Suspension roasting system for carbon-containing gold ore

The technology of suspension roasting and suspension roasting furnace is applied in the field of suspension roasting system of carbon-containing gold ore, which can solve the problems of high cost, low efficiency and uneven product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

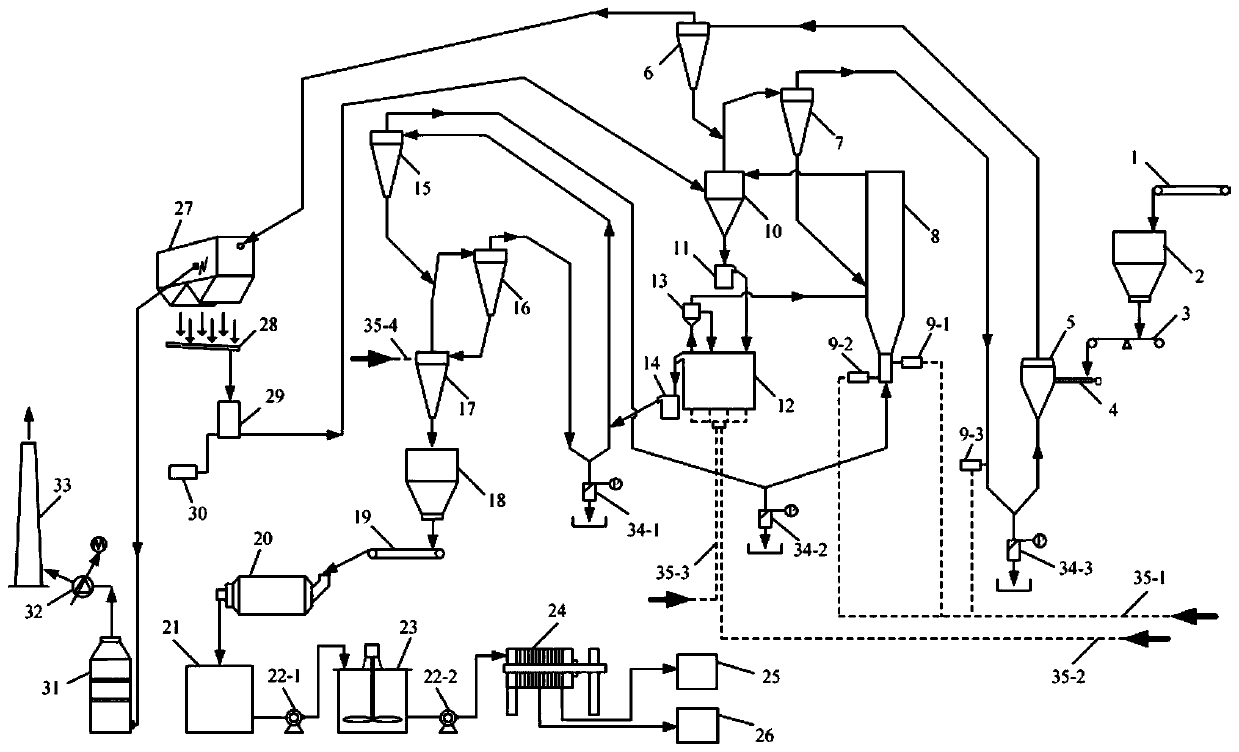

[0074] The structure of carbon-bearing gold ore suspension roasting system is as follows: figure 1 As shown, it includes feeding bin 2, Venturi dryer 5, first cyclone preheater 6, second cyclone preheater 7, pre-oxidation suspension roaster 8, heat separation cyclone 10, strong oxidation suspension roaster 12 , collection bin 18, grinding machine 20, collection tank 21, leaching tank 23, dust collector 27 and induced draft fan 32;

[0075] A feeding belt 1 is provided above the feeding bin 2 for transferring materials to the feeding bin 2;

[0076] A loss-in-weight feeder 3 is provided between the feed bin 2 and the screw feeder 4, and the loss-in-weight feeder 3 is opposite to the outlet of the feed bin 2 and the feeding end of the screw feeder 4 respectively;

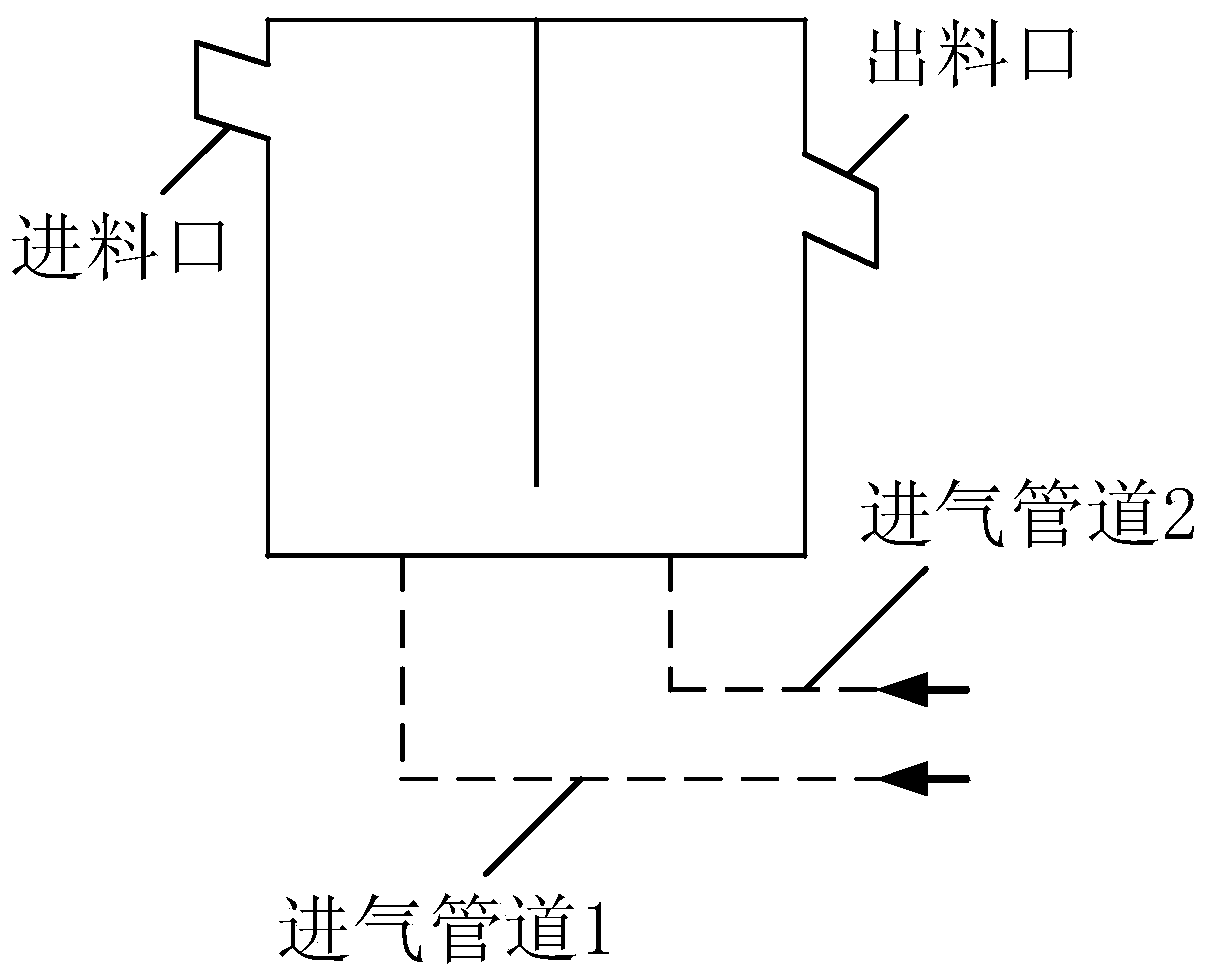

[0077]The screw feeder 4 is opposite to the inlet of the Venturi dryer 5; the outlet of the Venturi dryer 5 communicates with the inlet of the first cyclone preheater 6, and the outlet of the first cyclone preheater ...

Embodiment 2

[0101] System structure is the same as embodiment 1;

[0102] The carbon-containing gold ore Au content 16.93g / t that adopts, the mass percentage of C 5.82%, the mass percentage of As 0.35%, the mass percentage of S 7.35%, method is the same as embodiment 1, and difference is:

[0103] (1) Grinding to a particle size of -0.074mm accounts for 85% of the total mass to obtain fine ore;

[0104] (2) controlling the temperature of the material at the outlet of Venturi drier 5 is 140°C;

[0105] (3) The solid material is preheated to 400°C in the second cyclone preheater 7;

[0106] (4) The dearsenic roasting temperature is 680°C, and the residence time of fine ore in the pre-oxidation roaster is 18 minutes;

[0107] (5) The strong oxidation roasting temperature is 570°C, and the amount of oxygen introduced is O 2 1.2 times the amount required for the complete reaction of C and S in the pre-oxidized calcined powder; the volume concentration of oxygen in the strong oxidation suspe...

Embodiment 3

[0112] System structure is the same as embodiment 1;

[0113] The carbon-containing gold ore Au content 24.17g / t that adopts, the mass percent of C 17.56%, the mass percent of As 0.14%, the mass percent of S 8.21%, method is the same as embodiment 1, difference is:

[0114] (1) Grinding to a particle size of -0.074mm accounts for 90% of the total mass to obtain fine ore;

[0115] (2) controlling the temperature of the material at the outlet of Venturi drier 5 is 150°C;

[0116] (3) The solid material is preheated to 450°C in the second cyclone preheater 7;

[0117] (4) The dearsenic roasting temperature is 700°C, and the residence time of fine ore in the pre-oxidation roaster is 15min;

[0118] (5) The strong oxidation roasting temperature is 600°C, and the amount of oxygen introduced is O 2 1.3 times the amount required for the complete reaction of C and S in the pre-oxidized roasted powder; the volume concentration of oxygen in the strong oxidation suspension roaster is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com