Medical micro-power torsion screwdriver

A screwdriver and micro-power technology, applied in the field of medical equipment, can solve the problems of increasing the workload of equipment nurses, the deviation of screw screwing direction, and increasing the workload of medical care, etc., and achieves easy promotion and use, adjustable torque, and easy replacement of batch heads. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

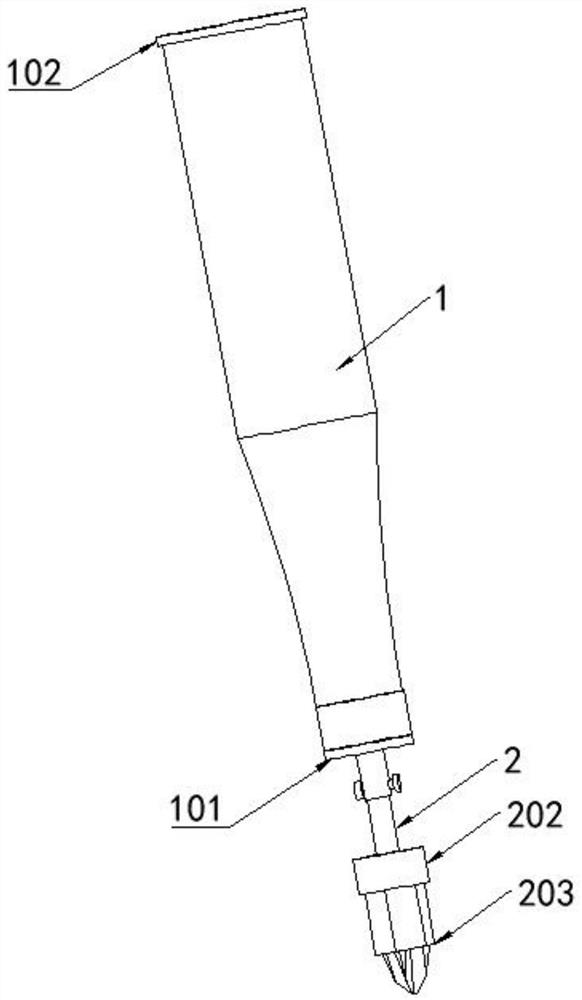

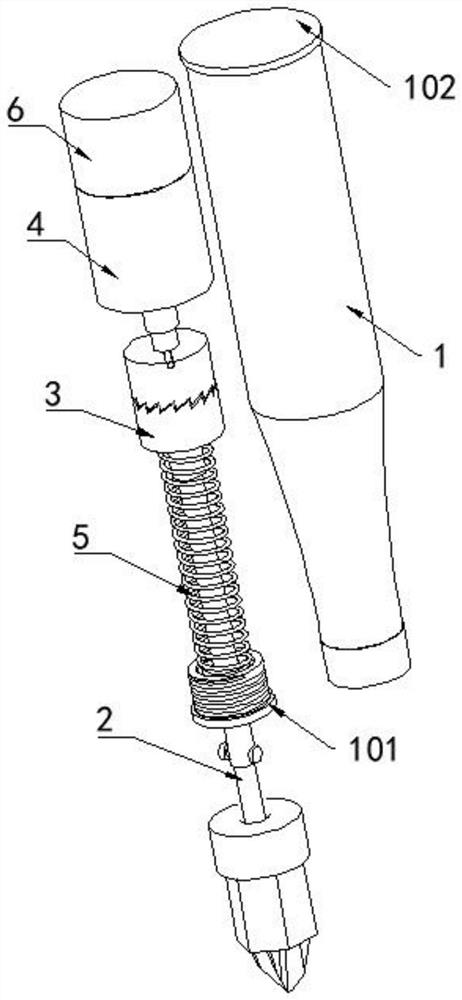

[0038] Such as figure 1 or Figure 5 As shown, the present invention provides a medical micro-power torque screwdriver, comprising a screwdriver handle 1, a screwdriver shaft 2, a coaxial interlocking sleeve 3 and a micro motor 4, the front end and the rear end of the screwdriver handle 1 are respectively provided with a front end cover 101 and a The rear end cover 102 and the front end cover 101 are provided with a front end socket, the coaxial interlocking sleeve 3 and the micro motor 4 are located in the screwdriver handle 1, and a spring 5 is arranged between the coaxial interlocking sleeve 3 and the inner wall of the front end cover 101 , the screwdriver rod 2 runs through the front end socket and the inner ring of the spring 5 is connected with one end of the coaxial interlocking sleeve 3 , and the other end of the coaxial interlocking sleeve 3 is connected with the micro motor 4 . The coaxial interlocking sleeve 3 is used as a torque control device to connect the micro...

Embodiment 2

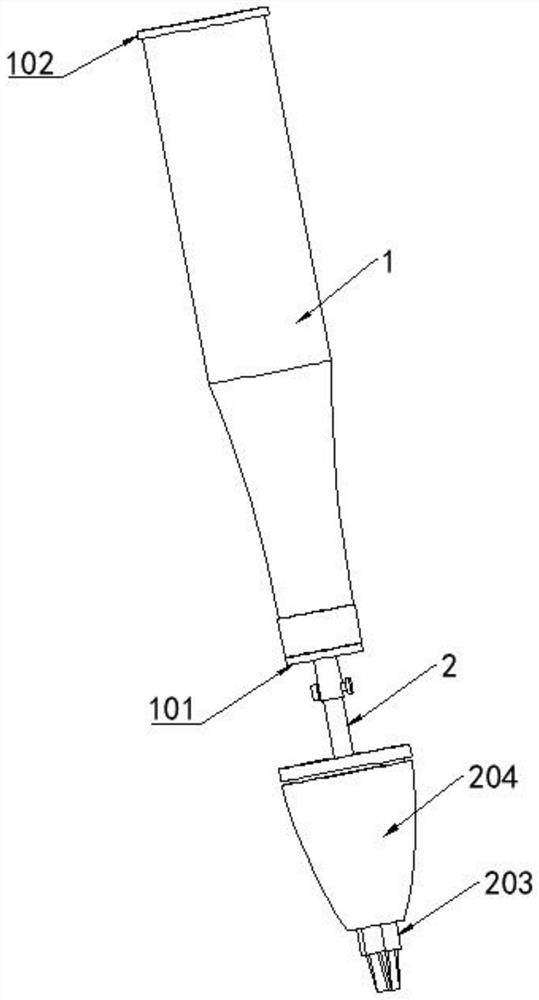

[0051] Such as image 3 Shown:

[0052] The difference between this embodiment and Embodiment 1 is that the transmission rod 201 and the bit 203 are not connected by the bit sleeve 202 but the electric drill chuck 204 is used. Let me repeat.

[0053] The screwdriver rod 2 includes a transmission rod 201, an electric drill chuck 204 and a bit 203. One end of the transmission rod 201 is connected to one end of the coaxial interlocking sleeve 3, and the other end of the transmission rod 201 and the bit 203 pass through the electric drill chuck 204. connect. Compared with the bit sleeve 202, the electric drill chuck 204 has a wider application range, and the clamping is firmer, and the probability or amplitude of possible eccentric swing is smaller. As an assembly product, the electric drill chuck 204 is easy to be sold in the market. It can be bought online, such as self-tightening drill chuck, etc., and its specific structure will not be described in detail.

[0054] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com