Preparation and processing technology of modified asphalt

A modified asphalt and processing technology technology, applied in the field of modified asphalt processing, can solve the problems of inability to ensure stable and efficient melting and mixing work, inability to ensure efficient and thorough mixing and stirring work, and inability to automatically clean modified asphalt, etc. Achieve the effect of increasing the variety of use, avoiding clogging and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

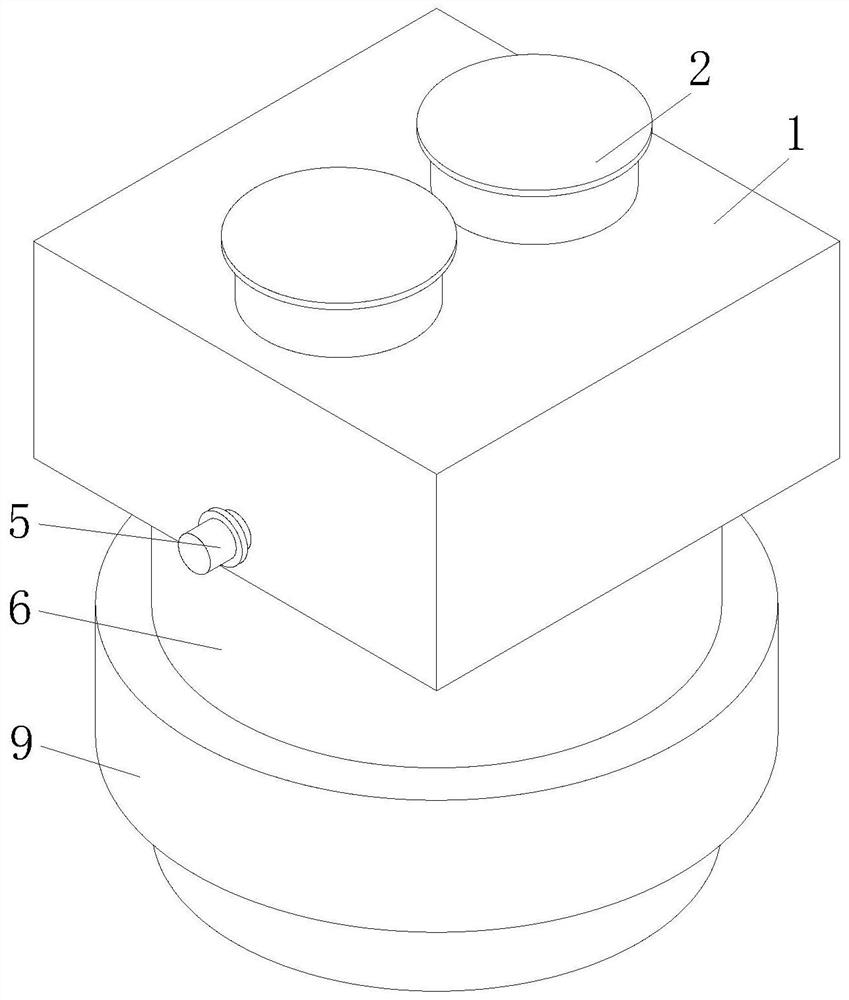

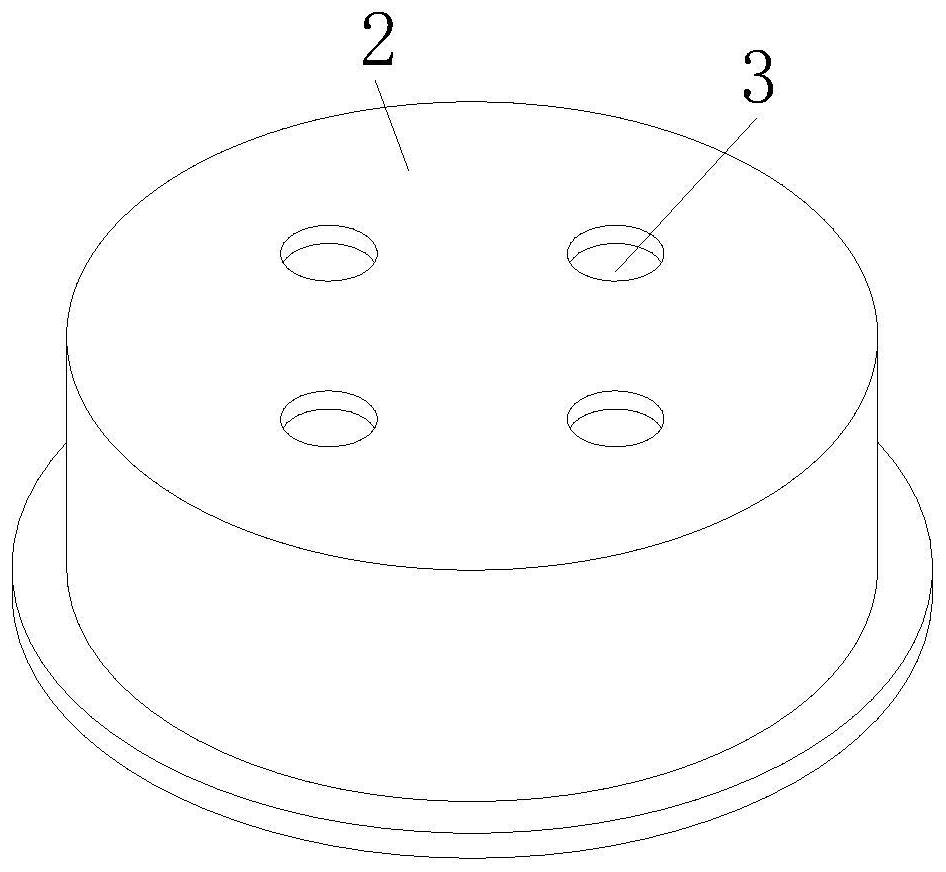

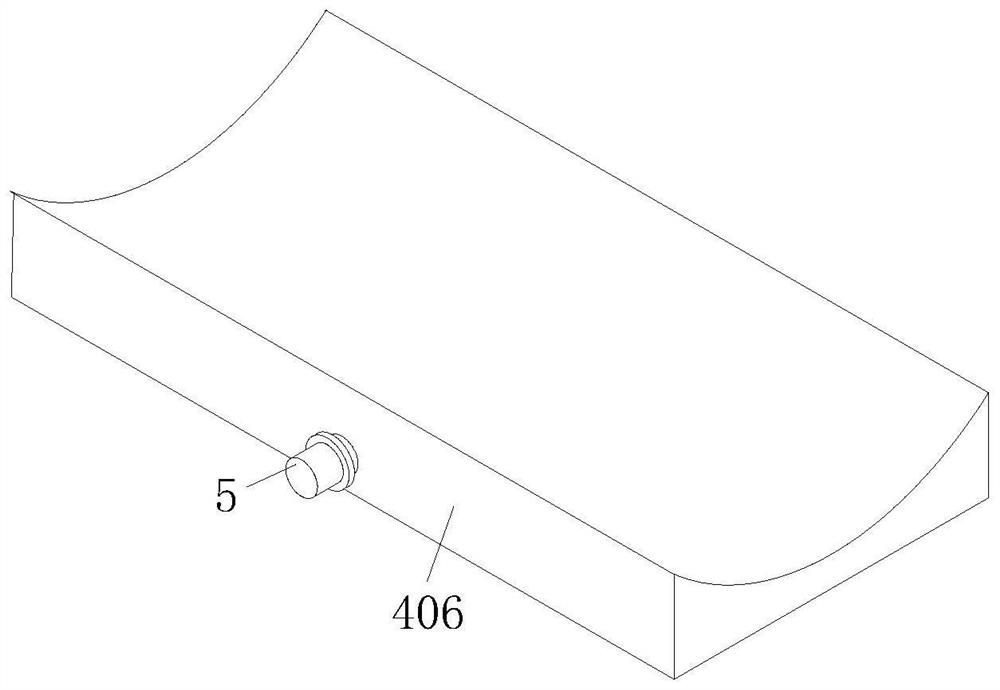

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0042] Such as Figure 1-9 Shown, a kind of modified asphalt preparation processing technology, comprises the following steps:

[0043] A. Convey asphalt raw material: transport the asphalt raw material to the preparation and processing device by using the feed pipe for heating and melting;

[0044] B. Convey modified material: transport the modified material to be used to the processing device, and the device can stably transport it to the asphalt raw material after grinding and pulverizing it;

[0045] C. Efficient mixing and stirring: the processing device uses its internal stirring mechanism to efficiently mix and stir asphalt raw materials and modified materials to make modified asphalt;

[0046] D. Cleaning and conveying modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com