Method for optimizing metal parts of SLM formed overhanging structure

A technology of metal parts and optimization methods, applied in the direction of process efficiency improvement, energy efficiency improvement, additive processing, etc., can solve problems such as poor molding quality, molding failure, warping deformation, etc., achieve small deformation, reduce quantity, The effect of reducing the tendency of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

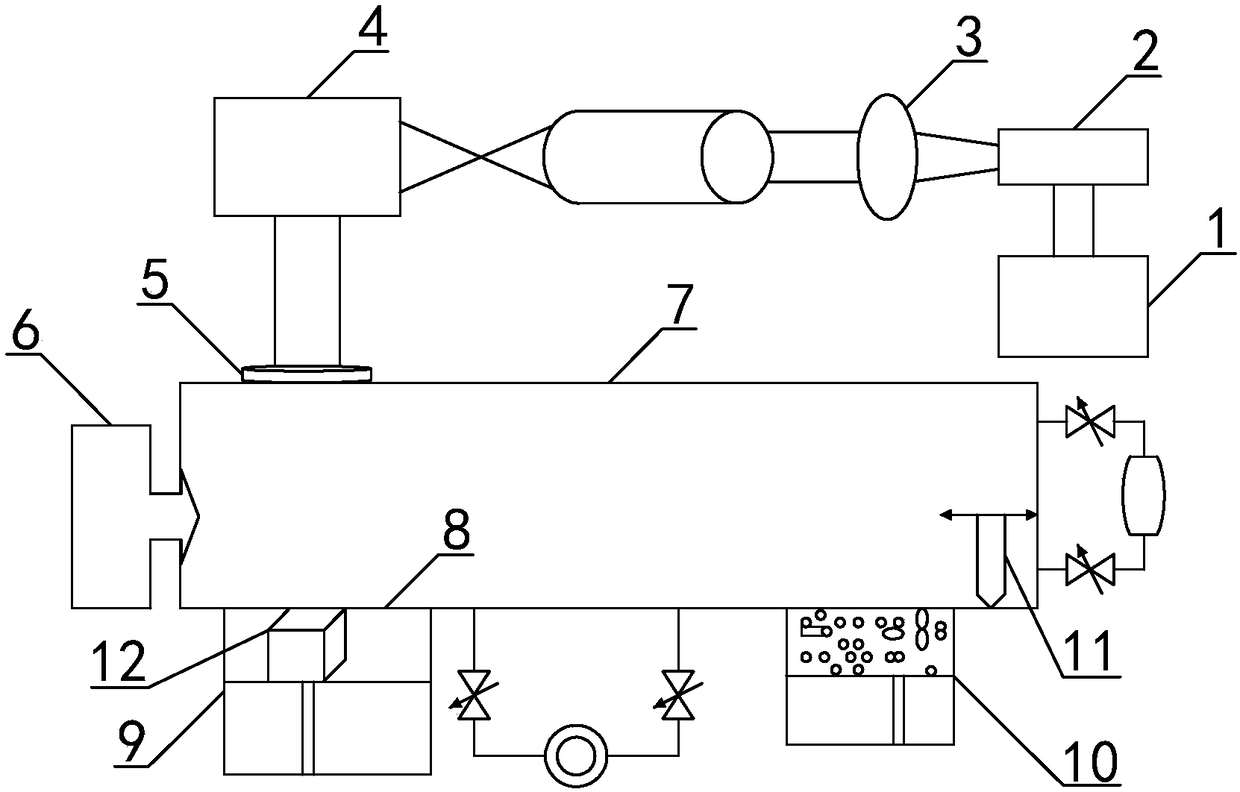

[0023] refer to Figure 4 to Figure 7 , the present invention is a method for optimizing metal parts of a SLM forming overhang structure, comprising the following steps:

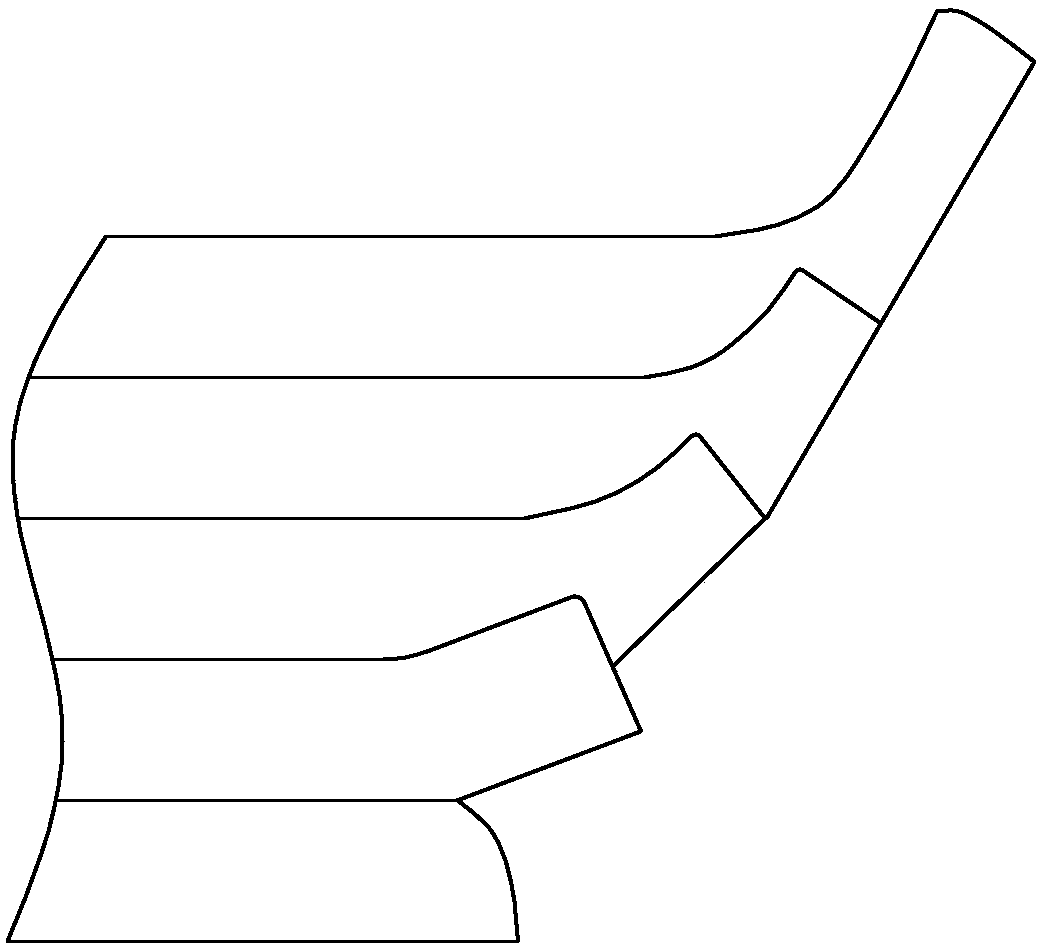

[0024] S1. Optimization of the spatial position: change the spatial position of the metal parts 12 to make the inclination angle of the overhanging structure larger, and increase the inclination angle of the overhanging structure in the parts of the metal part 12 that are difficult to polish;

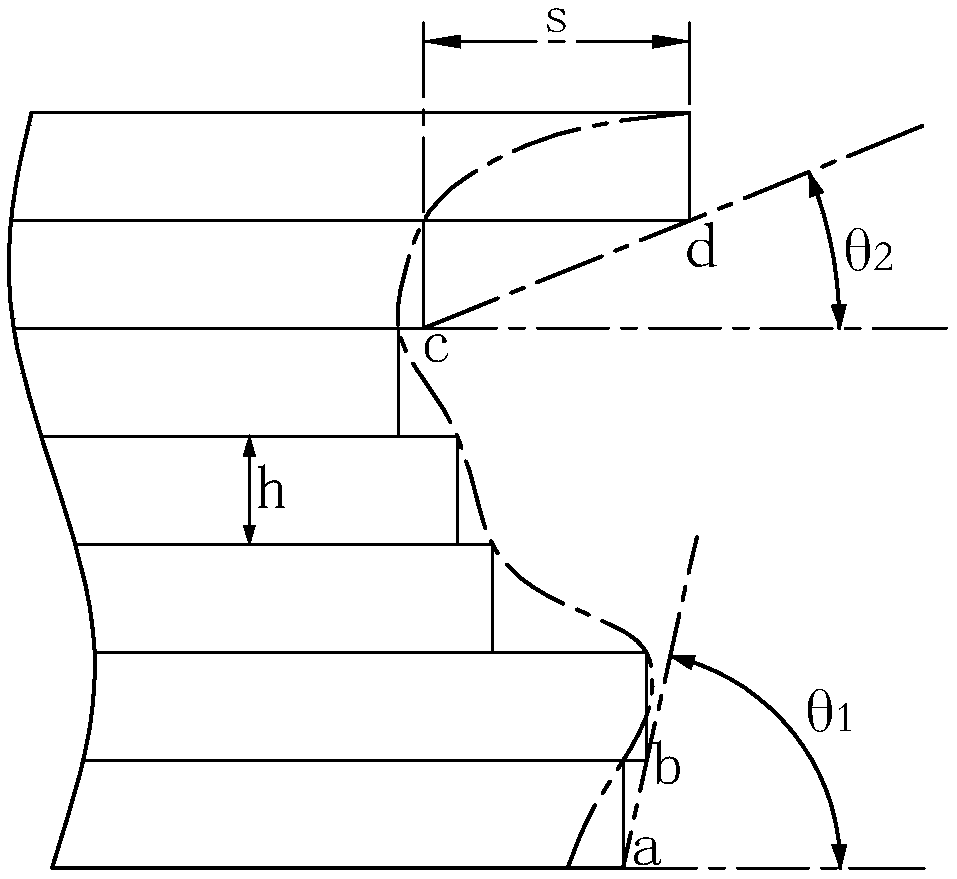

[0025] S2. Optimization of support structure: add a support structure to the overhanging structure of the metal part 12 after step S1, the support mechanism is a plurality of hollow thin-walled cross supports 13 with sawtooth 14, and a plurality of hollow thin-walled cross supports 13 constitutes a network structure, and part of the structure of the sawtooth 14 is embedded in the entity of the metal part 12;

[0026] S3. Optimization of local energy: When the SLM is formed into the overhanging structure, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com