Integrated desulfurization and denitrification system for activated carbon

A desulfurization, denitrification and activated carbon technology, applied in the field of flue gas desulfurization and denitrification, can solve the problems of limited contact area, difficult to prolong the contact time between activated carbon and delayed contact, activated carbon blockage, etc., and achieve the effect of prolonging the adsorption time, reducing the height, and reducing the overall height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

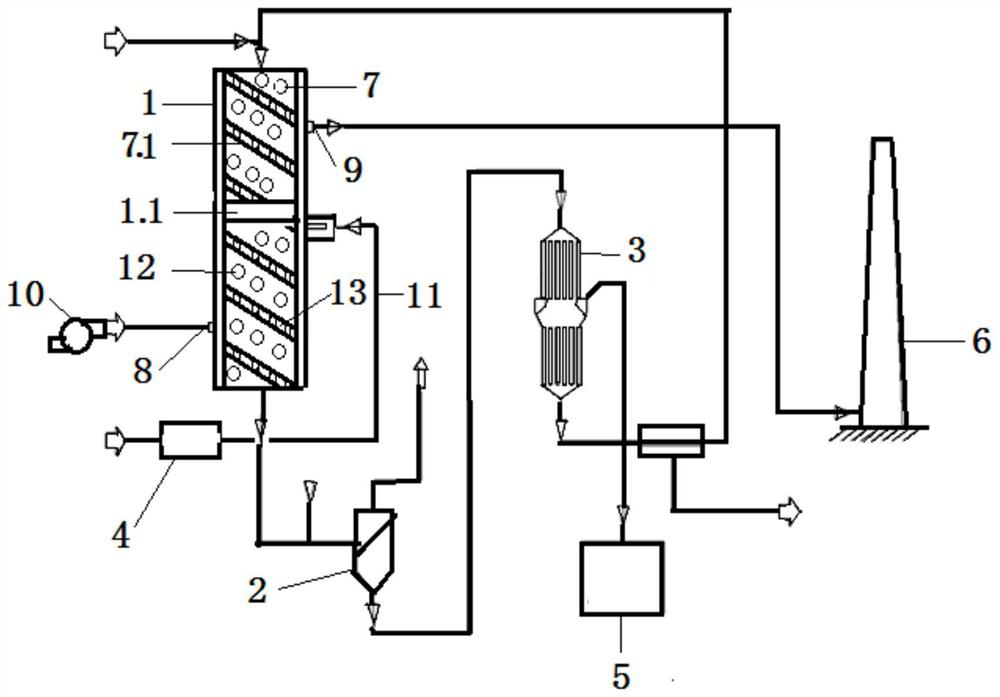

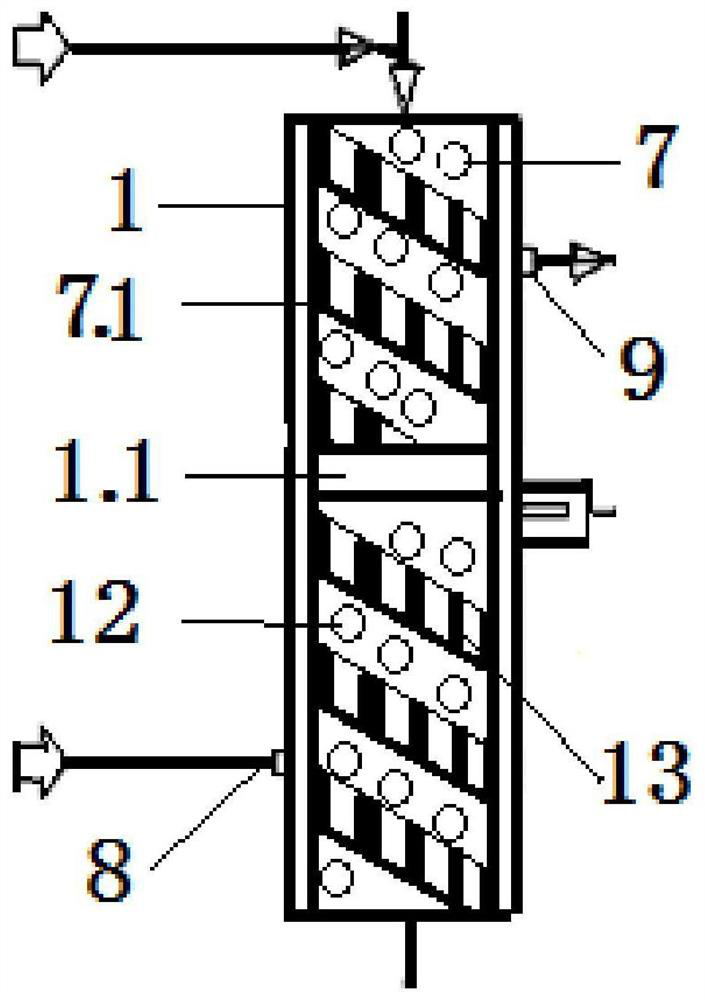

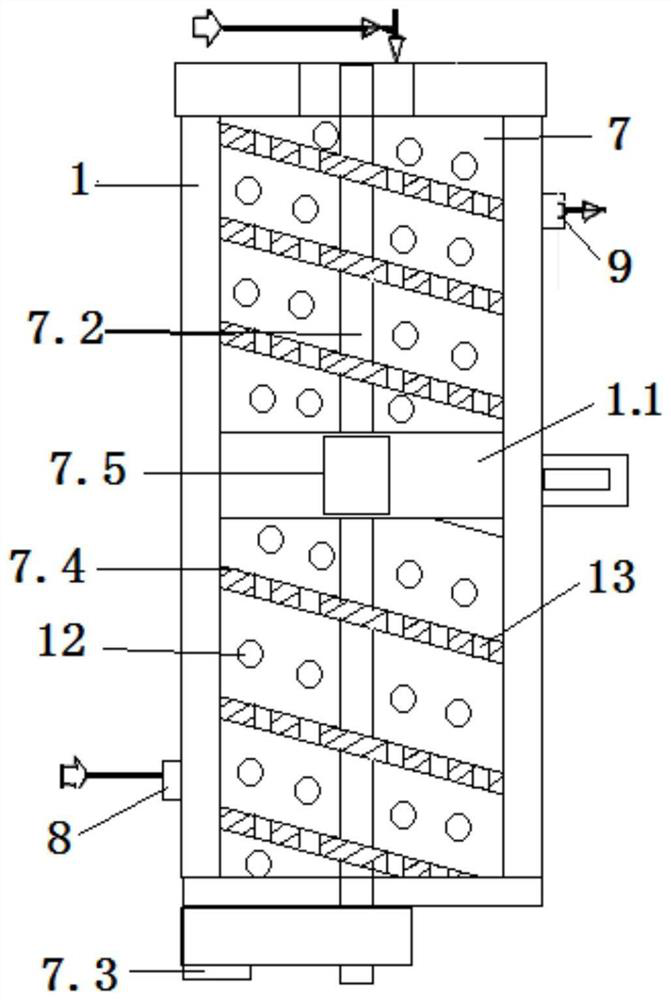

[0024] Such as figure 1 , 2 As shown, the present invention is an activated carbon integrated desulfurization and denitration system, the system includes a booster fan 10 connected in sequence, an adsorption tower 1, an activated carbon delivery device 2, an activated carbon analysis tower 3, an ammonia water supply device 4, and an acid production device 5 And the chimney 6, a spiral conveying channel 7 for activated carbon is provided in the adsorption tower 1, the spiral conveying channel 7 is vertically arranged, and a horizontal smoke inlet communicating with the spiral conveying channel 1 is provided on one side of the adsorption tower 1 Passage 8, on the other side of described adsorption tower 1, be provided with the horizontal exhaust passage 9 that communicates with spiral conveying passage 7, horizontal smoke inlet passage 8 is connected with booster blower 10 through pipeline, and horizontal smoke exhaust passage 9 is connected with pipeline through pipeline. The ...

Embodiment 2

[0027] Such as figure 1 , 2 As shown, on the basis of Example 1, in order to facilitate the smooth entry of ammonia into the absorption tower 1, and to obtain sufficient contact with the activated carbon 12 by flowing upward smoothly, a further preferred embodiment of the present invention is that the spiral The plate 7.1 is divided into upper and lower sections in the adsorption tower 1. A cavity section 1.1 is provided between the upper spiral plate section and the lower spiral plate section. The position of the cavity section 1.1 corresponds to the installation position of the ammonia gas delivery pipeline 11.

Embodiment 3

[0029] Such as figure 1 , 2 As shown, on the basis of Example 2, in order to facilitate the increase of the contact area and contact time between the flue gas and the activated carbon 12, the activated carbon 12 can fully absorb the SO in the flue gas 2 and NO X , the further preferred embodiment of the present invention also has several through-holes 13 uniformly distributed on the surface of the spiral plate 7.1, wherein the through-holes 13 can be made into conical holes that are small on the top and big on the bottom, so that the activated carbon will prevent the through-holes clogged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com