Patents

Literature

127results about How to "Increase the use of diversity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

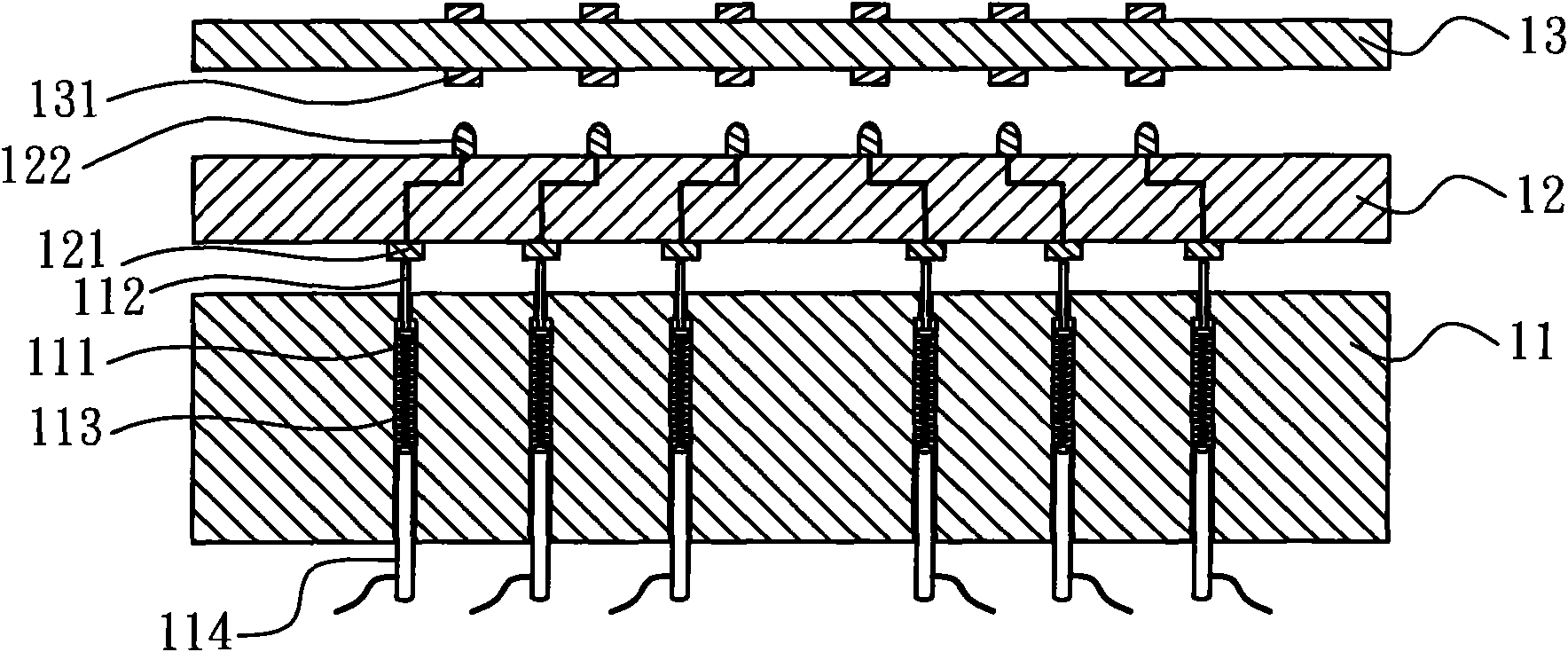

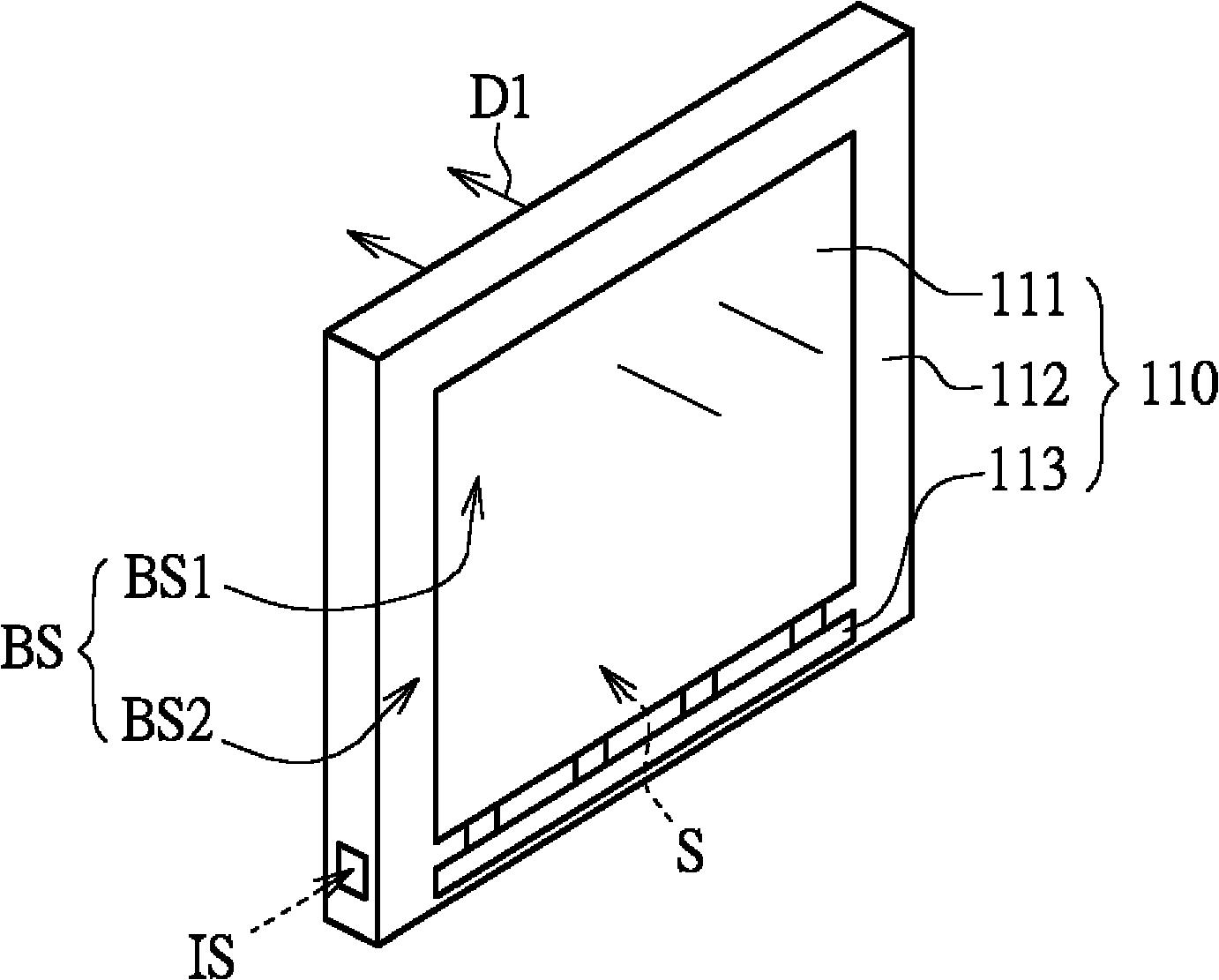

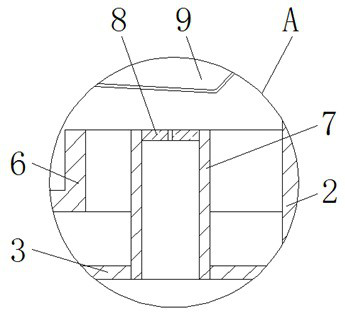

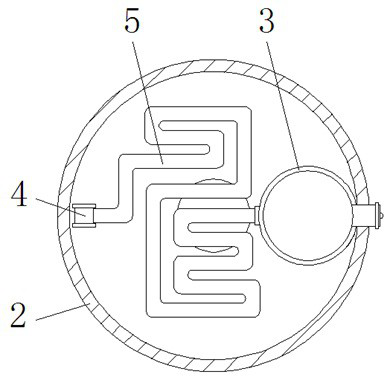

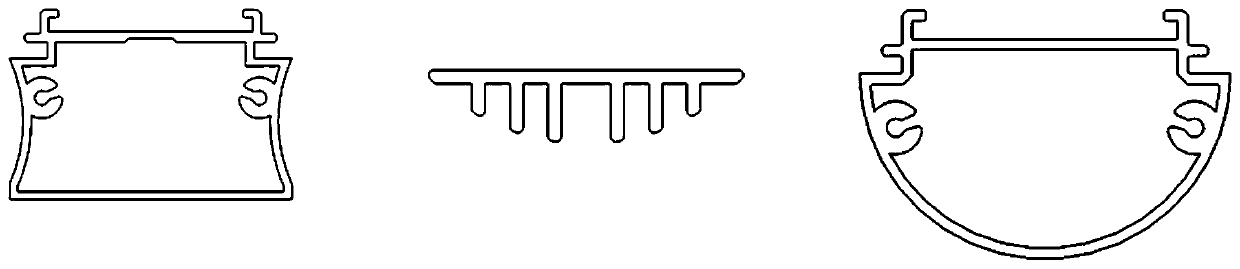

Electrical test adapter plate of sealing base plate and method thereof

ActiveCN102012470ARaise the limits of testingIncrease the use of diversityElectrical testingComputer engineering

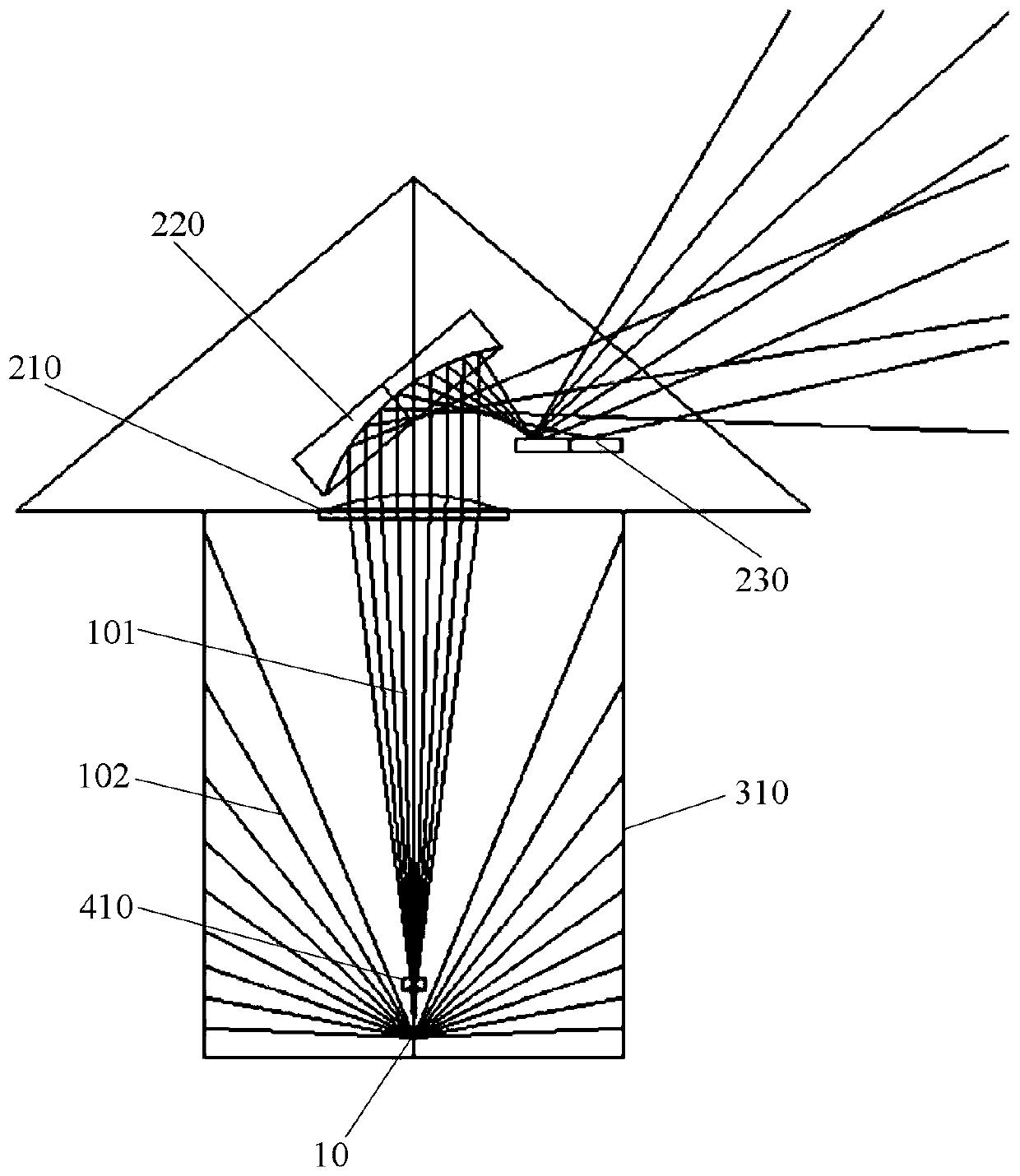

The invention discloses an electrical test adapter plate of a sealing base plate and a method thereof. Adapting pads with proper size for being used as convex pad-shaped contact points are directly formed on the surface of the adapter plate; the convex pad-shaped contact points have size design, such as smaller arrangement distance, proper convex height, and the like so that the convex pad-shapedcontact points can smoothly get in contact with the adapting pad in an opening of a welding prevention layer of a base plate; and the adapter plate is particularly suitable for detecting the base plate with tiny adapting pad distance. Accordingly, the adapter plate of the invention has test limit improving effect and expanded application range.

Owner:ASE SHANGHAI

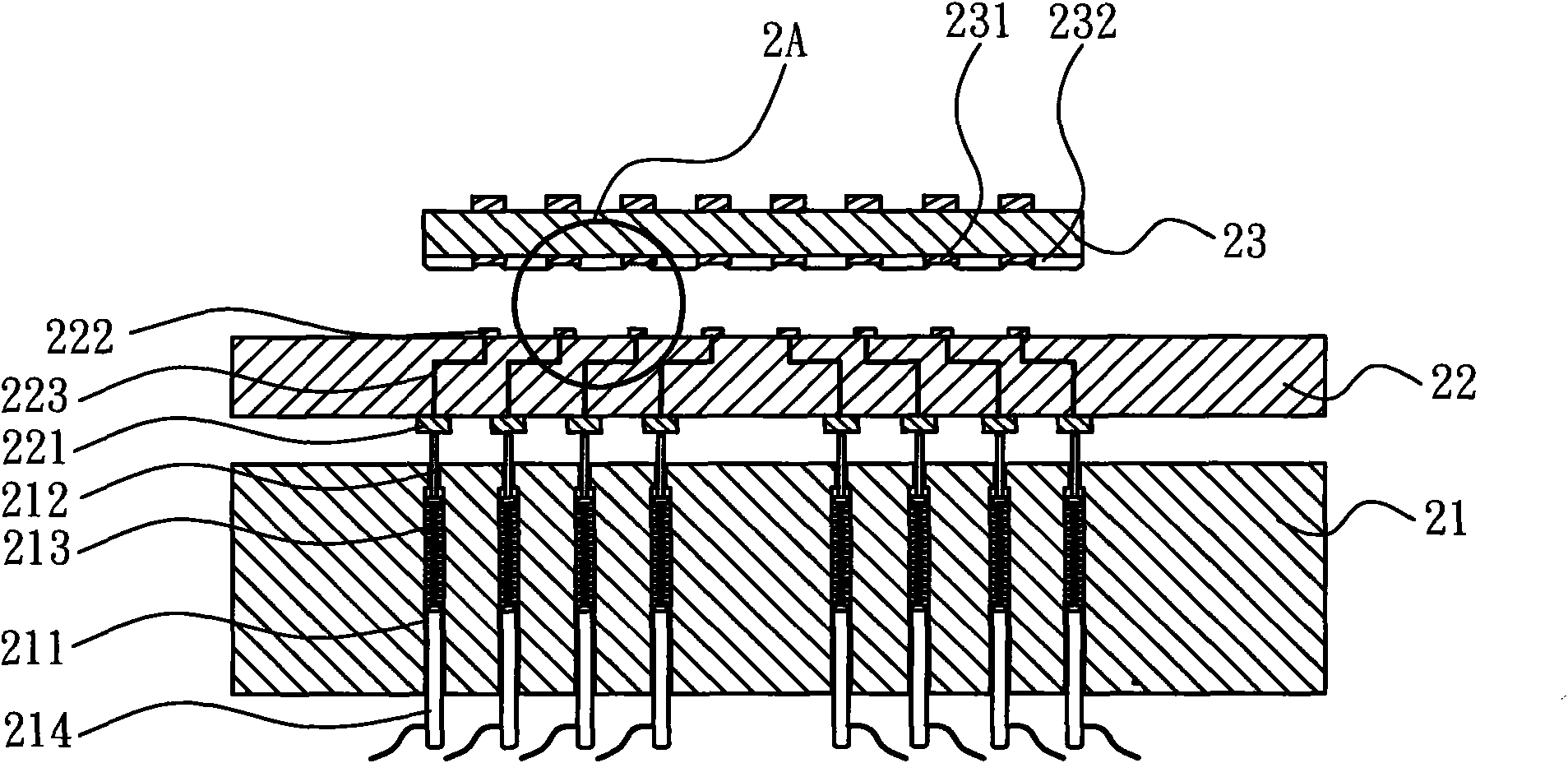

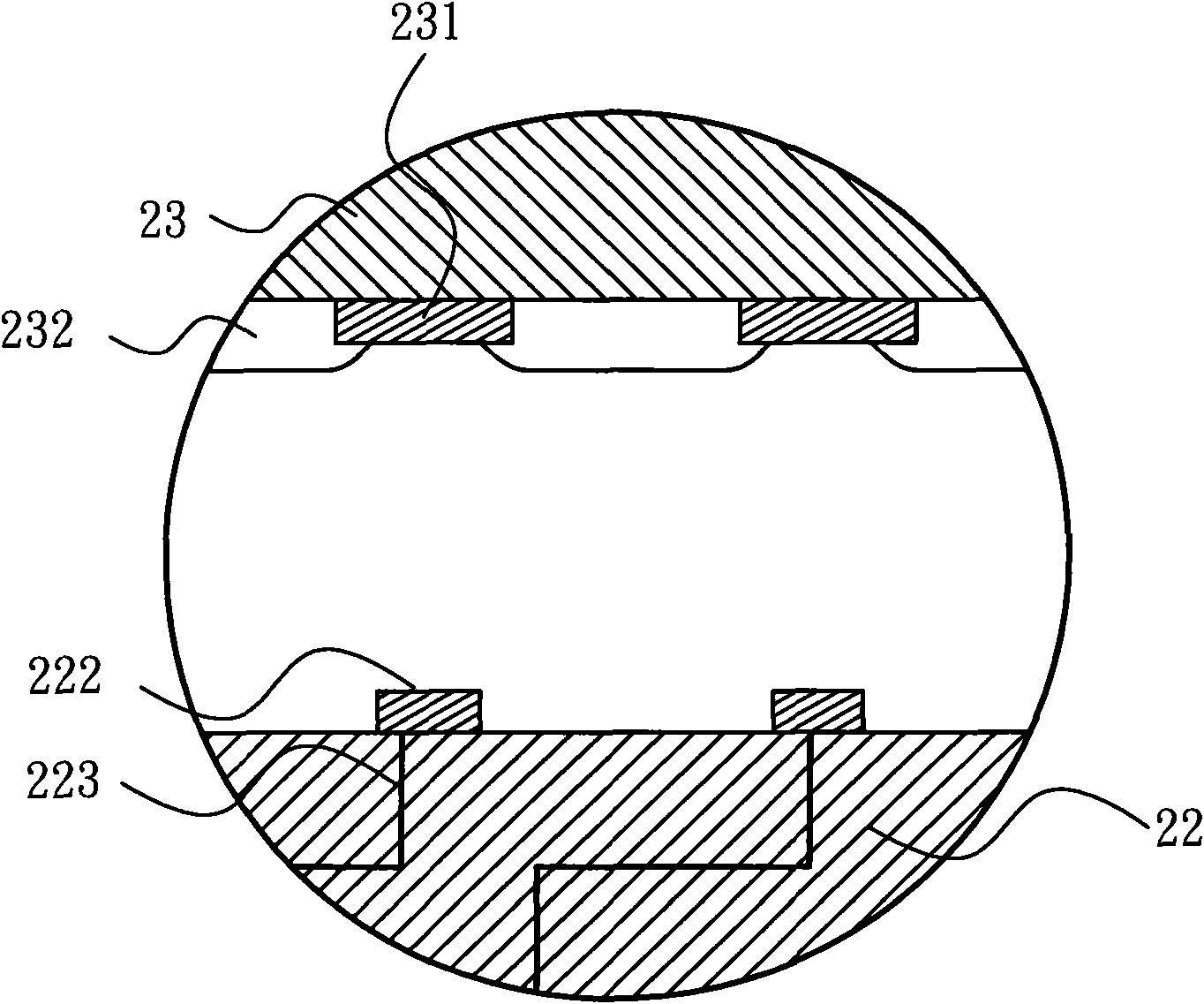

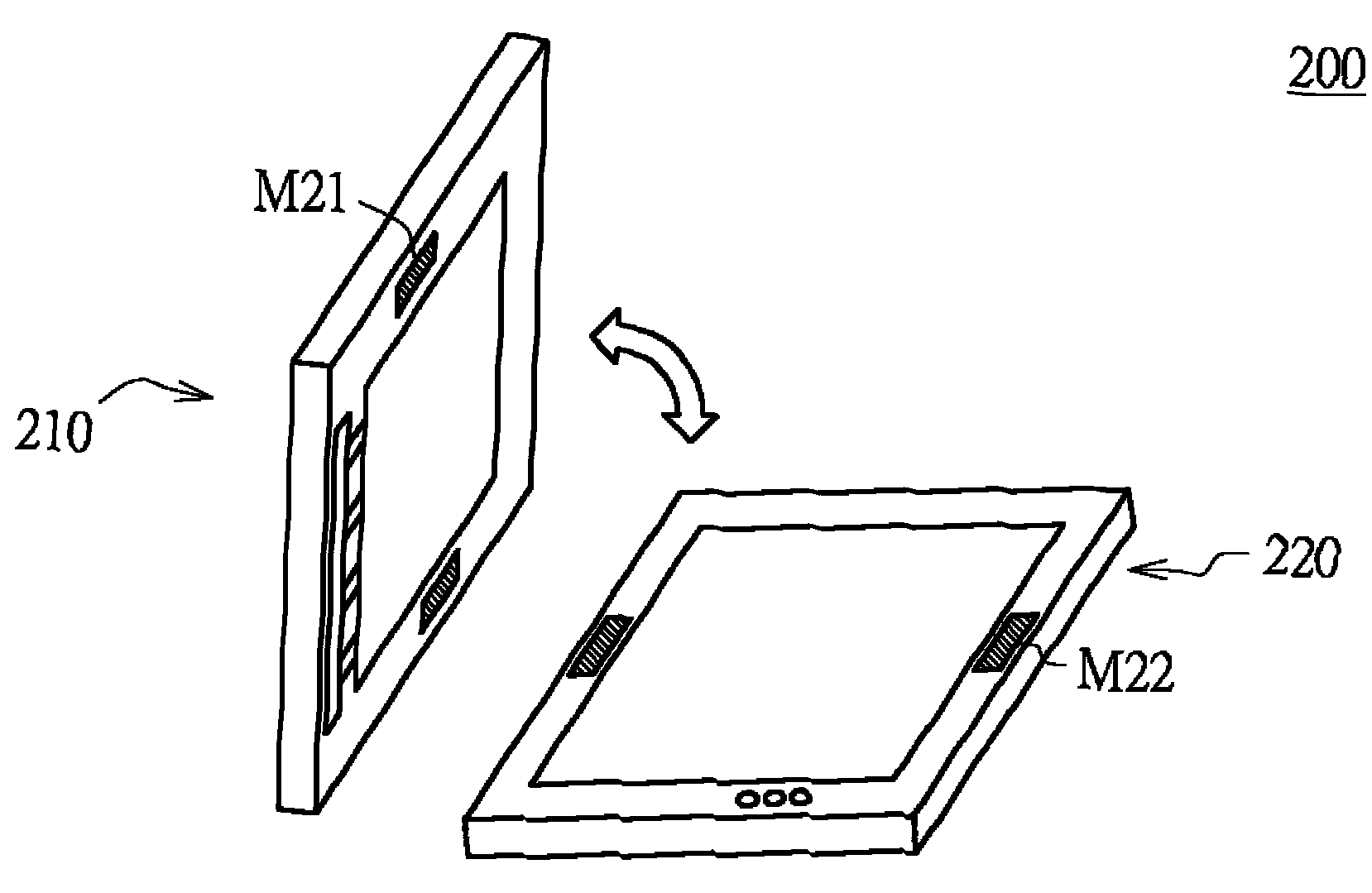

Display device

InactiveCN102184681AIncrease the use of diversityStatic indicating devicesIdentification meansDisplay deviceControl circuit

The invention relates to a display device which comprises a display panel module and a back light module, wherein the display panel module comprises a display panel unit, a shell and a non-transparent control circuit; the shell comprises a first combining mechanism; the back light module comprises a back light unit and a second combining mechanism; and the second combining mechanism is used for being combined with or separated from the first combining mechanism selectively. Through the display device, the user can match the display panel module and the back light module freely, thus increasing the use diversity of the display device; and when one of the display panel module and the back light module is damaged, only the damaged part needs to be replaced.

Owner:BENQ CORP

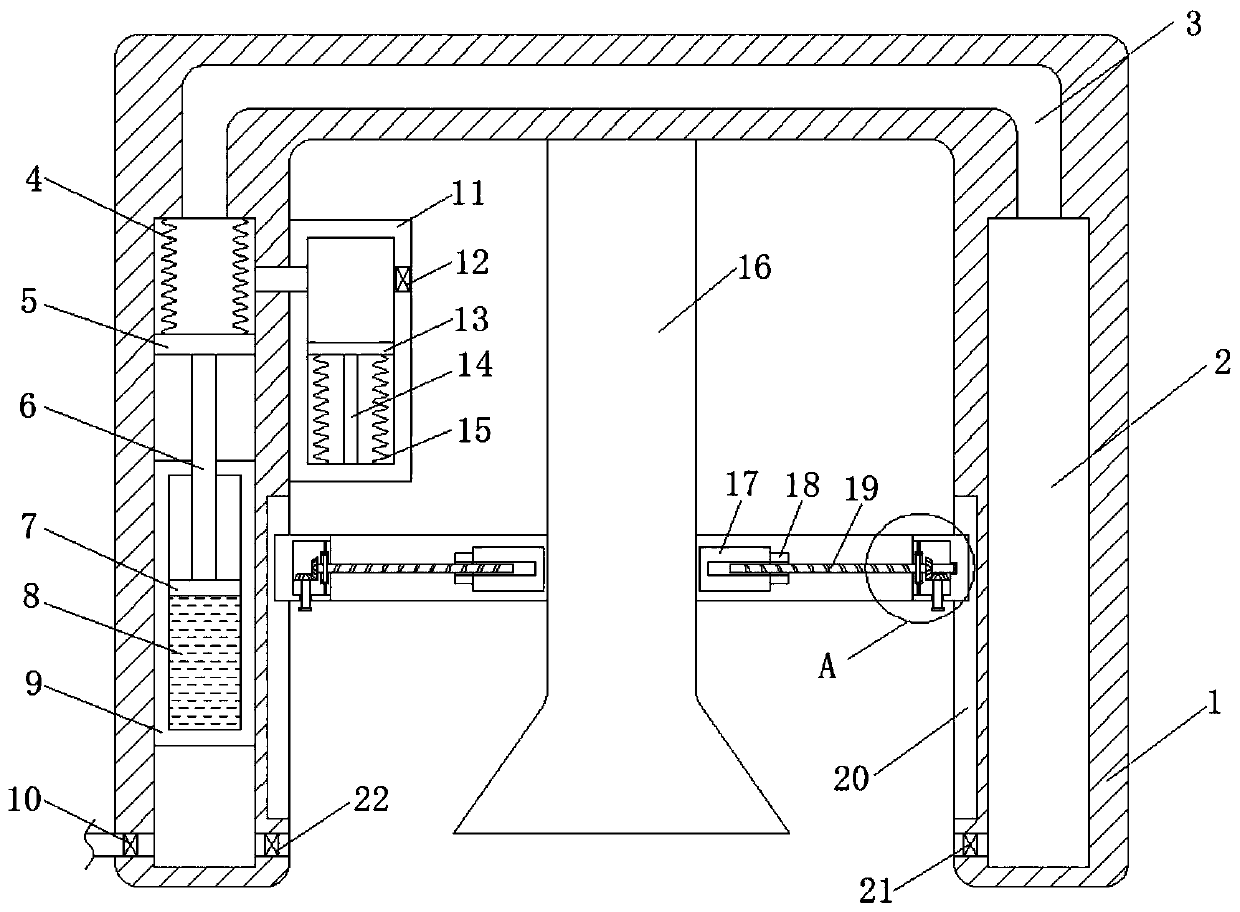

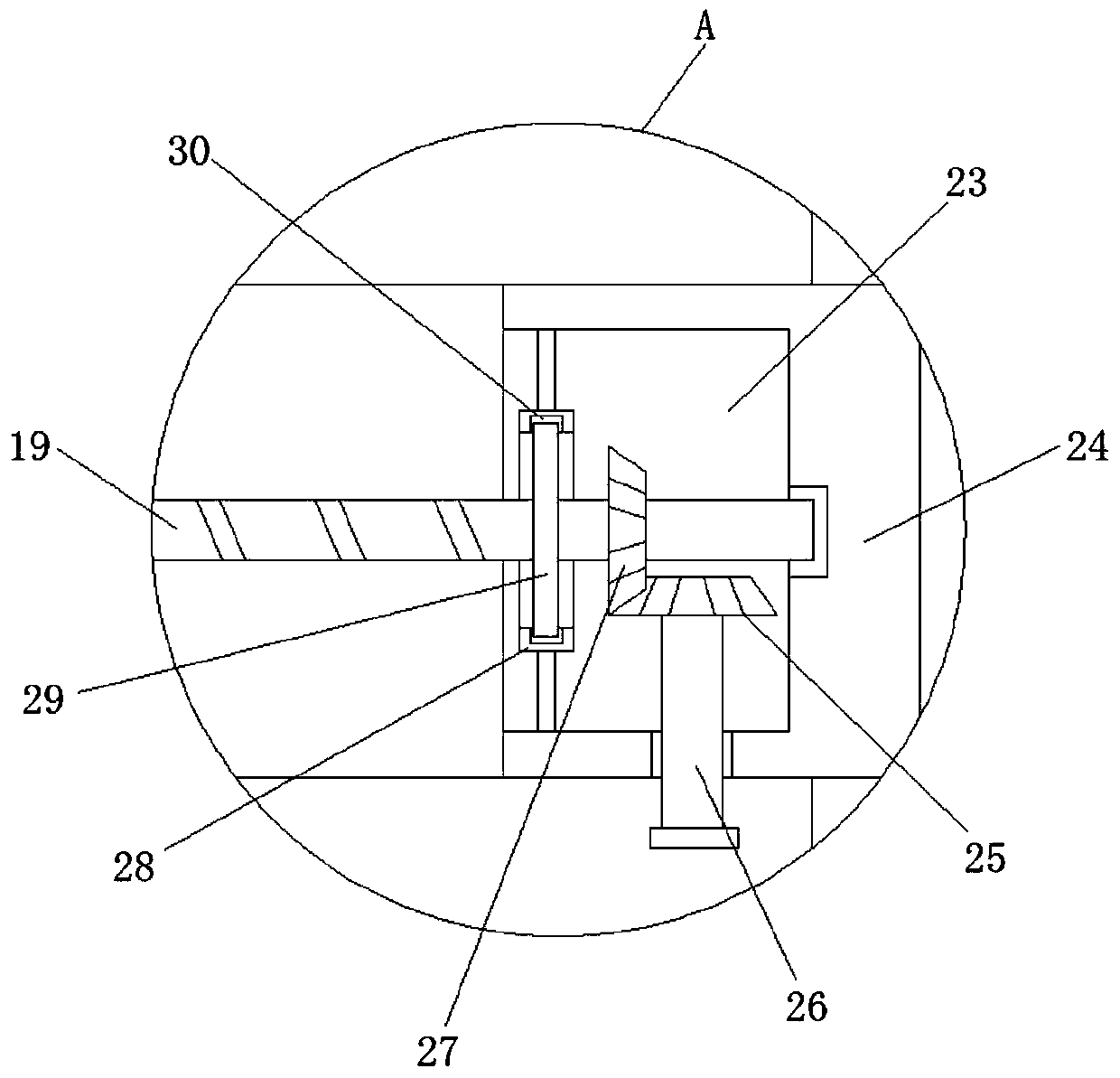

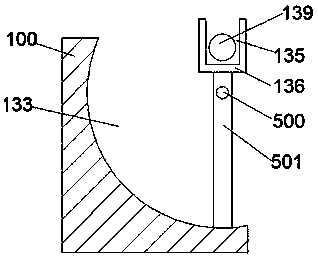

Lamp for textile workshop

ActiveCN110608425ALower the heatExtended service lifeLighting applicationsLighting heating/cooling arrangementsPositive pressureBoiling point

The invention discloses a lamp for a textile workshop. The lamp for the textile workshop comprises a lampshade and a bulb connected to the inner top of the lampshade in a threaded manner. Two first gas cavities are formed in the opposite side walls of the lampshade. The inner wall of the lampshade is provided with a first annular groove. The first gas cavities are internally provided with a drivedevice for cleaning the surface of the bulb. A fixing device for mounting and fixing the bulb is arranged in the first annular groove. Low-boiling point evaporation liquid in a liquid storage cylindergenerates steam when being heated, a second piston is made to move upward, a first piston is made to move upward, so that the inside of the first gas cavity on the left side is at the negative pressure, the inside of the first gas cavity on the right side is at the positive pressure, a first one-way valve and a second one-way valve are opened at the same time, dust on the bulb is cleaned and recycled, a bimetal sheet in a heat absorption box is heated and bent to enable a third piston to move downwards, so that hot gas in the lampshade is sucked d into the heat absorption box, hot gas is discharged through the first one-way valve of the first gas cavity communicating with the heat absorption box, and moisture on the bulb is evaporated.

Owner:浏阳市恒信包装印刷有限公司

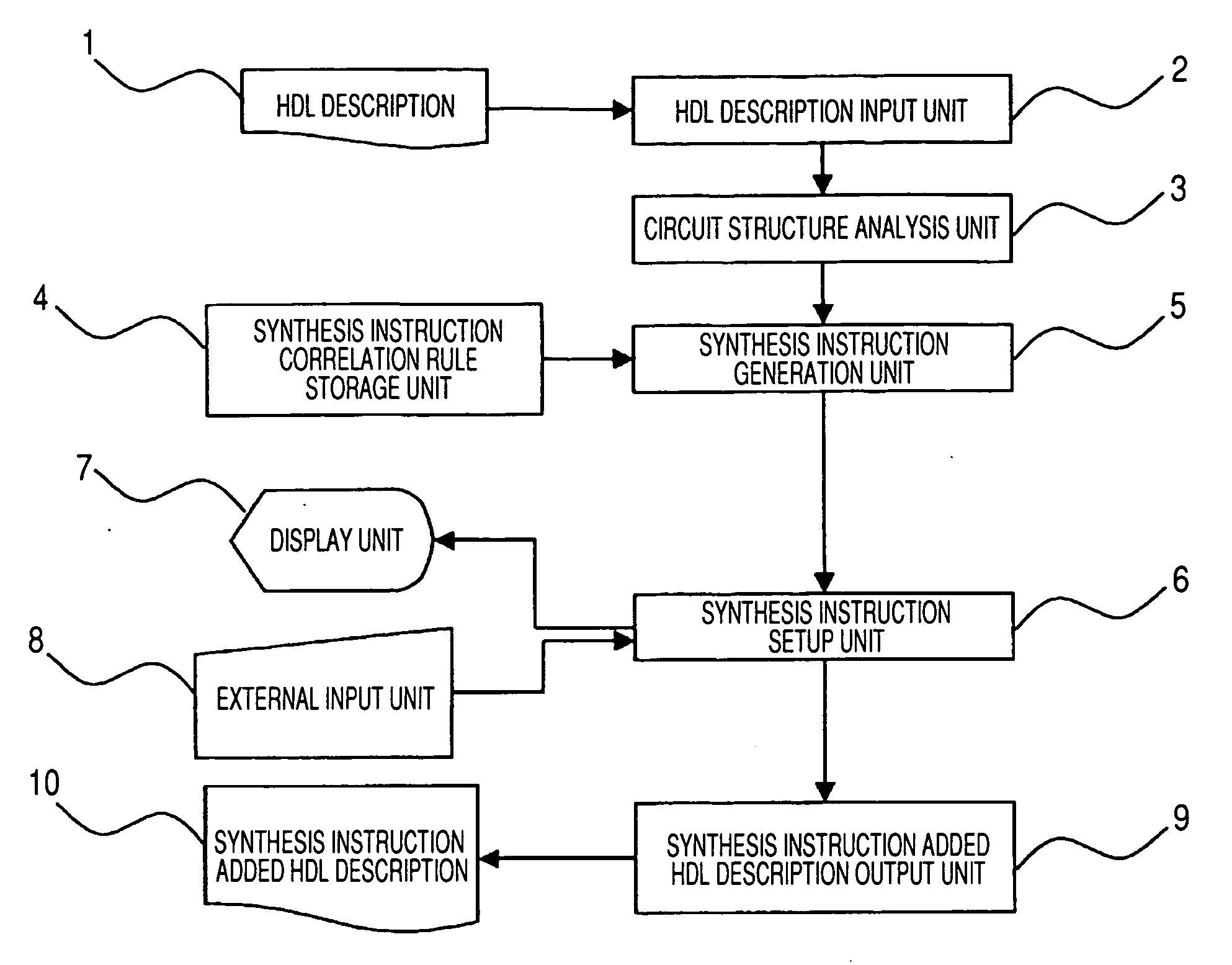

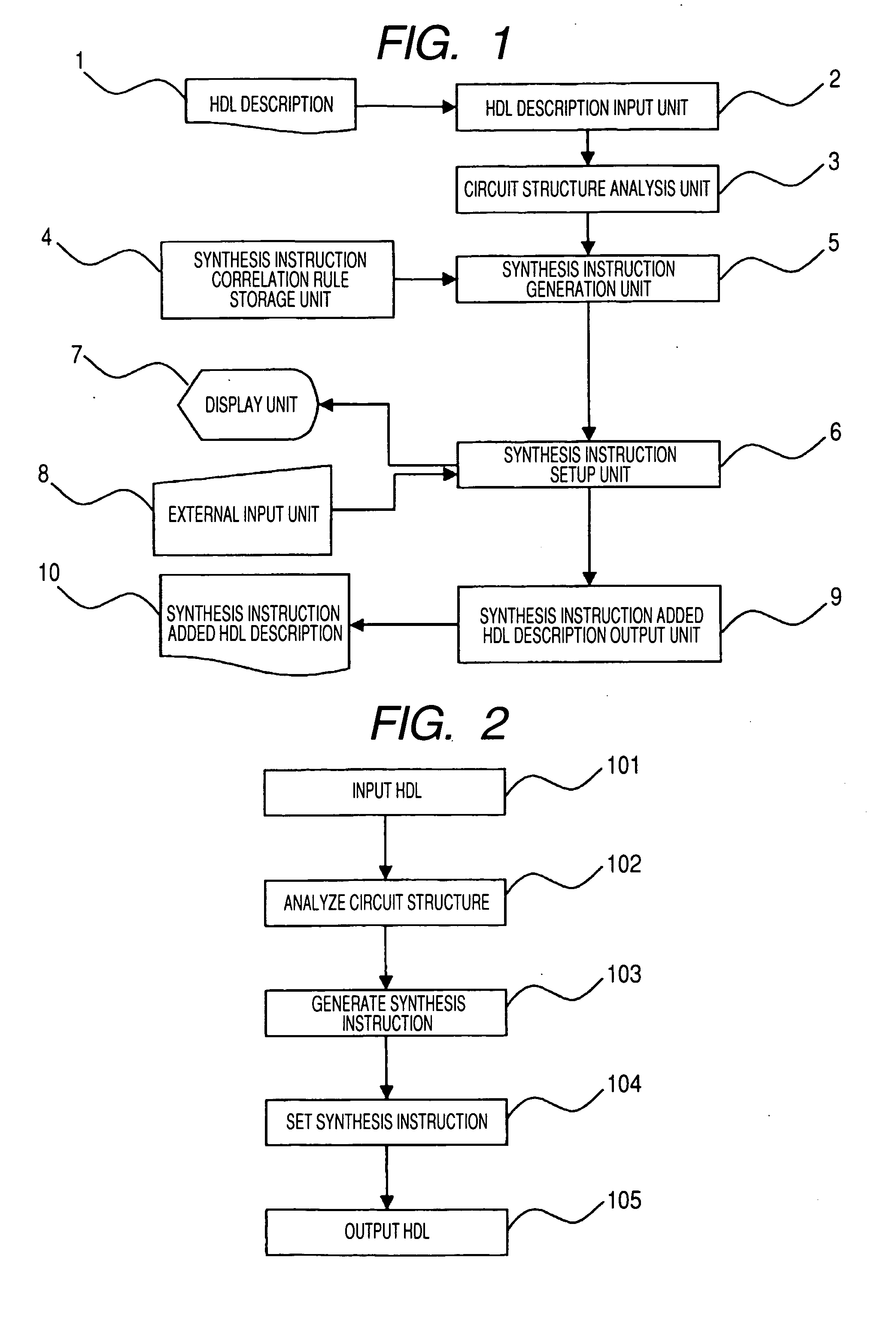

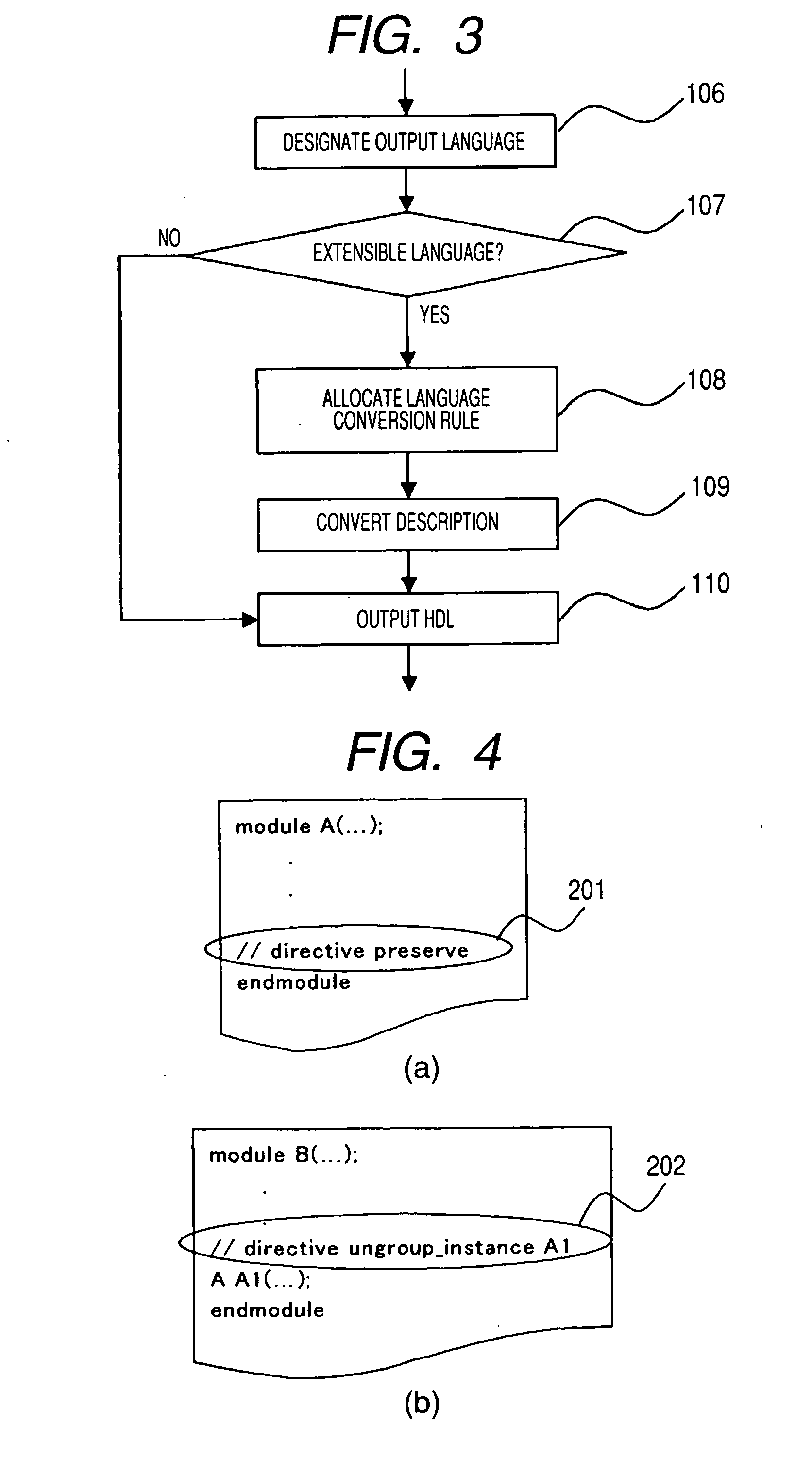

Logic circuit design support apparatus, and logic circuit design support method employing this apparatus

InactiveUS20070083844A1Simple preparation processReduce in quantityCAD circuit designSoftware simulation/interpretation/emulationStructure analysisMultiplexer

A circuit structure analysis unit performs structure analysis for logic circuit information, obtained from an HDL description, and acquires analysis results for function parts, such as a register, an operation unit and a multiplexer. A synthesis instruction generation unit compares the analysis results with a synthesis instruction correlation rule, and automatically generates a synthesis instruction to control a logic synthesis method. Finally, an HDL description output unit outputs a synthesis instruction added HDL description, wherein a synthesis instruction is inserted into the original HDL description. When the synthesis instruction added HDL description is employed in the logic synthesis, starting at the top hierarchical level, a synthesis instruction for the logic circuit is not required in a synthesis execution script.

Owner:PANASONIC CORP

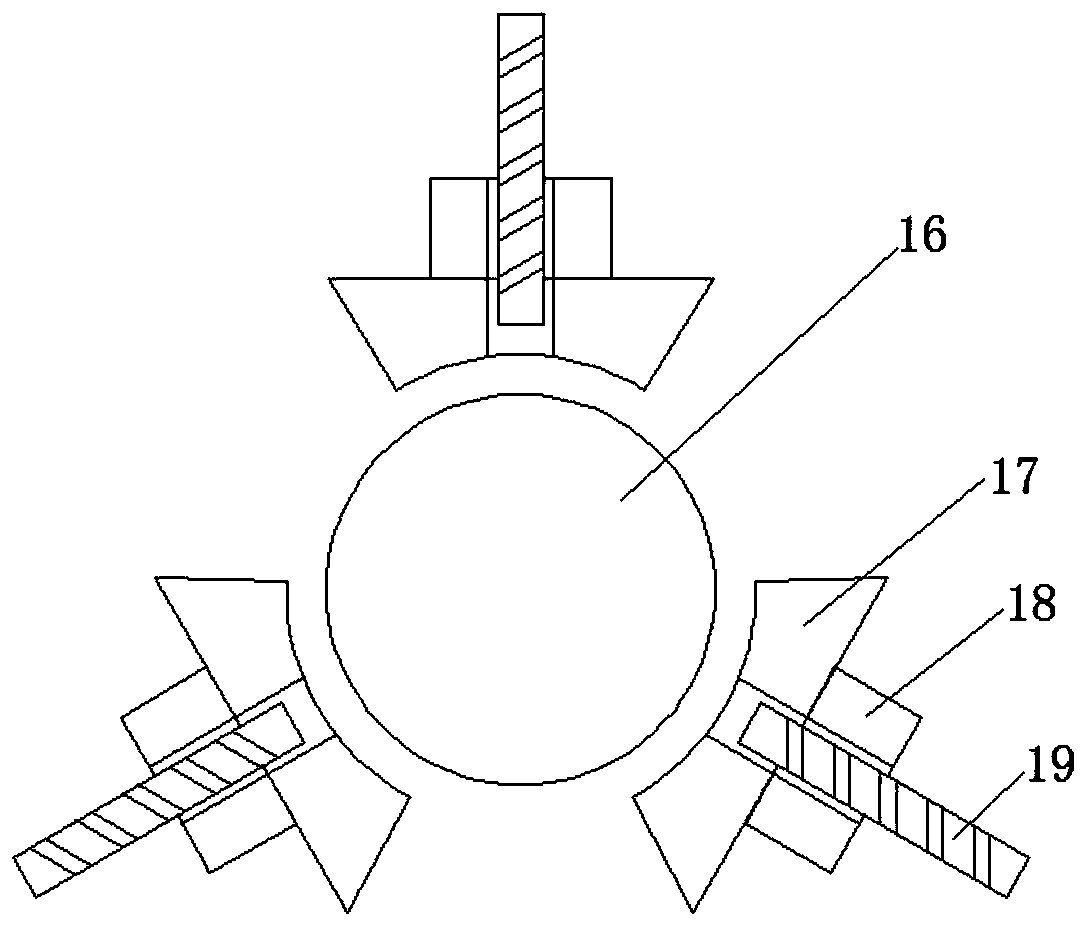

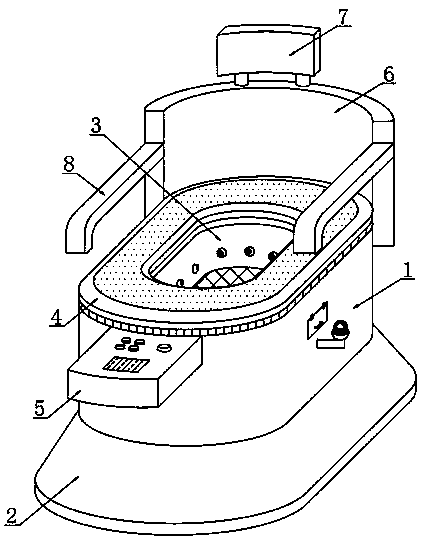

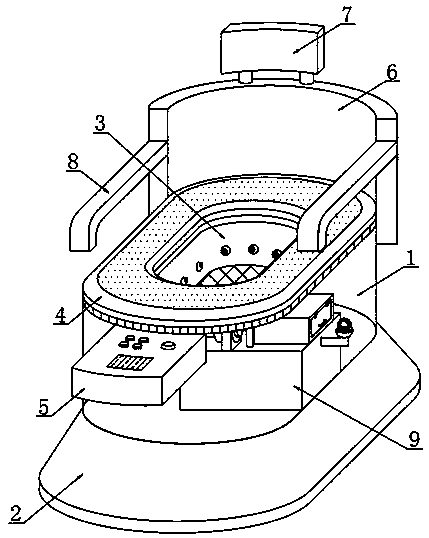

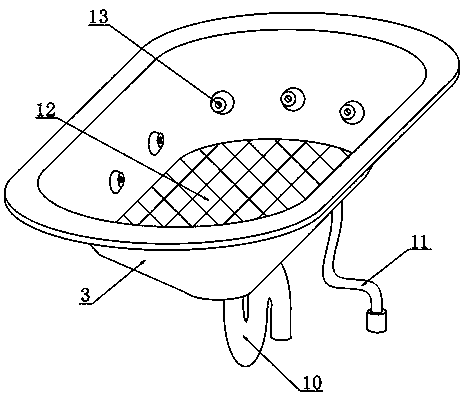

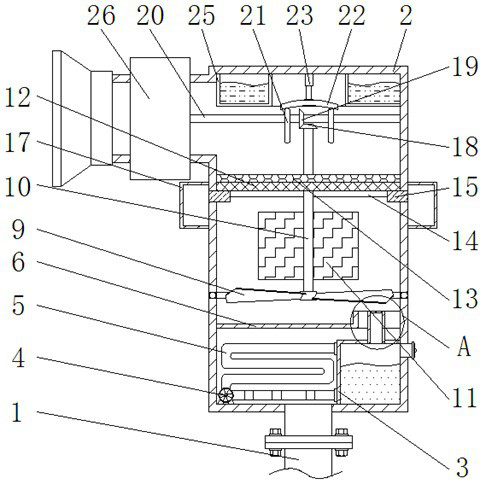

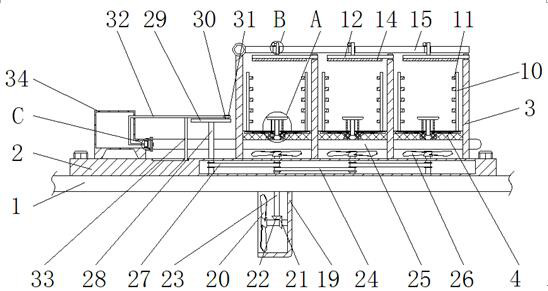

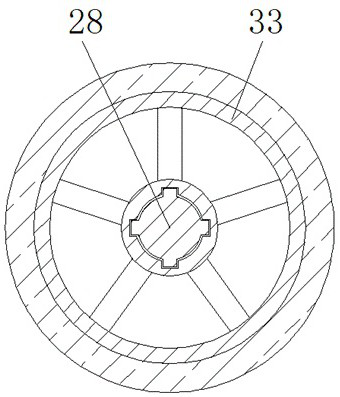

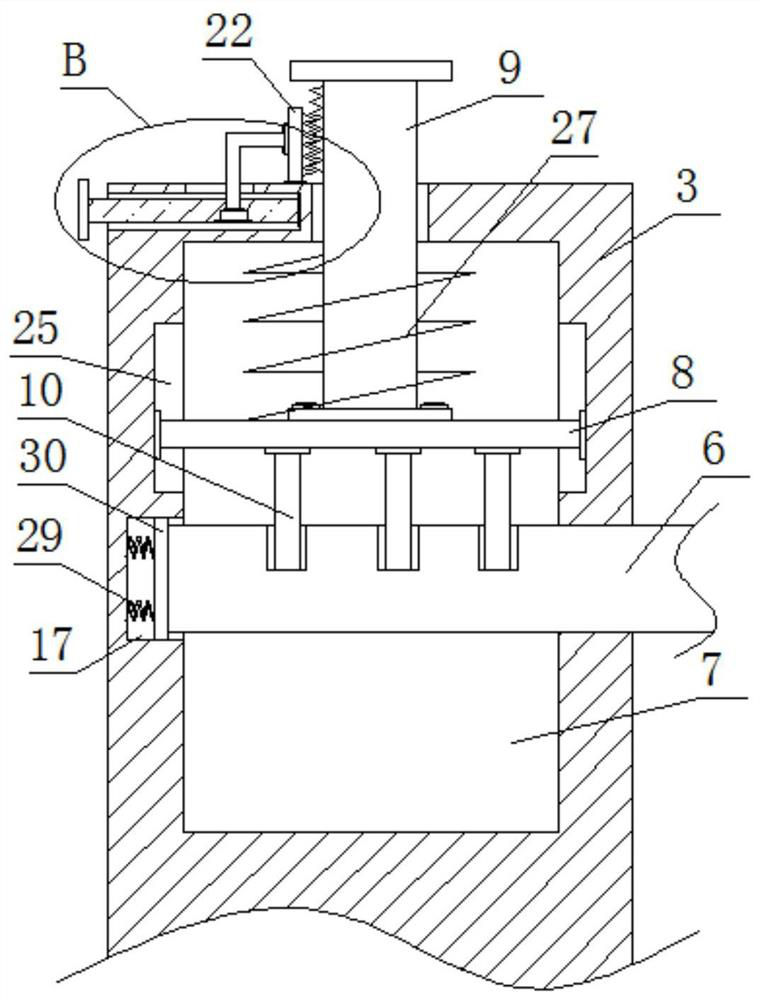

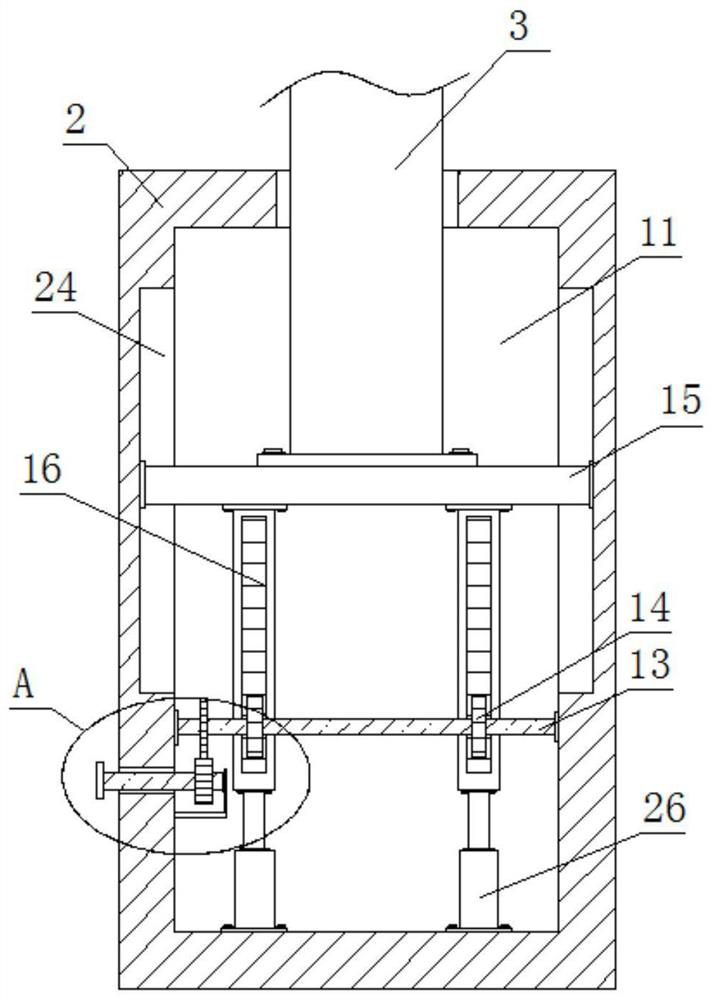

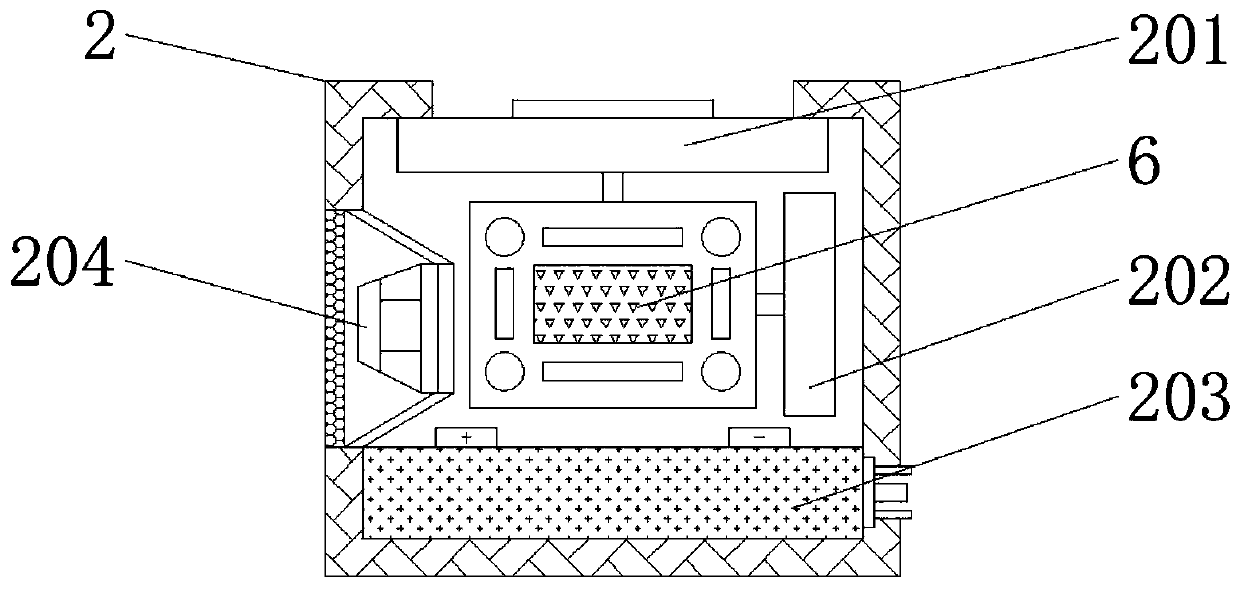

Multifunctional sitz bath instrument for postpartum care of gynecology department

InactiveCN110917018AComfortable to useIntegrating the comfort of useBathing devicesSitz bathEngineering

The invention discloses a multifunctional sitz bath instrument for postpartum care of a gynecology department and in particular relates to the technical field of sitz bath instruments. The instrumentcomprises a sitz bath instrument shell, wherein a base is welded on the lower surface of the sitz bath instrument shell; a control box is mounted at the upper end of the front surface of the sitz bathinstrument shell; a cushion is mounted on the upper surface of the sitz bath instrument shell; a sitz bath basin is mounted at the upper end inside the sitz bath instrument shell; a spraying fumigation component is mounted at the front end inside the sitz bath instrument shell; a backrest is welded on the rear surface of the sitz bath instrument shell; a headrest is mounted above the backrest; armrests are welded on the front surface of the backrest; a blow-down tube is welded with the lower surface of the sitz bath basin in a communicating manner; and a water outlet net is mounted at the lower end inside the sitz bath basin. The multifunctional sitz bath instrument for postpartum care of the gynecology department, which is disclosed by the invention, is provided with a sponge layer on the cushion, is provided with a heating plate for fumigation, and is provided with the armrests and the backrest, and is high in cleaning efficiency.

Owner:孙肖慧

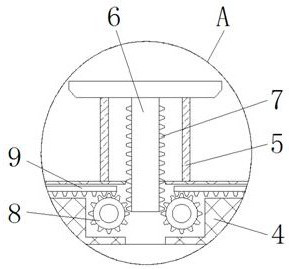

Multipurpose tray

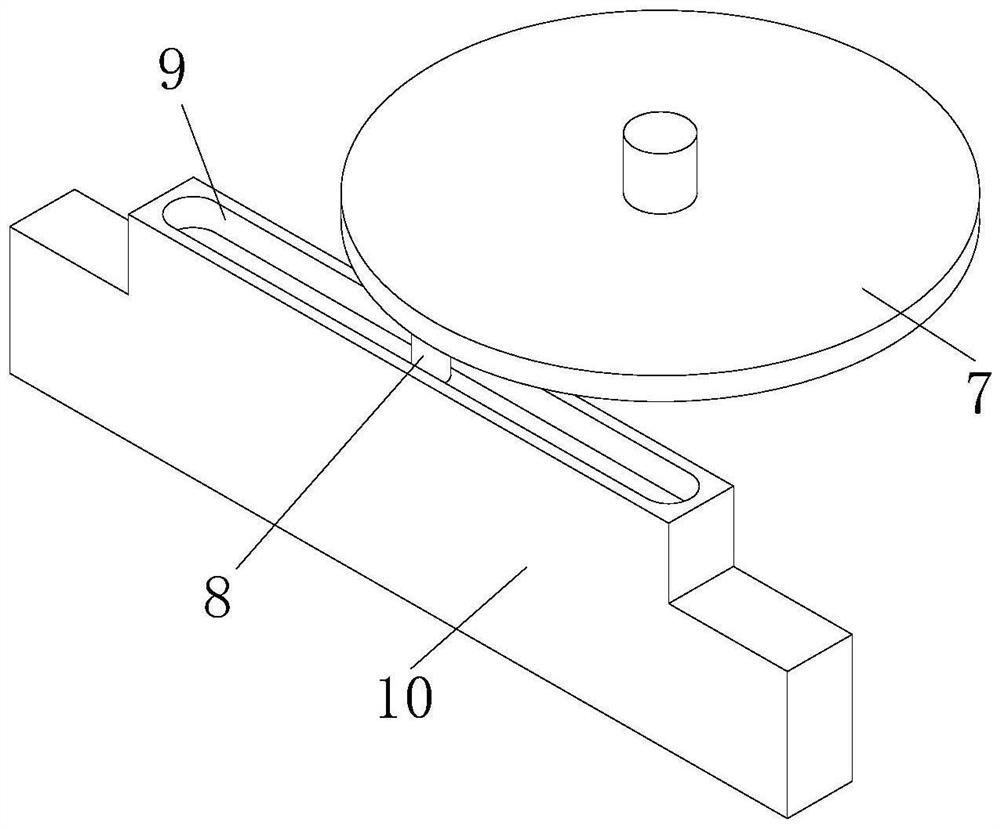

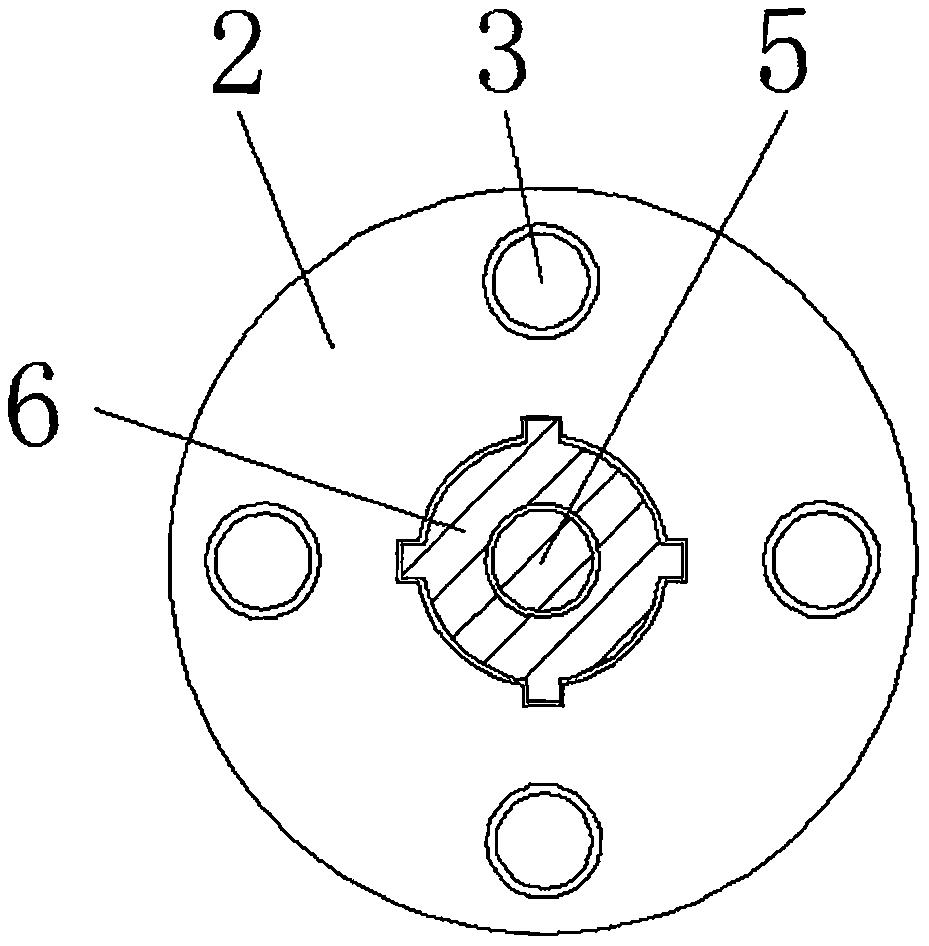

ActiveCN107521807AExtended service lifeIncrease the use of diversityRigid containersImpellerEngineering

The invention discloses a multipurpose tray which comprises a supporting plate. A groove is formed in the top of the supporting plate, sliding grooves communicated with the groove are formed in the two opposite sides of the supporting plate, two adjustable supporting frames rotationally connected into the sliding grooves are arranged in the groove, and each adjustable supporting frame is provided with an ancillary supporting mechanism; each adjustable supporting frame comprises a driving plate, a driven plate and a gear, wherein the driving plate and the driven plate are hinged, a connecting rod is hinged to the eccentric position of the gear, and the connecting rod is hinged to the end of the driving plate; gears in the two adjustable supporting frames are meshed; and each ancillary supporting mechanism comprises an air bag arranged in the groove and located between the corresponding driving plate and the corresponding driven plate and an impeller connected with one gear through an adjustable connecting shaft coaxially, wherein an impeller shell for protecting the impeller is arranged on the outer side of each impeller, and the impeller shells are communicated with the air bags. Compared with the prior art, the tray using diversification is improved, and the service life of the driving plates and the driven plates is prolonged.

Owner:重庆旭永科技发展有限公司

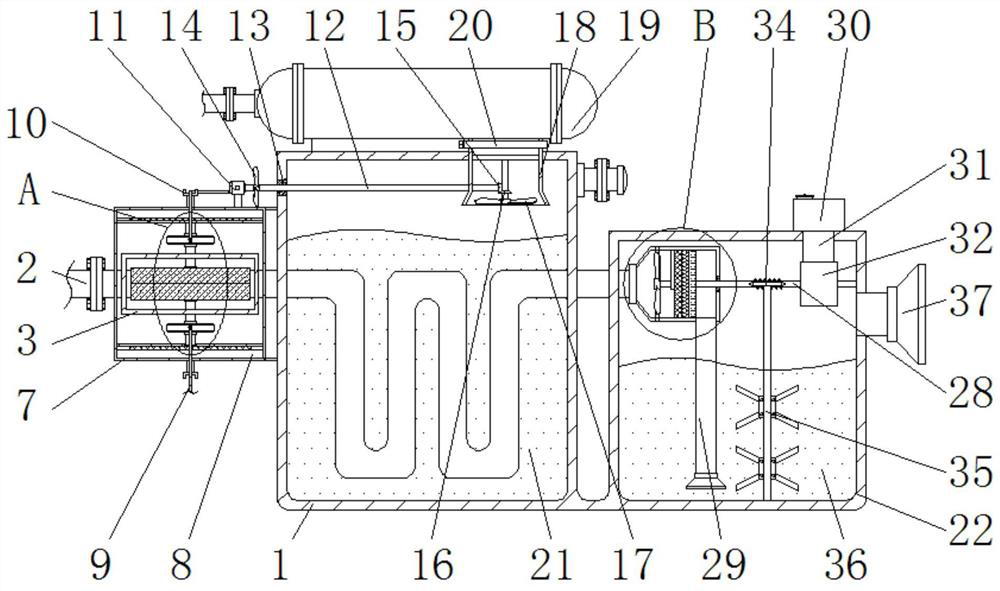

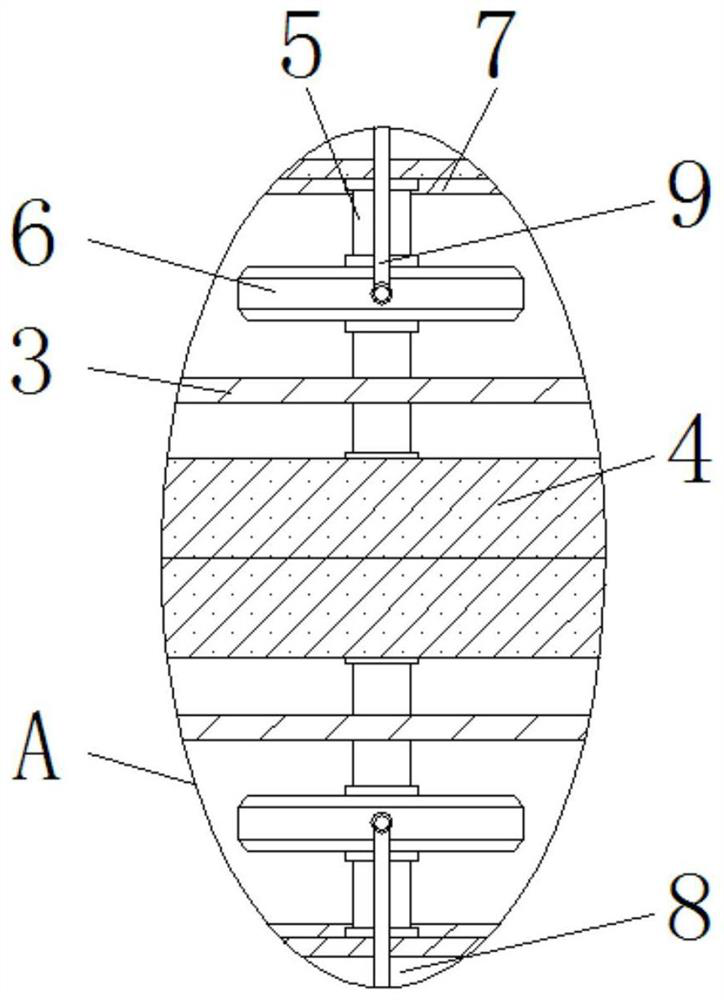

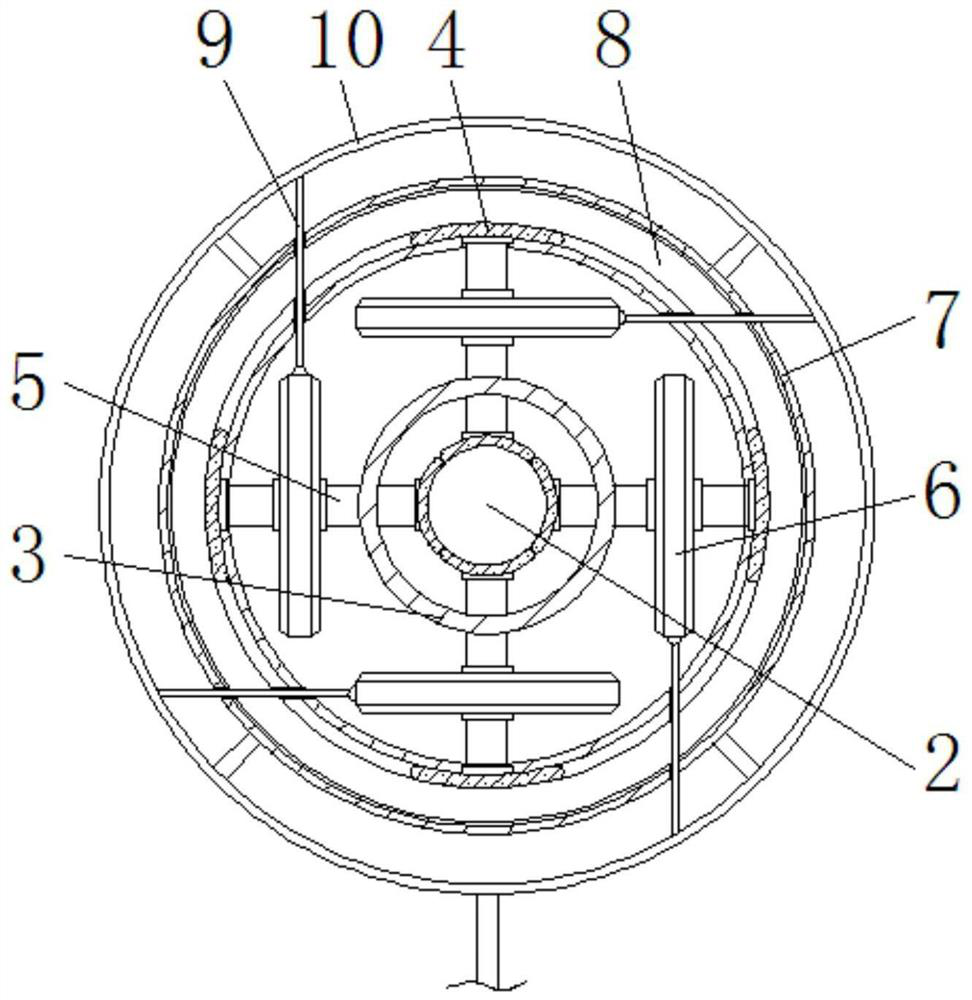

Ship tail gas treatment device capable of recycling heat energy in multiple stages

ActiveCN111706843AIncrease profitIncrease heatGas treatmentDispersed particle filtrationThermal waterHeat energy

The invention discloses a ship tail gas treatment device capable of recycling heat energy in multiple stages. The ship tail gas treatment device capable of recycling the heat energy in the multiple stages comprises a recycling box, a temperature difference power generation sheet, a steam collection tank, a filter screen plate and a material dropping groove; a gas inlet pipe is connected to the recycling box through a bolt; a heat insulation pipe is connected to the gas inlet pipe through a bolt; an exhaust fan is connected to a second conical gear through a shaft; the exhaust fan is connectedto the interior of a collection frame through a shaft; the collection frame is mounted on the steam collection tank through a bolt; the steam collection tank is connected to the recycling box througha bolt; and purified water is arranged in the recycling box. The ship tail gas treatment device capable of recycling the heat energy in the multiple stages is provided with the steam collection tank;heat energy radiated by tail gas during passing through the gas inlet pipe can heat the purified water so that hot water for daily use can be provided for a ship; the exhaust fan can pump steam into the steam collection tank to be collected so that convenience can be provided for the follow-up ship heating work; and the heat energy can be utilized in multiple stages so that heat energy resources are effectively saved.

Owner:SHANDONG MINGCHUAN AUTOMOBILE GRP CO LTD

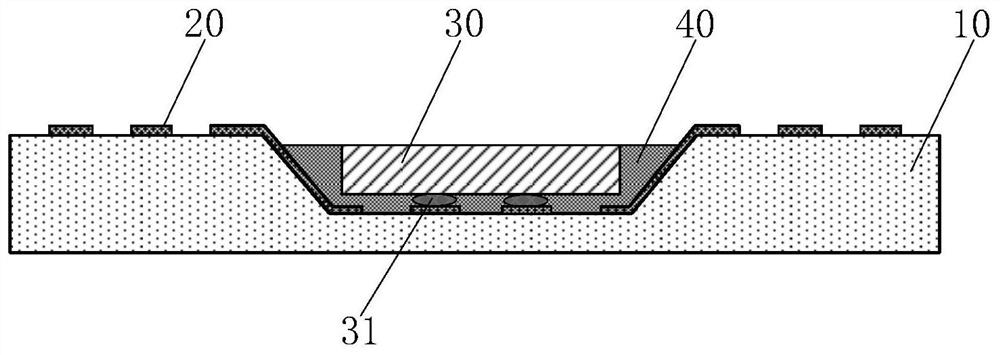

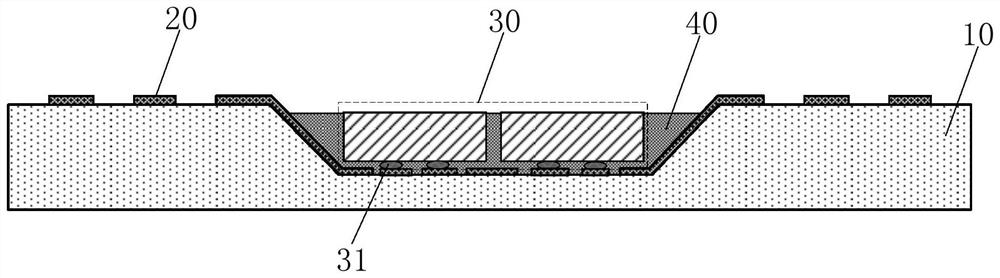

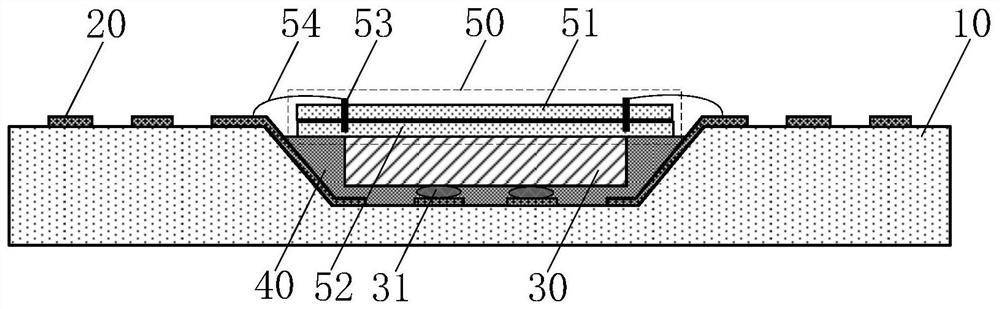

Chip packaging structure and method

ActiveCN111613585ASmall space sizeHighly integratedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor technologySemiconductor

The invention relates to the technical field of semiconductors, and particularly relates to a chip packaging structure and method. The structure comprises a substrate, a rewiring layer, a first chip unit and a first packaging layer, wherein the substrate is provided with an accommodating space; the rewiring layer is arranged in the accommodating space and on the surface of the substrate; the firstchip unit is arranged on the rewiring layer in the accommodating space and is provided with a first conductive connection point; the first conductive connection point is connected with the rewiring layer; and the first packaging layer fills the accommodating space. According to the chip packaging structure provided by the invention, the rewiring layer is arranged in the accommodating space of thesubstrate and on the surface of the substrate, and the first chip units are arranged in the accommodating space and connected with the rewiring layer, so that the space size of the packaging structure is saved, the integration degree is improved, the accommodating space is filled with the first packaging layer, the first chip unit is packaged, and the problem of large warping is avoided.

Owner:NAT CENT FOR ADVANCED PACKAGING

Wind pressure-driven waste gas treatment filtering device with cooling structure

InactiveCN111957188AReduce usageIncrease the use of diversityGas treatmentDispersed particle filtrationFan bladeMechanics

The invention discloses a wind pressure-driven waste gas treatment filtering device with a cooling structure. The device comprises an air inlet pipe, flow guide fan blades, a collecting frame and an atomizing nozzle, a device shell is in bolted connection with the air inlet pipe, a water tank is in bolted connection with the interior of the device shell, an isolation plate is in bolted connectionwith the interior of the device shell, flow guide fan blades are installed in the device shell, a fixing shaft is fixedly welded to the flow guide fan blades, a magnetic plate is in bolted connectionwith the fixing shaft, and a scraping rod is in bolted connection with the fixing shaft. The device is provided with the magnetic plate, the flow guide fan blades can drive the magnetic plate to rotate in the device shell through the fixing shaft, then heavy metal particles in industrial waste gas can be conveniently and rapidly adsorbed and collected, the interior of a subsequent device can be effectively prevented from being blocked, and meanwhile subsequent recycling work of the heavy metal particles is facilitated.

Owner:季高

Multifunctional LED lighting and emergency lamp and control method

PendingCN110657356AEasy to disassembleEasy interchangeElectric circuit arrangementsLighting elementsWireless routerEmergency light

The invention provides a multifunctional LED lighting and emergency lamp. The multifunctional LED lighting and emergency lamp comprises a multifunctional lamp and a power-off monitoring device. The multifunctional lamp comprises an LED lamp panel, a power control board, a battery pack, a universal switching component, monitoring camera equipment, wireless and wired audio equipment, a lampshade, alamp shell, an emergency display component, a T8 adapter, a human body infrared induction and light-sensitive induction module and an environment detection module; and the power-off monitoring devicecomprises an upper shell, a lower shell, a power control board, a battery pack, a wireless and wired module and a power plug. The power-off monitoring device is in wireless connection with one or moremultifunctional lamps, meanwhile, the multifunctional lamps can be wirelessly connected, and the multifunctional lamps and the power-off monitoring device can be wirelessly connected with current communication equipment such as a wireless router and the like at the same time. The multifunctional LED lighting and emergency lamp can be used in multiple working conditions at the same time and is comprehensive in function and high in practicability.

Owner:JRF PHOTONICS TECH CO LTD

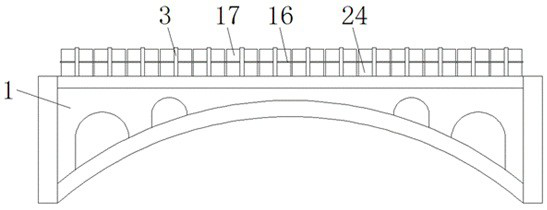

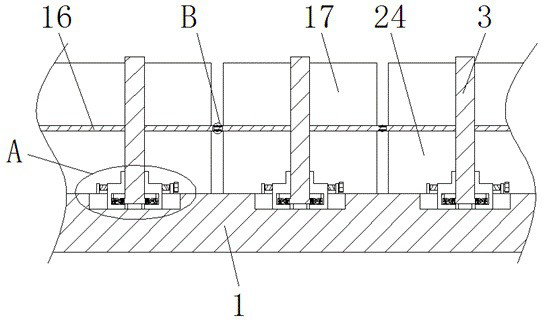

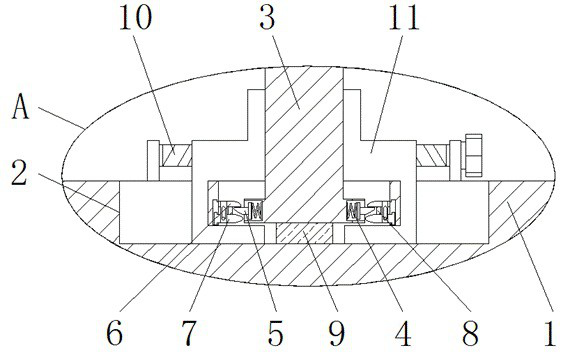

Emergency anti-collision bridge capable of rapidly building simple bridge through railings

ActiveCN111778836AQuick buildEasy to useClimate change adaptationBridge structural detailsGear wheelArchitectural engineering

The invention discloses an emergency anti-collision bridge capable of rapidly building a simple bridge through railings. The emergency anti-collision bridge comprises a bridge body, protection rods, protective plates, lower breast boards and connecting rods. Limiting grooves are formed in the bridge body; stand column rods are connected into the limiting grooves in a clamping manner; rubber pads are connected into the limiting grooves through screws; two-way threaded rods are installed on the fixed base and rotationally connected to the bridge body; gear tooth rods are connected to the stand column rods in a clamped mode; the protection rods are connected to the top ends of the gear tooth rods through screws; circular gears are connected to the gear tooth rods in an engaged mode; and the circular gears are welded and fixed to the fixed shaft. According to the emergency anti-collision bridge capable of rapidly building the simple bridge through the railings, through the protection plates, when an automobile collides with the stand column rods on the bridge body, the protection plates can stably press down and limit the automobile, then the automobile can be effectively prevented from overturning after collision, and the use safety of the bridge is improved.

Owner:山西路桥第八工程有限公司

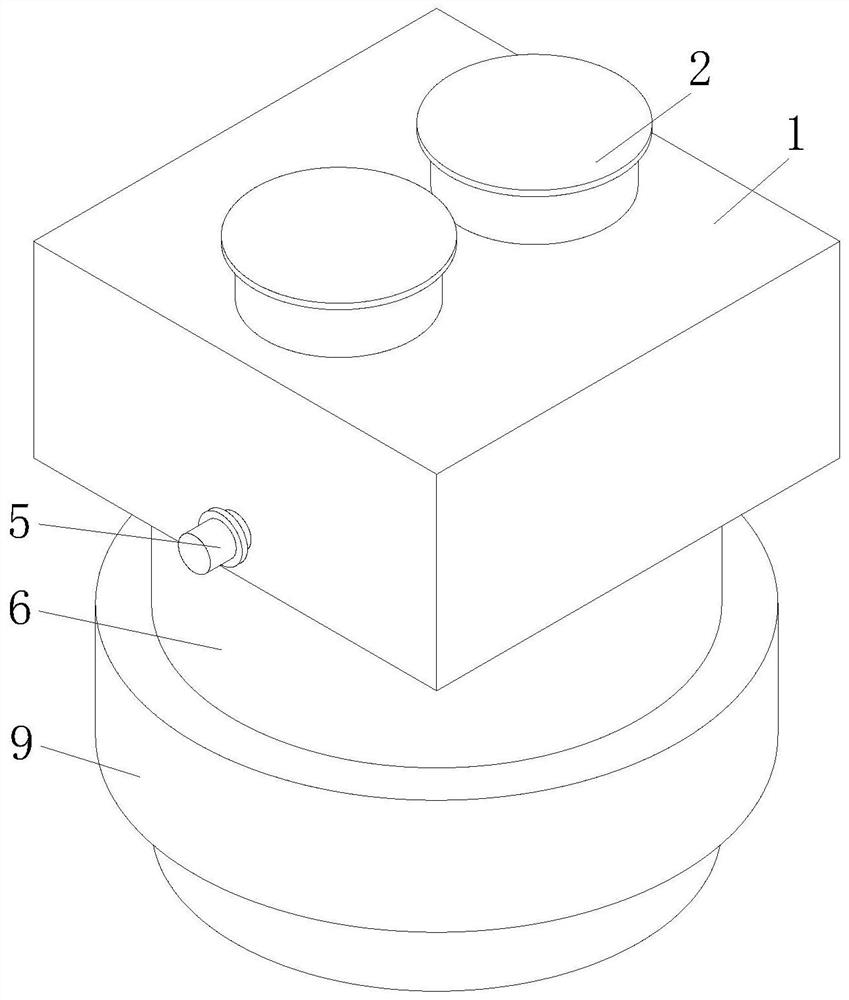

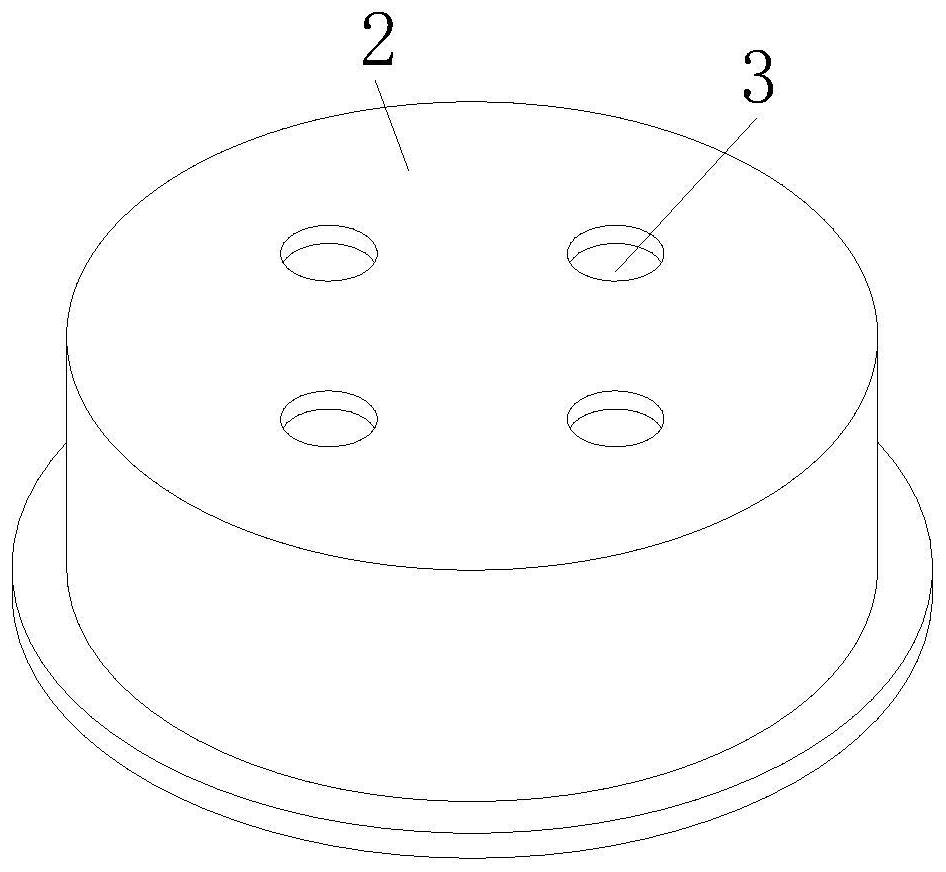

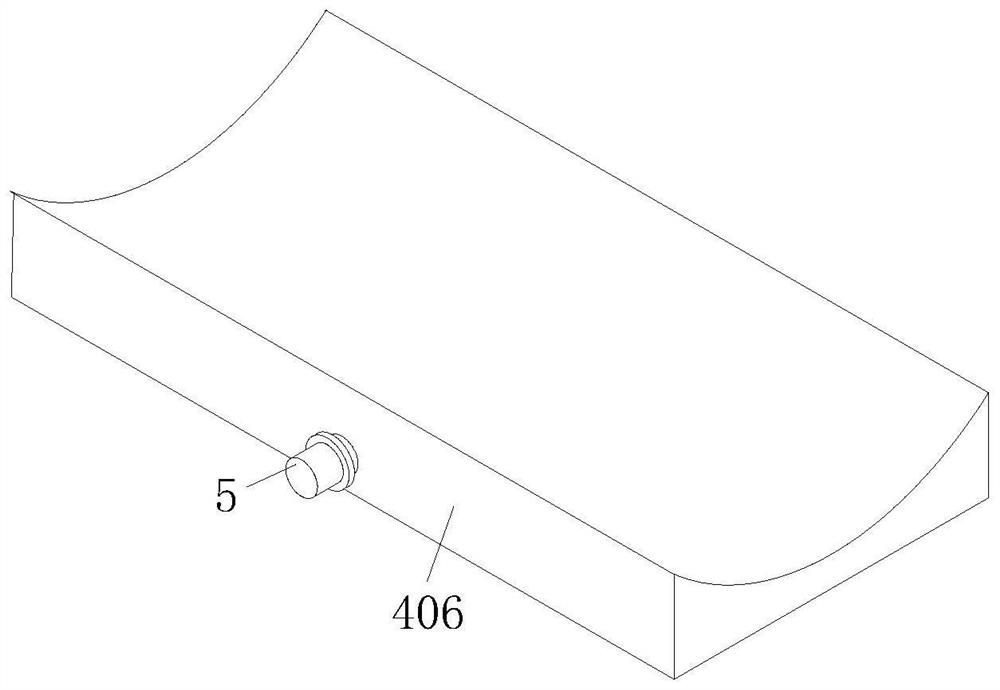

Heat dissipation box body for packaging lithium ion battery

ActiveCN111682141AEasy to useEffective limit fixed workSecondary cellsCell component detailsEngineeringFan blade

The invention discloses a heat dissipation box body for packaging a lithium ion battery. The heat dissipation box body comprises an automobile bottom plate, a clamping plate, shunting fan blades, a cooling pipe and a push plate; a mounting plate is in bolted connection with the automobile bottom plate; a box shell is connected with the mounting plate through screws; gear columns are connected witha first gear tooth plate in a meshed mode; second gear tooth plates are connected with the gear columns in a meshed mode, and the tail end of each second gear tooth plate is connected with the bottomend of a clamping plate through screws; the clamping plate is connected with a filter screen plate in a clamped mode, and a rubber block is connected with the clamping plate through screws. The heatdissipation box body for packaging the lithium ion battery is provided with the clamping plate; the lithium ion battery drives a limiting rod to move downwards; the first gear tooth plate can drive second gear tooth plates on the two sides to move towards the middle at the same time through the gear columns; lithium ion batteries can be conveniently, rapidly and effectively limited and fixed one by one in cooperation with the clamping plate; and the situation that the lithium ion batteries are inconvenient to attach and fix for subsequent heat dissipation can be effectively prevented.

Owner:重庆宏美制冷设备有限公司

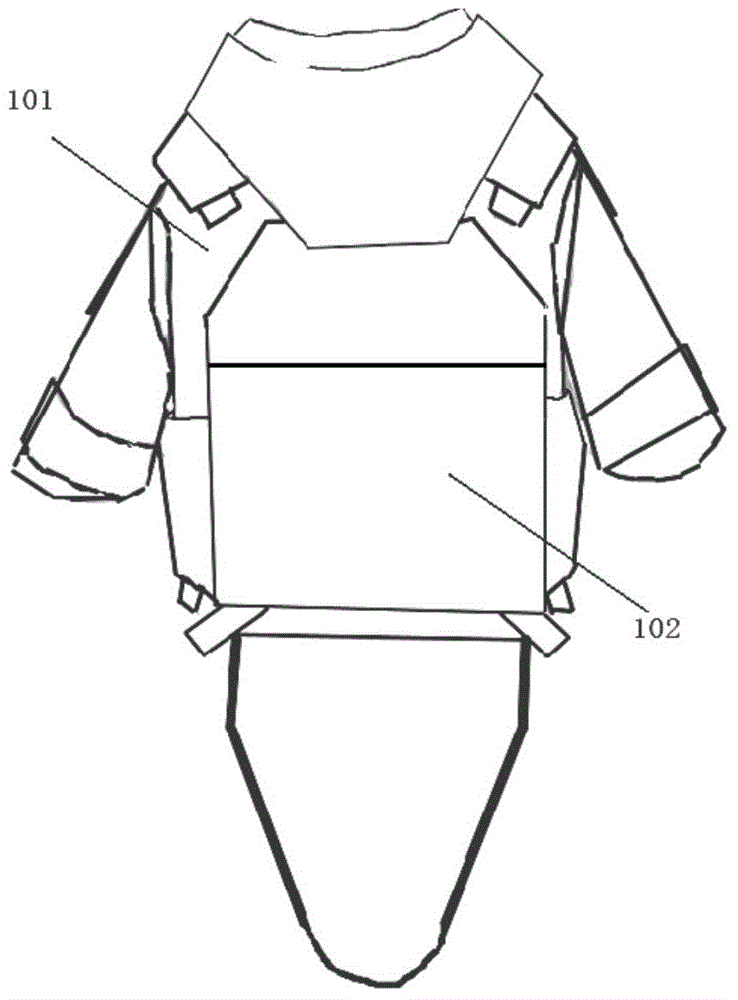

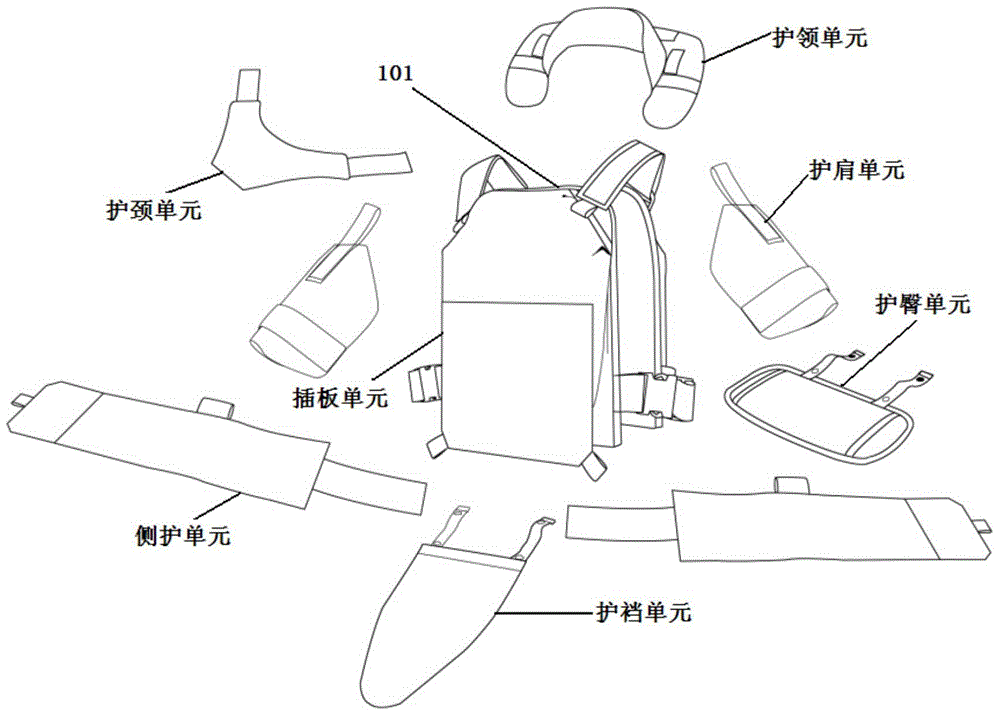

Body armor applicable to various battle requirements

InactiveCN105135946AIncrease the use of diversityAvoid wastingPersonal protection gearEngineeringBody armor

The invention provides a body armor applicable to various battle requirements, which comprises a body armor body. The body armor is characterized by comprising an bulletproof unit, wherein the corresponding joint position of the coat layer of the body armor body is provided with a joint device; the corresponding bulletproof unit is also provided with a joint device used for the fastening connection of the coat layer and the bulletproof unit; the bulletproof unit comprises a shoulder protection unit, a collar protection unit, a neck protection unit, a plugboard unit, a foul-proof cup unit, a hip protection unit and a lateral protection unit. According to the invention, different bulletproof units are increased and combined, so that the body armor is more flexible and changeable and is applicable to requirements of various occasions, the equipment investment is set in one time, and the process and production are intensive; the body armor is particularly suitable for rapid reaction and capital saving of army construction, avoids the waste of repeat purchase, and protects the environment, and meanwhile the use diversity of users is increased.

Owner:BEIJING PT PROTECTION TECH

Big data heat dissipation device convenient for cleaning heat dissipation port and use method thereof

ActiveCN110955311AEasy to cleanEffective coolingGas treatmentDispersed particle filtrationReciprocating motionTransmission belt

The invention discloses a big data heat dissipation device convenient for cleaning a heat dissipation port and a use method thereof. The device comprises a device shell, a wet curtain and a filter screen plate, a driving motor is welded on the device shell, a worm is in shaft connection with the driving motor, a first bevel gear is welded to the worm, a filter screen plate is connected to the device shell through screws, the filter screen plate is connected into a rubber pad in a clamped mode, the rubber pad is riveted to the device shell, a transmission belt is connected to the worm in a clamped mode, the transmission belt is connected to a reciprocating threaded rod in a clamped mode, and an adsorption rod is fixed to the reciprocating threaded rod. The big data heat dissipation device convenient for cleaning the heat dissipation port is provided with the adsorption rod, under the action of the transmission belt, the worm can drive the reciprocating threaded rod to rotate, under theaction of the reciprocating threaded rod, the adsorption rod can reciprocate on the filter screen plate, dust and impurities remaining on the filter screen plate can be adsorbed and removed, and the use safety of the device is improved.

Owner:盐城吉研智能科技有限公司

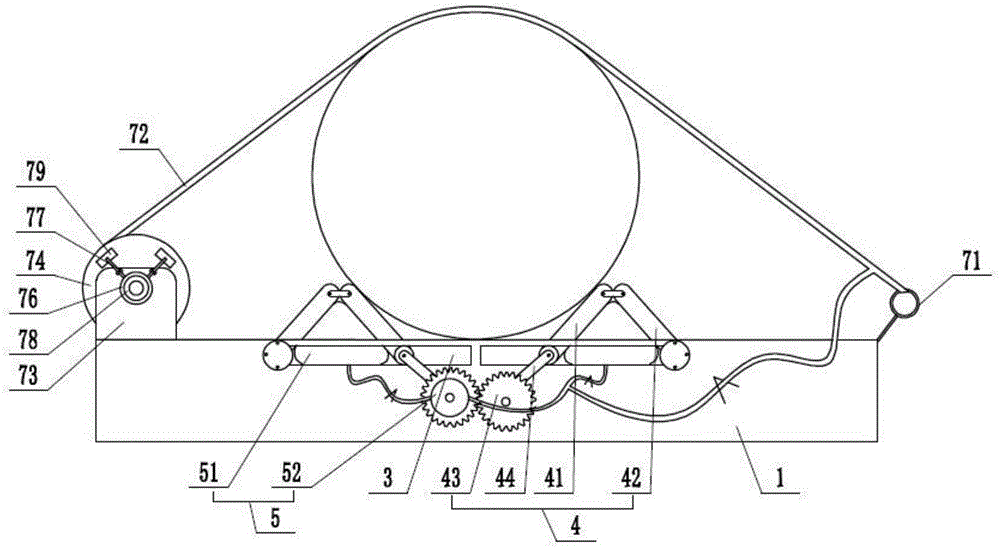

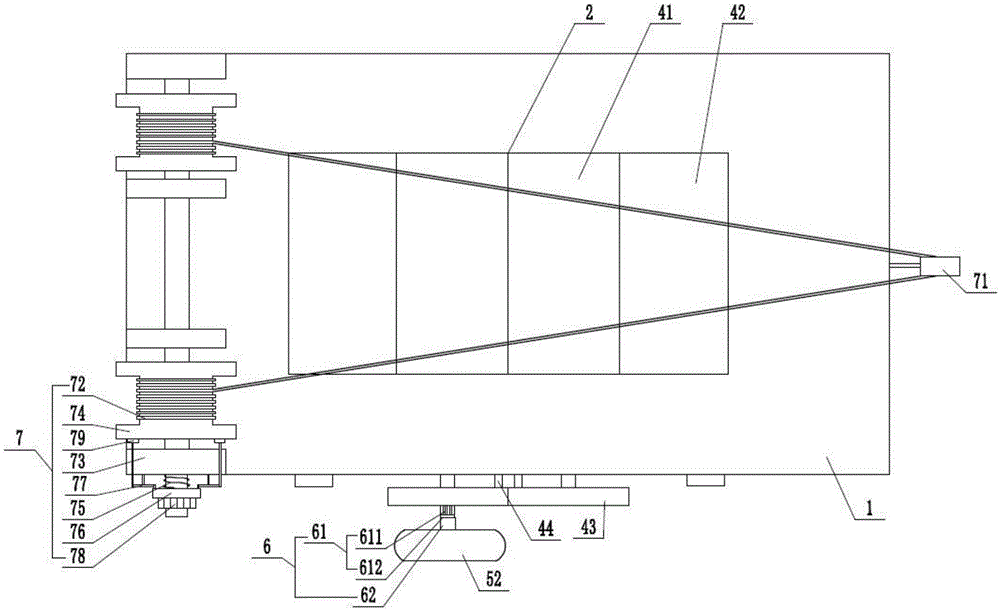

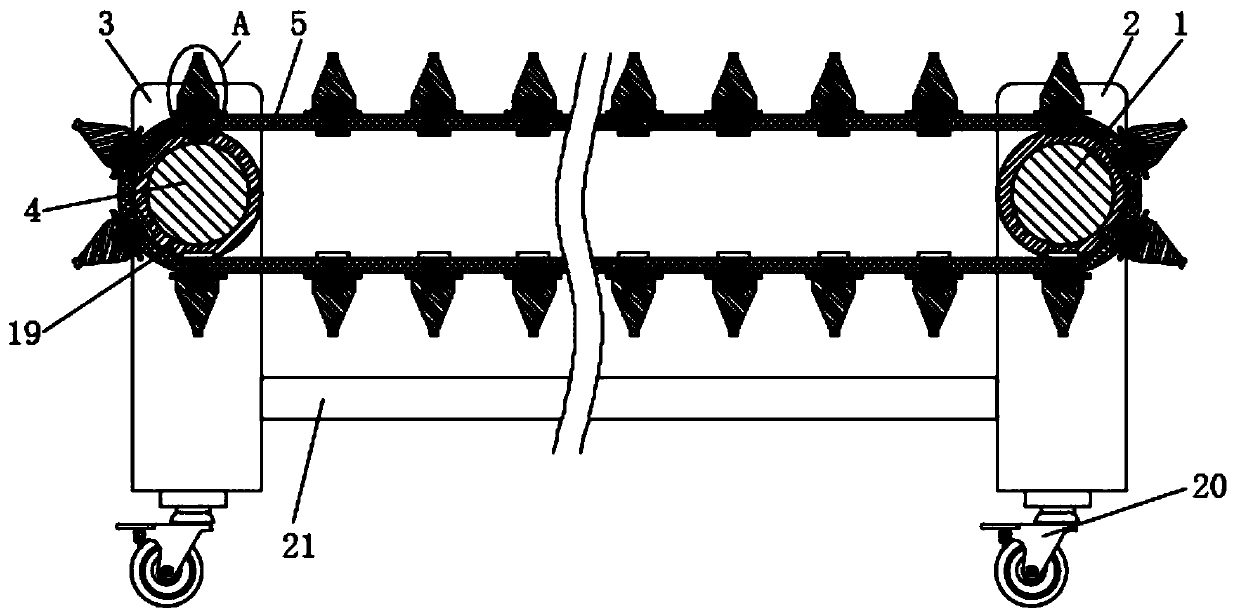

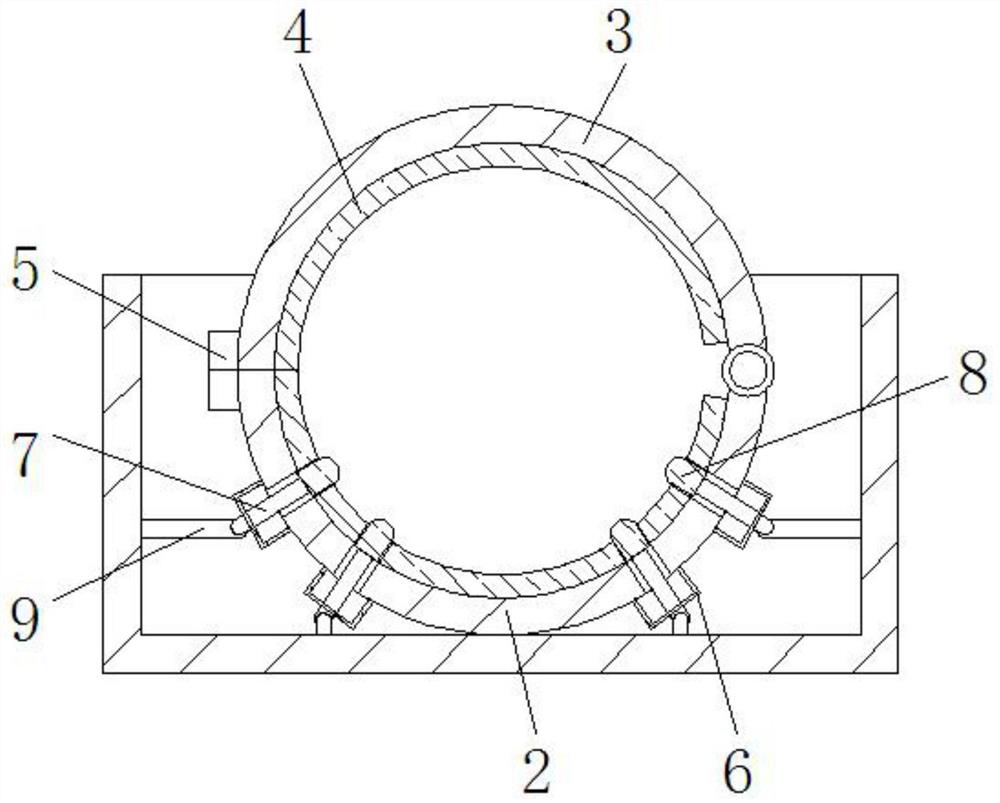

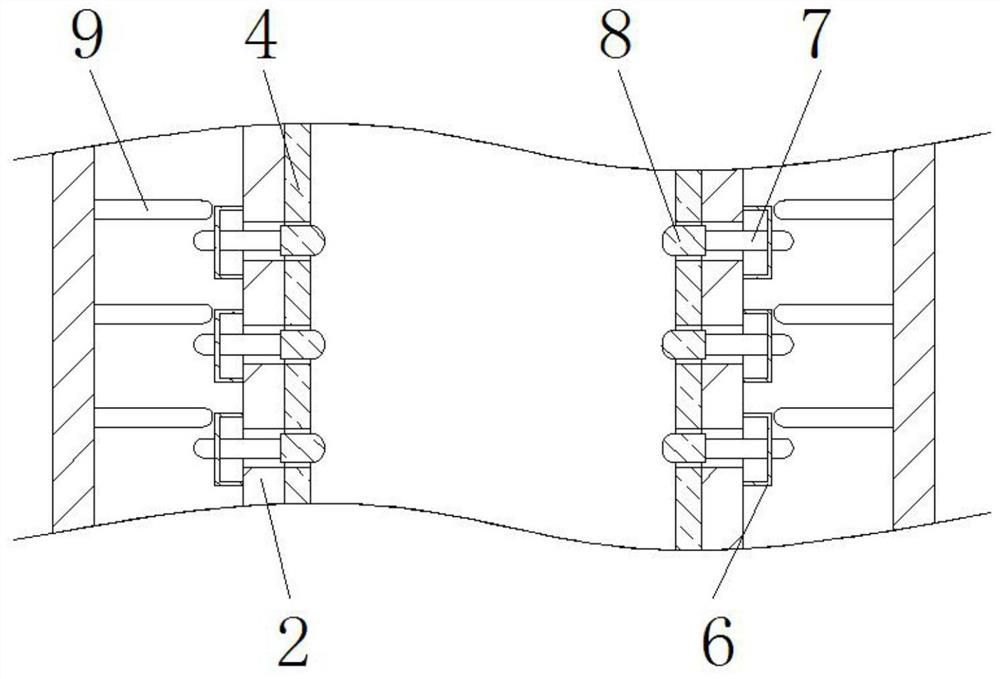

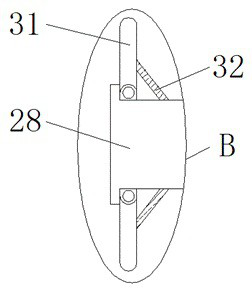

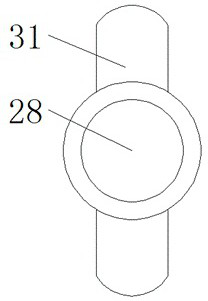

Conveying equipment for stainless steel tube producing and machining

InactiveCN109704024AThe delivery method can be adjustedExpand the scope of production and processingConveyorsSupporting framesElectric machineryEngineering

The invention discloses conveying equipment for stainless steel tube producing and machining. The conveying equipment for stainless steel tube producing and machining comprises a driving roll, the front side and the back side of the surface of the driving roll are each provided with a first bracket, second brackets are arranged on the left sides of the first brackets, a driven roll is movably installed on the inner sides of the second brackets, and the surface of the driven roll is sleeved with a driving belt. According to the conveying equipment for stainless steel tube producing and machining, a conveying mode is adjusted by adjusting a conveying mechanism, then a motor is started to drive the driving roll to rotate, the driving roll drives the driven roll to rotate together through thedriving belt, the driving belt rotates to drive positioning blocks to achieve following moving to complete different modes of conveying, and therefore the problem that transverse tube conveying or longitudinal tube conveying of an existing tube conveying device can not be adjusted for use is solved. The conveying equipment for stainless steel tube producing and machining has the advantage of beingadjustable in conveying mode, the using diversity is increased, the practicability is improved, and the producing and machining range is widened.

Owner:沈勤娟

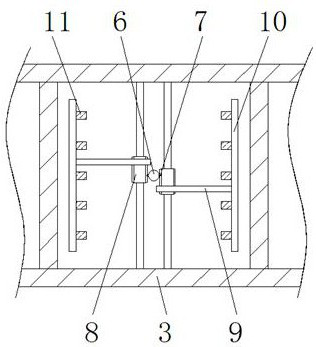

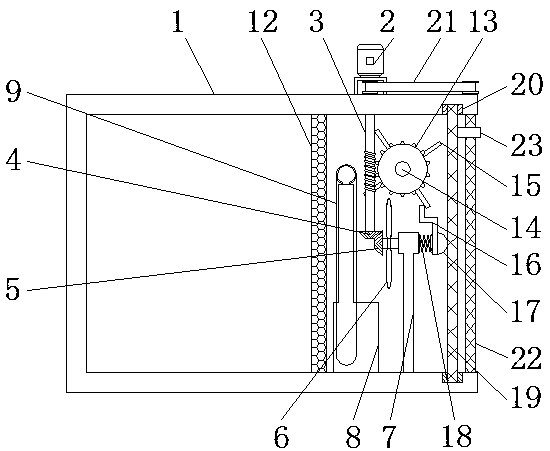

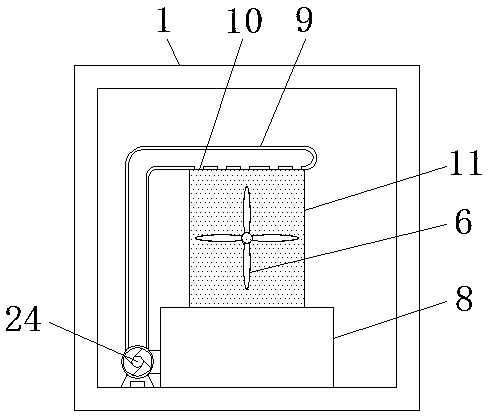

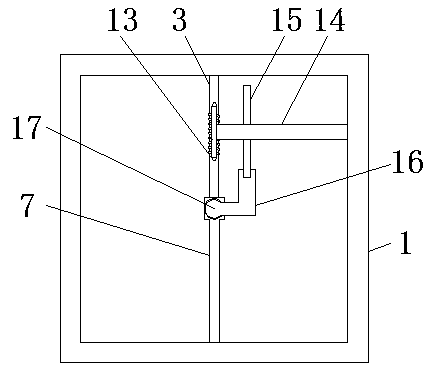

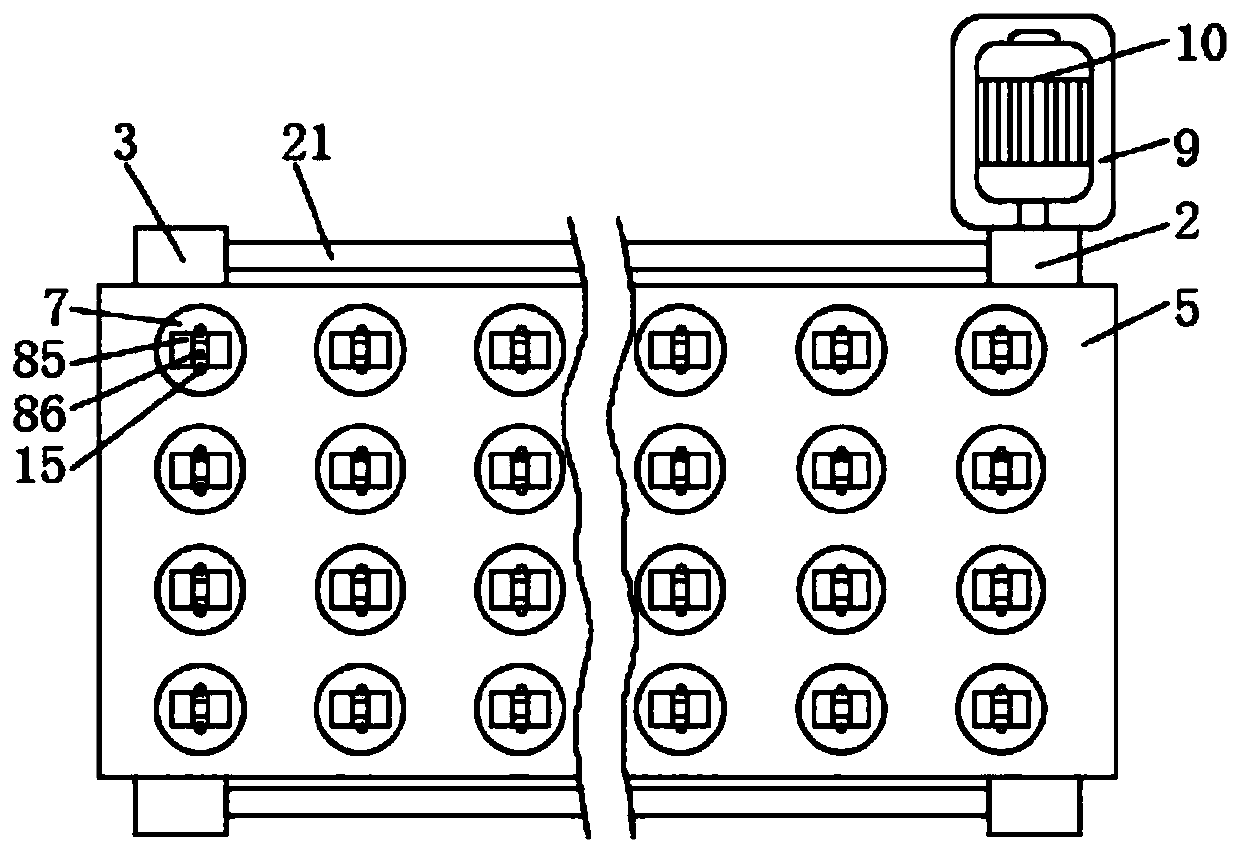

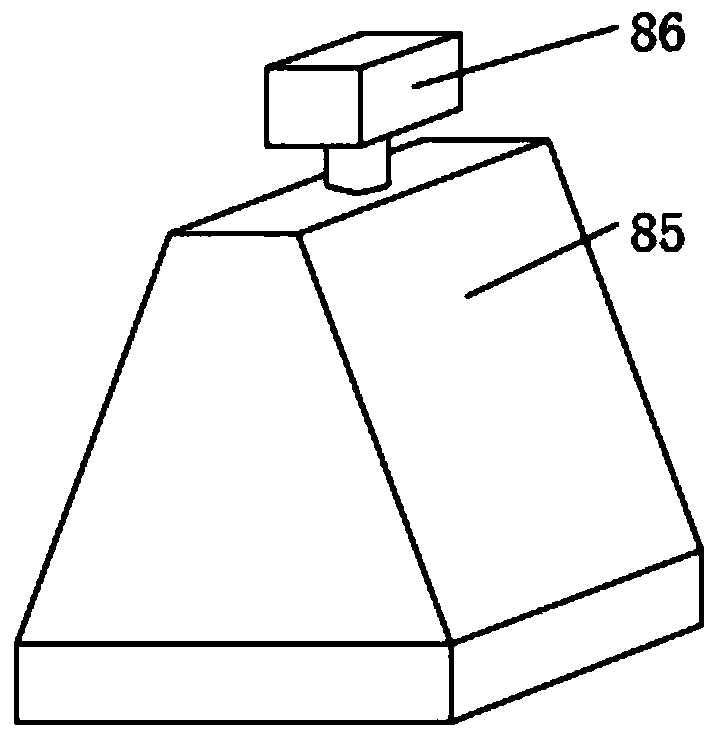

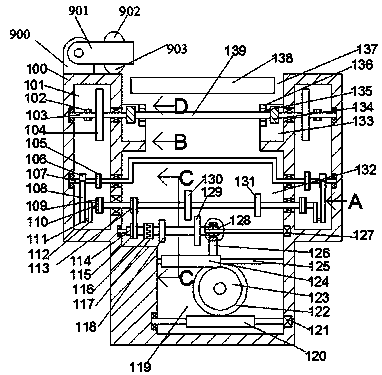

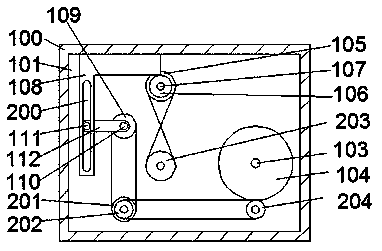

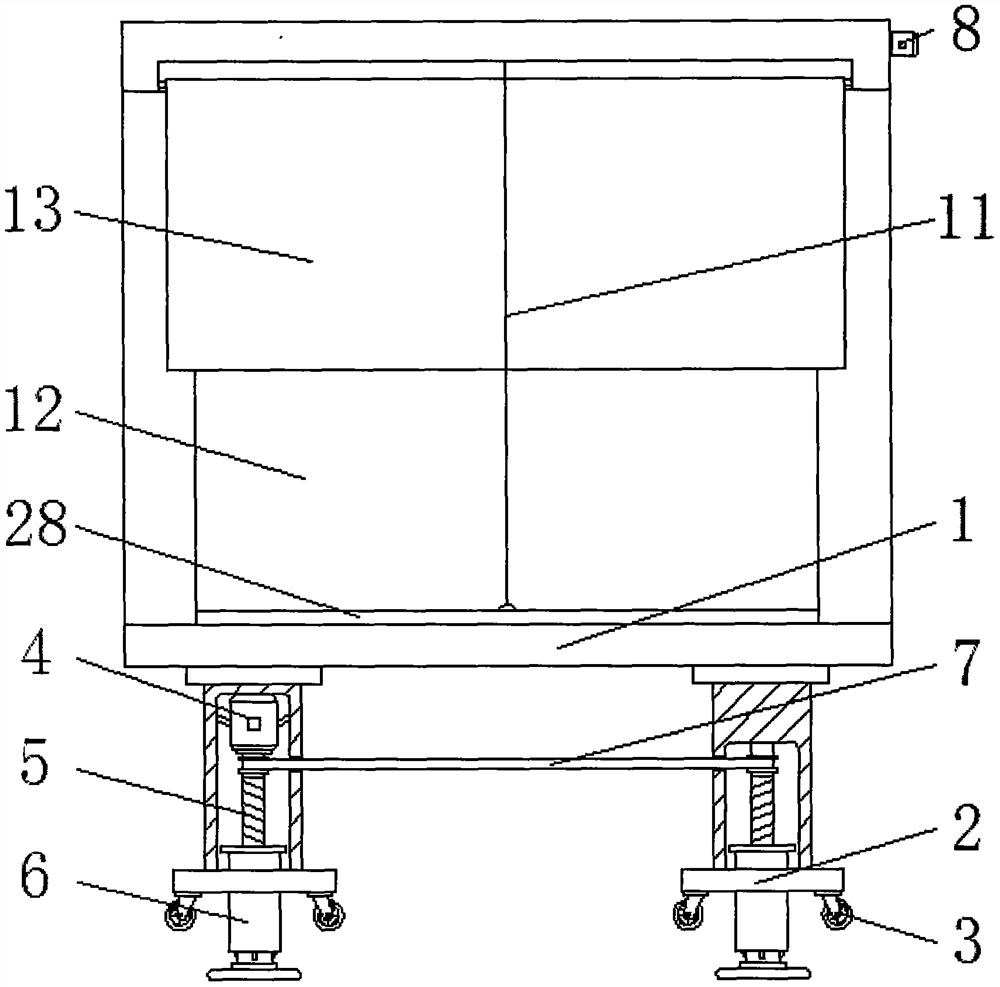

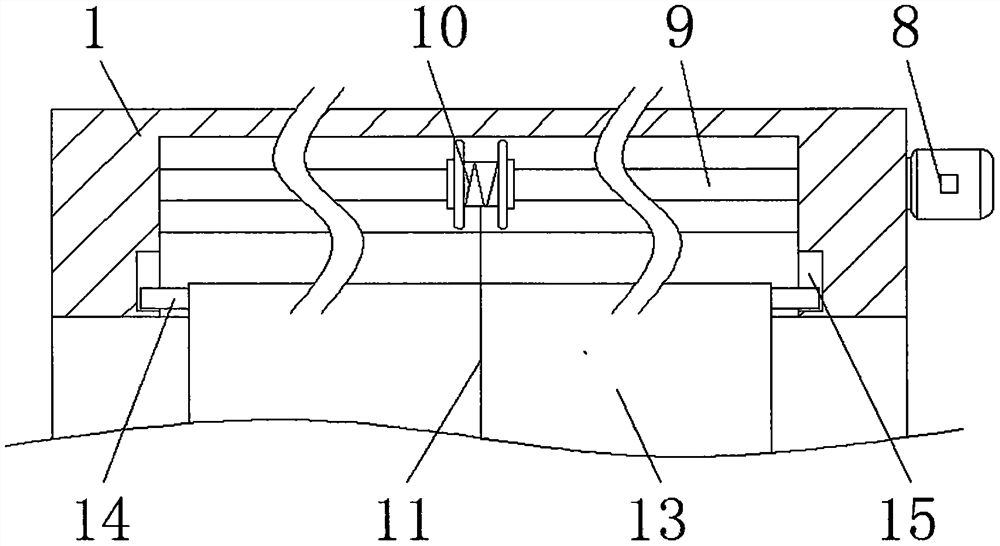

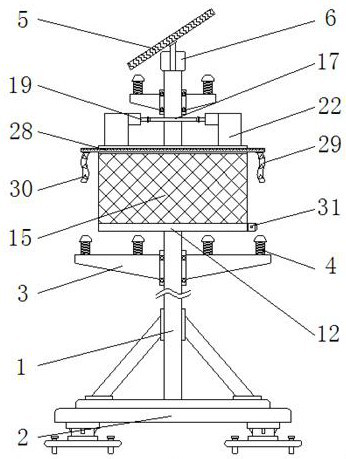

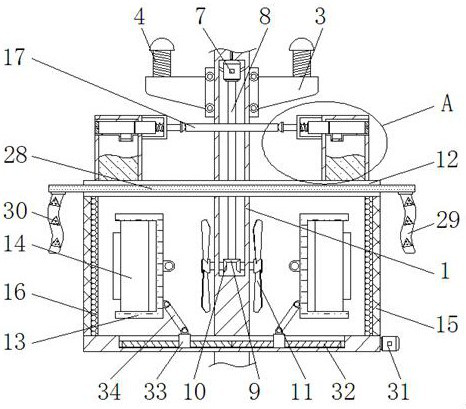

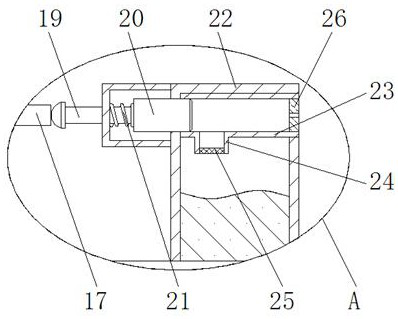

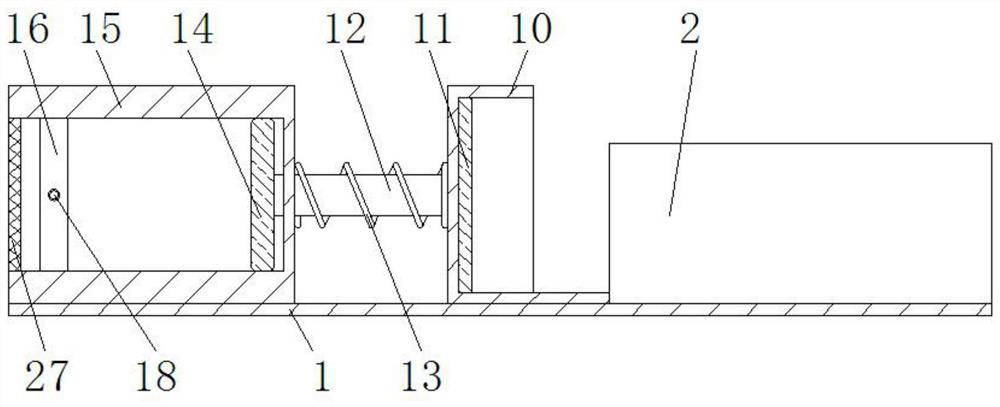

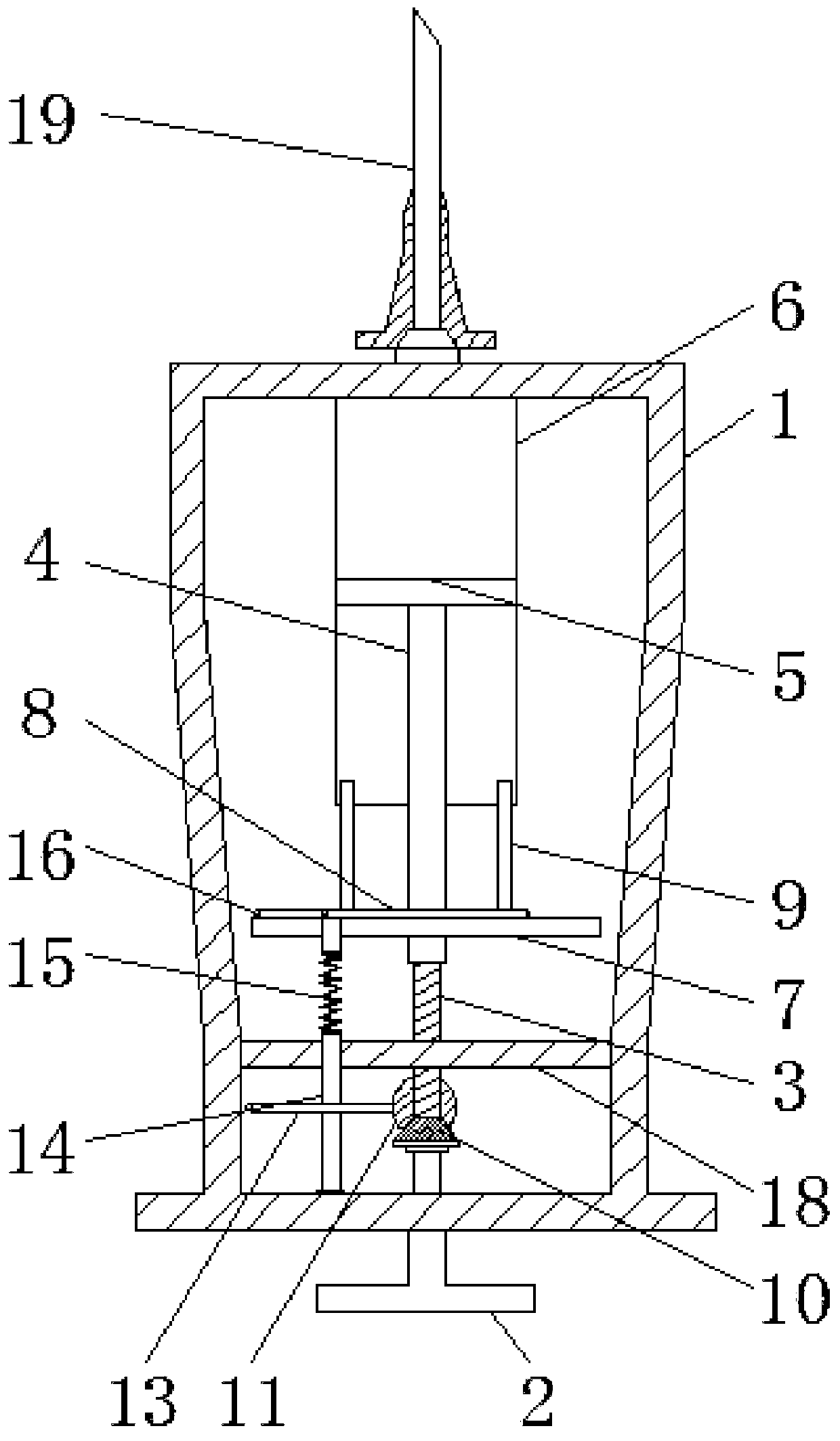

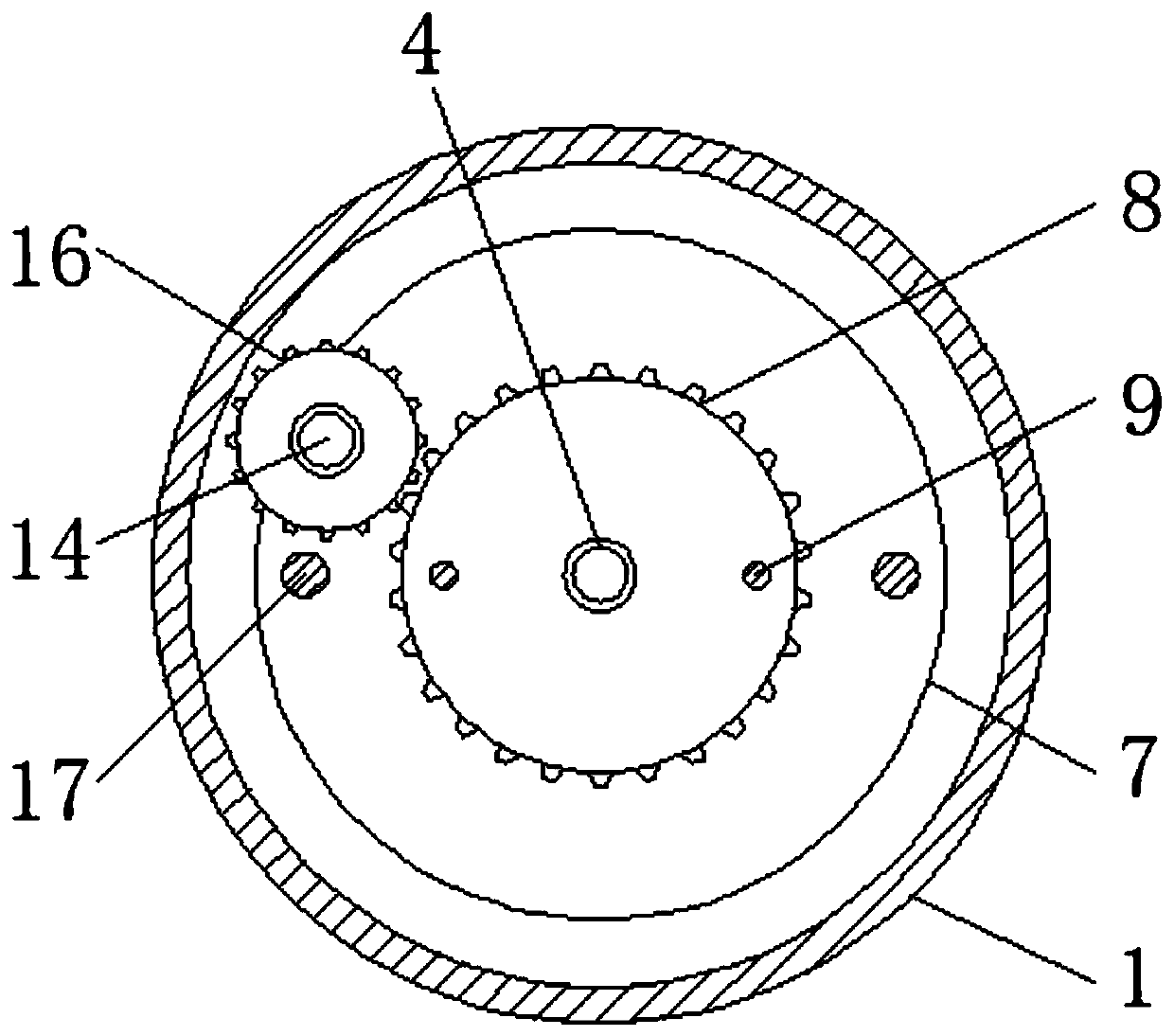

Starter for looms employing big data

The invention discloses a starter for looms employing big data. The starter comprises a box body; a transmission cavity is fixed in the box body; a worm is rotationally arranged in the left and rightend walls of the transmission cavity; the worm is driven by a rotary motor fixed in the right end wall of the transmission cavity; the rear end wall of the transmission cavity is rotationally providedwith a worm wheel and rotary gear meshing with the worm; a connection rod is fixed to the left and right end walls of the transmission cavity; a slide rack meshing with the rotary gear is slidably arranged on the outer surface of the connection rod; a connection block is fixed to the upper surface of the slide rack; the upper end wall of the transmission cavity is communicated with a working cavity. The starter herein is simple in structure and convenient to use, allows equipment transmission speed to be automatically controlled in automated manner, provides higher equipment application diversity and usability, can provide efficient discharging through an auto-disengaging mechanism functionality, has lower manpower cost and provides improved equipment reliability and production efficiency.

Owner:东阳市明汇服装有限公司

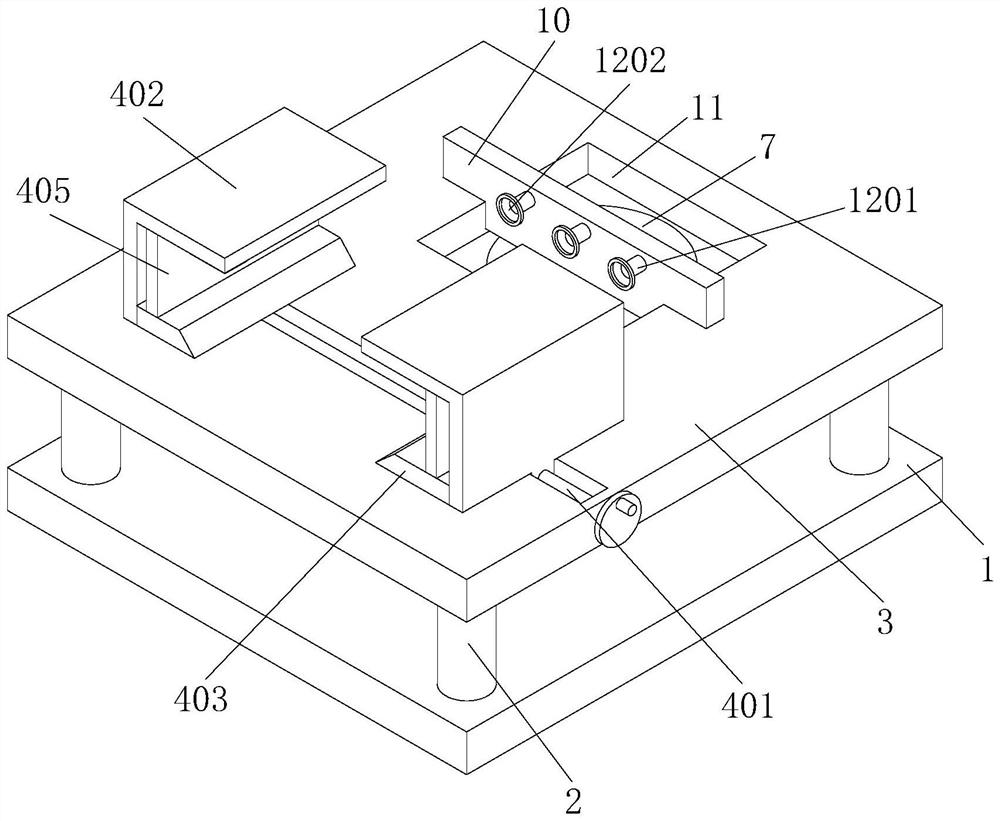

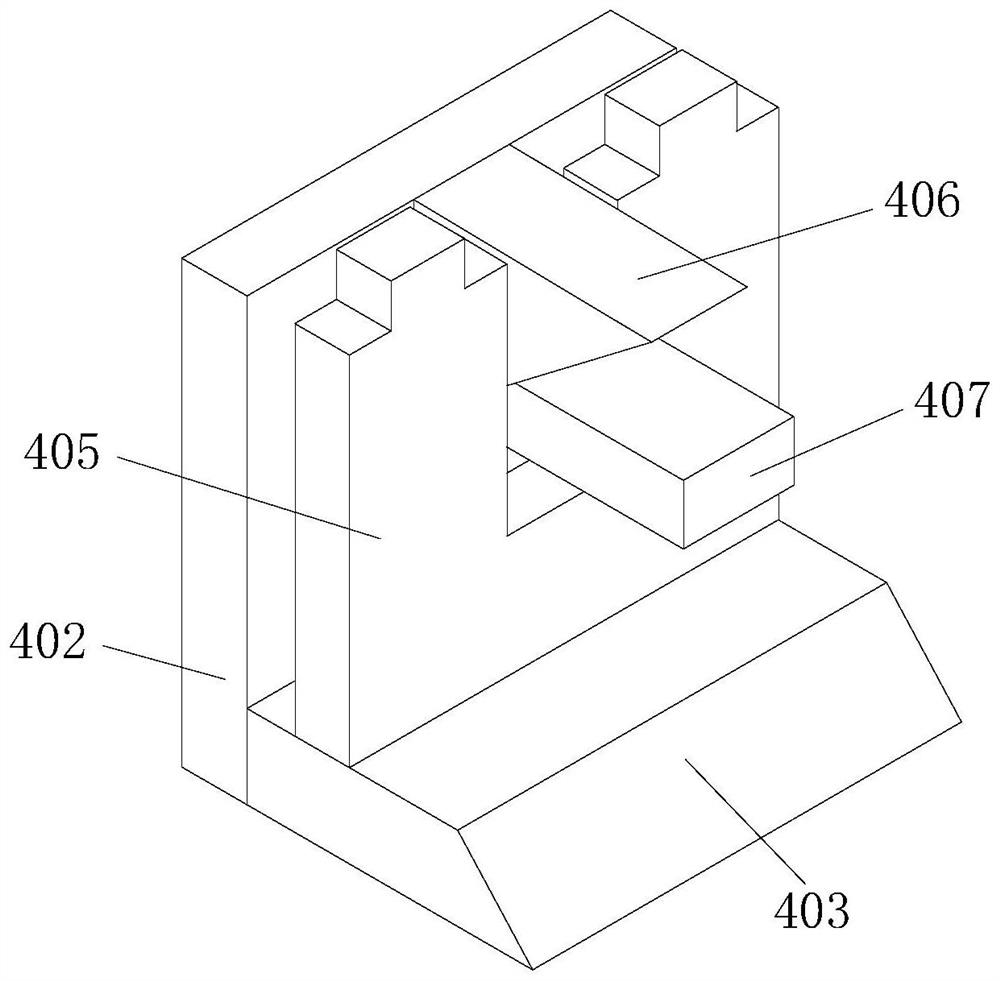

Door and window frame deburring device and processing method

PendingCN114571309AConvenience guaranteedImprove efficiencyEdge grinding machinesGrinding carriagesStructural engineeringSelf adaptive

The invention belongs to the field of doors and windows, and particularly relates to a door and window frame deburring device and a processing method.The door and window frame deburring device comprises a fixed base, a supporting rod is fixedly welded to the fixed base, a workbench is fixedly welded to the top of the supporting rod, and a self-adaptive grinding mechanism is installed on the workbench; a servo motor is fixedly welded to the bottom end face of the fixed base, a rotating plate is fixedly welded to an output shaft of the servo motor, the first sliding groove is formed in the bottom of a mounting plate, the mounting plate is slidably connected into a limiting groove in a limited mode, the limiting groove is formed in the workbench, and an adsorption connecting assembly is mounted on the mounting plate. The problems that an existing burr removing device cannot conduct burr grinding and removing work on the upper corner and the lower corner of the two side edges of the aluminum alloy windows of different specifications and sizes at the same time, and meanwhile scraps generated by grinding cannot be automatically and stably collected and treated are solved.

Owner:张浩浩

Sociology demonstration teaching device with teaching interaction structure

ActiveCN112133140AWith teaching interactive structureConvenient and quick dust cleaning workCleaning using toolsElectrical appliancesGear wheelGear tooth

The invention discloses a sociology demonstration teaching device with a teaching interaction structure, and the device comprises an installation frame, a supporting rod, an upper protection plate, acleaning brush, an expression reply plate, and a clamping plate, the lower part of the installation frame is in screw connection with a fixed rod, and the bottom end of the fixed rod is provided witha universal wheel through a bolt, and the interior of the upper protection plate is in screw connection with a gear tooth rod. And a first circular gear is connected to the gear tooth rod in an engaged mode, a second circular gear is connected to the first circular gear in an engaged mode, and cleaning brushes are connected to the first circular gear and the second circular gear through screws. The sociology demonstration teaching device with the teaching interaction structure is provided with the cleaning brush, and when the lower protection plate moves upwards into the upper protection plateto be stored, the first circular gear can drive the second circular gear to rotate at the same time under the action of the gear tooth rod; and at the moment, dust cleaning work can be conducted on the touch display screen conveniently and rapidly in combination with all the cleaning brushes, and the use efficiency of the device is effectively improved.

Owner:ZHEJIANG UNIV OF FINANCE & ECONOMICS

Signal transceiving device for 5G base station construction

ActiveCN111901702ATimely and effective heat dissipationGuaranteed stabilityBatteries circuit arrangementsElectric powerTransceiverInterference resistance

The invention discloses a signal transceiving device for 5G base station construction. The device comprises a fixing column, a cooling fan, a storage box, an anti-interference magnetic ring, a reflective lens and a support rod, a fixing base is welded and fixed at the top end of the fixed column; and a second driving motor is fixedly welded toa device shell, the output end of the second driving motor is rotationally connected with a bidirectional threaded rod, a fixing block is arranged on the bidirectional threaded rod, the fixing block is slidably connected into the device shell, a supporting rod is movably connected to the fixing block, and the top end of the supporting rod is movably connected to the heat dissipation frame. The signal transceiving device for 5G base station construction is provided with the supporting rod; the bidirectional threaded rod drives the fixing blocks on the two sides to move towards the middle or the two sides at the same time, precise angle adjustment work can be conveniently and rapidly conducted on the signal transceiver on the heat dissipation frame in cooperation with the supporting rod, the debugging efficiency of the device is effectively improved, and the use efficiency of the device is improved.

Owner:北京华航测通科技有限公司

Strength-adjustable leg exercising device for orthopedic rehabilitation

InactiveCN112044029AAvoid secondary damageEffective protective workResilient force resistorsSuction-kneading massagePhysical medicine and rehabilitationLeg exercise

The invention discloses a strength-adjustable leg exercising device for orthopedic rehabilitation. The leg exercising device comprises a device shell, rubber blocks, a sealing cylinder, a protective baffle and a filter screen plate, wherein a fixed base is slidably connected to the device shell; a fixed cover plate is rotatably connected to the fixed base; rubber pads are connected to the fixed cover plate and the fixed base through screws; a buckle is installed on the fixed base through a bolt; rubber frames are connected to the fixed base through screws; ejector rods are connected to the rubber frames through screws; and the rubber blocks are connected to the top ends of the ejector rods through screws. The strength-adjustable leg exercising device for orthopedic rehabilitation is provided with the fixed cover plate, the legs of a patient are placed in a closed space formed by the fixed base and the fixed cover plate in a limited manner, and at the moment, the rubber pads in the fixed base and the fixed cover plate are combined with anti-skid pads in pedal frames, so that the legs of the patient can be effectively protected, and the patient can be effectively prevented from beingsecondarily injured during leg exercise.

Owner:李国富

Steel bridge asphalt pavement shear fatigue detection equipment

ActiveCN111735689AEasy laying workFacilitate experimental workMaterial strength using steady shearing forcesTransmission beltClassical mechanics

The invention discloses steel bridge asphalt pavement shear fatigue detection equipment. The equipment comprises a device shell, a clamping plate, a heat dissipation frame, rolling wheels and supporting rods; and a worm is rotationally connected into the device shell, a first driving motor is fixedly welded to the heat dissipation frame, the output end of the first driving motor is connected witha transmission belt in a meshed mode, the output end of the first driving motor is connected with a cooling fan through a shaft, a storage box is connected into the heat dissipation frame through screws, a small water pump is connected to the storage box through a flange, and a cooling pipe is connected to the small water pump through bolts. The steel bridge asphalt pavement shear fatigue detection equipment is provided with the heat dissipation frame, under the action of the small water pump, cooling liquid in the storage box can be conveyed into a cooling pipe, air around a cooling fan can be rapidly cooled, an asphalt sample can be rapidly and effectively cooled and formed, and the use efficiency of the equipment is effectively improved.

Owner:安徽荣港建筑工程有限公司

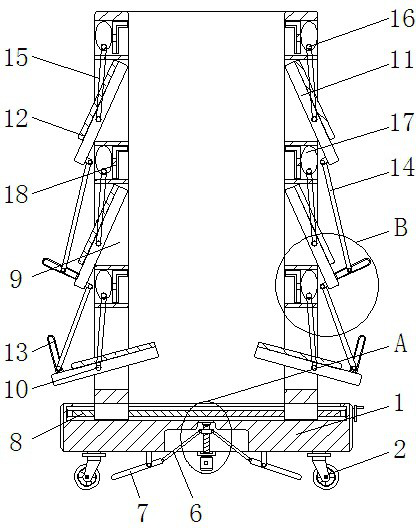

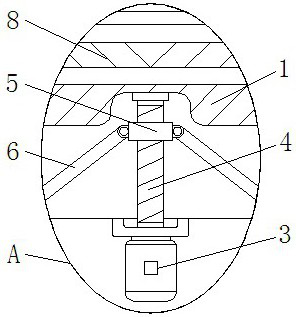

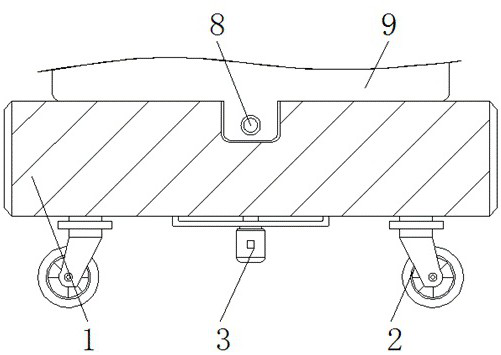

Protective transfer equipment for aero-engine production

InactiveCN112644577AConvenient and quick automatic layer-by-layer palletizingImprove efficiencySupporting partsHand carts with multiple axesStructural engineeringThreaded rod

The invention discloses protective transfer equipment for aero-engine production. The equipment comprises a device base, a supporting plate, a containing plate, an extrusion plate and a rubber air bag, wherein universal wheels are installed at the bottom end of the device base through screws, a servo motor is fixedly welded to the bottom end of the device base, and a bidirectional threaded rod is rotatably connected to the device base; and a fixing frame is movably connected to the two-way threaded rod, the fixing frame is slidably connected to the device base, and a fixing shaft is rotatably connected to the fixing frame. The protective transfer equipment for aero-engine production is provided with the placement plates, after aero-engines are placed on the placement plate at the bottommost layer, the placement plates on the two sides can be driven to rotate inwards at the same time, and at the moment, the placement plate on the upper layer can be pushed to rotate inwards to the initial position of the placement plate on the bottommost layer at the same time through combination of the placement plates, limiting frames and connecting rods; by repeating the steps, aero-engines can be automatically stacked layer by layer conveniently and quickly.

Owner:李磊

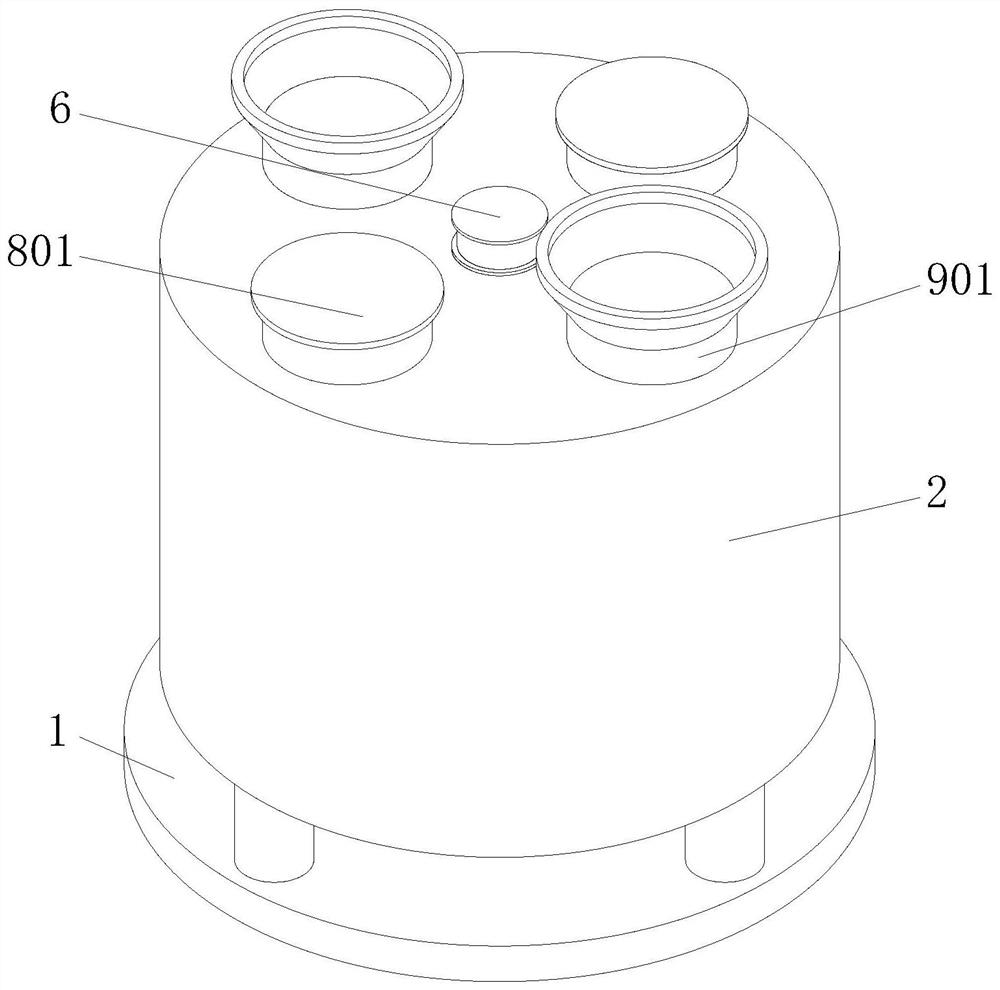

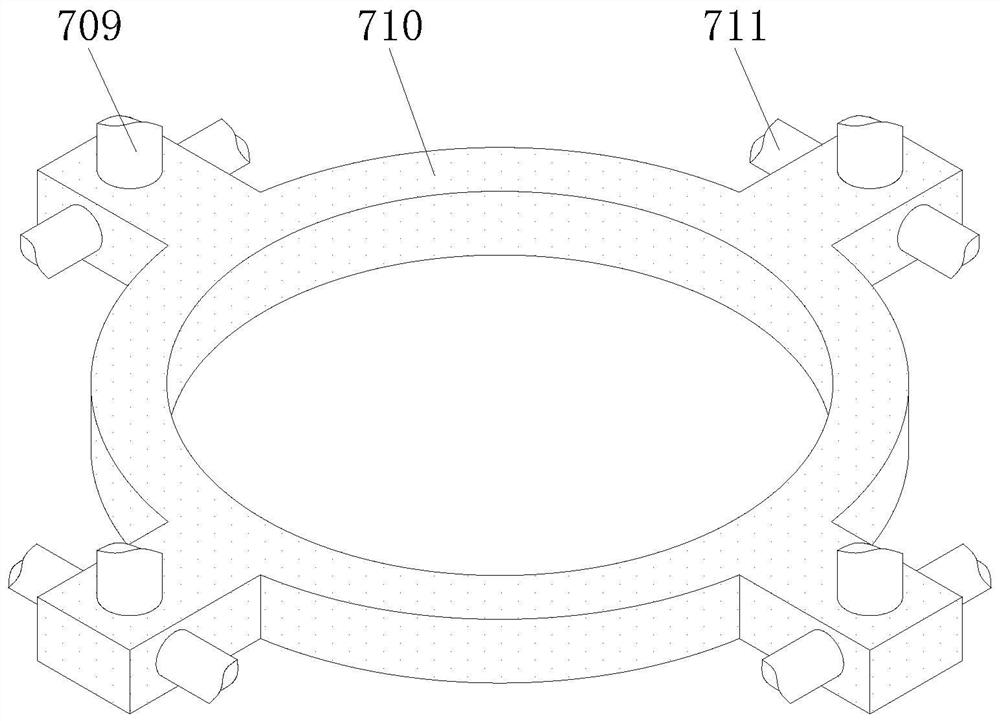

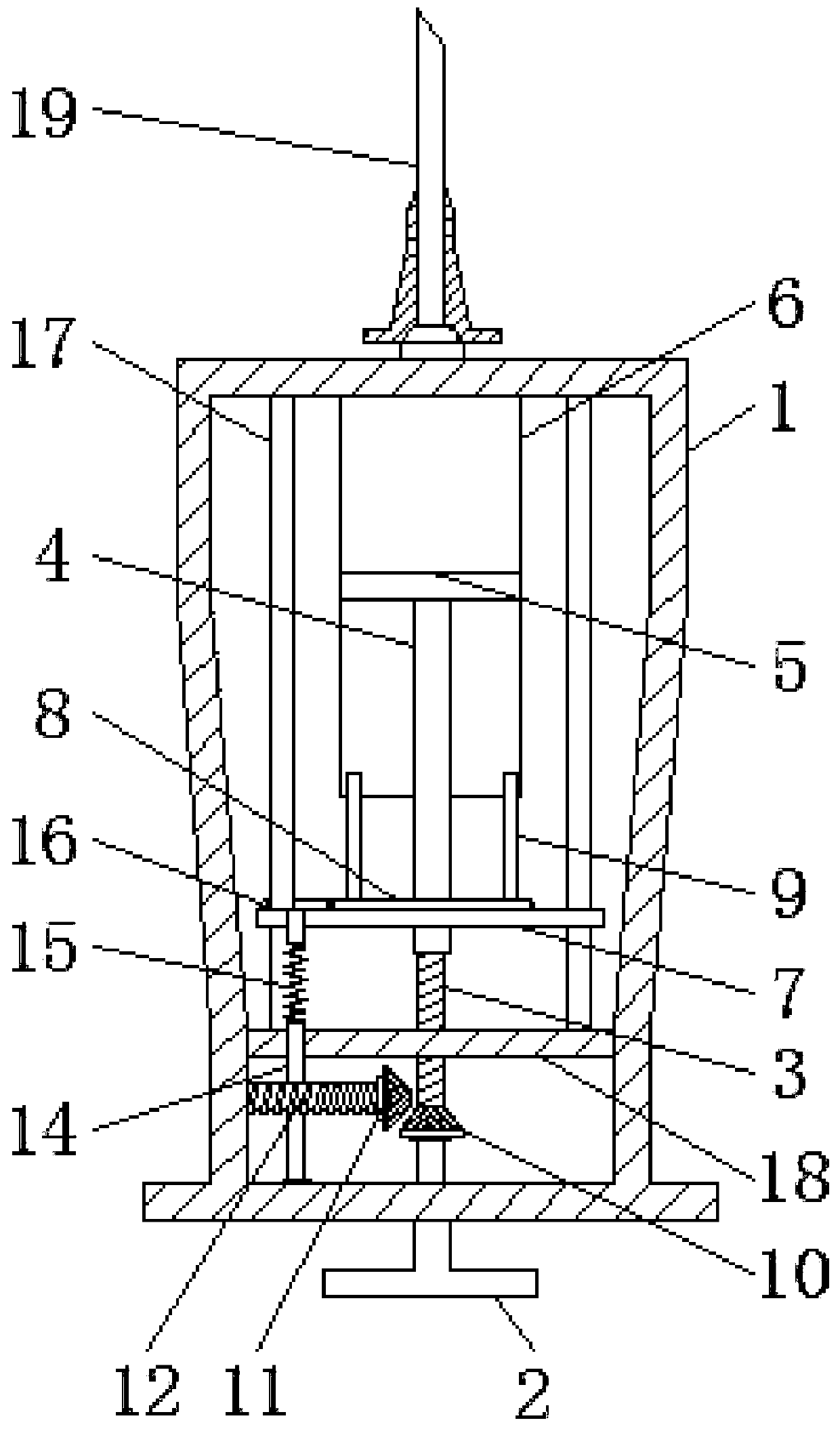

Environment-friendly water-based printing ink preparation process

InactiveCN113750902AQuick mix jobAvoid clumpingGas treatmentDispersed particle filtrationToxic gasProcess engineering

The invention belongs to the field of ink preparation, and particularly relates to an environment-friendly water-based printing ink preparation process which comprises the following steps: S1, conveying raw materials: intermittently and equivalently conveying various different raw materials at the same time by using a conveying mechanism, and containing the raw materials by using a mixing box; s2, heating and mixing: in the step S1, a conveying mechanism can drive an efficient mixing mechanism in a mixing box while working, so that various different raw materials in the mixing box can be heated, mixed and prepared; and s3,performing waste gas treatment: in the step S2, a filtering mechanism in a mixing box can be driven while an efficient mixing mechanism works, so that toxic gas generated in the mixing box can be automatically purified. The problem that an existing water-based printing ink preparation device cannot conveniently and stably purify waste gas in the working process is solved; therefore, the environment-friendly water-based printing ink preparation process needs to be provided to meet the requirements of users.

Owner:李金莲

Easy-cleaning interventional injector for cardiovascular treatment

ActiveCN110755716AEasy to cleanImprove the safety of useInfusion syringesIntravenous devicesEngineeringContrast medium

The invention discloses an easy-cleaning interventional injector for cardiovascular treatment. The easy-cleaning interventional injector comprises a fixing frame, a connecting plate and a fixing plate, a push rod is arranged on the fixed frame; a piston is arranged in an injection tube; the injection tube is fixed to the fixing frame, a connecting plate is arranged on a fixed sleeve rod, a first circular gear is installed on the connecting plate, a scraping rod is fixed to the first circular gear and arranged in the injection tube, a second circular gear is connected to the first circular gear, and the second circular gear is arranged on the connecting spring. The easy-cleaning interventional injector for cardiovascular treatment is provided with the scraping rod, under the action of the second circular gear, the first circular gear can drive the scraping rod to rotate, and when the fixed sleeve rod moves downwards, under the action of the connecting plate, the scraping rod rotates andmoves downwards at the same time, a contrast media attached to the interior of the injection tube can be removed, and the use efficiency of the injector is improved.

Owner:YICHANG CENT PEOPLES HOSPITAL

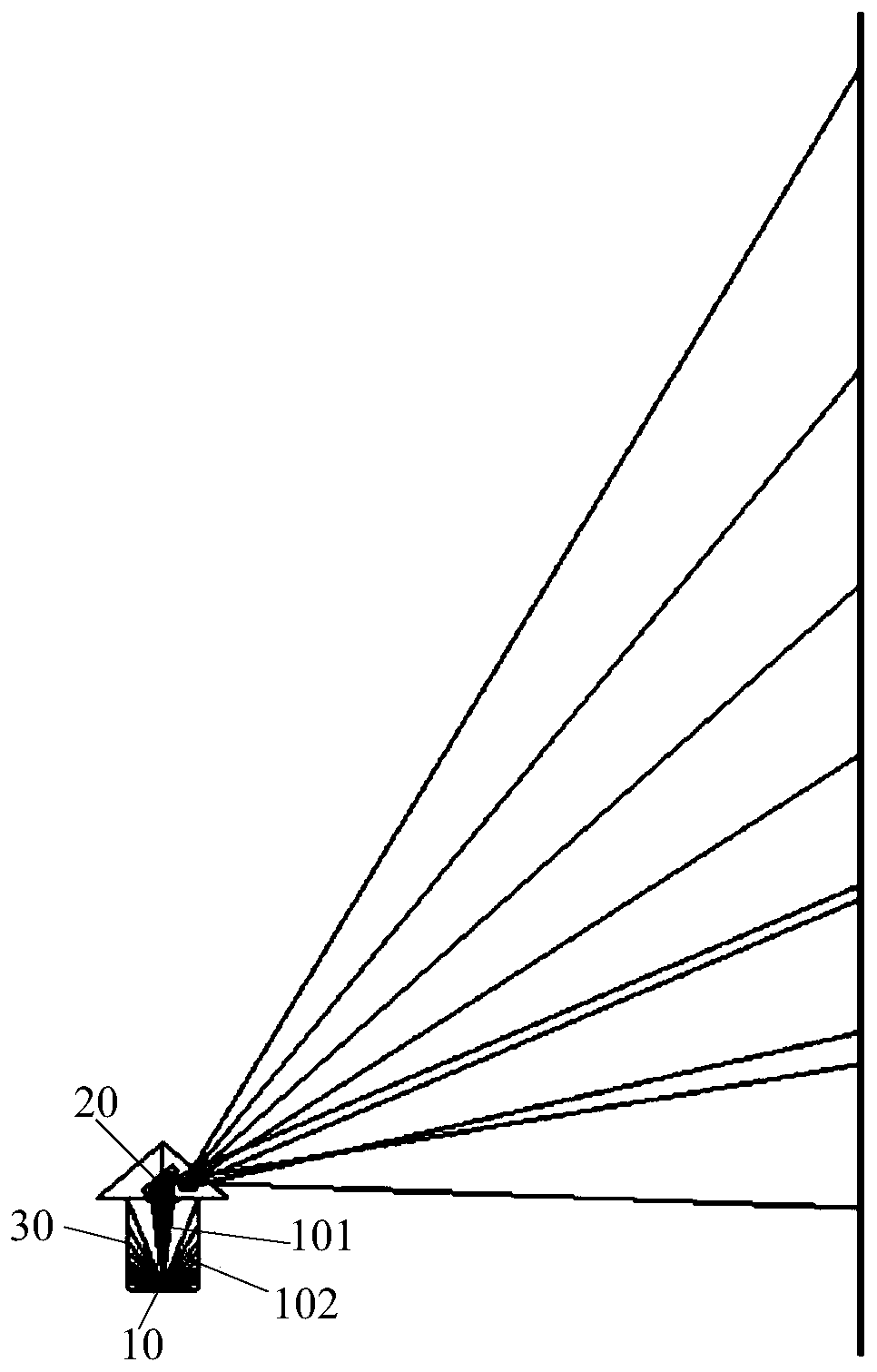

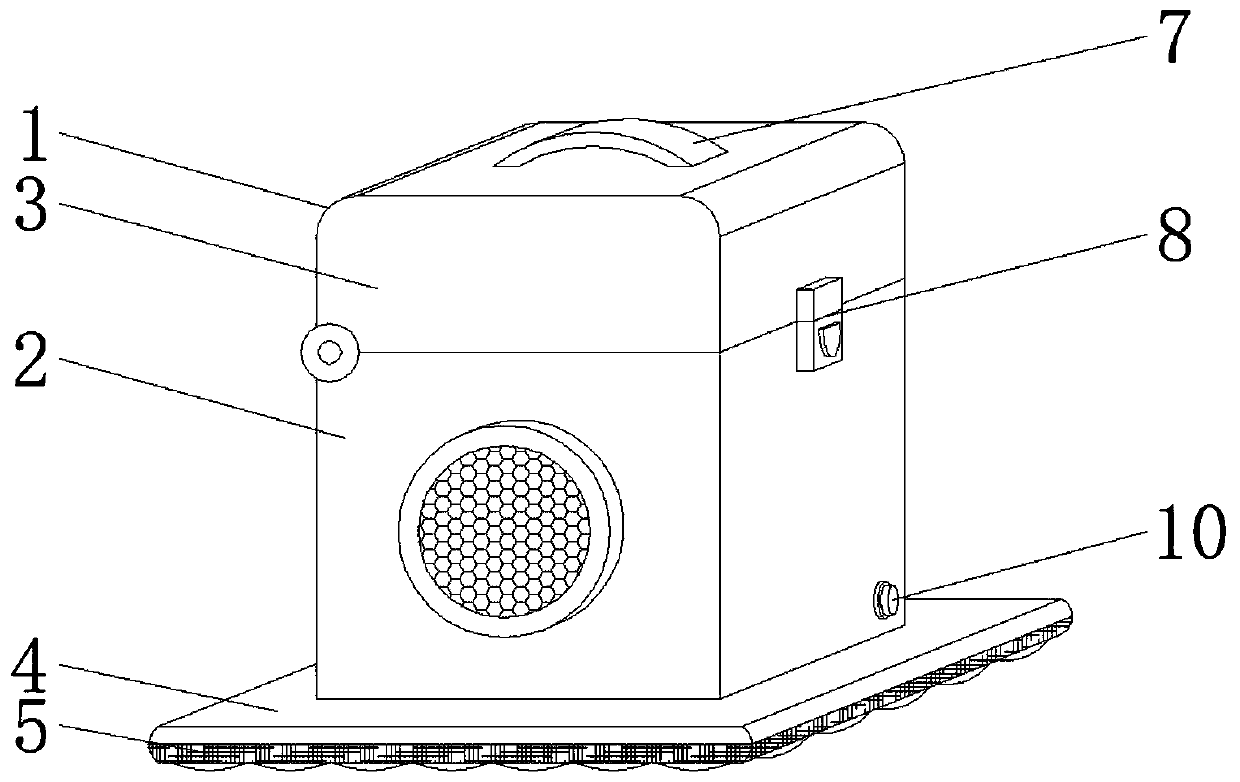

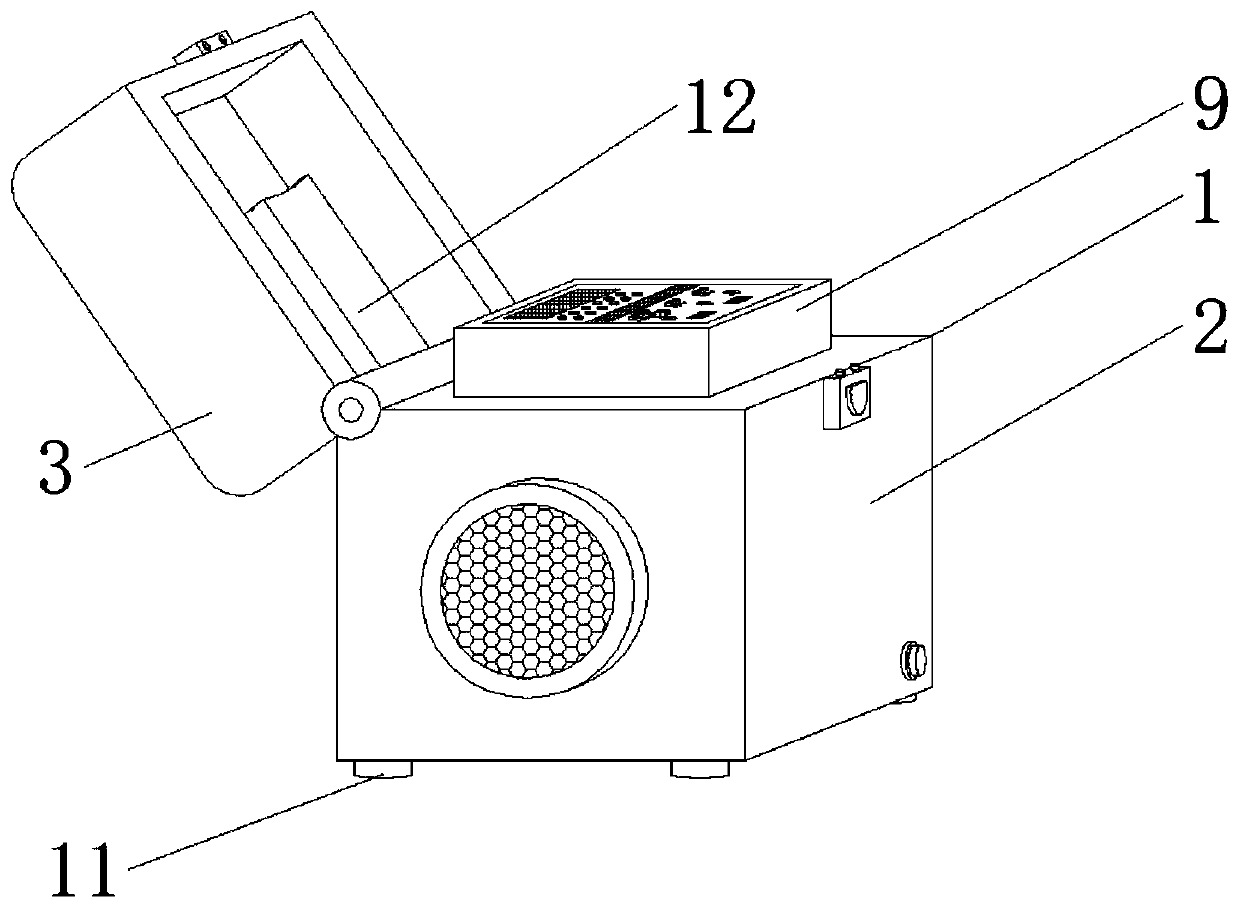

Lamp

PendingCN109737331AIncrease the use of diversityReduce volumeNon-electric lightingPoint-like light sourceEffect lightAtmosphere

The invention discloses a lamp, comprising a light source, wherein light emitted by the light source is divided into two parts, the first part of light is projected to a projection unit and exits to form a starry sky projection light, and the second part of light is projected to an illuminating unit to form an illuminating light. One part of light emitted by the light source is projected to the projection unit, to finally form a starry sky projection effect, and then play the roles of creating atmosphere and decorating; the other part of light is projected to the illuminating unit, to form a lighting effect of illuminating, so as to play a role of illuminating; the light has two module functions including the starry sky projection light and the illuminating light, and thus not only increasing the utilization rate of the light source, and avoiding light waste, but also improving the use diversity of the lamp, and meeting more use requirements; and the lamp is small in volume, low in cost and wider in application.

Owner:佛山市南海区协隆电器有限公司

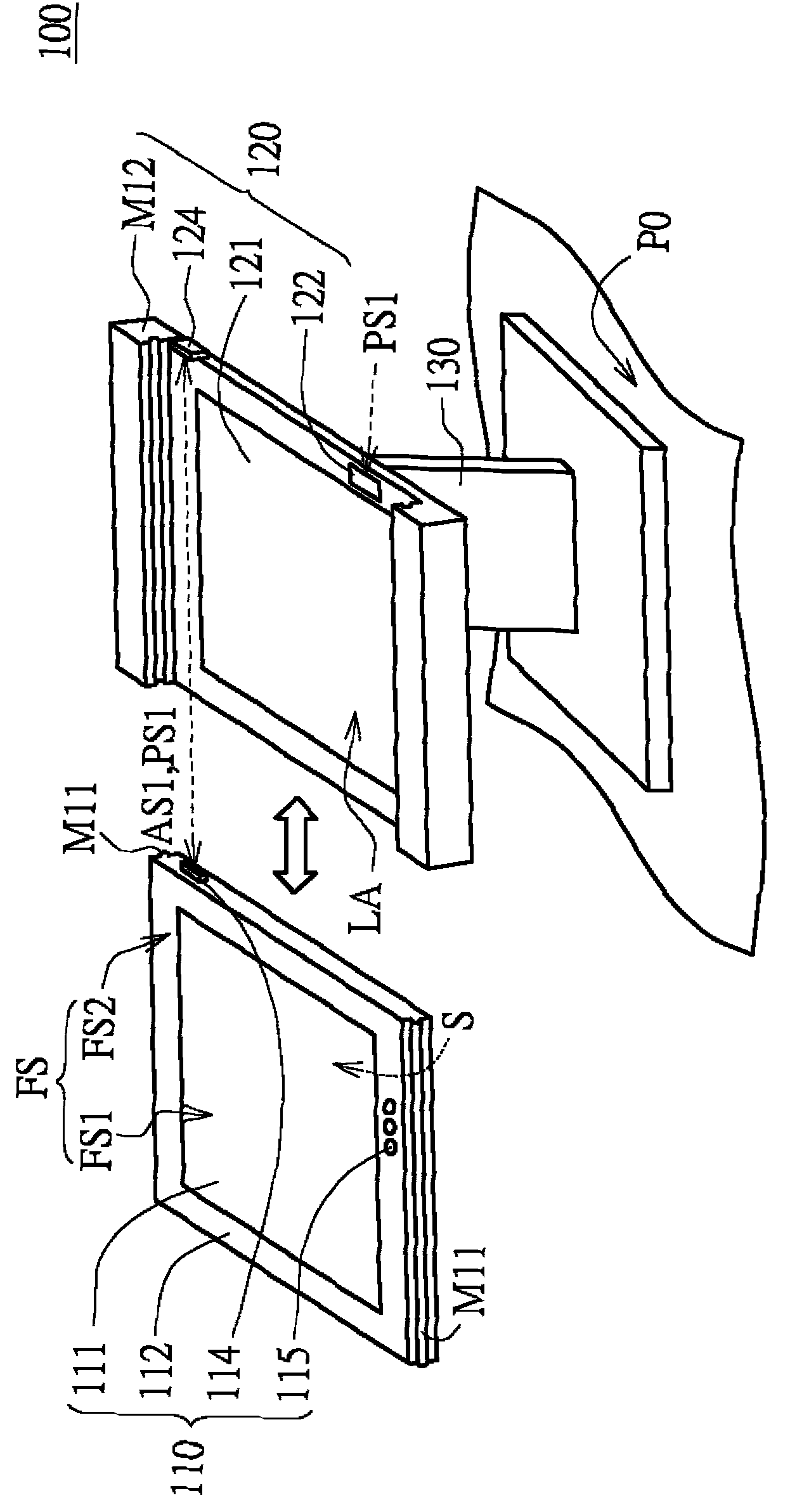

MRK system and method for controlling an MRK system

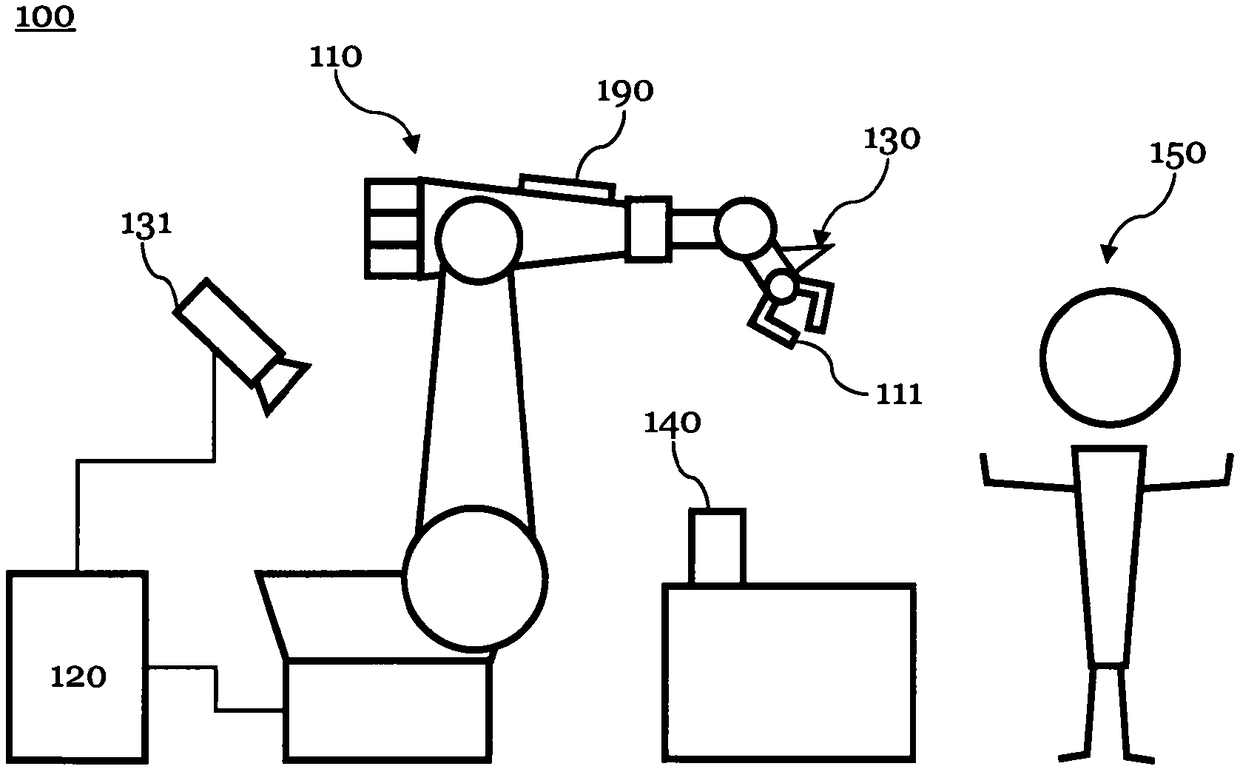

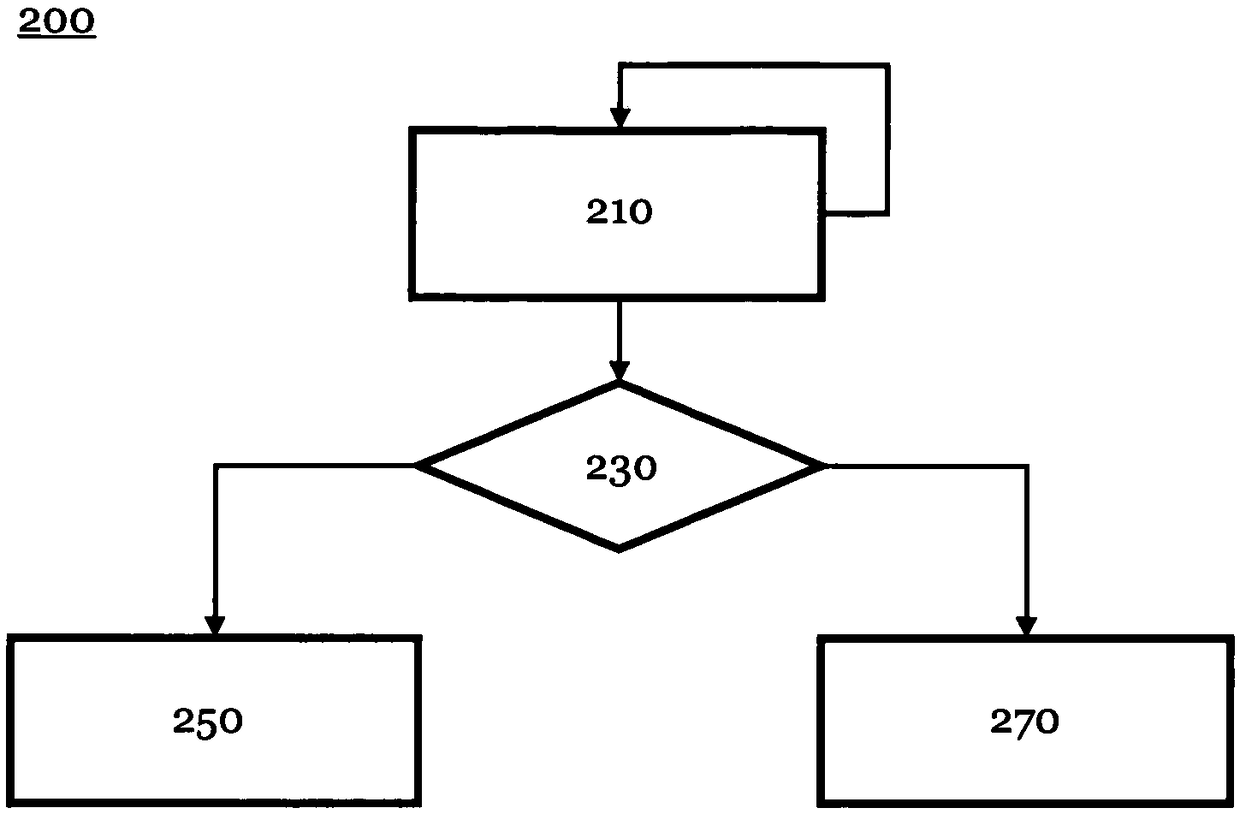

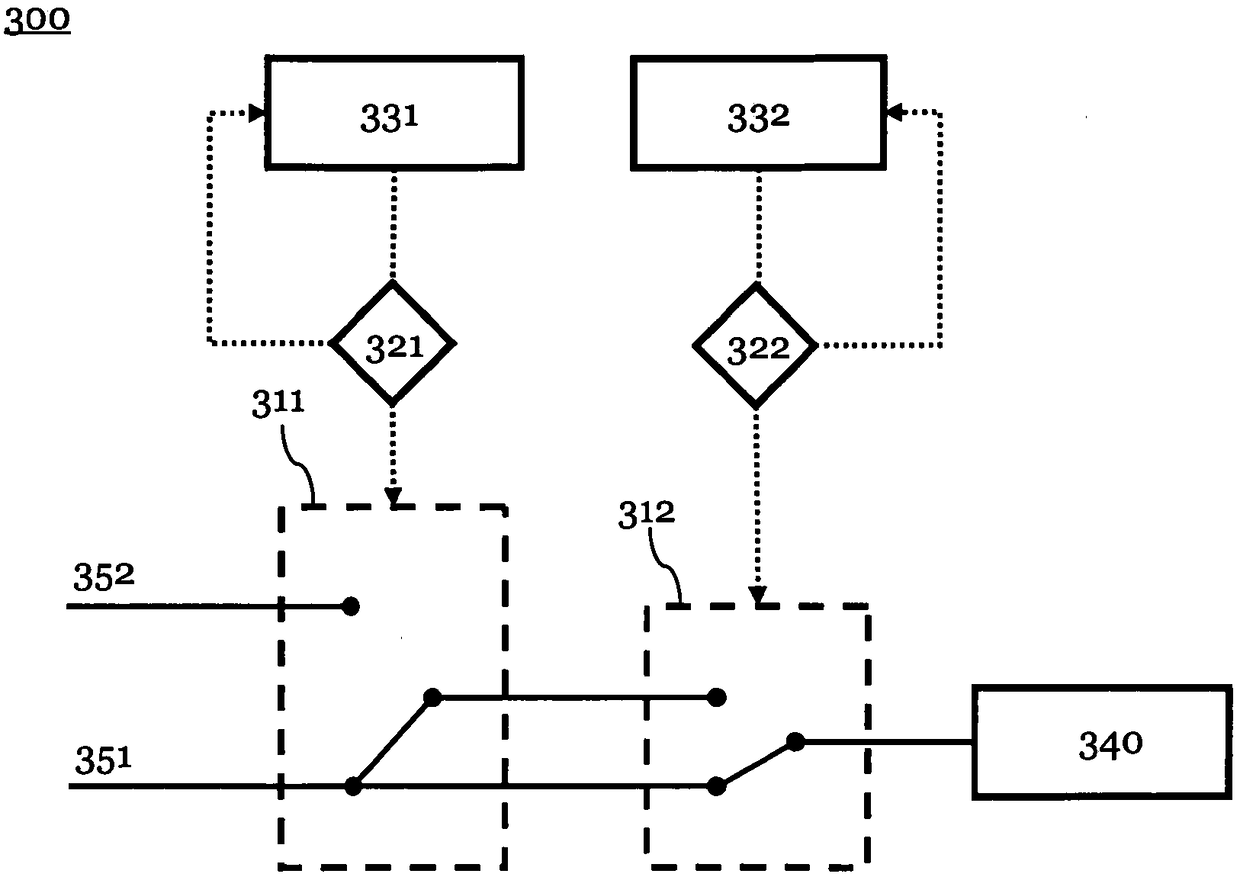

ActiveCN108136583ASimple methodSimple safety adjustment methodProgramme controlProgramme-controlled manipulatorEngineeringActuator

The invention relates to a method (200) for controlling a man-machine interaction system (100), and to an MRK system, the MRK system (100) comprising at least one manipulator (110) comprising an end effector (111), and the method comprising the following steps: use (210) of the end effector (111) in a first operating mode, the end effector (111) being operated in the first operating mode with reduced power (351; 451; 551); monitoring (230) whether a desired object (140) is manipulated when the end effector (111) is used in the first operating mode; and increasing (250) the power (352; 451; 551) used to operate the end effector (111) in order to use the end effector (111) in a second operating mode when the monitoring has indicated that a desired object (140) is being manipulated.

Owner:KUKA SYSTEMS

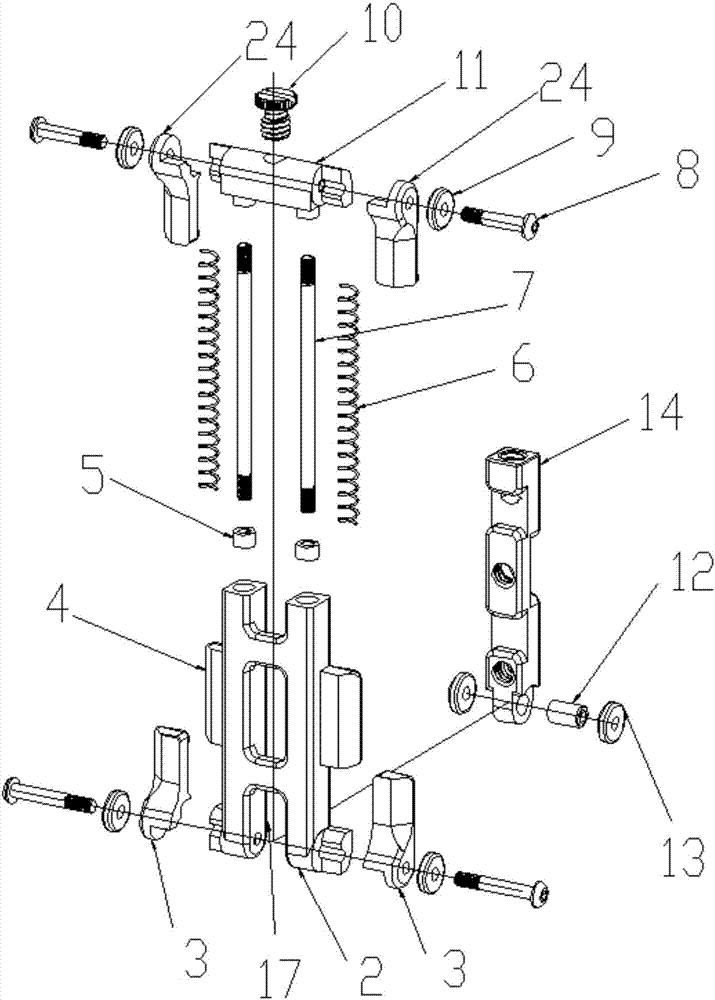

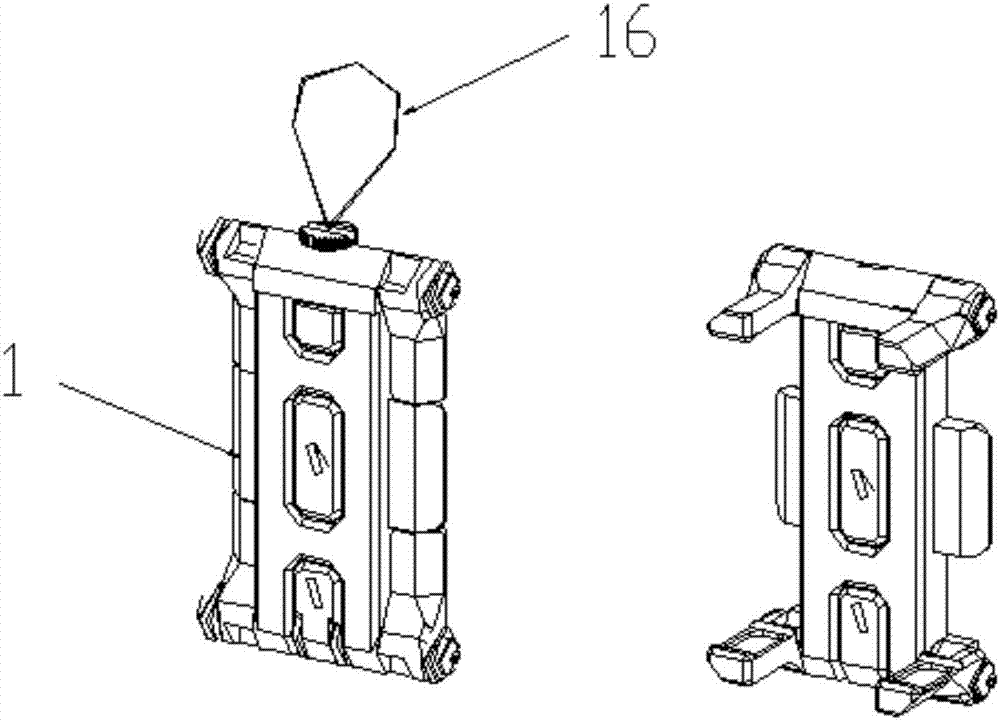

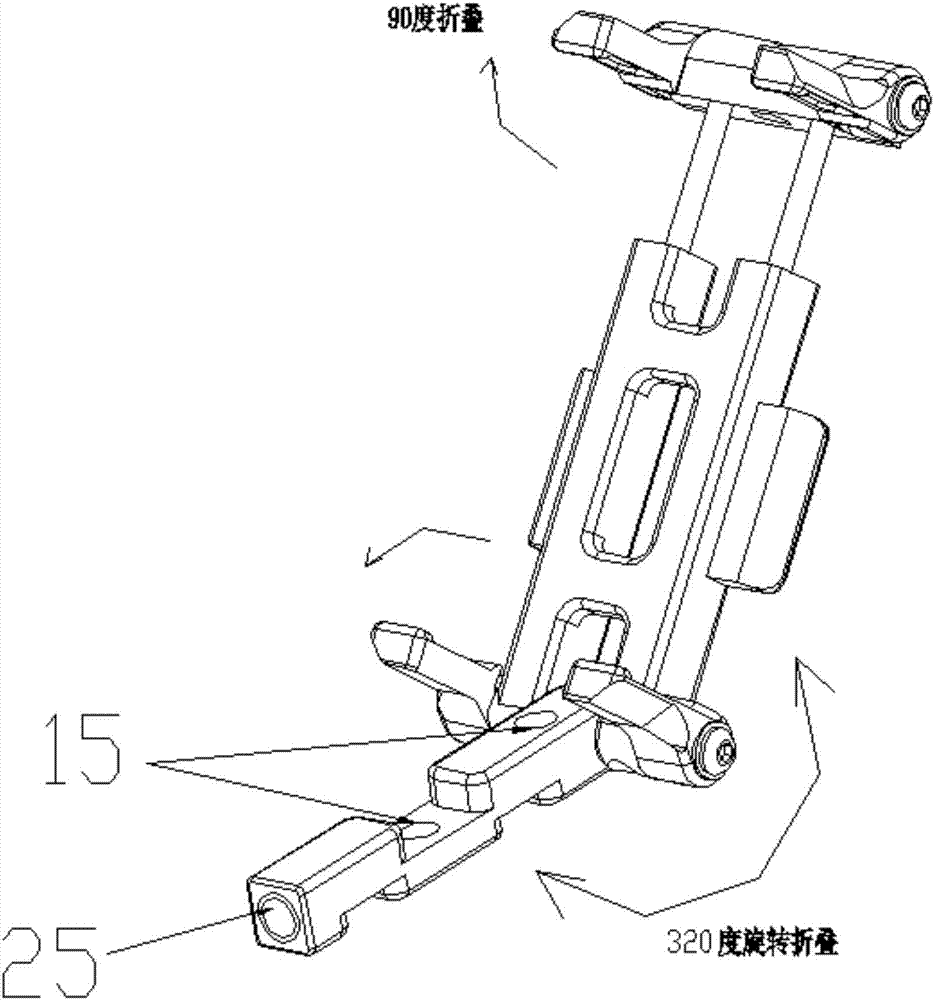

Multi-functional folding mobile phone holder

ActiveCN106969241ADoes not affect normal useEasy to carryClimate change adaptationStands/trestlesEngineeringMobile phone

The invention discloses a multi-functional folding mobile phone holder. The multi-functional folding mobile phone holder comprises a mobile phone holder body, wherein the mobile phone holder body comprises a main body, and a support foot mounting hole is formed in the bottom of the main body; a support foot is arranged in the support foot mounting hole; the support foot is rotatably connected with the mobile phone holder body; longitudinal screw connection holes are formed in the support foot; the longitudinal screw connection holes penetrate through the support foot; a transverse screw connection hole is formed in the end of the support foot; a camera screw is connected into the corresponding longitudinal screw connection hole; a pan tilt is arranged at the bottom of the mobile phone holder body; a first set screw is arranged on one side of the pan tilt; a support is arranged at the bottom of the pan tilt; and a second set screw is arranged on one side of the support. The multi-functional folding mobile phone holder is beneficial to improvement of the use diversification, realizes the purpose that one object has multiple functions, and is beneficial to improvement of the use effect.

Owner:北京海瑟科技有限公司

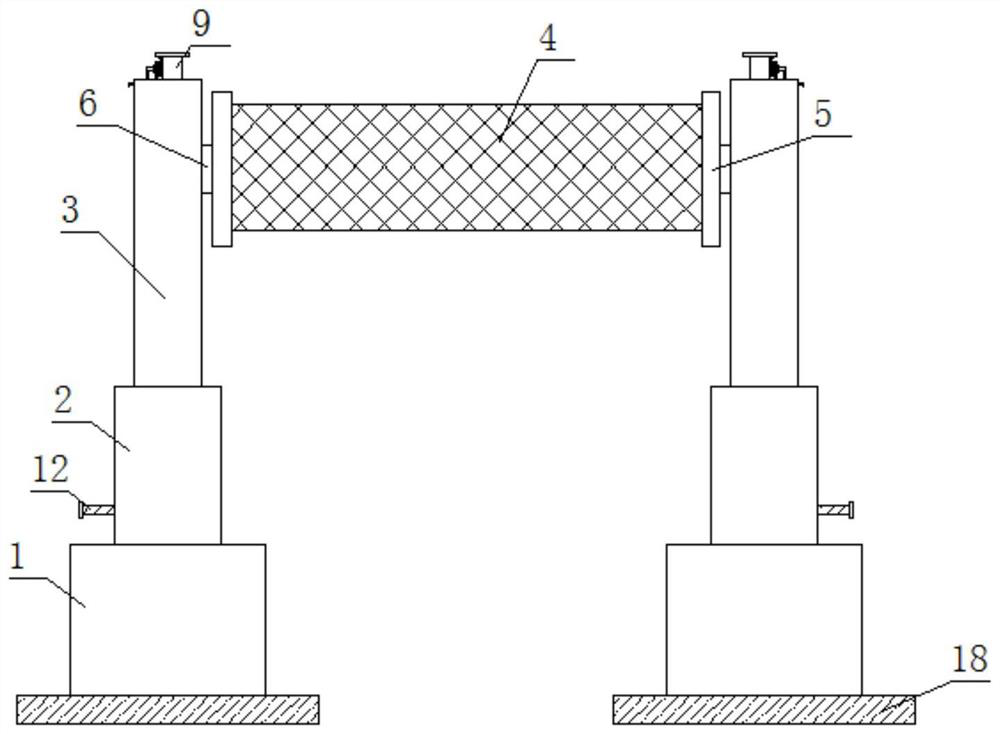

Lifting volleyball stand for teaching and training

ActiveCN111701210BStable positionEasy to useTennisRacket sportsPhysical medicine and rehabilitationSports equipment

The invention belongs to the field of sports equipment, and relates to an elevating volleyball rack for teaching and training. Positioning columns are fixedly connected to the outer sides of the connecting plates on both sides of the main body of the volleyball net, and adjustment seats are fixedly connected to the tops of the two bases. The two lifting components on the top are both driven and connected to the fixed column. The installation chamber provided on the two fixed columns is slidably connected to the moving plate. The top of the moving plate is fixedly connected and the top of the push plate extends to the top of the fixed column. It is fixedly connected with a handle, and the two sides of the positioning column respectively extend into two installation chambers. The top of the positioning column is symmetrically provided with a plurality of card slots, and the bottoms of the two moving plates are fixedly connected with a plurality of card slots. The bayonet pin solves the problem that the existing volleyball stand is inconvenient to disassemble and install the volleyball net during use, and at the same time the height of the volleyball stand cannot be adjusted according to the needs of the game, thereby making the volleyball stand low in practicability .

Owner:CHONGQING THREE GORGES MEDICAL COLLEGE

Computer-aided reading system and method with cross-language reading guide

InactiveCN110222348AGuaranteed stabilityImprove support stabilityNatural language translationElectrical appliancesComputer-aidedSpeech sound

The invention discloses a computer-aided reading system and method with a cross-language reading guide. The cross-language computer auxiliary device comprises a cross-language computer auxiliary device main body, a shell, a protective pad, a main controller and an equipment external control console, the periphery of the cross-language computer auxiliary device body is connected with a shell in a nested mode. The inner wall of the inner side of the shell is connected with the peripheral outer wall of the cross-language computer auxiliary device main body; the top end of the shell is movably connected with a top cover; the bottom end of the shell is in nested connection with a protective pad; a protective pad can effectively ensure the stability of the cross-language computer auxiliary device main body; meanwhile, the supporting stability can be further improved through the anti-skid layer arranged at the bottom end of the protective pad, the stability and protection are realized, the voice broadcaster is used for broadcasting, so that a user can conveniently correct grammatical pronunciation of translated words and sentences in learning, the reading quality is improved, the practicability of the intelligent grammatical pronunciation system is embodied, and the intelligent grammatical pronunciation system has a wide development prospect in the future.

Owner:上海元聚网络科技有限公司

Preparation and processing technology of modified asphalt

InactiveCN114311372AEfficient stirring and mixing workIncrease mixing rateSievingScreeningThermodynamicsProcess engineering

The invention belongs to the field of modified asphalt processing, and particularly relates to a modified asphalt preparing and processing technology which comprises a device shell, a storage box is connected to the top of the device shell through screws, a discharging hole is formed in the bottom of the storage box in a penetrating mode, and a grinding and smashing assembly is installed in the device shell. A mixing barrel is fixedly welded to the bottom of the device shell, an efficient mixing assembly is installed in the mixing barrel, a mounting plate is fixedly welded to the mixing barrel, an electric heating pipe is installed in the mounting plate through bolts, and a conveying pipe is connected to the bottom of the mixing barrel through bolts. The problems that an existing modified asphalt preparing and processing device can only conduct single mixing and stirring work on asphalt raw materials and modified materials, can only conduct single-state stirring during stirring, cannot conduct multi-state efficient stirring on the asphalt raw materials with large viscosity, and is poor in stirring efficiency are solved. The high efficiency and the thoroughness of the subsequent mixing and stirring work cannot be ensured.

Owner:张素芬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com