Micro stirrer driven by a multi-core fiber

A multi-core optical fiber and micro-stirring technology, which is applied in the direction of cladding optical fiber, optical waveguide coupling, optical waveguide light guide, etc., can solve the problems of laser optical tweezers, such as bulky, difficult to move, high cost, etc., to save operating space and increase strength , The effect of saving reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

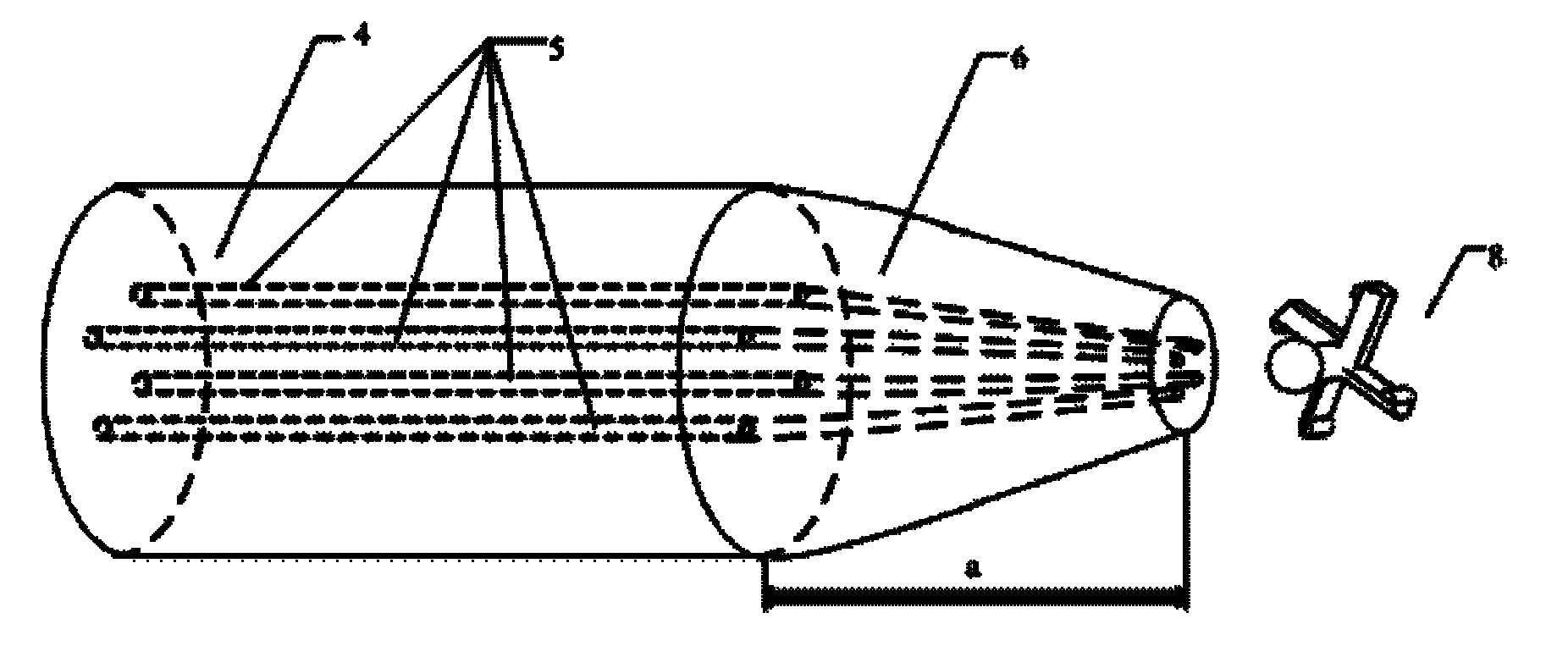

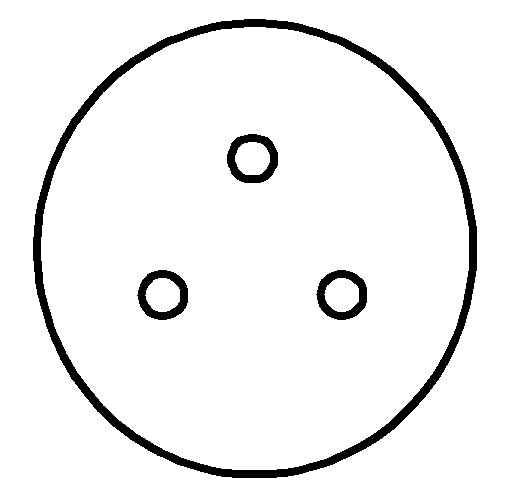

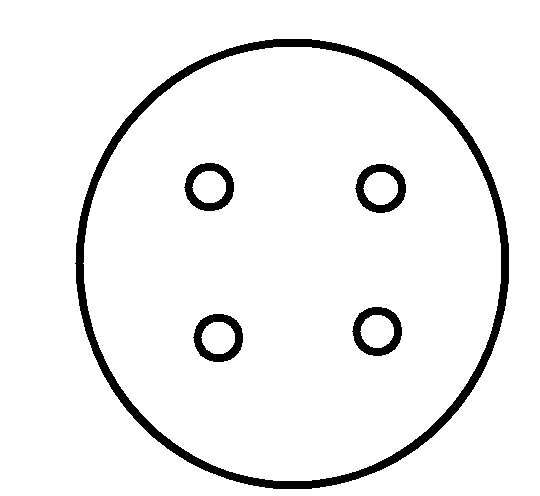

[0025] to combine figure 1 , 2, 3, the present invention is based on the micro-stirrer driven by multi-core optical fiber and comprises the multi-core optical fiber of the taper shape 6 that a section of multi-core optical fiber 4 is made through fusion tapering and the tiny particle 8 that is made of composite material, and multi-core optical fiber has 3-4 fiber cores 5. The tiny particles are located at the cone end of the cone-shaped multi-core fiber. The non-taper end of the cone-shaped multi-core fiber is connected to the light source through the light source tail fiber. The multiple cores of the cone-shaped multi-core fiber act on the vertical suspension at the same time tiny particles in the liquid. Simultaneously combine Figure 6-1 to Figure 6-3 , the upper body of the tiny particle is a sphere and a rotating shaft made of a material with a lower dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com