Hydraulic control system for working machine

A technology for hydraulic control systems and working machines, which can be applied to fluid pressure actuation system components, mechanical equipment, earth movers/shovels, etc., and can solve problems such as wasted energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

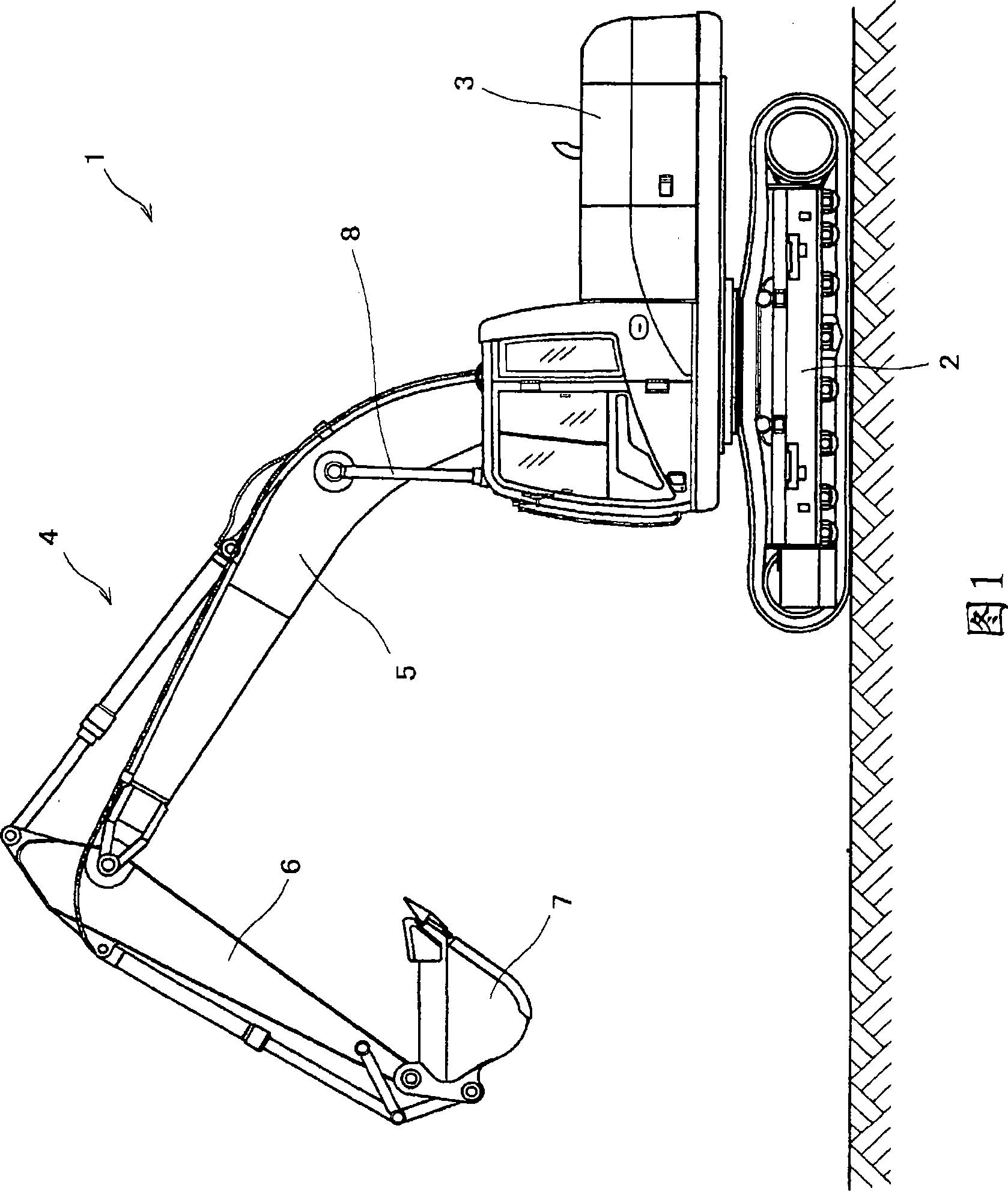

[0007] Embodiments of the present invention will be described below with reference to the drawings. In FIG. 1, reference numeral 1 is a hydraulic excavator as an example of a working machine. This hydraulic excavator 1 includes a crawler-type undercarriage 2, an upper swing body 3 rotatably supported above the undercarriage 2, and In parts such as the working part 4 in front of the upper turning body 3, the working part 4 further includes a boom (boom) 5 supported on the upper turning body 3 at a base end portion that is freely swingable up and down, and is supported on the front and rear swinging body freely. An arm (arm) 6 at the front end of the boom 5 , a bucket 7 attached to the front end of the arm 6 , and the like.

[0008] Reference numeral 8 is a pair of left and right boom cylinders (corresponding to hydraulic cylinders in the technical solution of the present invention) that perform telescopic motions to swing the above-mentioned boom 5 up and down. 8a (equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com