Alternating load loading device for bearing testing machine, based on screw rod transmission mechanism

A technology of screw drive and bearing test, which is applied in the direction of transmission device, mechanical bearing test, mechanical equipment, etc. It can solve the problems of single loading characteristic and inability to realize variable load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

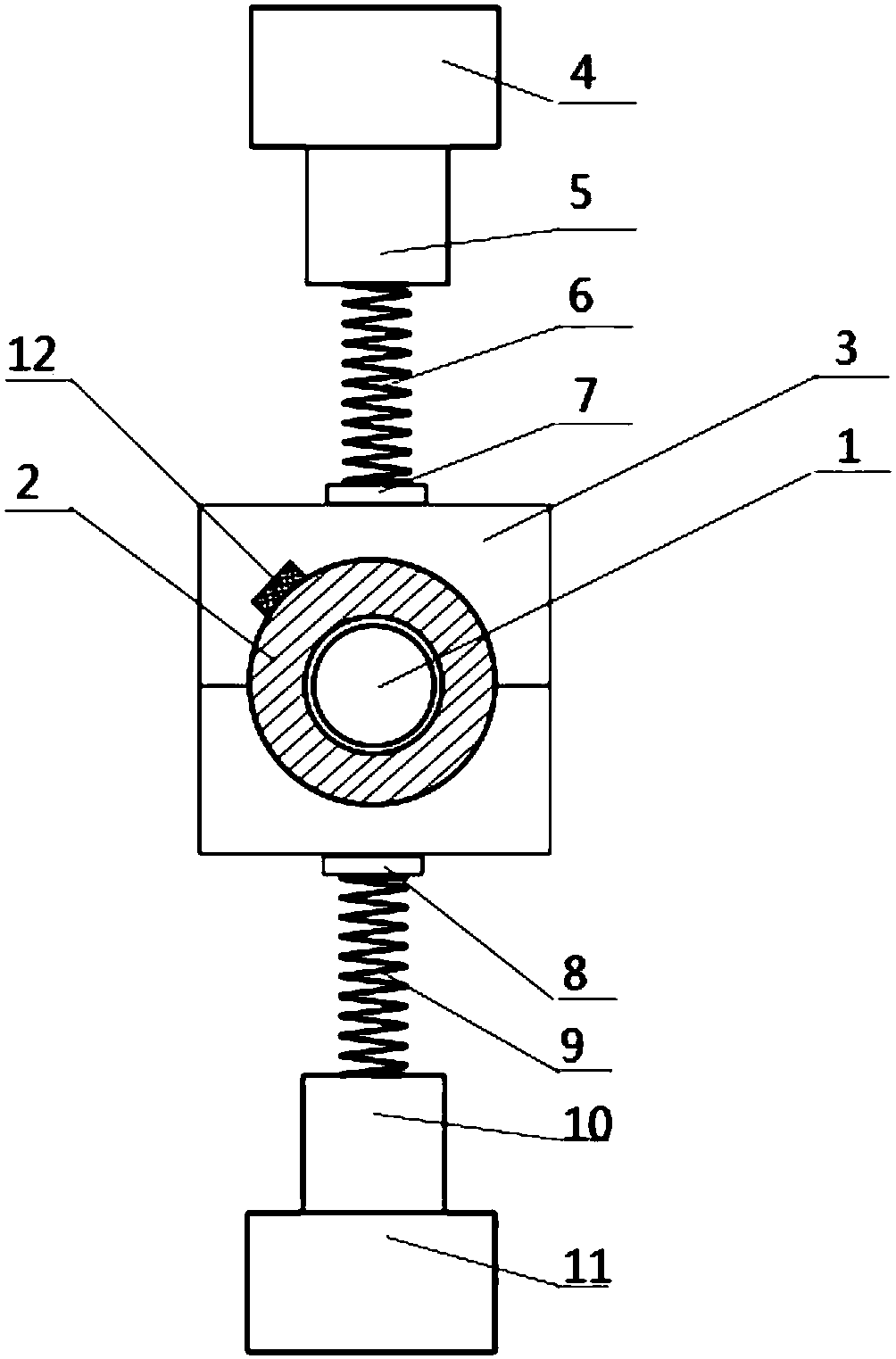

[0022] Such as figure 2 As shown, an alternating load loading device for a bearing testing machine based on a screw drive mechanism, the bearing testing machine includes a rotating shaft 1, the tested bearing 2 is installed on the rotating shaft 1, and the loading device includes a fixture 3, and a plurality of rotary motors-screw drive mechanism-spring units arranged around the fixture 3, the rotary motor-screw drive mechanism-spring assembly includes sequentially connected rotary motors, screw drive mechanisms and springs, the rotary motor Drive the screw drive mechanism to move, control the spring to be stretched or compressed, and apply alternating loads to the tested bearing 2 in the fixture 3 .

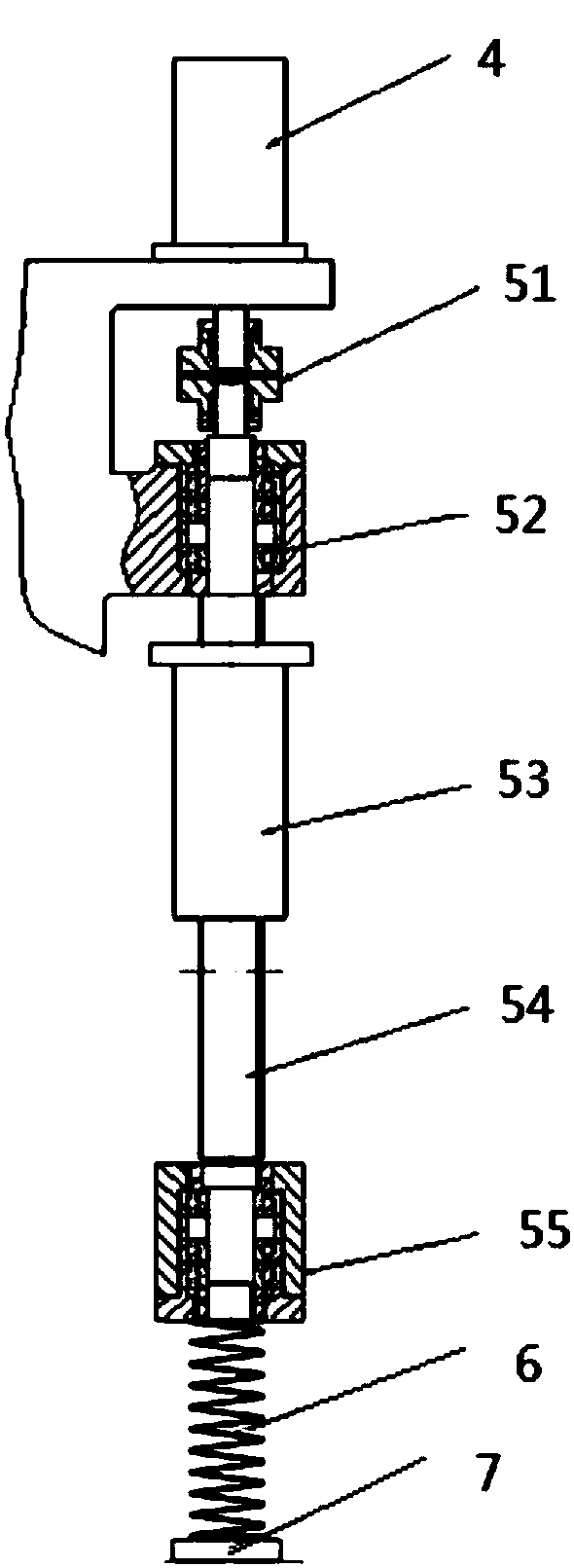

[0023] Wherein, there are two rotating motor-screw drive mechanism-spring assemblies: assembly A and assembly B, which are arranged symmetrically on the upper and lower sides of the fixture 3 . The component A includes: a rotating motor A4, a screw drive mechanism A5 and a spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com