Multipurpose encapsulating equipment

A packaging equipment, multi-purpose technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as limited use, impact on packaging operations, and impact on operation accuracy, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

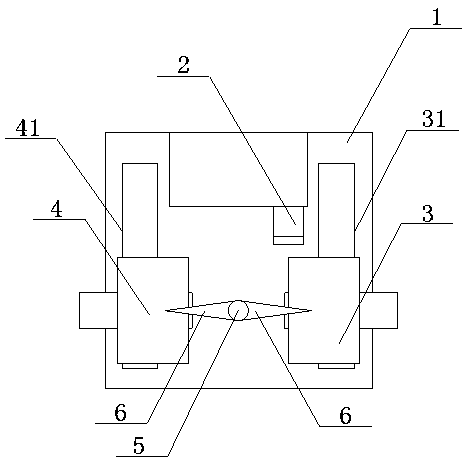

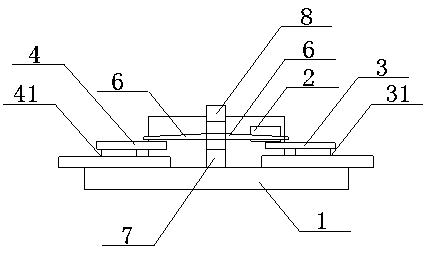

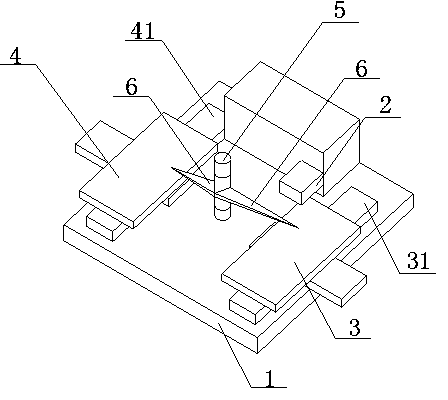

[0031] This embodiment is the most preferred for implementing the present invention. Such as Figure 1-3 As shown, the multi-purpose packaging equipment in this embodiment includes a machine base 1, a dispensing mechanism 2, a packaging table 3, and a motion mechanism 31 that drives the packaging table 3 to move, and the motion mechanism 31 can drive the packaging table 3 along the X, Y Direction movement; this multi-purpose packaging equipment also includes: a wafer platform 4, which is arranged on the support 1 and is located on one side of the packaging platform 3, for placing pre-prepared bare chips and electronic components, bare chips and electronic components It can be pre-placed in a box, which is convenient for the loading swing arm to take; the main shaft 5 is arranged between the packaging table 3 and the wafer receiving table 4, and the main shaft 5 can be arranged along the Z-axis direction; two loading Swing arm 6, it is installed on the main shaft 5, and is eve...

Embodiment 2

[0041] Others are the same as those described in Embodiment 1, except that there are three chip loading swing arms, which are also installed on the main shaft 5, and are evenly arranged along the circumference of the main shaft 5, and can package three different being encapsulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com