Microwave processing multi-phase fluidized bed reactor and process for treating phosphogypsum

A multi-phase fluidized bed and microwave treatment technology, applied in the field of reactors, can solve the problems such as the inability of gas to form a standard flow field, the inability to achieve local control of gas, and the inability to achieve local heating, so as to improve the chemical reaction rate and improve chemical Effect of reaction rate, enhanced two-phase flow and heat and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

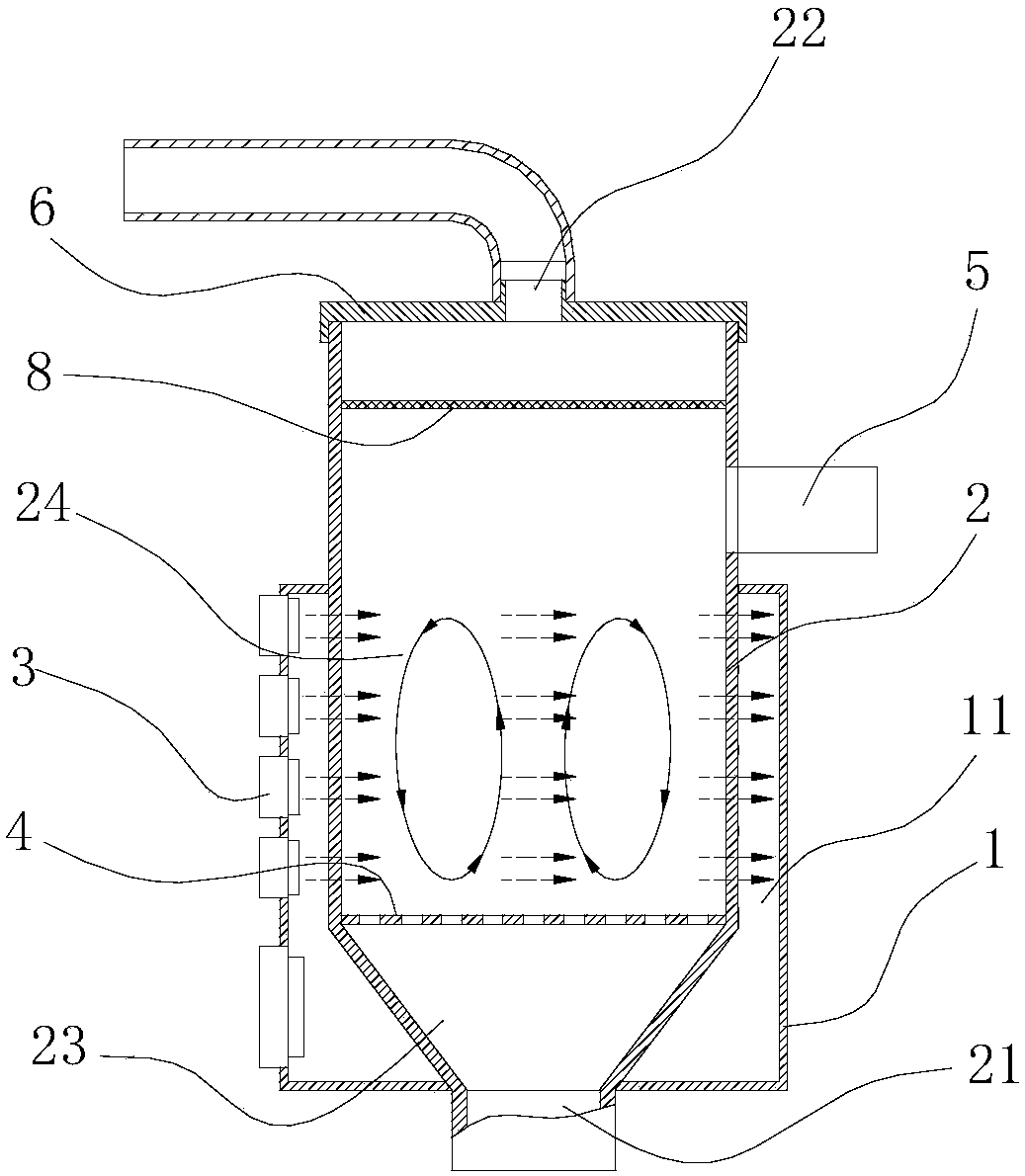

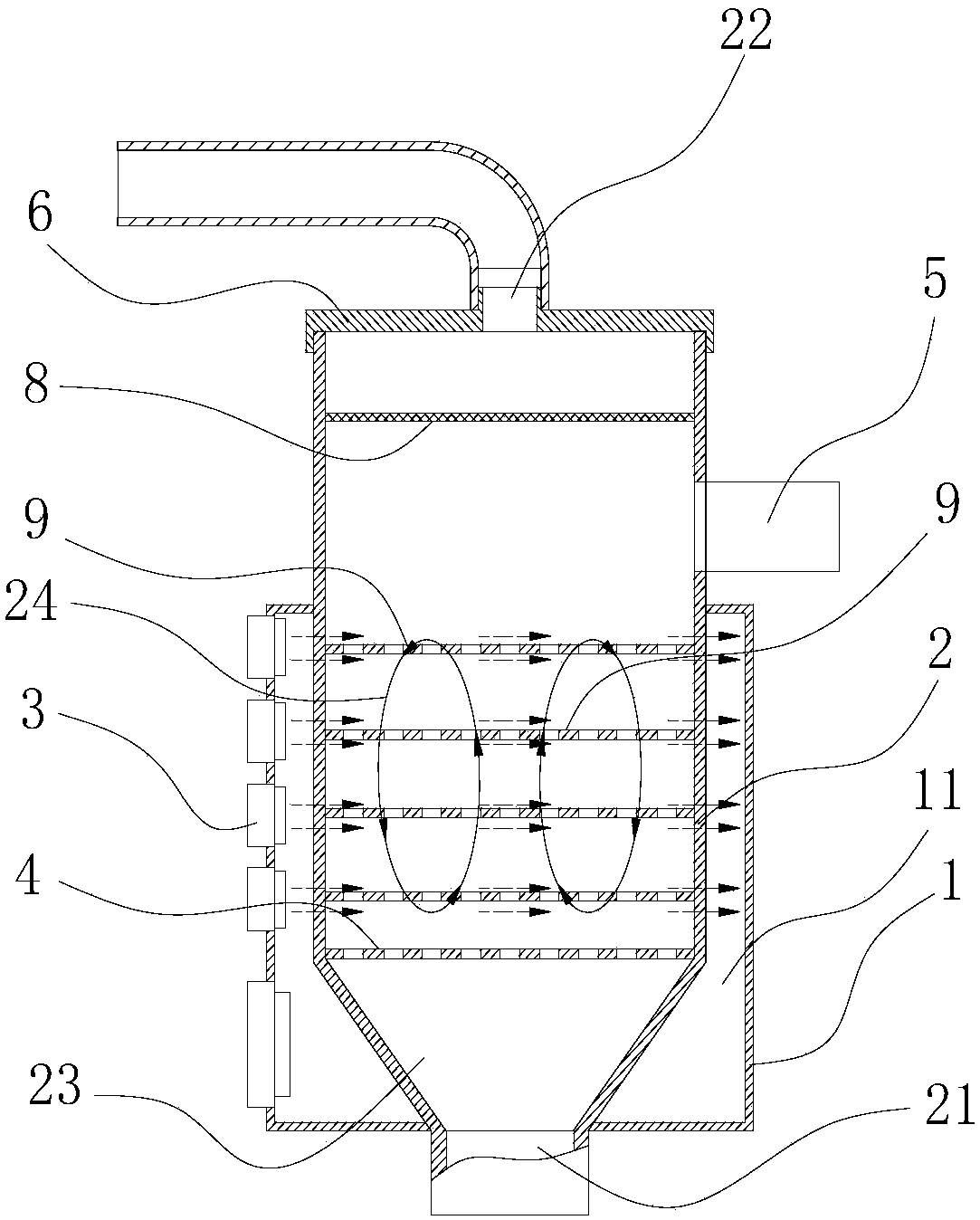

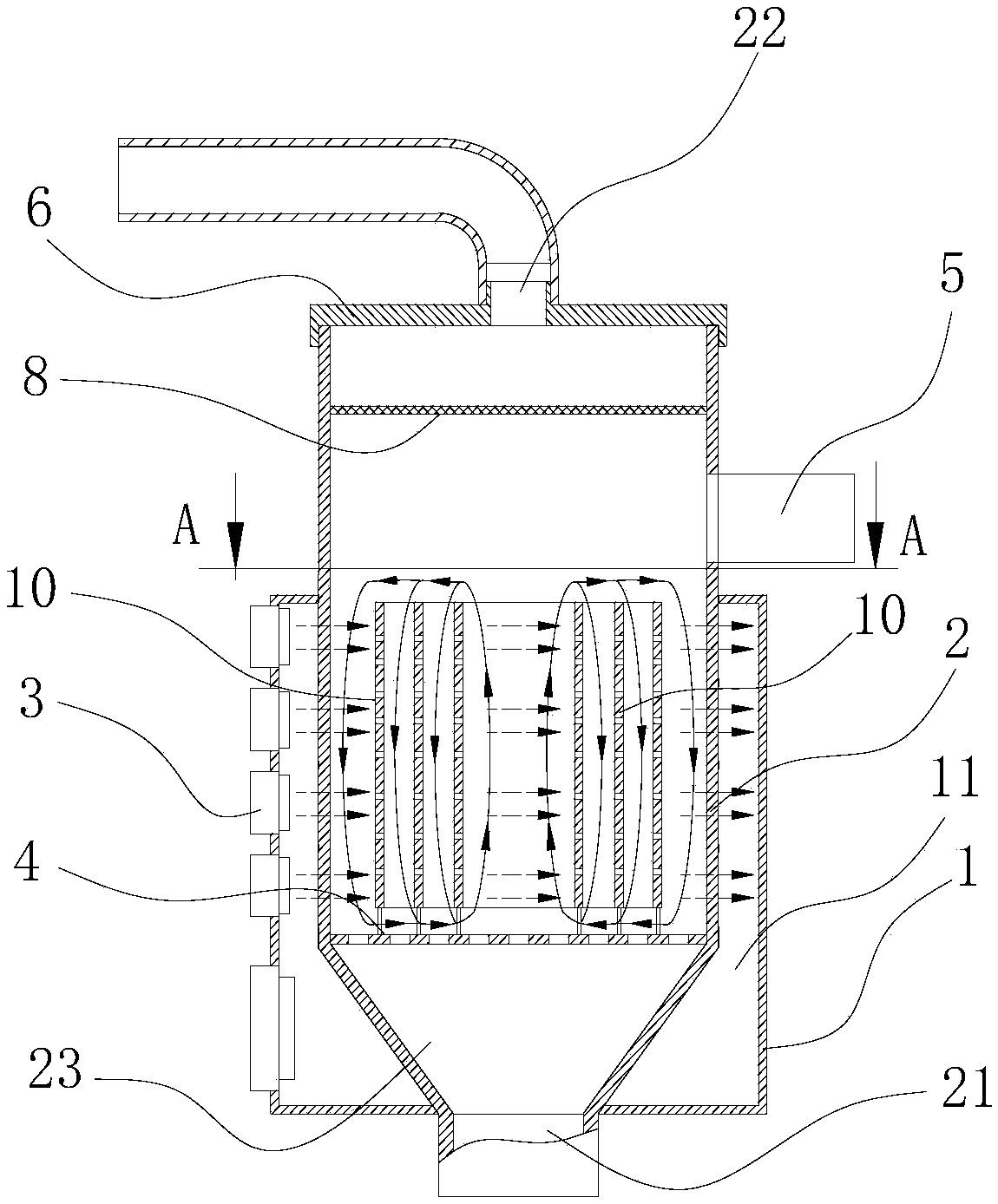

Method used

Image

Examples

Embodiment 1

[0087] Industrial reaction of phosphogypsum by microwave treatment in a multiphase fluidized bed reactor: S 2 (g)+CaSO 4 →CaS+2SO 2 (g) process, including the following steps:

[0088] A, liquid sulfur and solid calcium sulfate particles are injected into the reactor 2 along the feed port 5; the molar ratio of the solid calcium sulfate particles and liquid sulfur is 1:10;

[0089] B. The bottom of the reactor 2 is heated by the microwave generator 3 corresponding to the gasification deposition chamber 23 on the microwave reflecting shell 1, and the inside of the reactor 2 is heated by the microwave generator 3 corresponding to the fluidization reaction chamber 24 on the microwave reflecting shell 1. The material is heated; so that the temperature of sulfur reaches 200 ° C;

[0090] C, control the pressure in the reactor 2, so that the pressure in the reactor 2 is less than 1Mpa;

[0091] D, the gas obtained by the reaction of sulfur and calcium sulfate is discharged throug...

Embodiment 2

[0093] Industrial reaction of phosphogypsum by microwave treatment in a multiphase fluidized bed reactor: S 2 (g)+CaSO 4 →CaS+2SO 2 (g) process, including the following steps:

[0094] A, liquid sulfur and solid calcium sulfate particles are injected into the reactor 2 along the feed port 5; the molar ratio of the solid calcium sulfate particles and liquid sulfur is 1:5;

[0095] B. The bottom of the reactor 2 is heated by the microwave generator 3 corresponding to the gasification deposition chamber 23 on the microwave reflecting shell 1, and the inside of the reactor 2 is heated by the microwave generator 3 corresponding to the fluidization reaction chamber 24 on the microwave reflecting shell 1. The material is heated; so that the temperature of sulfur reaches 400 ° C;

[0096] C, control the pressure in the reactor 2, so that the pressure in the reactor 2 is less than 1Mpa;

[0097] D, the gas obtained by the reaction of sulfur and calcium sulfate is discharged through...

Embodiment 3

[0099] Industrial reaction of phosphogypsum by microwave treatment in a multiphase fluidized bed reactor: S 2 (g)+CaSO 4 →CaS+2SO 2 (g) process, including the following steps:

[0100] A, liquid sulfur and solid calcium sulfate particles are injected into the reactor 2 along the feed port 5; the molar ratio of the solid calcium sulfate particles and liquid sulfur is 1:3;

[0101] B. The bottom of the reactor 2 is heated by the microwave generator 3 corresponding to the gasification deposition chamber 23 on the microwave reflecting shell 1, and the inside of the reactor 2 is heated by the microwave generator 3 corresponding to the fluidization reaction chamber 24 on the microwave reflecting shell 1. The material is heated; the temperature of sulfur reaches 600°C;

[0102] C, control the pressure in the reactor 2, so that the pressure in the reactor 2 is less than 1Mpa;

[0103] D, the gas obtained by the reaction of sulfur and calcium sulfate is discharged through the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com