Synthesis process for ultra-branching nylon 6

A technology of hyperbranched nylon and synthesis method, which is applied in the field of synthesis of hyperbranched nylon 6, can solve the problems of low melt index, limited additive usage, small melt index, etc., achieve low melt flow index, shorten molding time, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be explained with reference to the following examples and comparative examples, but the present invention is not limited to these examples.

[0023] Table 1 example feeding ratio unit: gram

[0024] Feed components

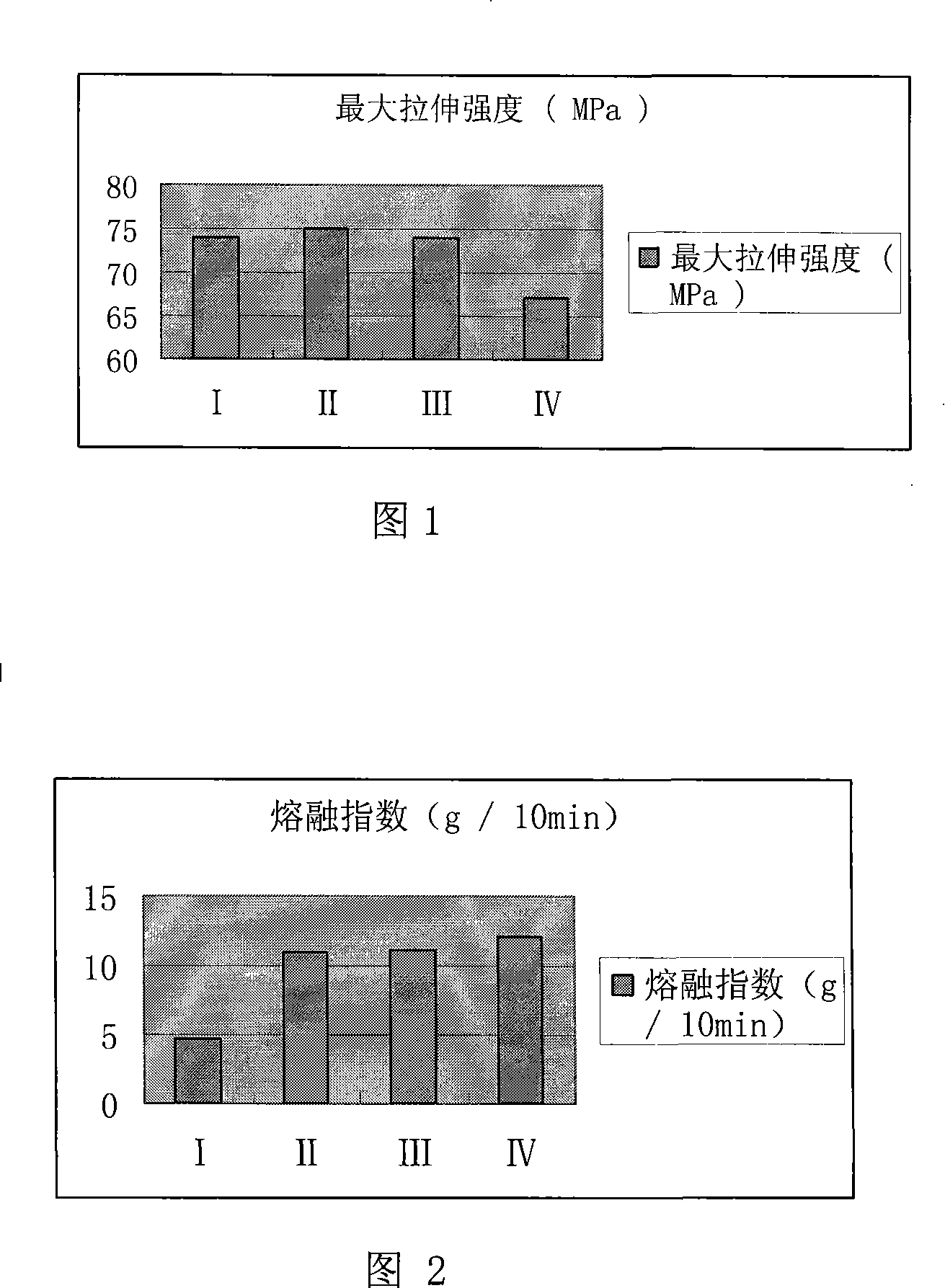

Comparative example I

Example II

Example III

Example IV

PAMAM

Glacial acetic acid

66 salt

950

-

-

-

1.0

40

50

850

2.8(2.0G)

3.0

2.5

0.9

20

25

1000

4.0(2.0G)

7.5

6.0

0.5

22

40

500

1.3(1.0G)

4.2

3.0

0.4

15

20

[0025] Preparation Process:

[0026] Salt formation: Add the amount of adipic acid into polyamide-amine, add the amount of distilled water, and stir at 65°C to 75°C for 2 to 4 hours; then add hexamethylenediamine according to the amount (because hexamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com