Environment-friendly water-based printing ink preparation process

A technology of printing ink and preparation process, which is applied in the direction of mixer, dispersed particle filtration, gas treatment, etc., which can solve the problem of not being able to ensure the stability and high efficiency of water-based printing ink preparation, not being able to mix multiple raw materials evenly, and not being able to purify waste gas Work and other issues, to achieve the effect of increasing the efficiency and stability of use, increasing the diversity of use, and ensuring uniformity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

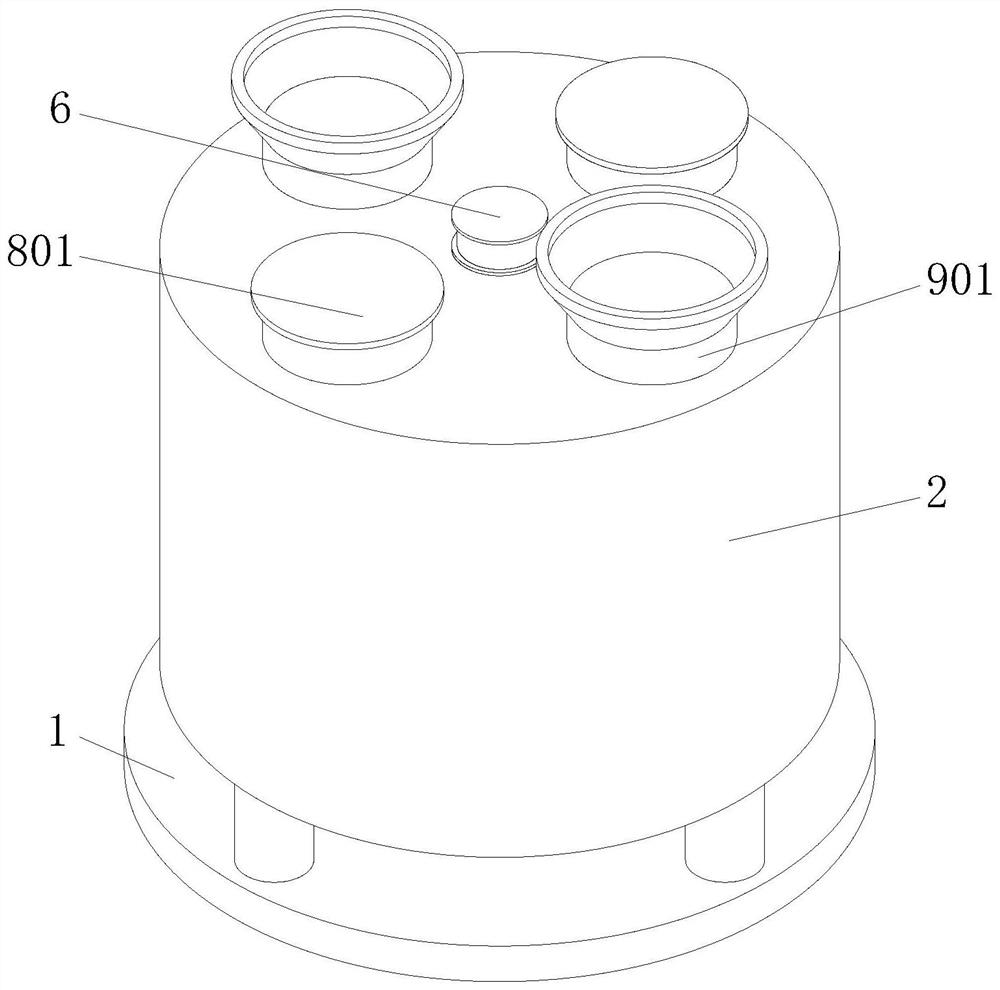

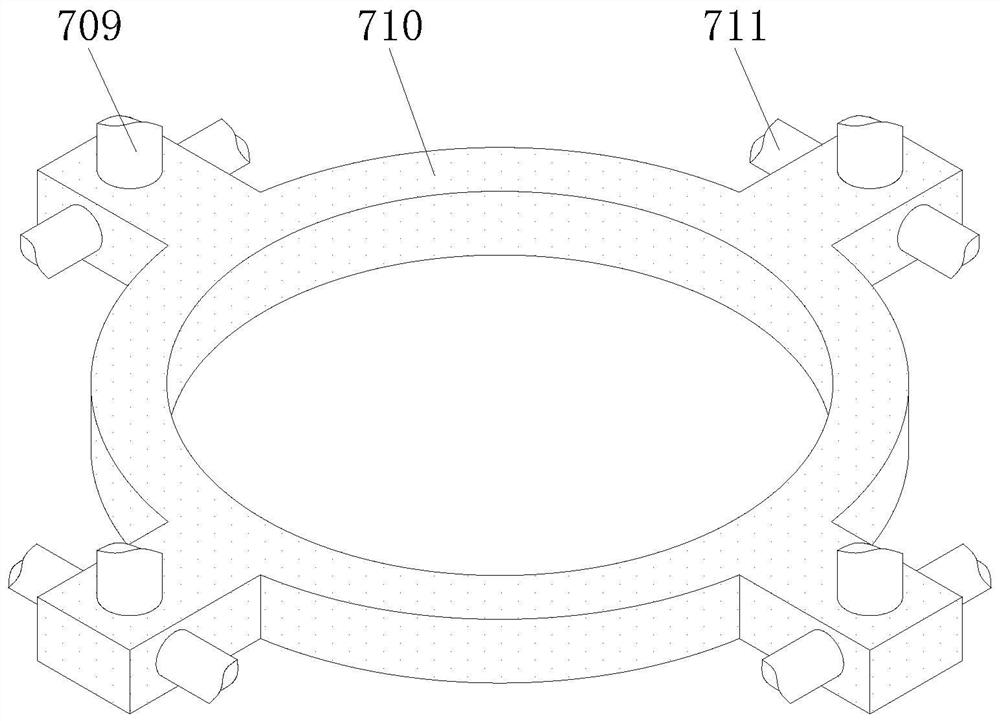

[0042] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

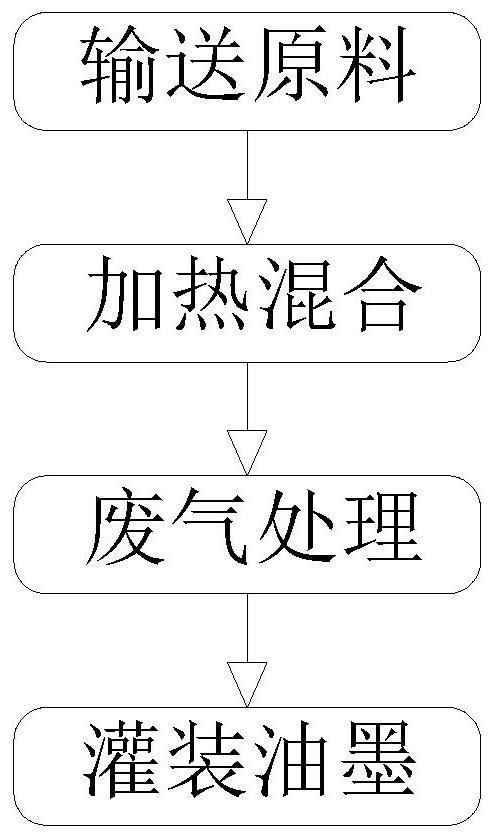

[0043] like Figure 1-11 Shown, a kind of environment-friendly water-based printing ink preparation process comprises the following steps:

[0044] S1. Conveying raw materials: the conveying mechanism can be used to carry out intermittent equal-quantity conveying work for a variety of different raw materials at the same time, and use the mixing box for storage;

[0045] S2. Heating and mixing: in step S1, while the conveying mechanism is working, it can drive the high-efficiency mixing mechanism in the mixing box, and then can heat and mix various raw materials in the mixing box for preparation;

[0046] S3. Exhaust gas treatment: in step S2, the high-efficiency mixing mechanism can drive the filter mechanism in the mixing box at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com