Sludge treatment system and treatment method thereof

A kind of sludge treatment and sludge technology, applied in the direction of temperature control sludge treatment, dehydration/drying/thickened sludge treatment, combustion method, etc., can solve the problems of high utilization cost, pipeline blockage, difficult treatment, etc. Achieve the effect of avoiding pyrolysis oil from clogging the pipeline, high thermal efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

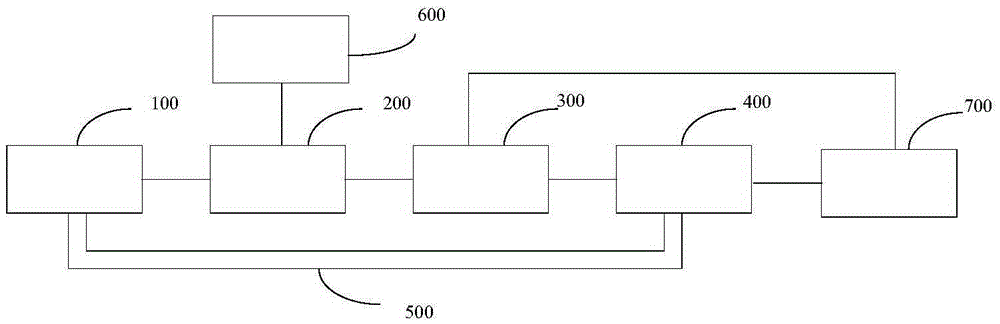

[0067] In this example, the sludge with a water content of 80% is used as raw material to treat the sludge, wherein the composition of the sludge is shown in Table 1, refer to Figure 7 , the specific sludge treatment steps of this implementation are as follows:

[0068] Table 1 Domestic sludge physical properties (wt%) (air-dry basis)

[0069]

[0070] (1) The sludge is sent to the feeding device through the conveying system, and the feeding device enters the sludge drying device through the feeding port, and is dried by superheated steam at 180°C to a moisture content of 40%, and then transported into the pyrolysis furnace;

[0071] (2) Pyrolysis of sludge: the main equipment for pyrolysis is a heat-free regenerative pyrolysis furnace, which includes a pyrolysis furnace, a regenerative gas radiant tube burner, and Auxiliary mechanisms such as cloth and output. The furnace bottom is a rotatable annular furnace bottom, and the regenerative gas radiant tube burner is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com