Liquid non-submerged impinging stream reaction device and reaction method

A technology of impinging flow reaction and reaction device, which is applied in chemical/physical/physical-chemical nozzle reactors, chemical instruments and methods, hydrocarbon oil cracking, etc., and can solve problems such as insufficient strengthening effect of new substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

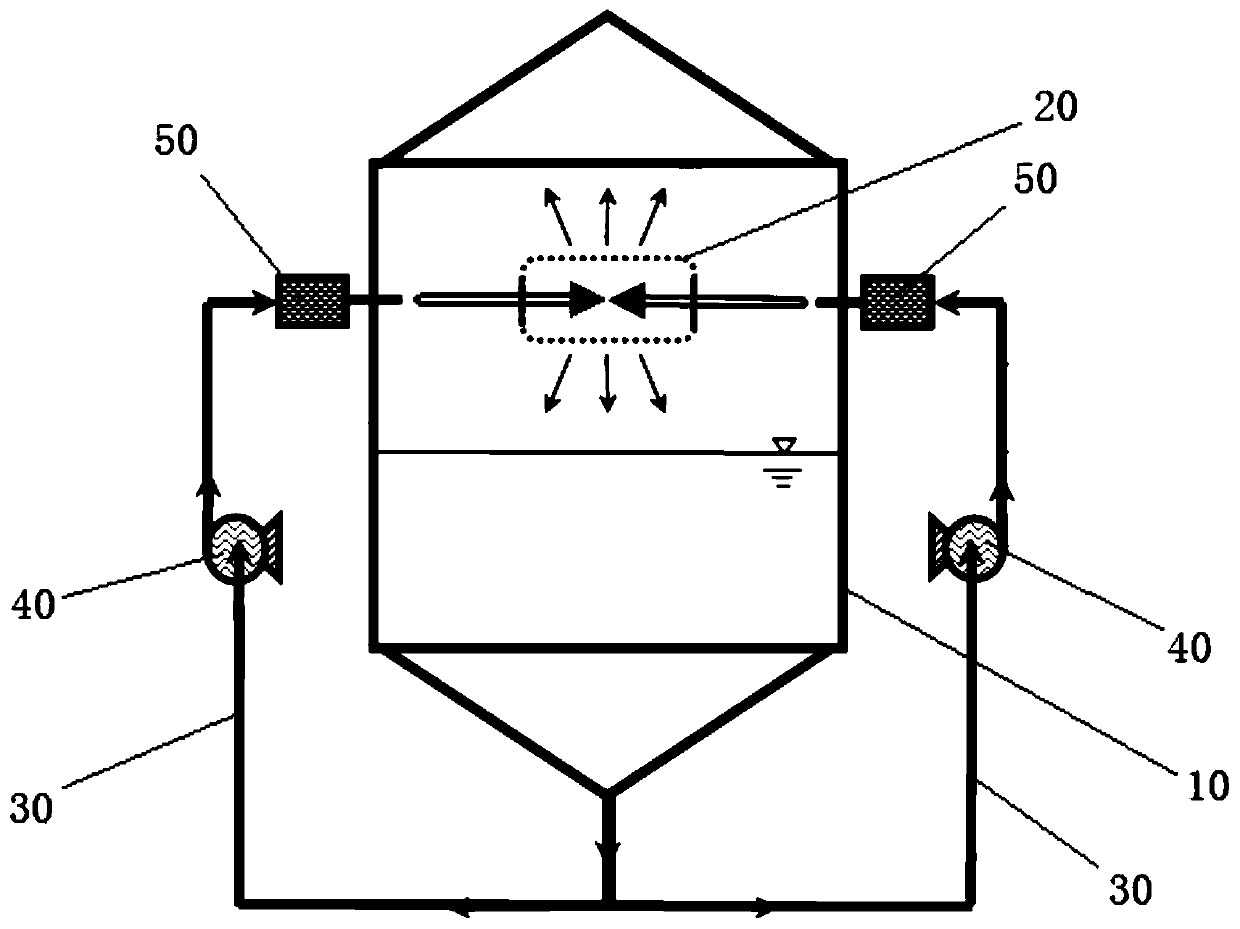

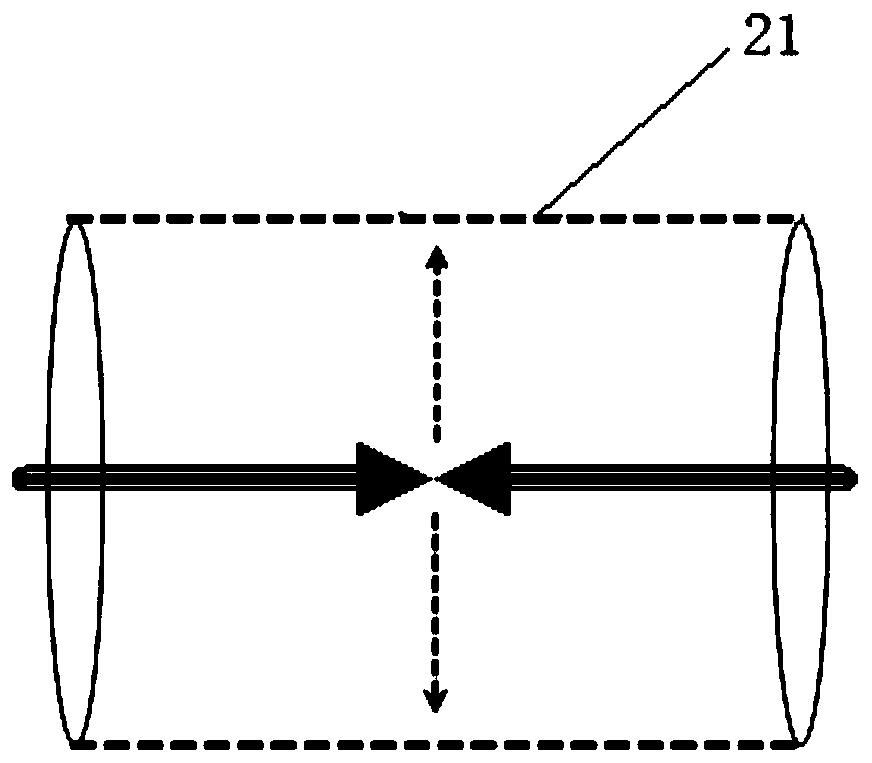

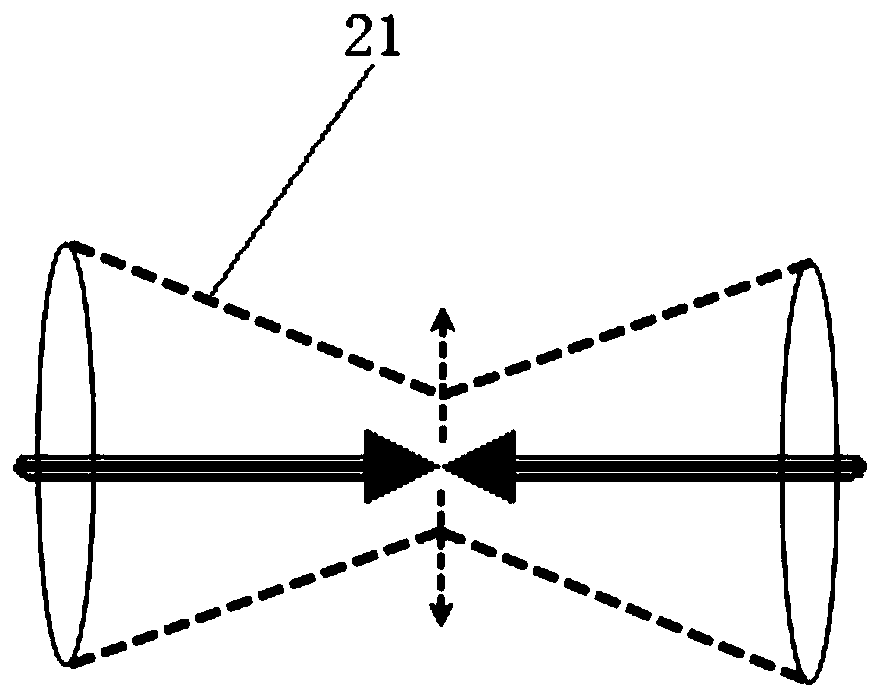

[0090] use figure 1 The reaction device shown, in which the non-submerged impinging flow reaction module adopts figure 2 Shown, carry out the catalytic hydrogenation of vacuum residuum to prepare light chemical oil (gasoline and diesel oil), process condition is as follows:

[0091] The liquid mixed raw materials of vacuum residue, hydrogen and catalyst are sprayed into the inlets on both sides of the non-submerged impinging flow reaction module through the nozzle. After the impact, the secondary fluid diffuses at 90° with the direction of movement of the raw material, and has a secondary impact with the cylinder and the multiple pore structures set on it, and cavitation and shear effects destroy the molecular bonds. The qualitative product is collected from above the reaction housing. After strengthening, the unreacted material or the heavy part after the reaction falls into the bottom of the reaction shell in liquid phase, and returns here to react through the driving dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com