Pickling device for chilli pickled vegetable production

A technology of pickles and peppers, which is applied in the direction of food science, etc., can solve the problems of inconvenient access to peppers and pickles, single structure of the pickling device, and low efficiency of pickling pickles, so as to avoid low pickling efficiency and high-efficiency stirring and mixing , the effect of reducing the operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

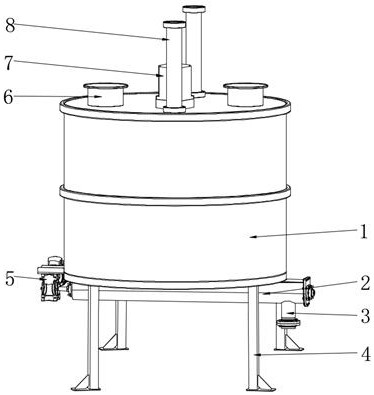

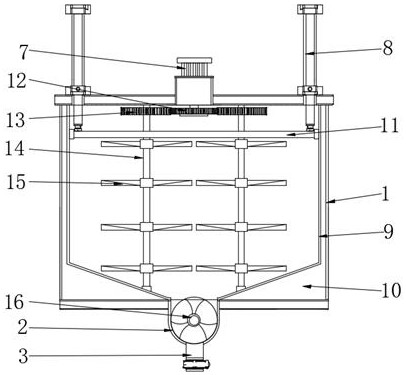

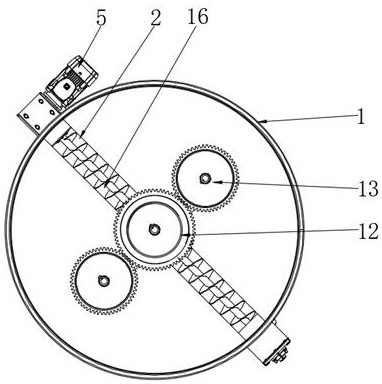

[0019] As shown in the attached picture: see Figure 1~3 , in an embodiment of the present invention, a pickling device for the production of chili pickles, comprising a pickling tank 1, the bottom of the pickling tank 1 is fixed with a support tripod 4 at the edge position, and the pickling tank 1 A discharge pipe 2 is connected to the lower part in the middle, and a conveying motor 5 is fixed at one end of the discharge pipe 2, and the inner side of the discharge pipe 2 is connected with a screw conveying paddle 16, and the bottom of the discharge pipe 2 is located at the other end. Discharging port 3 is provided, and the outer diameter of screw conveying paddle 16 is adapted to the internal diameter of discharge pipeline 2, and the length of screw conveying paddle 16 is identical with the diameter length of pickling tank body 1, after pickling pepper pickled vegetables Finally, the conveying motor 5 works to drive the screw conveying paddle 16 to rotate, and the chili pickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com