Patents

Literature

39results about How to "Control elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

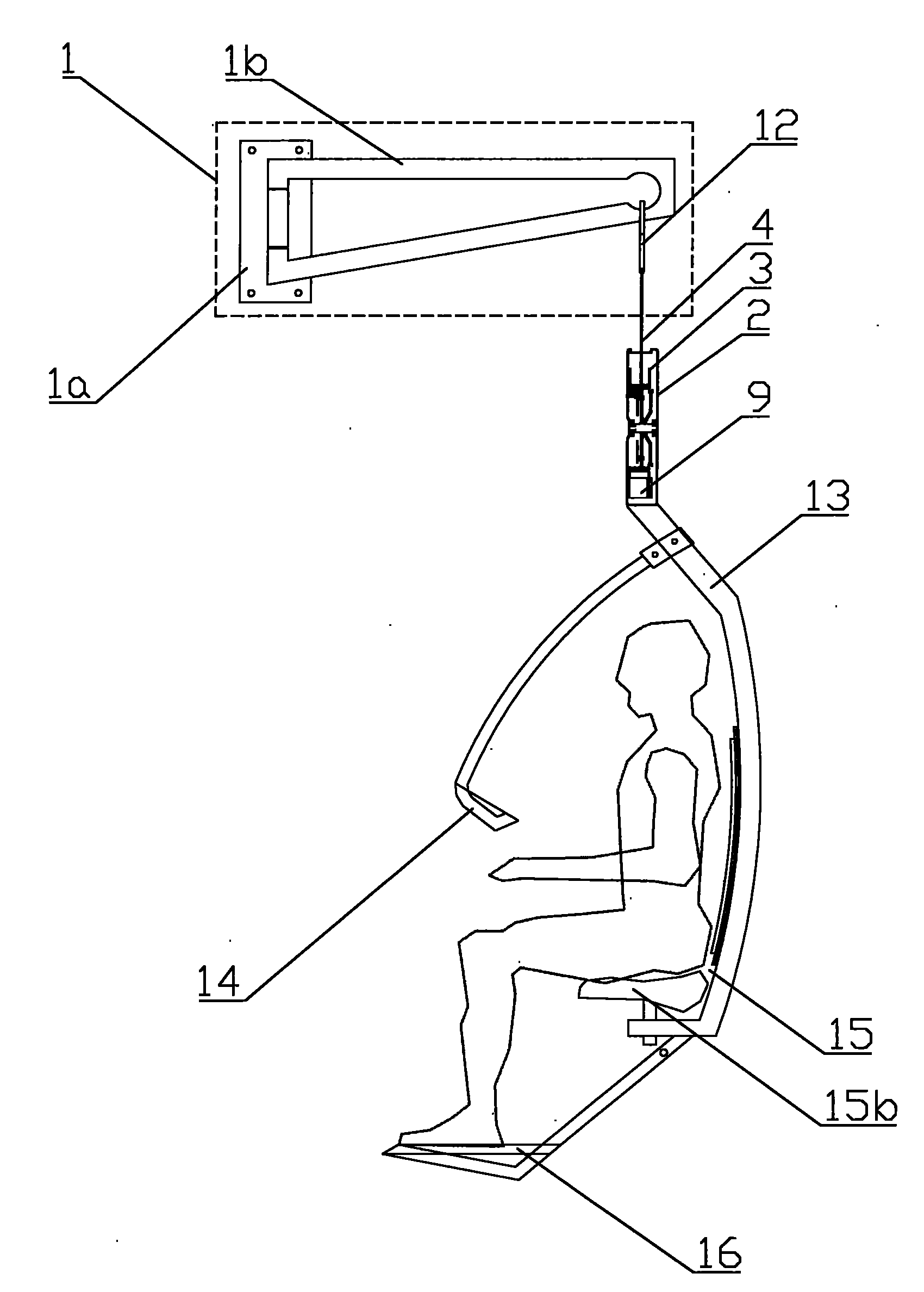

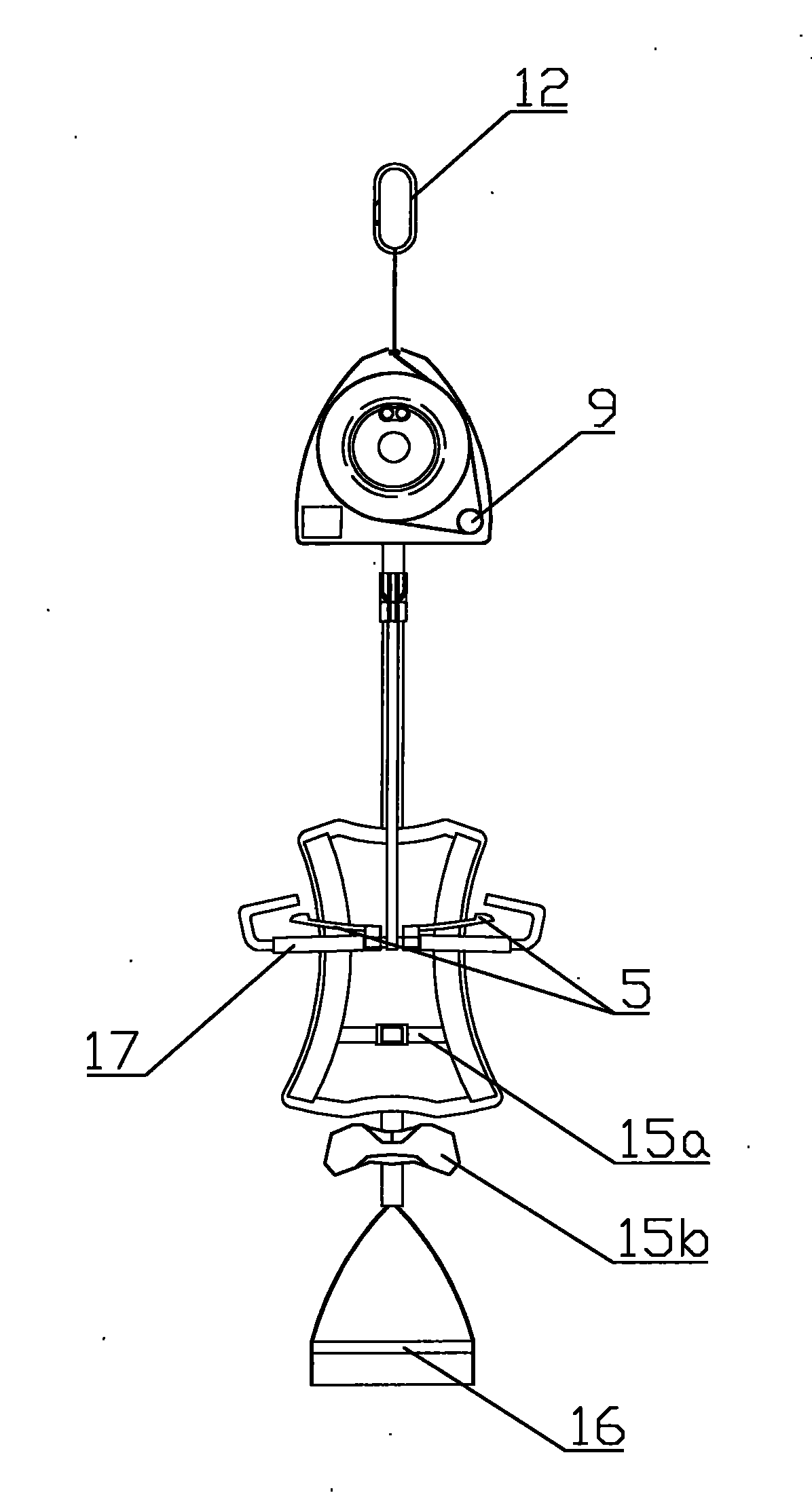

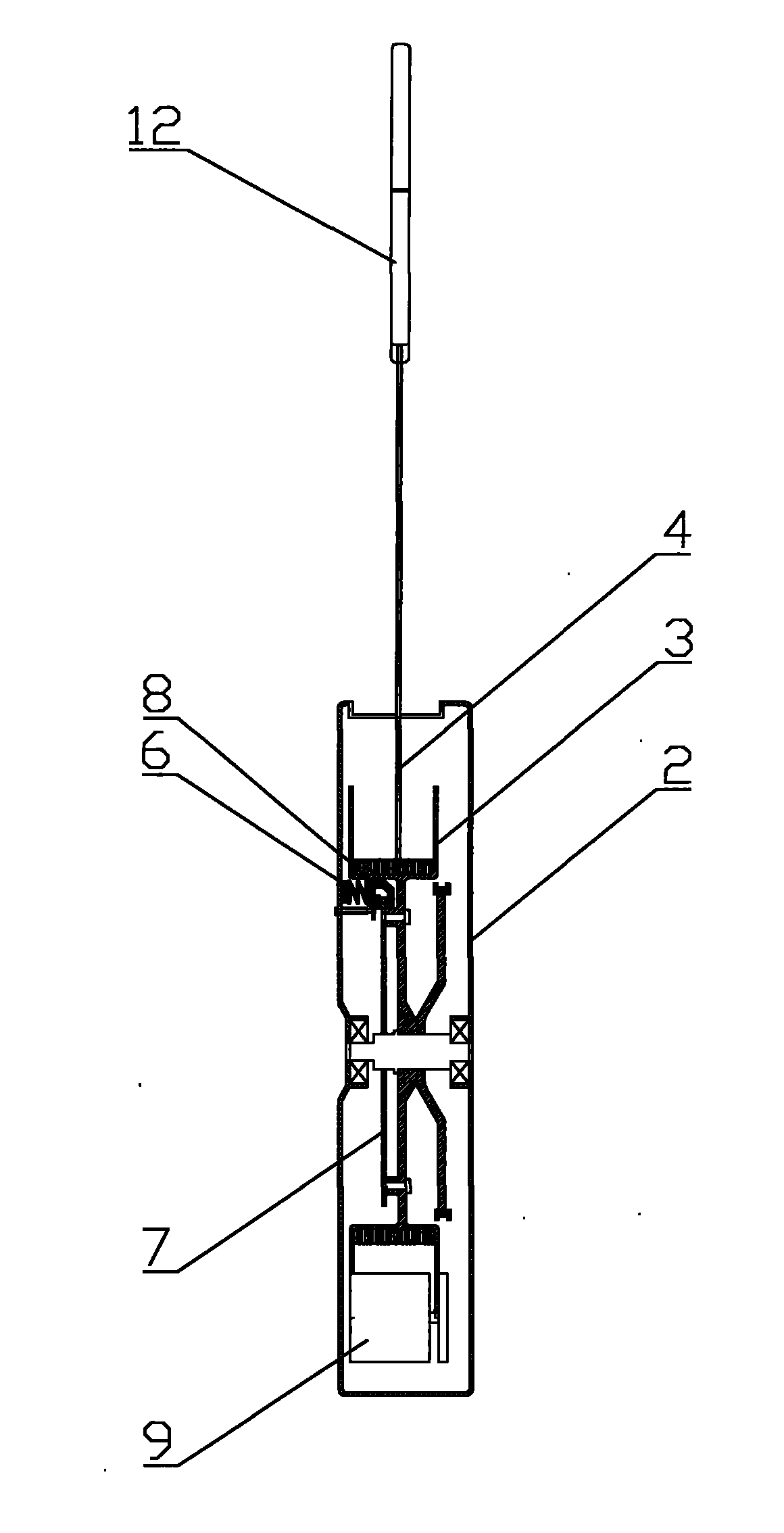

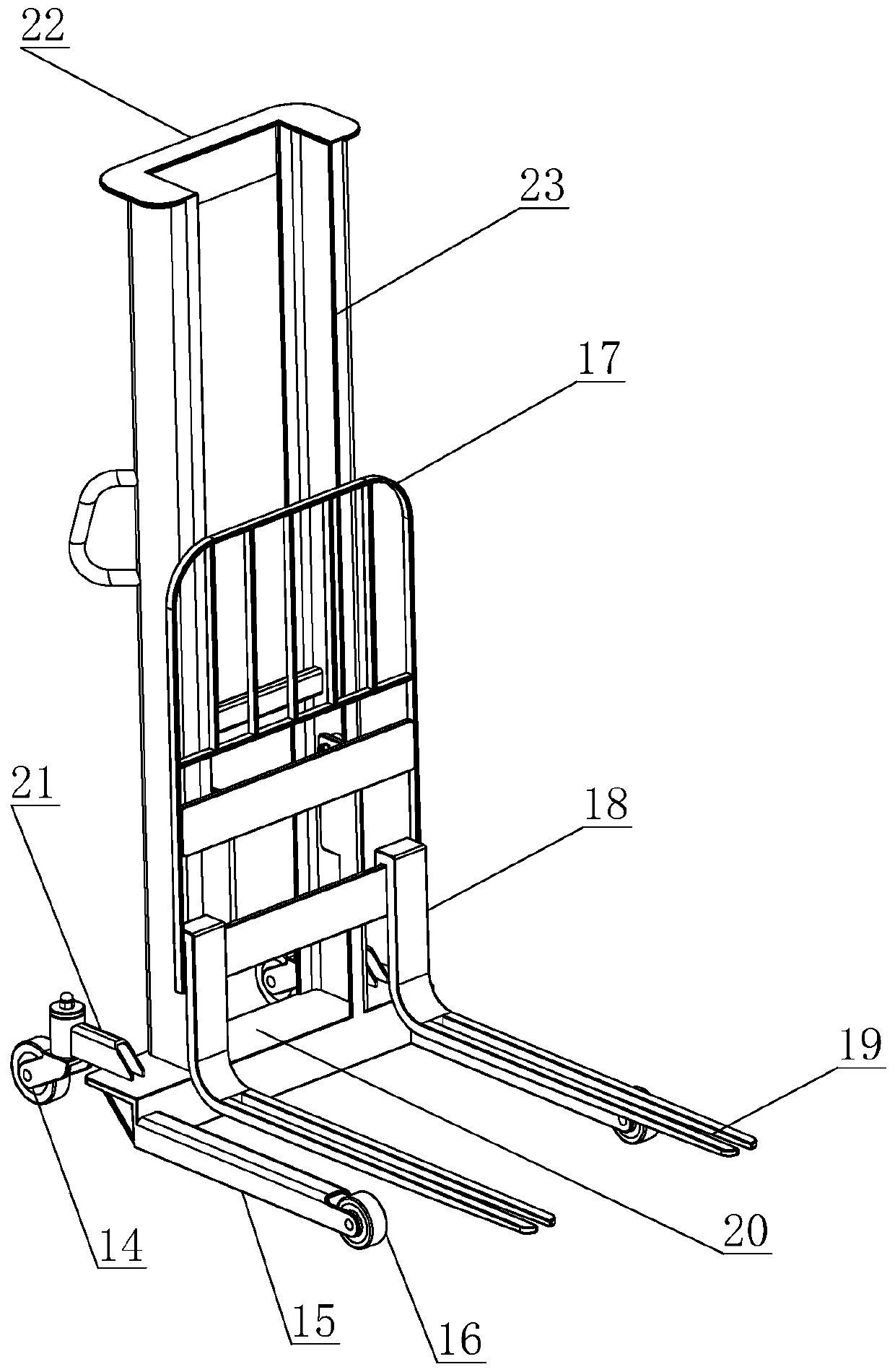

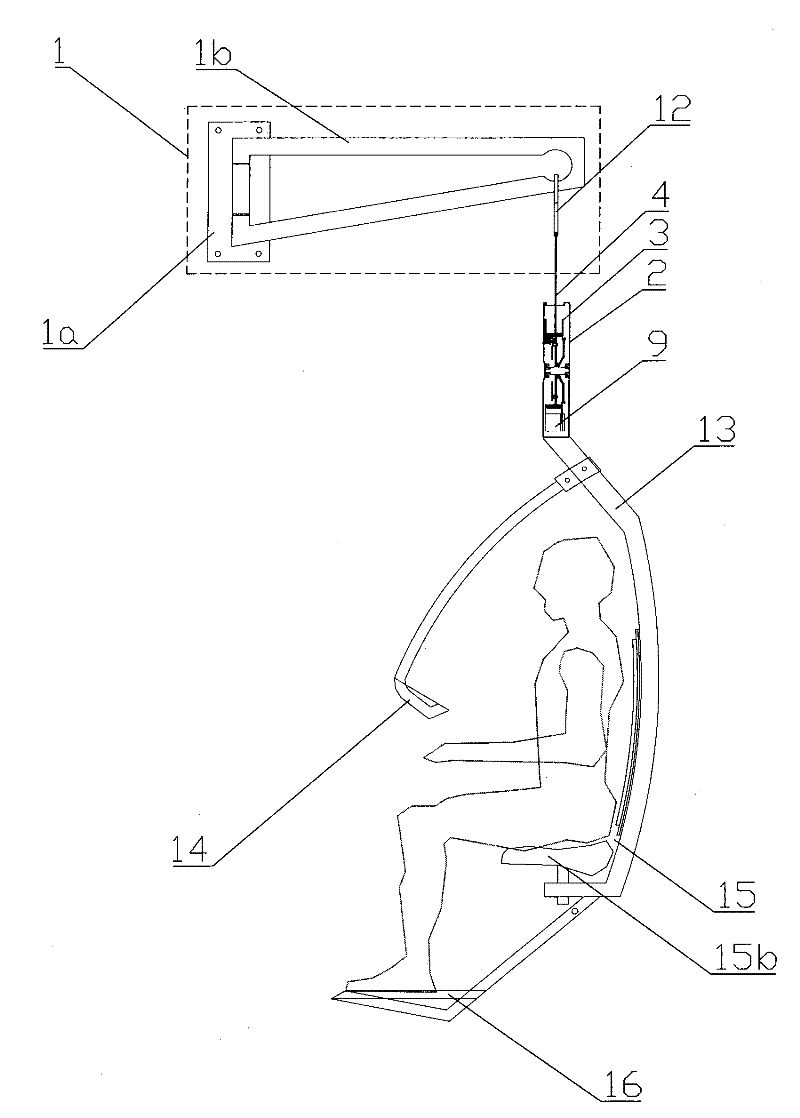

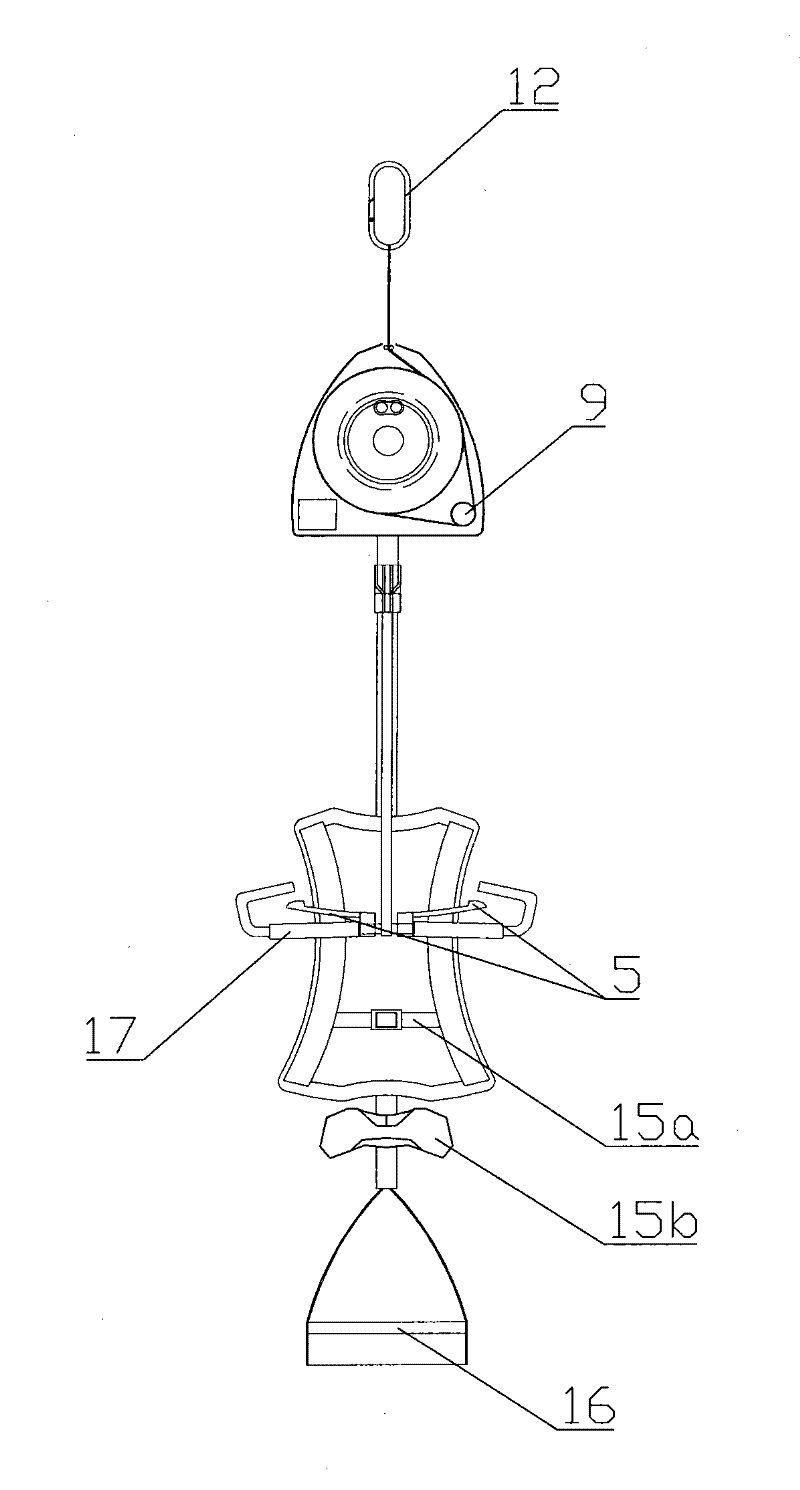

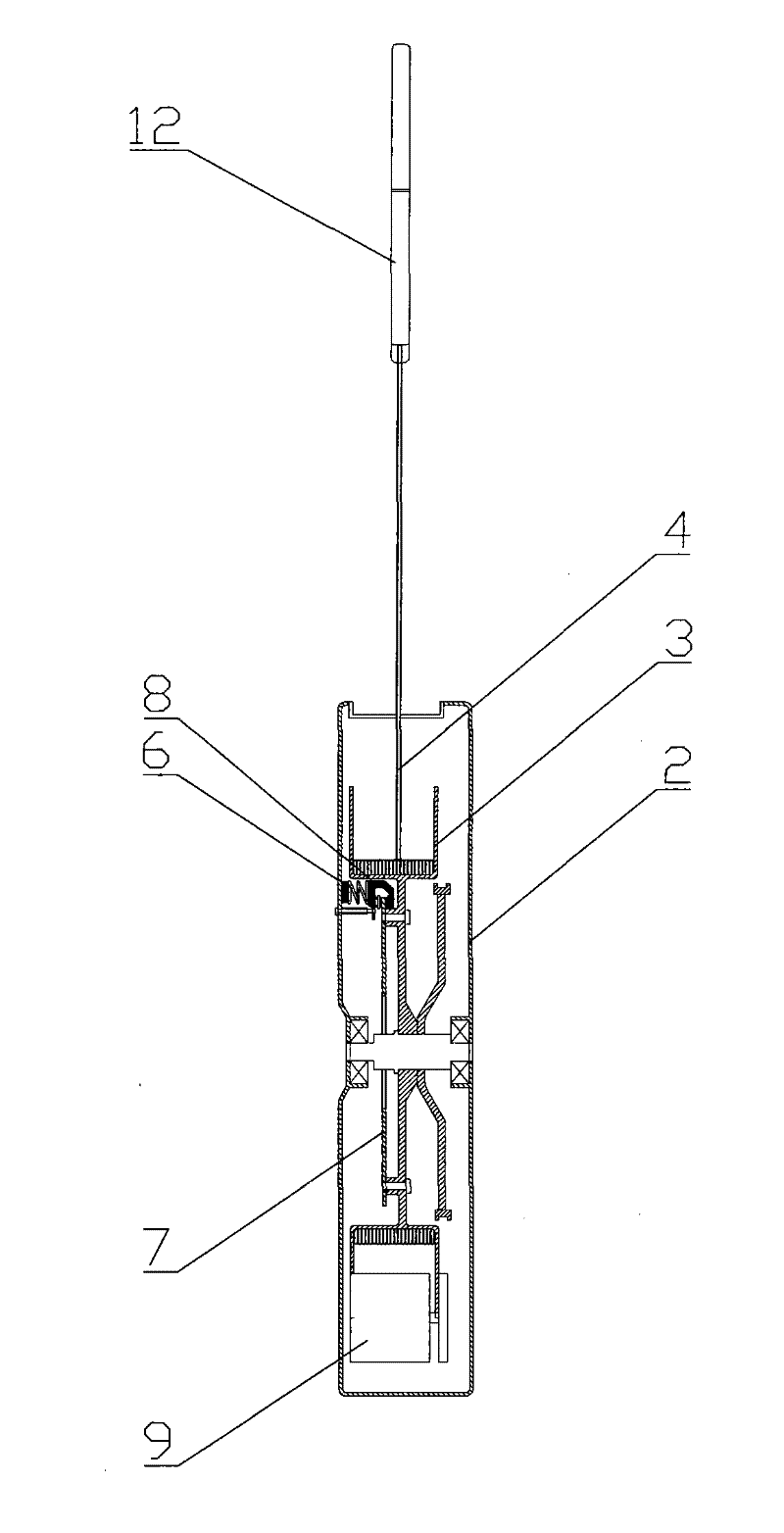

Tower escape apparatus

The invention discloses a tower escaper apparatus which comprises a bearing fixing support, a rope winding device, a riding accommodation device and a descending control device. The coiling device comprises a shell and a winding roll, the winding roll is wound with a bearing rope, and the rope winding device is suspended on the bearing fixing support through a free end of the bearing rope; the riding accommodation device is fixedly connected below the shell; and the descending control device comprises a friction brake and a descending operation handle which are tightly clasped to the winding roll in a normal state, and the descending operation handle is in transmission fit with the friction brake. When in use, the bearing fixing support is arranged on a window or a balcony or other places, a person can control the friction braking force of the friction brake to the winding roll through the descending operation handle so as to control the descending speed of the riding accommodation device to be in a safety range, and meanwhile, ground staff can unlock the winding roll through a reset unlocking mechanism and remotely control a motor through a remote controller to drive the winding roll to rotate so as to ensure that the riding accommodation device returns to a high place and can be used by other people for escape. In addition, the invention is comfortable in use and suitable for various people.

Owner:CHONGQING JIAOTONG UNIVERSITY

Chain connecting link

InactiveCN101421538AImprove carrying capacitySimple structureChain fasteningsLongitudinal planeEngineering

The invention relates to a chain connecting link, which has two link brackets (4, 5) coupled via their limbs (6, 9), and a bar (14a-14c) that is inserted transversely between the limbs (6, 9) of the link brackets (4, 5). One limb (6) of each link bracket (4, 5) comprises a neck section (7) and a journal (8) thicker than the neck section, and a neck recess (10) and a journal recess (11) are provided in a matching fashion at the other limb (9) of the link bracket (4, 5). According to the invention, conically configured flank surfaces (12) with respect to the vertical central longitudinal plane (MLE) are provided at each journal (8) and at each journal recess (11).

Owner:THIELE GMBH & CO KG

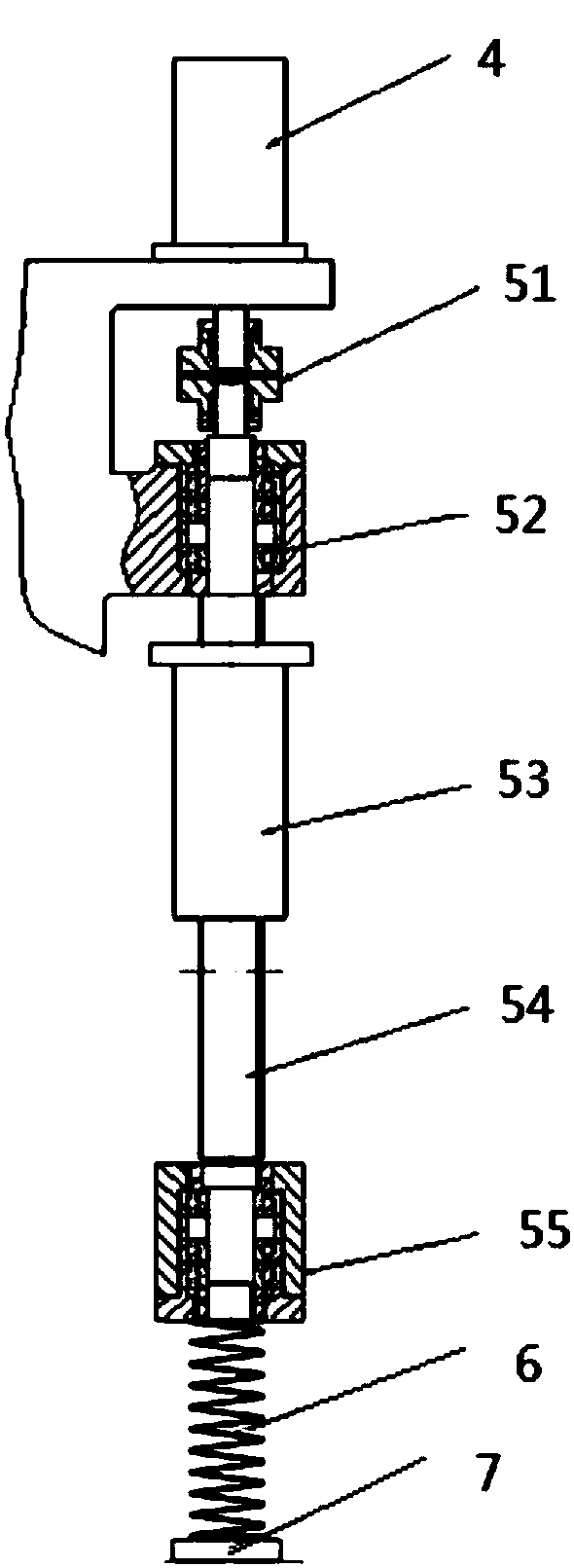

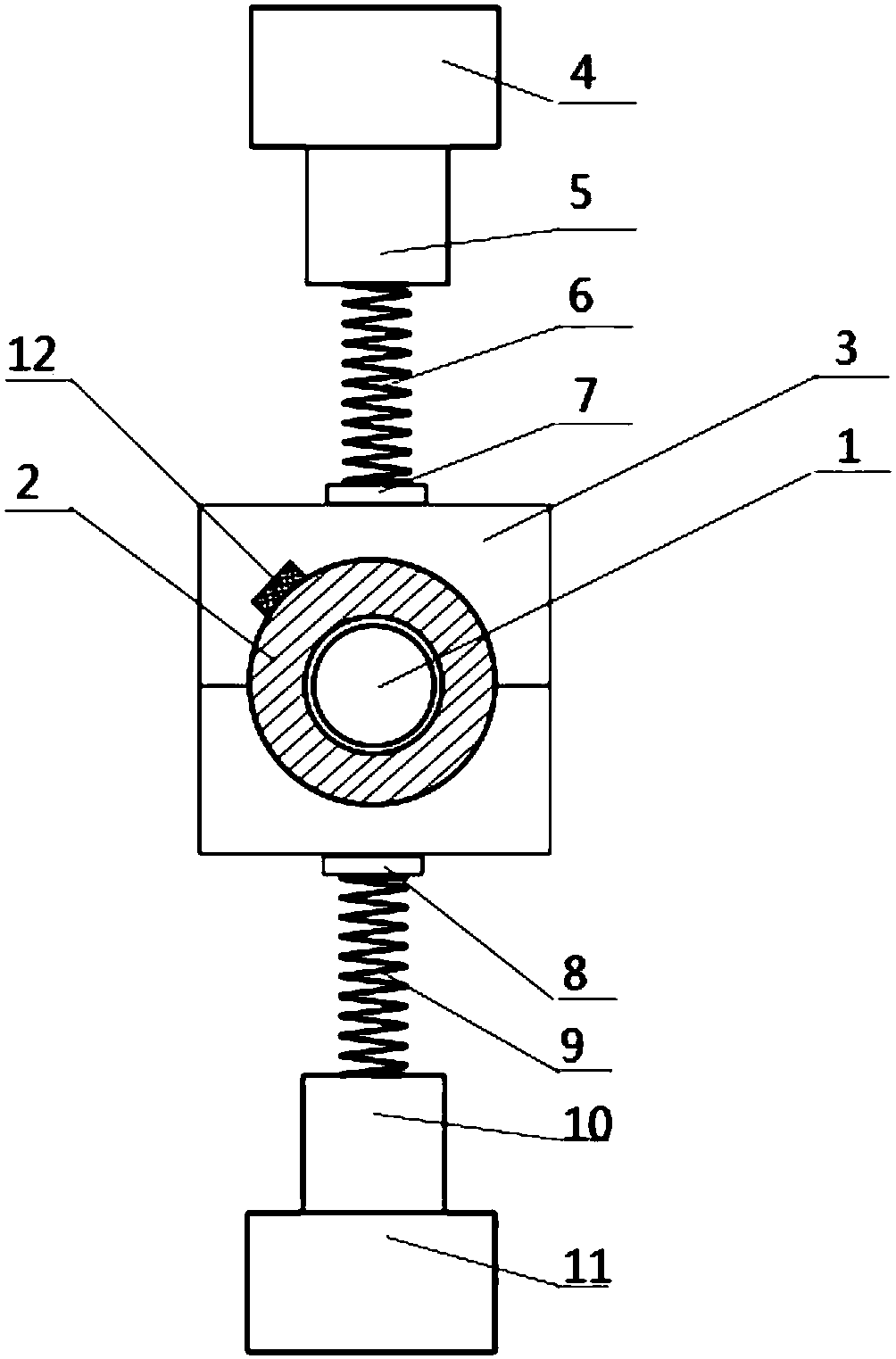

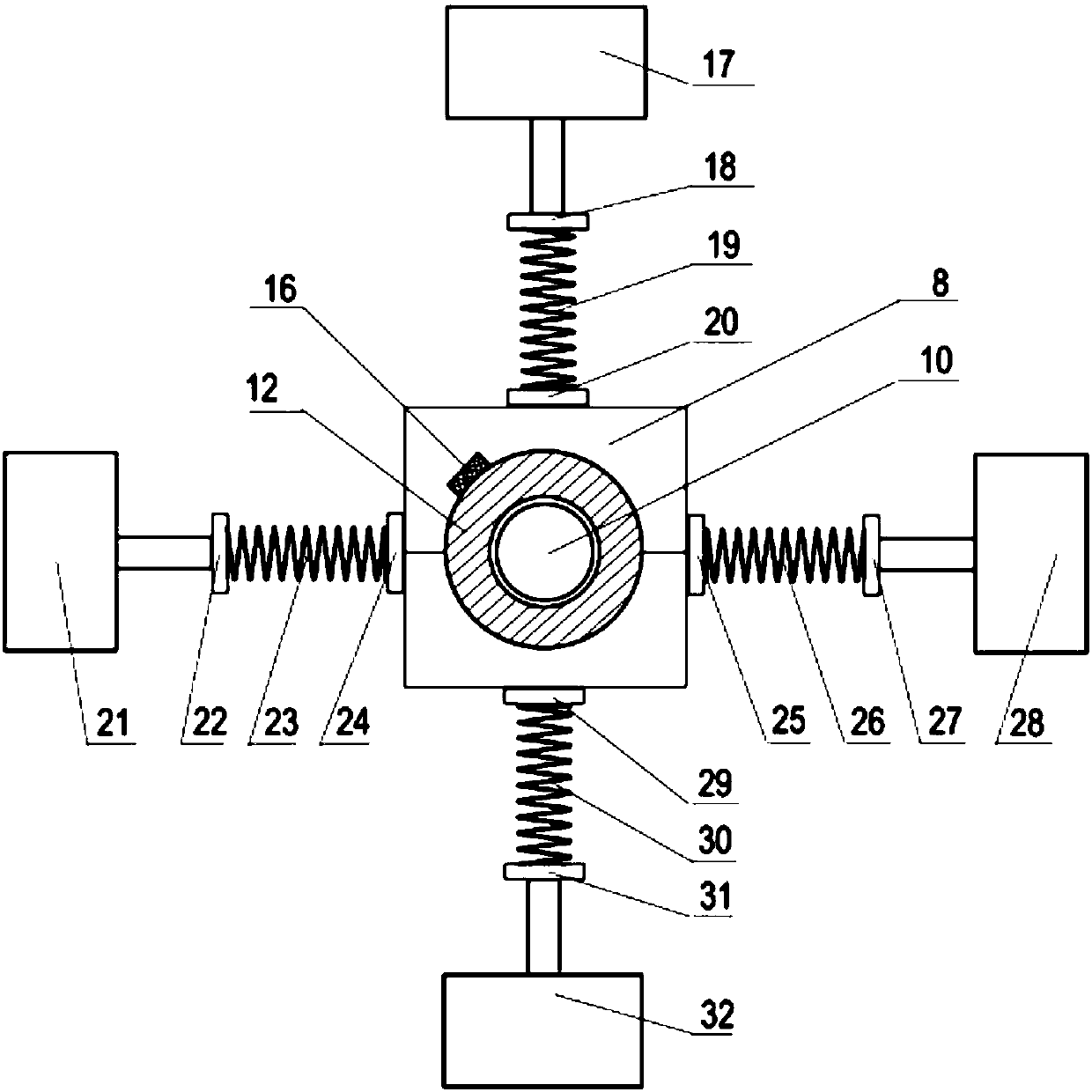

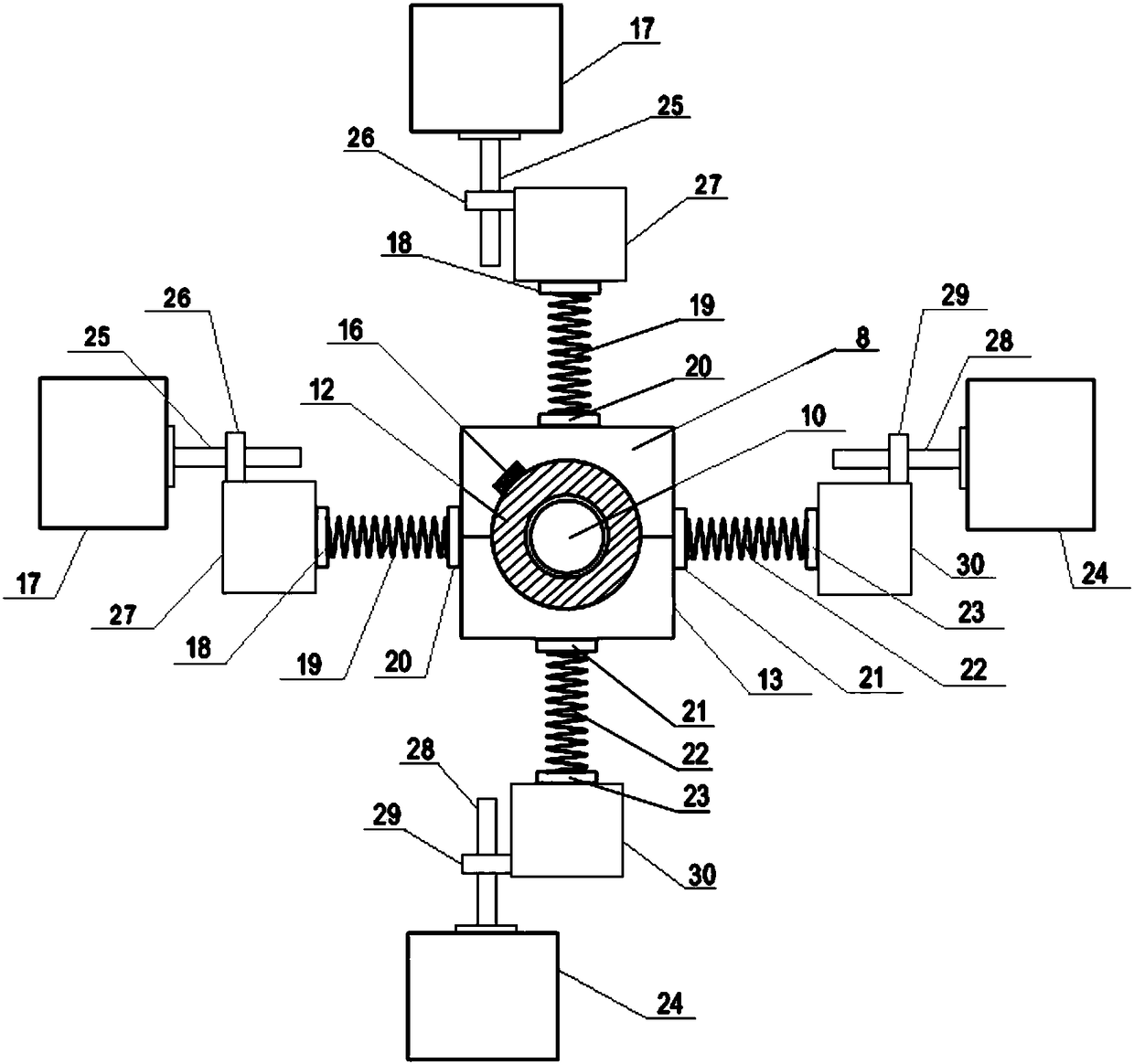

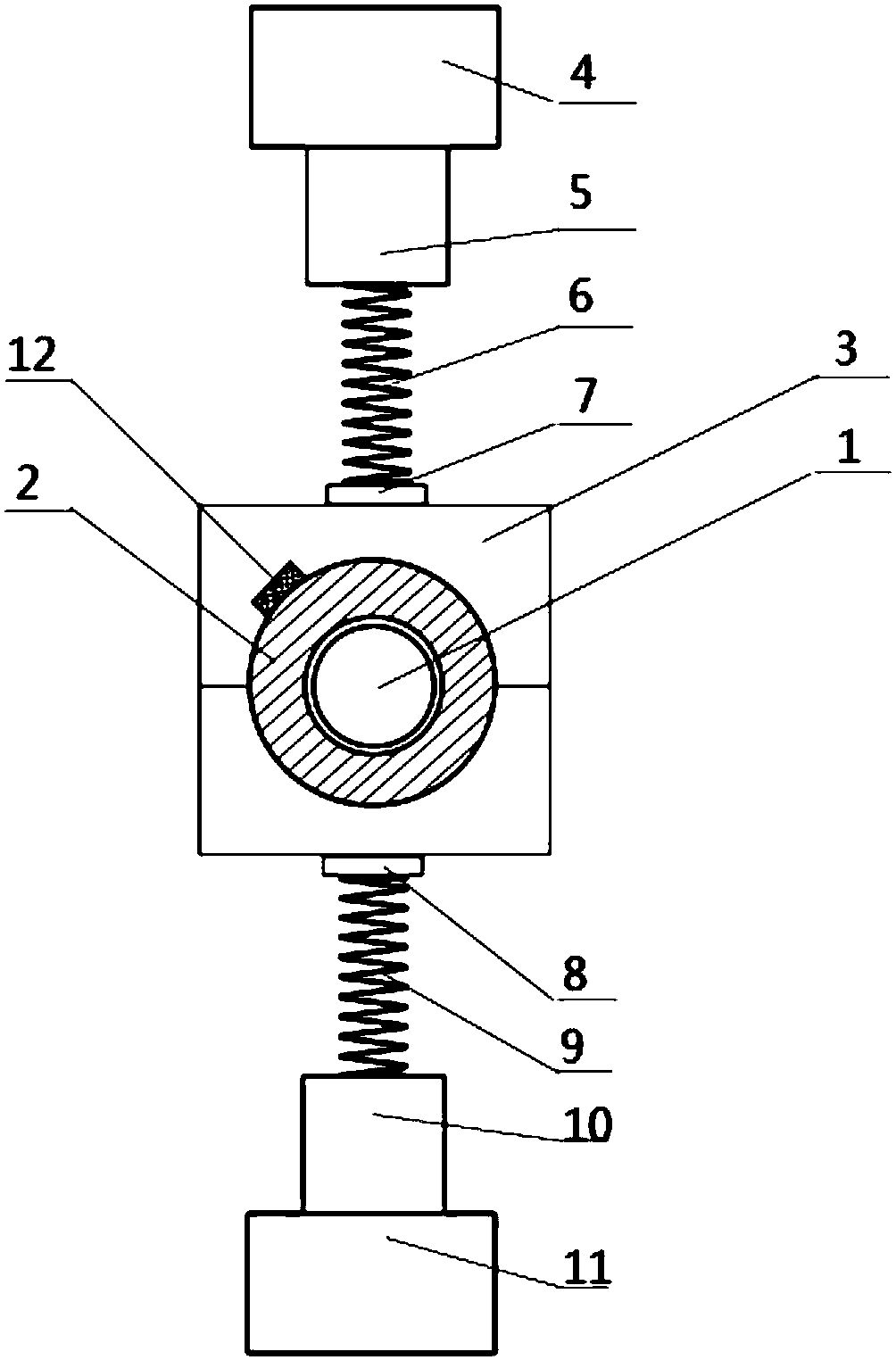

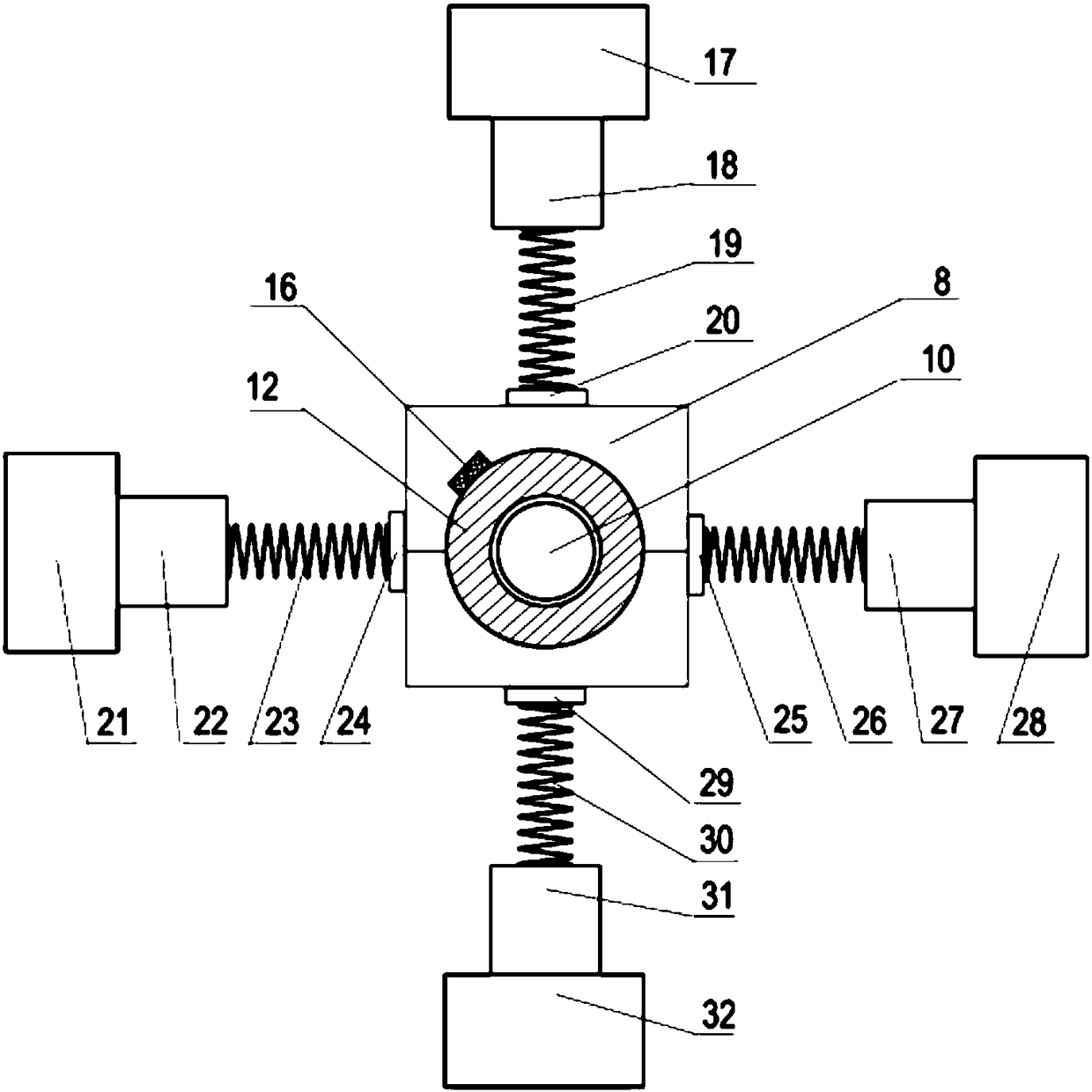

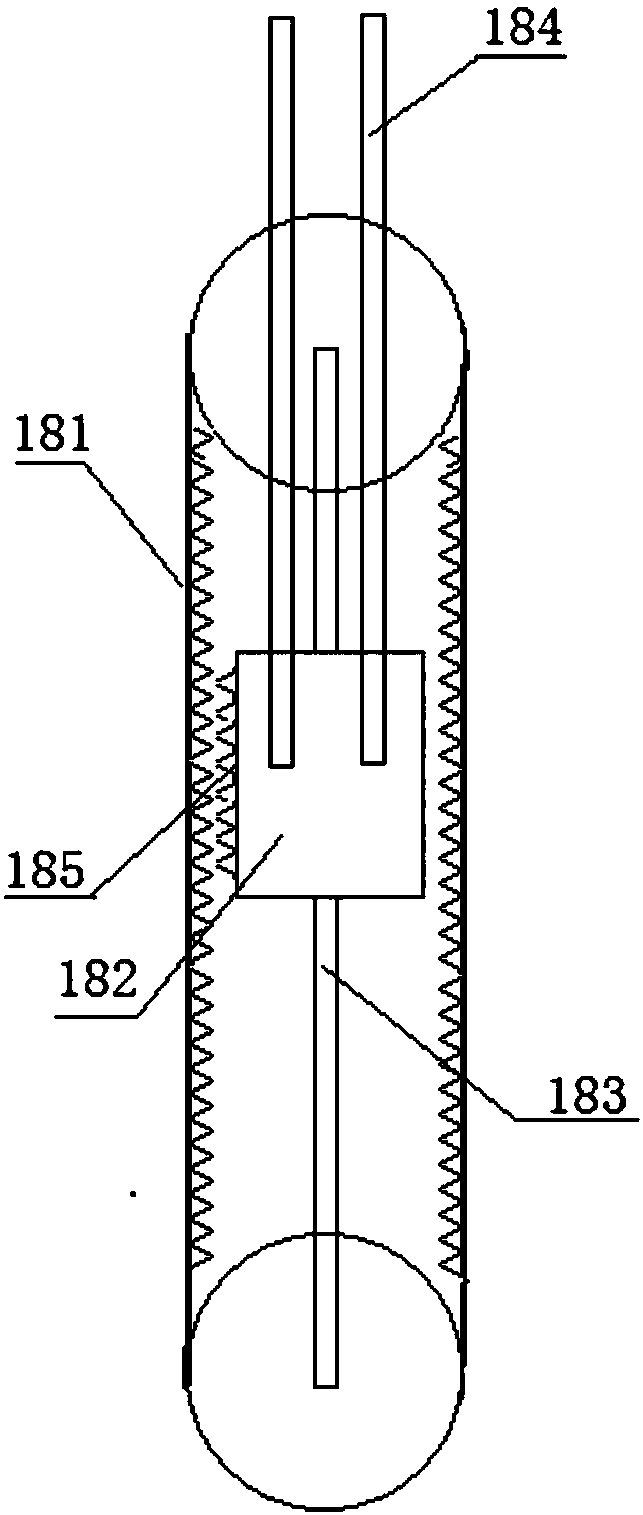

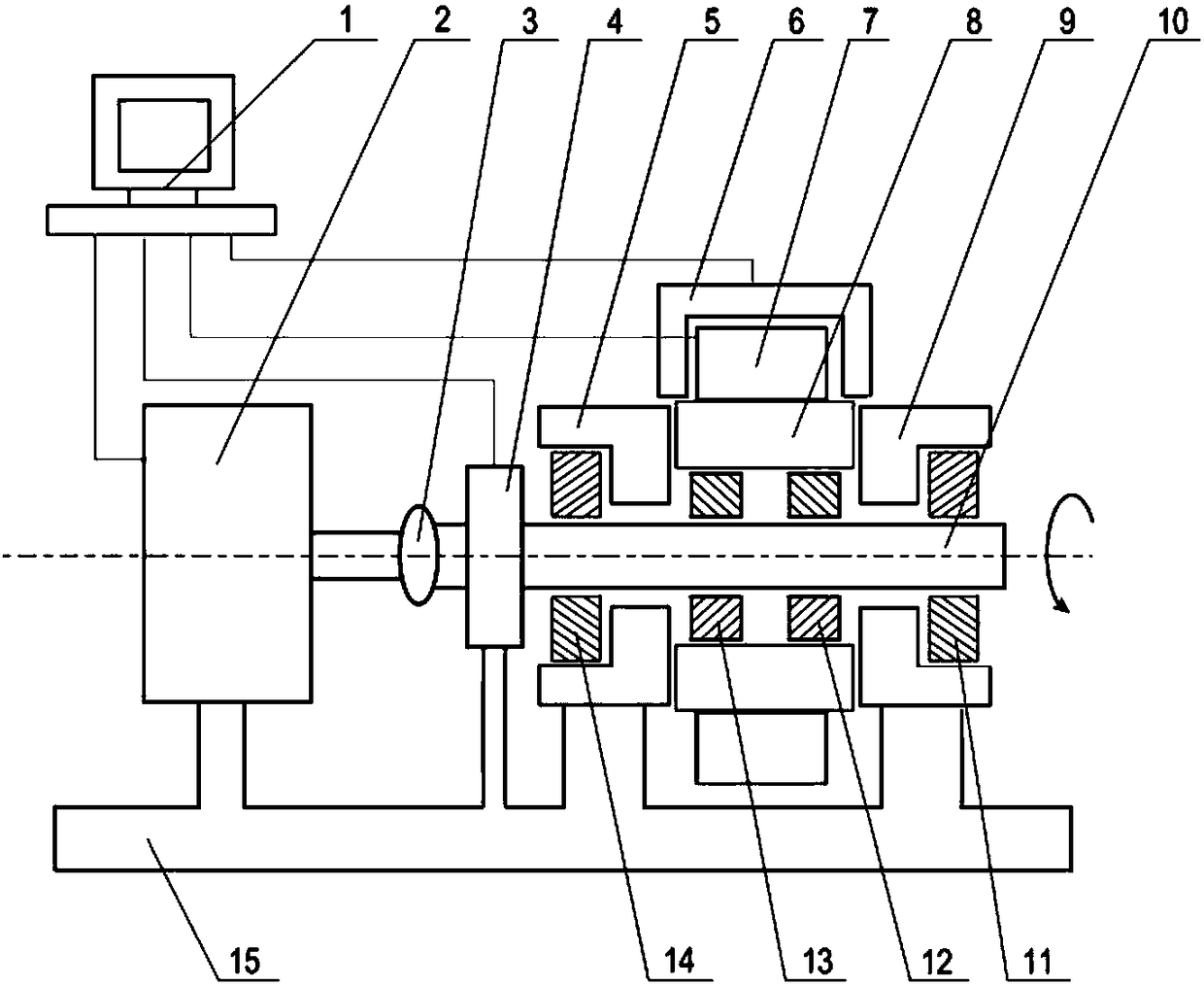

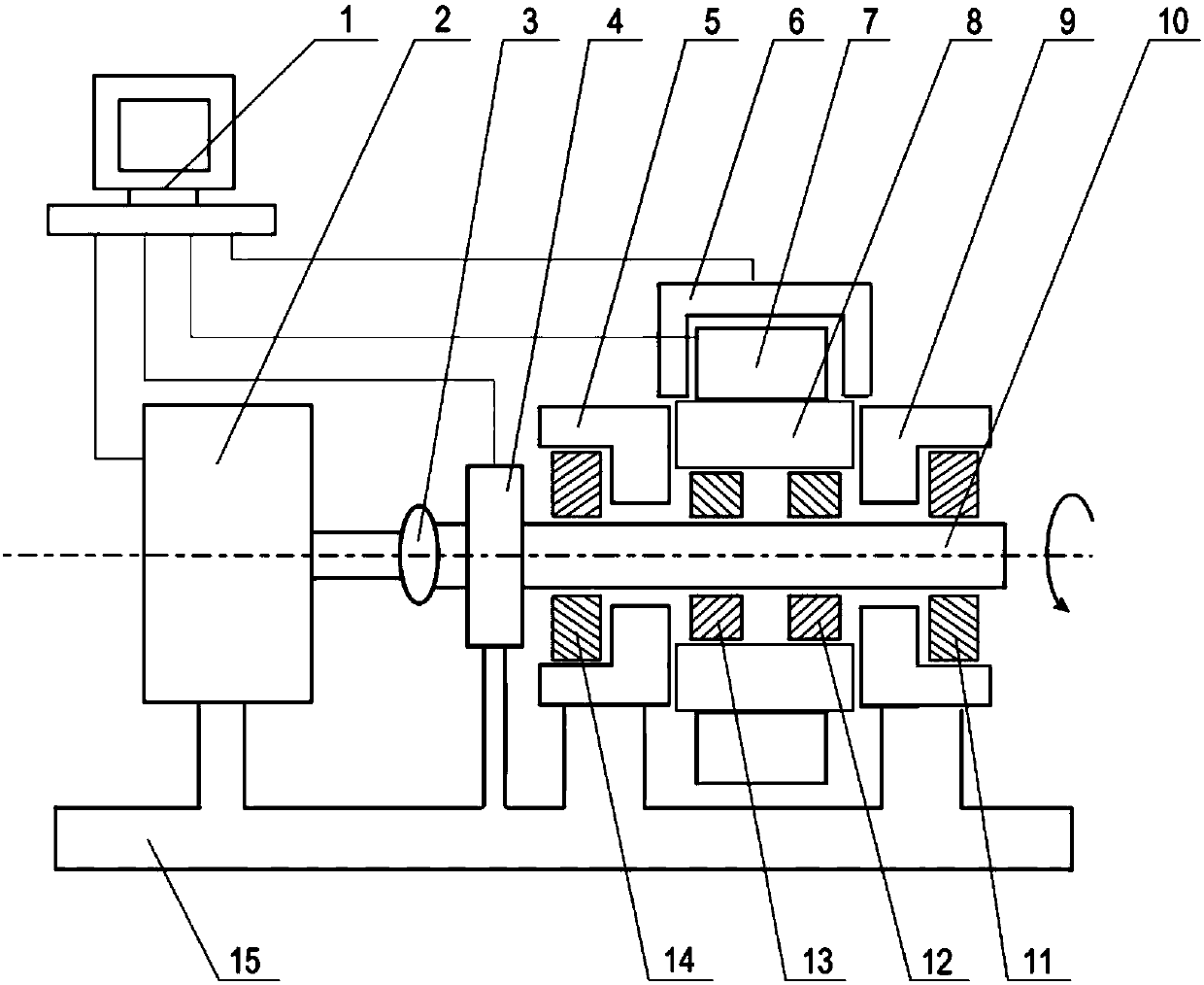

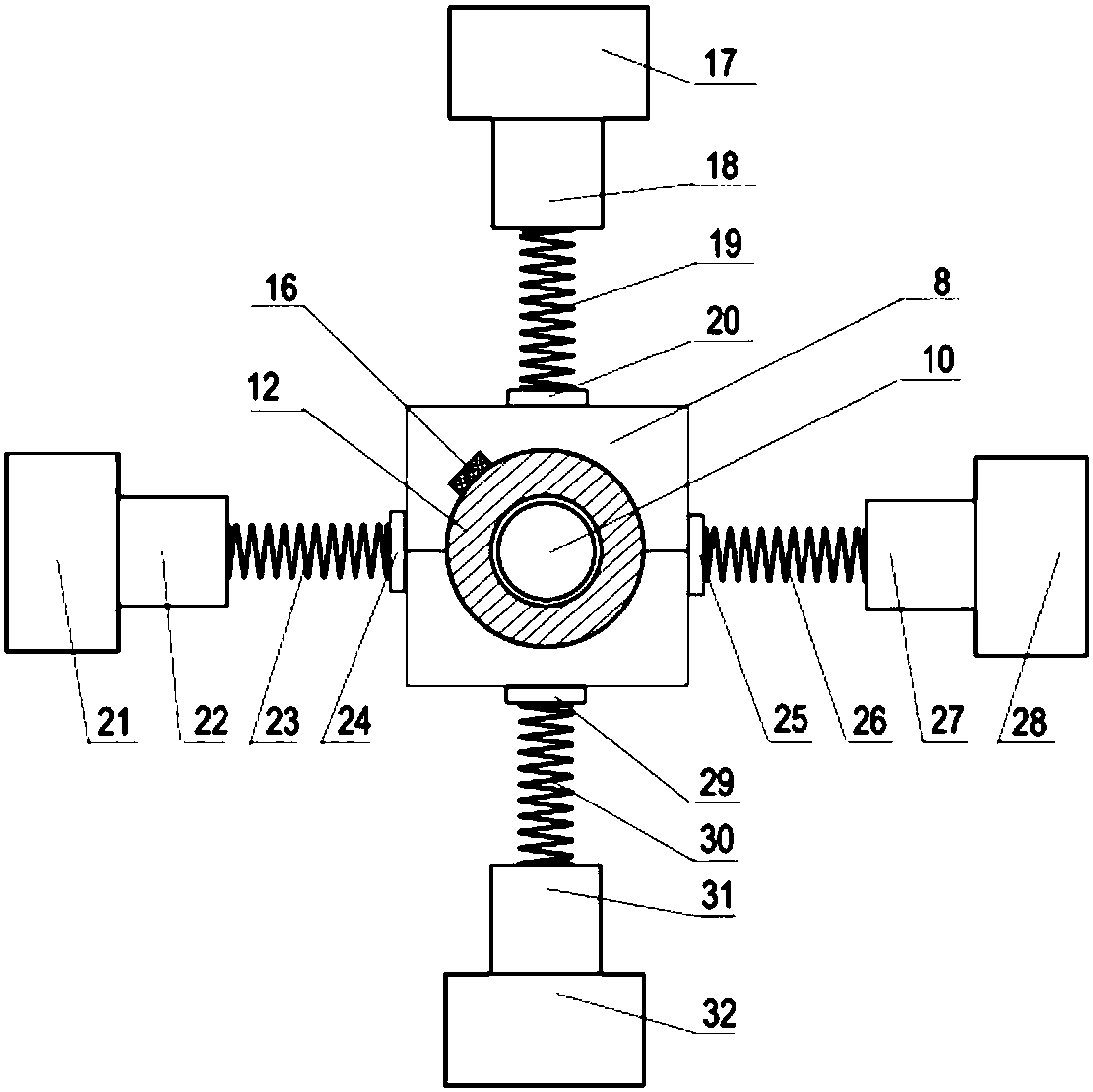

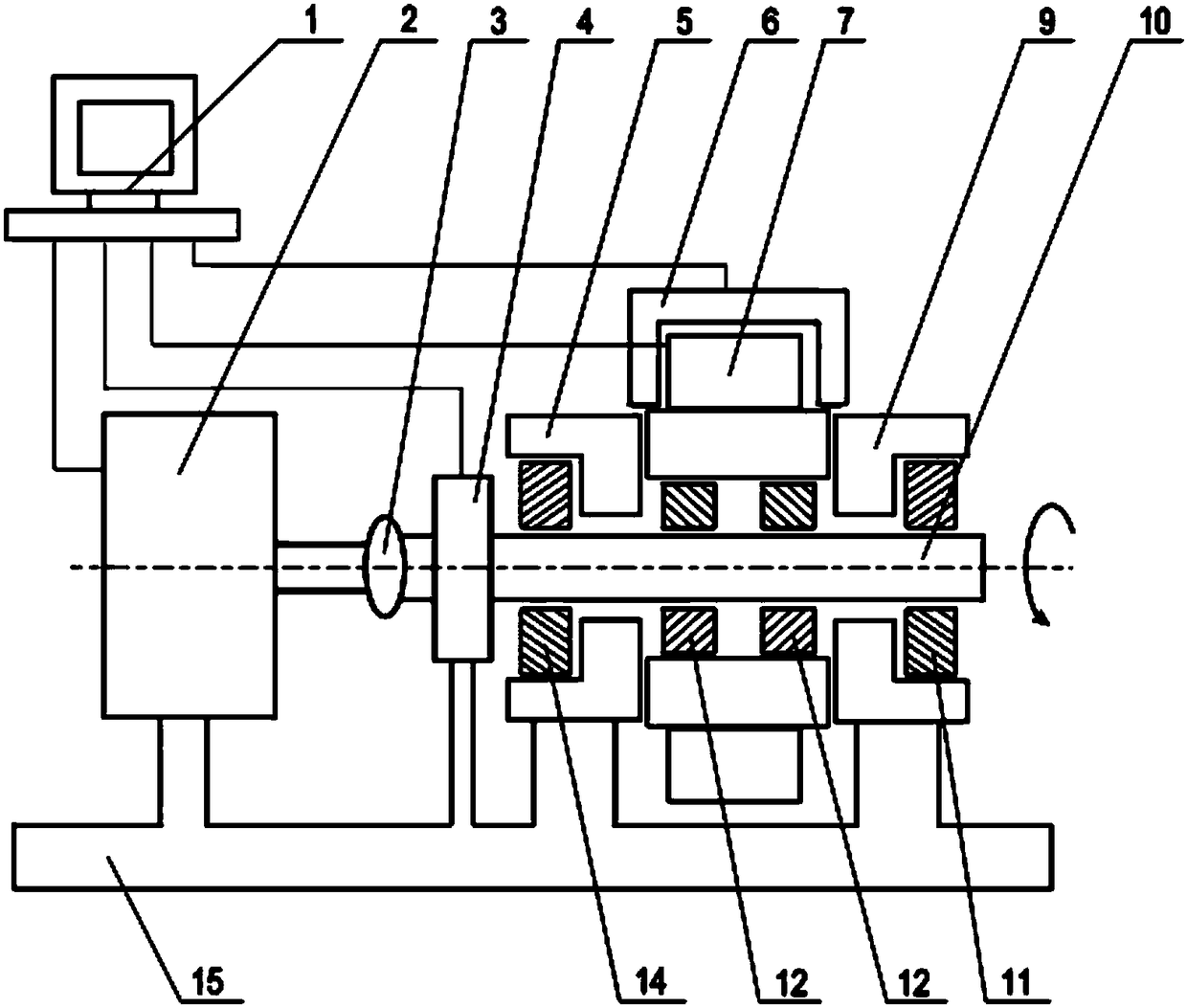

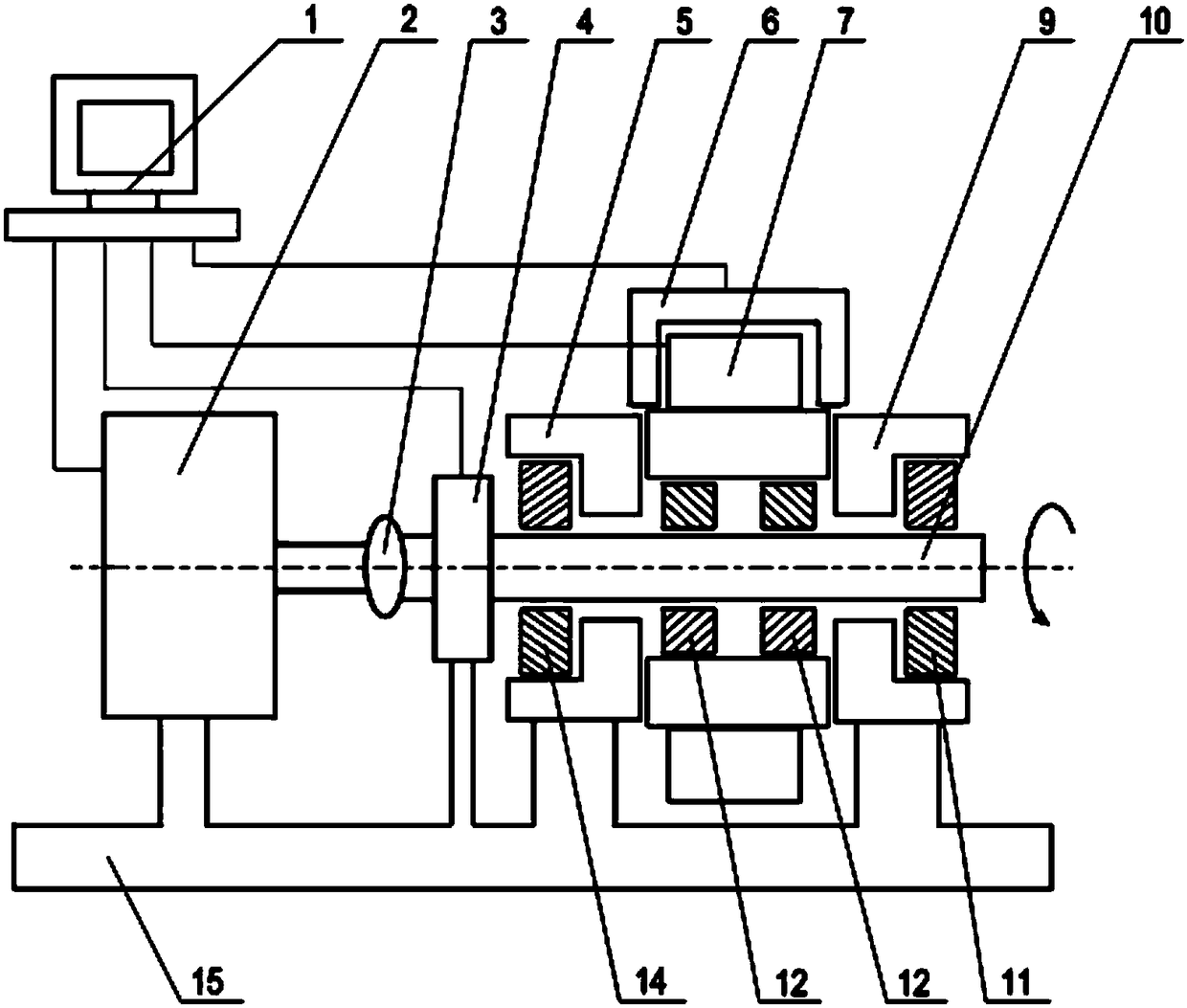

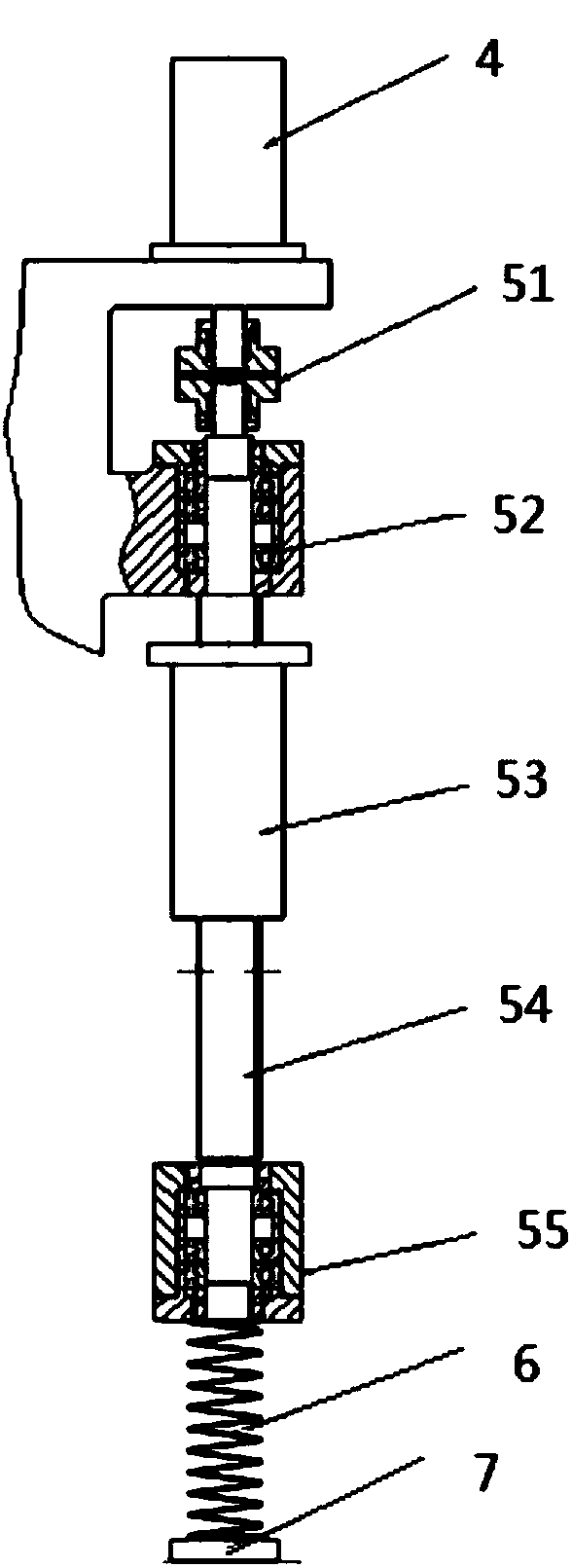

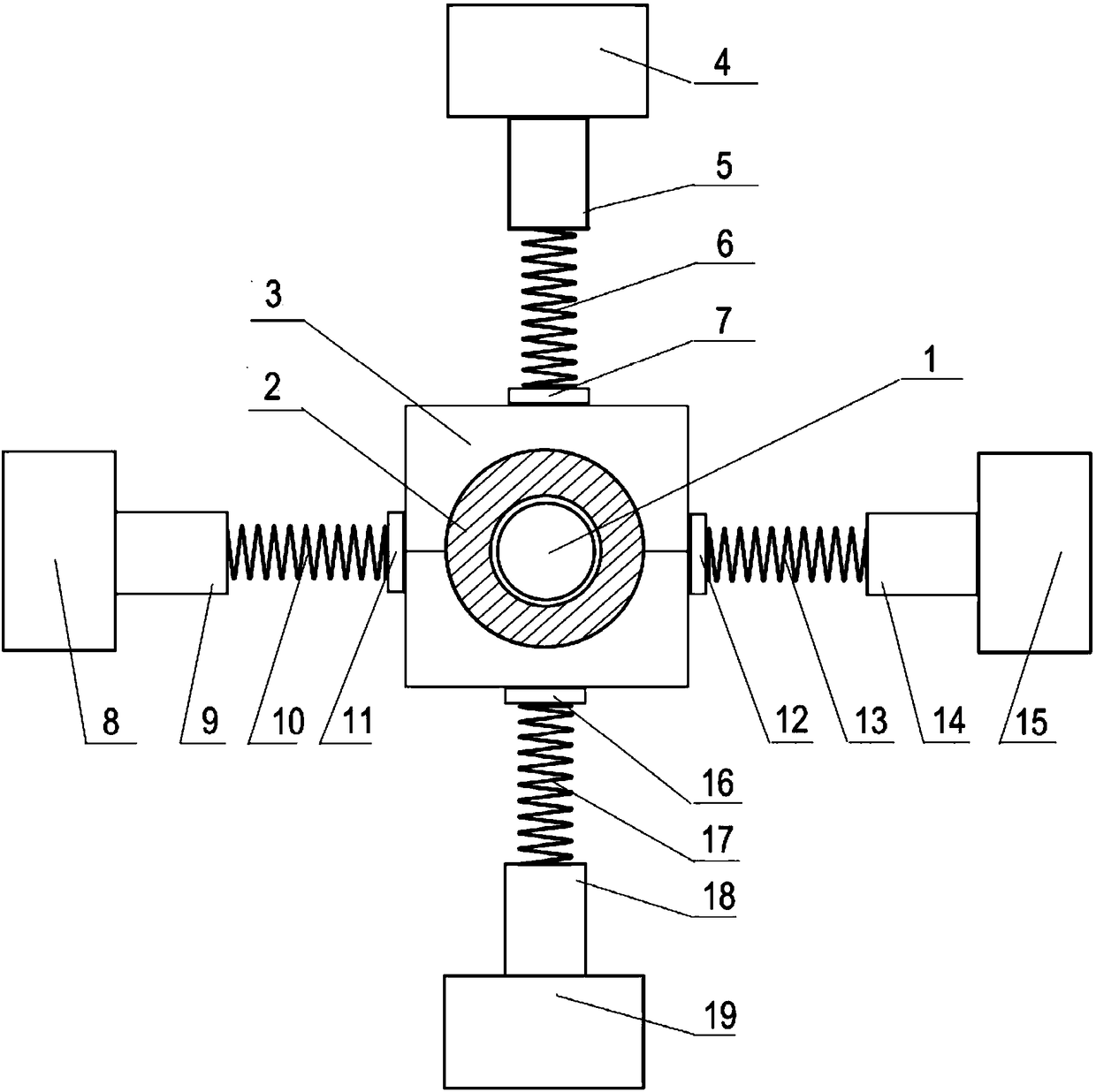

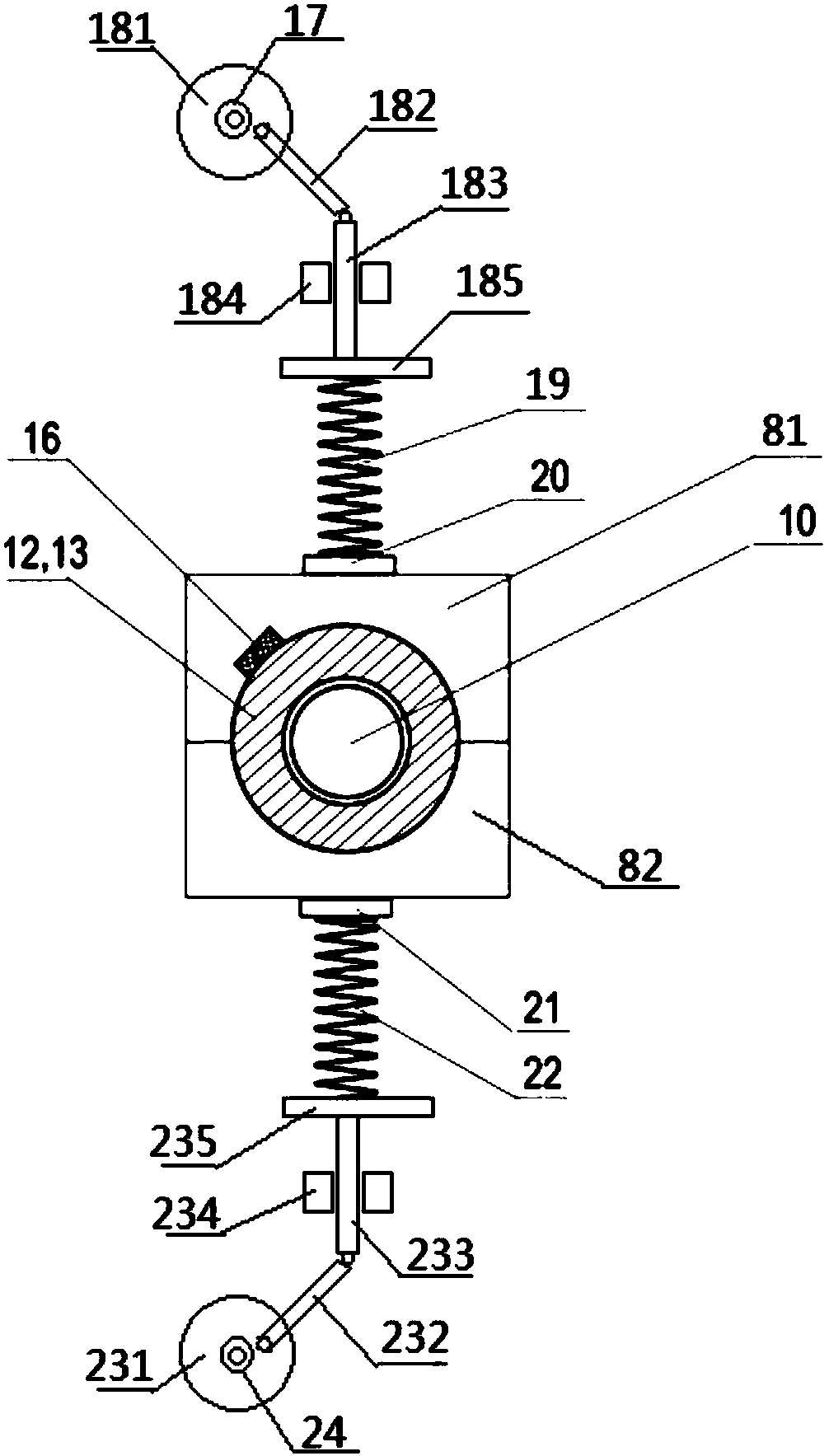

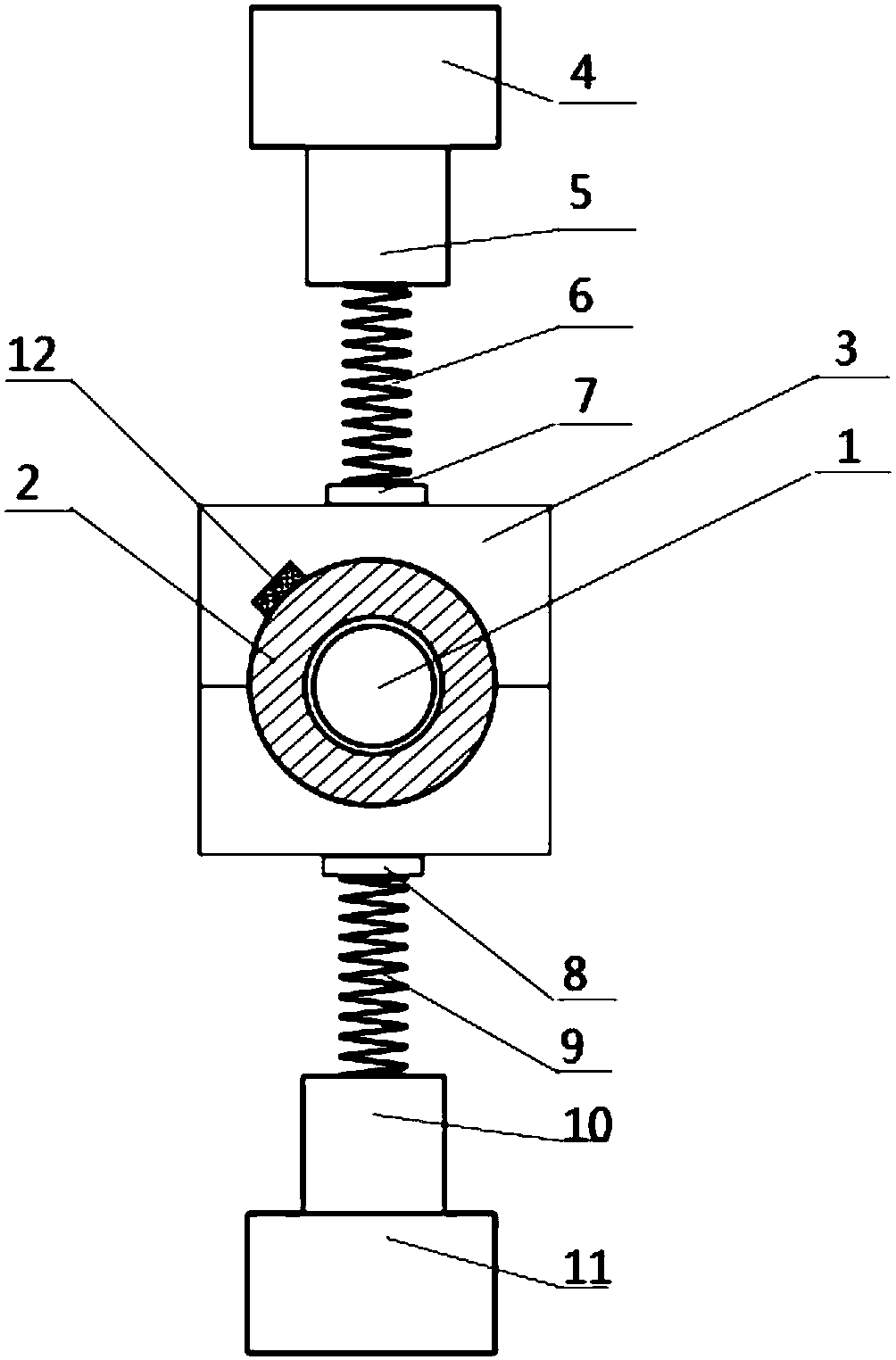

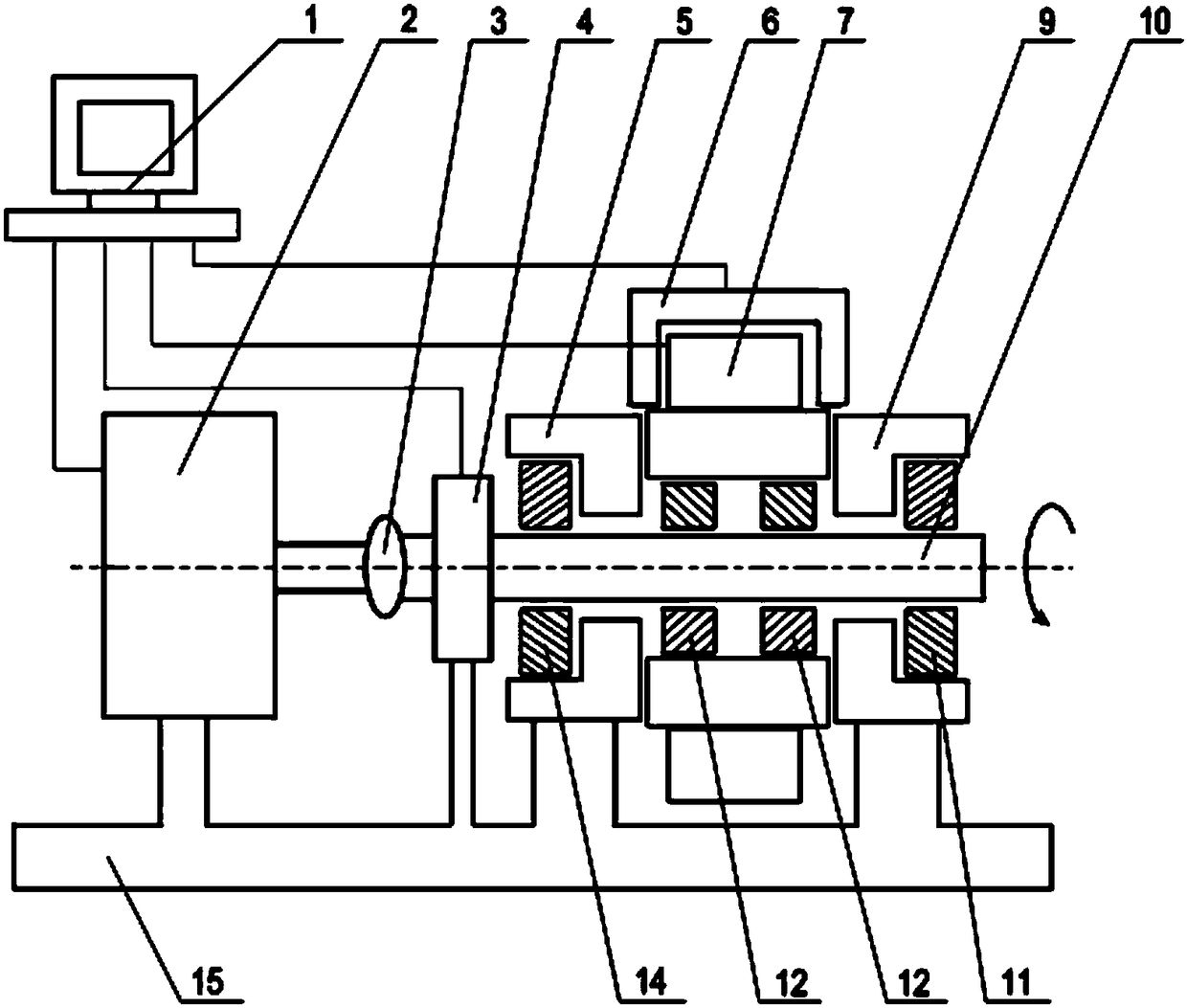

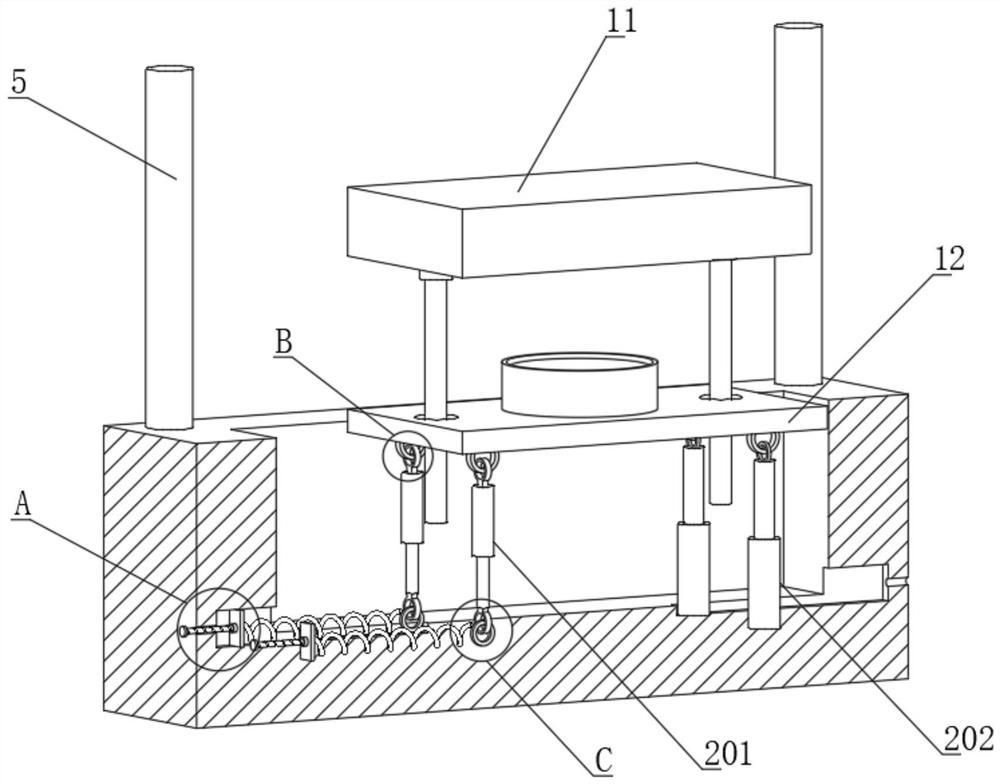

Alternating load loading device for bearing testing machine, based on screw rod transmission mechanism

InactiveCN108267316AControl elasticityChange the amount of compression/stretchMachine bearings testingGearingEngineeringMotor drive

The invention relates to an alternating load loading device for a bearing testing machine, based on a screw rod transmission mechanism. The bearing testing machine includes a rotating shaft (1), wherein a tested bearing (2) is arranged on the rotating shaft (1). The alternating load loading device includes a clamp (3) and a plurality of rotary motor-screw rod transmission mechanism-spring assemblies surrounding the clamp (3), wherein each rotary motor-screw rod transmission mechanism-spring assembly includes successively connected rotary motor, screw rod transmission mechanism and spring; eachscrew rod transmission mechanism includes a shaft coupling (51), a screw rod bearing (52), a screw-nut (53), a screw rod (54) and a bearing pedestal (55); and the rotary motor drives the screw rod transmission mechanism to move to control the spring to generate stretching or compression deformation and apply alternating load to the tested bearing (2) in the clamp (3). Compared with the prior art,the alternating load loading device for a bearing testing machine has the advantages of being able to realize the real condition load of the internal combustion engine.

Owner:SHANGHAI JIAN QIAO UNIV

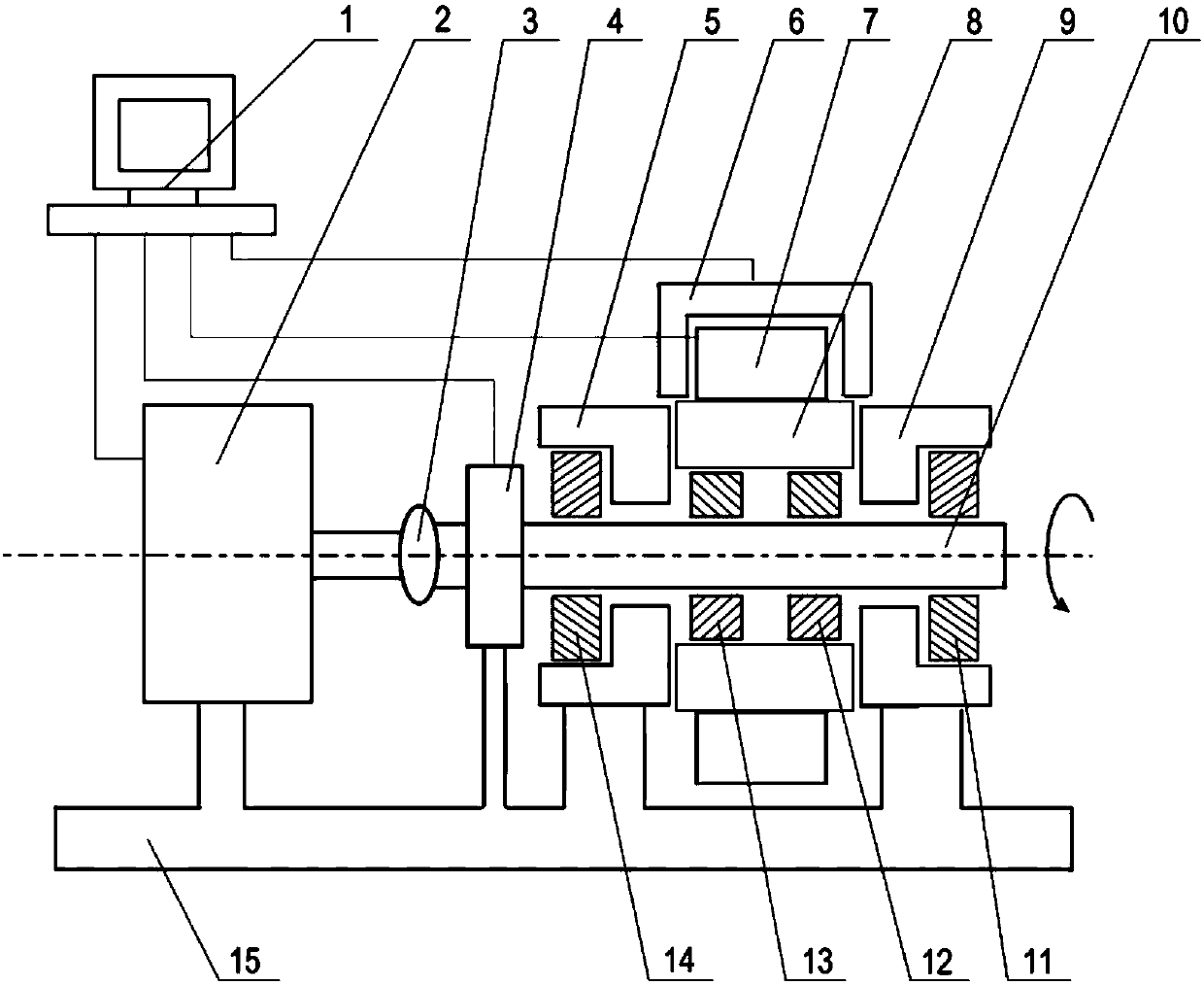

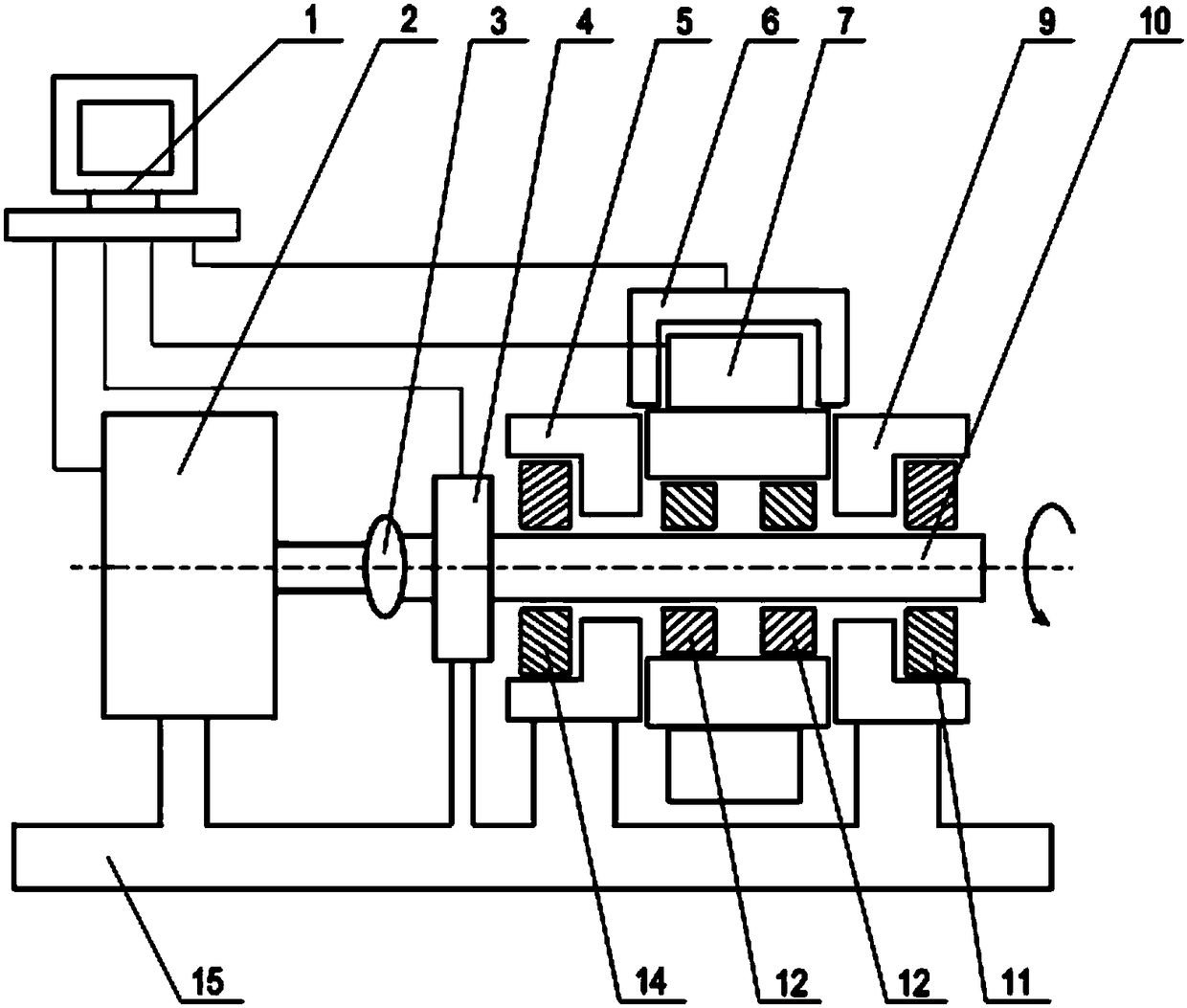

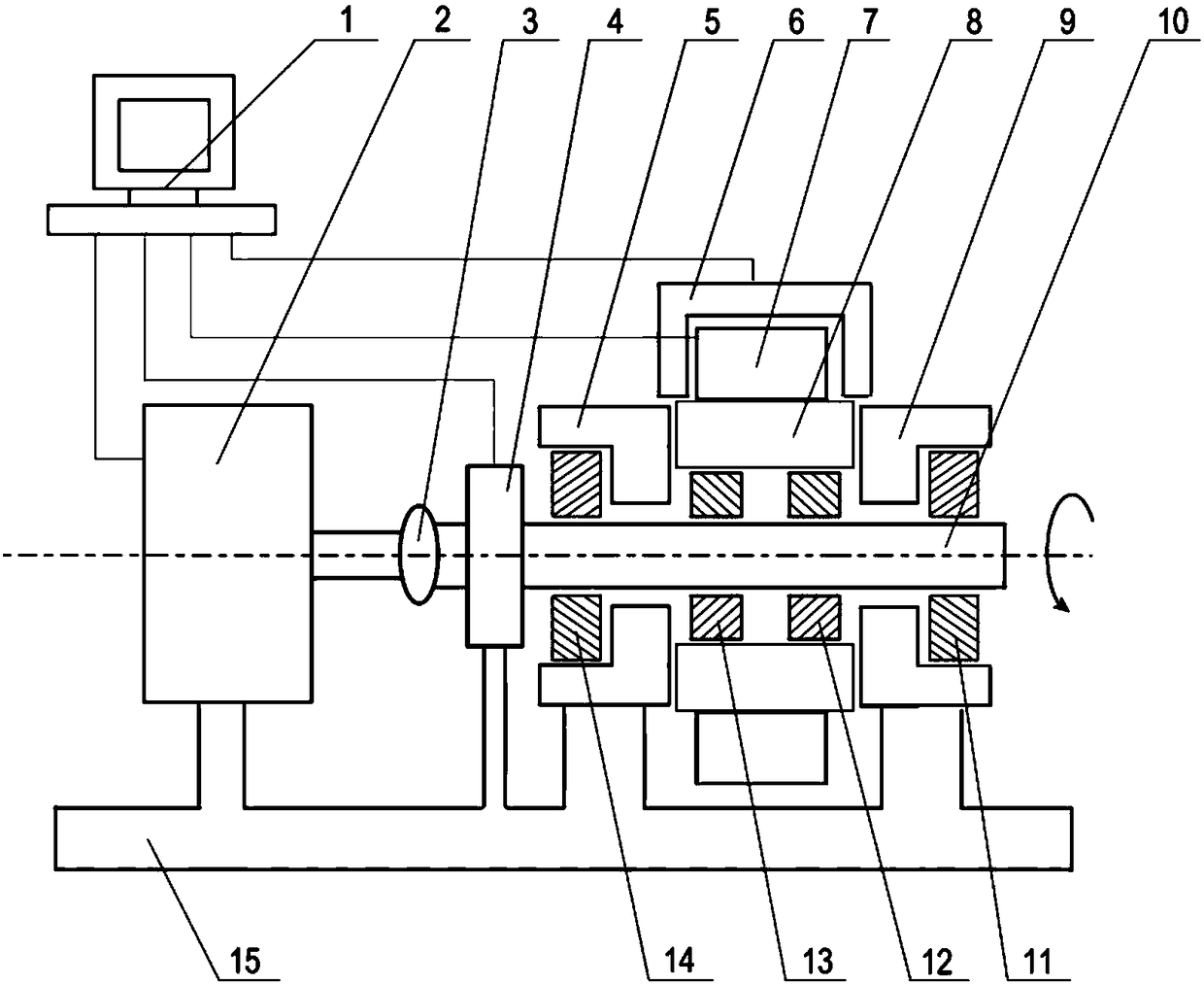

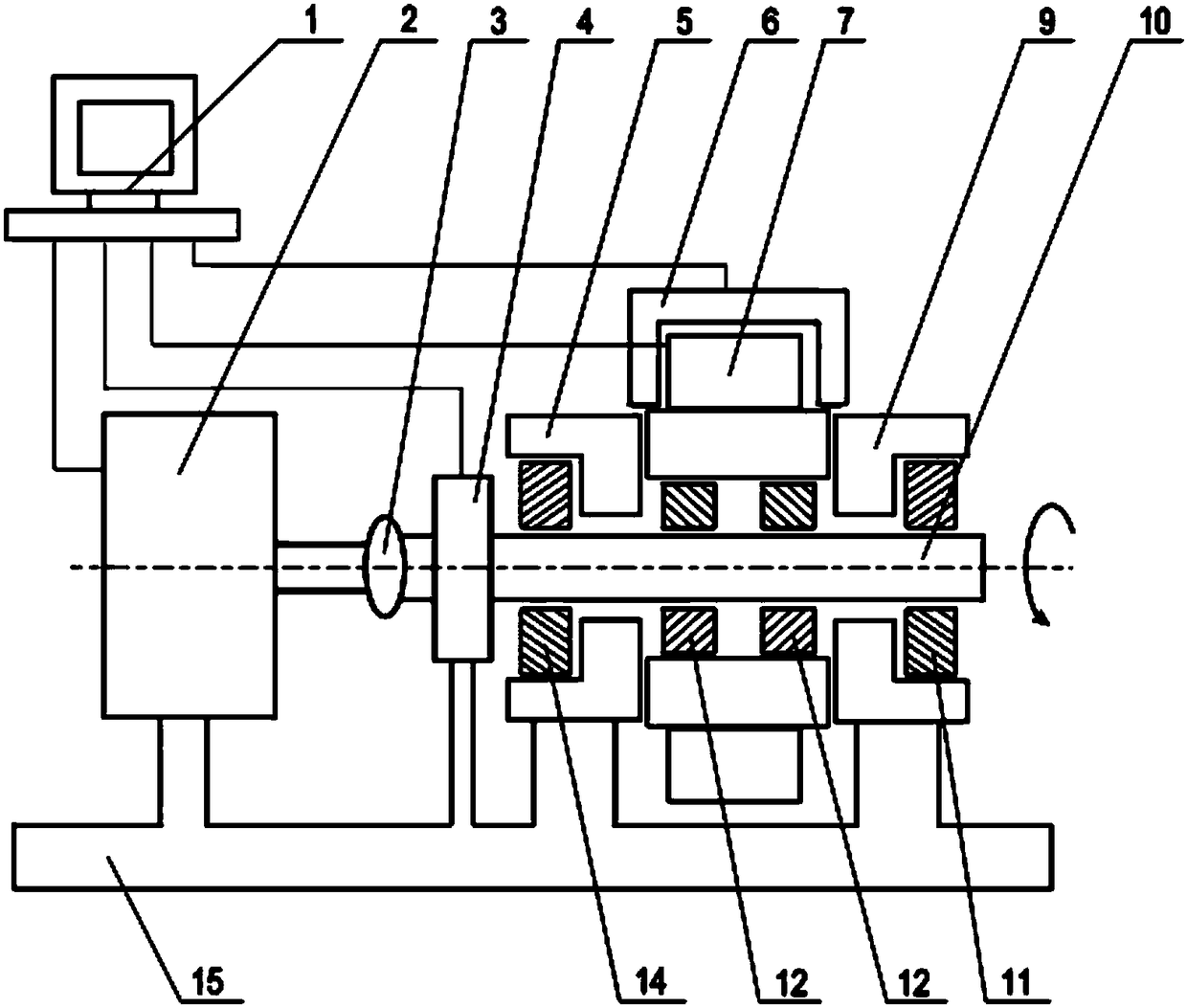

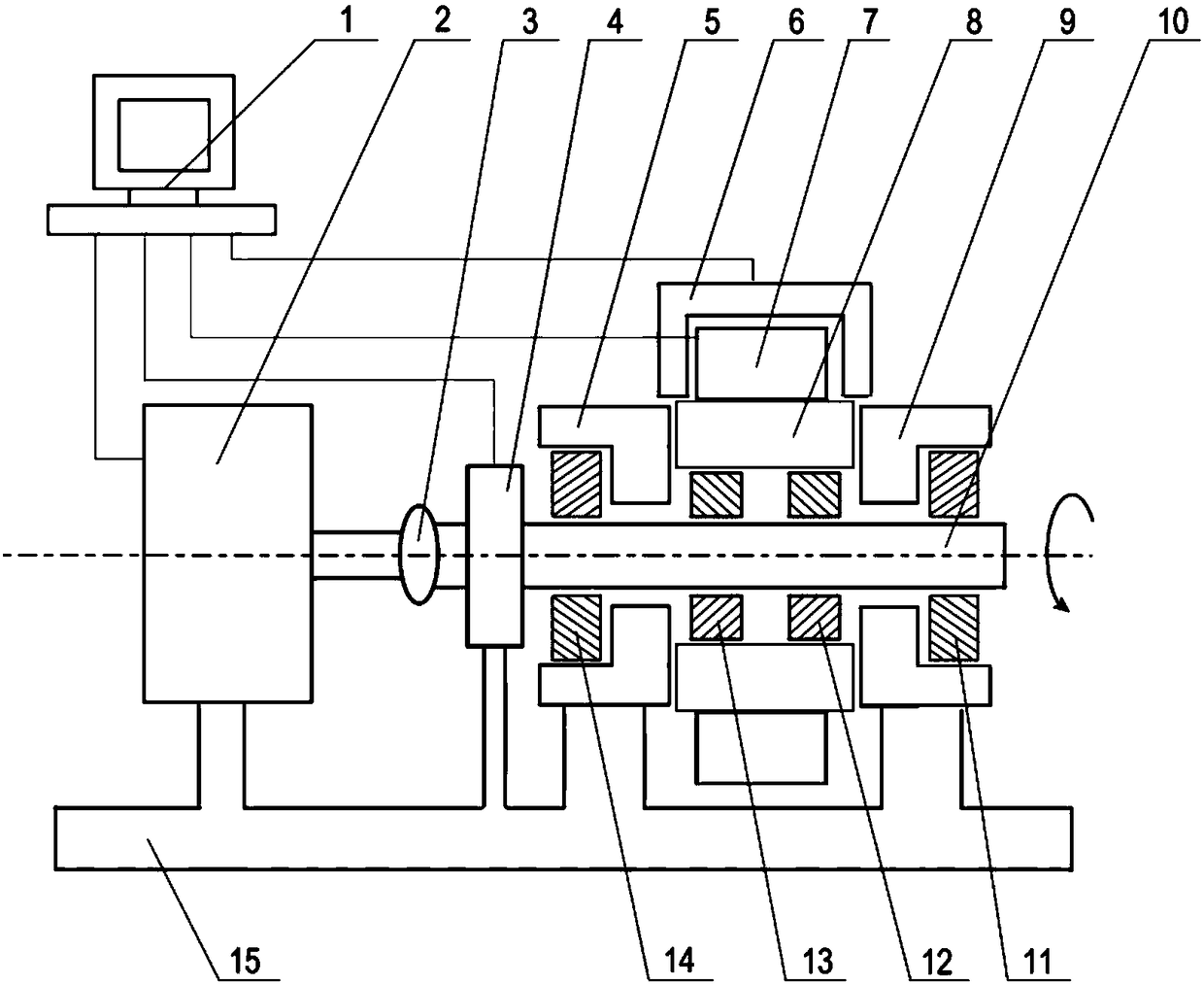

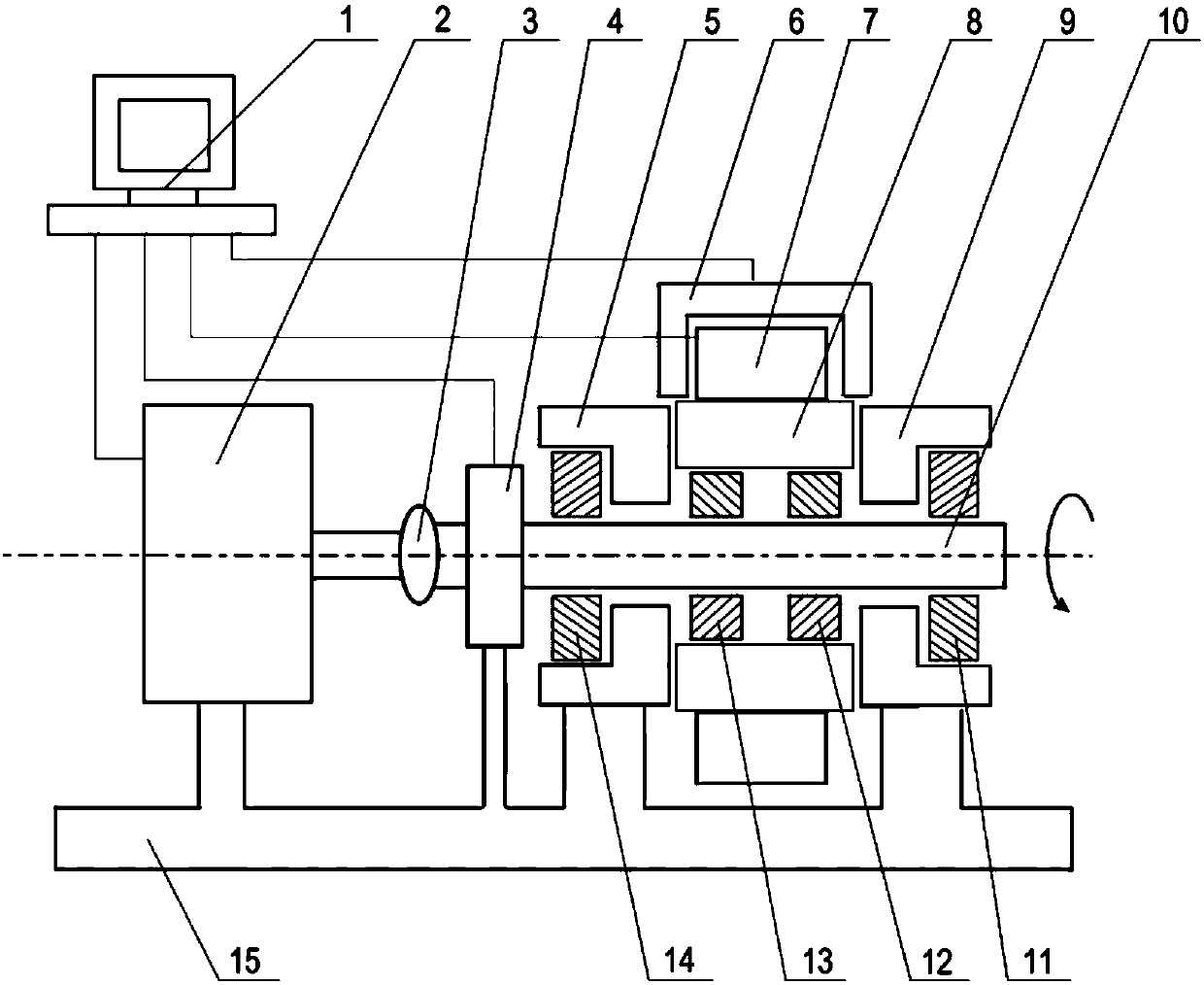

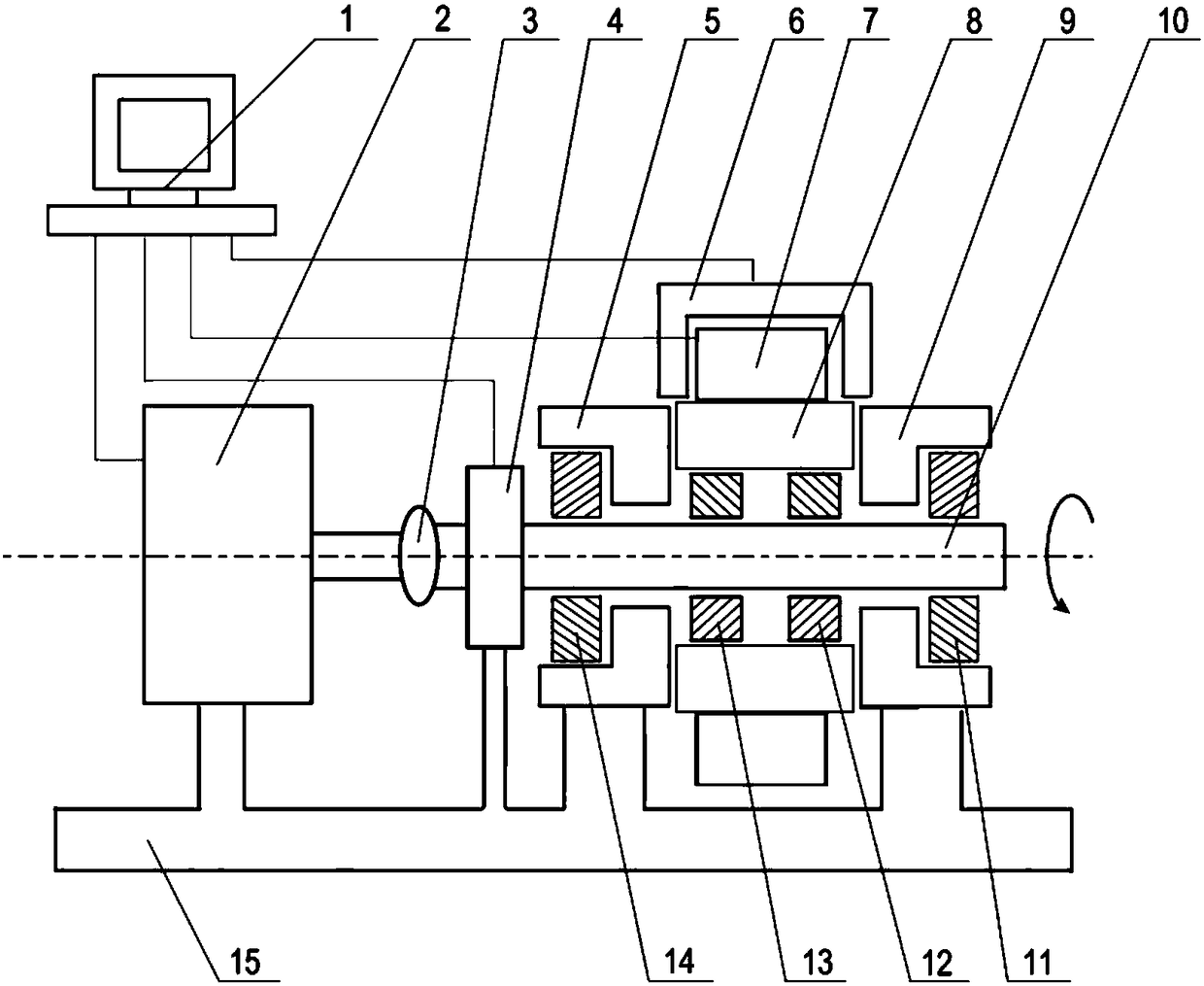

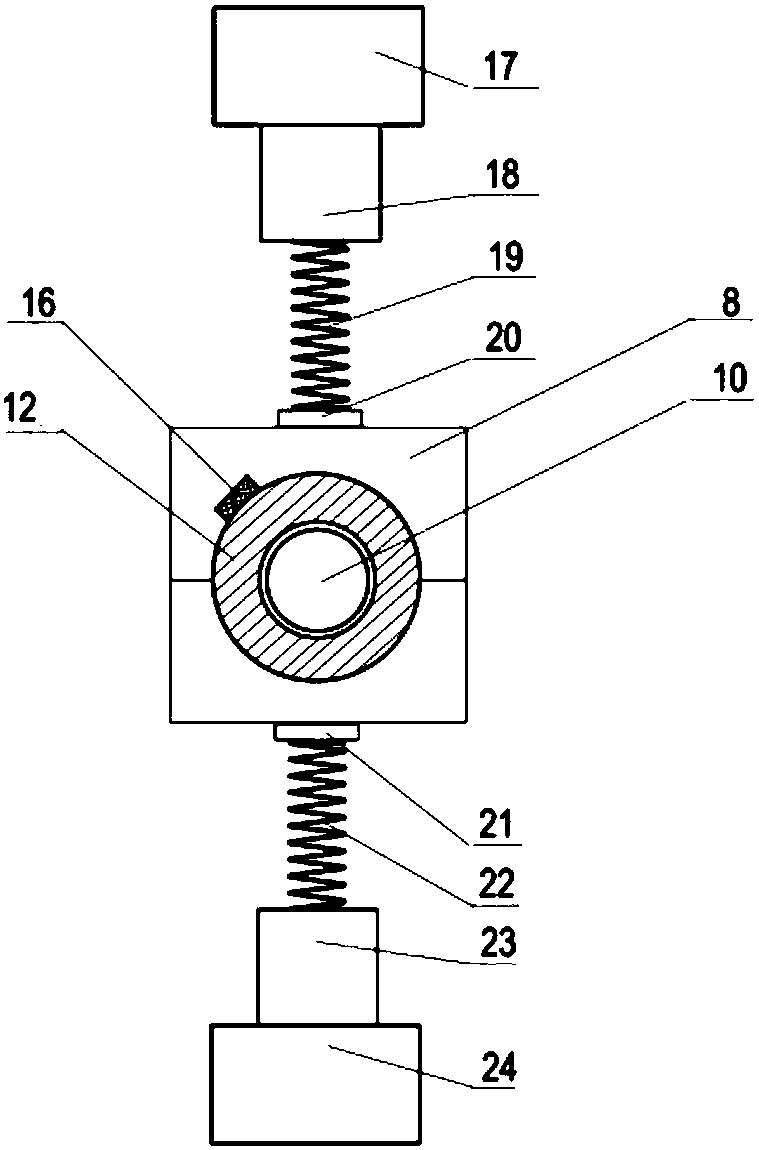

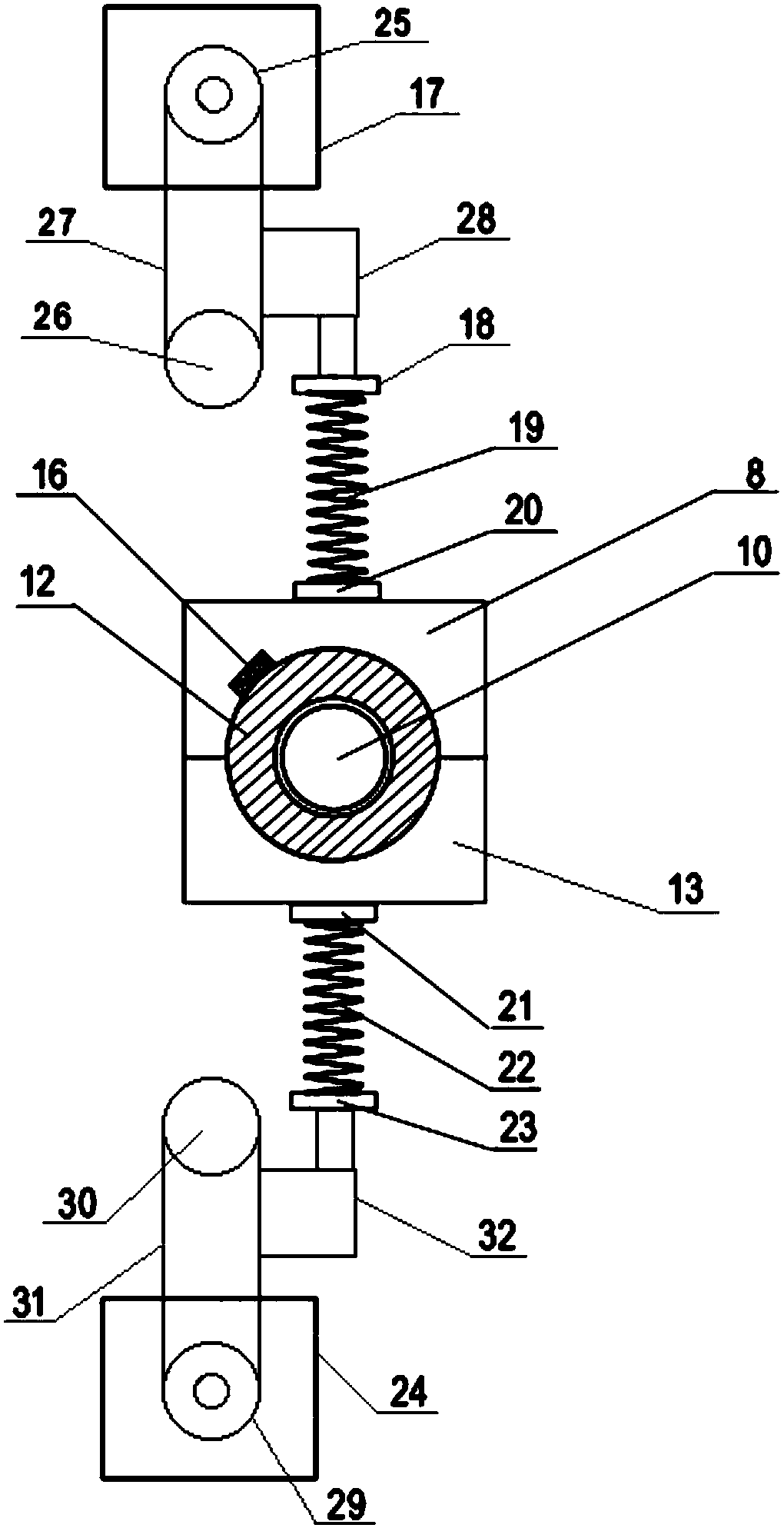

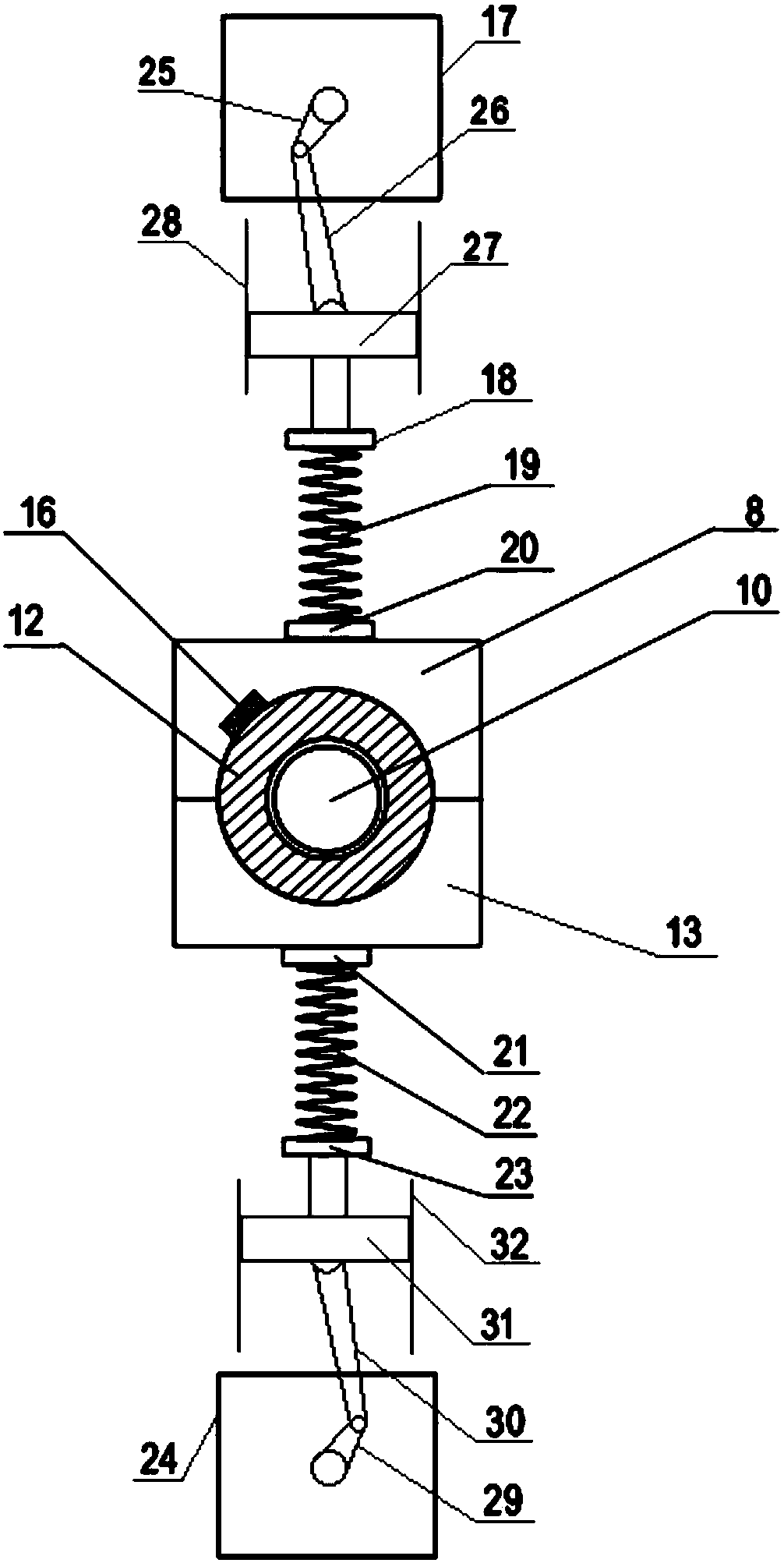

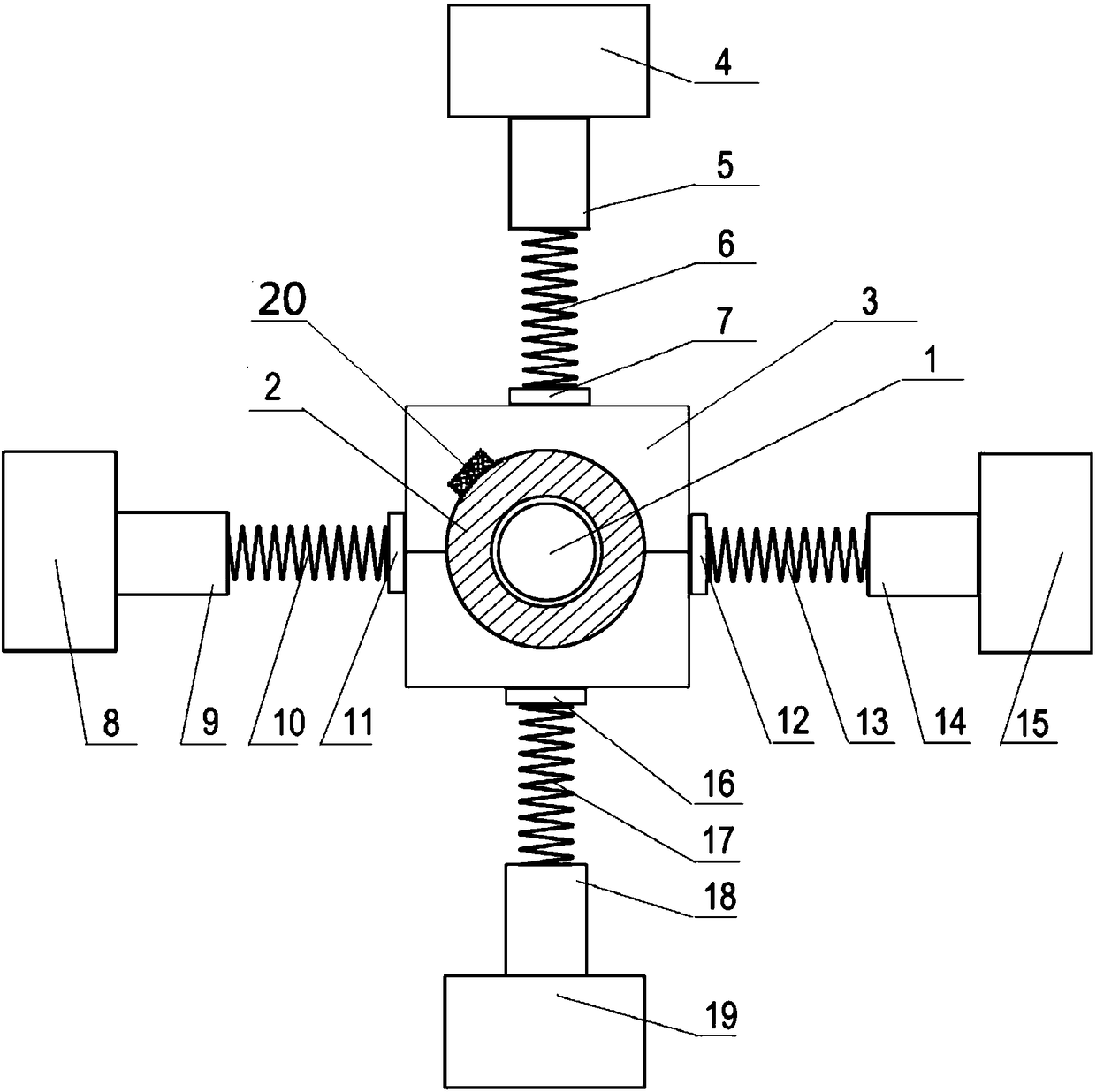

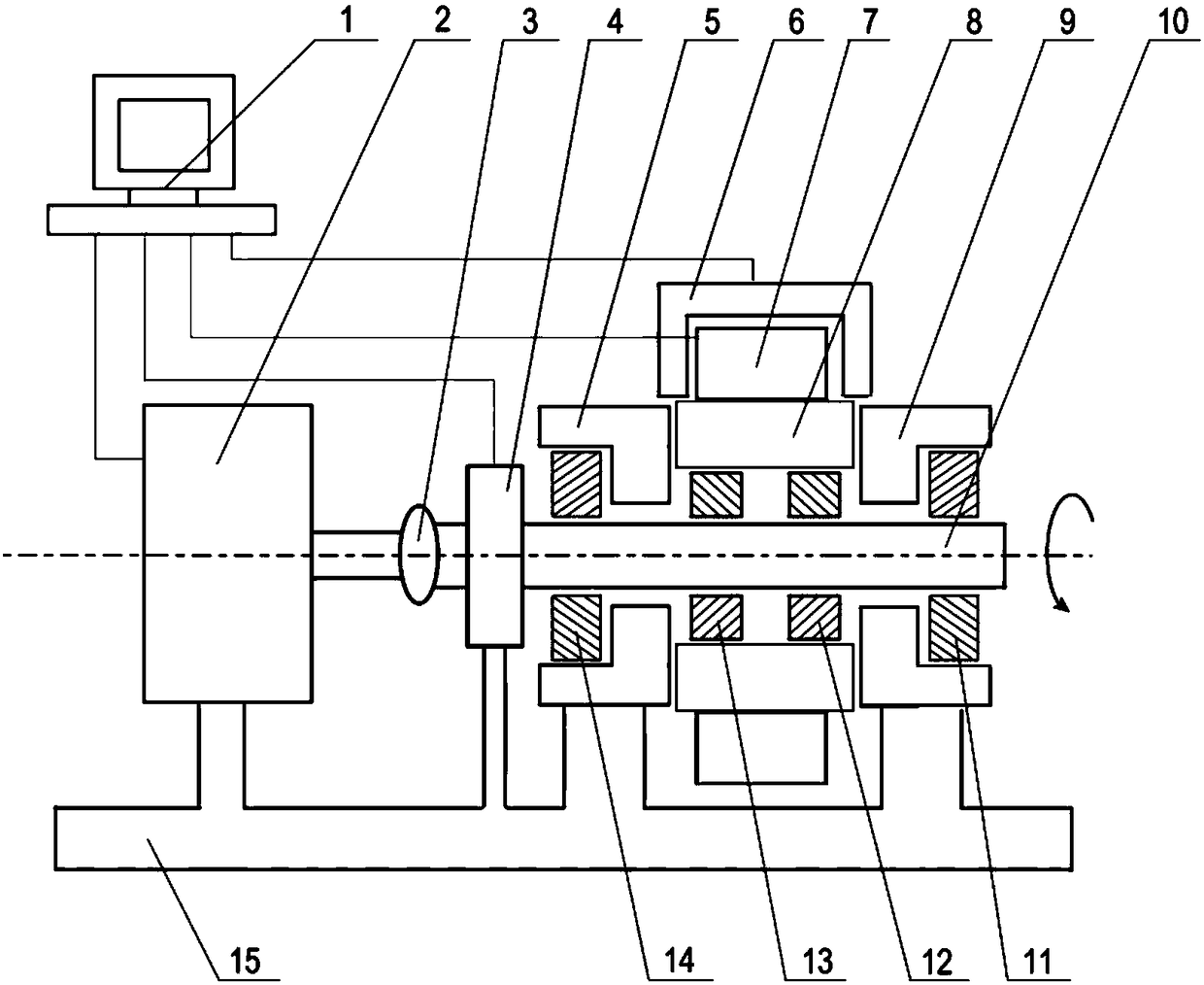

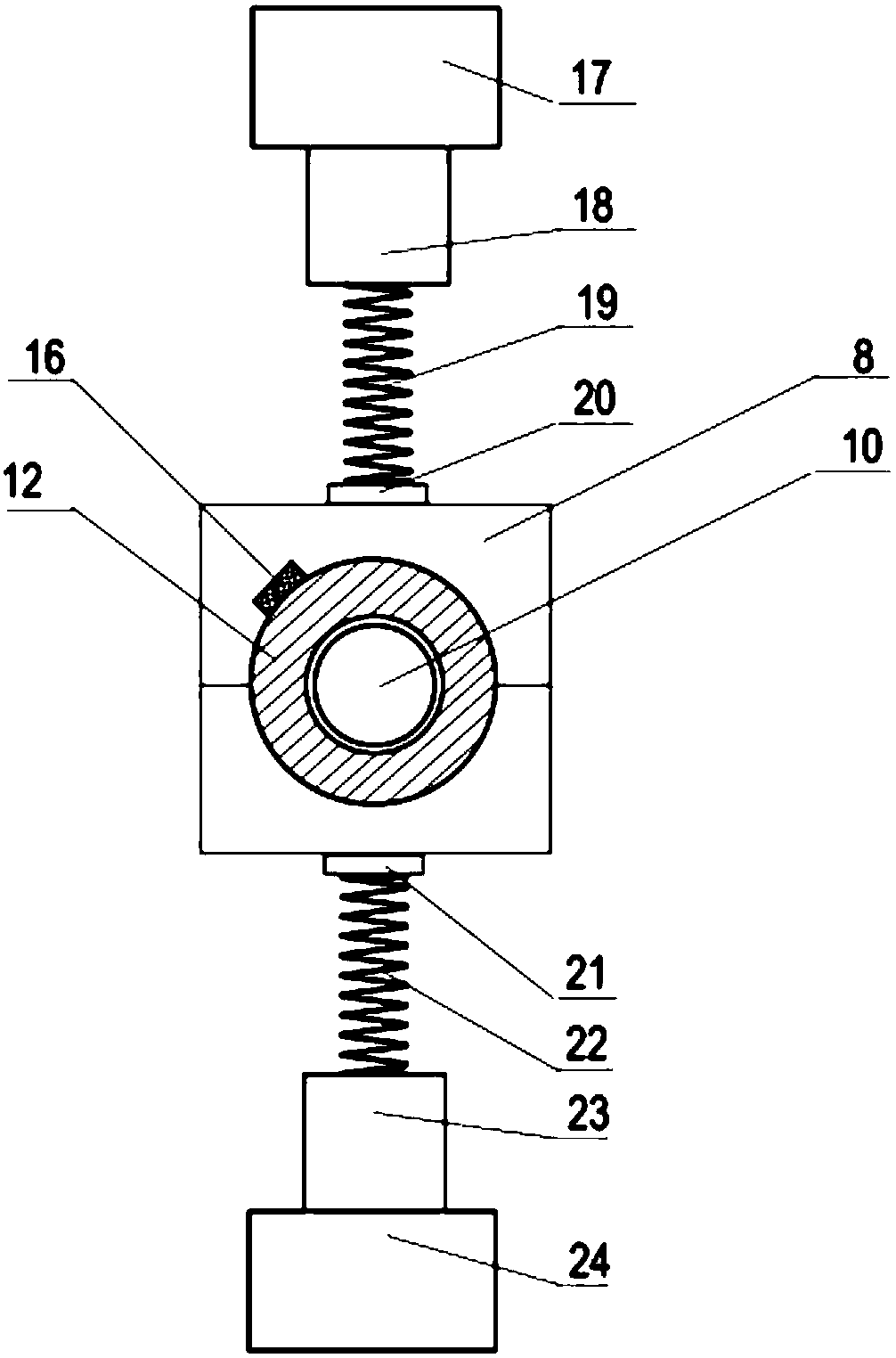

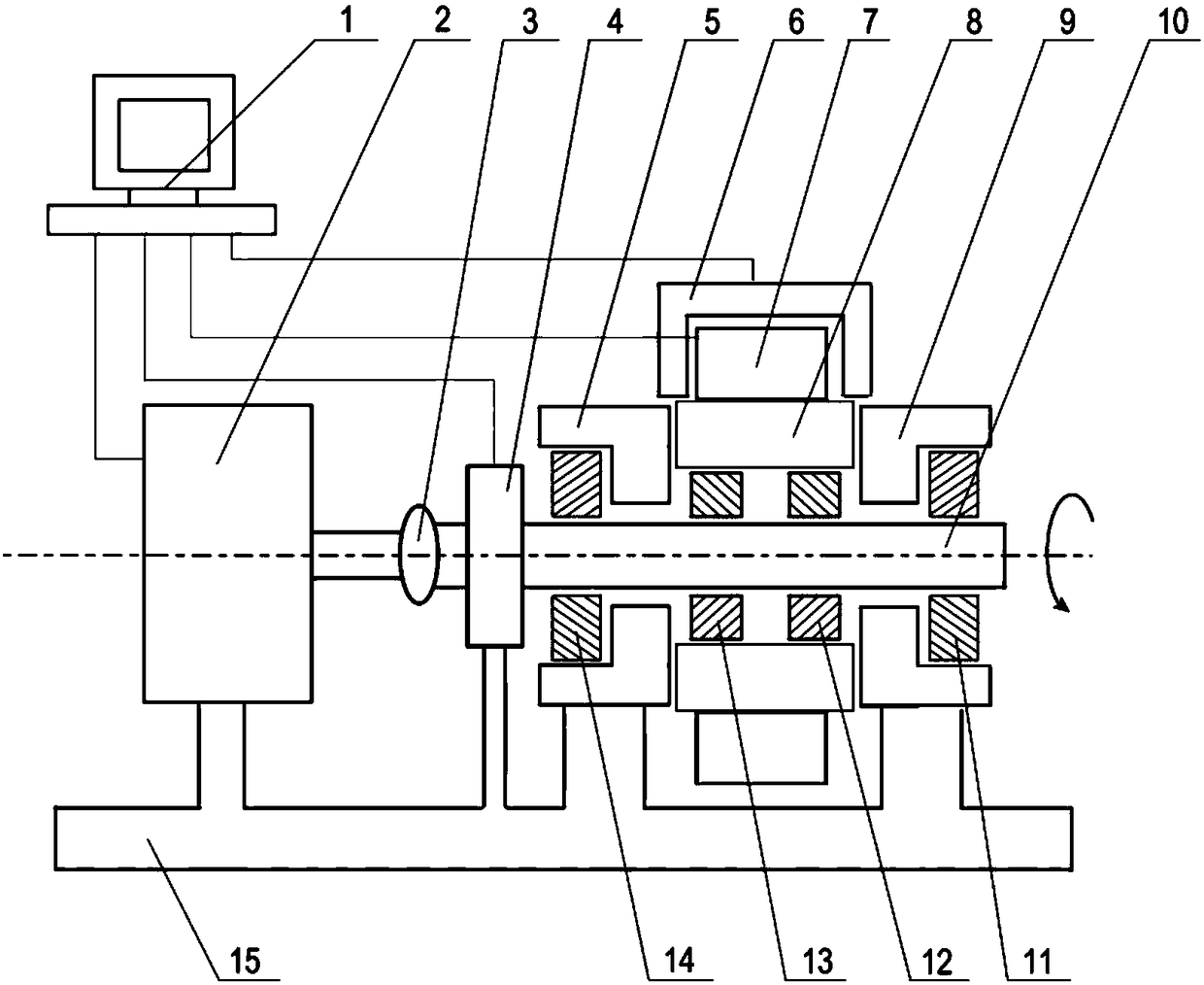

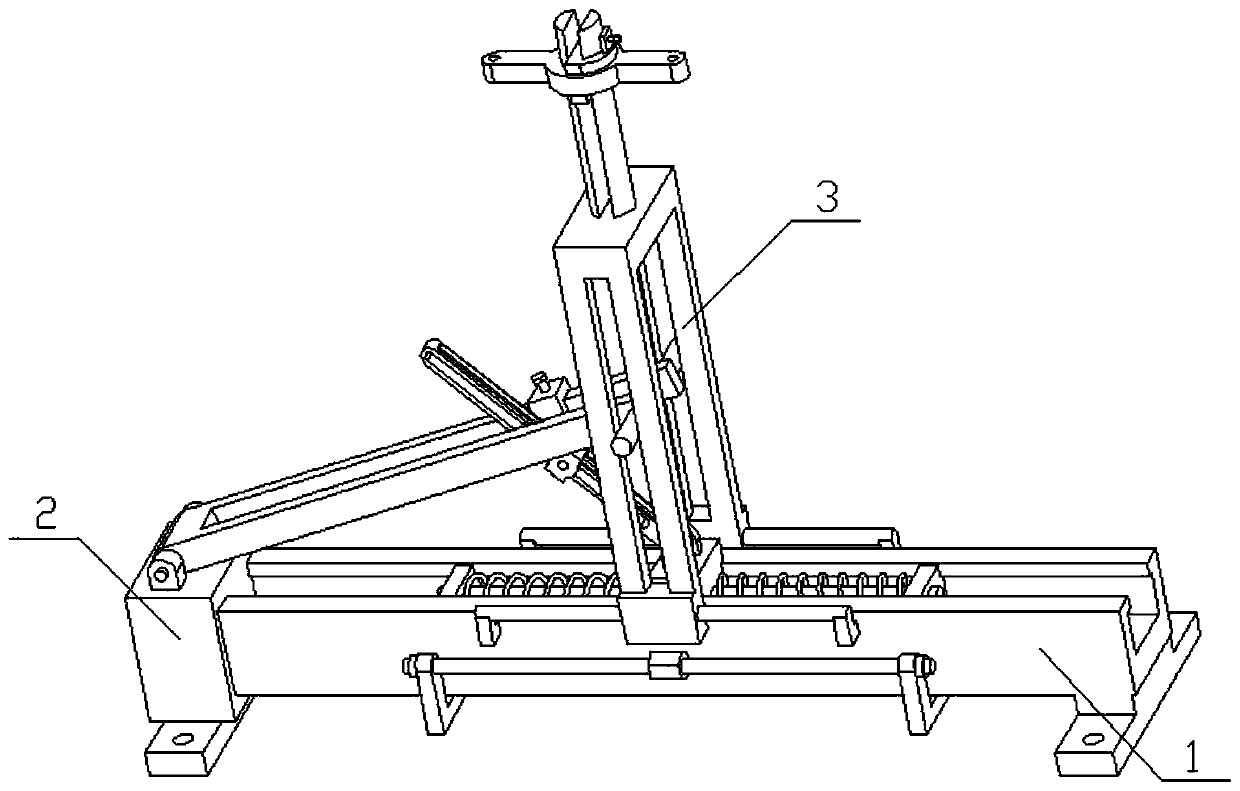

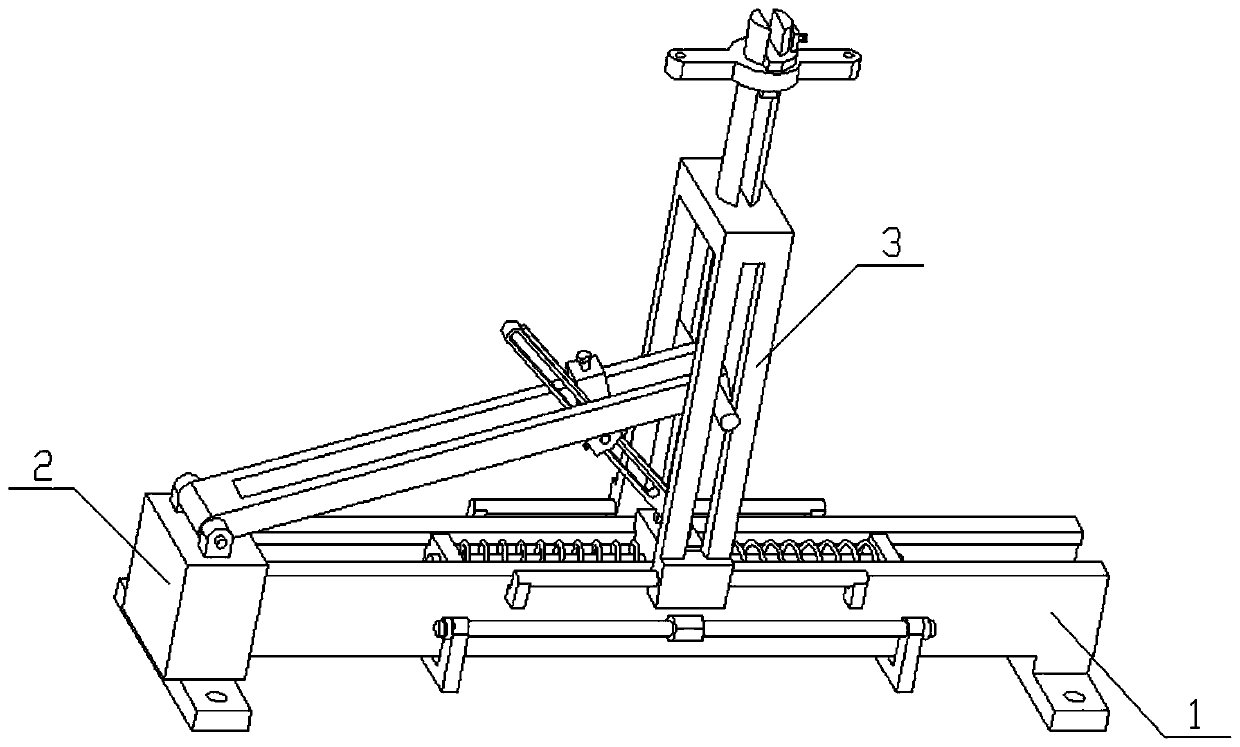

Rolling bearing fatigue life testing device capable of loading alternating load

InactiveCN108020416AControl elasticityChange the amount of compression/stretchMachine bearings testingRolling-element bearingEngineering

The invention relates to a rolling bearing fatigue life testing device capable of loading an alternating load, and the device controls the rotation of a drive motor through a computer, and drives a rolling bearing to rotate at a given speed. In an alternating load loading unit, the tension / compression quantity of a spring is affected through the displacement of a linear motor. Because of the changes of the tension / compression quantity of the spring, the spring can apply different acting forces in variable directions to the surface of a movable clamping tool. A plurality of alternating load loading units are added in different regions of the movable clamping tool, thereby achieving the loading of the alternating load. A torque meter and a temperature sensor can be used for detecting the performances of the rolling bearing in an operation process. Compared with the prior art, the device can achieve the loading of the alternating load of the rolling bearing simply and conveniently, and performs the fatigue life testing of the rolling bearing through combining with the actual working conditions of the internal combustion engine. The device is simple in structure, saves the space, and is more precise and direct in control.

Owner:SHANGHAI JIAN QIAO UNIV

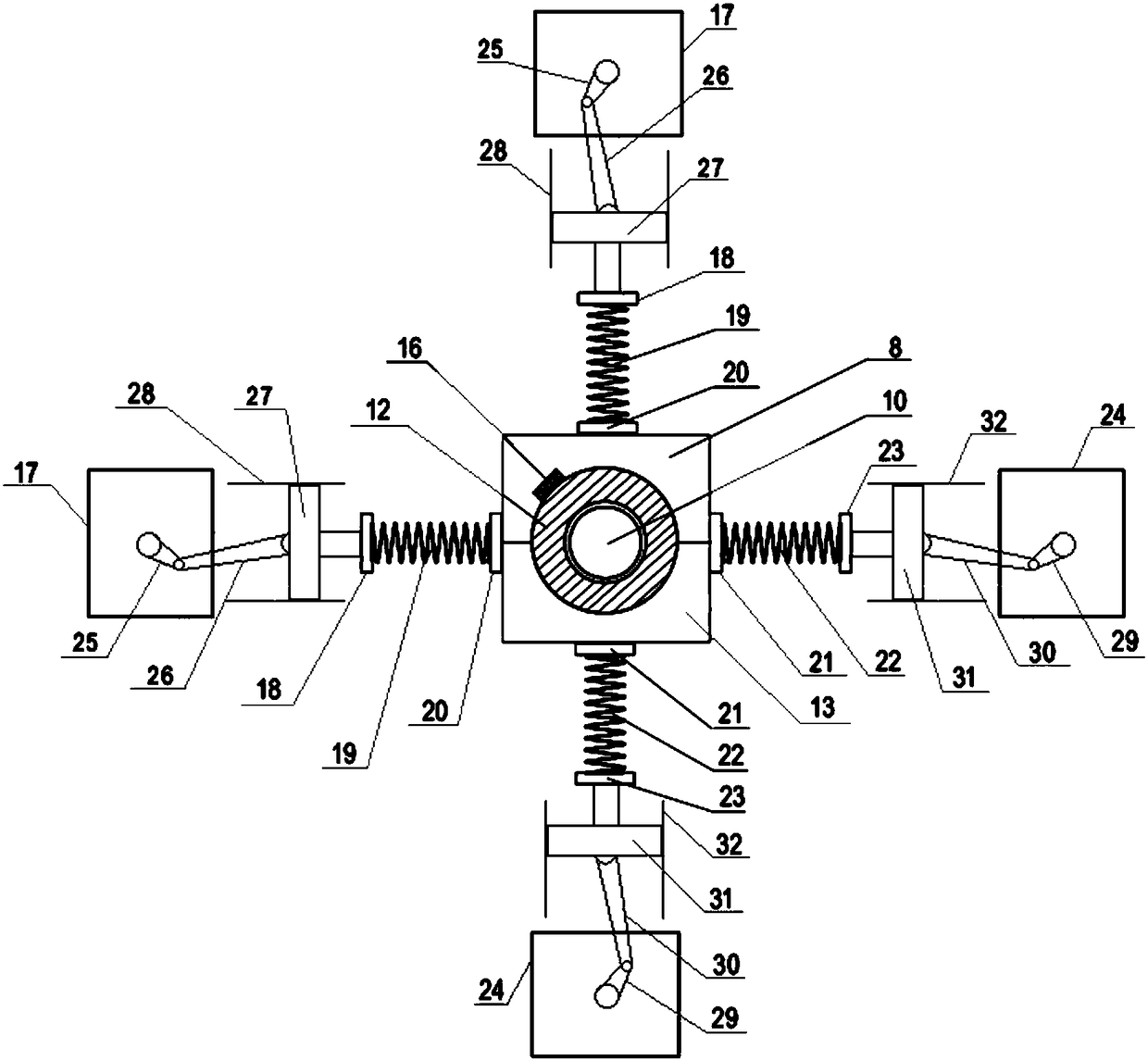

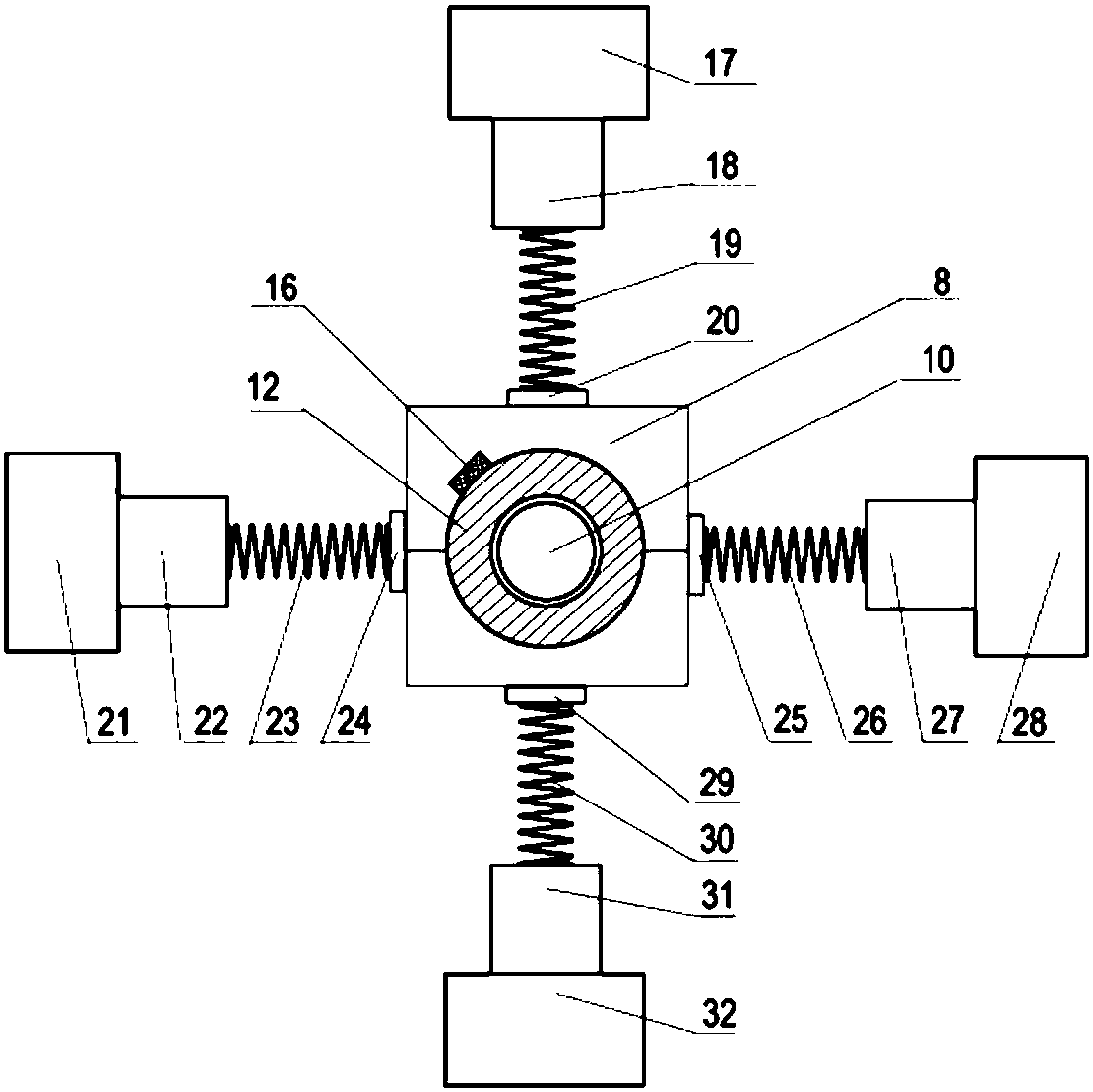

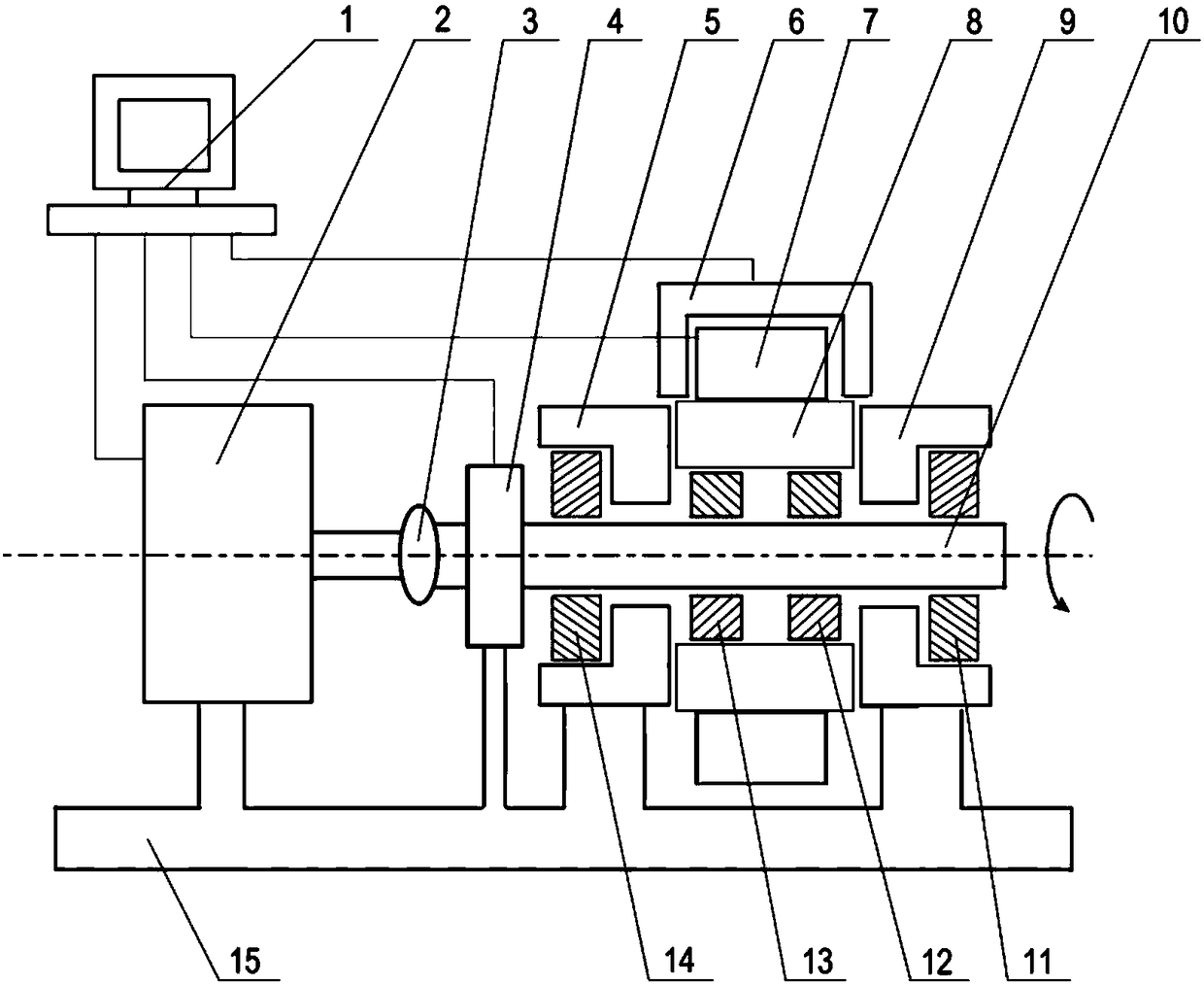

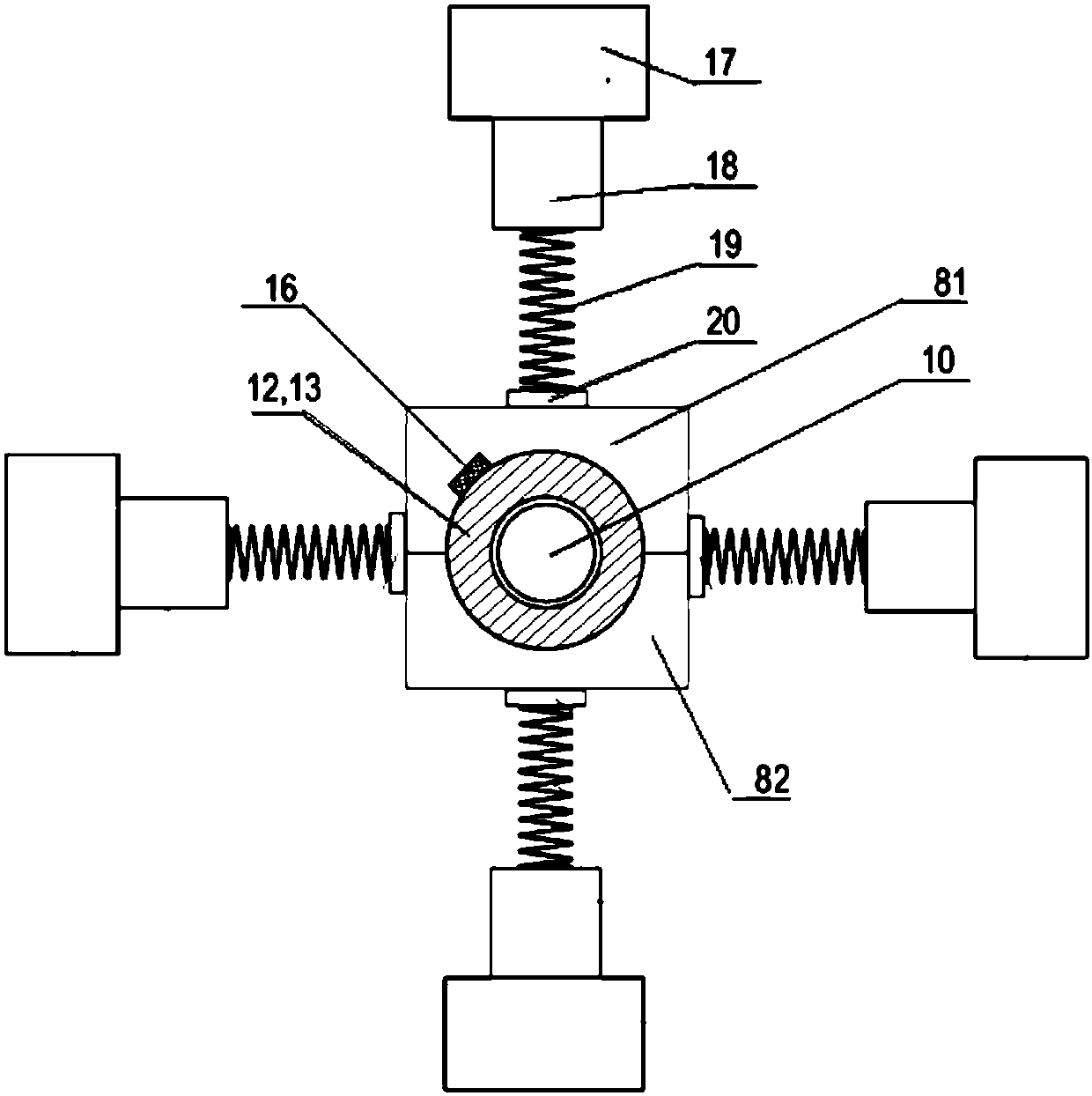

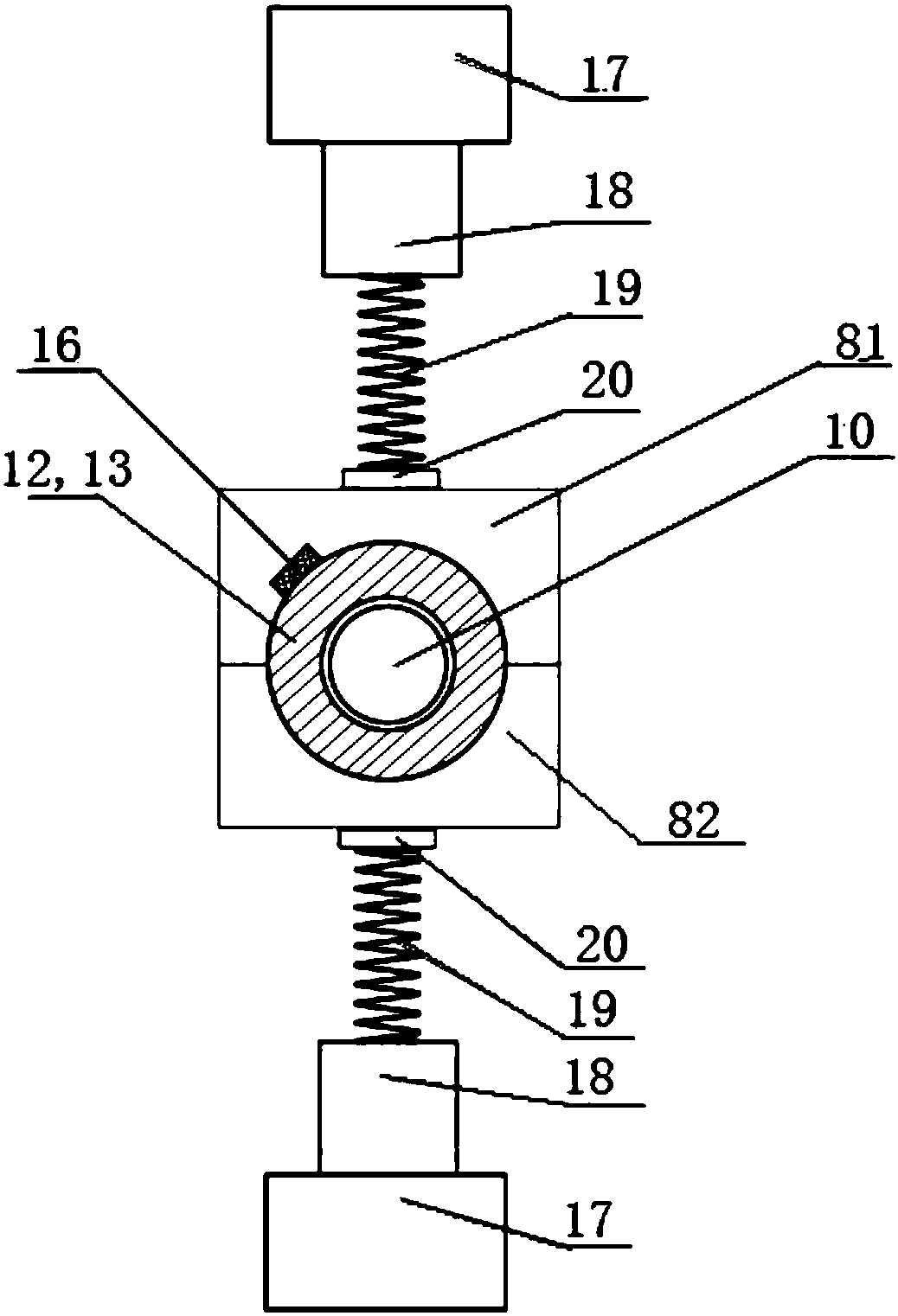

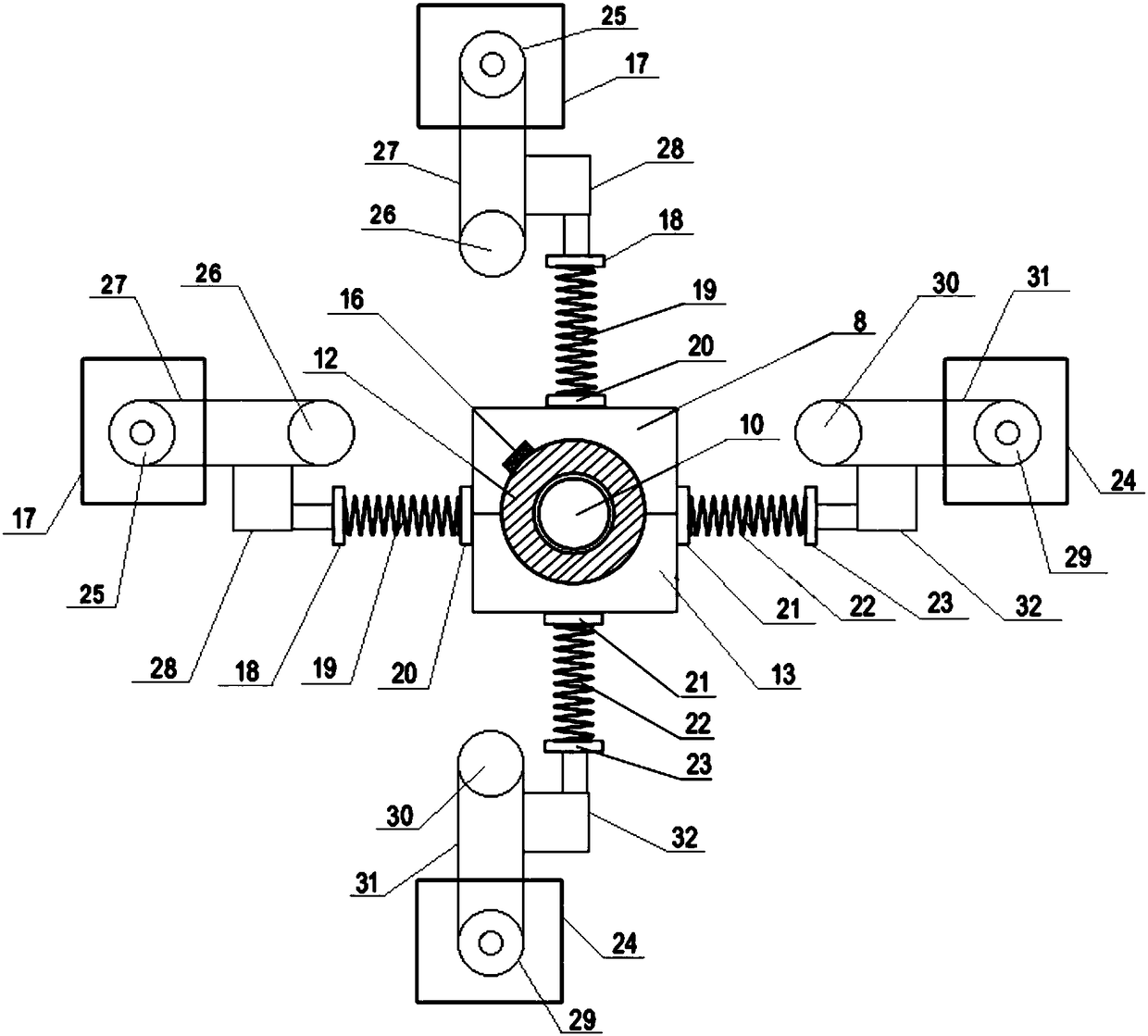

Bearing testing apparatus capable of applying radial alternating load

InactiveCN108036947AControl elasticityChange the amount of compression/stretchMachine bearings testingCouplingComputer module

The invention relates to a bearing testing apparatus capable of applying radial alternating loads. The apparatus comprises a computer, a rotary motor, a rotary shaft, an alternating load loading module and test accompanying bearings, wherein the rotary motor is controlled by the computer, the output shaft of the rotary motor is connected to the rotary shaft through a coupling; a tested sliding bearing sleeves on the rotary shaft; a movable clamp sleeves on the sliding bearing; the test accompanying bearings are arranged on the left and right sides of the sliding bearing; fixed clamps are arranged on the outer sides of the test accompanying bearings to fix and support; the alternating load loading module is arranged on the movable clamp and is composed of four groups of assemblies which aresymmetrical in pairs in four directions. Each of the assemblies comprises a linear motor, a spring and a connecting device. Compared with the prior art, the apparatus can load alternating loads in four direction and two radial directions of the bearing.

Owner:SHANGHAI JIAN QIAO UNIV

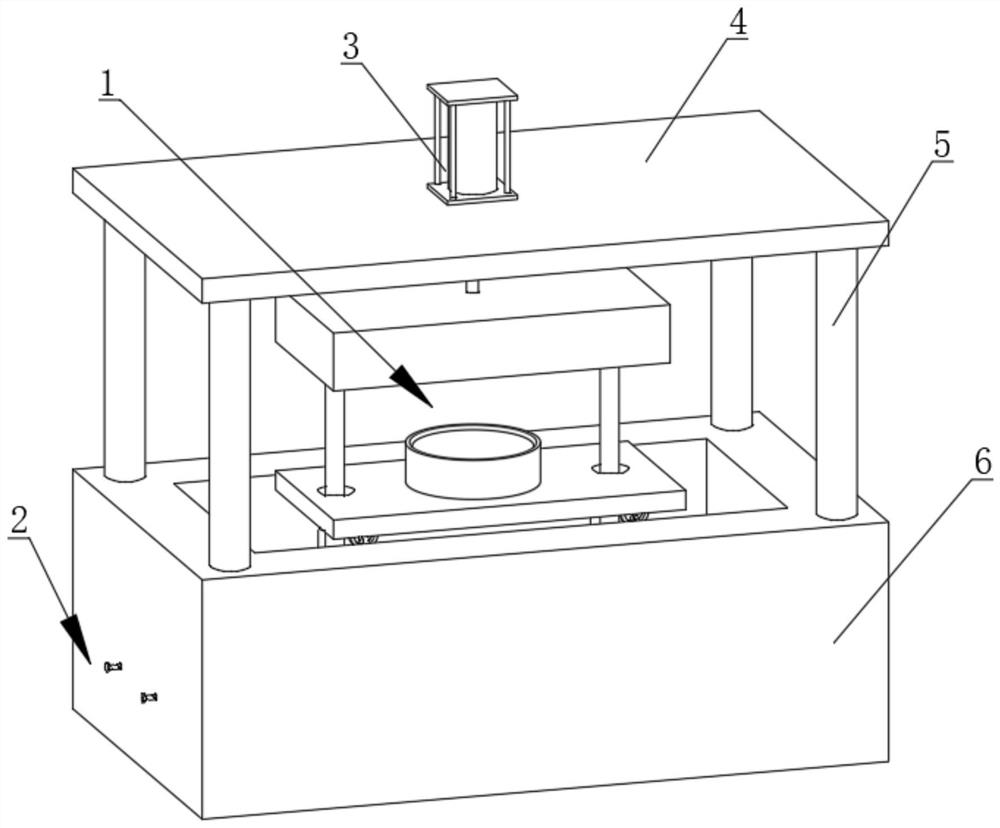

Rolling bearing performance testing device capable of applying radial alternating load based on crank connecting rod

InactiveCN108254185AAccurate and reliable performance test resultsControl elasticityMachine bearings testingRolling-element bearingElectric machine

The invention relates to a rolling bearing performance testing device capable of applying radial alternating load based on a crank connecting rod. The testing device comprises a workbench, a rotatingshaft supporting mechanism, a rotating shaft, a driving motor and a radial alternating load loading unit. The radial alternating load loading unit consists of a loading unit bracket, a clamping blockassembly and a pair of radial crank connecting rod loading mechanisms being arranged on the loading unit bracket and being perpendicular to each other. The radial crank connecting rod loading mechanisms include first rotary motors, second rotary motors, first crank connecting rod assemblies, first spring loading assemblies, second crank connecting rod assemblies, and second spring loading assemblies. Compared with the prior art, the rolling bearing performance testing device has the following beneficial effects: the first rotary motors and the second rotary motors apply radial alternating loads on a rolling bearing in the clamping block assembly by the first spring loading assemblies and the second spring loading assemblies so as to simulate the real working condition of the dynamic loading rolling bearing in the internal combustion engine, so that the high accuracy and reliability of the performance testing result of the rolling bearing are guaranteed.

Owner:SHANGHAI JIAN QIAO UNIV

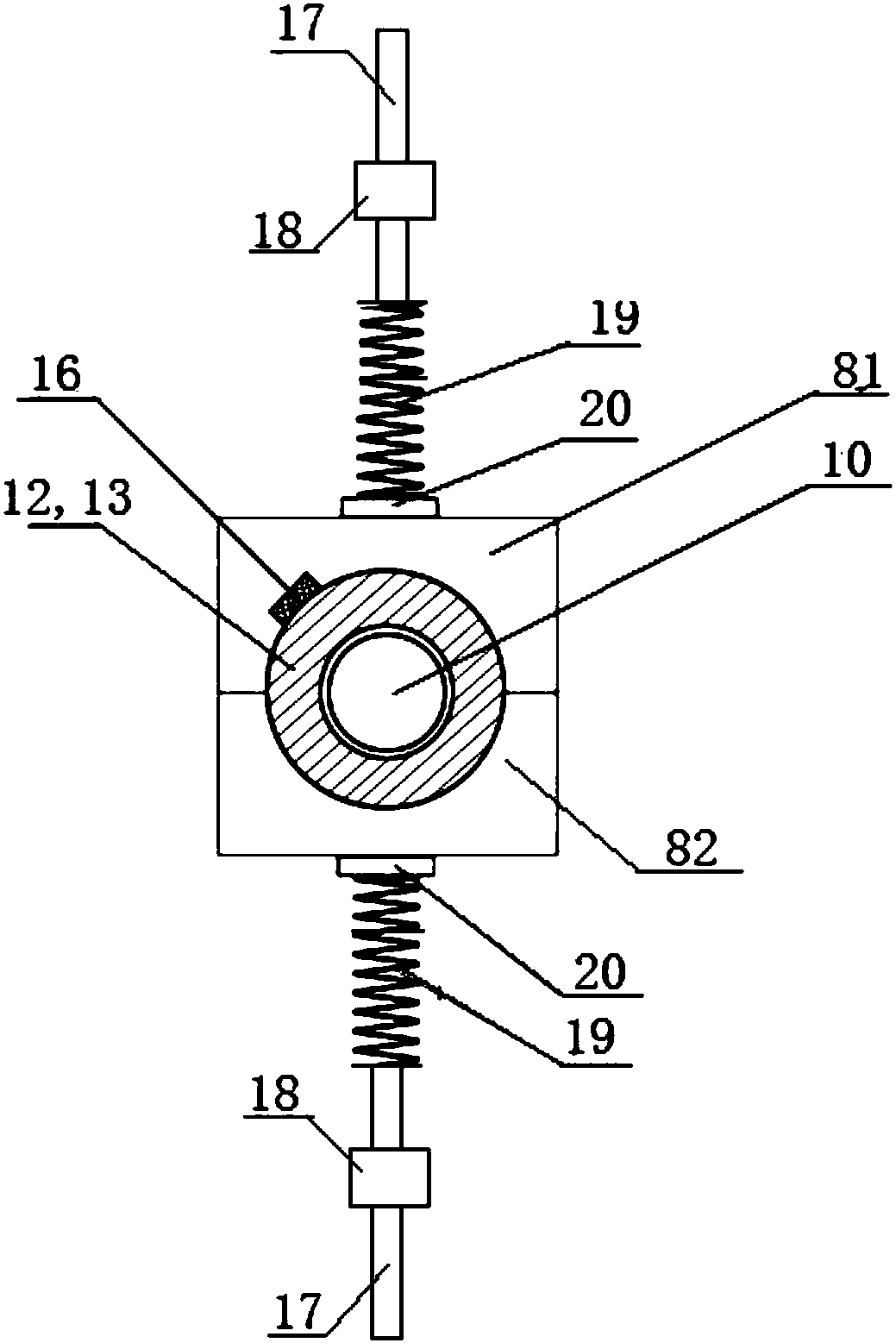

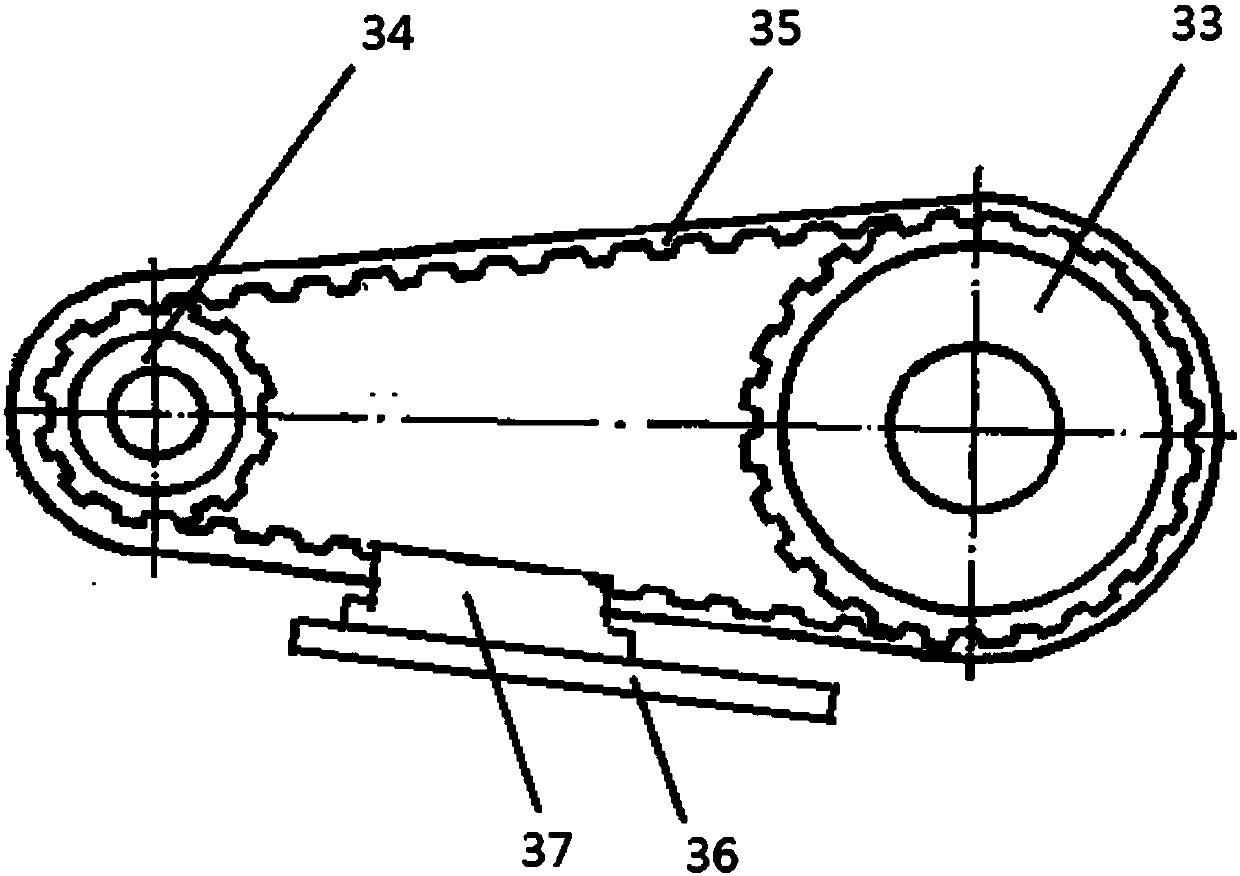

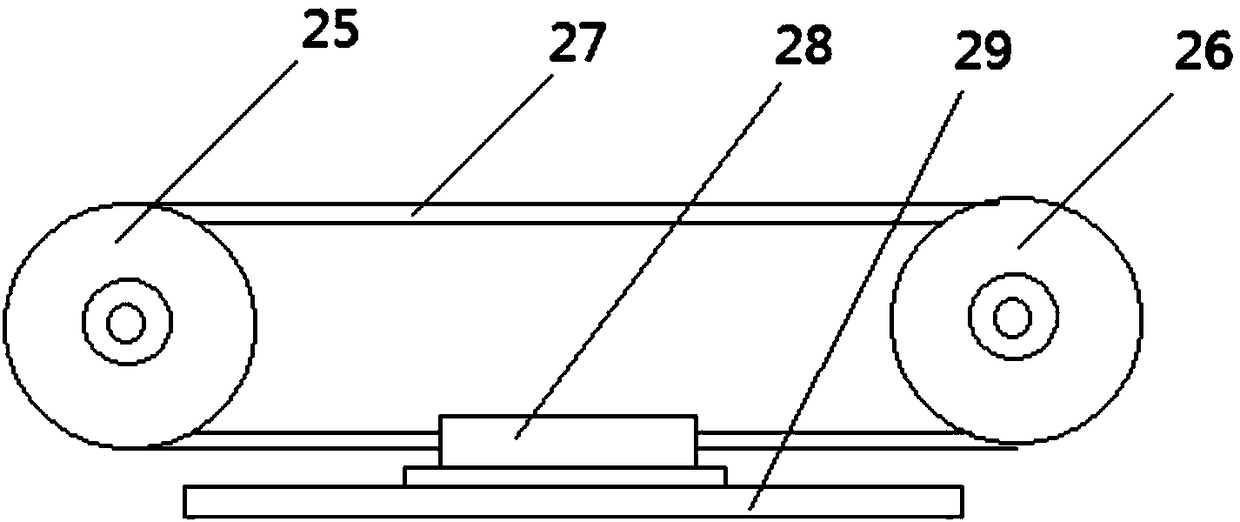

Bearing test device for applying radial alternating load based on synchronous belt drive mechanism

The invention relates to a bearing test device for applying radial alternating load based on a synchronous belt drive mechanism. The bearing test device comprises a computer which is connected with adriving motor. The output shaft of the driving motor is connected with a rotating shaft through a coupler. The rotating shaft is externally sleeved by a detected bearing which is a sliding bearing. The bearing test device also comprises a radial alternating load loading module which is arranged on the detected bearing. The radial alternating load loading module comprises a temperature sensor whichis arranged on the detected bearing and loading parts which are arranged on the external side of the detected bearing and symmetrical in the four directions. Each loading part comprises a rotating motor, the synchronous belt drive mechanism which is connected with the rotating motor, a spring which is connected with the synchronous belt drive mechanism and a connecting mechanism which is connected with the other end of the spring. The synchronous belt drive mechanism comprises a driving wheel, a driven wheel and a slide block. The driving wheel and the driven wheel are connected through a chain, and the slide block is clamped on the chain to synchronously move along with the chain. Loading of the alternating load of four directions and two radial directions on the bearing can be realized.

Owner:SHANGHAI JIAN QIAO UNIV

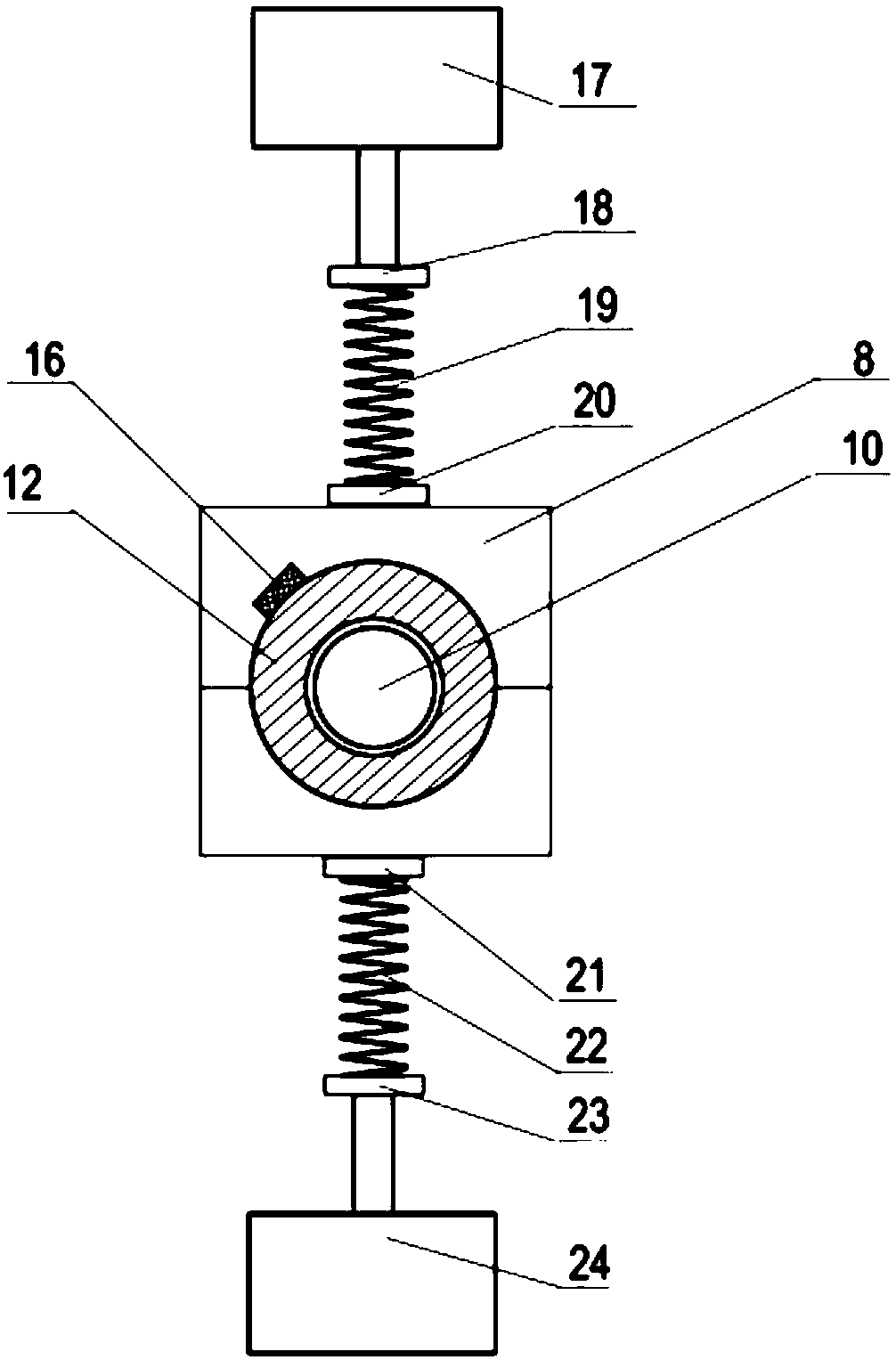

Bearing test device capable of loading alternating load

InactiveCN108168888AControl elasticityChange the amount of compression/stretchMachine bearings testingEngineeringPlain bearing

The invention relates to a bearing test device capable of loading alternating load. The bearing test device comprises a computer, a rotating motor, a rotating shaft, an alternating load loading moduleand assistant test components. The rotating motor is controlled by the computer. The output shaft of the rotating motor is connected with the rotating shaft through a coupler. The rotating shaft is sleeved by a tested sliding bearing. The left and right sides of the sliding bearing are provided with the assistant test components. The alternating load loading module is arranged on a flexible clampand composed of two sets of components which are vertically symmetrical. Each component comprises a linear motor, a spring and a connecting device. Compared with the bearing test devices in the priorart, the engine dynamically loaded bearing test can be developed.

Owner:SHANGHAI JIAN QIAO UNIV

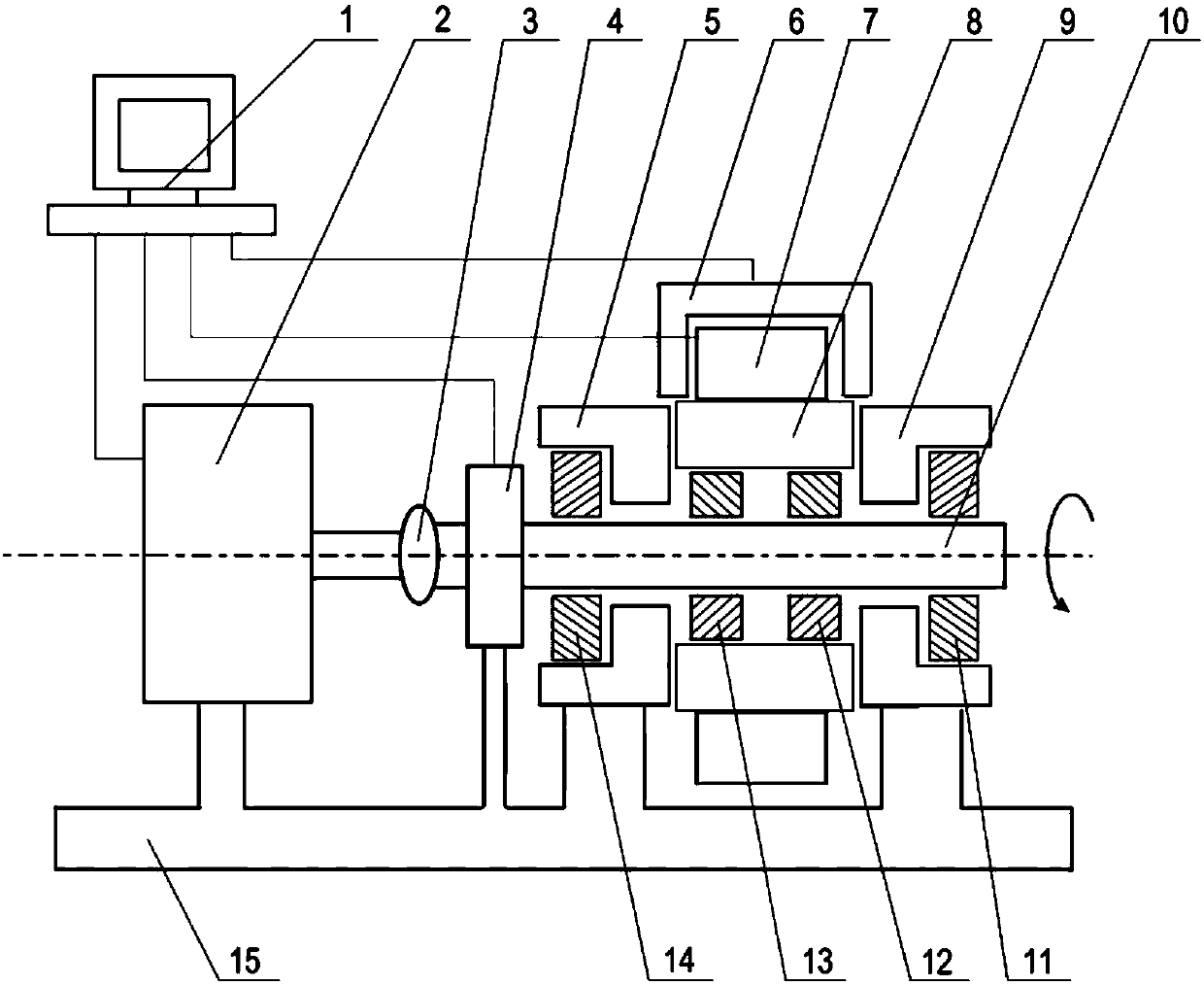

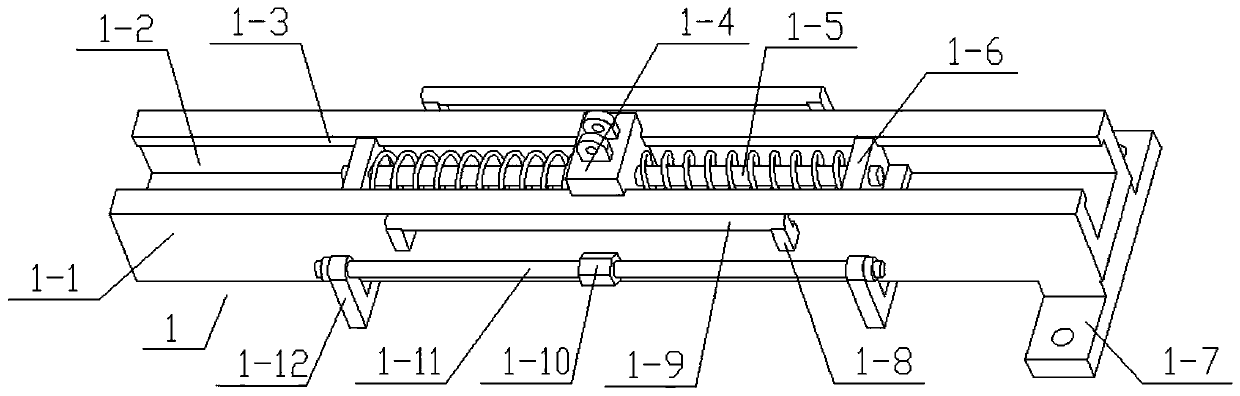

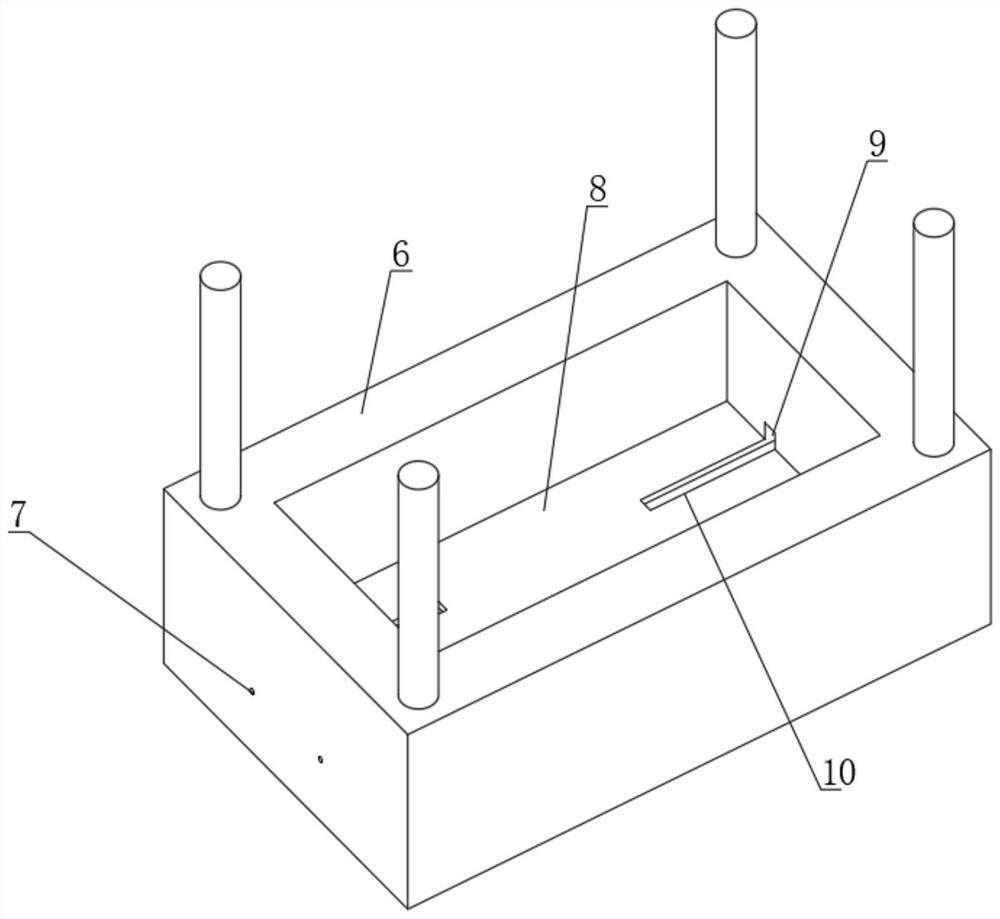

Rolling bearing performance testing device for applying radial alternating loads based on lead screw transmission

InactiveCN108152039AAccurate and reliable performance test resultsControl elasticityMachine bearings testingDrive motorEngineering

The invention relates to a rolling bearing performance testing device for applying radial alternating loads based on lead screw transmission. The rolling bearing performance testing device comprises aworking platform, a rotary shaft supporting mechanism, a rotary shaft, a driving motor and a radial alternating load loading unit, the radial alternating load loading unit comprises a loading unit support, a clamping block assembly and a pair of lead screw transmission radial loading mechanisms which are perpendicular to each other and are arranged on the loading unit support, and each lead screwtransmission radial loading mechanism comprises a first rotary motor, a second rotary motor, a first lead screw transmission assembly, a first spring loading assembly, a second lead screw transmission assembly and a second spring loading assembly. Compared with the prior art, the first rotary motors and the second rotary motors can apply radial alternating loads to rolling bearings in the clamping block assembly respectively through the first spring loading assemblies and the second spring loading assemblies to simulate the actual working condition of the mobile-load rolling bearings in an internal combustion engine, and the accuracy and reliability of the rolling bearing performance testing result are guaranteed.

Owner:SHANGHAI JIAN QIAO UNIV

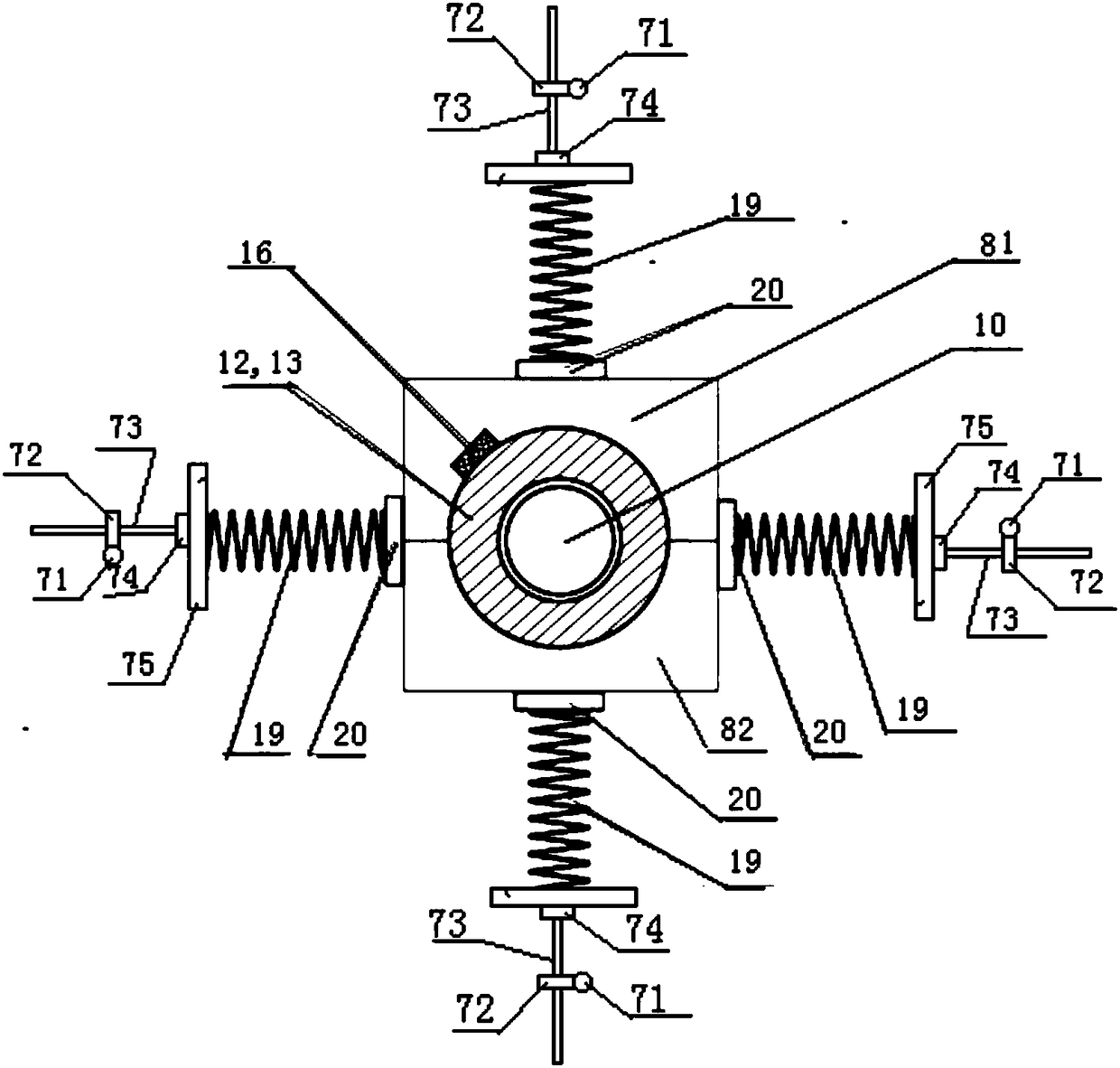

Rolling bearing fatigue life testing system for loading radial alternating load by lead screw drive

InactiveCN108254186AControl elasticityController) to control the elasticityMachine bearings testingLinear motionRolling-element bearing

The invention relates to a rolling bearing fatigue life testing system for loading a radial alternating load by lead screw drive. According to the system, a computer is used for controlling rotation of a driving motor to drive a rolling bearing to make rotation. The rotation motion of a rotary motor is transformed into a linear motion by a lead screw transmission mechanism in a lead screw transmission radial alternating load loading unit, so that the stretching / compression amount of the spring is affected; and because of changing of the stretching / compression amount of the spring, the spring is able to apply acting forces with different degrees and changeable directions at a movable clamp. Loading of the radial alternating load of the bearing is realized by adding a plurality of lead screwtransmission radial alternating load loading units in different areas of the moving clamp. A torquemeter and a temperature sensor are used for detecting performances of the rolling bearing in operation. Compared with the prior art, the testing system has the following beneficial effects: loading of the radial alternating load of the rolling bearing can be realized simply, conveniently and accurately; and the fatigue life testing of the rolling bearing is carried out by combining the real working condition of the internal combustion engine.

Owner:SHANGHAI JIAN QIAO UNIV

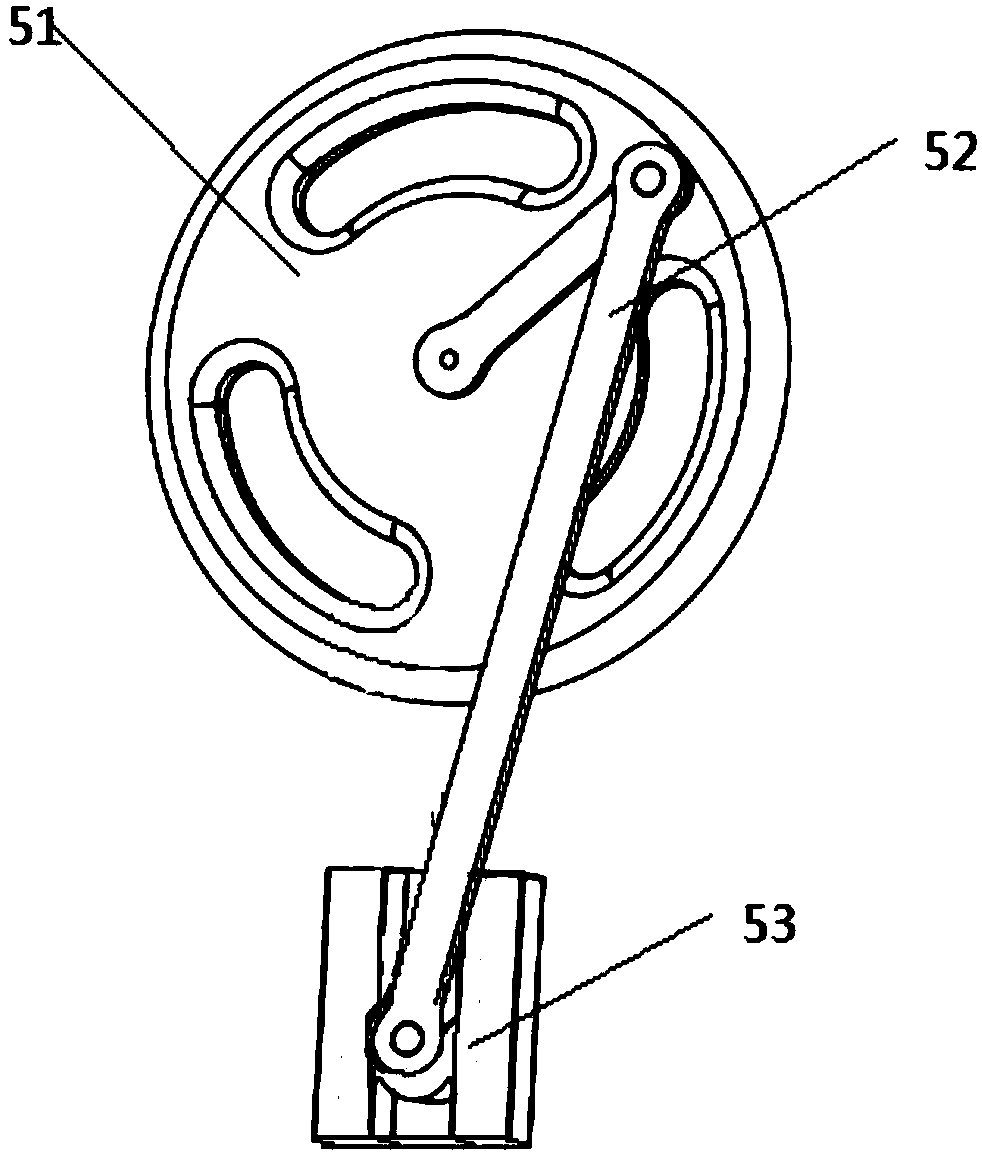

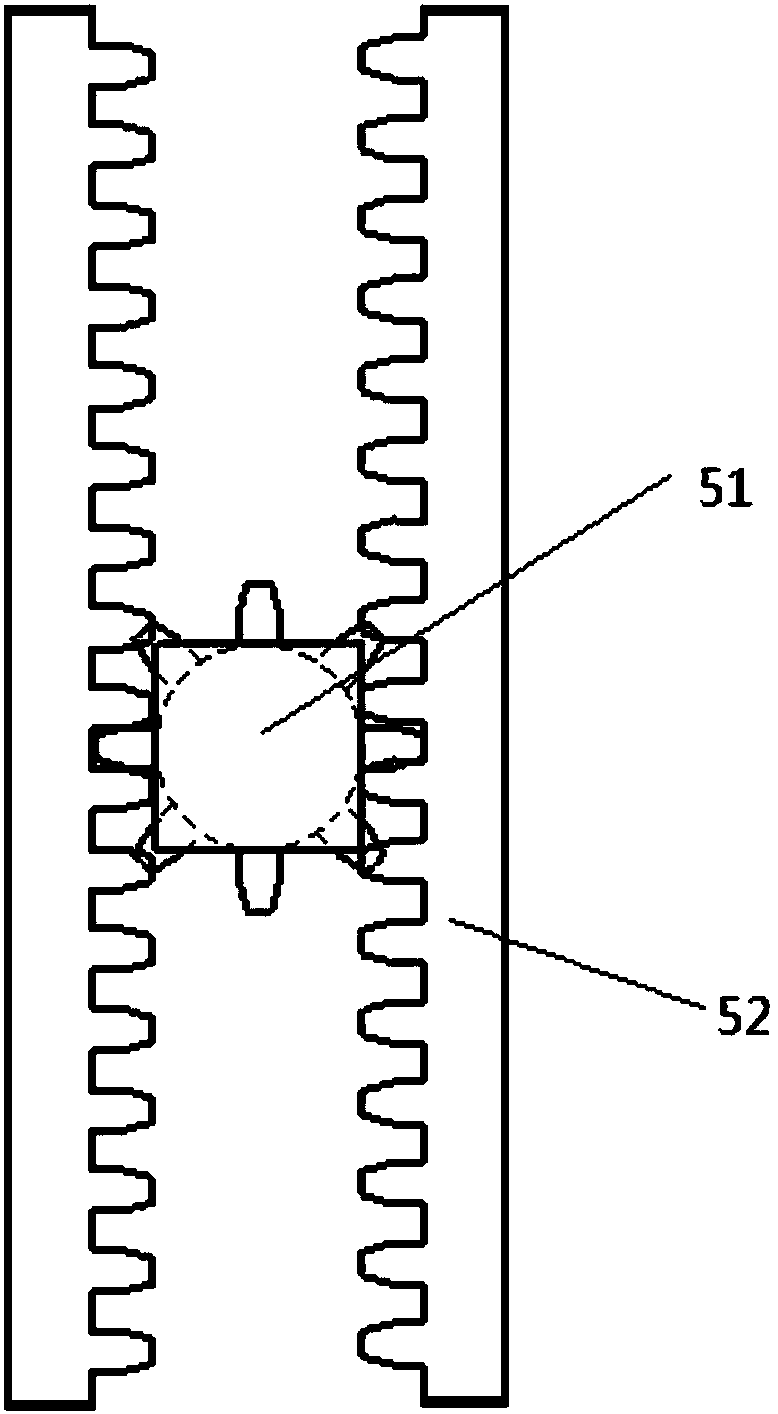

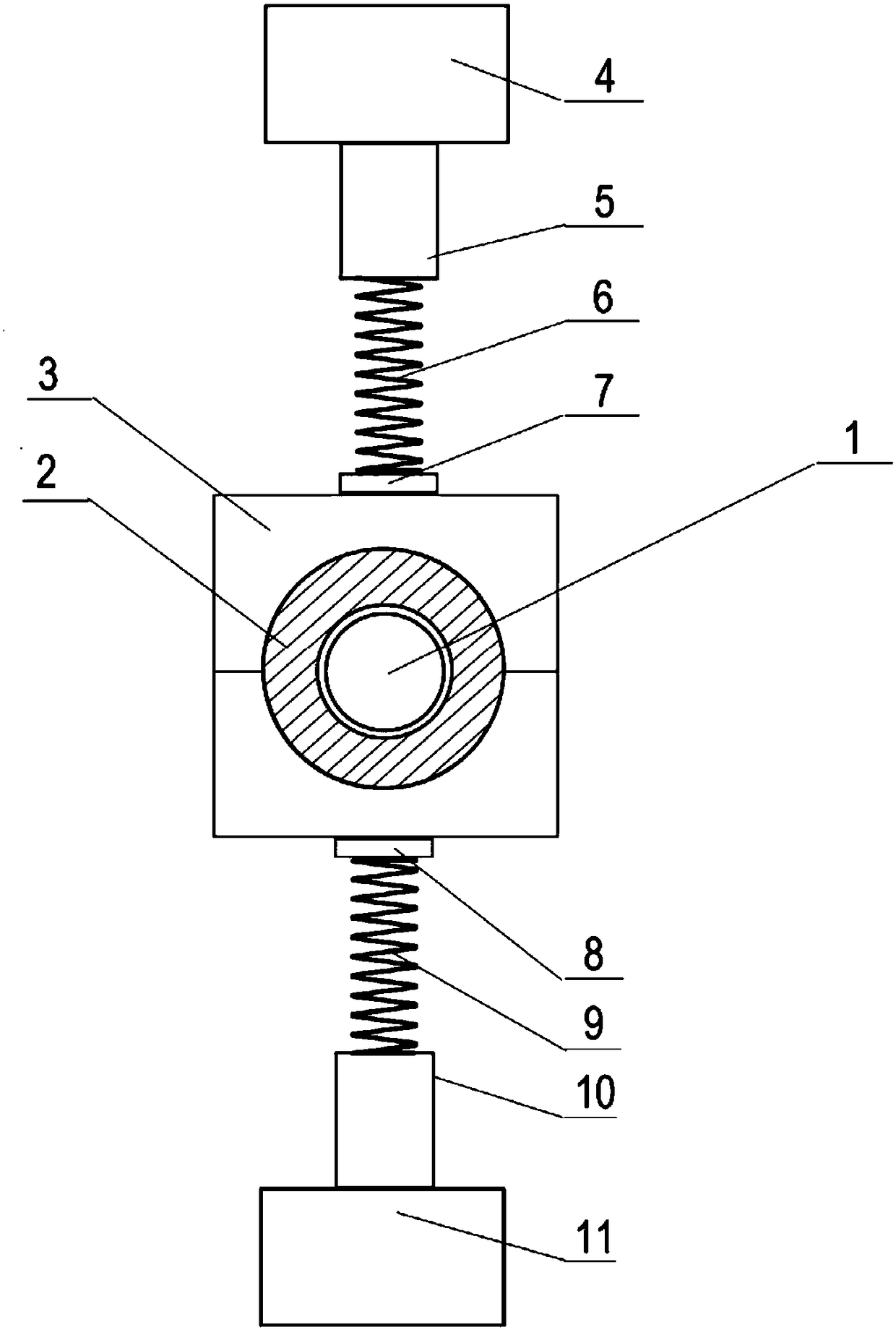

Crank-connecting-rod-mechanism-based alternating load loading device for bearing testing machine

InactiveCN108254191AControl elasticityChange the amount of compression/stretchMachine bearings testingFlywheelEngineering

The invention relates to a crank-connecting-rod-mechanism-based alternating load loading device for a bearing testing machine. The bearing testing machine is composed of a rotating shaft (1); and a tested bearing (2) is installed at the rotating shaft (1). The crank-connecting-rod-mechanism-based alternating load loading device is characterized in that the loading device comprises a clamp (3) anda plurality of rotary motor-crank-connecting-rod-mechanism-spring assemblies arranged around the clamp (3). All rotary motor-crank-connecting-rod-mechanism-spring assemblies include rotary motors, crank-connecting-rod mechanisms, and springs, wherein the units are connected successively; the crank-connecting-rod mechanisms include flywheels (51), connecting rods (52) and connecting blocks (53); and the rotary motors drive the crank-connecting-rod mechanisms to move to control the springs to make stretching or compression deformation, thereby applying an alternating load on the tested bearing (2) in the clamp (3). Compared with the prior art, the crank-connecting-rod-mechanism-based alternating load loading device has the advantage of being capable of realizing the real working condition load of the internal combustion engine.

Owner:SHANGHAI JIAN QIAO UNIV

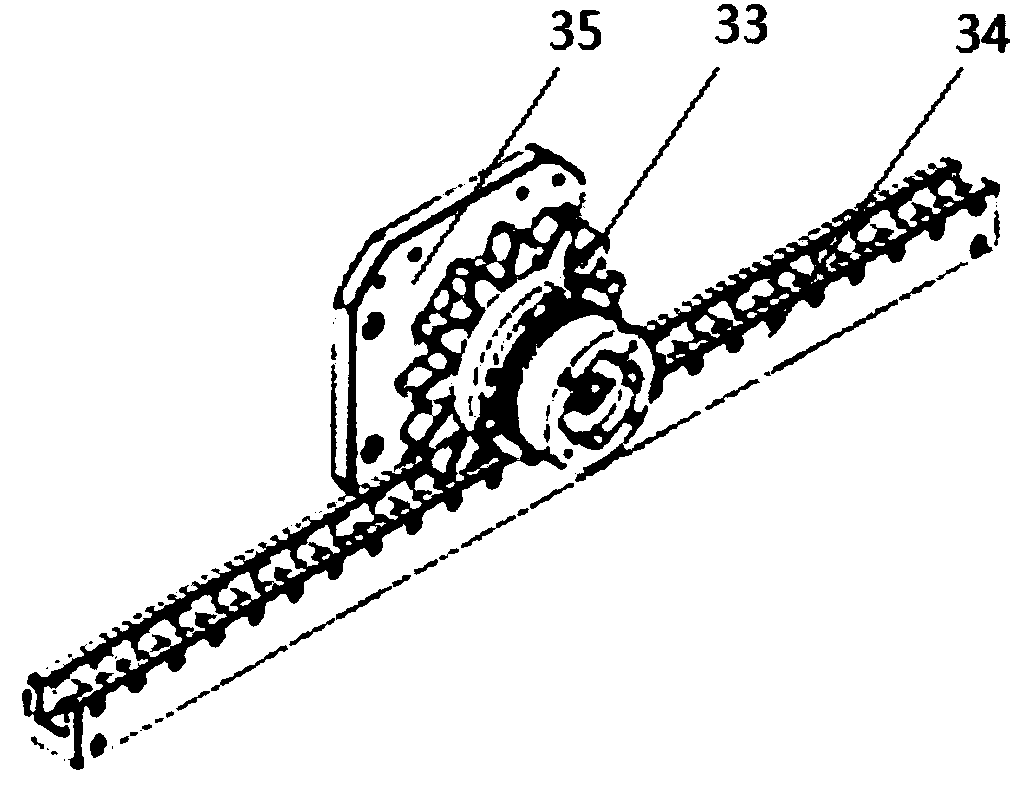

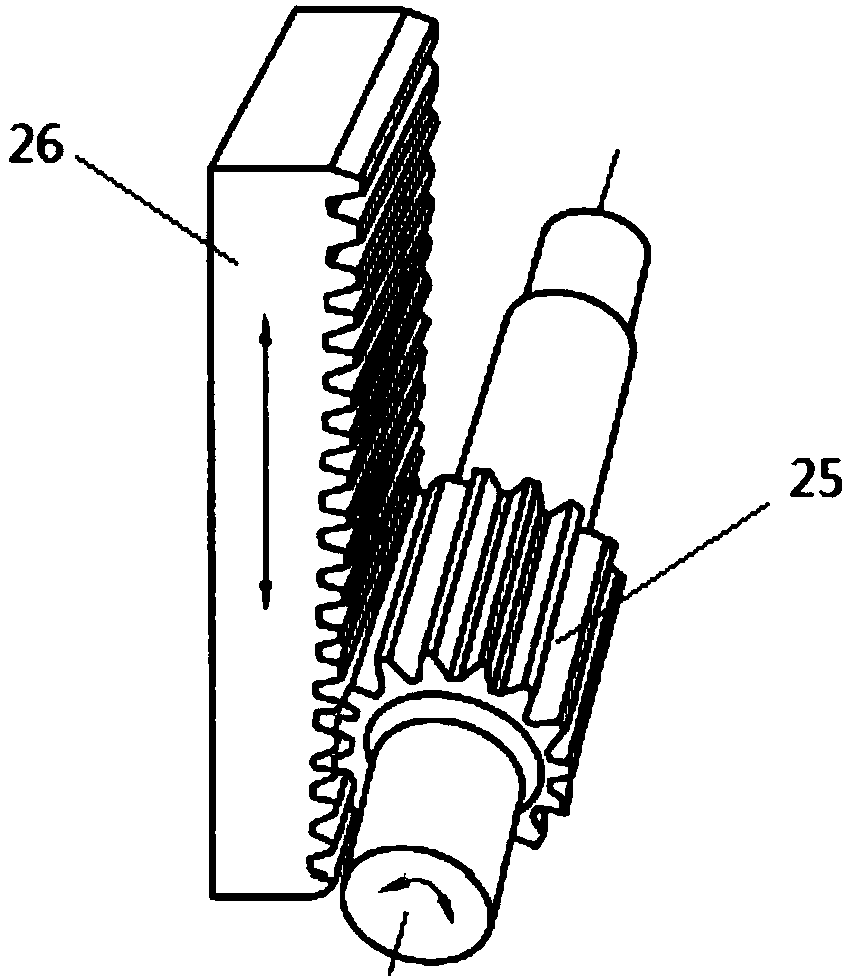

Rack-and-pinion-transmission-based bearing test device capable of applying radial alternating load

InactiveCN108254184AControl elasticityChange the amount of compression/stretchMachine bearings testingDrive motorEngineering

The invention relates to a rack-and-pinion-transmission-based bearing test device capable of applying a radial alternating load. The bearing test device is composed of a computer and a drive motor connected to a computer; and an output shaft of the drive motor is connected with a rotary shaft through a coupling. A detected bearing sleeves the outside of the rotary shaft. A radial alternating loadloading module arranged at the detected bearing consists of a temperature sensor arranged at the detected bearing and loading parts being arranged at the outer side of the detected bearing and being symmetric in four directions; and the loading parts include rotary motors, rack-and-pinion transmission mechanisms connected with the rotary motors, springs connected with the rack-and-pinion transmission mechanisms, and connecting mechanisms connected to the other ends of the springs. Compared with the prior art, the rack-and-pinion-transmission-based bearing test device has the following beneficial effect: alternating load loading of the bearing in four directions and two radial directions is realized.

Owner:SHANGHAI JIAN QIAO UNIV

System for testing fatigue life of rolling bearing by loading radial alternating load through conveying belt

InactiveCN108036944AControl elasticityController) to control the elasticityMachine bearings testingDrive motorEngineering

The invention relates to a system for testing the fatigue life of a rolling bearing by loading a radial alternating load through a conveying belt. According to the system, the rotation of a driving motor is controlled by virtue of a computer, the rolling bearing is driven to rotate at a given rotation speed, and the rotation motion of a rotating motor is converted into a linear motion by virtue ofa conveying belt transmission mechanism in a conveying belt transmission radial alternating load loading unit, so that the stretching / compression amount of a spring can be influenced; by virtue of the change of the stretching / compression amount of the spring, different sizes of action forces in variable directions can be applied to the surface of a movable clamp, and the alternating load of the bearing can be loaded by increasing a plurality of conveying belt transmission radial alternating load loading units in different regions of the movable clamp; and a torquemeter and a temperature sensor are used for detecting the performance appearance of the rolling bearing in the rotation process of the rolling bearing. Compared with the prior art, the system has the advantages that the loading of the radial alternating load of the rolling bearing can be accurately realized, and the fatigue life test for the rolling bearing can be carried out by combining with real working conditions of internal combustion engine.

Owner:SHANGHAI JIAN QIAO UNIV

Antifriction bearing fatigue life testing device of conveyor belt transmission loading alternating load

InactiveCN108267314AControl elasticityController) to control the elasticityMachine bearings testingRolling-element bearingEngineering

The invention relates to an antifriction bearing fatigue life testing device of conveyor belt transmission loading alternating load. The antifriction bearing fatigue life testing device of conveyor belt transmission loading alternating load controls rotation of a driving motor through a computer so as to drive an antifriction bearing to operate at the given rotating speed, wherein in a conveyor belt transmission alternating load loading unit, the rotary movement of the rotary motor can be converted into rectilinear motion through a conveyor belt transmission mechanism, thus influencing tension / compression amount of a spring; because of changing of the tension / compression amount of the spring, the spring can apply acting force with different magnitude and changeable direction to the surfaceof a movable clamp; and by adding a plurality of conveyor belt transmission alternating load loading units in different areas of the movable clamp, loading of the bearing alternating load can be realized, and a torquemeter and a temperature sensor can be used for detecting the performance during the operating process of the antifriction bearing. Compared with the prior art, the antifriction bearing fatigue life testing device of conveyor belt transmission loading alternating load can simply and conveniently realize loading the antifriction bearing alternating load, and can perform the antifriction bearing fatigue life test by combining with the real working condition of an internal combustion engine.

Owner:SHANGHAI JIAN QIAO UNIV

Bearing test device capable of loading alternating loads based on rack and pinion transmission mechanism

InactiveCN108279123AControl elasticityChange the amount of compression/stretchMachine bearings testingCouplingElectric machine

The invention relates to a bearing test device capable of loading alternating loads based on a rack and pinion transmission mechanism. The device comprises a computer and a driving motor connected with the computer; an output shaft of the driving motor is connected with a rotating shaft through a shaft coupling device; a bearing to be detected is arranged outside the rotating shaft in a sleeving manner; the detected to be detected bearing is provided with an alternating load loading assembly which consists of rotating electric motors that are arranged symmetrically up and down, the rack and pinion transmission mechanism connected to the rotating electric motors, a spring connected to the transmission mechanism and a connection mechanism arranged at a tail end of the spring; the connectionmechanism is connected to the bearing to be detected via a movable clamp. Compared with technologies of the prior art, the bearing test device is advantageous in that a rotation angle of the rotatingelectric motor is controlled via a computer, and the alternating load loading assembly is used for changing a stretching / compression amount of the spring so as to control the elastic force of the spring, and alternating load loading of the bearing can be realized.

Owner:SHANGHAI JIAN QIAO UNIV

Bearing test device capable of applying radial alternating load based on lead screw transmission mechanism

InactiveCN108051207AControl elasticityChange the amount of compression/stretchMachine bearings testingCouplingComputer module

Owner:SHANGHAI JIAN QIAO UNIV

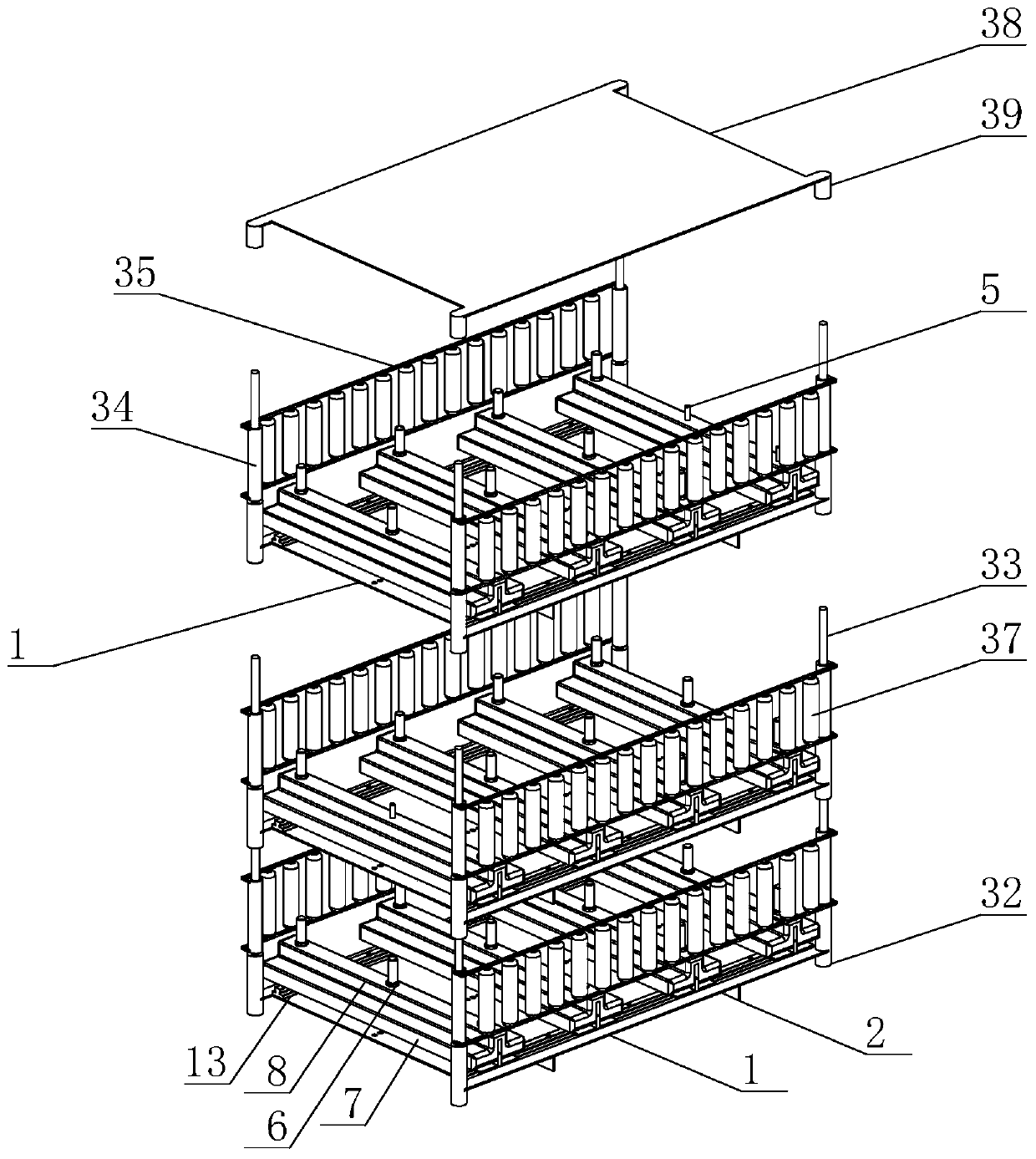

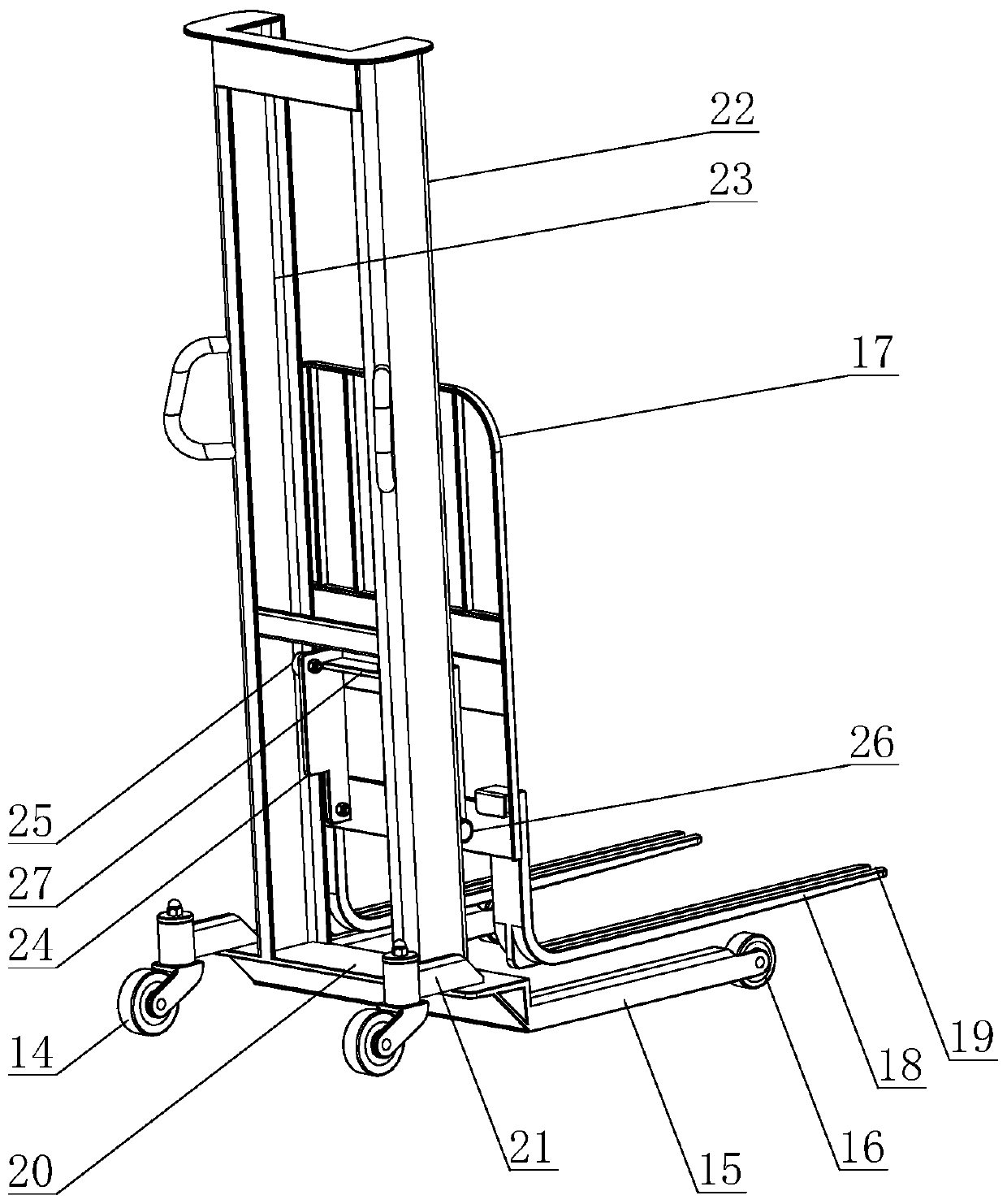

Construction site tile handling device

ActiveCN108706205BStructural simplification and versatilityAvoid noiseLifting devicesExternal framesEngineeringSlide plate

The invention discloses a ceramic tile carrying device for a construction site, and relates to the field of building facilities. The ceramic tile carrying device comprises a transfer mechanism and a shelf mechanism, wherein a slide plate which can be detachable and can adjust spacing is arranged on the shelf mechanism; a cushion block which is detachable with the slide plate is arranged on the slide plate; the cushion block is of a steel wire cotton structure; acting force between the cushion block and the slide plate is transmitted through a spring; the transfer mechanism comprises a car body; a lifting frame capable of lifting is arranged on the car body; and an L-shaped fork frame which is matched with the rack mechanism for use is arranged on the lifting frame. The ceramic tile carrying device has the beneficial effects that: damages, on ceramic tiles, of big and small vibrations caused by road bumps in the way are avoided, and the construction cost is greatly reduced; and the ceramic tile carrying device has very strong universality, and is suitable for carrying various ceramic tiles and related friable materials.

Owner:凤阳瑞泰来玻璃制品有限公司

Tower escape apparatus

The invention discloses a tower escaper apparatus which comprises a bearing fixing support, a rope winding device, a riding accommodation device and a descending control device. The coiling device comprises a shell and a winding roll, the winding roll is wound with a bearing rope, and the rope winding device is suspended on the bearing fixing support through a free end of the bearing rope; the riding accommodation device is fixedly connected below the shell; and the descending control device comprises a friction brake and a descending operation handle which are tightly clasped to the winding roll in a normal state, and the descending operation handle is in transmission fit with the friction brake. When in use, the bearing fixing support is arranged on a window or a balcony or other places, a person can control the friction braking force of the friction brake to the winding roll through the descending operation handle so as to control the descending speed of the riding accommodation device to be in a safety range, and meanwhile, ground staff can unlock the winding roll through a reset unlocking mechanism and remotely control a motor through a remote controller to drive the winding roll to rotate so as to ensure that the riding accommodation device returns to a high place and can be used by other people for escape. In addition, the invention is comfortable in use and suitable for various people.

Owner:CHONGQING JIAOTONG UNIVERSITY

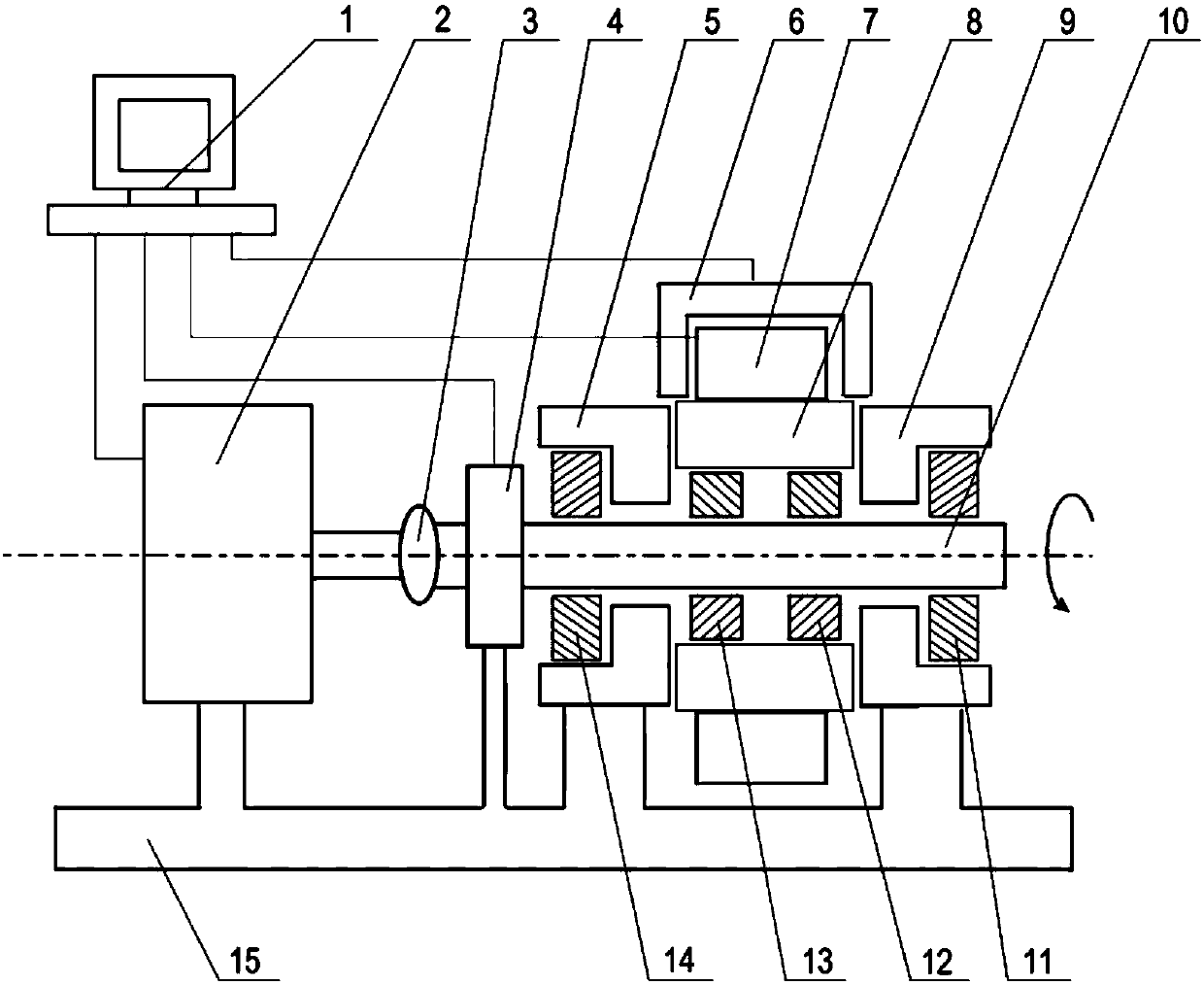

Antifriction bearing performance testing apparatus based on belt drive and being able to load alternating load

InactiveCN108267317AAccurate and reliable performance test resultsControl elasticityMachine bearings testingDrive motorEngineering

The invention relates to an antifriction bearing performance testing apparatus based on belt drive and being able to load alternating load. The antifriction bearing performance testing apparatus includes a work bench, a rotating shaft supporting mechanism, a rotating shaft, a driving motor and an alternating load loading unit, wherein the alternating load loading unit includes a clamp block assembly, a first rotary motor and a second rotary motor; a first synchronous loading mechanism is arranged between the first rotary motor and the clamp block assembly; and a second synchronous loading mechanism is arranged between the second rotary motor and the clamp block assembly. Compared with the prior art, in the antifriction bearing performance testing apparatus based on belt drive and being able to load alternating load, the first rotary motor and the second rotary motor can load alternating load to the antifriction bearing in the clamp block assembly through the first synchronous loading mechanism and the second synchronous loading mechanism respectively, so as to simulate the real working condition of the dynamic load antifriction bearing in an internal combustion engine, thus guaranteeing that the antifriction bearing performance test result is accurate and reliable.

Owner:SHANGHAI JIAN QIAO UNIV

Rolling bearing performance testing device based on loadable alternating load of crank connecting rod

InactiveCN108303254AThe test results are accurate and reliableSimultaneous testingMachine bearings testingGearingDrive motorEngineering

The invention relates to a rolling bearing performance testing device based on the loadable alternating load of a crank connecting rod. The rolling bearing performance testing device comprises a workbench, a rotating shaft supporting mechanism, a rotating shaft, a driving motor and an alternating load loading unit, wherein the alternating load loading unit comprises a clamping block assembly, a first rotating motor and a second rotating motor, a first crank connecting rod transmission loading mechanism is arranged between the first rotating motor and the clamping block assembly, and a second crank connecting rod transmission loading mechanism is arranged between the second rotating motor and the clamping block assembly. Compared with the prior art, the rolling bearing performance testing device has the advantages that the first rotating motor and the second rotating motor can load alternating load on the rolling bearing in the clamping block assembly through the first crank connectingrod transmission loading mechanism and the second crank connecting rod transmission loading mechanism, so that the true working condition of the dynamic loading of the rolling bearing in the internalcombustion engine is simulated, and the accurate and reliable performance test result of the rolling bearing is guaranteed.

Owner:SHANGHAI JIAN QIAO UNIV

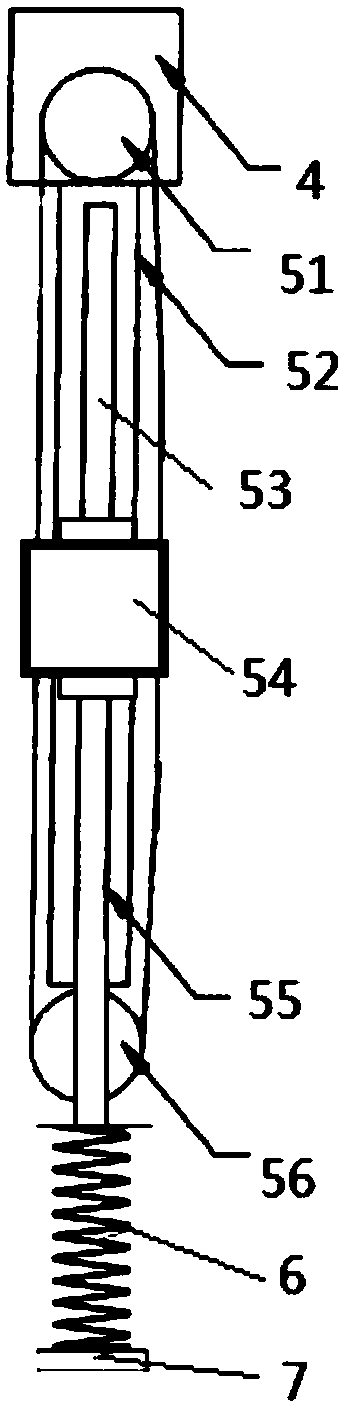

Lead-screw-driving-based radial alternating load loading device for bearing testing machine

InactiveCN108254187AControl elasticityChange the amount of stretch/compressionMachine bearings testingCouplingElectric machine

The invention relates to a lead-screw-driving-based radial alternating load loading device for a bearing testing machine. The bearing testing machine comprises a rotating shaft (1); and a tested bearing (2) is installed on the rotating shaft (1). The loading device is composed of a clamp (3) and rotary motor-lead screw driving mechanism-spring assemblies arranged around the clamp (3) in axial symmetry and radio symmetry; the lead screw driving mechanisms include couplers (51) ), lead screw bearings (52), lead screw nuts (53), lead screws (54) and bearing bases (55); the rotary motors are connected with the lead screw bearings (52) and the lead screws (54) successively by the couplers (51); the lead screw nuts (53) are arranged at the lead screws (54); and the bearing bases (55) are arranged at the bottoms of the lead screws (54) and are connected with springs. Compared with the prior art, the lead-screw-driving-based radial alternating load loading device has advantages of being capable of realizing the real working condition load of the internal combustion engine and the like.

Owner:SHANGHAI JIAN QIAO UNIV

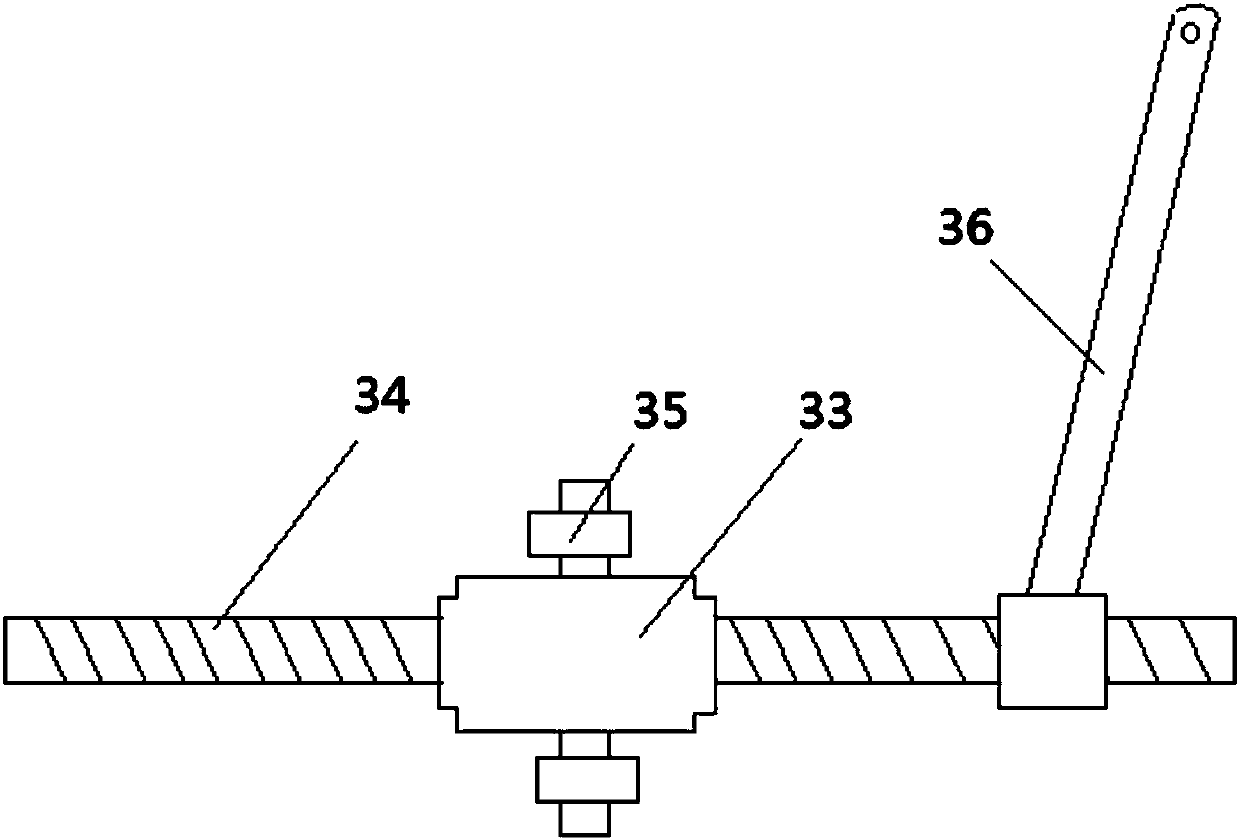

Synchronous-belt-transmission-mechanism-based bearing test device capable of loading alternating load

InactiveCN108254182AControl elasticityChange the amount of compression/stretchMachine bearings testingDrive wheelElectric machine

The invention relates to a synchronous-belt-transmission-mechanism-based bearing test device capable of loading an alternating load. The bearing test device is composed of a computer and a driving motor connected by the computer. An output shaft of the driving motor is connected to a rotating shaft through a coupler; and a detected sliding bearing sleeves the outside of the rotating shaft and consists of a bearing base and a bearing bush being embedded into bearing base and having a smooth inner side. An alternating load loading assembly is arranged on the detected bearing and consists of rotary motors arranged in an up-down symmetric manner, synchronous belt transmission mechanisms connected with the rotary motors, springs connected with the transmission mechanisms, and connecting mechanisms arranged at the tail ends of the springs; and the connecting mechanisms are connected with the detected bearing by moving clamps. The synchronous belt transmission mechanisms include driving wheels, driven wheels, and sliding blocks. According to the invention, the elastic force of the spring is controlled by changing the compression / stretching amount of the spring, so that the loading of thealternating load of the bearing is realized.

Owner:SHANGHAI JIAN QIAO UNIV

Rack-and-pinion-transmission-based radial alternating load loading device for bearing testing machine

InactiveCN108254190AControl elasticityChange the amount of stretch/compressionMachine bearings testingElectric machineInternal combustion engine

The invention relates to a rack-and-pinion-transmission-based radial alternating load loading device for a bearing testing machine. The bearing testing machine comprises a rotating shaft (1); and a tested bearing (2) is installed at the rotating shaft (1). The loading device is composed of a clamp (3) and a rotary motor-rack-and-pinion-transmission-mechanism-spring assemblies arranged around the clamp (3) in axial symmetry and radio symmetry; the rotary motor-rack-and-pinion-transmission-mechanism-spring assembly arranged in axial symmetry applies an axial alternating load on the tested bearing (2) in the clamp (3); and the rotary motor-rack-and-pinion-transmission-mechanism-spring assembly arranged in radial symmetry applies a radial alternating load on the tested bearing (2) in the clamp(3). Compared with the prior art, the rack-and-pinion-transmission-based radial alternating load loading device has advantages of being capable of realizing the real working condition load of the internal combustion engine and the like.

Owner:SHANGHAI JIAN QIAO UNIV

Antifriction bearing fatigue life testing device of crank connecting rod drive loading alternating load

InactiveCN108267318AControl elasticityChange the amount of compression/stretchMachine bearings testingRolling-element bearingDrive motor

The invention relates to an antifriction bearing fatigue life testing device of crank connecting rod drive loading alternating load. The antifriction bearing fatigue life testing device of crank connecting rod drive loading alternating load controls rotation of a driving motor through a computer so as to drive an antifriction bearing to operate at the given rotating speed, wherein in a crank connecting rod drive alternating load loading unit, the rotary movement of the rotary motor can be converted into rectilinear motion through a crank connecting rod drive mechanism, thus influencing tension / compression amount of a spring; because of changing of the tension / compression amount of the spring, the spring can apply acting force with different magnitude and changeable direction to the surfaceof a movable clamp; and by adding a plurality of crank connecting rod drive alternating load loading units in different areas of the movable clamp, loading of the bearing alternating load can be realized, and a torquemeter and a temperature sensor can be used for detecting the performance during the operating process of the antifriction bearing. Compared with the prior art, the antifriction bearing fatigue life testing device of crank connecting rod drive loading alternating load can simply and conveniently realize loading the antifriction bearing alternating load, and can perform the antifriction bearing fatigue life test by combining with the real working condition of an internal combustion engine.

Owner:SHANGHAI JIAN QIAO UNIV

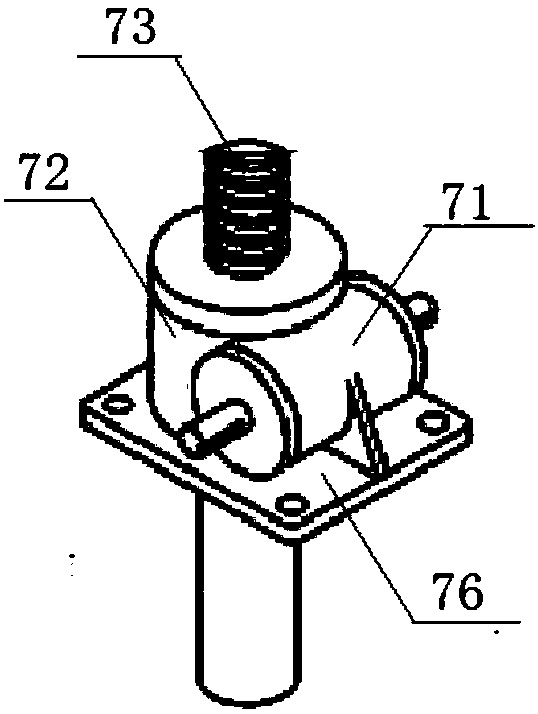

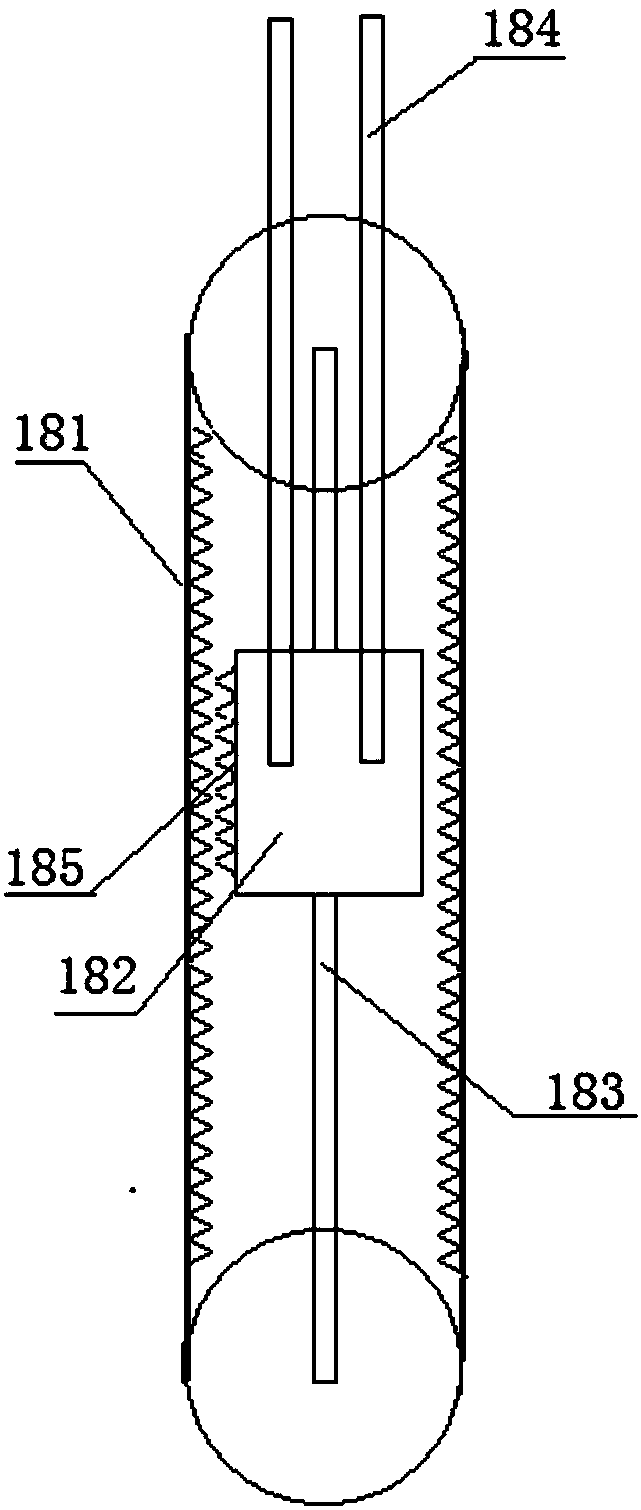

A steel wire stay

ActiveCN108397517BEasy to adapt to specific situationsControl elasticityRopes and cables for vehicles/pulleyTextile cablesArchitectural engineeringFront and back ends

The invention relates to a fixing base, in particular to a steel wire pull rope fixing base. One end of a steel wire pull rope can be tightened on a device; the left and right ends of the device can be tightened into the steel wire rope; and the steel wire pull rope can be pulled by a slight distance after straightening for specific conditions of the steel wire pull rope in actual use. A base rodinner groove is formed in a base rod; convex edges are arranged on the front and back inner sides of the upper end of the base rod; a middle slide block is slidingly connected between the two convex edges; the left and right ends of the middle slide block are fixedly connected with spring sleeve rods; two spring stoppers are symmetrically arranged at the left and right ends in the base rod inner groove; the outer ends of the two spring sleeve rods are slidingly connected to the two spring stoppers; springs sleeve the two spring sleeve rods; the springs are positioned between the middle slide block and the spring stoppers; two round rail rods are provided; round rail rod edge bases are fixedly connected to the left and right ends of the round rail rods; and the two round rail rods are fixedly connected to the front and back ends of the base rod through the round rail rod edge bases.

Owner:VITAL INT ELEVATORING EQUIP

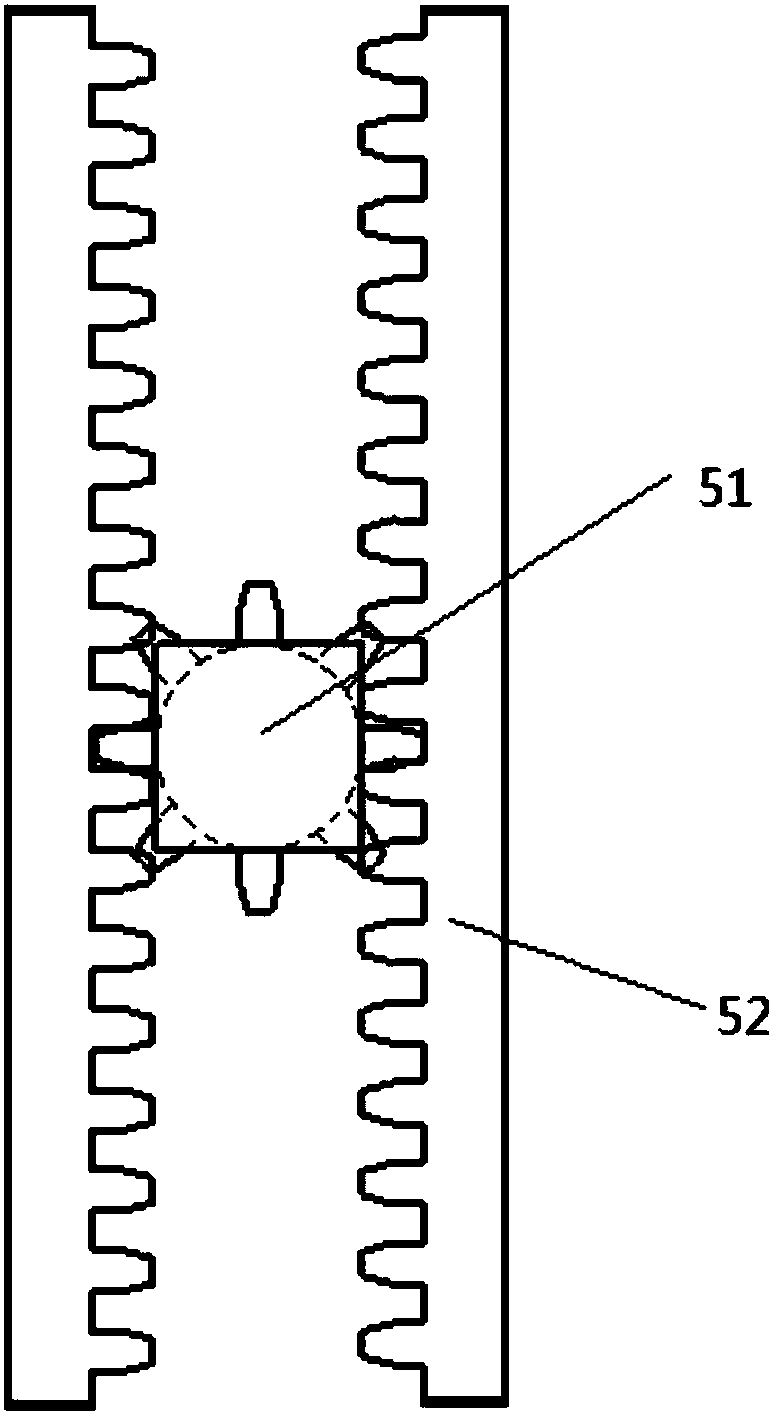

Synchronous-belt-transmission-mechanism-based alternating load loading device for bearing testing machine

InactiveCN108254188AControl elasticityChange the amount of compression/stretchMachine bearings testingMotor driveEngineering

The invention relates to a synchronous-belt-transmission-mechanism-based alternating load loading device for a bearing testing machine. The bearing testing machine includes a rotating shaft (1); and atested bearing (2) is installed on the rotating shaft (1). The loading device comprises a clamp (3) and a plurality of rotary motor-synchronous belt transmission mechanism-spring assemblies arrangedaround the clamp (3); the synchronous belt transmission mechanisms include transmission wheels, synchronous belts (52), and connection blocks (54); the transmission wheels are connected with the rotary motors; the synchronous belts (52) are connected with the transmission wheels and the connection blocks (54); and the connection blocks (54) are connected with springs. The rotary motors drive the synchronous belt transmission mechanisms to move to control the spring deformation, so that an alternating load is applied to the tested bearing (2) in the clamp (3). Compared with the prior art, the synchronous-belt-transmission-mechanism-based alternating load loading device is capable of realizing the real working condition load of the internal combustion engine and the like.

Owner:SHANGHAI JIAN QIAO UNIV

Gea-rack transmission-based alternating load loading device for bearing testing machine

InactiveCN108593292AControl elasticityChange the amount of compression/stretchMachine bearings testingMotor driveElectric machine

The present invention relates to a gear-rack transmission-based alternating load loading device for a bearing testing machine. The bearing testing machine comprises a rotation shaft (1). A tested bearing (2) is mounted on the rotation shaft (1). The loading device comprises a clamp (3), and a plurality of rotary motor-gear-rack transmission mechanism-spring assemblies disposed around the clamp (3); and the rotary motor-gear-rack transmission mechanism-spring assembly includes a rotary motor, a gear-rack transmission mechanism and a spring which are connected with one another sequentially, wherein the rotary motor drives the gear-rack transmission mechanism to move so as to control the spring to be tensioned or compressed and deformed, so that an alternating load can be applied to the tested bearing (2) in the clamp (3). Compared with the prior art, the loading device of the invention has the advantage of capacity of realizing the real working condition load of an internal combustion engine and other advantages.

Owner:SHANGHAI JIAN QIAO UNIV

Rolling bearing performance test device based on belt drive with radial alternating load

InactiveCN108195585AAccurate and reliable performance test resultsControl elasticityMachine bearings testingElectric machineRolling-element bearing

The invention relates to a rolling bearing performance test device based on belt drive with radial alternating load, comprising a workbench, a rotary shaft support mechanism, a rotary shaft, a drivingmotor and a radial alternating load application unit; the radial alternating load application unit comprises a loading unit support, a clamp block component and a pair of synchronous belt radial loading mechanisms mutually perpendicularly arranged on the loading unit support; each synchronous belt radial loading mechanism comprises a first rotary motor, a second rotary motor, a first synchronousbelt component, a first spring loading component, a second synchronous belt component and a second spring loading component. Compared with the prior art, the rolling bearing performance test device based on belt drive with radial alternating load has the advantages that the first rotary motor and the second rotary motor can apply radial alternating load to a rolling bearing in the clamp block component respectively through the first spring loading component and the second spring loading component so as to simulate true working conditions of a dynamic load rolling bearing in an internal combustion engine, and it is ensured that rolling bearing performance test results are accurate and reliable.

Owner:SHANGHAI JIAN QIAO UNIV

Upward waste blanking structure

PendingCN114570830AShorten molding timeReduce the amount of operationShaping toolsNon-rotating vibration suppressionStructural engineeringWaste material

The invention relates to the technical field of dies, in particular to an upward waste blanking structure which comprises an upper plate and a bottom plate, the upper surface of the bottom plate is fixedly connected with the upper plate through four supporting rods, the bottom plate is provided with a collecting groove, the collecting groove is provided with a waste collecting assembly, the waste collecting assembly is connected to the lower end of a lower die plate, and the lower die plate is fixedly connected with the upper plate. An air cylinder is fixedly connected to the upper surface of the upper plate, an output shaft of the air cylinder penetrates through the upper plate in a sliding mode, the end of the output shaft of the air cylinder is fixedly connected to the upper surface of the upper die plate, and waste cutting assemblies are arranged on the upper die plate and the lower die plate. And therefore, waste on the upper surface of the lower die plate obliquely flows into the collecting groove, the effect of automatically collecting the waste is achieved, the operation amount of workers is reduced, meanwhile, the forming time of the die is shortened, and the production rate of equipment is increased.

Owner:重庆晋川精密五金有限公司

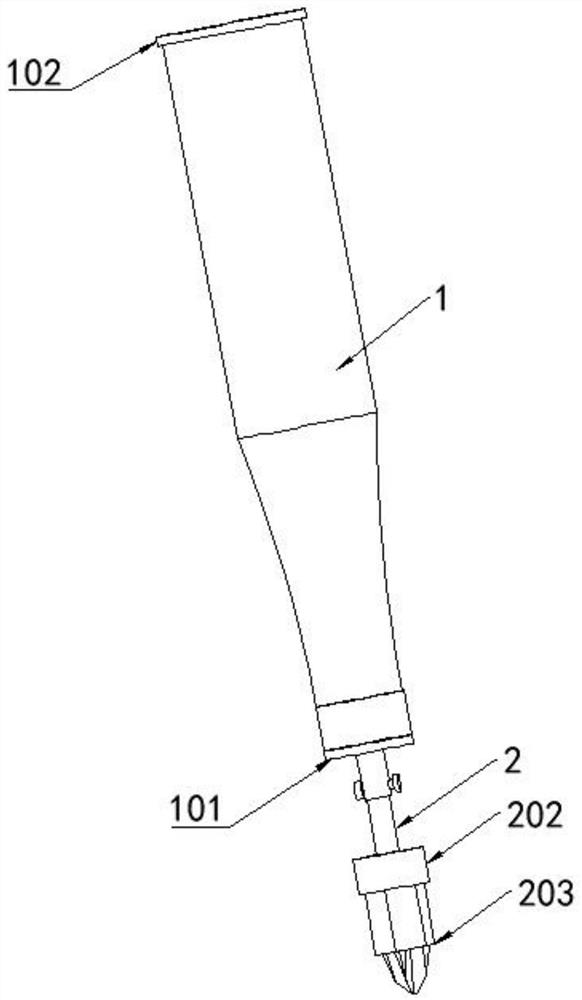

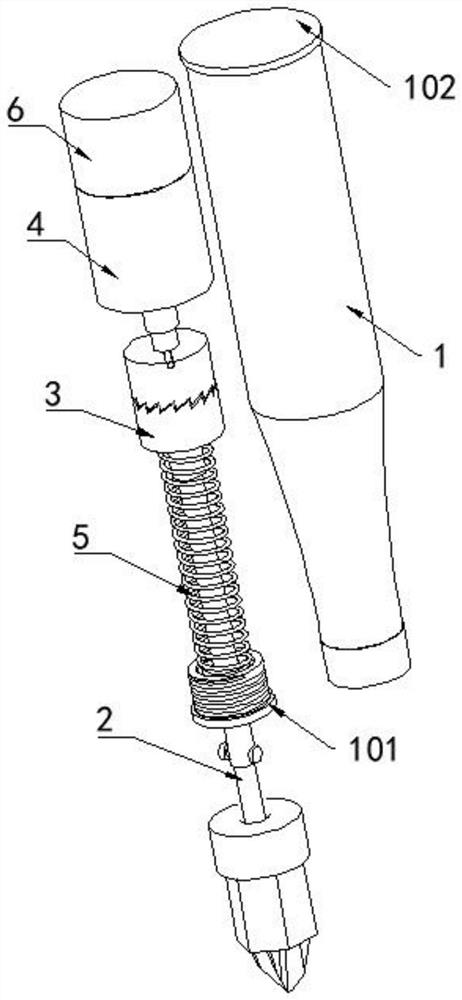

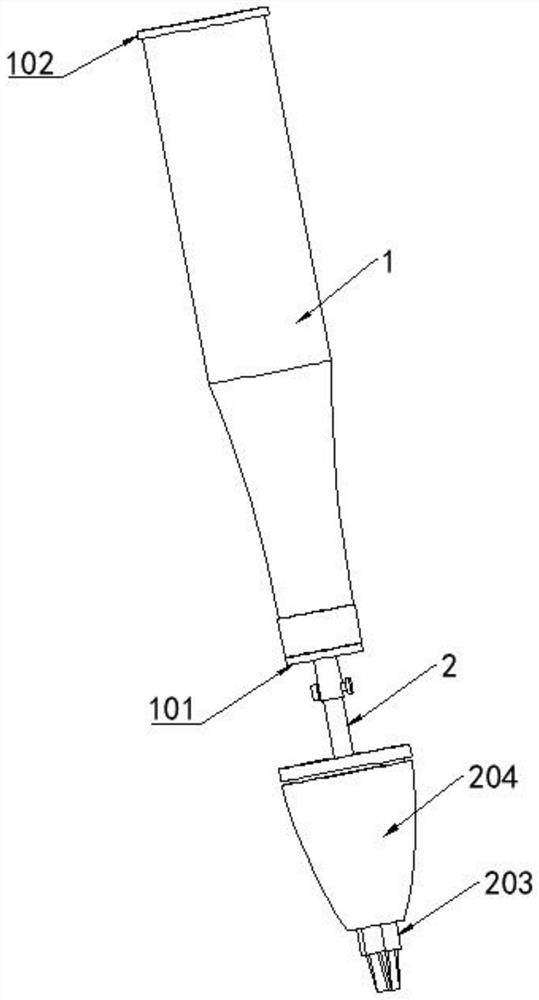

Medical micro-power torsion screwdriver

PendingCN112790854AQuick and easy bit changeLower acquisition costsOsteosynthesis devicesElectric machineryMicro motor

The invention provides a medical micro-power torsion screwdriver which comprises a screwdriver handle, a screwdriver rod, a coaxial mutually-clamped sleeve and a micro motor; a front end cover and a rear end cover are arranged at the front end and the rear end of the screwdriver handle respectively, a front end inserting opening is formed in the front end cover, the coaxial mutually-clamped sleeve and the micro motor are both located in the screwdriver handle, A spring is arranged between the coaxial mutually- clamped sleeve and the inner wall of the front end cover, the screwdriver rod penetrates through the front end inserting opening and an inner ring of the spring to be connected with one end of the coaxial mutual clamping sleeve, and the other end of the coaxial mutually-clamped sleeve is connected with the micro motor. By adopting a micro motor and a torsion control system, the problem of excessive physical labor caused by holding a handheld electric drill for a long time by medical staff is solved, and the adverse conditions of screw tail slipping and cold welding are avoided; a bit sleeve or an electric drill chuck is adopted, the medical micro-power torsion screwdriver is compatible with bits of different sizes, torsion is adjustable, the adaptability is high, bacterial contamination is obviously reduced compared with a common electric drill, andthe medical micro-power torsion screwdriver is very suitable for hospitals and medical staff.

Owner:崔威

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com