Antifriction bearing performance testing apparatus based on belt drive and being able to load alternating load

A rolling bearing and alternating load technology, which is applied in the field of rolling bearing performance test devices, can solve the problems of single loading characteristics, inability to load with variable loads, and inability to test rolling bearings under dynamic load of internal combustion engines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

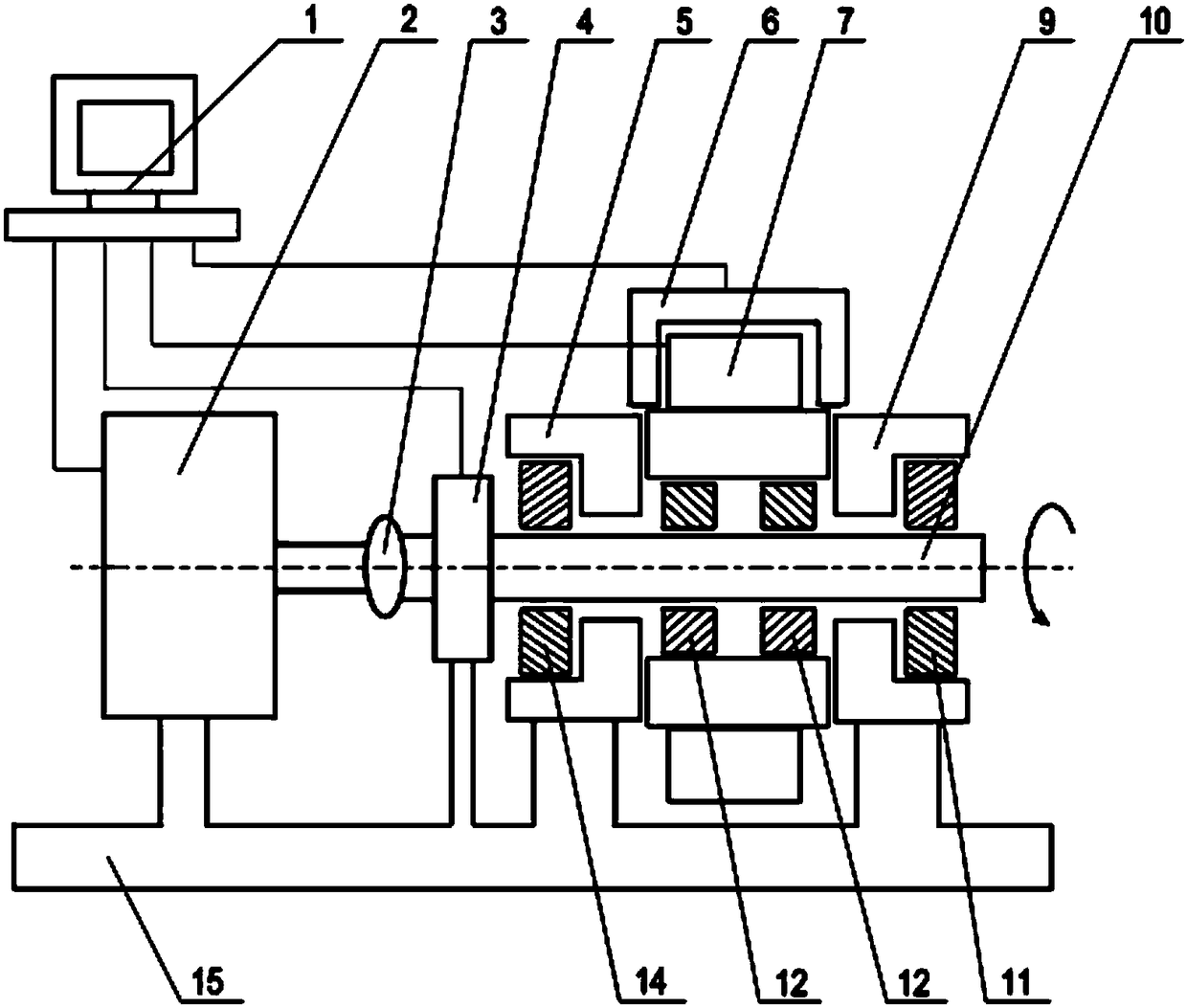

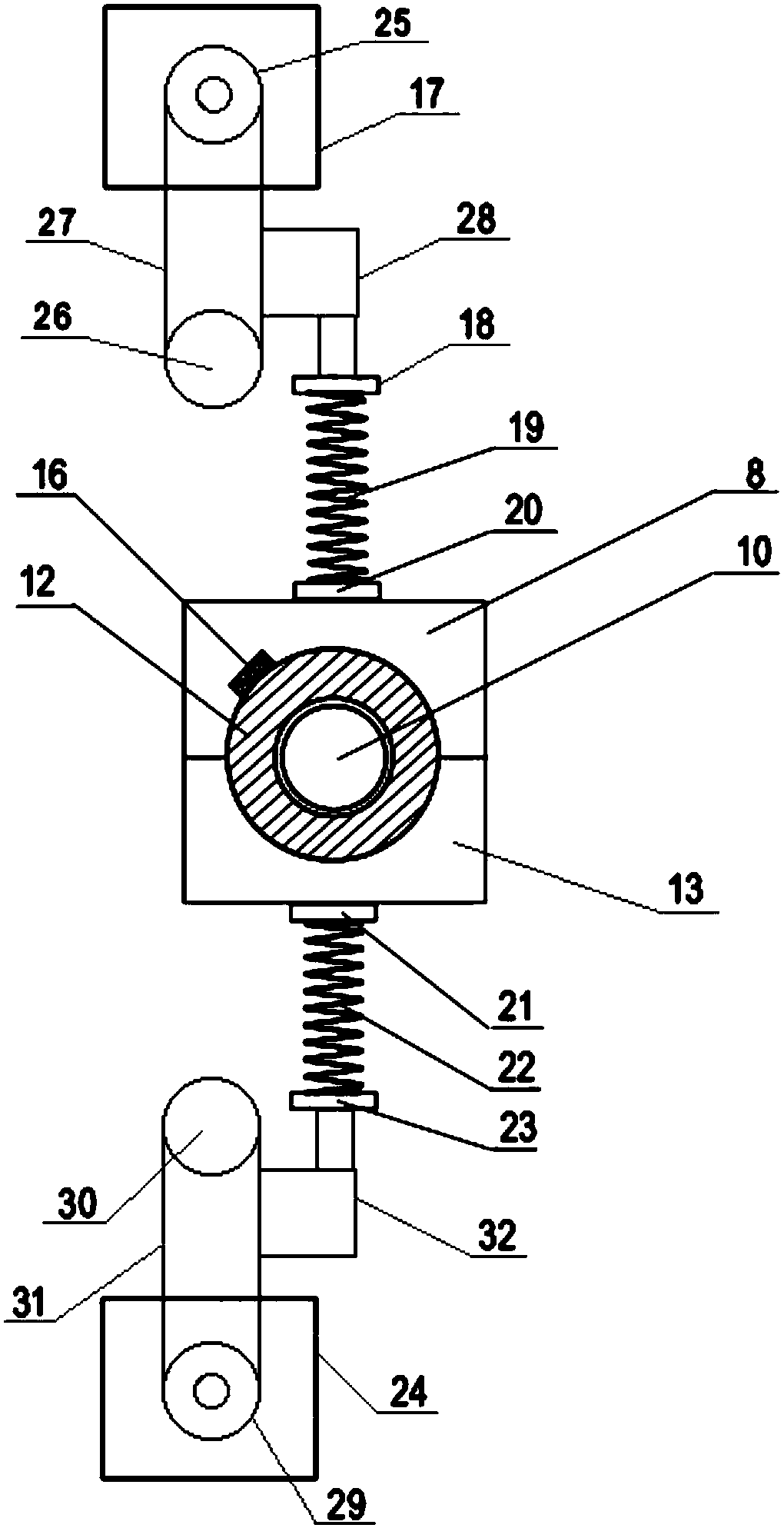

[0032] like figure 1 The rolling bearing performance test device based on belt transmission that can be loaded with alternating loads is shown. The rolling bearing 12 includes a bearing inner ring, a bearing outer ring sleeved outside the bearing inner ring, and a retaining ring arranged between the bearing outer ring and the bearing inner ring. frame and a plurality of rolling elements evenly arranged on the cage along the circumference of the inner ring of the bearing. The device includes a worktable 15, a rotating shaft supporting mechanism arranged on the working table 15, and a rotating shaft that runs through the rotating shaft supporting mechanism in the horizontal direction. 10. The driving motor 2 arranged on the workbench 15 and connected to one end of the rotating shaft 10 and the alternating load loading unit 7 arranged on the workbench 15 and adapted to the rotating shaft 10, such as figure 2 As shown, the alternating load loading unit 7 includes a clamp block as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com