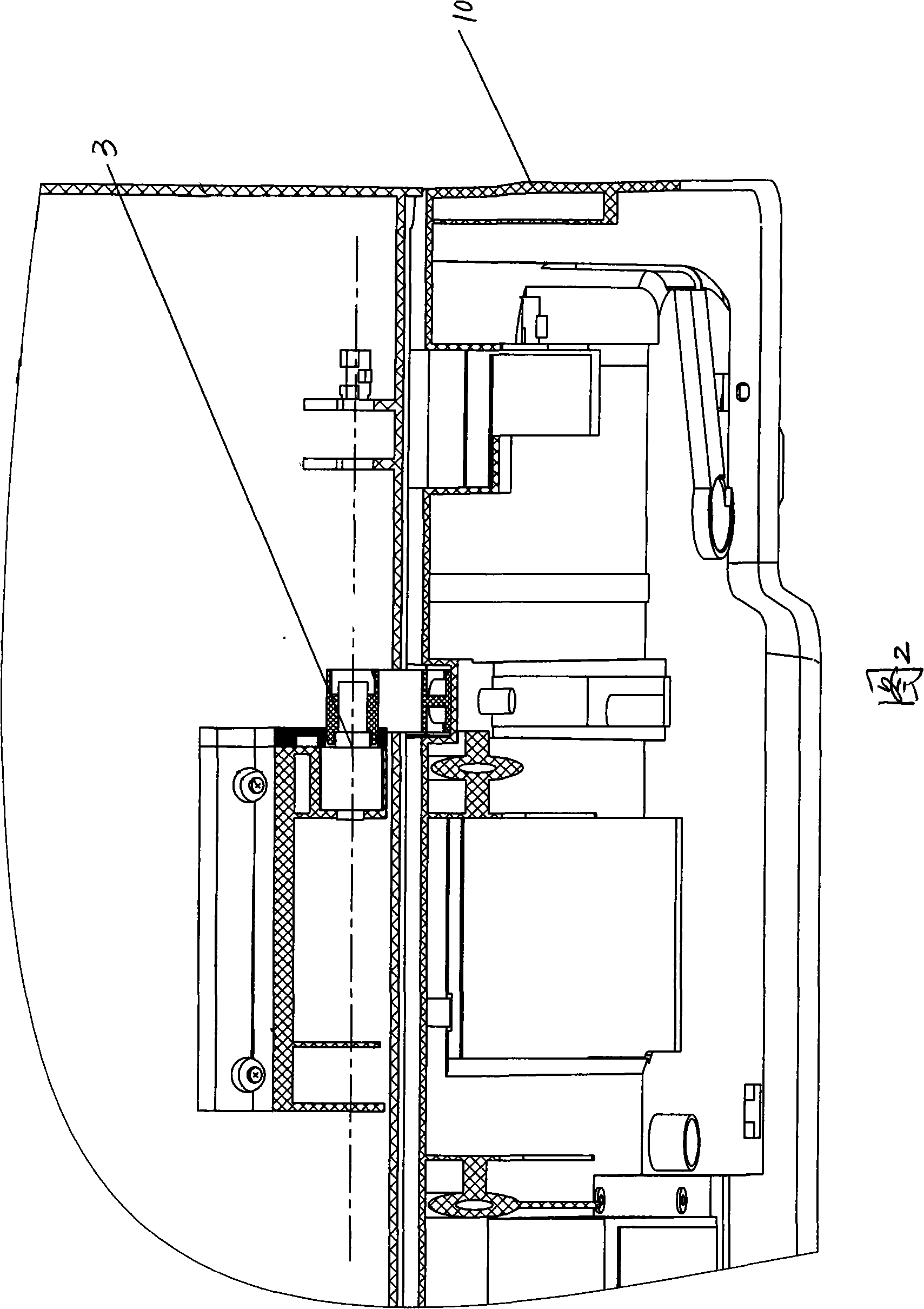

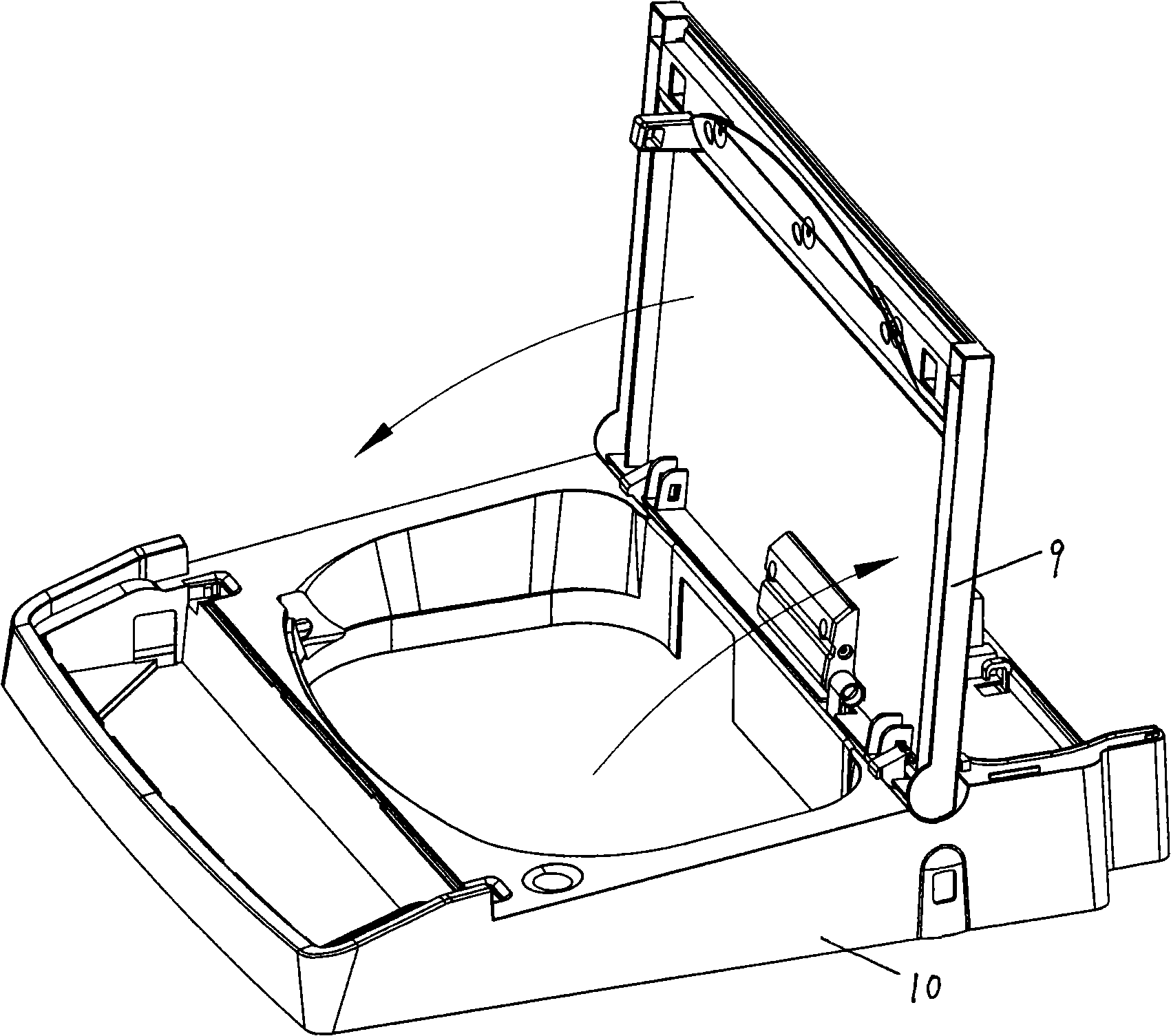

Damping adjustment rotating shaft mechanism for washing machine cover plate

InactiveCN101324023AOvercome the violent impact phenomenonReduce trafficOther washing machinesTextiles and paperEngineeringSelf weight

The invention discloses a damping adjusting and shaft rotating mechanism that can be used in cover boards of washing machines and comprises a shaft sleeve, a fin board is respectively arranged at the left and right sides of an inner wall of the shaft sleeve and has flow impelling action, a rotating shaft is arranged inside the shaft sleeve, a wing plate with a middle opening is respectively arranged at the left and right sides of the rotating shaft, and a spring leaf is respectively spliced in the opening of each wing plate; gaps between the rotating shaft and the shaft sleeve are filled with damping liquid or damping paste, a sealing gland bush is arranged between the rotating shaft and an end part of the shaft sleeve so as to prevent the damping liquid or the damping paste from leaking out, the fin boards and the wing plates are interlaced, and the rotating shaft can rotate inside the shaft sleeve. The damping adjusting and shaft rotating mechanism of the invention leads integral cover boards of the washing machines to have constant speed in the closing process, overcomes the phenomenon that the cover board has fierce impact on a face frame due to self weight in the rotating and declining process, and leads the cover board to slowly decline and lightly fall over the face frame.

Owner:HEFEI MIDEA WASHING MACHINE

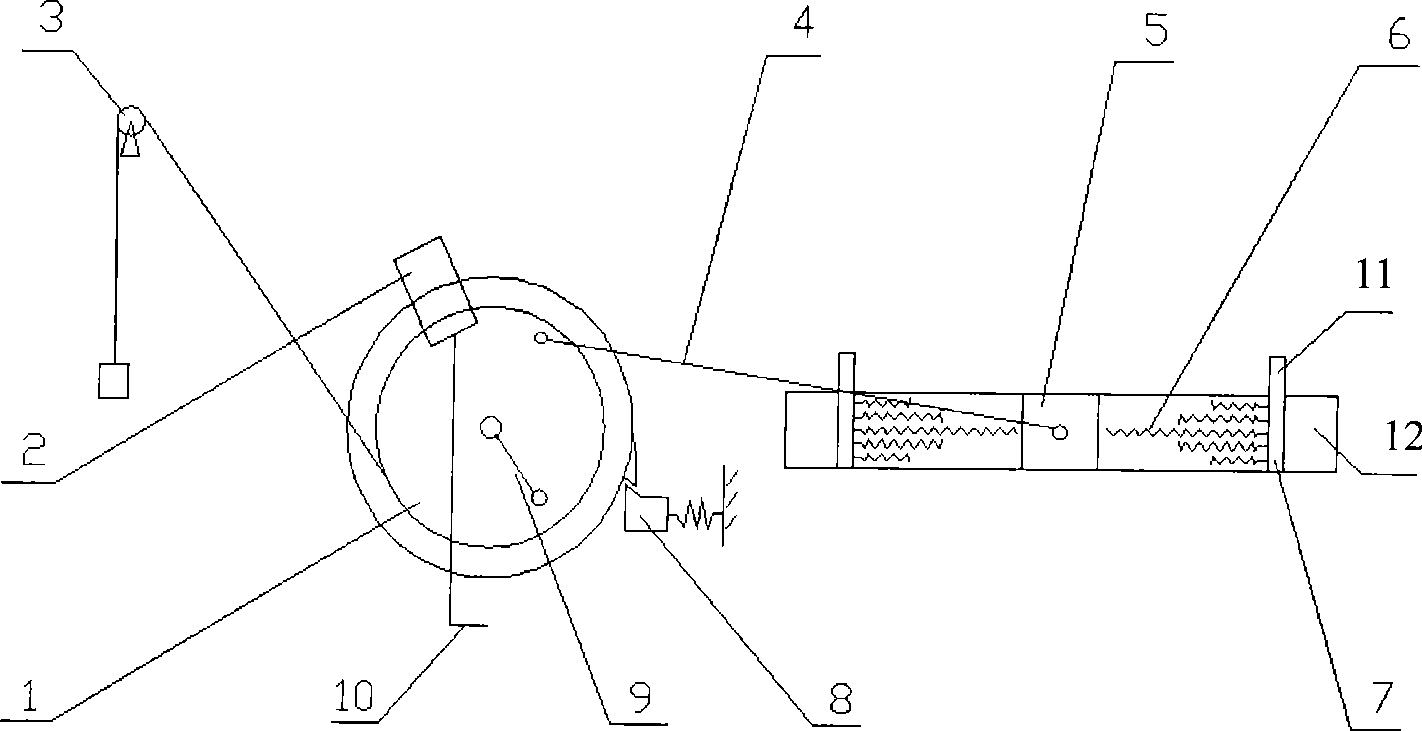

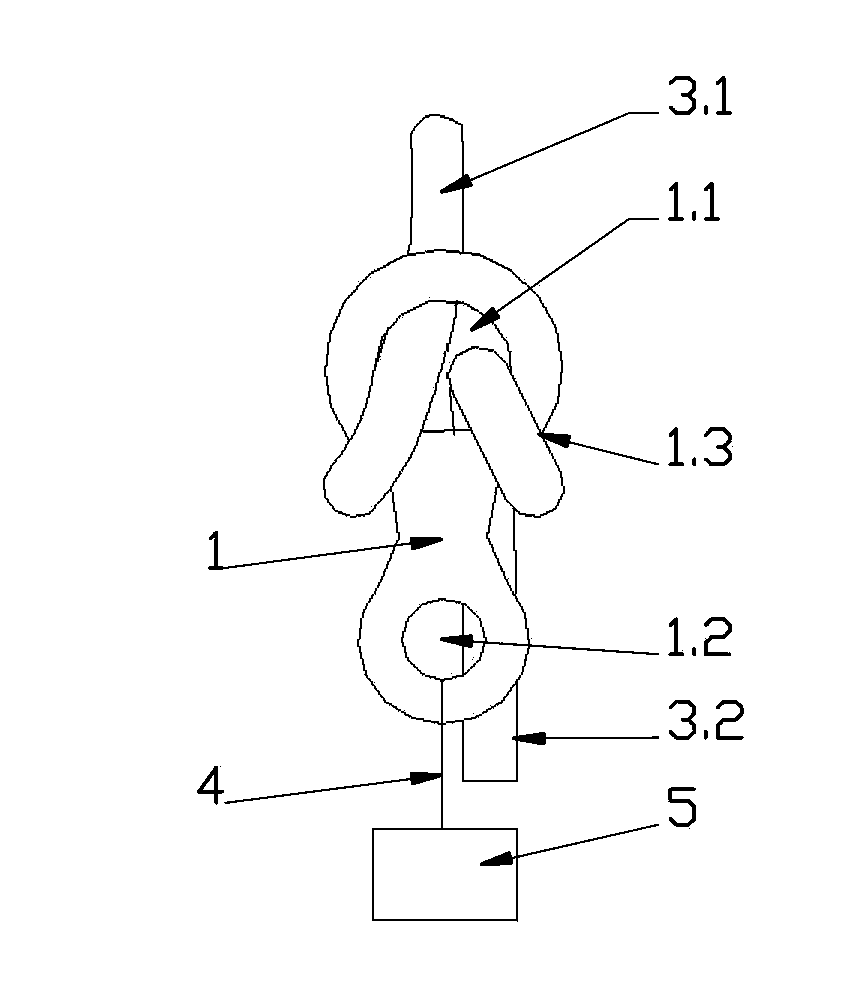

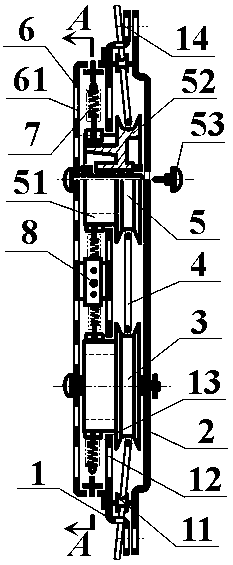

Indoor rock-climbing safeguard device

The invention pertains to indoor sports apparatus and more particularly relates to an indoor rock climbing safety device. In respect of the existing indoor rock climbing, a safety man pulls and releases ropes to cause a climber to ascend and descend safely. Great potential safety hazard exists: a significant safety accident can occur with a slight negligence. The indoor rock climbing safety device consists of a rope and a fixed pulley (3); a wound roll (1) is arranged at one end of the rope, a crank handle (9), a brake block (2), a unidirectional stop tooth (8) and a connecting rod (4) are arranged on the wound roll (1); the connecting rod (4) is connected with a sliding block (5); springs (6) are arranged at both ends of the sliding block (5); a brake pedal (10) is connected with the brake block (2); and an adjusting gear (7) is arranged at one end of the spring (6). The indoor rock climbing safety device has the advantages of controlling the descending speed of the climber within a safety scope, ensuring the safety of the climber in an emergency situation, and having simple operation, safeness and reliability.

Owner:SHANGHAI UNIV OF ENG SCI

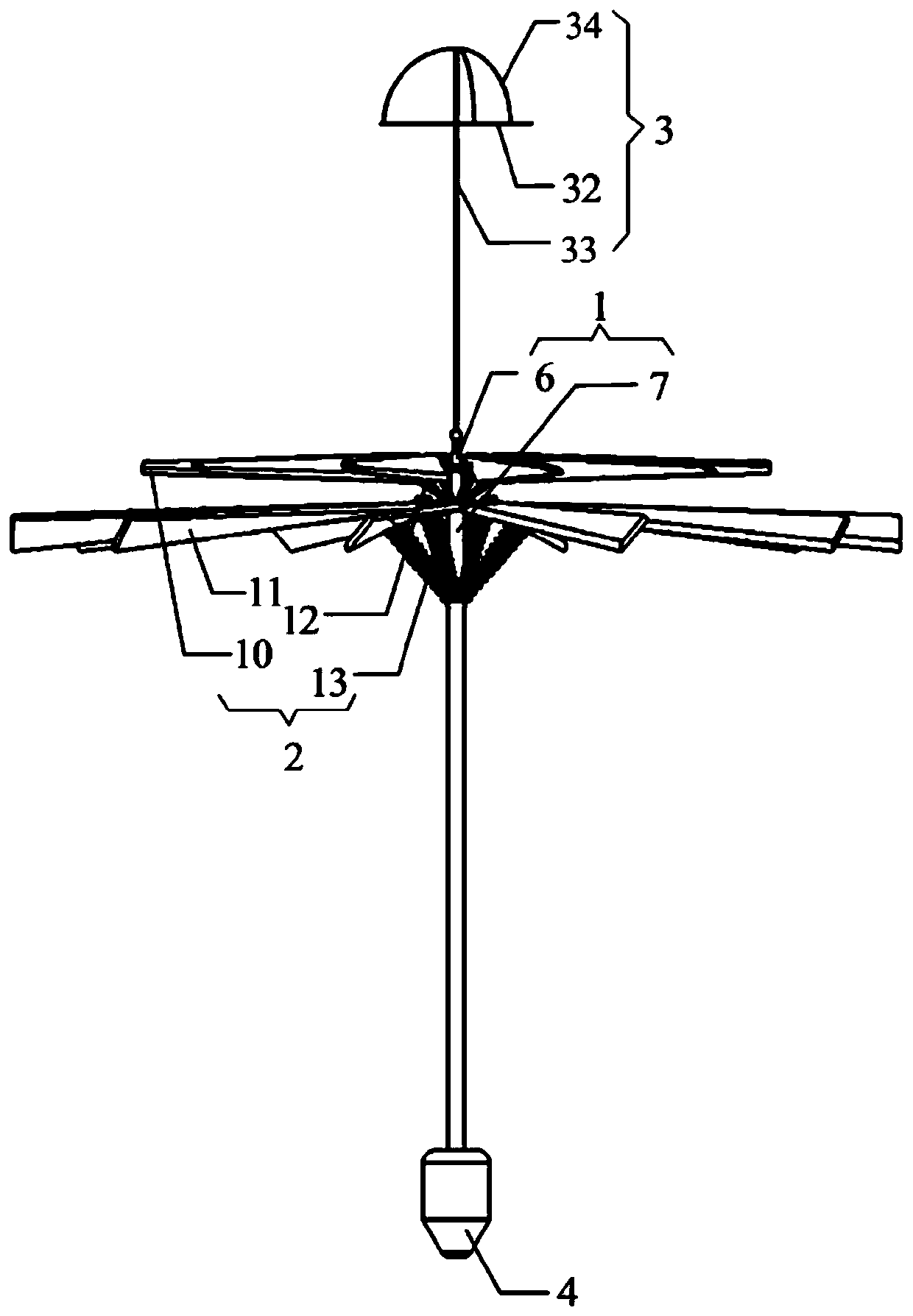

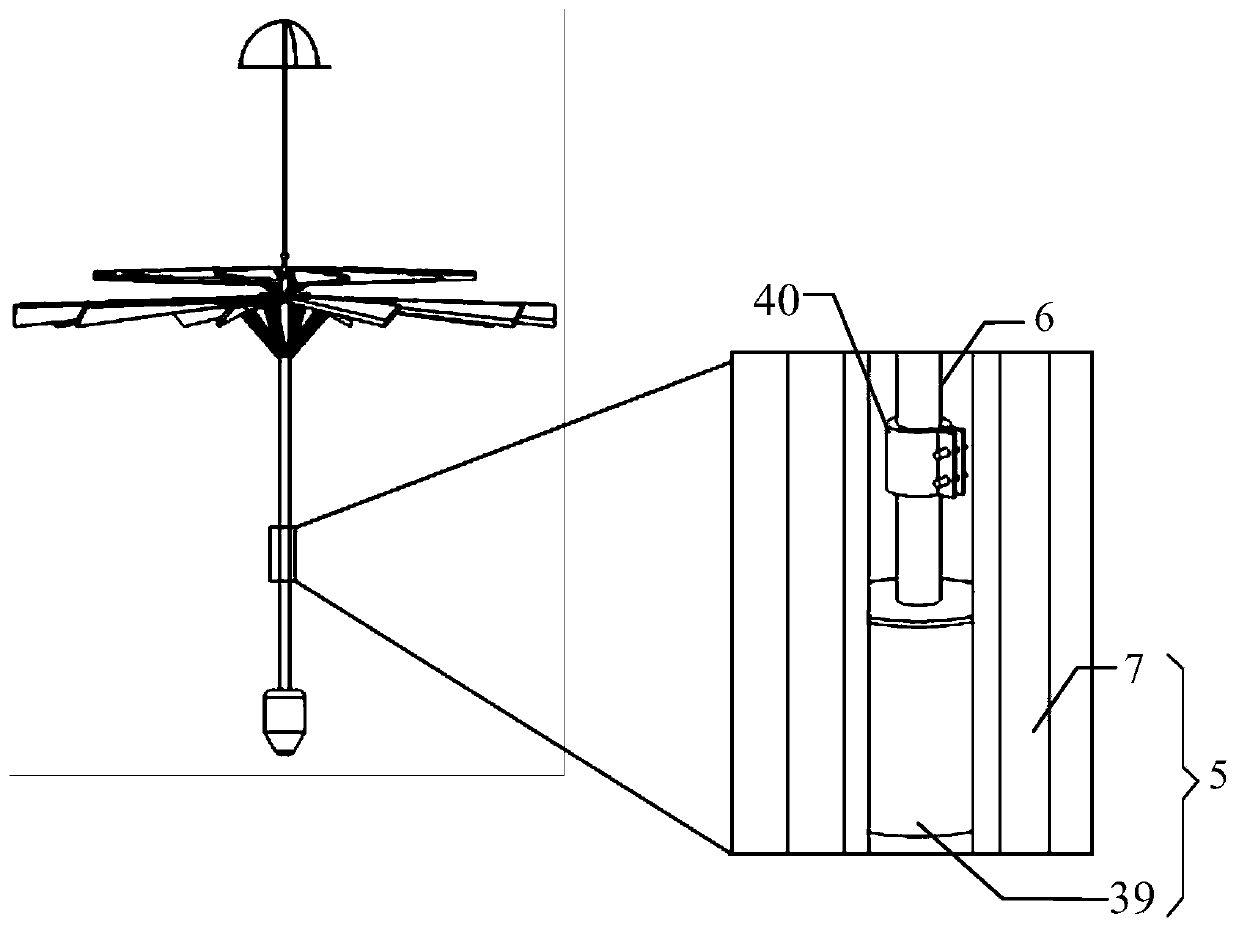

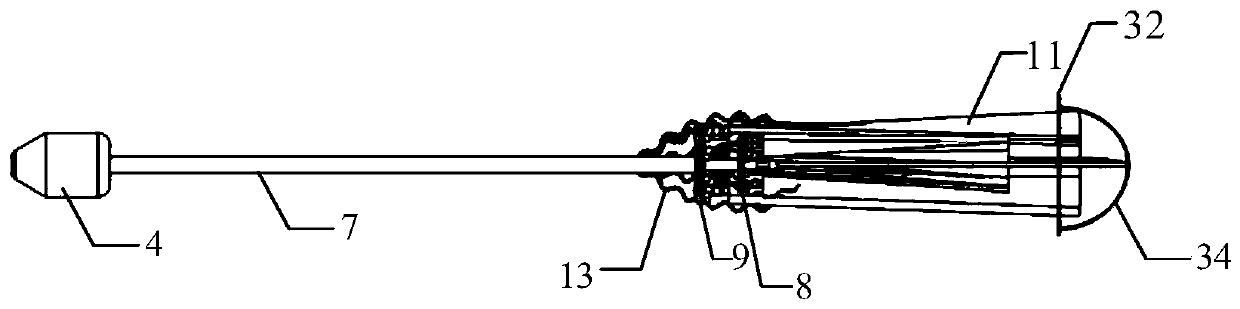

Downward-throwing type sonde with dandelion-like structure

The invention discloses a downward-throwing type sonde with a dandelion-like structure. Upper and lower rotor wings of the sonde are not liable to damage in a severe environment, the normal use can beguaranteed even if a small number of rotor wings are damaged, and the sonde can be suitable for the detection of typhoon and other severe weather. When the upper and lower rotor wings are in a closedstate, the sonde is catapulted to a preset height, the upper and lower rotor wings are automatically opened, then the upper and lower rotor wings slowly fall down, a double-layer rotor wing structureis adopted, the inclination directions of the upper and lower rotor wings are opposite, airflow in opposite directions is generated under the action of an external environment, the rotation directions of the upper and lower rotor wings are opposite, air resistance can be enhanced, and longer hang time is obtained. By adjusting inclination angles of the upper and lower rotor wings, the descendingspeed of the sonde can be controlled, and ideal hang time is obtained. The analog resistance is adjusted by using a microcontroller, the relative torsional moment borne by each upper rotor wing and each lower rotor wing during rotation is changed, the relative rotation speed of the upper and lower rotor wings is changed, the descending speed of the sonde can be controlled, and the ideal hang timeis obtained.

Owner:BEIHANG UNIV

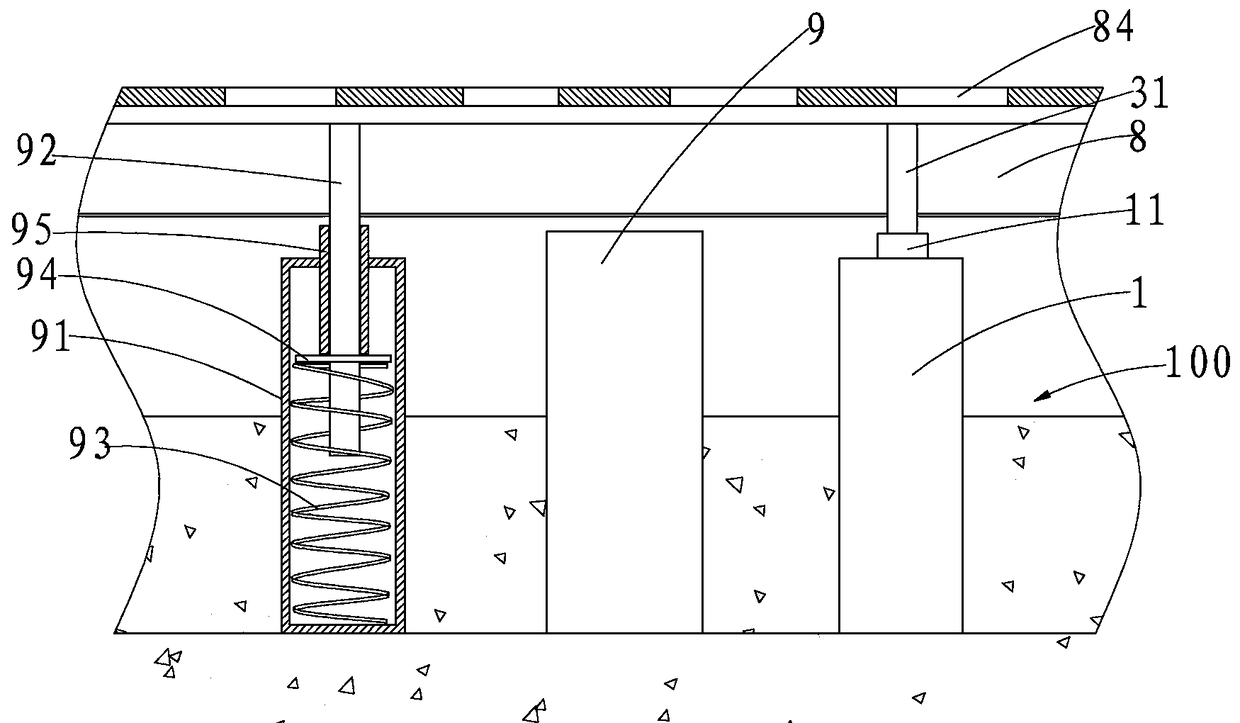

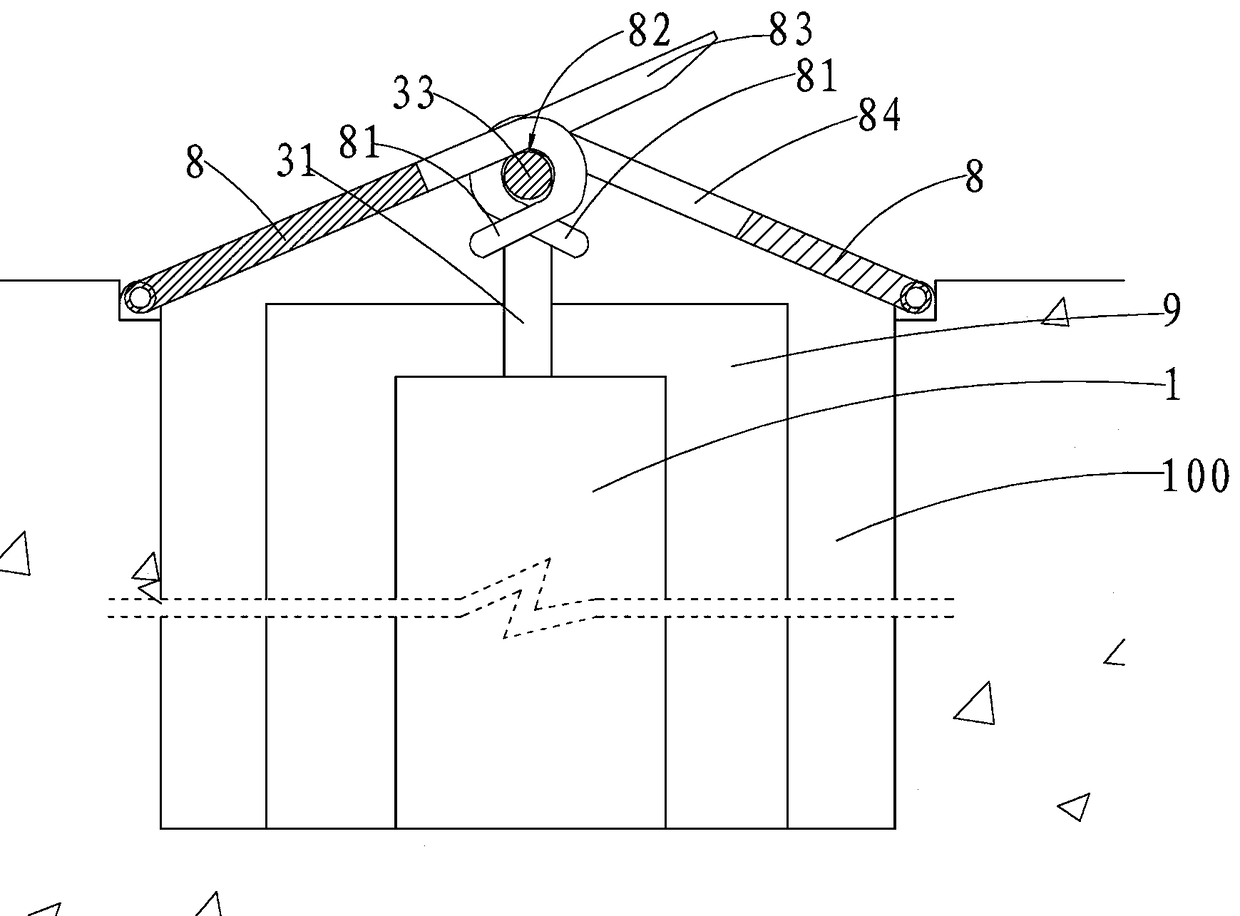

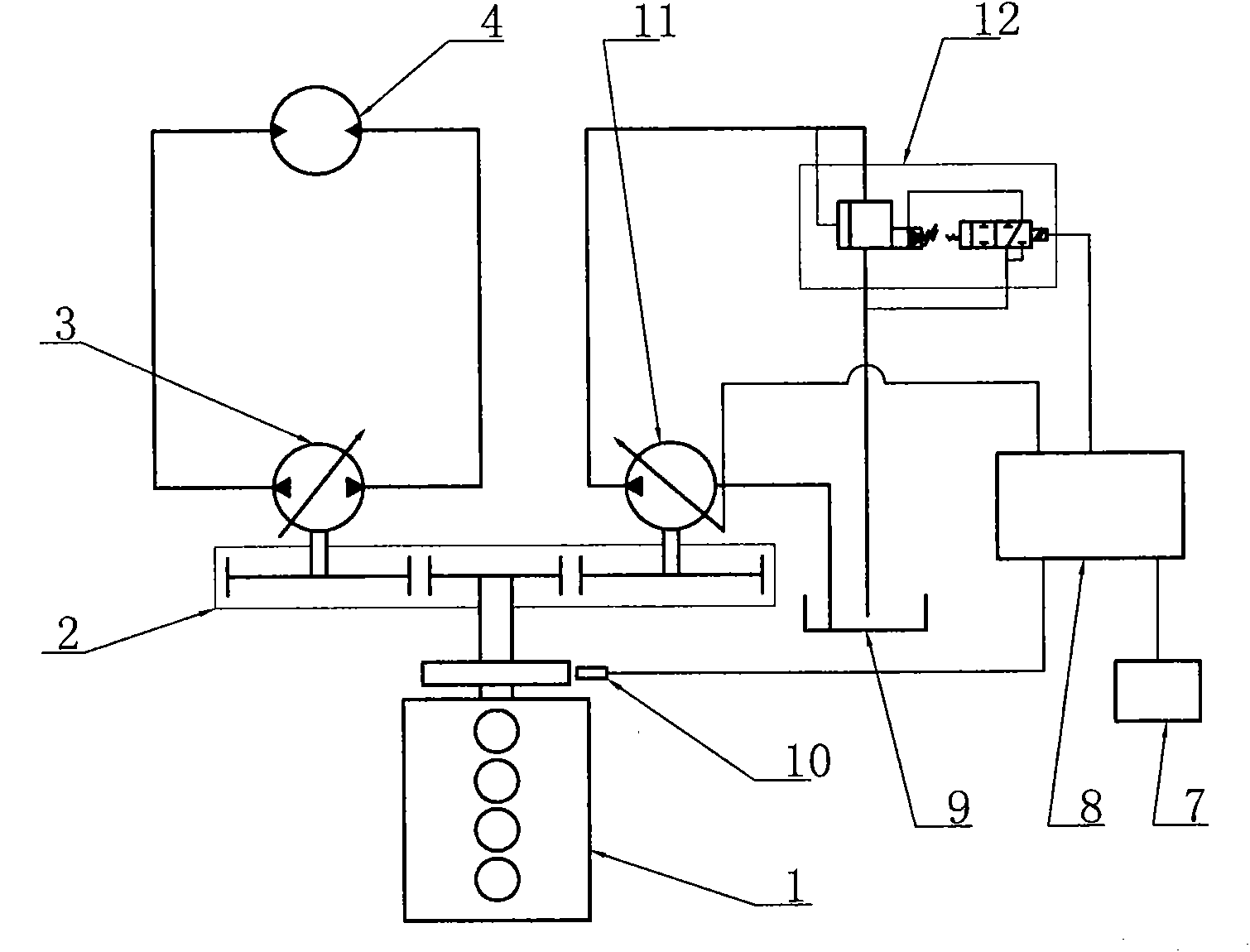

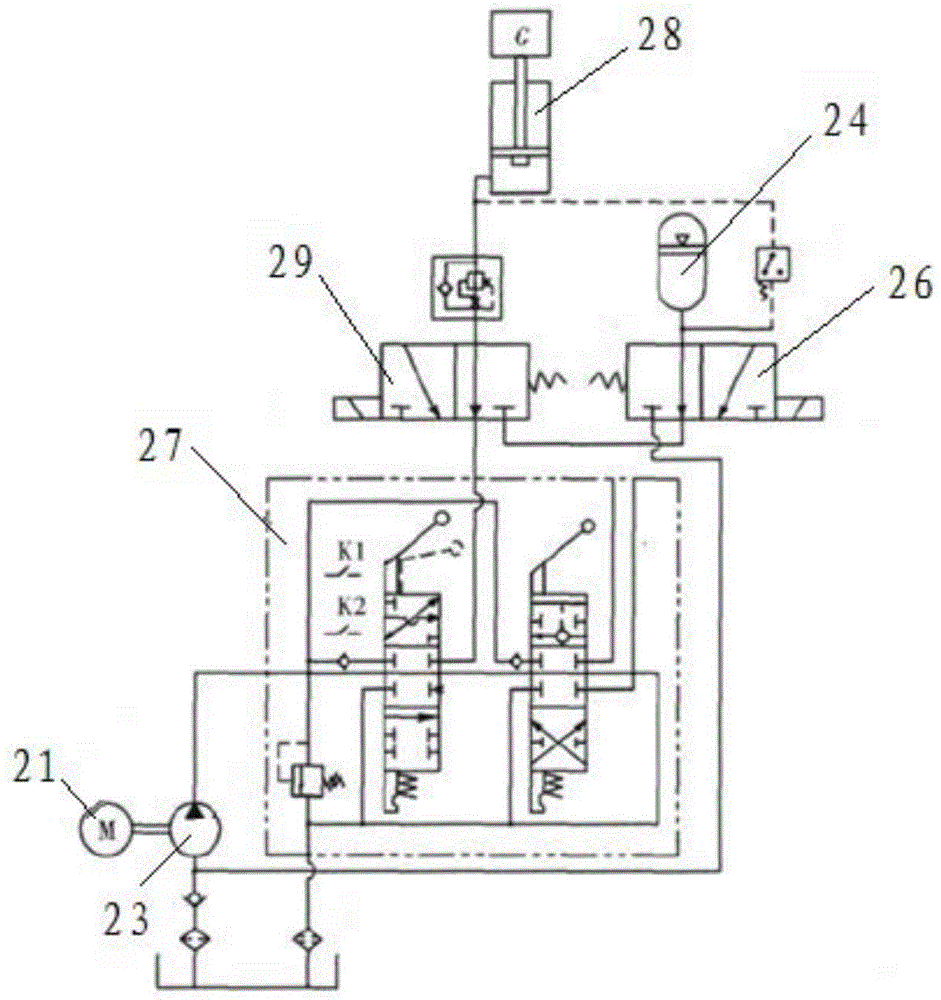

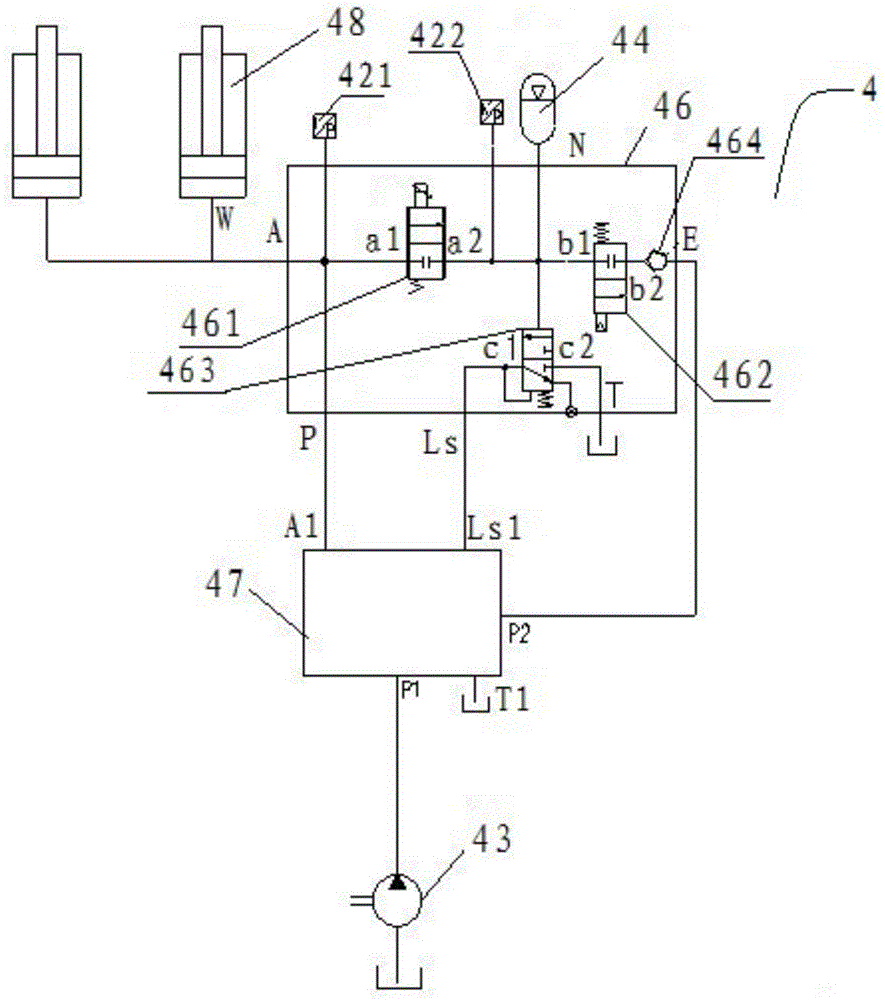

Energy recovery control system and lifting equipment

ActiveCN105697429AControlled descent speedFluid-pressure actuator testingLifting devicesControl systemHydraulic pump

The invention discloses an energy recovery control system and lifting equipment. The energy recovery control system comprises a hydraulic pump, a main valve, a hydraulic execution element, an energy accumulator, a first control valve and a second control valve; the main valve has a first main valve pressure oil port, a second main valve pressure oil port, a main valve working oil port and a main valve oil discharge port; the hydraulic execution element has an execution element working oil port; an outlet of the hydraulic pump is connected with the first main valve pressure oil port; the main valve working oil port is connected with the execution element working oil port; the execution element working oil port is connected with the energy accumulator through the first control valve; the first control valve controls the connection and the disconnection of the actuation element working oil port and the energy accumulator; the energy accumulator and the second main valve pressure oil port are connected through the second control valve; and the second control valve controls the connection and the disconnection of the energy accumulator and the second main valve pressure oil port. The energy recovery control system can directly act the energy, absorbed by the energy accumulator, on the main valve when being applied to the lifting equipment, and is wider in application range.

Owner:XUZHOU HEAVY MASCH CO LTD

Escaping device from fire disaster

The invention relates to a fire escape device, comprising a movable window body and a main body provided with a window locker. The upper side of the movable window body is axially connected to a security window; a dropper and a waist span-type T-shaped safety belt are also arranged in the main body; U-shaped latch hooks are fixed at two sides of the dropper; two bearings are horizontally arranged in the dropper; a loose axle is arranged above the part between the two bearings; a long hand lever controls the loose axle to move up and down; a list of shafts are vertically arranged at one side of one shaft in two horizontal shafts; one end of a safety rope is fixed in the main body, and the other end thereof enters into the dropper, passes through the two horizontal shafts and then bends, extends from the dropper along a vertical shaft, and then is fixed on the dropper in a folding manner; a limited board is arranged on the upper part of the window locker; the limited board is connected with a T-shaped threaded rod and is operated by the hand lever; the limited board butts against the lower movable side of the movable window body. The fire escape device has the advantages that the escape passageway can be inaugurated rapidly, and the device corresponds with the structure of the existing window body; the operation is convenient; the safety is high.

Owner:刘世君

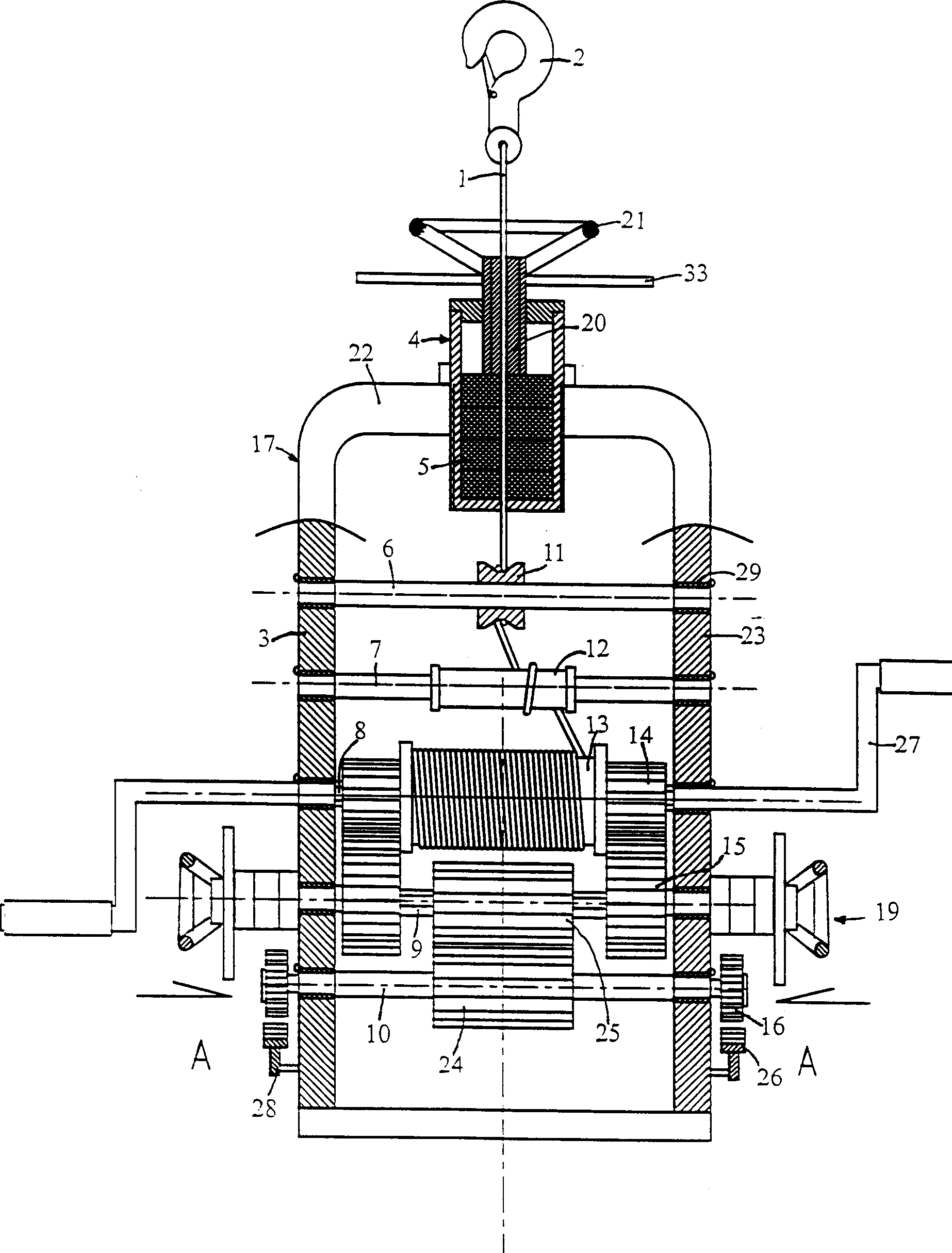

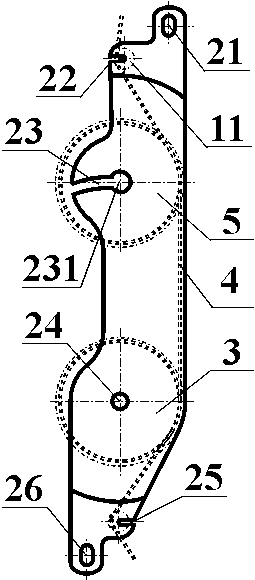

High-altitude escape self-rescue device

InactiveCN102526902AChange the size of the wrap angleControlled descent speedBuilding rescueEngineeringPulley

The invention relates to a high-altitude escape self-rescue device, which comprises a shell and a rope, wherein a handle is fixedly connected with a lead screw in the shell; the left and right elliptical threads of the lead screw are connected with left and right slide blocks respectively; the left and right slide blocks are connected with two feeding rods in a sliding way; left and right movable pulleys are hinged with the left and right slide blocks respectively; two fixed pulleys are hinged with left and right brackets respectively; the left and right brackets are fixedly connected with the shell; the rope is wound on the two fixed pulleys in a staggered way, and is arranged between the two movable pulleys; the top surface of the shell is provided with a rope inlet positioning mechanism; and the bottom surface of the shell is provided with a rope outlet and a lug where a safety vest is arranged. The device has a simple structure, high manufacturability, small size and light weight, is smooth and safe, and is easy and convenient for operating.

Owner:YANCHENG INST OF TECH

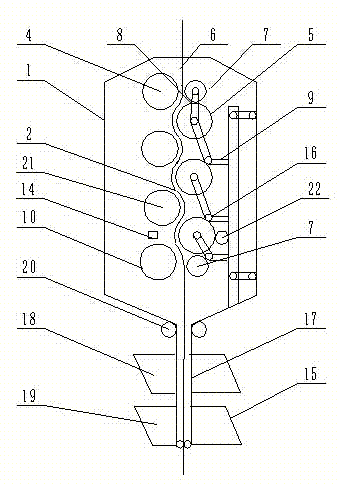

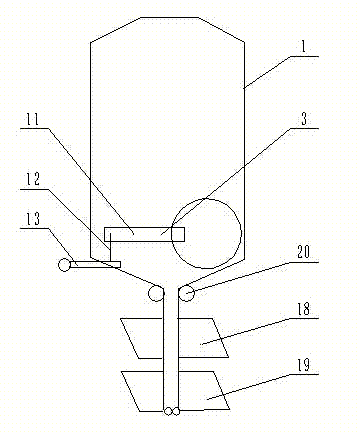

Device for lowering persons from high-rise building

A device for rescuing from high building is composed of rope with hook at its one end and passing through a packing box in slide mode, left and right vertical plates, a quasi-roller and its axle, transition roller and its axle, hub roller and its axle, active decelerating gear, driven decelerating gear and braking gear and their axle.

Owner:姜北宏

High-rise automatic escape device

The invention provides a high-rise automatic escape device, comprising a frame and a sliding mechanism, wherein the sliding mechanism comprises a left gear set and a right gear set which are meshed with each other; a rope is arranged between the left gear set and the right gear set; the rope is linked with the left gear set and the right gear set; the outer sides of gears at the upper end and the lower end of the right gear set are respectively provided with a compressing wheel; the compressing wheels are used for compressing the rope; a compressing wheel supporting arm is arranged between the compressing wheel and each of the gears at the upper end and the lower end of the right gear set; a pinion in the right gear set is connected with the frame through a spring bracket; a braking gear is arranged below the left gear set at the lower part of the frame; a speed limiter is arranged between the braking gear and the left gear set; the escape device is further provided with a motor which is capable of controlling the escape device to ascend and descend; the motor is linked with the left gear set or the right gear set. The high-rise automatic escape device has the advantages of safety, reliability and convenience in use, and simple structure.

Owner:徐振权

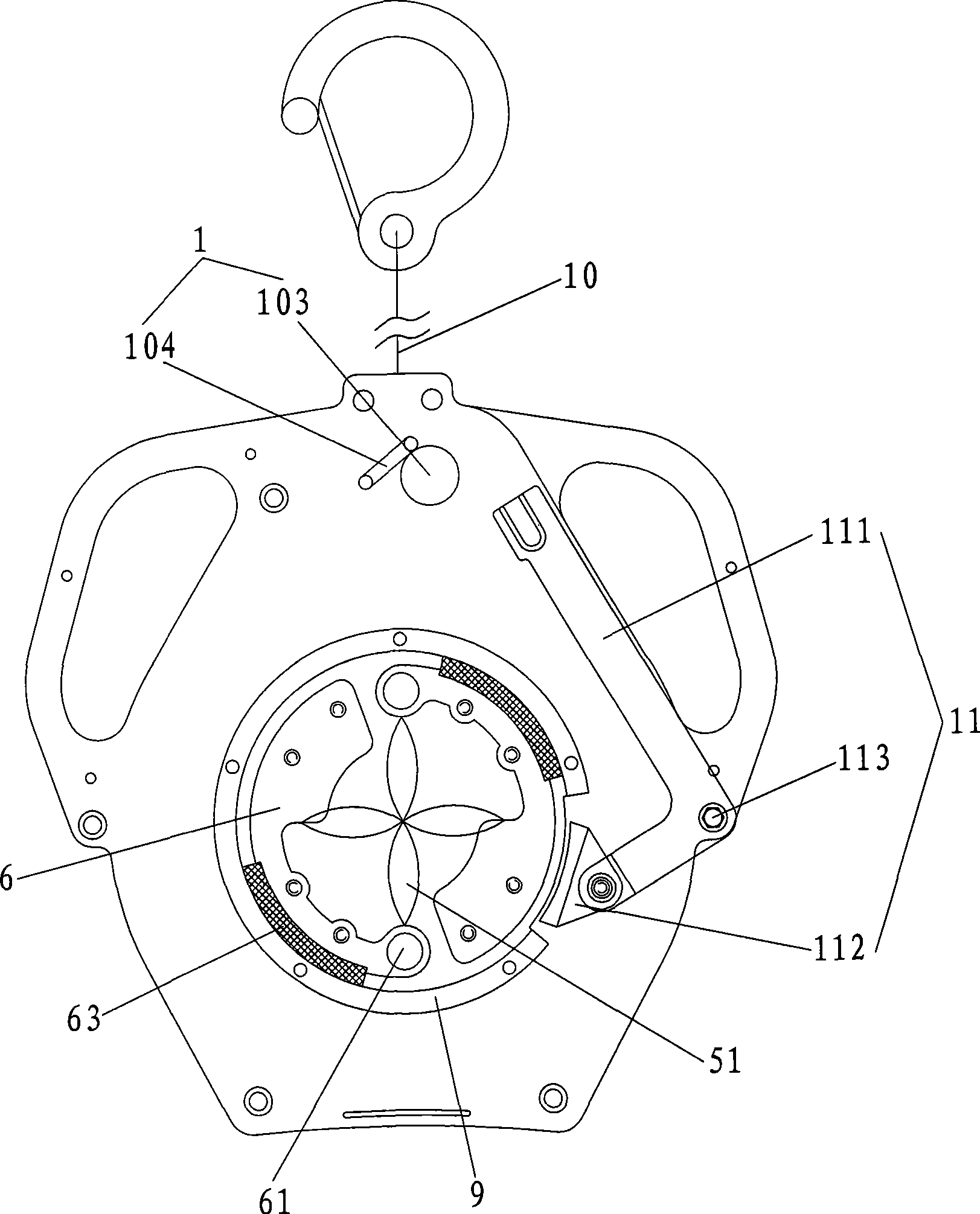

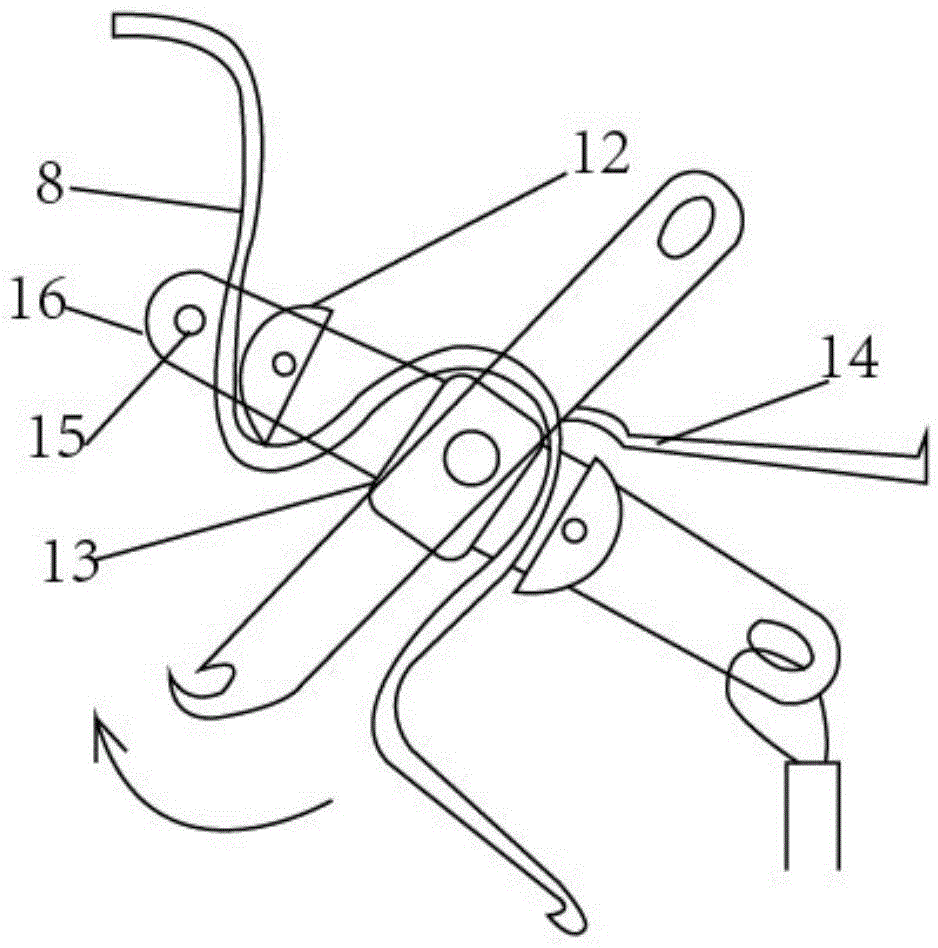

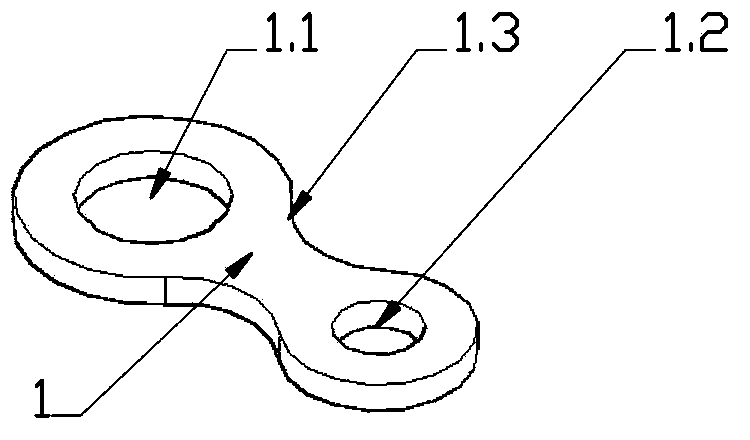

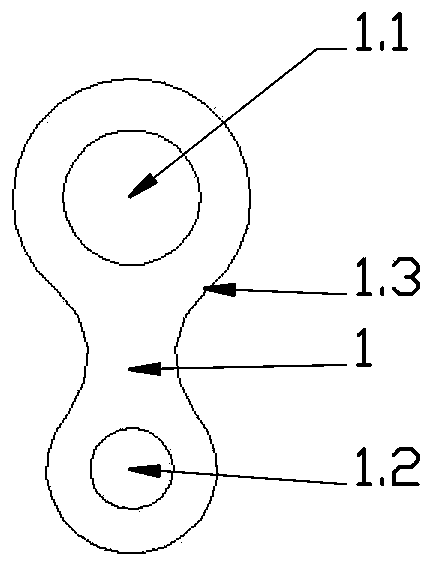

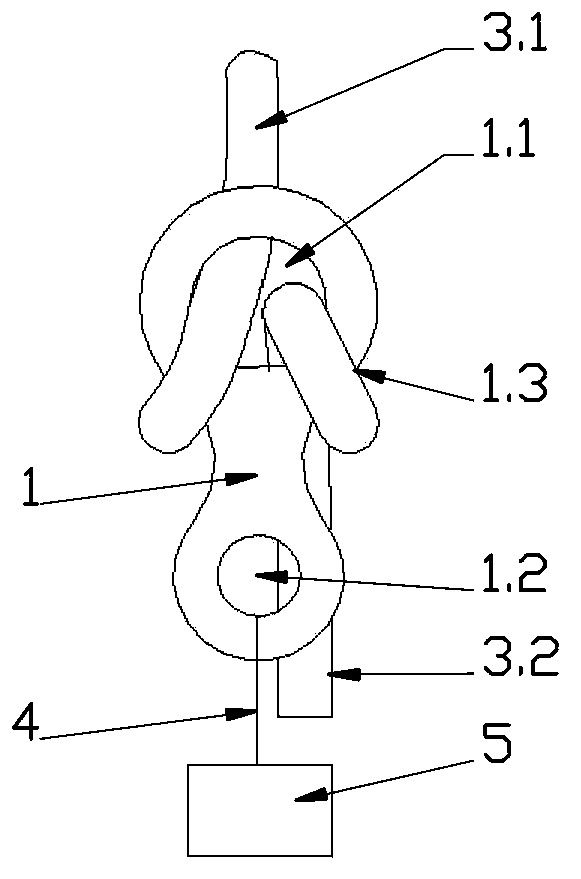

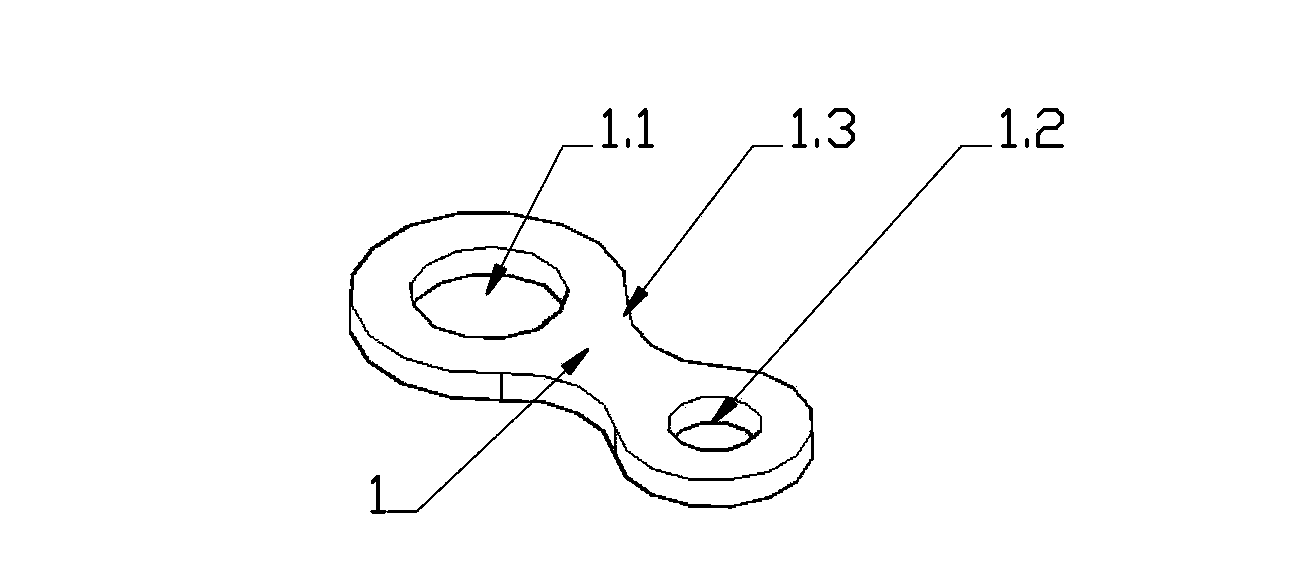

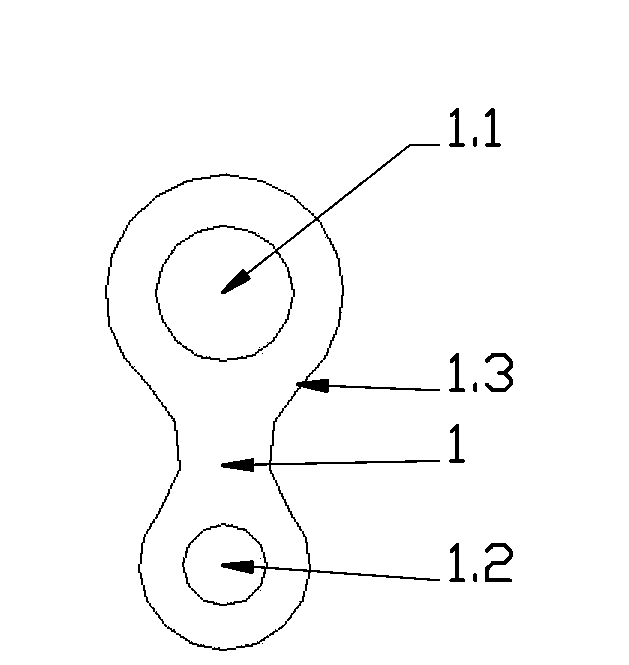

Cross-section-variable rope reel and hanging device thereof

InactiveCN103785122AControlled descent speedEnsure safetySafety beltsMountaineeringEngineeringFriction force

A cross-section-variable rope reel comprises a reel body and a mounting hole, and is characterized in that a cross-section-variable rope groove is formed in the rope reel; and when a rope is wound on different portions of the groove of the rope reel, the frictional forces between the rope and the groove of the rope reel are different. Moreover, the invention also provides a hanging device comprising the cross-section-variable rope reel. The hanging device consists of a hanging body and a U-shaped rope threading piece, wherein a hanging hole is formed in the hanging body; the U-shaped rope threading piece is arranged on the hanging body; a U-shaped opening of the U-shaped rope threading piece and the hanging body form a rope threading hole; the hanging hole is formed in the lower side of the hanging body; the cross-section-variable rope reel, a reel body fixing device and a rope pressing device are arranged on the hanging body; the rope pressing device slides back and forth; and the cross-section-variable rope reel is arranged on the reel body fixing device. When the cross-section-variable rope reel is used, a working rope threads through the rope threading hole and is wound on the cross-section-variable rope reel, a fixed end of the working rope is fixed at a high position, a free end of the working rope hangs down to a low position, and a user is fixedly connected with the hanging hole. When stopping operating the reel body fixing device with the hands, the user hangs in air, and the descending speed can be controlled when the rope reel is manually operated to rotate.

Owner:何少敦

Cross-section-variable rope reel and hanging device thereof

A cross-section-variable rope reel comprises a reel body and a mounting hole, and is characterized in that a cross-section-variable rope groove is formed in the rope reel; and when a rope is wound on different portions of the groove of the rope reel, the frictional forces between the rope and the groove of the rope reel are different. Moreover, the invention also provides a hanging device comprising the cross-section-variable rope reel. The hanging device consists of a hanging body and a U-shaped rope threading piece, wherein a hanging hole is formed in the hanging body; the U-shaped rope threading piece is arranged on the hanging body; a U-shaped opening of the U-shaped rope threading piece and the hanging body form a rope threading hole; the hanging hole is formed in the lower side of the hanging body; the cross-section-variable rope reel, a reel body fixing device and a rope pressing device are arranged on the hanging body; and the cross-section-variable rope reel is arranged on the reel body fixing device. When the cross-section-variable rope reel is used, a working rope threads through the rope threading hole and is wound on the cross-section-variable rope reel, a fixed end of the working rope is fixed at a high position, a free end of the working rope hangs down to a low position, and a user is fixedly connected with the hanging hole. When stopping operating the reel body fixing device with the hands, the user hangs in air, and the descending speed can be controlled when the rope reel is manually operated to rotate.

Owner:TONGLING RIKE ELECTRONICS

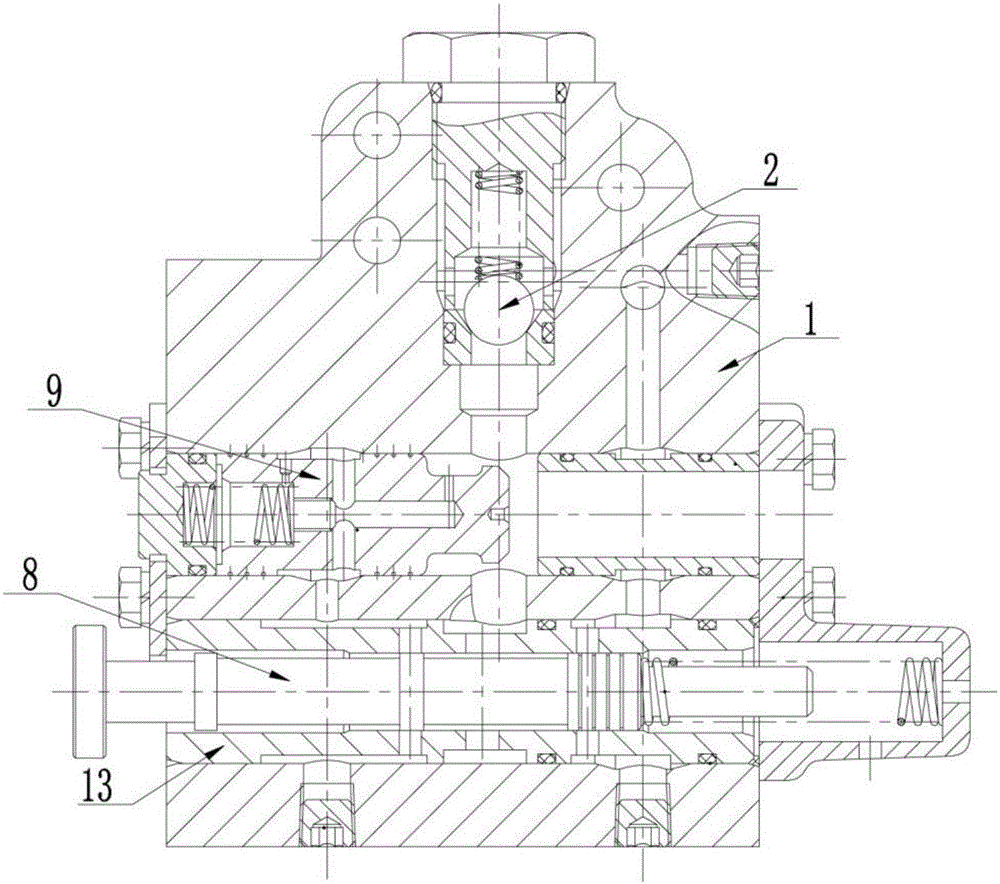

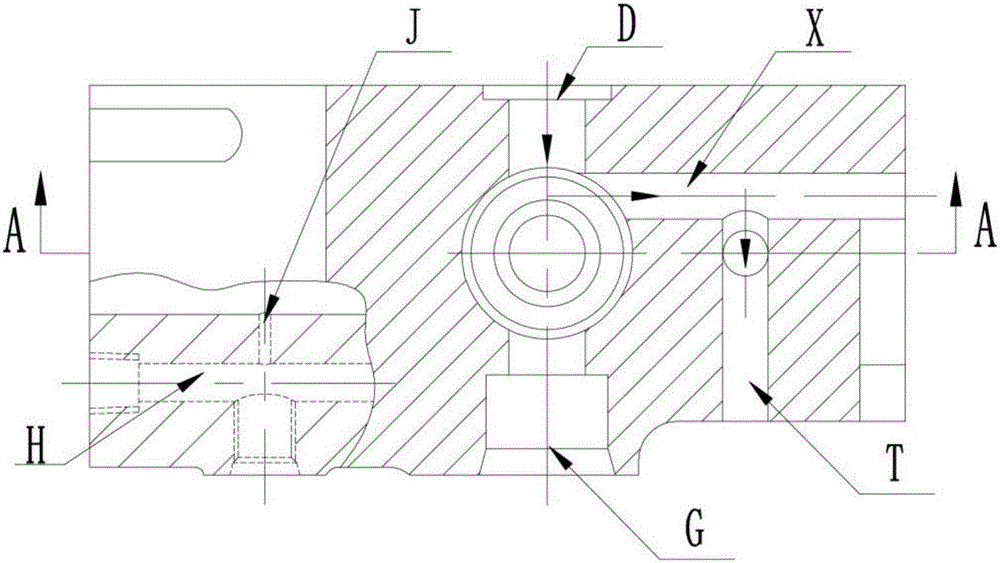

Built-in hydraulic distributor

ActiveCN106015146AReduce idle travelHigh sensitivityServomotor componentsServometer circuitsEngineeringCheck valve

The invention discloses a built-in hydraulic distributor which comprises a distributor shell and a main control valve, an oil return valve and a check valve which are arranged in the shell; an oil inlet, an oil cylinder oil inlet and an oil return opening are formed in the distributor shell; a lowering valve is arranged in a main control valve hole; a lowering valve compressing sleeve and a lowering valve adjusting bolt are arranged at the right side of the lowering valve; the lowering valve is arranged at the right side of the main control valve; the oil cylinder oil inlet communicates with the oil inlet chamber of the lowering valve by an oil cylinder oil drainage oil line; the oil outlet chamber of the lowering valve communicates with the oil return opening; the lowering valve comprises a lowering valve core and a lowering valve seat; the lowering valve compressing sleeve compresses the lowering valve seat; and the lowering valve adjusting bolt compresses on the lowering valve compressing sleeve. The built-in hydraulic distributor can improve the lowering and lifting sensitivity, and the hydrostatic sedimentation value of a hydraulic lifter is ensured by the sealing state of the lowering valve and the check valve, thus being more reliable, good in airtightness, steady in use performances, high in reliability, and convenient to dismantling and maintenance.

Owner:SHANDONG HONGYU AGRI MACHINERY

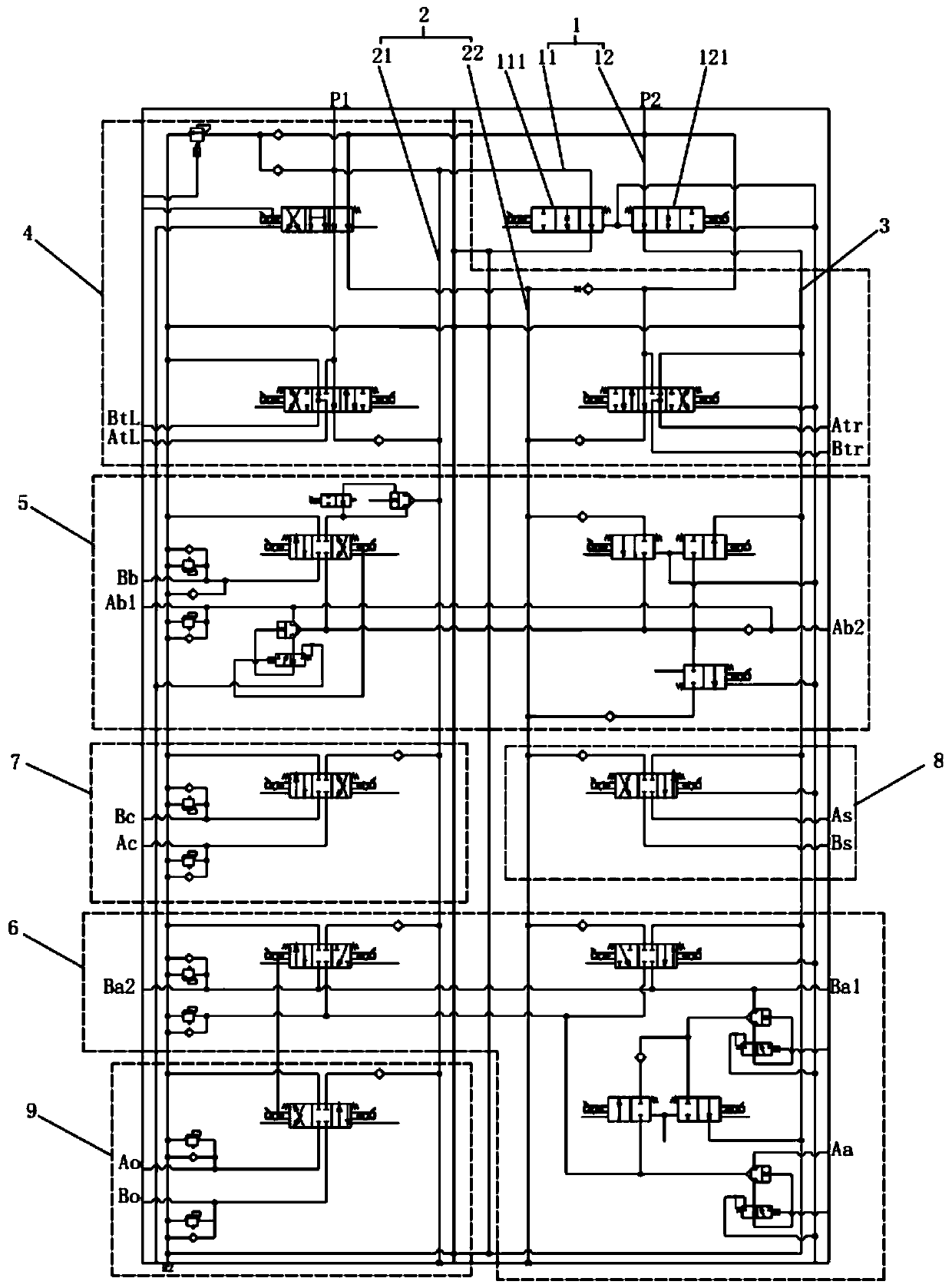

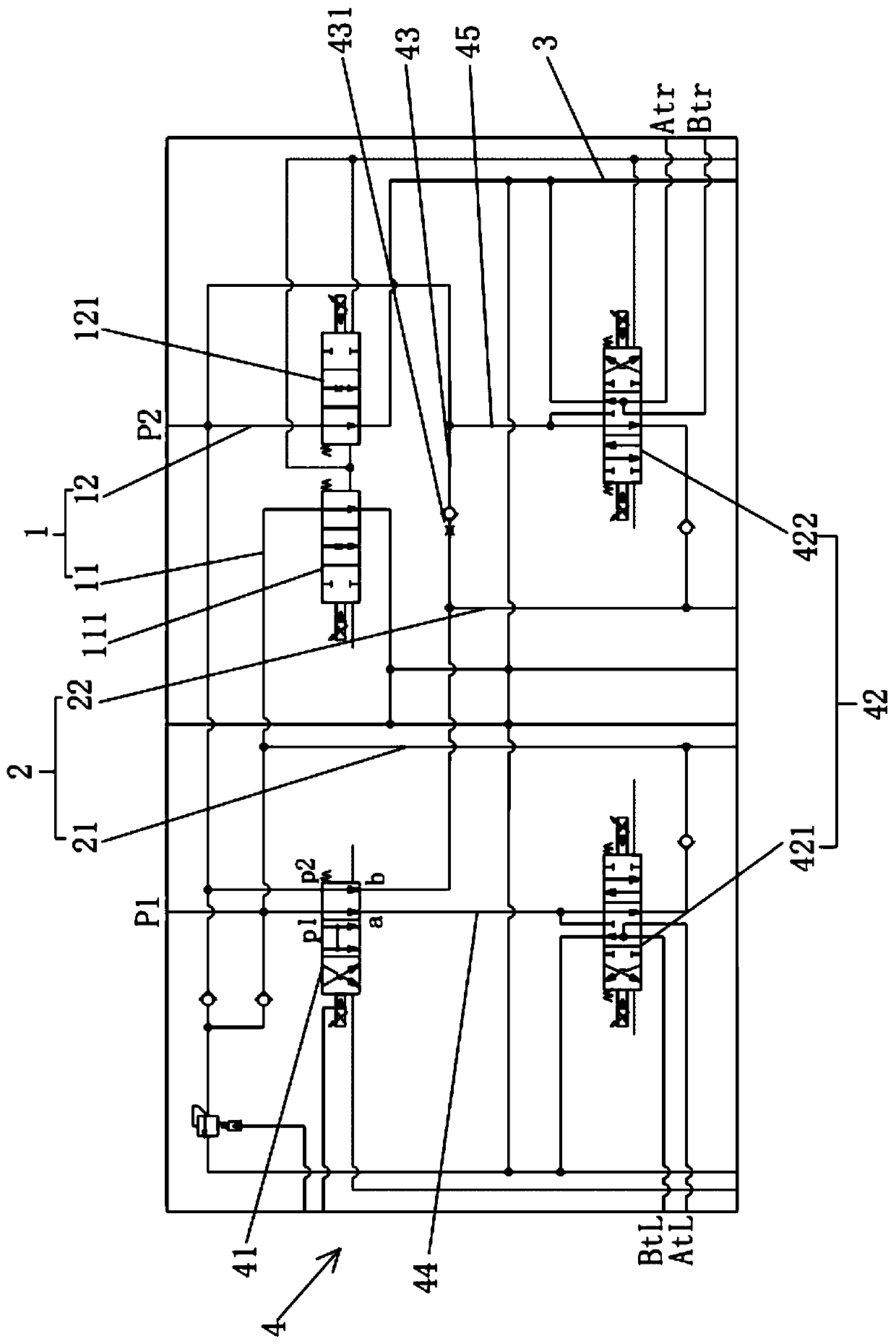

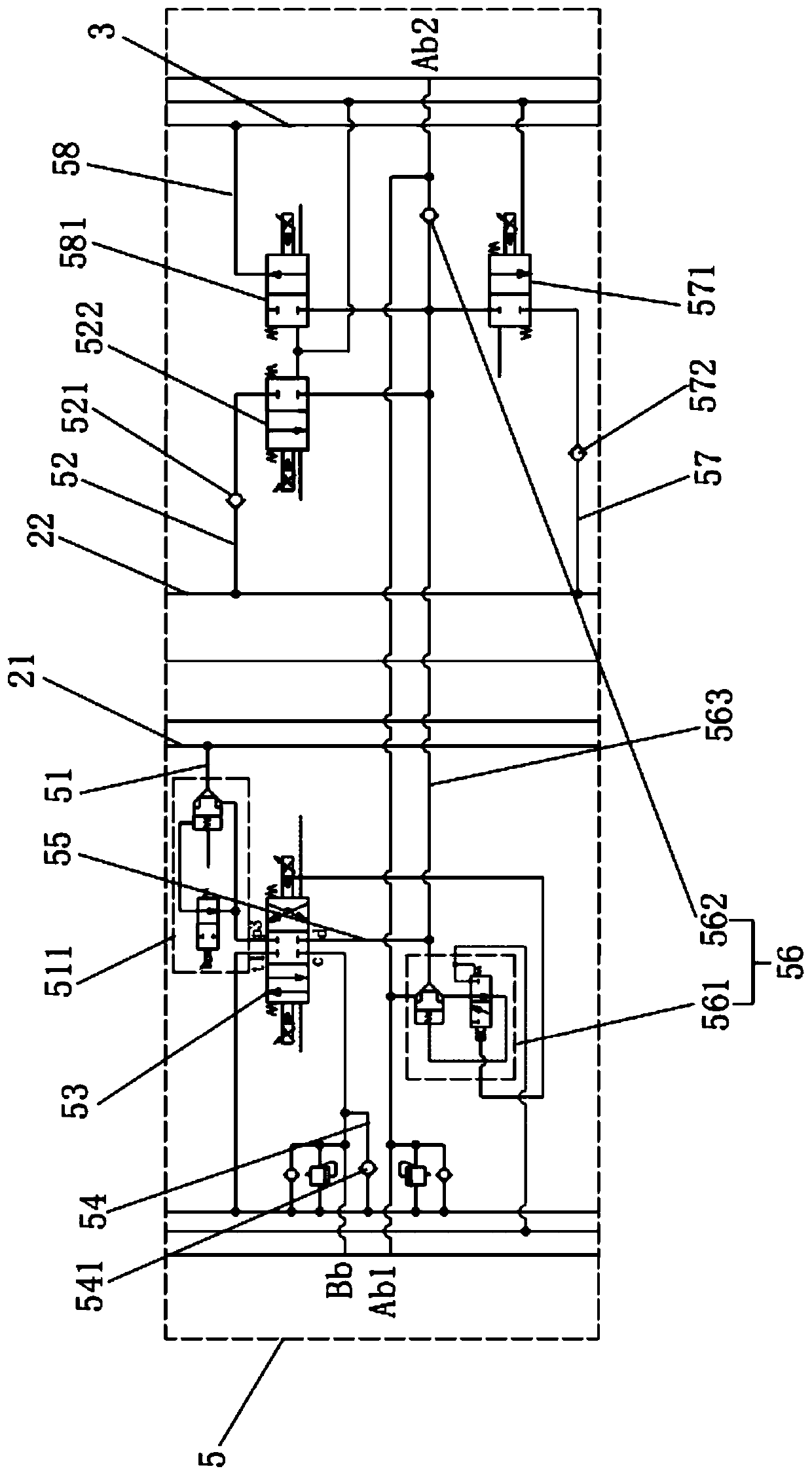

Hydraulic control device of working machine

PendingCN110541854APlay the role of speed regulationQuick responseServomotor componentsMechanical machines/dredgersHydraulic pumpControl valves

The invention relates to the field of hydraulic control, in particular to a hydraulic control device of a working machine. The hydraulic control device of the working machine comprises at least one hydraulic pump, at least one hydraulic actuator, at least one control valve and at least one oil discharging oil path, wherein the at least one hydraulic pump is used for spraying out working oil, the at least one hydraulic actuator is operated through the working oil supplied from the at least one hydraulic pump, the at least one control valve is arranged for each hydraulic actuator and conduct operation on the supply of the working oil from the hydraulic pump to the corresponding hydraulic actuator so as to correspondingly control the actions of the hydraulic actuators, the at least one oil discharging oil path is arranged for each hydraulic pump, the working oil pumped by each hydraulic pump can be directly returned through the oil discharging oil paths, the oil discharging oil paths areprovided with oil discharging valves, and the oil discharging valves control the connection and disconnection and oil flux of the oil discharging oil paths. The technical problems that in the prior art, the bypass throttling is adopted for speed regulation control, the system oil paths are complex and the system response is low are solved.

Owner:JIANGSU HENGLI HYDRAULIC TECH CO LTD

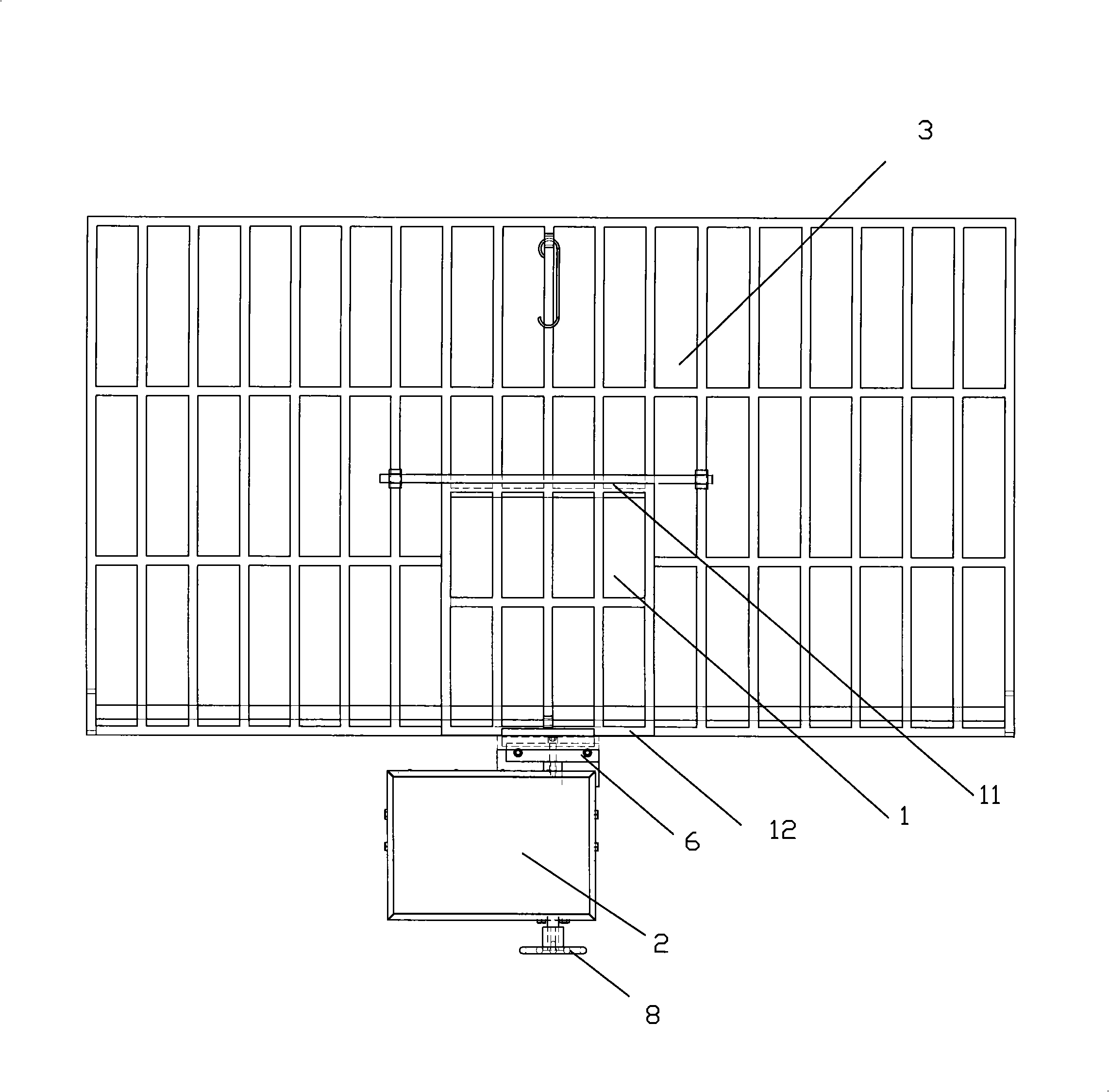

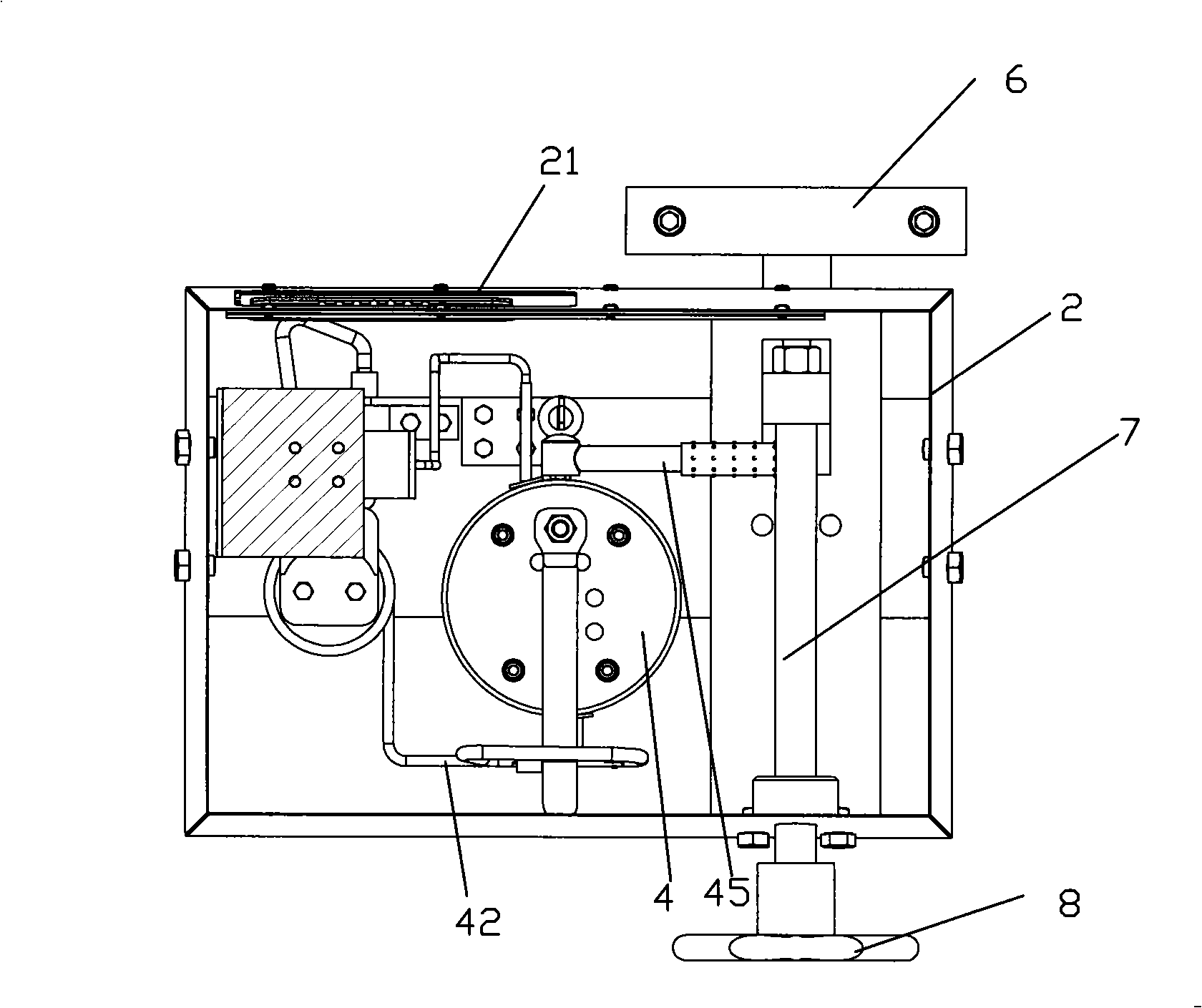

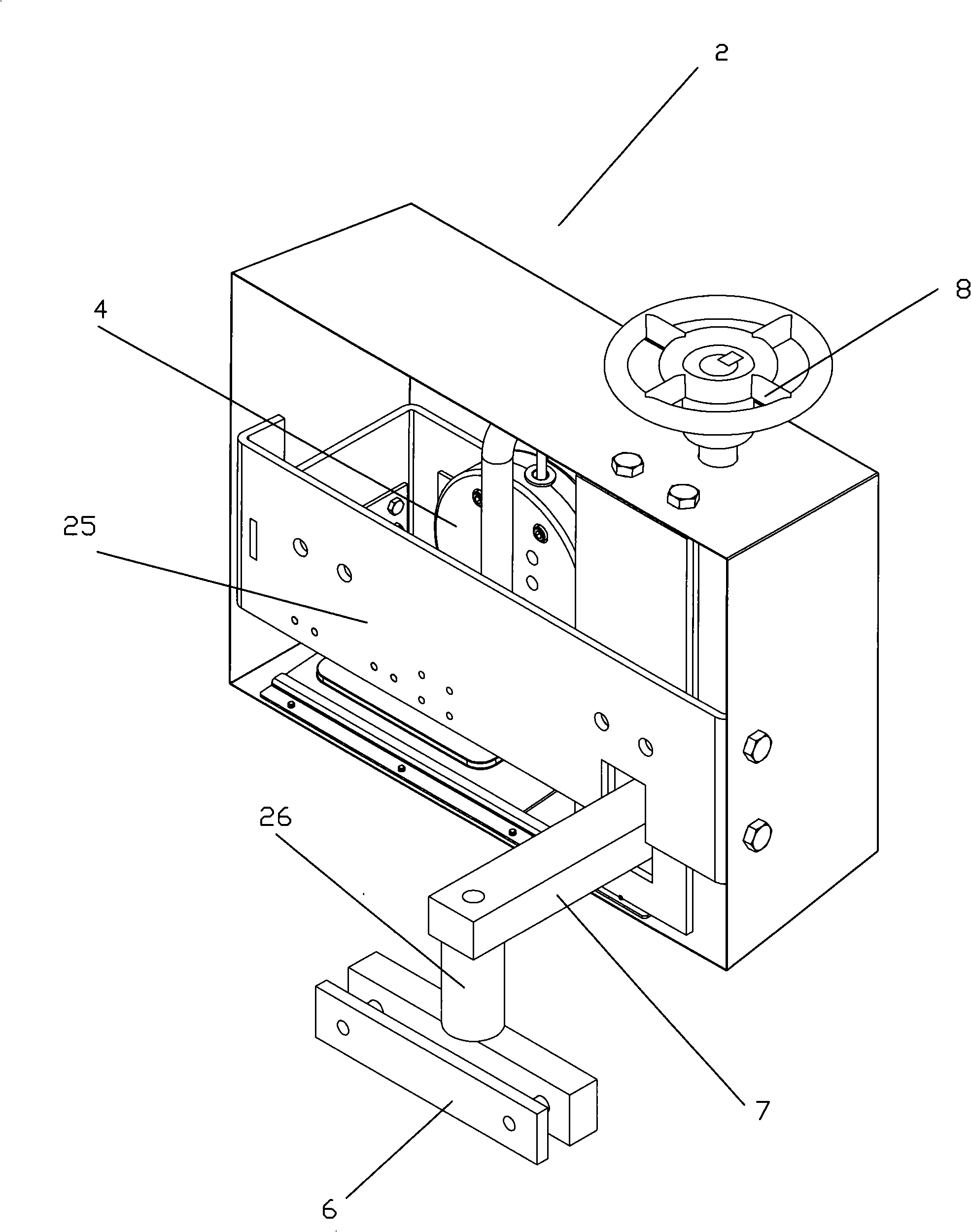

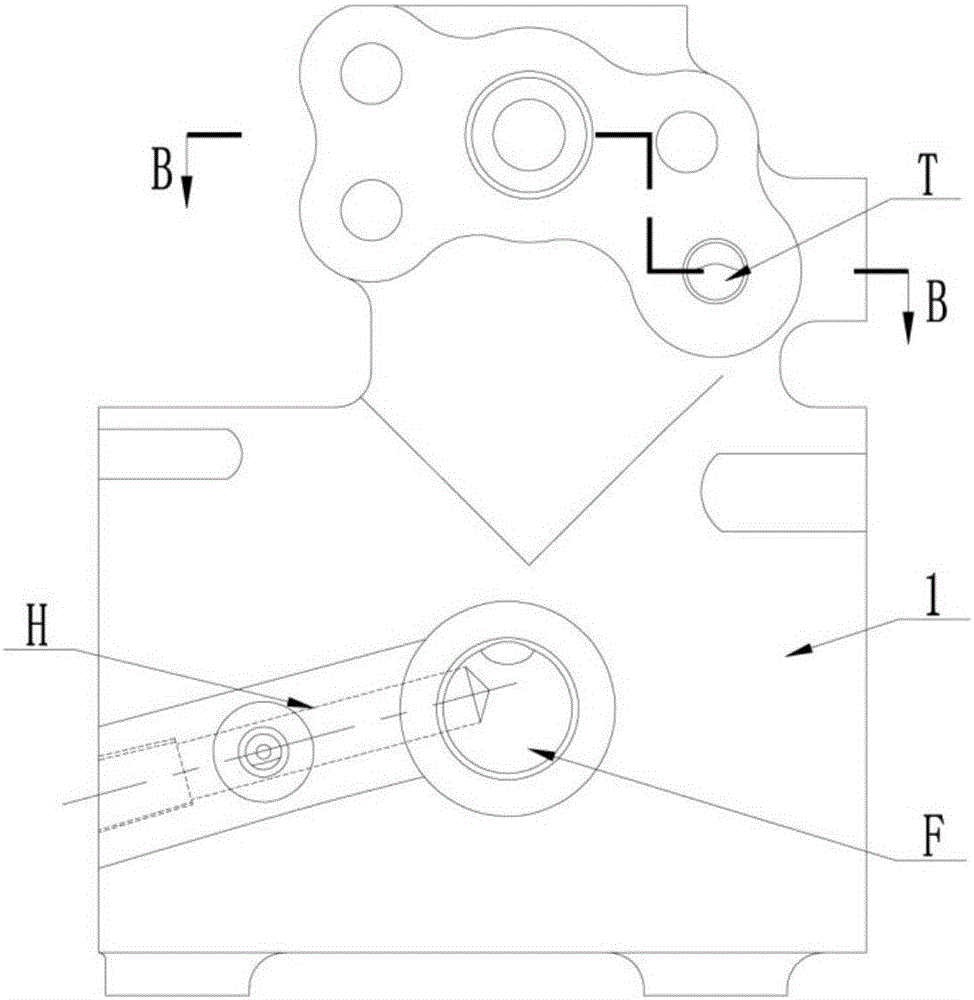

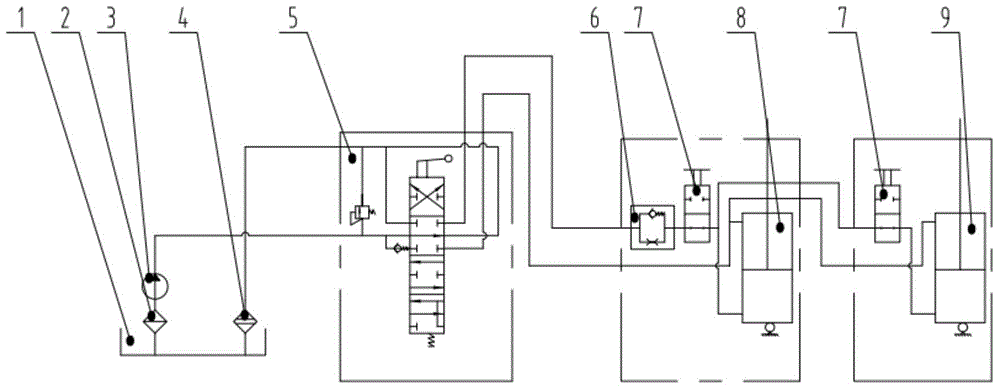

Forced compression device of low power roller tractor

InactiveCN104782258AControlled descent speedImprove protectionAgricultural machinesAdjusting devicesCompression devicePosition control

The invention discloses a forced compression device of a low power roller tractor. The device comprises a lifter, a hydraulic oil cylinder is arranged in the lifter, the lifter is connected with a lifting rod, the lower end of the lifting rod is hinged to a lower link, the device further comprises an oil absorption filter, an oil absorption gear pump, an oil return filter, a floating multiway valve, a right oil cylinder and a left oil cylinder, one end of the oil absorption gear pump is connected to the hydraulic oil cylinder through the oil absorption filter, the other end of the oil absorption gear pump is connected with the inlet path of the floating multiway valve, the floating multiway valve is connected with the right oil cylinder and the left oil cylinder in sequence, the upper end of the right oil cylinder and the upper end of the left oil cylinder are both hinged to the lifting rod, a loop of the floating multiway valve is connected to the hydraulic oil cylinder through the oil return filter, a position control operation handle is further installed on the lifter, and the operation handle is connected with the floating multiway valve through a Q-shaped support. By means of the device, the problems that it is difficult for the low power roller tractor to break ground in hard soil, and the ploughing depth is shallow are solved.

Owner:SHANDONG CHANGLIN DEUTZ FAHR MACHINERY

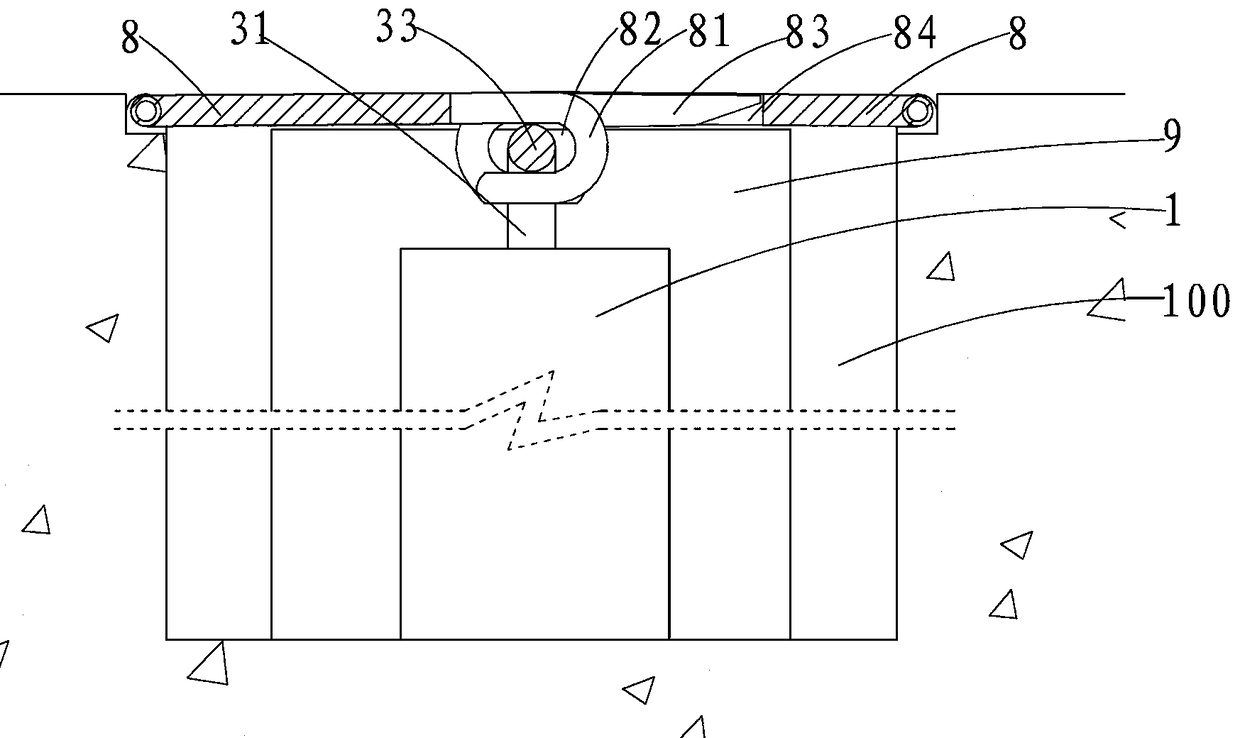

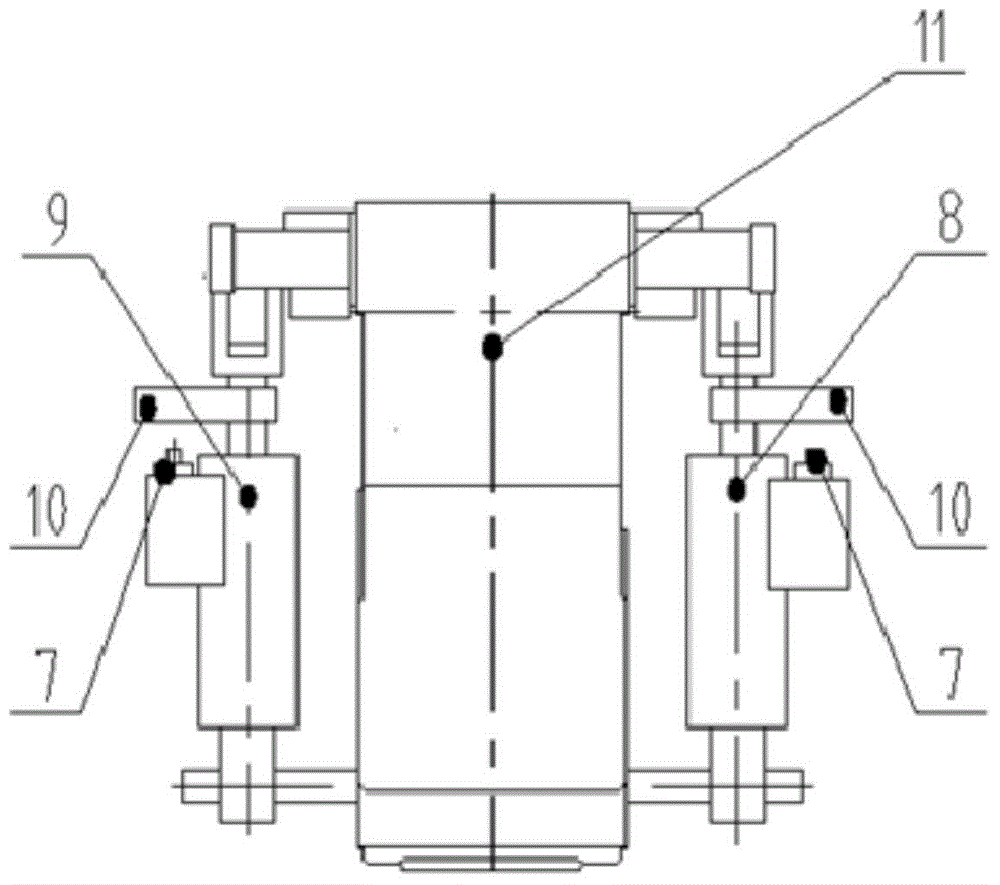

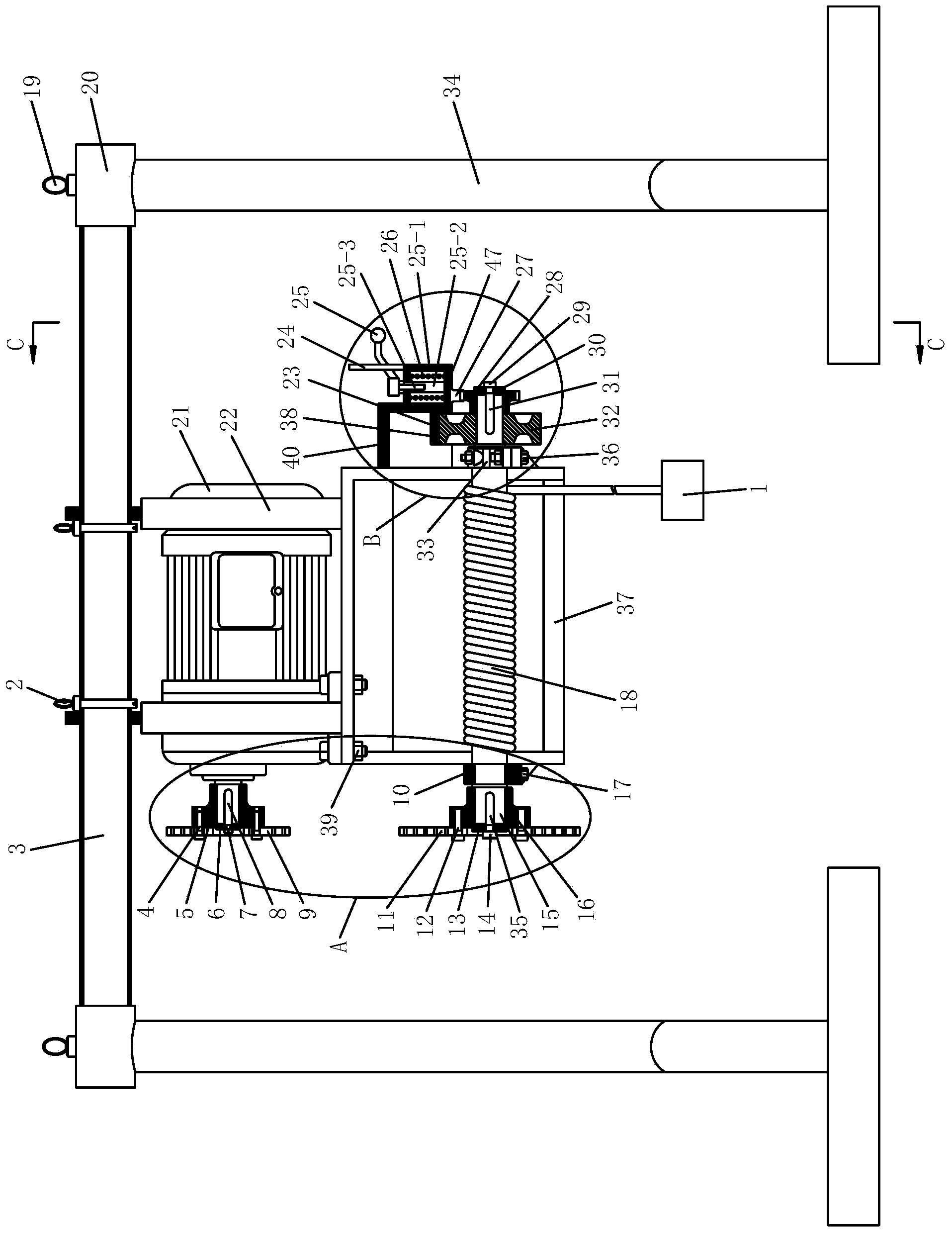

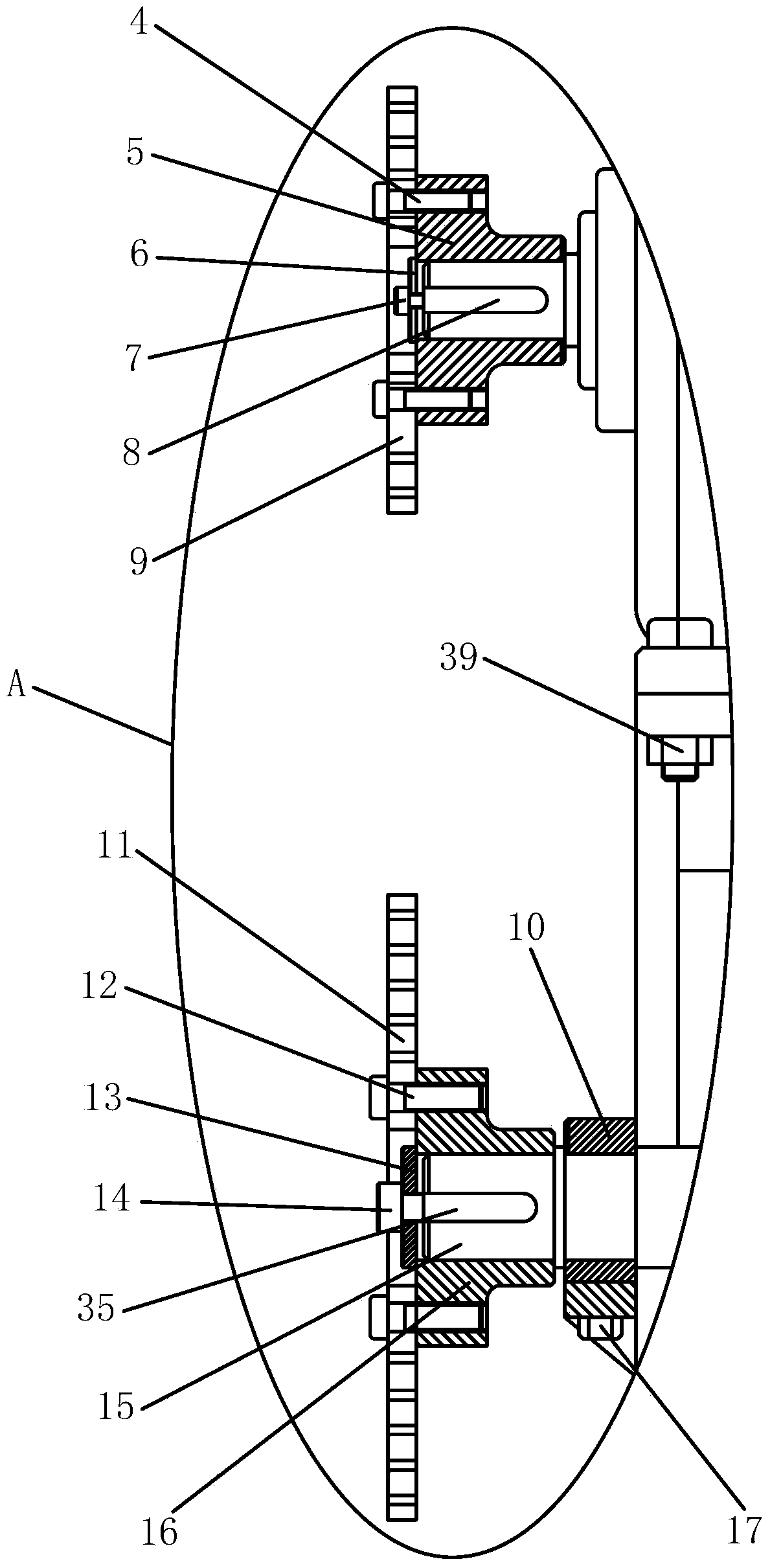

Farm-oriented portable submersible pump hoister

The invention discloses a farm-oriented portable submersible pump hoister which comprises two supporting frames, a hoisting motor, a motor fixing frame, an rolling shaft, a friction braking device and a rachet braking device. The friction braking device and the rachet braking device are arranged on the right side of the motor fixing frame. Upper ends of the two supporting frames are connected through a supporting beam. The hoisting motor is arranged at the top of the motor fixing frame. The motor fixing frame is fixedly arranged between the two supporting frames and is located under the supporting beam. The motor fixing frame is connected with the supporting beam through a pull plate. A driving chain wheel flange is arranged on an output shaft of the hoisting motor. A driving chain wheel is arranged on the outer side of the driving chain wheel flange. The rolling shaft is rotatably arranged on the lower portion of the motor fixing frame. A driven chain wheel flange is arranged at the left end of the rolling shaft. A driven chain wheel is arranged on the outer side of the driven chain wheel flange. The driven chain wheel is connected with the driving chain wheel through a chain. A steel wire rope is wound on the rolling shaft. The farm-oriented portable submersible pump hoister enables a submersible pump to be hoisted to certain height conveniently, can control the descending speed of the submersible pump, and is convenient to manufacture and low in manufacture cost.

Owner:CHANGAN UNIV

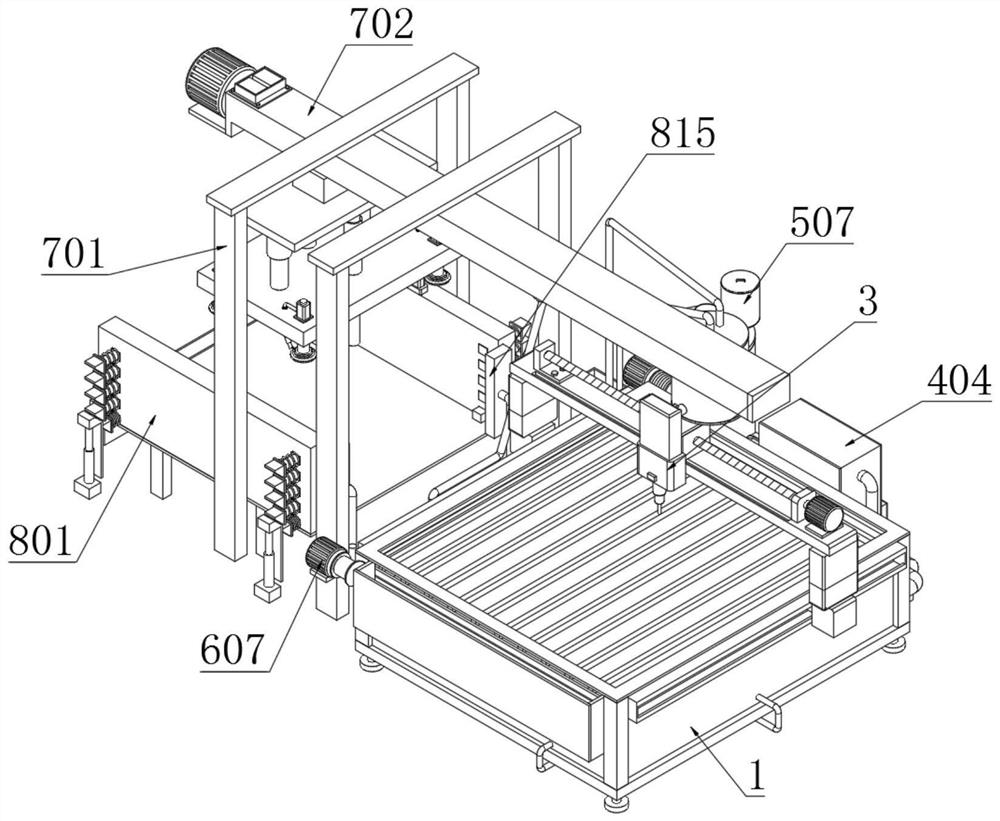

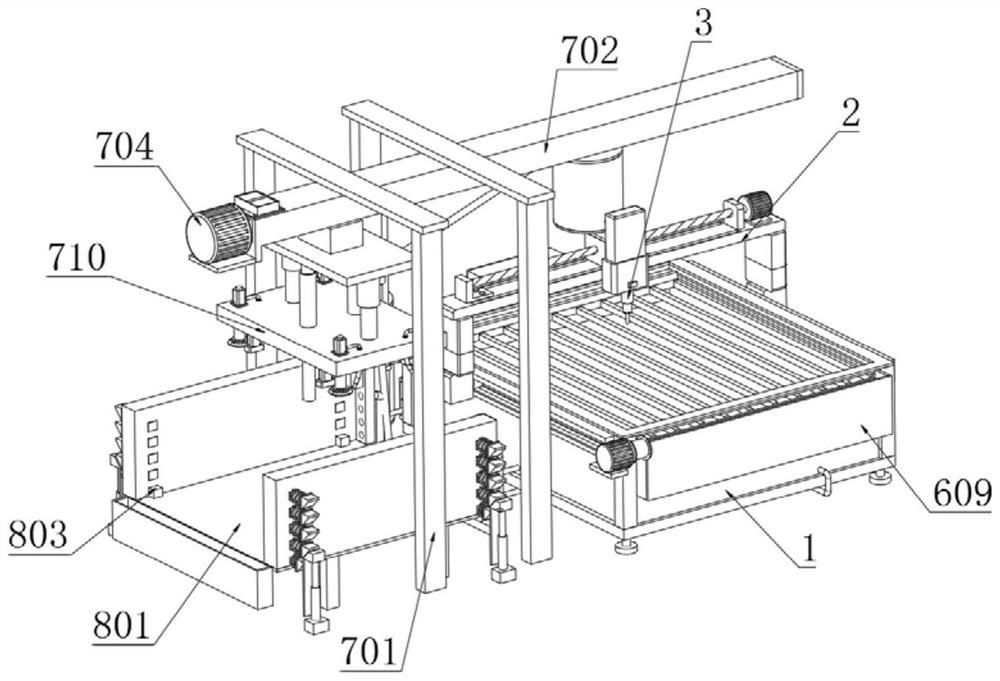

Automatic numerical control machine tool for precision machining

InactiveCN112621570AScientific and reasonable structureEasy to useBlast gunsAbrasive feedersNumerical controlWater flow

The invention discloses an automatic numerical control machine tool for precision machining. The automatic numerical control machine tool for precision machining is characterized in that a drainage pump is fixedly installed at the bottom end of a separation box body, one end of the drainage pump is fixedly connected with a three-way connector, one end of the three-way connector is connected with a connecting water pipe through hot melting, and a four-way connector is fixedly installed at one end of the connecting water pipe; and connecting branch pipes are connected to one end and two sides of the four-way connector through hot melting, a uniform distribution box is fixedly installed at one end of each connecting branch pipe, and drainage holes are formed in the middle of each uniform distribution box at equal intervals. According to the automatic numerical control machine tool, mixed liquid is pumped into the separation box body for separation, separated water is drained into a cutting groove through the uniform distribution boxes and the drainage holes, the discharged water generates a certain water flow impact force, and the uniform distribution boxes on the two side parts of the cutting groove form a certain included angle, so that the water flow is kept impacting in the direction of extracting the mixed liquid, scraps generated by cutting and abrasives used for cutting can be discharged out of the cutting groove along with the water flow, and the scraps generated by cutting and the abrasives used for cutting are prevented from being deposited.

Owner:韦立有

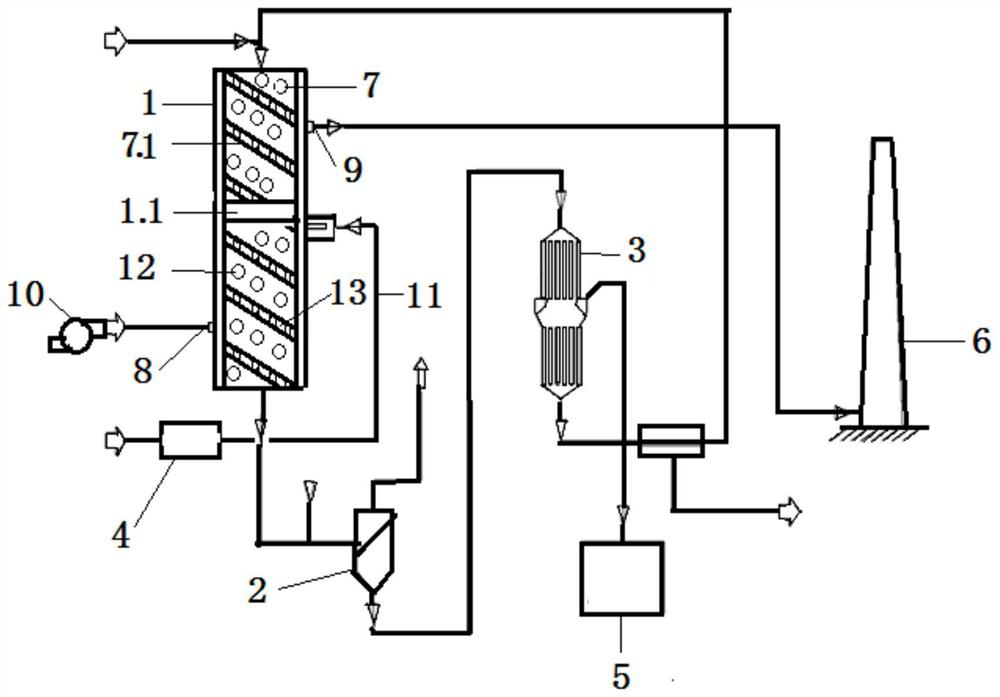

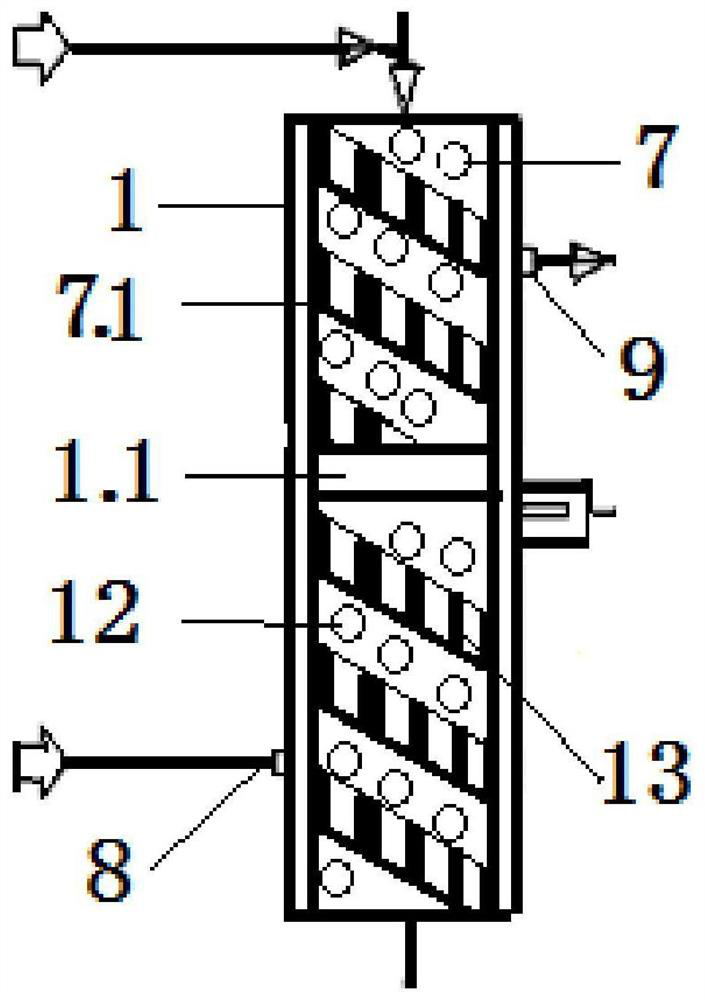

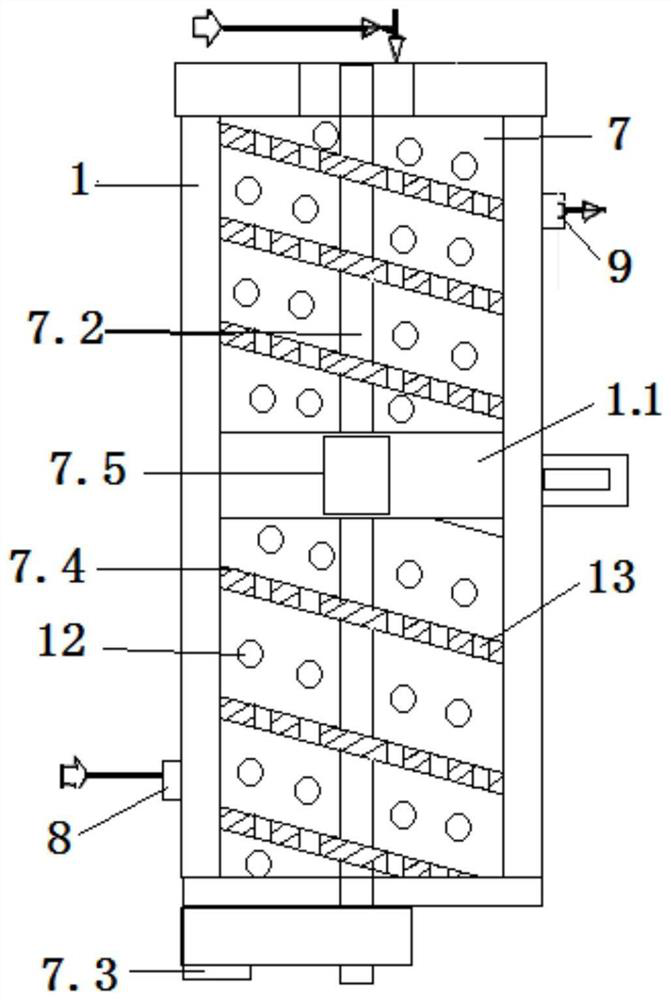

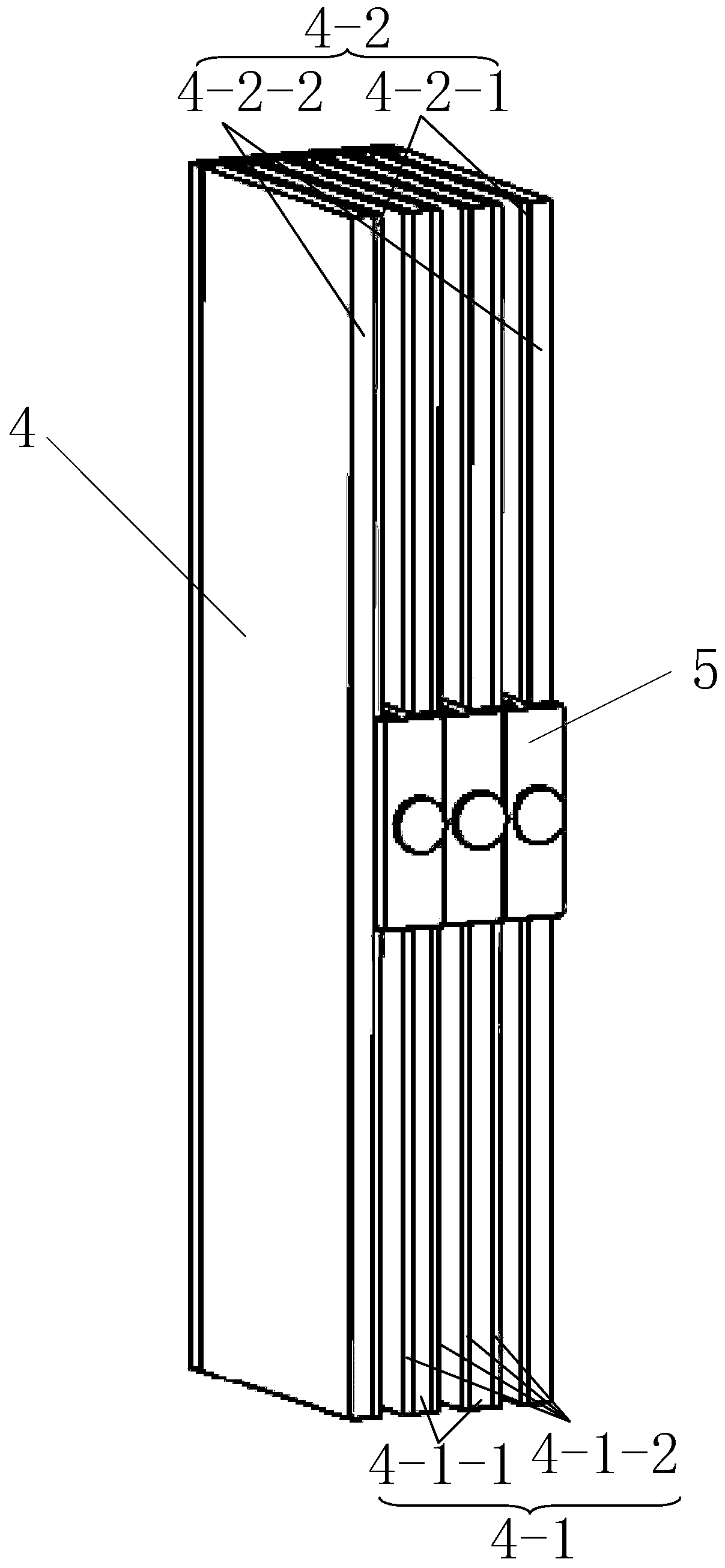

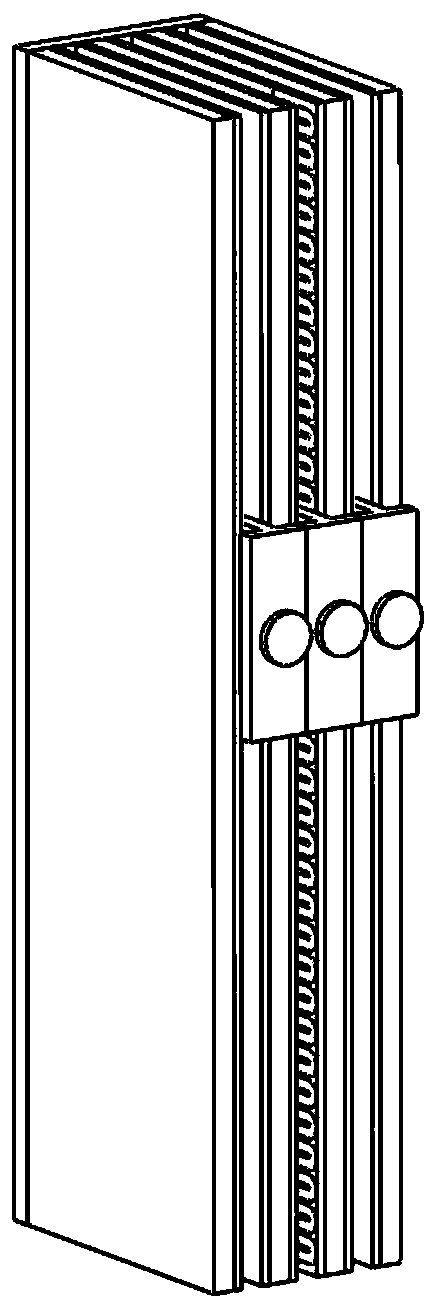

Integrated desulfurization and denitrification system for activated carbon

PendingCN113441007ALower the altitudeExtended absorption timeGas treatmentDispersed particle separationActivated carbonFlue gas

The invention discloses an integrated desulfurization and denitrification system for activated carbon. The integrated desulfurization and denitrification system comprises a booster fan, an adsorption tower, an activated carbon conveying device, an activated carbon desorption tower, an ammonia water supply device, an acid making device and a chimney which are connected in sequence, wherein a spiral conveying channel for activated carbon is arranged in the adsorption tower and is vertically arranged; a transverse smoke inlet channel communicating with the spiral conveying channel is arranged on one side of the adsorption tower; a transverse smoke exhaust channel communicating with the spiral conveying channel is arranged on the other side of the adsorption tower; the transverse smoke inlet channel is connected with the booster fan through a pipeline; the transverse smoke exhaust channel is connected with the chimney through a pipeline; and an ammonia gas conveying pipeline communicating with the spiral conveying channel is also arranged at the middle upper part of one side of the adsorption tower. According to the integrated desulfurization and denitrification system for activated carbon, activated carbon can fall at a constant speed in the absorption tower, time for absorption between the activated carbon and flue gas can be prolonged, a contact area between the activated carbon and flue gas is increased, and the overall height of the absorption tower can be reduced.

Owner:河北领阔环保科技有限公司

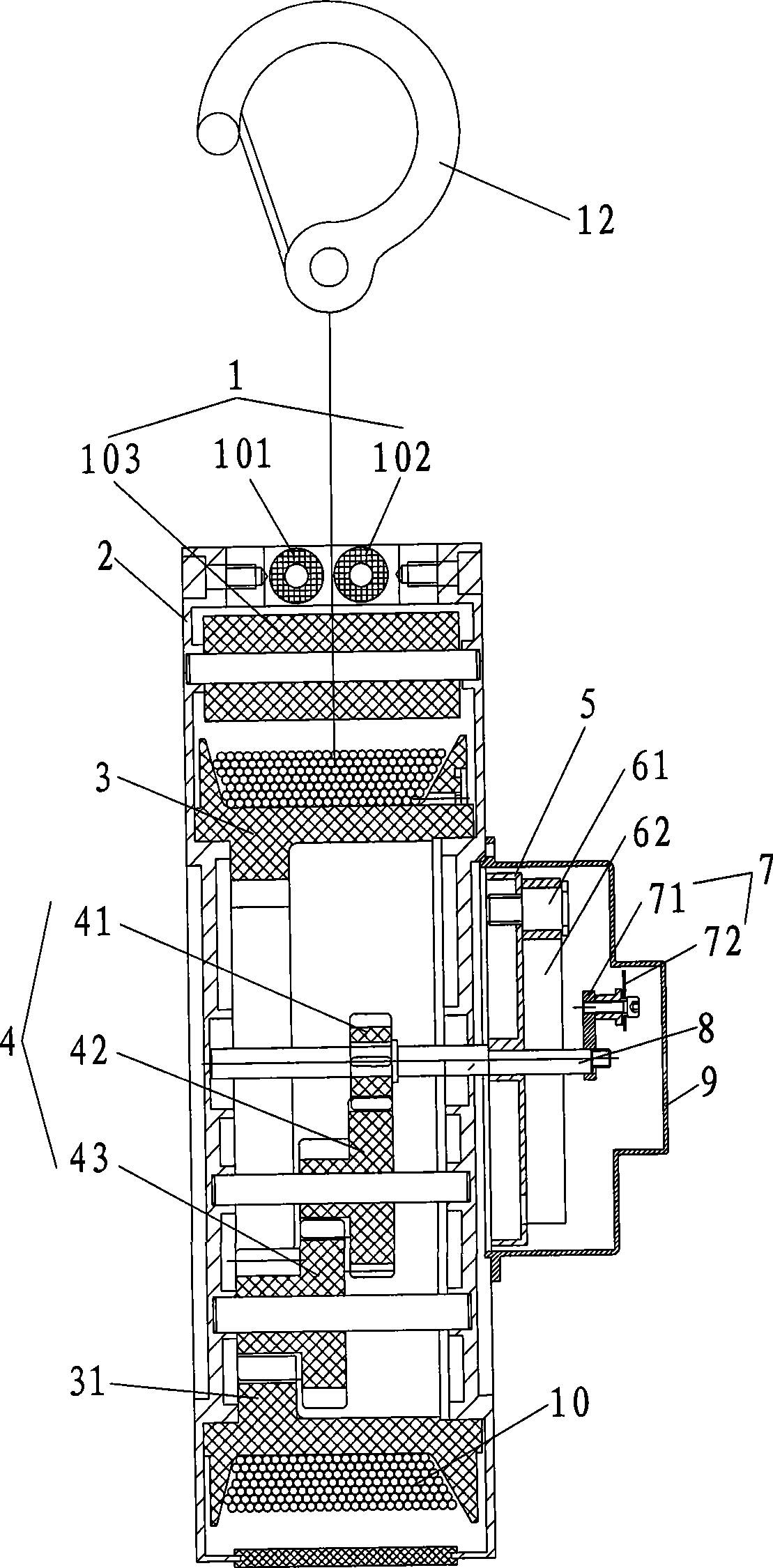

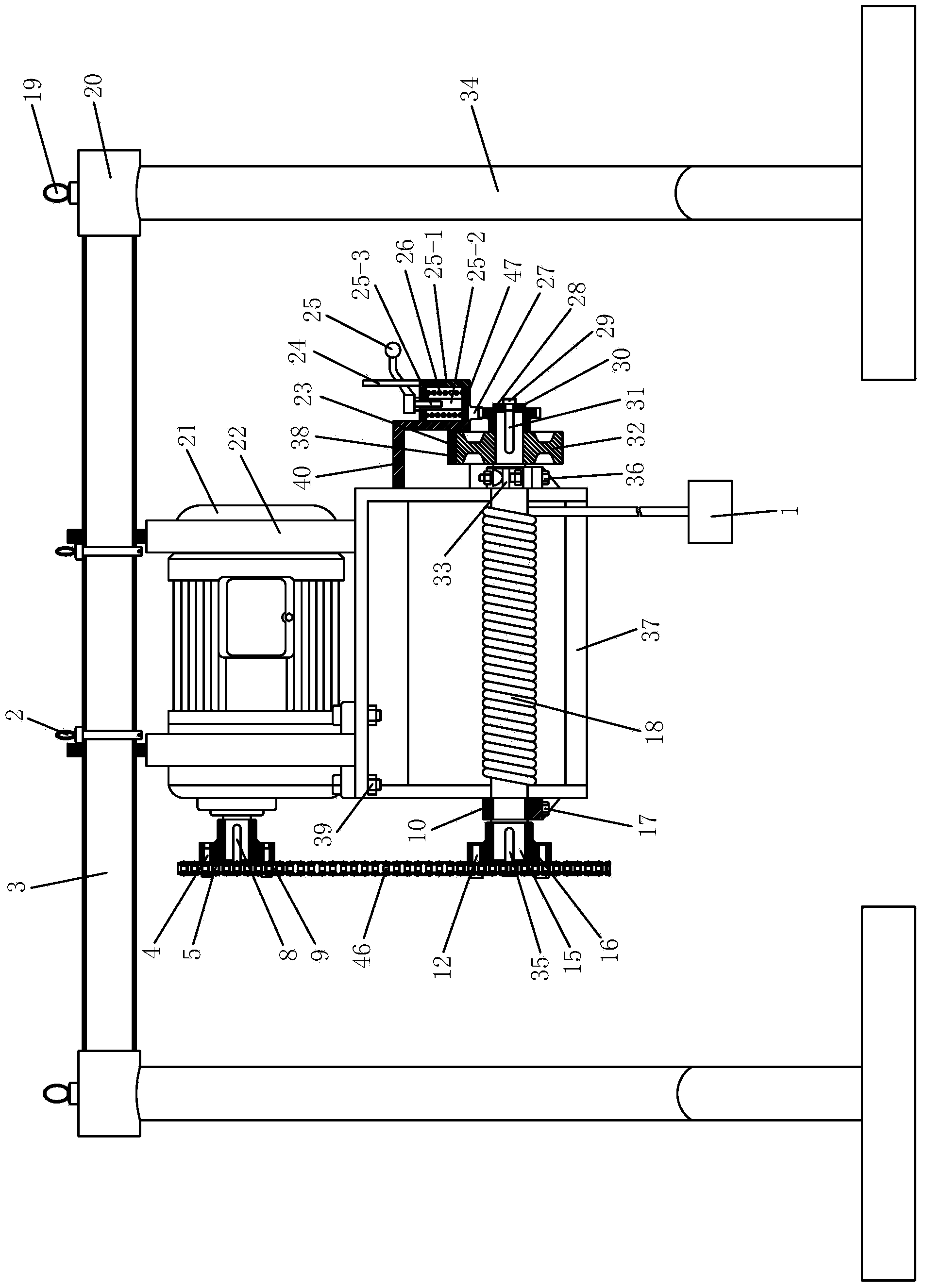

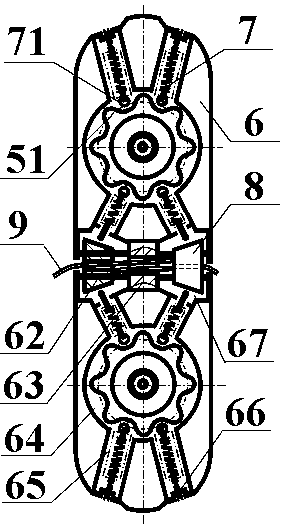

Descending machine for absorbing energy through damping element

ActiveCN110115809AExtended service lifeControlled descent speedBuilding rescueForeign matterEnergy absorption

The invention relates to a descending machine for absorbing energy through a damping element, and belongs to the technical field of firefighting and motion equipment. A lower rope wheel (3) and an upper rope wheel (5) butt against rubber springs (7) through grooves, so that the rubber springs (7) extend and absorb kinetic energy of personal descending. The rubber springs (7) butt against the lowerrope wheel (3) and the upper rope wheel (5) through rollers (71), and relatively roll to prevent the sliding friction with ropes (4), so that the service life of the ropes (4) is prolonged. The rubber springs (7) are wrapped by rubber layers, and are clamped with a secondary plate heat dissipating gap (61) and a main plate heat dissipating gap (12) through the rubber layers to prevent invasion and blockage of foreign matters, so that the safety and the reliability can be guaranteed; and the heat dissipating parts leave away from the lower ropes (4) for full heat dissipation. The damping energy absorption effect of the rubber springs (7) is adjusted through adjusting screws (66) and control ropes (9) to prevent acute fluctuation of the descending speed and to prevent the panic.

Owner:SHANDONG INST OF BUSINESS & TECH

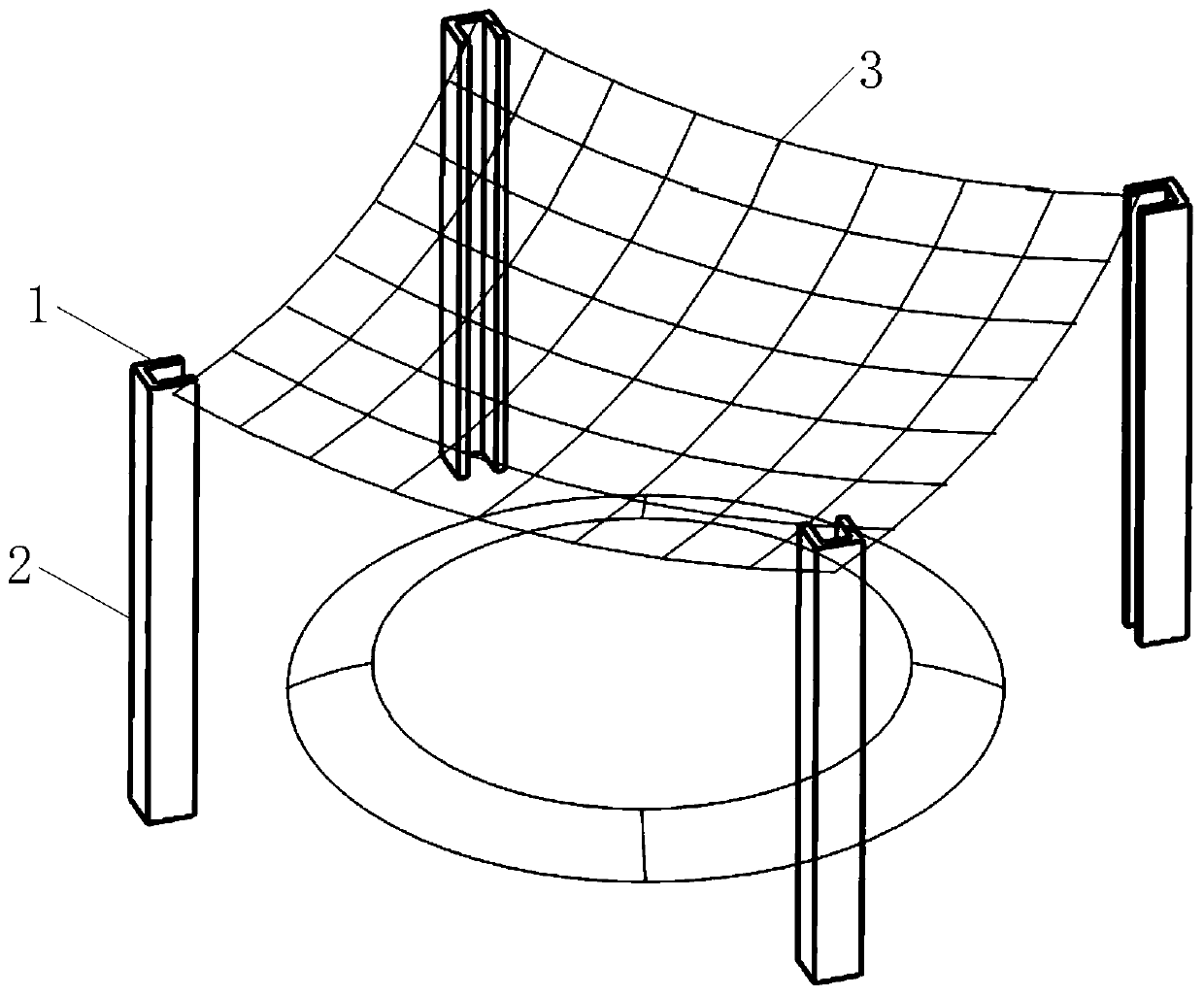

Spacecraft recycling linear electromagnetic damping device

ActiveCN110185732AControlled descent speedSlow down the landing speedCosmonautic ground equipmentsSystems for re-entry to earthStatorMagnet

The invention provides a spacecraft recycling linear electromagnetic damping device, relates to the field of spacecraft recycling, and aims at solving disadvantages of parachute landing systems that are conventionally used as spacecraft recycling devices, like large diameter and large weight of the parachute surface, and occupying spacecraft load resources. When preparing recycling, a plurality ofevenly arranged support frames support recycling nets, and net corners of the recycling nets are respectively connected with linear electromagnetic damper movers of the support frames. When the spacecraft falls into the recycling nets, the linear electromagnetic damper movers are pulled downward; meanwhile, permanent magnets on stators cut third conductor plates on the movers to generate magneticfields; and braking forces are generated to buffer the descent process of the spacecraft falling into the recycling nets and control the falling speed of the spacecraft. After the recycling process is completed, the movers and the recycling nets are lifted by drive coils integrated in the linear electromagnetic dampers to prepare for a next spacecraft recycling. The device is used for recycling aspacecraft.

Owner:HARBIN INST OF TECH

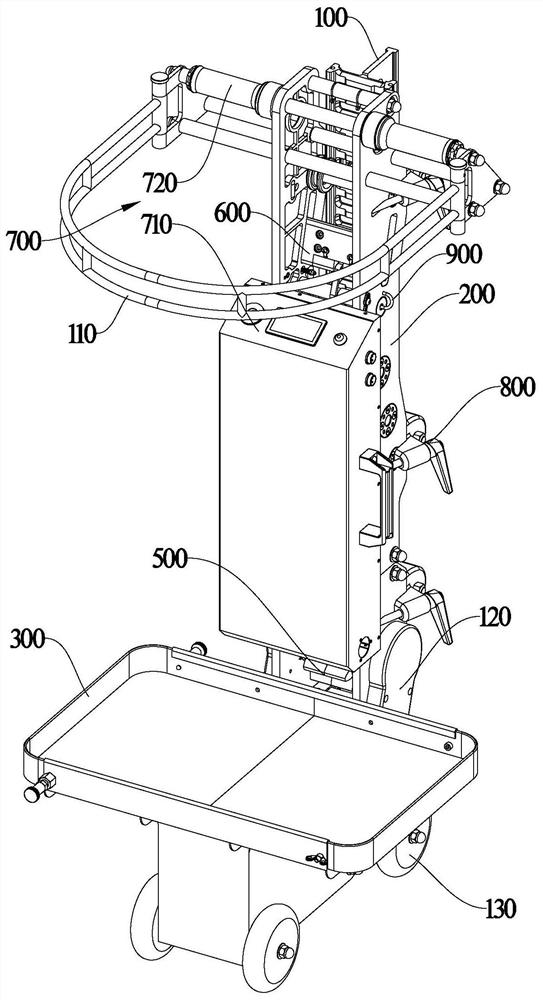

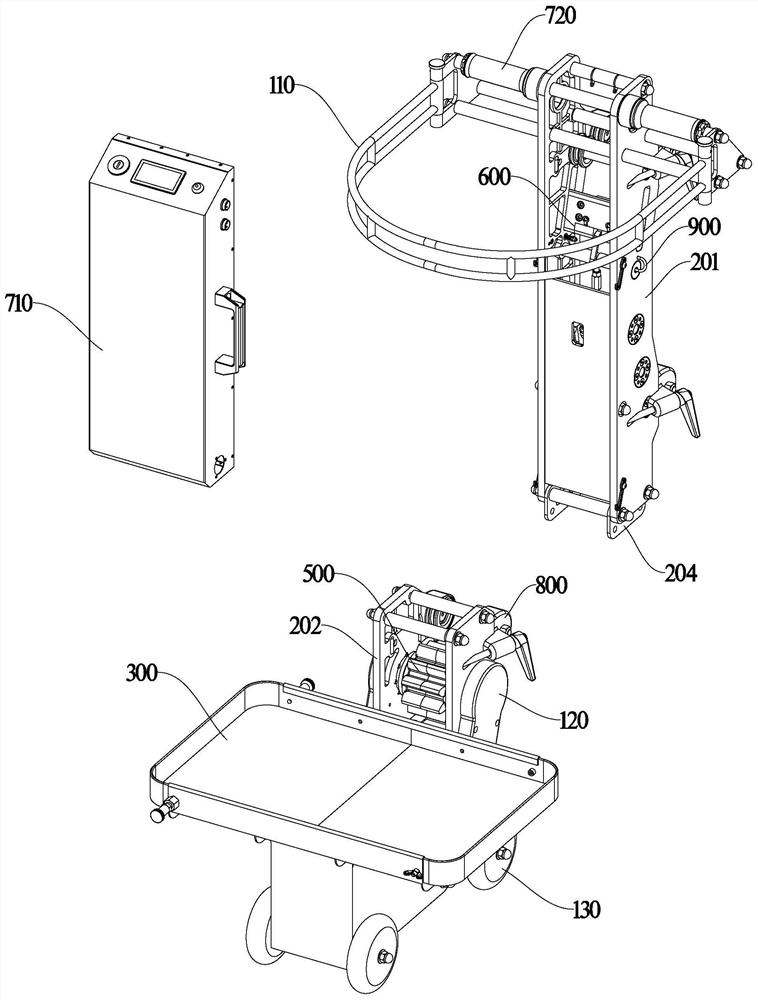

Lifting device

PendingCN111646386AConvenient area operationEasy to transportLifting framesStructural engineeringMechanical engineering

The invention provides a lifting device. The lifting device comprises a guide rail, a mounting rack, a loading platform, a power assembly, a lifting assembly, a locking assembly, a control assembly and a roller assembly; the roller assembly comprises fixed rollers and movable rollers, wherein multiple groups of the fixed rollers and the movable rollers are arranged on the mounting rack at intervals along the vertical direction; the fixed rollers are rotatably arranged at the inner side of the mounting rack, and are suitable for abutting against the front side of the guide rail; the movable rollers are arranged at the outer side of the mounting rack, and are suitable for abutting against the rear side of the guide rail; the fixed rollers and the movable rollers cooperate with each other torealize the horizontal limit and vertical movement of the mounting rack relative to the guide rail; and each movable roller comprises a rotating rod, a sliding block, a wheel body and a locking element. The lifting device provided by the invention has the advantages of being in modularized split arrangement, convenient in assembly and disassembly, safe and reliable, and stable in operation.

Owner:NINGBO TIANHONG POWER APPLIANCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com