Closed hydraulic circuit of hoisting winding engine

A hydraulic oil circuit, machine-closed technology, applied in the field of hydraulic oil circuit, can solve the problems of affecting the descending speed of the hoist and high oil temperature in the small cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

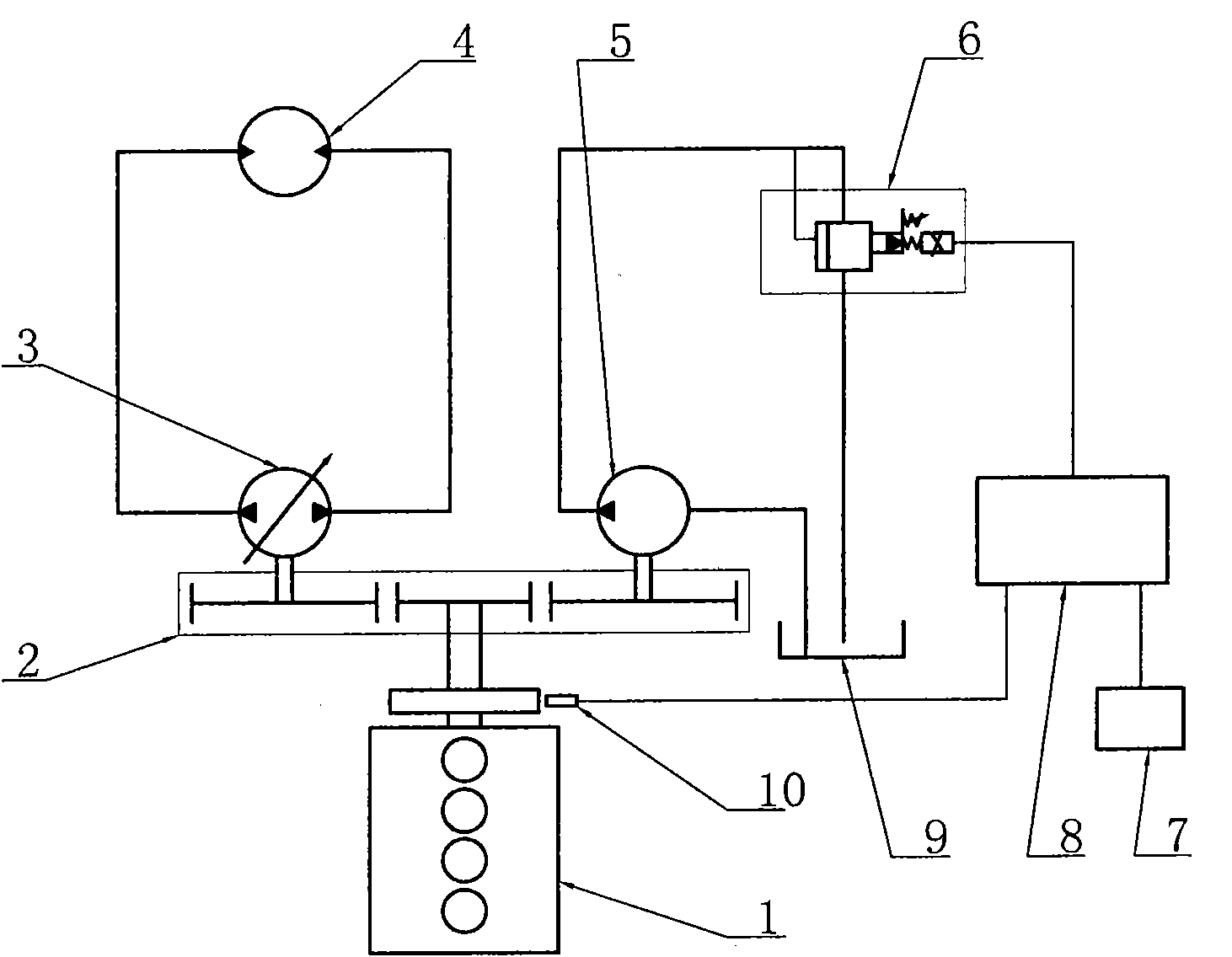

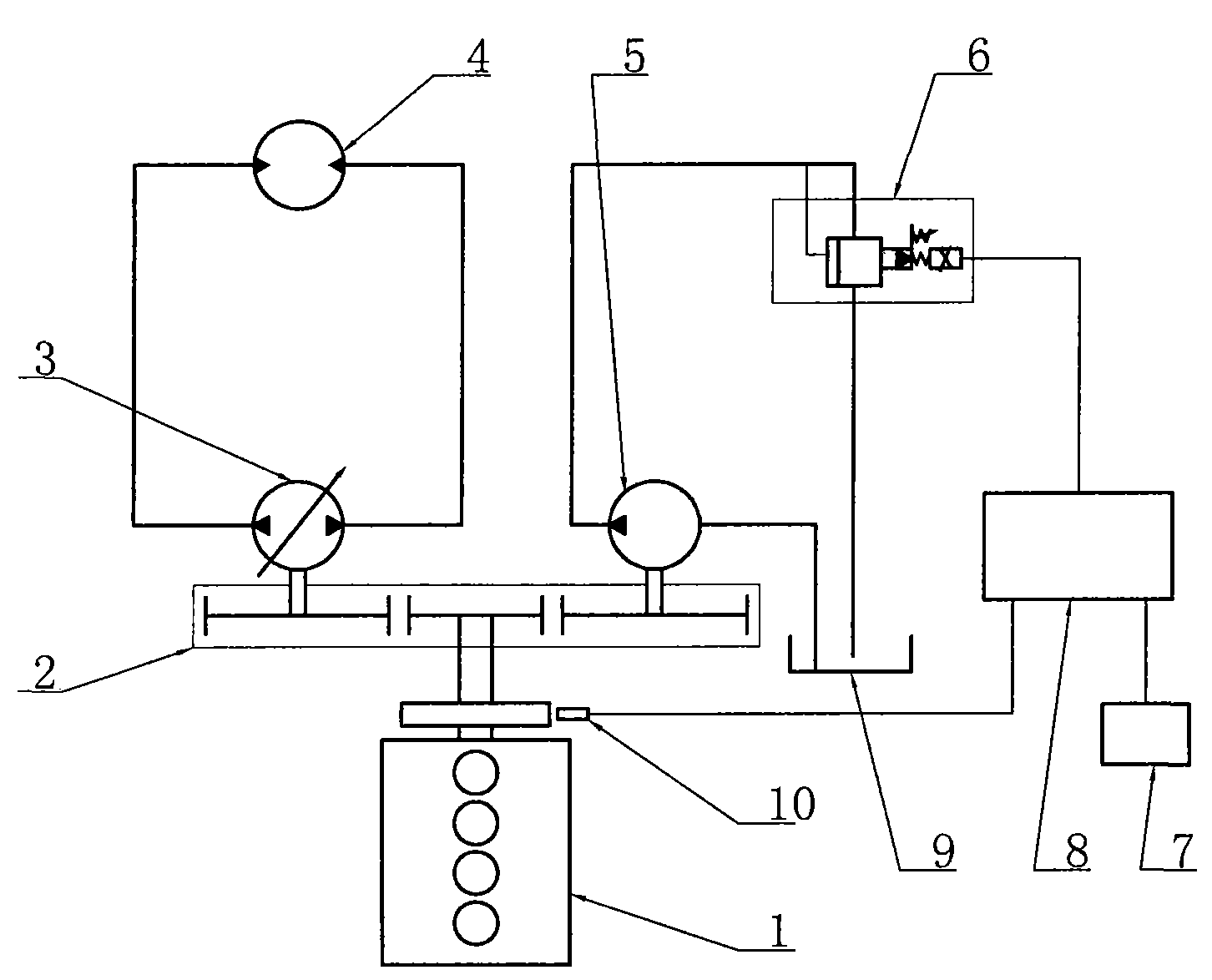

[0018] Such as figure 1 As shown, the brake hydraulic pump 5 is a quantitative hydraulic pump, and the overflow valve 6 is an electro-hydraulic proportional overflow valve. The overflow pressure is proportional to the current input to the pressure control terminal of the electro-hydraulic proportional overflow valve. The oil discharge port of the brake hydraulic pump 5 is connected to the hydraulic oil tank 9 through the relief valve 6 , and the pressure control terminal of the relief valve 6 is connected with the output terminal of the control unit 8 . The control unit 8 outputs instructions to the relief valve 6 according to the actual speed of the diesel engine 1 and the overspeed increment of the speed set by the speed controller 7 . When the control unit 8 detects that the actual rotational speed of the diesel engine 1 exceeds the preset rotational speed, and an overspeed increment occurs, the control unit 8 outputs current to the electro-hydraulic proportional overflow v...

Embodiment 2

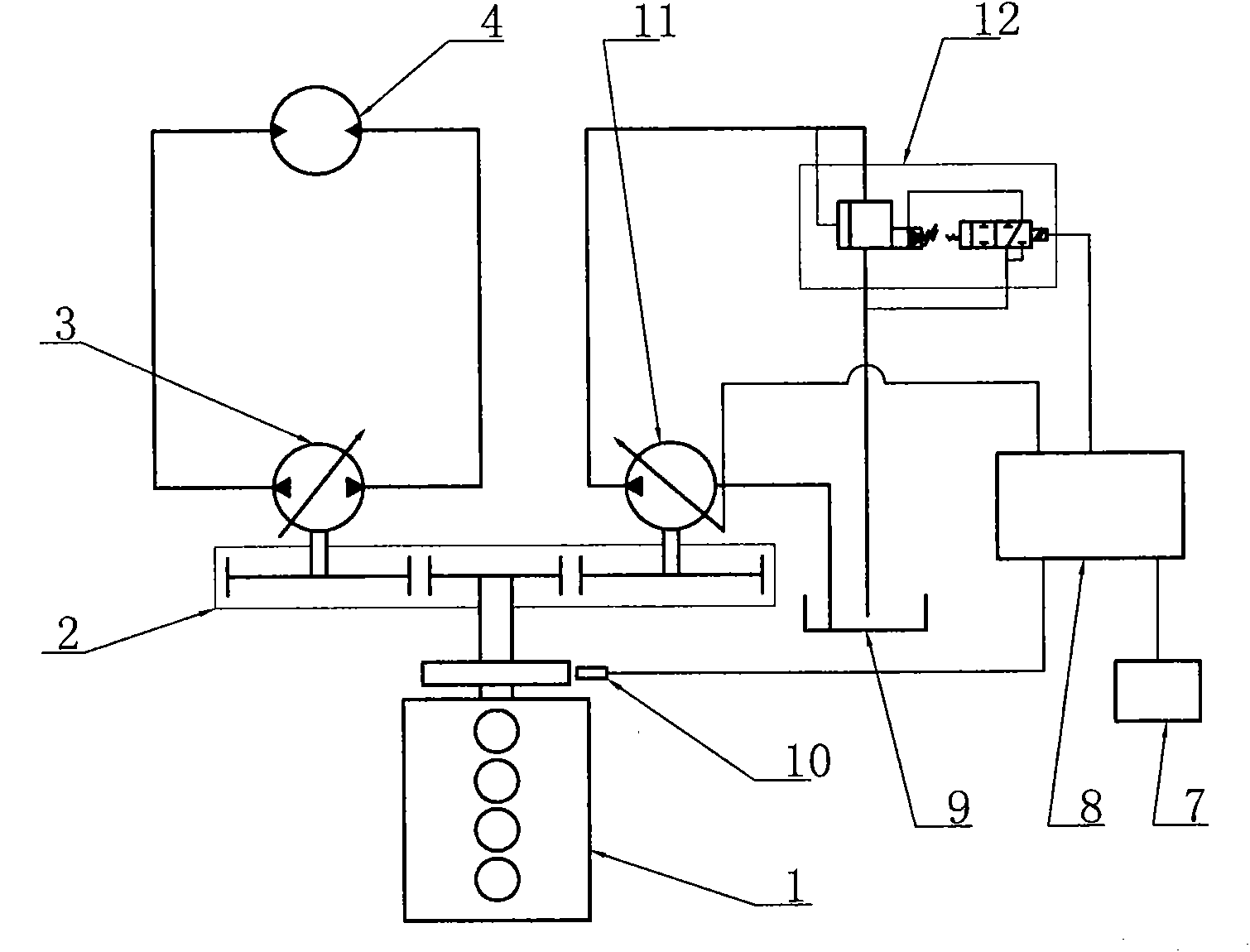

[0020] Such as figure 2 As shown, the brake hydraulic pump 5 adopts an electronically controlled proportional variable hydraulic pump 11 , and the control terminal of the electronically controlled proportional variable hydraulic pump 11 is electrically connected to the output port of the control unit 8 . The relief valve 6 adopts a common relief valve 12 with an unloading function. The displacement of the electronically controlled proportional variable hydraulic pump 11 is proportional to the current input to its control terminal; the control terminal of the electronically controlled proportional variable hydraulic pump 11 is connected to the output port of the control unit 8 . When the control unit 8 detects that the actual speed of the diesel engine 1 exceeds the set speed and an overspeed increment occurs, the control unit 8 outputs an instruction to the unloading overflow valve 12 to make the unloading overflow valve 12 reach the set pressure; At the same time, the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com