Sludge two-grade united energy-saving drying device and method

A technology of sludge drying and drying device, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve problems such as sticking walls, and achieve the effects of fast drying rate, high thermal efficiency, and no mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

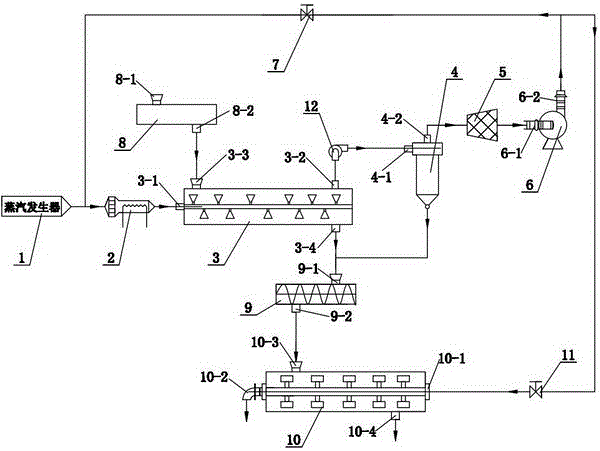

[0025] like figure 1 As shown, a sludge two-stage combined energy-saving drying device and method, including a steam generator 1, a heater 2, a direct stirring dryer 3, a cyclone dust collector 4, a filter 5, a steam compressor 6, a valve 7, Sludge pump 8, indirect sludge dryer 9, screw feeder 10, valve 11, fan 12. Feed port 8-1 and discharge port 8-2 of the sludge pump, feed port 2-3 and discharge port 2-4 of the direct stirring dryer, feed port 9-1 and discharge port of the screw feeder Port 9-2, feed port 10-1 and discharge port 10-2 of the indirect sludge dryer form a logistics channel. A steam generator 1, a heater 2, a direct stirring dryer 3, a fan 12, a cyclone dust collector 4, a filter 5, a steam compressor 6, and a valve 7 are connected in sequence to form a first-stage drying. Steam compressor 6, valve 11, hollow paddle dryer 10 form secondary drying. Heater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com