Upward waste blanking structure

A scrap and blanking technology, which is applied in the field of upward punching out of scrap structures, can solve problems such as low working efficiency of molds, achieve the effects of improving practicability and safety, reducing molding time, and saving operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

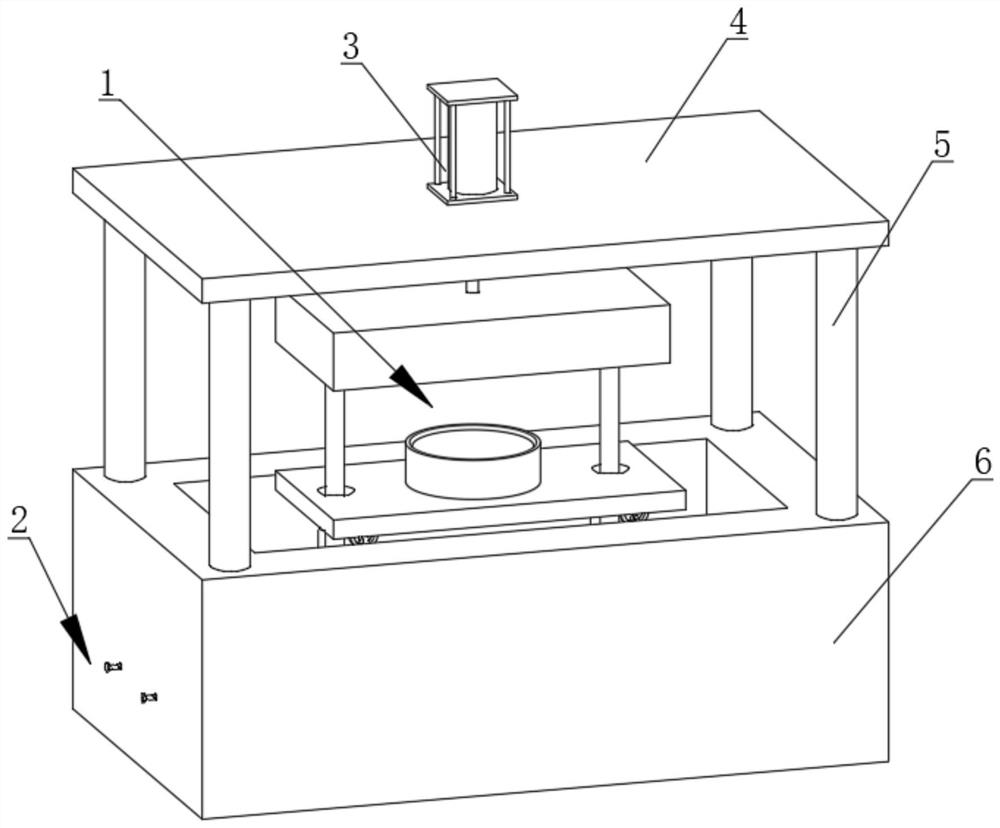

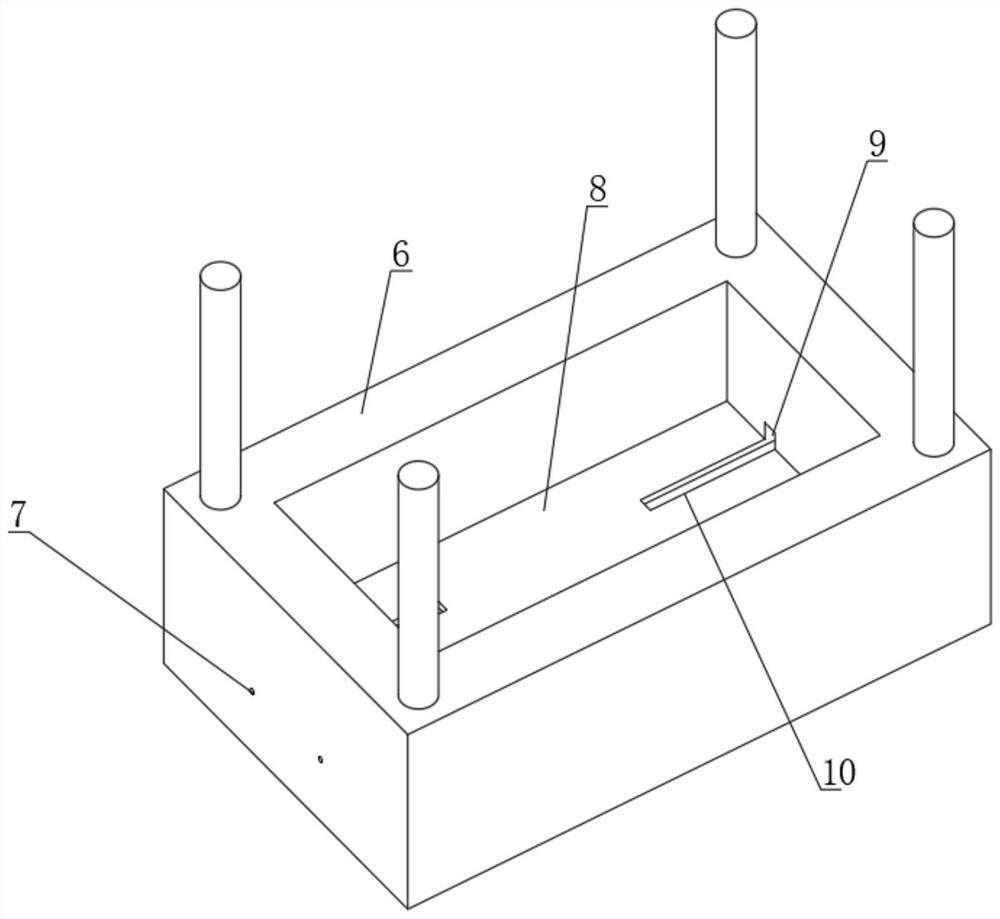

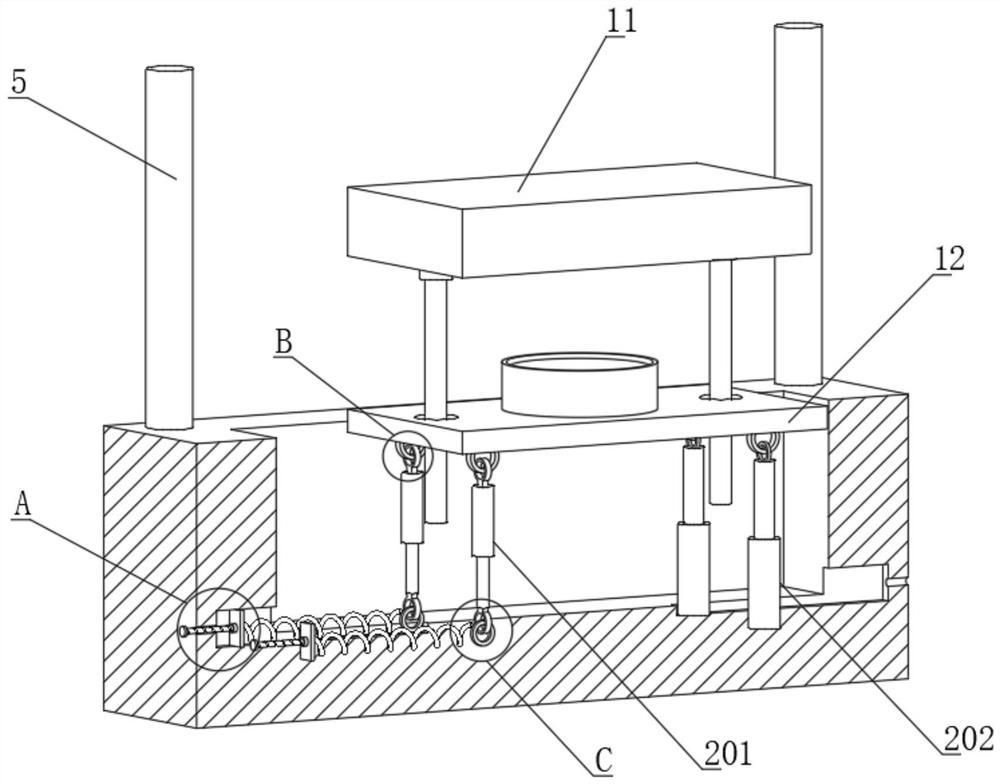

[0032] like Figure 1-9 As shown, an upwardly punched waste structure includes an upper plate 4 and a bottom plate 6, the upper surface of the bottom plate 6 is fixedly connected with the upper plate 4 through four support rods 5, the bottom plate 6 is provided with a collection groove 8, and the collection groove 8 A waste collection assembly 2 is arranged on the upper plate, the waste collection assembly 2 is connected to the lower end of the lower template 12, the upper surface of the upper plate 4 is fixedly connected with a cylinder 3, the output shaft of the cylinder 3 slides through the upper plate 4, and the output shaft end of the cylinder 3 It is fixedly connected to the upper surface of the upper template 11. The upper template 11 and the lower template 12 are provided with a waste cutting assembly 1. Both sides of the lower end of the upper template 11 are provided with movable rods 106. The movable rods 106 cooperate with the limit holes 102. On the top, two limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com