Patents

Literature

512results about How to "Increase filtration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological organic fertilizer prepared by aerobic fermentation of biogas residue and preparation method thereof

InactiveCN103848698AWon't burnDecompose thoroughlyBio-organic fraction processingWaste based fuelMicrobial agentPseudomonas

The invention provides a biological organic fertilizer prepared by aerobic fermentation of a biogas residue and a preparation method thereof. The preparation method comprises the steps: mixing the biogas residue and a swelling agent to form a fermentation raw material, inoculating a compound microbial agent in the fermentation raw material, uniformly mixing for fermenting, and adding urea, diammonium phosphate, a potassium chloride inorganic salt, brown nitrogen-fixing bacteria, mycorrhiza fungi, silicate bacteria, photosynthetic bacteria acetic bacteria, bifidobacterium, and saccharomycetes after the fermentation is completed to prepare the biological organic fertilizer, wherein the compound microbial agent comprises strains of bacillus, pseudomonas, staphylococcus, streptomyces, penicillium, aspergillus and trichoderma. The compound microbial agent prepared by using the biological organic fertilizer has a pertinence to aerobic fermentation of the biogas residue, and is capable of effectively increasing the fermentation rate of the biogas residue, shortening the fermentation time and realizing high-additional value production, innocent treatment and recycling of the biogas residue; and the problem of resources and environment of villages and small towns is solved, and the rapid development of construction of new countryside and towns and cities can be promoted.

Owner:青岛福瑞斯生物能源科技开发有限公司

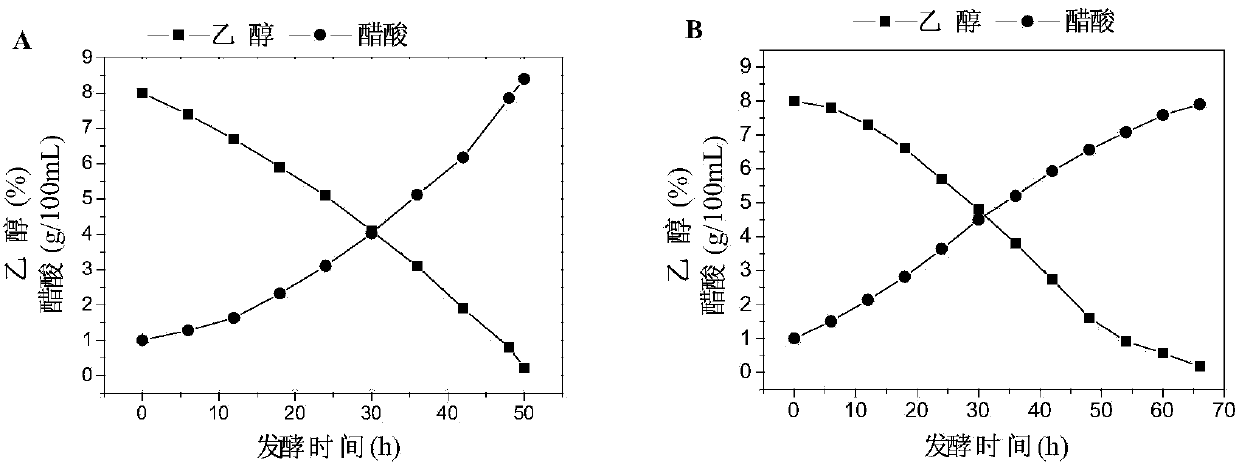

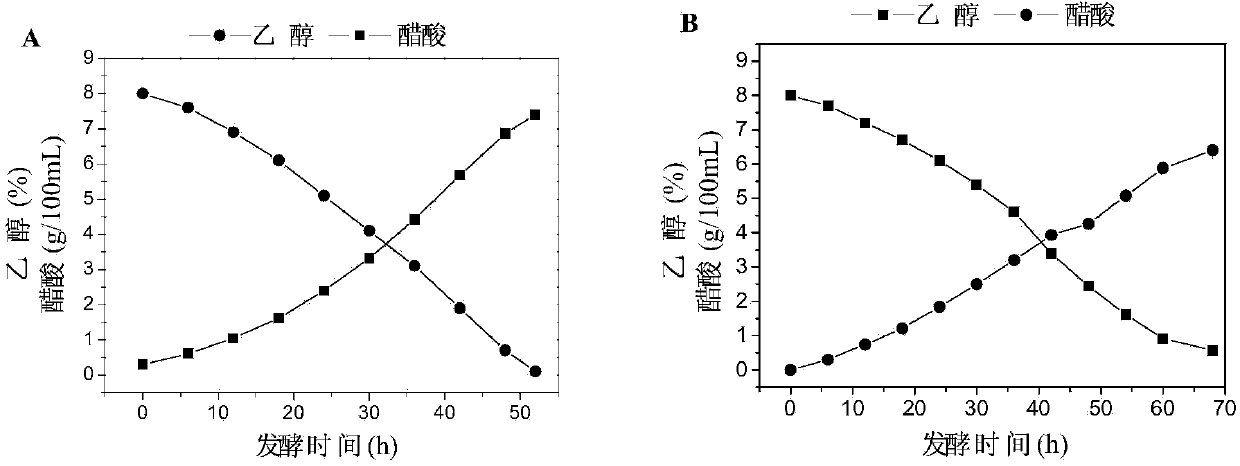

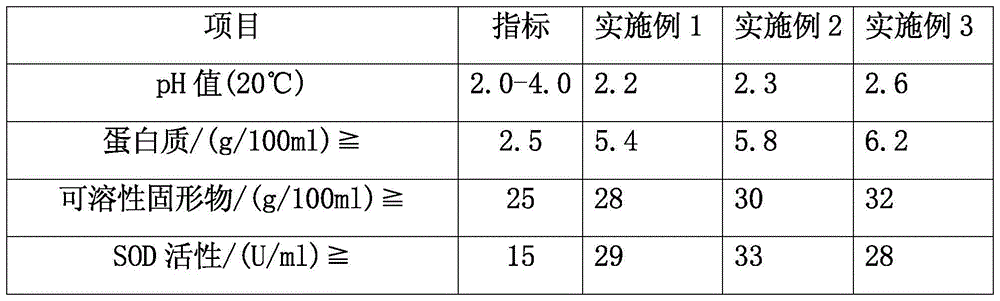

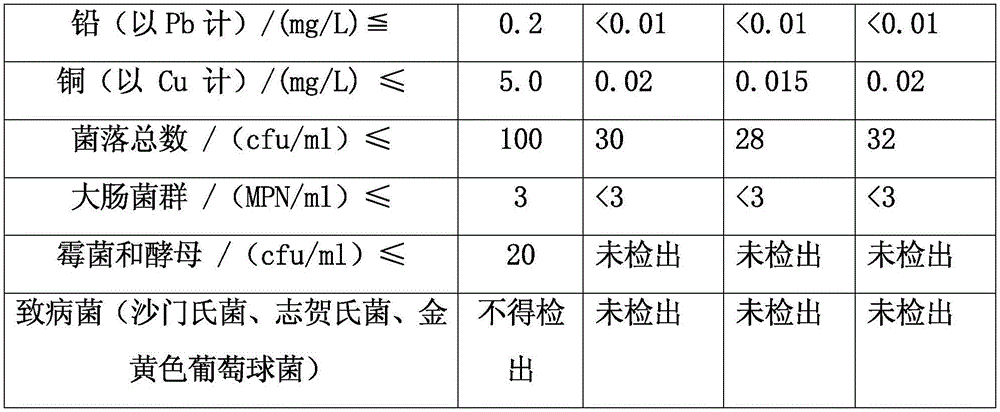

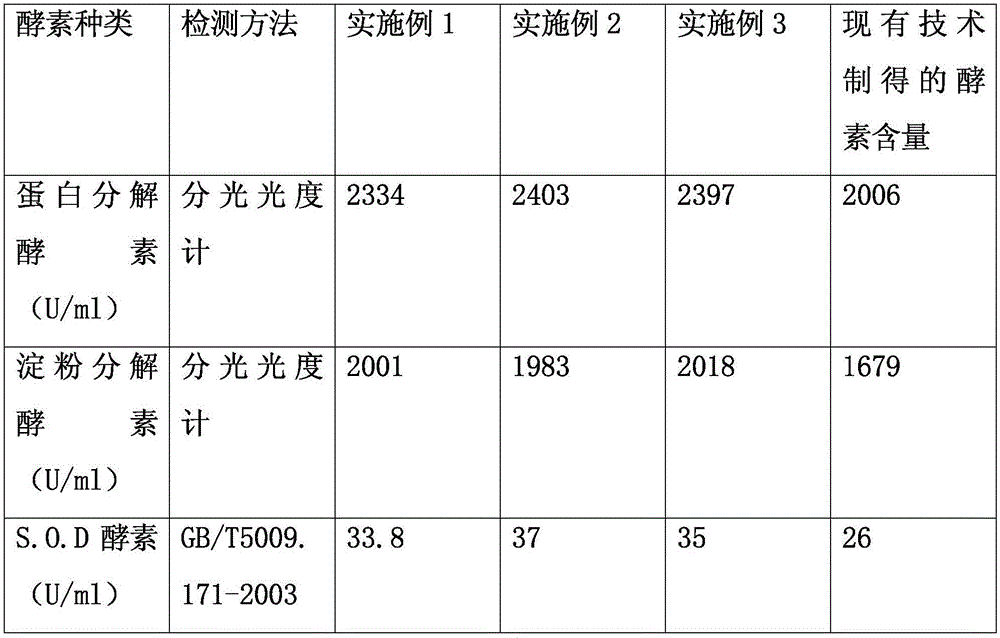

Kiwi fruit enzyme and preparation method thereof

InactiveCN105962343ASolve technical problems that are difficult to retainGuaranteed stabilityFood ingredient functionsPectinaseActinidia

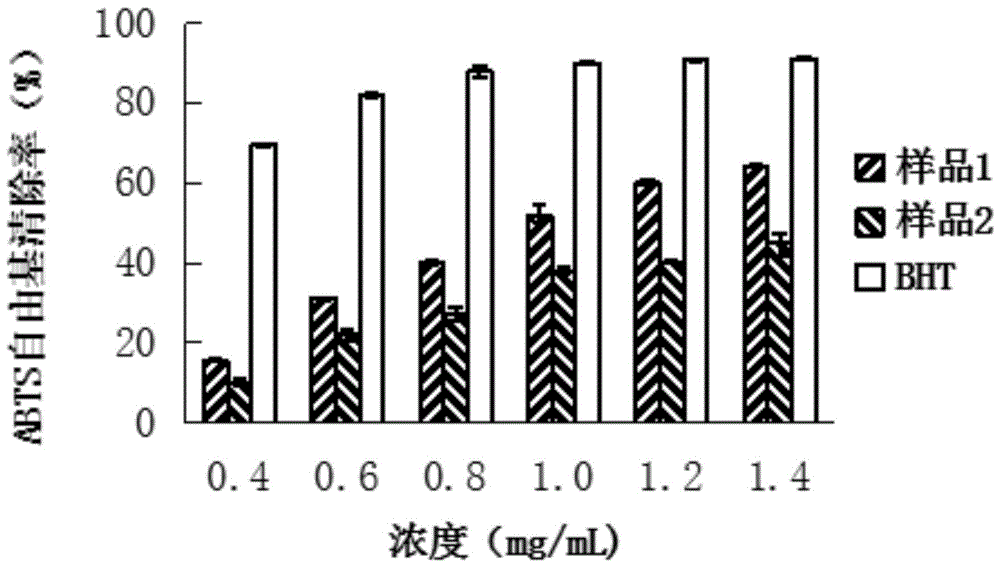

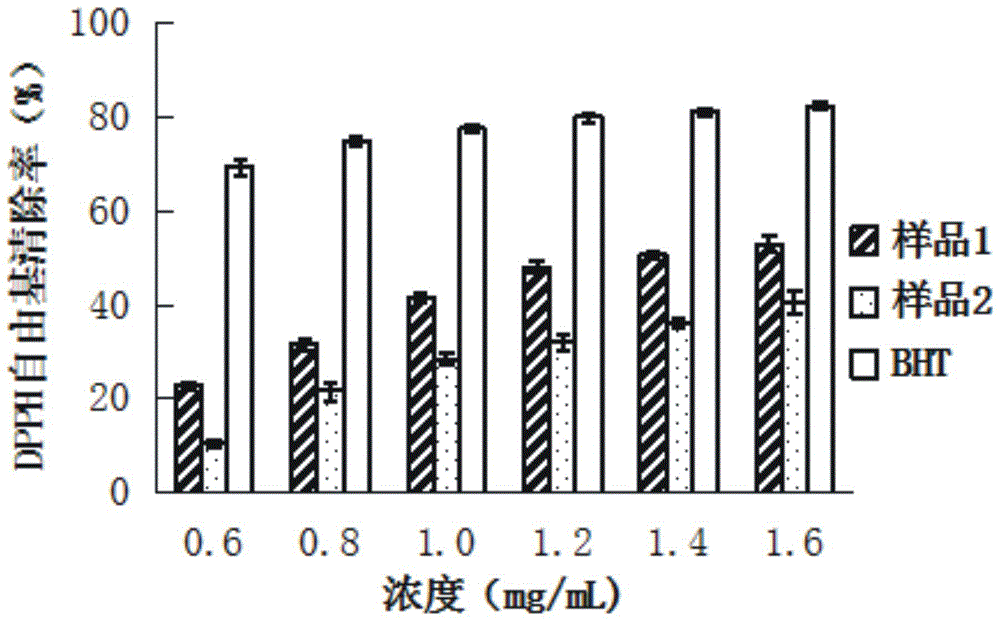

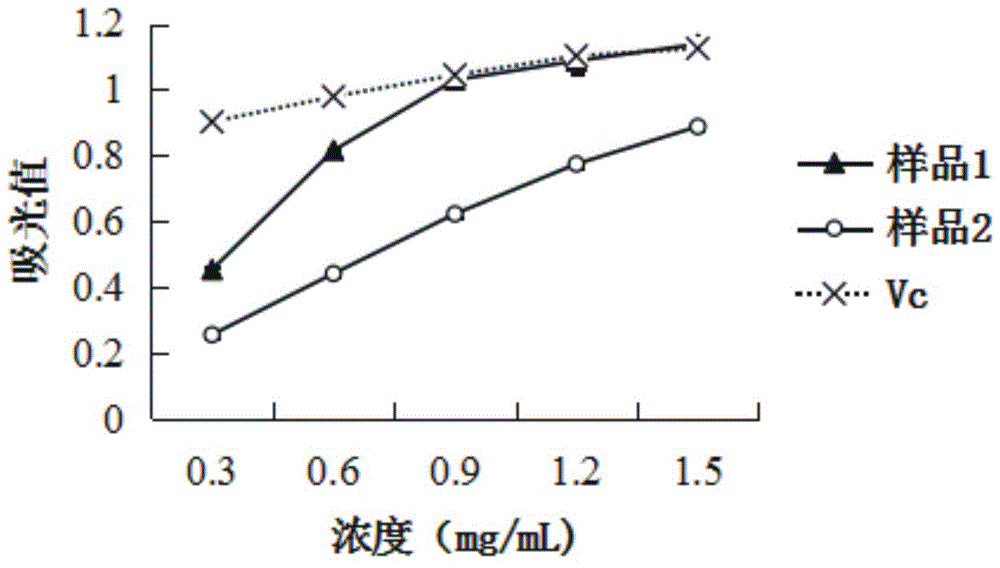

The invention discloses a preparation method of kiwi fruit enzyme with high anti-oxidation activity. A formula is characterized in that fresh kiwi fruits are adopted as raw materials, fruit skin is reserved for pulping after washing and deburring the kiwi fruits, and enzymolysis is carried out on kiwi fruit pulp by adding a composite enzyme preparation (which is prepared from pectinase, cellulose, hemicellulase, protease and diastase), so that the juice yield and the production efficiency are improved; then, a multi-strain symbiotic fermentation technology and a grading inoculation process are adopted, and fermentation and ageing are carried out on a product by sequentially adding saccharomycetes, acetic acid bacteria and lactic acid bacteria; finally, the purpose of removing bacteria is achieved through the technologies of kieselguhr filter, membrane filter and the like, so that continuous fermentation of the product is ended, the stability of the shelf life is ensured, and meanwhile, the activity of active ingredients and enzyme is maximum kept. The enzyme prepared through the preparation method has the characteristics of high anti-oxidation activity, richness in enzymes and high enzyme activity; the appearance is clear and transparent, the flavor is sour, sweet and gentle, and the fruity fragrance is elegant.

Owner:成都兴食尚食品研发设计中心(有限合伙)

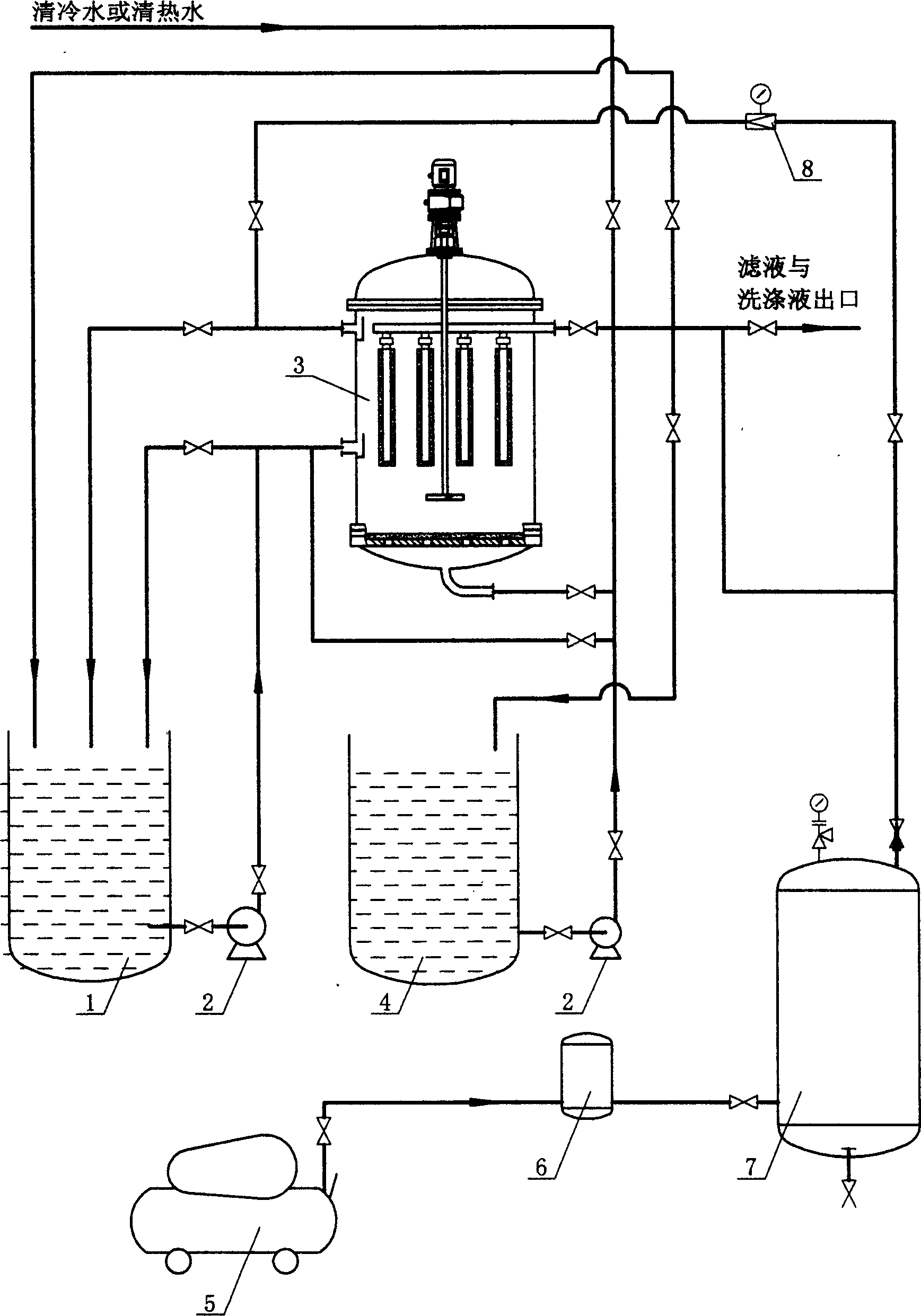

Filtration and washing technology in preparing metal or non metal fine granular powder

ActiveCN1686593AOvercome the disadvantages of filtrationHigh yieldFiltration circuitsEngineeringSpherical form

A filtering and washing process for preparing the metallic or non-metal fine particles includes filtering, washing, blow-drying of filtered cake, discharging and cleaning filter. Said filtering step features use of the precise millipore filter with at least two filter regions for respective filtering. Said washing step includes reversely blowing the washing liquid to drop the filtered cake onto filter plate, instantaneously reversely blowing compressed air several times, and stirring the mixture of filtered cake and washing liquid.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

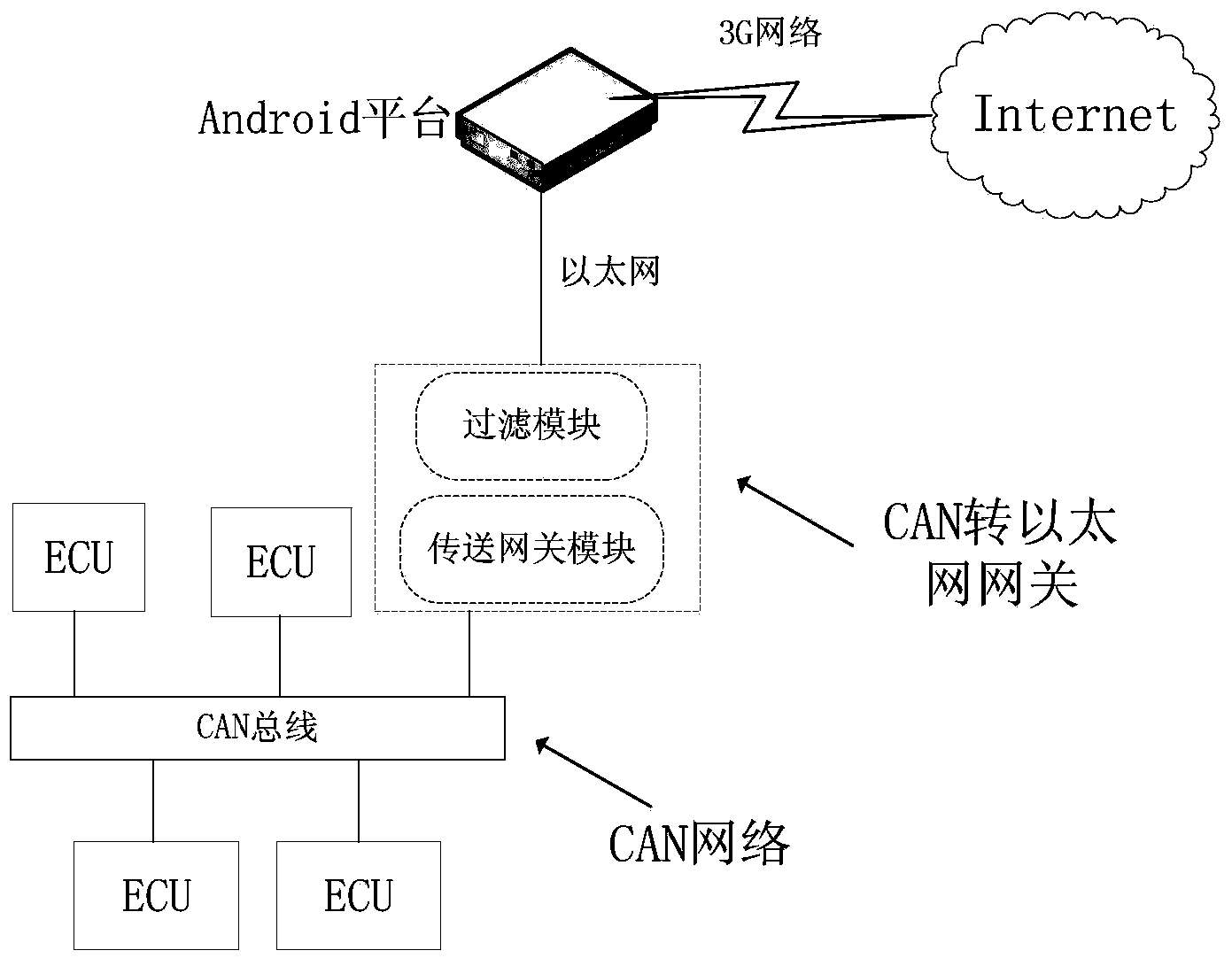

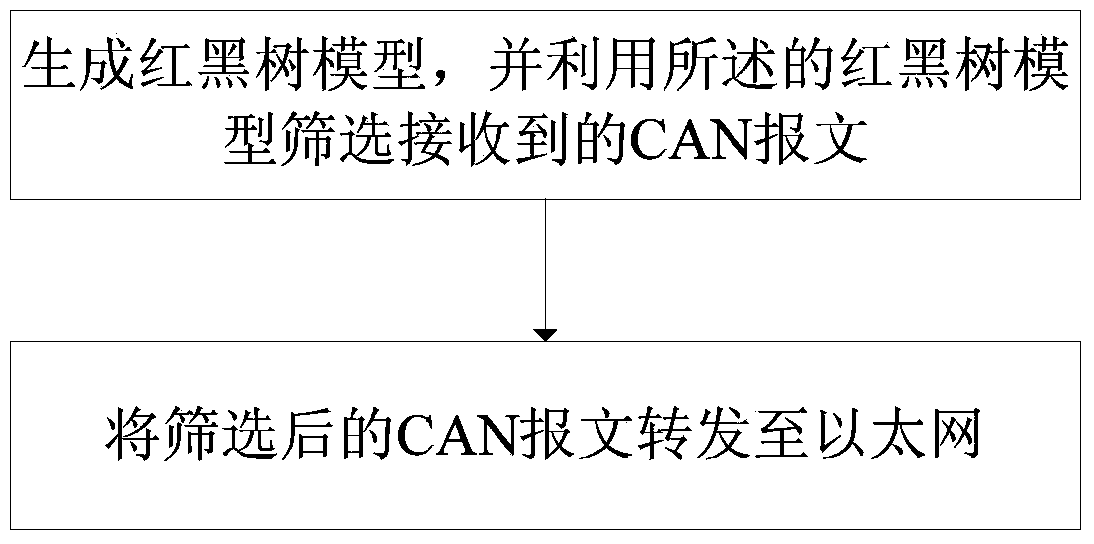

CAN (Controller Area Network) to Ethernet gateway with filtering function and data transmission method based on gateway

ActiveCN103812765AIncrease forwarding rateReduce consumptionNetwork connectionsTraffic capacitySearch data structure

The invention discloses a CAN (Controller Area Network) to Ethernet gateway with a filtering function and a data transmission method based on the gateway. The CAN to Ethernet gateway with the filtering function comprises a filtering module for generating a red-black tree model according to the configuration of a host, and screening received CAN messages by using a red-black tree, and a transmission gateway module for forwarding the screened CAN messages to the Ethernet. The gateway is provided with the filtering module, the filtering module is used for screening the received CAN messages, and the transmission gateway module is used for only forwarding the screened CAN messages, thereby lowering the flow consumption. Moreover, by organizing a searched data structure through the red-black tree model, a judgment on whether received CAN messages have matched configuration or not can be made rapidly by searching the red-black tree to finish screening.

Owner:ZHEJIANG UNIV

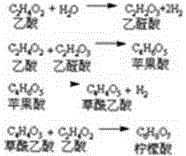

Multifunctional enzyme vinegar

InactiveCN106119055AHigh in nutrientsHigh in acetic acidMicroorganism based processesVinegar preparationRed yeast riceAspergillus niger

The invention relates to the technical field of food, and particularly relates to multifunctional enzyme vinegar. The multifunctional enzyme vinegar comprises the following raw materials in parts by weight: 10-50 parts of starch raw material, 20-60 parts of fruits, 20-60 parts of vegetable, 1-3 parts of aspergillus niger, 1-2 parts of aspergillus oryzae, 10-20 parts of Daqu, 5-10 parts of Chinese koji, 5-10 parts of red yeast rice, 2-4 parts of yeast, 0.15-0.4 part of lactic acid bacteria, and 4-7 parts of acetic acid bacteria. In the enzyme vinegar, total acid is greater than 11g / 100 mL, citric acid is greater than 2g / 100 mL, malic acid is greater than g / 100 mL, and lactic acid is greater than 1 g / 100 mL. the invention further relates to a preparation method of the enzyme vinegar. The enzyme vinegar is rich in nutrients, and mellow in mounthfeeling, the proportion of total acid to non-volatile acid is proper, and the enzyme vinegar has multiple nutritional health-care efficacies of strengthening the stomach, moistening intestine, calming down and relieving thirsty, reducing blood pressure and blood lipid, being anti-oxidant and anti-aging, and the like.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

Hydroxymethylated lignin and application thereof

The invention relates to the technical field of organic chemical engineering, especially a hydroxymethylated lignin which is prepared by the following steps: after filtering lignin with black liquor, reacting with formaldehyde at 60-90 DEG C for 1-2 hours, adding acetone to continue the reaction for 1-2 hours, cooling to room temperature after the reaction finishes, carrying out acid precipitation, filtering and drying to obtain the hydroxymethylated lignin. The invention also relates to application of the hydroxymethylated lignin in preparing polyurethane foam. The used lignin is corn cob lignin black liquor, the production conditions are mild, and the lignin in the black liquor still has the structure of the natural lignin and has higher hydroxy content and higher compatibility with polyether glycol; and thus, the hydroxymethylated lignin has the advantages of higher activity, higher purity and higher dispersity. When being used for preparing polyurethane hard foam, the hydroxymethylated lignin lowers the production cost, has excellent properties and enhances the competitive power of the product.

Owner:JINAN SHENGQUAN GRP SHARE HLDG CO LTD

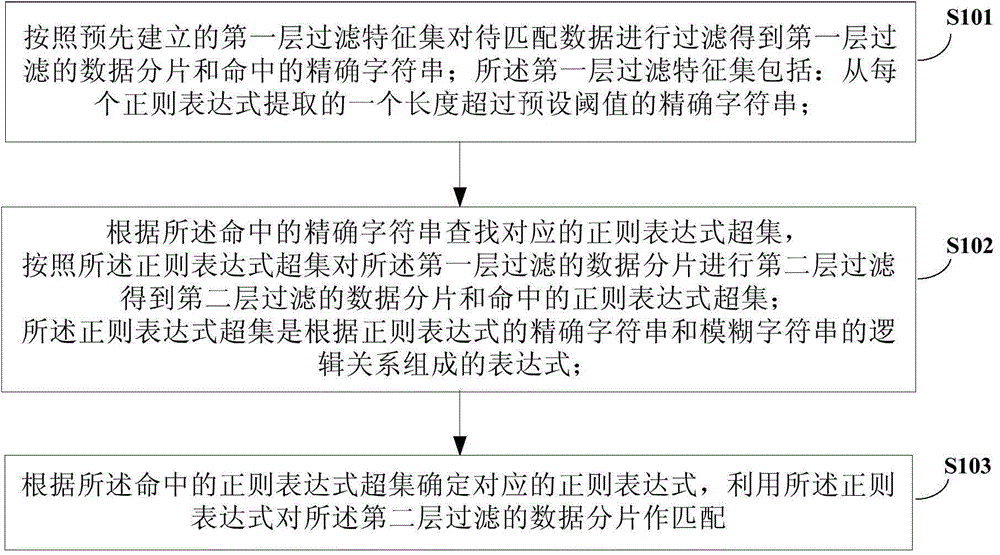

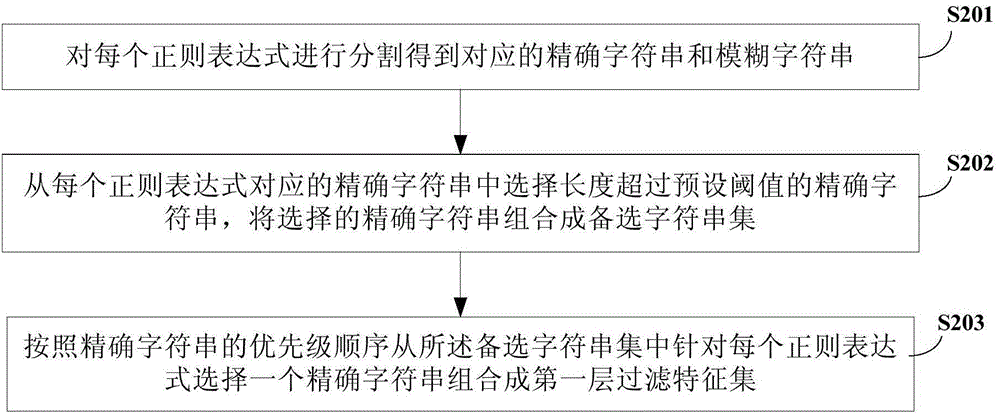

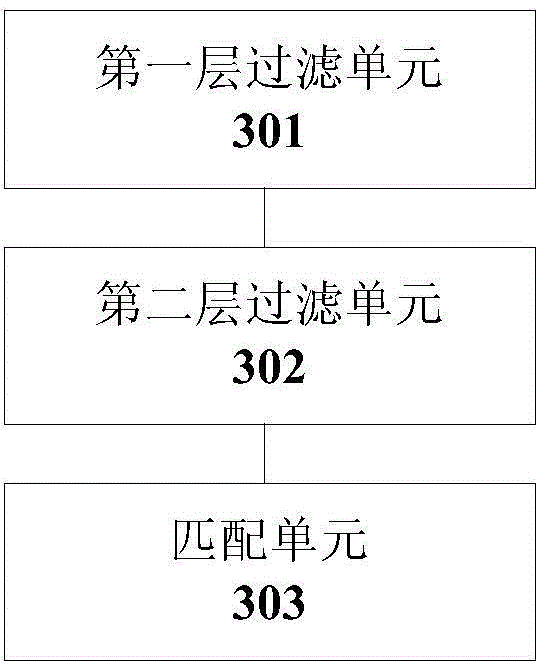

Multi-mode regular expression matching method and apparatus

ActiveCN104899264ALower pass rateImprove filtering effectOther databases queryingSpecial data processing applicationsData segmentFeature set

The present invention provides a multi-mode regular expression matching method and apparatus. The method comprises: filtering to-be-matched data according to a fist layer filter feature set to obtain data segments and targeted exact character strings upon the first layer filtering; searching for a corresponding regular expression superset according to the targeted exact character strings, and conducting second layer filtering on the data segments obtained via the first layer filtering to obtain data segments and a targeted regular expression superset upon the second layer filtering; determining a corresponding regular expression according to the targeted regular expression superset, and matching the data segments upon the second layer filtering by using the regular expression. According to the technical solutions provided by the present invention, the filtering rate and effect are improved via two layer filtering, thereby ensuring stability of the matching performance, and preventing passage of pure data.

Owner:NEUSOFT CORP

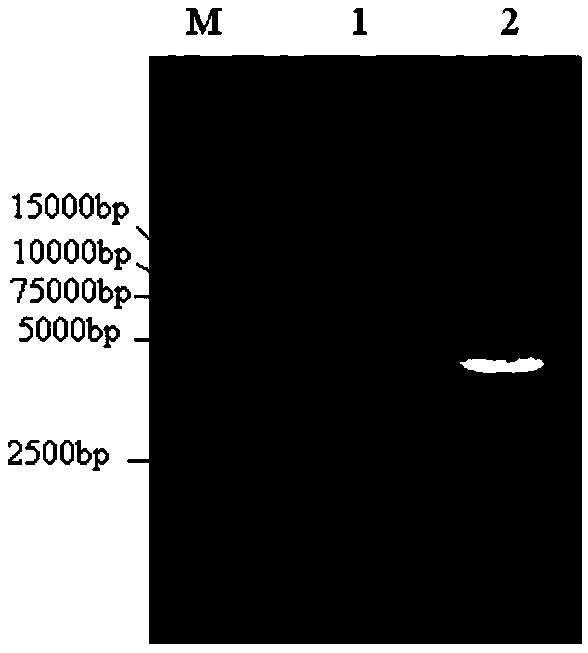

Genetic engineering acetic acid bacteria of overexpressing coenzyme PQQ (pyrroloquinoline quinone) synthetic proteins and application of bacteria

ActiveCN103740629AIncrease concentrationSimultaneous synthesisBacteriaMicroorganism based processesEthanol dehydrogenaseIn vivo

The invention relates to a building method of genetic engineering acetic acid bacteria of recombinantly expressing coenzyme PQQ (pyrroloquinoline quinone) synthetic proteins. The PQQ biosynthetic proteins are PqqA, PqqB, PqqC, PqqD, PqqE, and functional equivalents thereof. An alcohol dehydrogenase promoter from acetobacter pasteurianus and a coenzyme PQQ synthetic protein gene cluster pqqABCDE sequence are orderly connected into plasmids which can be stably copied in the acetic acid bacteria, so as to recombine pBBR-padh-pqq; recombinant plasmid pBBR-padh-pqq is transferred into the acetic acid bacteria, so as to obtain the genetic engineering acetic acid bacteria of overexpressing the coenzyme PQQ synthetic proteins. Thus, the concentration of in vivo coenzyme PQQ of the acetic acid bacteria in the fermentation process of acetic acid is improved. Acetic acid fermentation is carried out by using the genetic engineering bacteria disclosed by the invention, the fermentation delay phase can be shortened, and the fermentation rate of the acetic acid is increased. Thus, the production cost is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

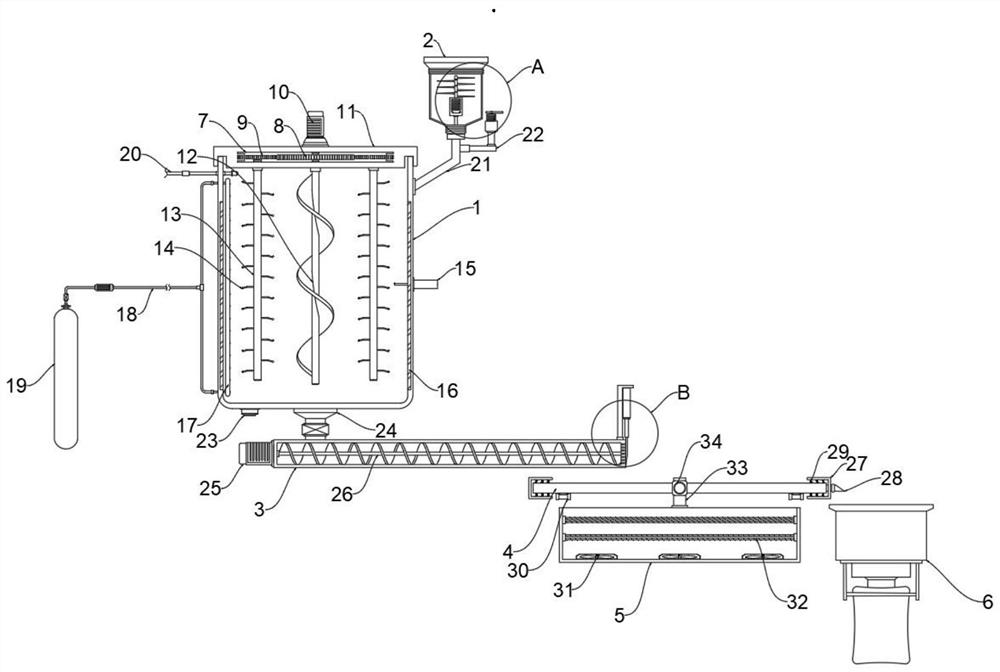

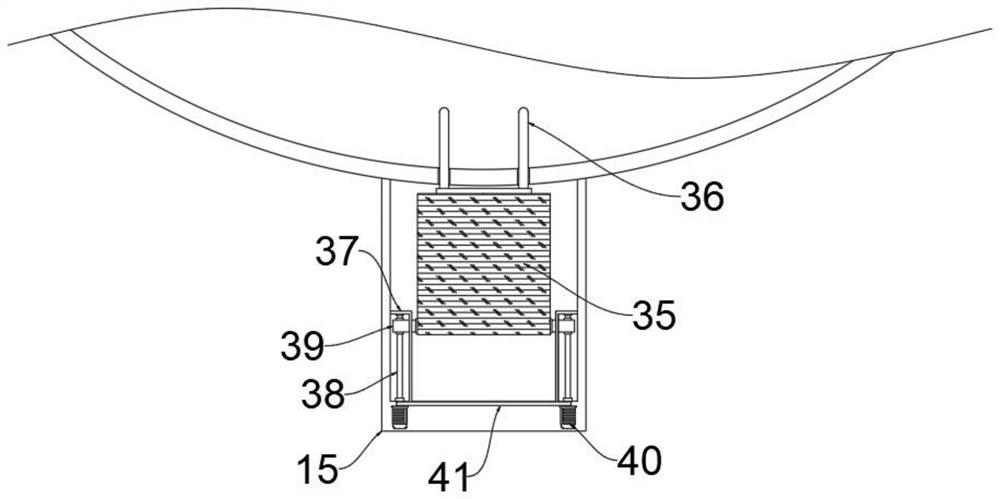

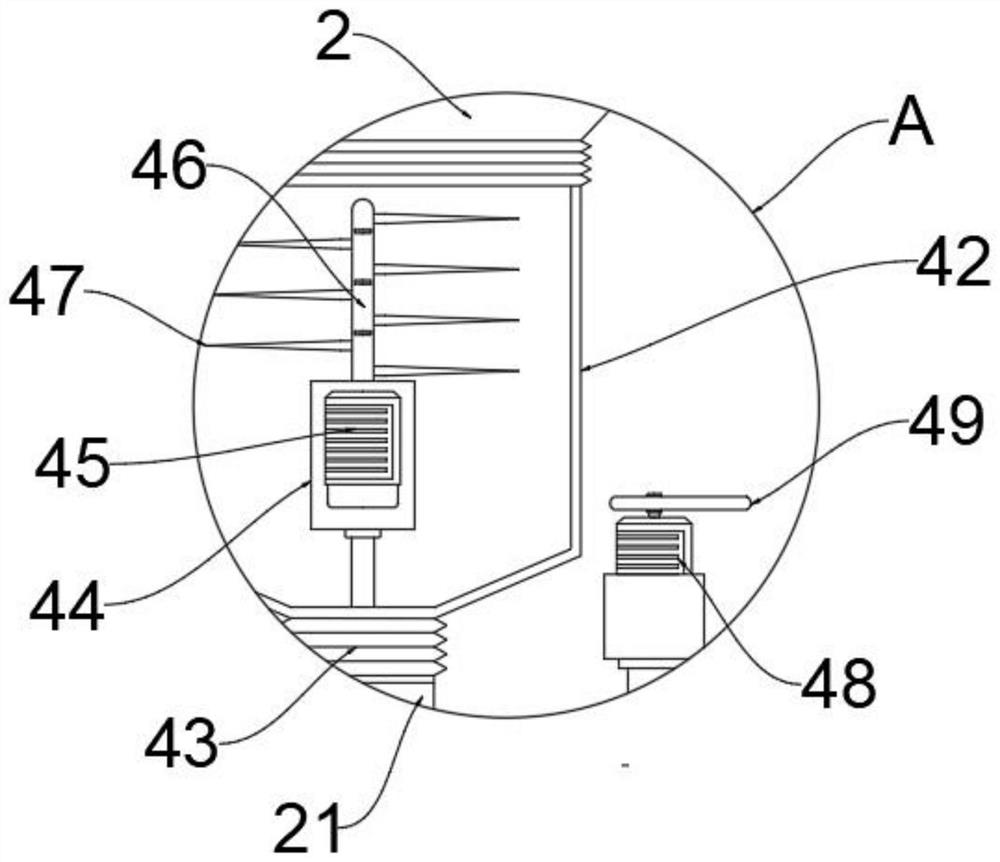

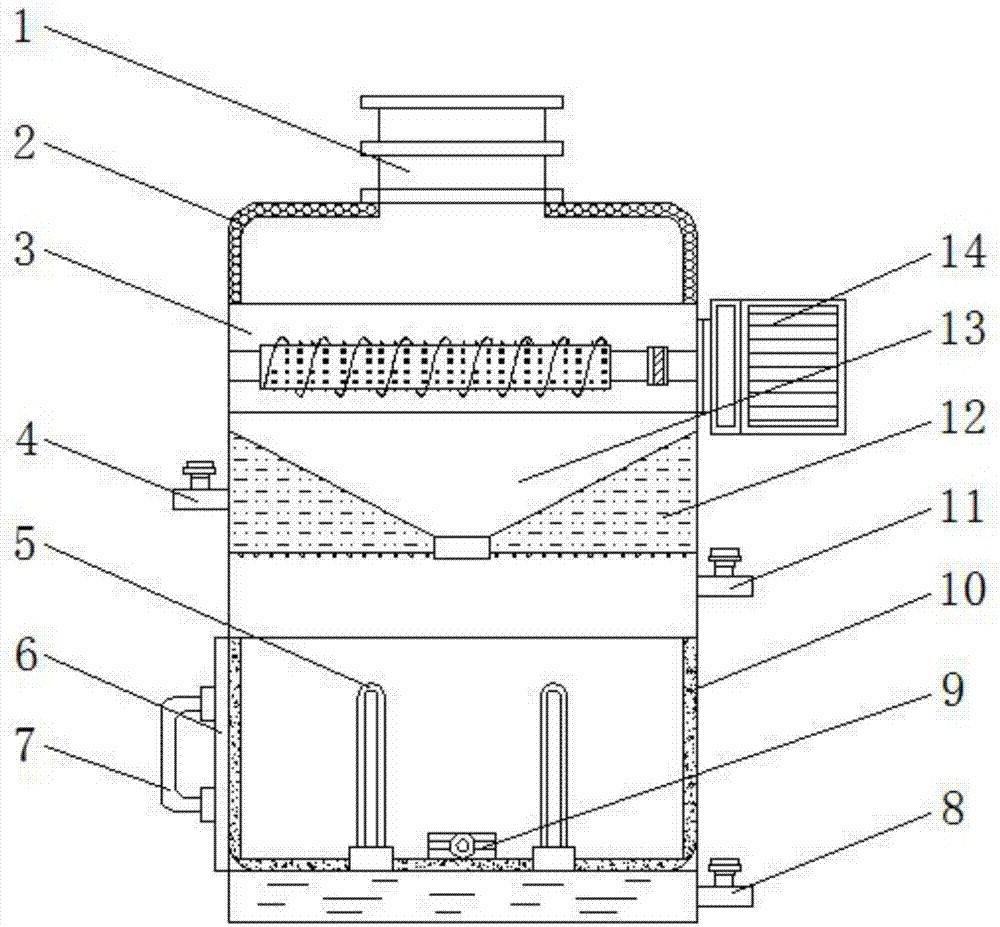

Fermentation packaging device for bio-fertilizer processing and using method thereof

InactiveCN112694358AGuaranteed response qualityReduce occupancyBio-organic fraction processingSolid materialFertilizerAgricultural engineering

The invention discloses a fermentation packaging device for bio-fertilizer processing and a using method thereof. The fermentation packaging device comprises a fermentation cylinder and an upper cover arranged at the upper end of the fermentation cylinder; a crushing cylinder which is installed on one side of the upper end of the upper cover, wherein a crushed material inlet is formed in the upper portion of the crushing cylinder; a moisture sensor which is mounted in a moisture detection device; a plurality of air nozzles which are arranged in sequence are arranged on one side of an oxygen supplementing pipe; a spiral conveying blade which is rotationally mounted in a conveying extrusion device; and a drying hopper which is arranged on one side of the lower end of the conveying extrusion device, wherein a mesh cage is arranged at the bottom of the drying hopper, and the interior of the drying hopper is of a cavity structure. On one hand, the requirements for moisture, temperature and oxygen can be met in the fermentation process of different materials, the reaction rate between the materials is increased in an external auxiliary mode, on the other hand, the fermented fertilizer is rapidly extruded and dried, and the drying efficiency of the biological fertilizer is improved through cooperation of the drying hopper and the drying device.

Owner:李彤

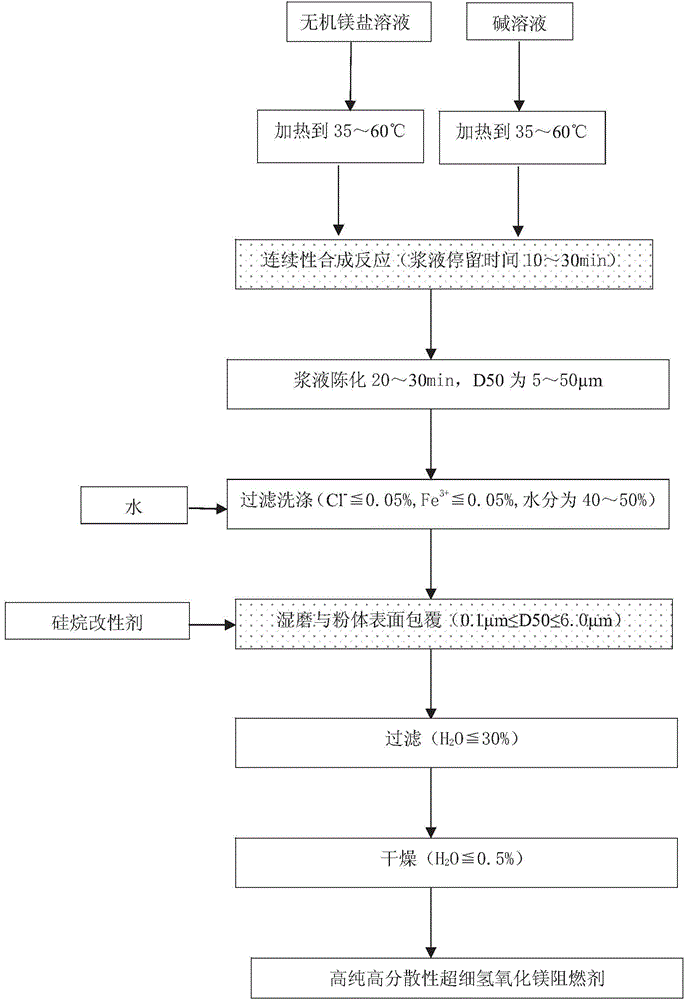

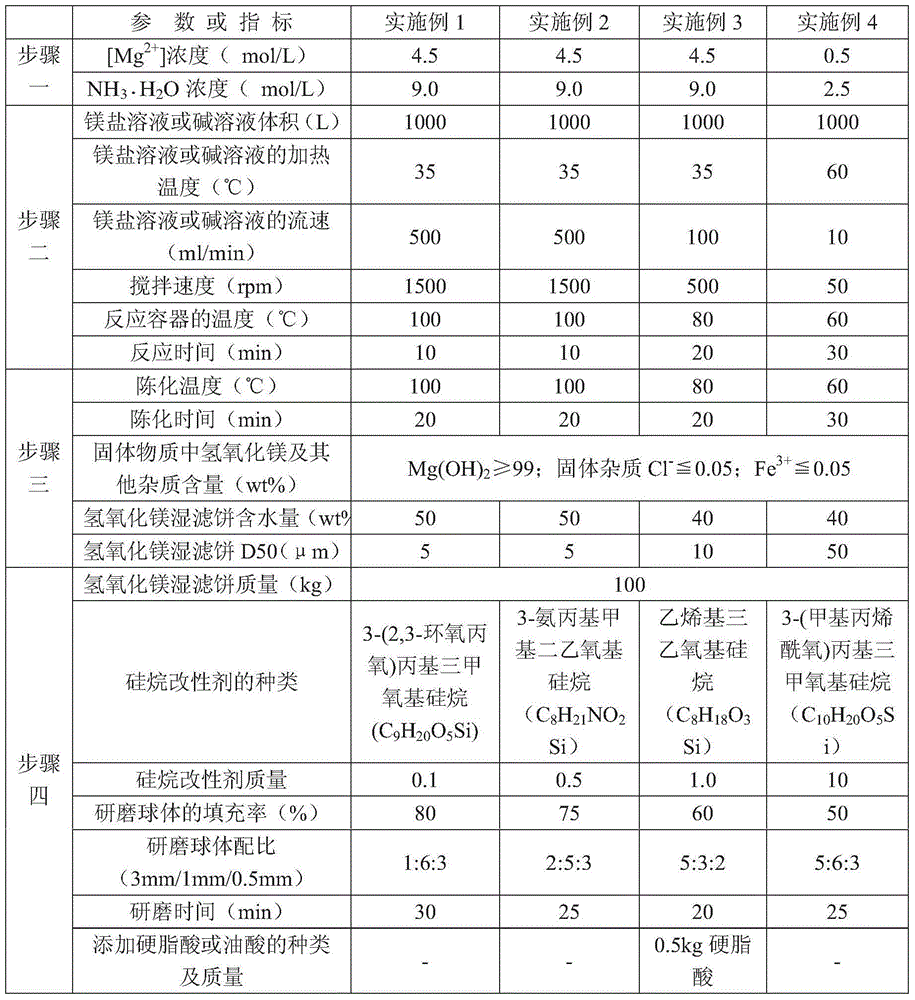

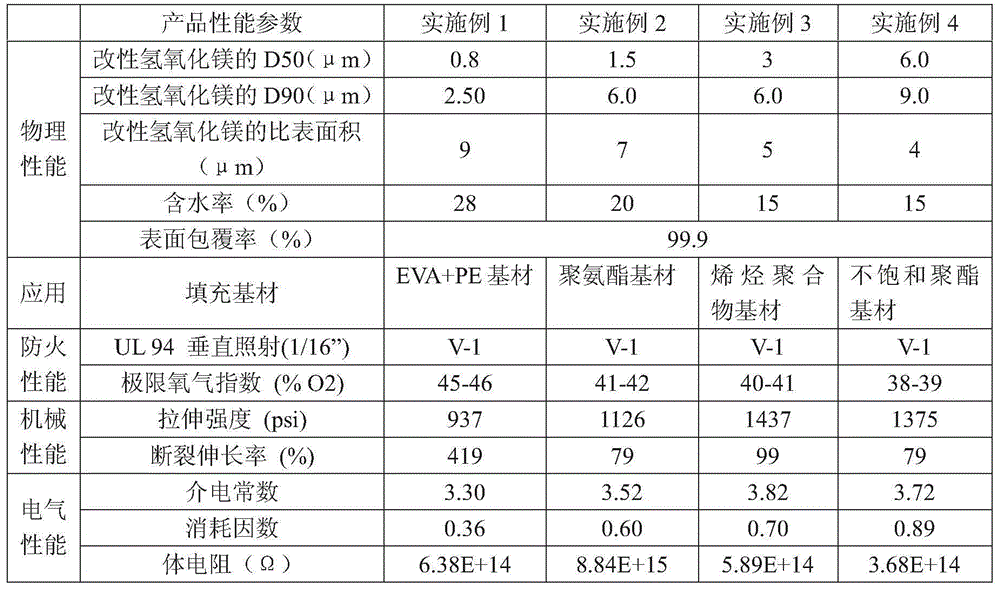

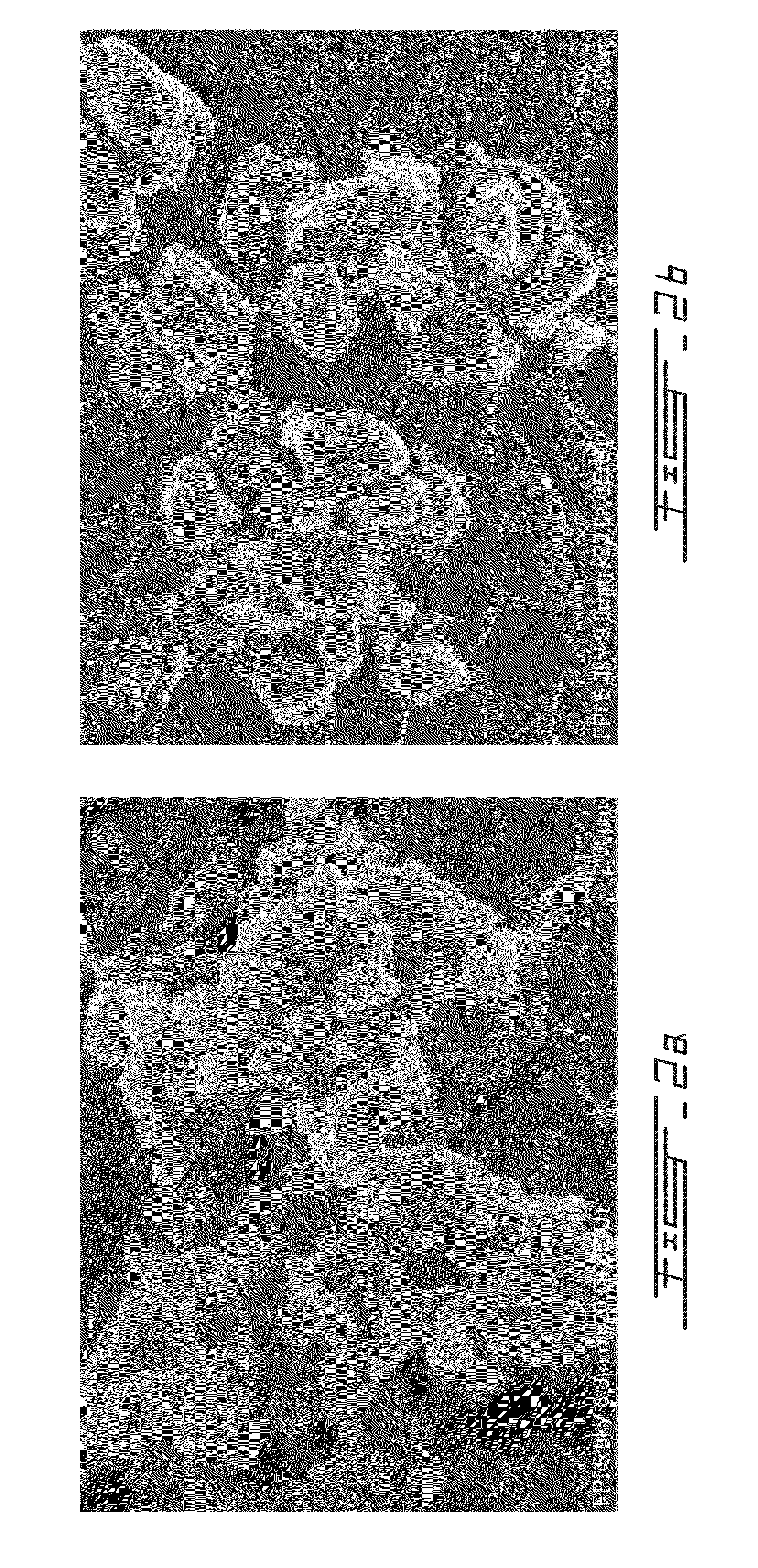

Method for preparing magnesium hydrate flame retardant

ActiveCN104592789AAddressing Purity IssuesSolve for uniformityPigment treatment with organosilicon compoundsPigment physical treatmentDispersityWet grinding

The invention discloses a method for integrally preparing a high-dispersity ultrafine magnesium hydroxide flame retardant, which comprises the following steps: continuously synthesizing high-purity magnesium hydroxide; and carrying out single cycle wet grinding and surface modification on magnesium hydroxide and integrally implementing particle size control and surface processing of the magnesium hydroxide flame retardant. According to the invention, the technical difficulties of control on purity, slurry viscosity, particle size, particle size distribution and specific surface area of the magnesium hydroxide flame retardant, the existence of the phenomena of secondary coagulation and bonding during the drying process and the like; a hydrophilic surface of magnesium hydroxide flame retardant powder is modified into a lipophilic surface, so that the intermiscibility and dispersity of the powder in a macromolecule polymeric material are improved, the influence of the high-dispersity ultrafine magnesium hydroxide flame retardant on the processing performance and the mechanical performance of a polymer product is reduced, and the comprehensive properties of the macromolecule polymer, such as flame retardance, processing, mechanics, electrics, are optimized.

Owner:江苏艾特克阻燃材料有限公司

Garbage enzyme preparation method utilizing fruit peels

The invention provides a garbage enzyme preparation method utilizing fruit peels. The preparation method comprises the following steps: the fruit peels are inoculated with an anaerobic bacterium for 10 to 20 days of anaerobic fermentation, and a first filtrate is reserved after filtering of the obtained product; fruit peel dregs are then inoculated with an aerobic bacterium for 5 to 15 days of aerobic fermentation, the fermentation continues for 5 to 10 days after white wine is added, and the product is then filtered; filtrates obtained through the two filtering processes are respectively concentrated and then mixed, molasses is added, the mixture is then inoculated with a beneficial bacterium, and garbage enzyme is obtained after 10 to 20 days of sealed storage. The garbage enzyme preparation method provided by the invention has the advantages that the effects of mildew of the fruit peels during fermentation are effectively avoided, so as to reduce the nitrite content, and ensure that the prepared fruit peel enzyme is healthy and unique; meanwhile, the enzyme content in the garbage enzyme is further increased, so as to improve the functional effects of the garbage enzyme; the fruit peels are used as raw materials, so as to achieve the effect of turning waste into wealth, and improve the waste utilization rate.

Owner:北海万物盛生物技术开发有限公司

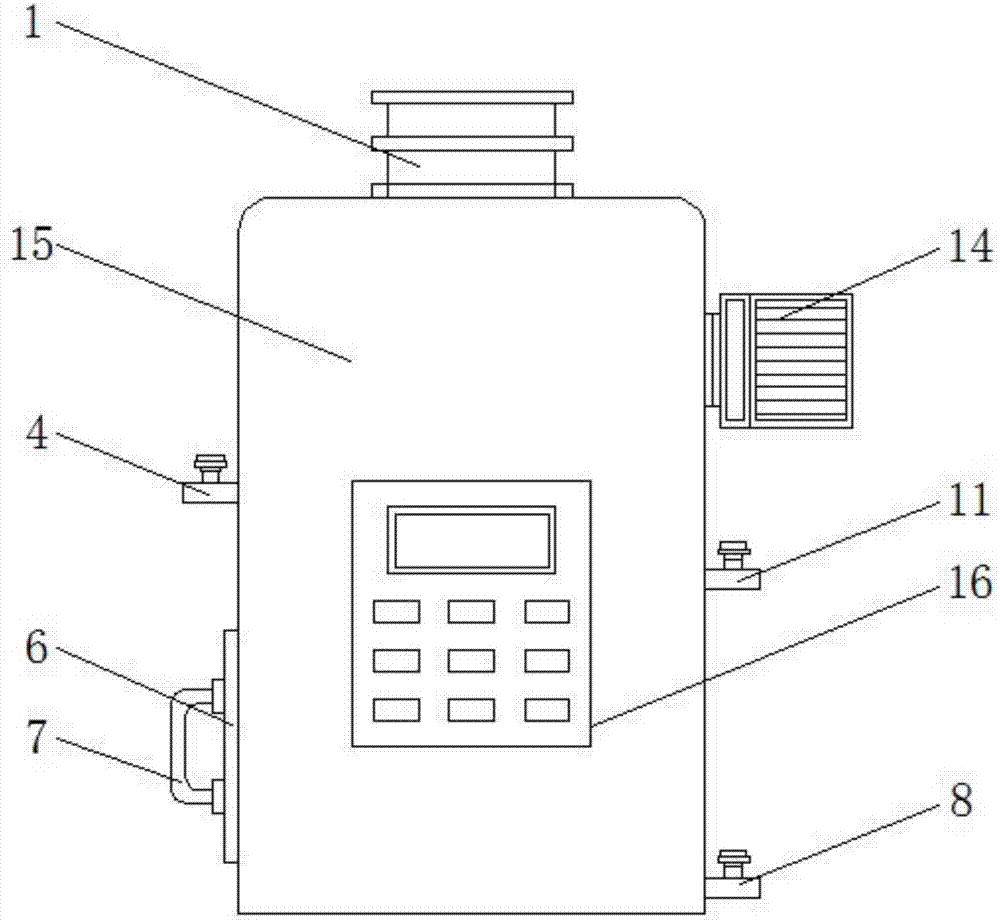

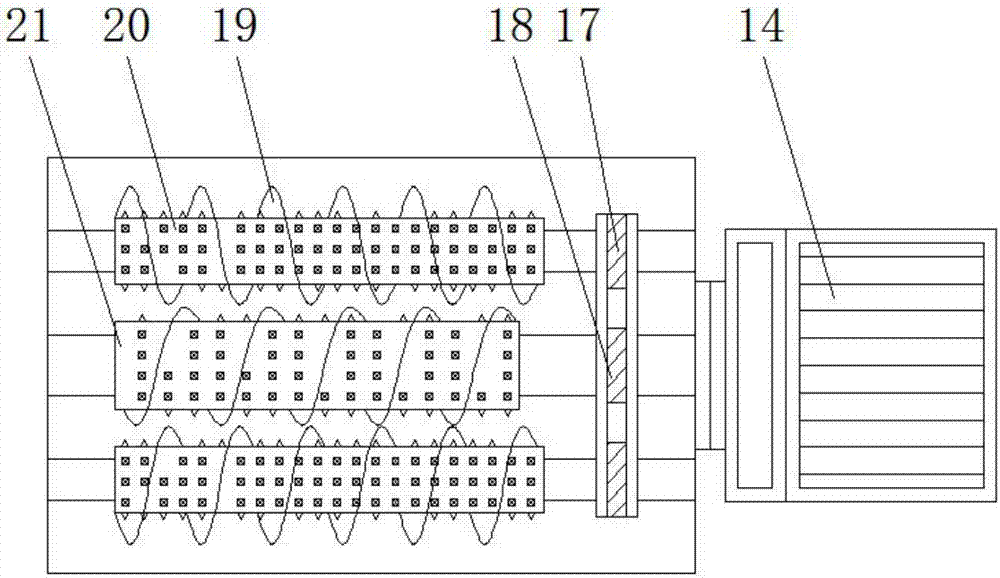

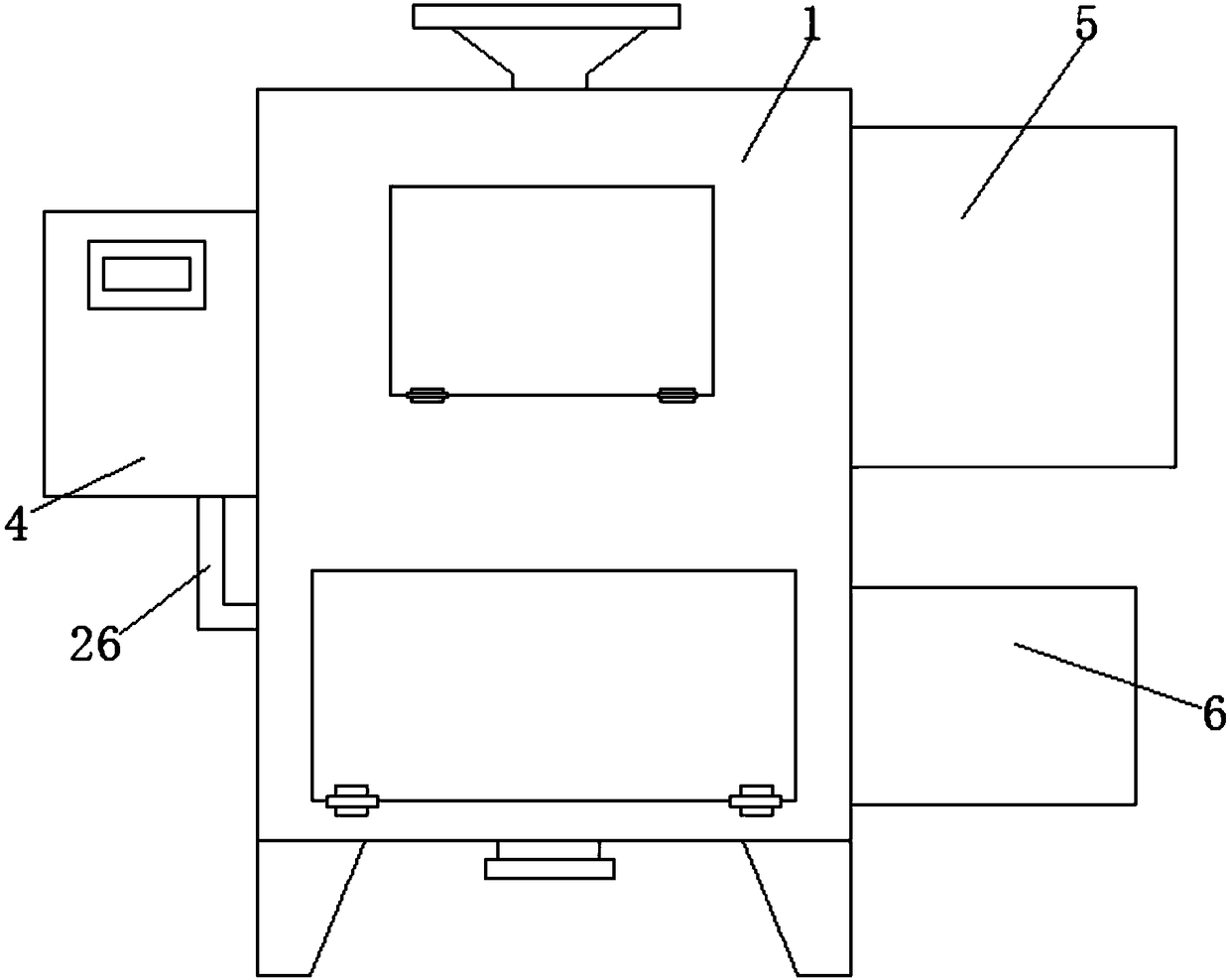

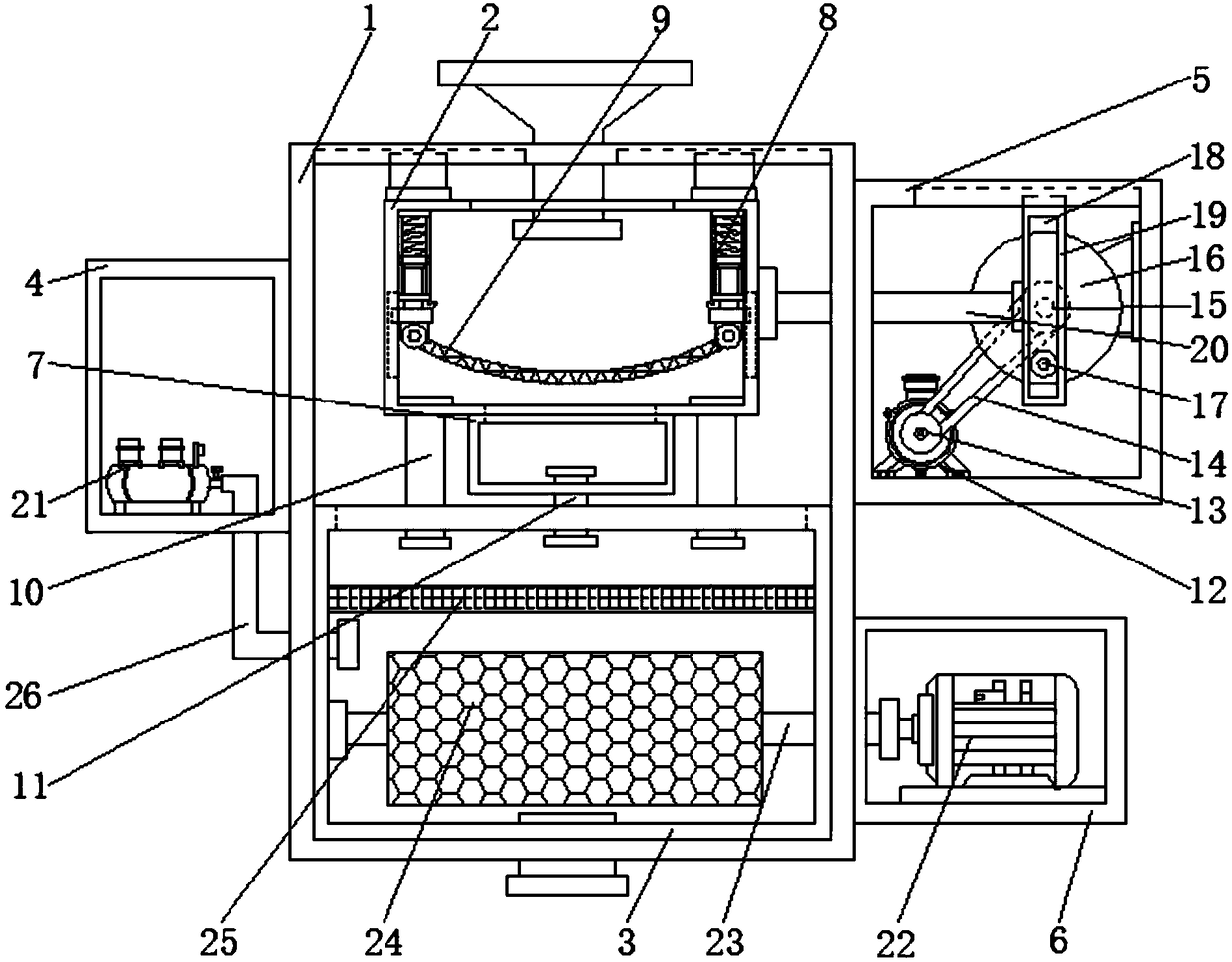

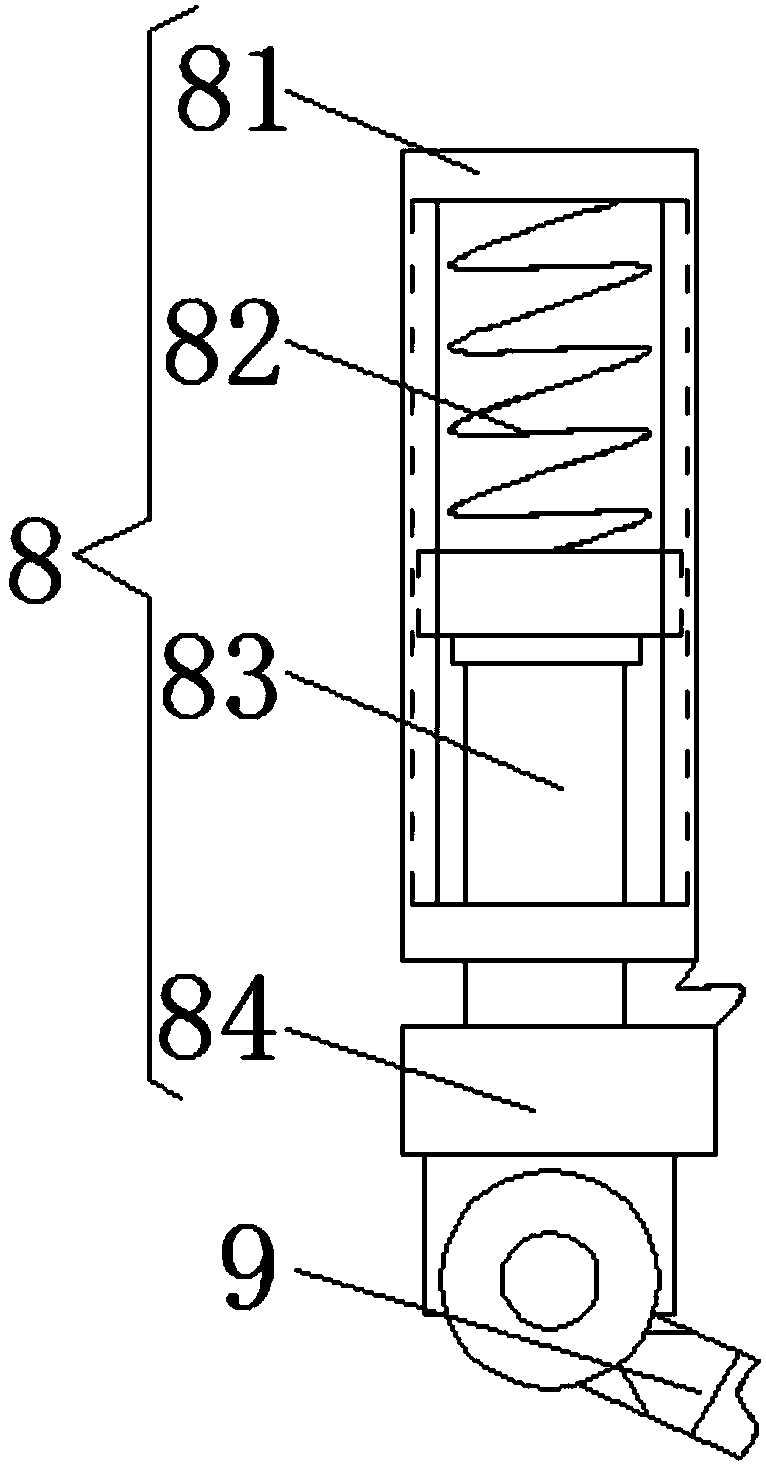

Sealing type kitchen waste fermenting machine

InactiveCN107297380AEasy to removeEasy to useGas treatmentSolid waste disposalDrive wheelDrive shaft

The invention discloses a sealing type kitchen waste fermenting machine. The machine comprises a machine body, a crushing device, a fermenting vessel, a motor and a control box, wherein a feeding port is formed in the top end of the machine body; a side door is mounted at the bottom end of one side of the machine body; a handle is mounted on the side door; a water inlet is formed in the machine body above the side door; a water outlet is formed in the bottom end of the other side of the machine body; an air inlet is formed in the machine body above the water outlet, and the motor is mounted on the machine body above the air inlet; the control box is mounted at one side of the machine body. According to the machine, a driving shaft, a driven shaft, a driving wheel, a driven wheel, stirring blades and the motor are mounted; when waste enters the crushing device, the driving shaft and the driving wheel are driven by the motor to rotate, the driven wheel is driven by the driving wheel through a belt, the driven shaft can be driven to rotate, big residues in the waste can be crushed through the stirring blades on the driving shaft and the driven shaft, so that the waste can be conveniently and comprehensively contacted with air to be fermented.

Owner:安徽星元环保科技有限公司

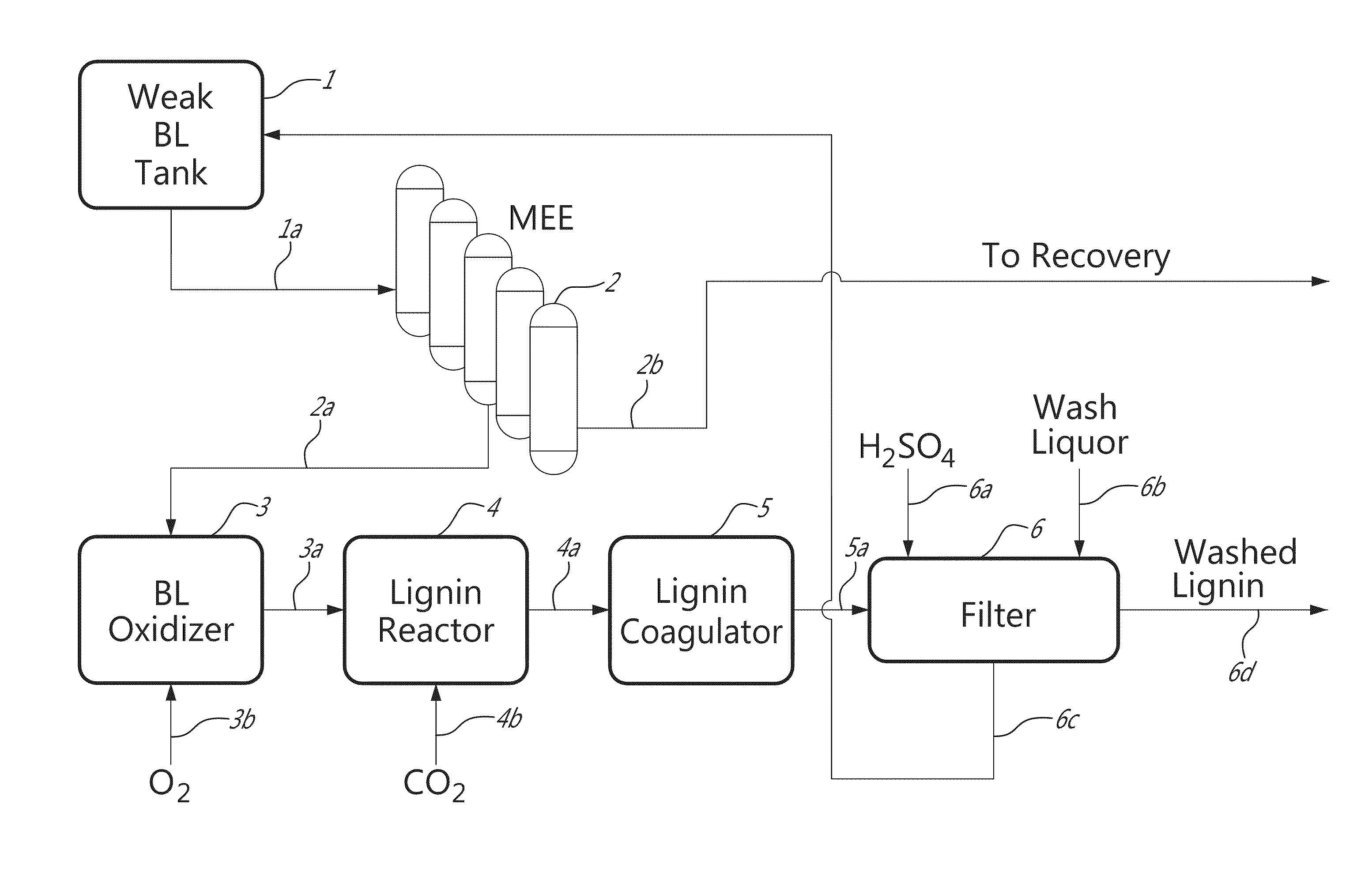

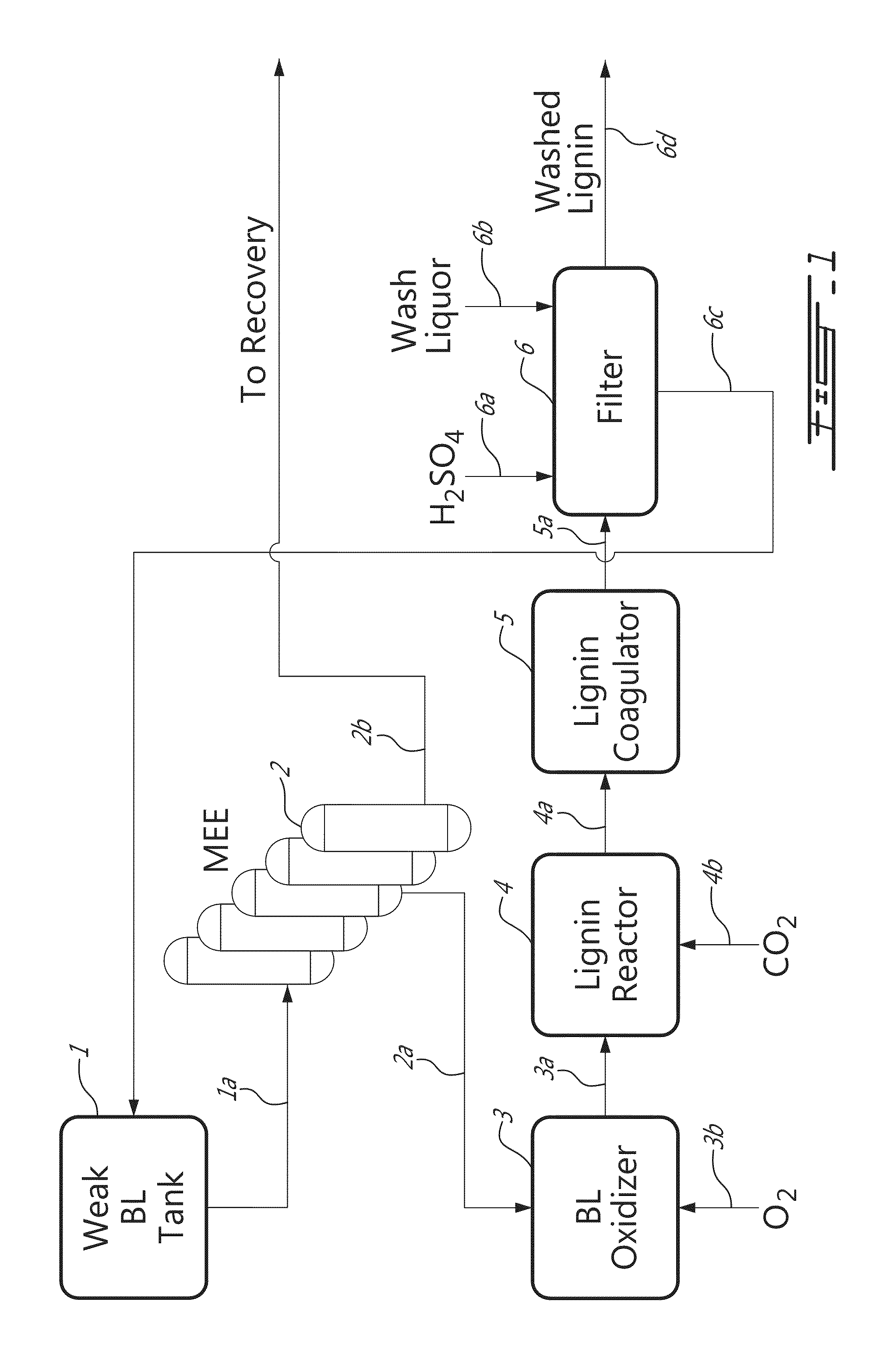

Method for separating lignin from black liquor

ActiveUS8771464B2Increase filtration rateIncrease contentLignin derivativesPulp by-products recoveryBlack liquorChemical composition

Owner:FPINNOVATIONS INC

Kitchen waste treatment and resourceful utilization method

ActiveCN110157747ATo promote metabolismImprove performanceClimate change adaptationWater contaminantsHigh concentrationMagnesium salt

The invention discloses a kitchen waste treatment and resourceful utilization method, and belongs to the technical field of solid waste treatment. The method includes the steps of modifying zeolite through the cooperation of magnesium salt, ferric salt and alkali liquor to obtain a material A, putting the material A into kitchen waste slurry for fermentation, and improving soil fertility with supernate of fermentation liquor as the denitrification carbon source and solid biogas residues as the good-performance nitrogen and phosphorus slow-release organic fertilizer. The method is easy to operate, the fermentation rate can be greatly increased, the rapid generation of organic acids with acetic acid and lactic acid as the main part is promoted, the organic acids serve as the denitrificationcarbon source, the efficient immobilized removal of nitrogen and phosphorus in the fermentation liquor can be realized, the defect that high-concentration nitrogen and phosphorus enter the denitrification carbon source is overcome, nitrogen and phosphorus can be transferred into the biogas residues to serve as the slow-release fertilizer, and the resourceful utilization of all kitchen waste is realized.

Owner:TONGJI UNIV

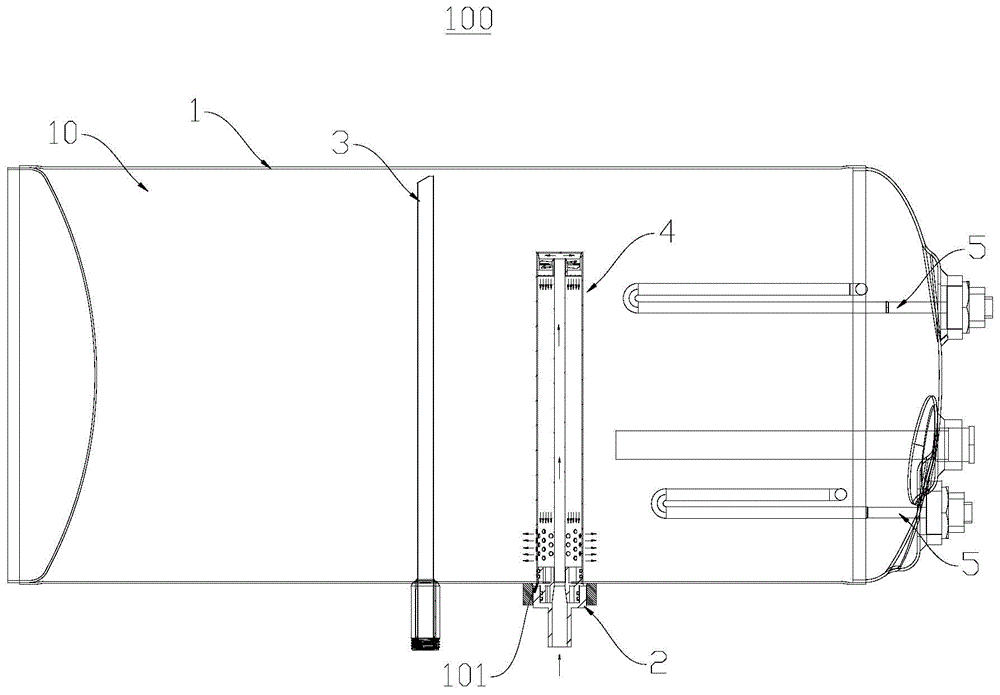

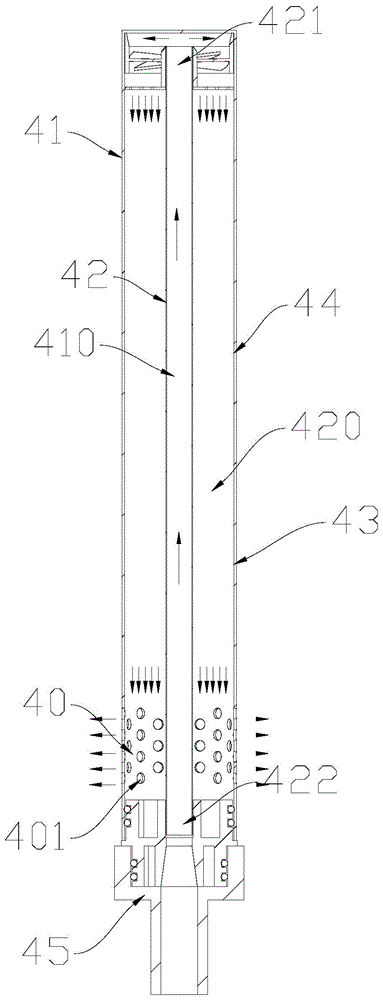

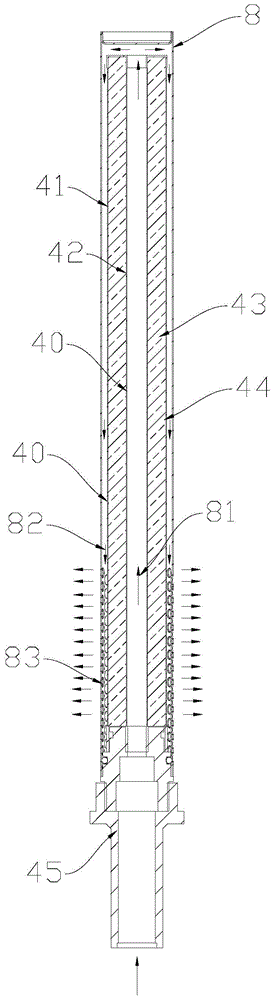

Water heater

The invention discloses a water heater. The water heater comprises an inner container, a water inlet pipe, a water outlet pipe and a filter device arranged in the inner container. The water heater is characterized in that the filter device comprises an outer layer, an inner layer and a filter medium; the filter medium is contained in an interlayer cavity formed by the outer layer and the inner layer; at least part of the outer layer and / or the inner layer is a region allowing the water flow to pass; and the filter device is located in the inner container. By the adoption of the structure, the filtering performance of the water heater can be improved, the contact time of the water flow in the filter medium is prolonged as much as possible, the contact area of the water flow in the filter medium can be increased as much as possible, the pressure required by filtering is lowered, and the filtering rate is increased.

Owner:A O SMITH CHINA WATER HEATER CO LTD

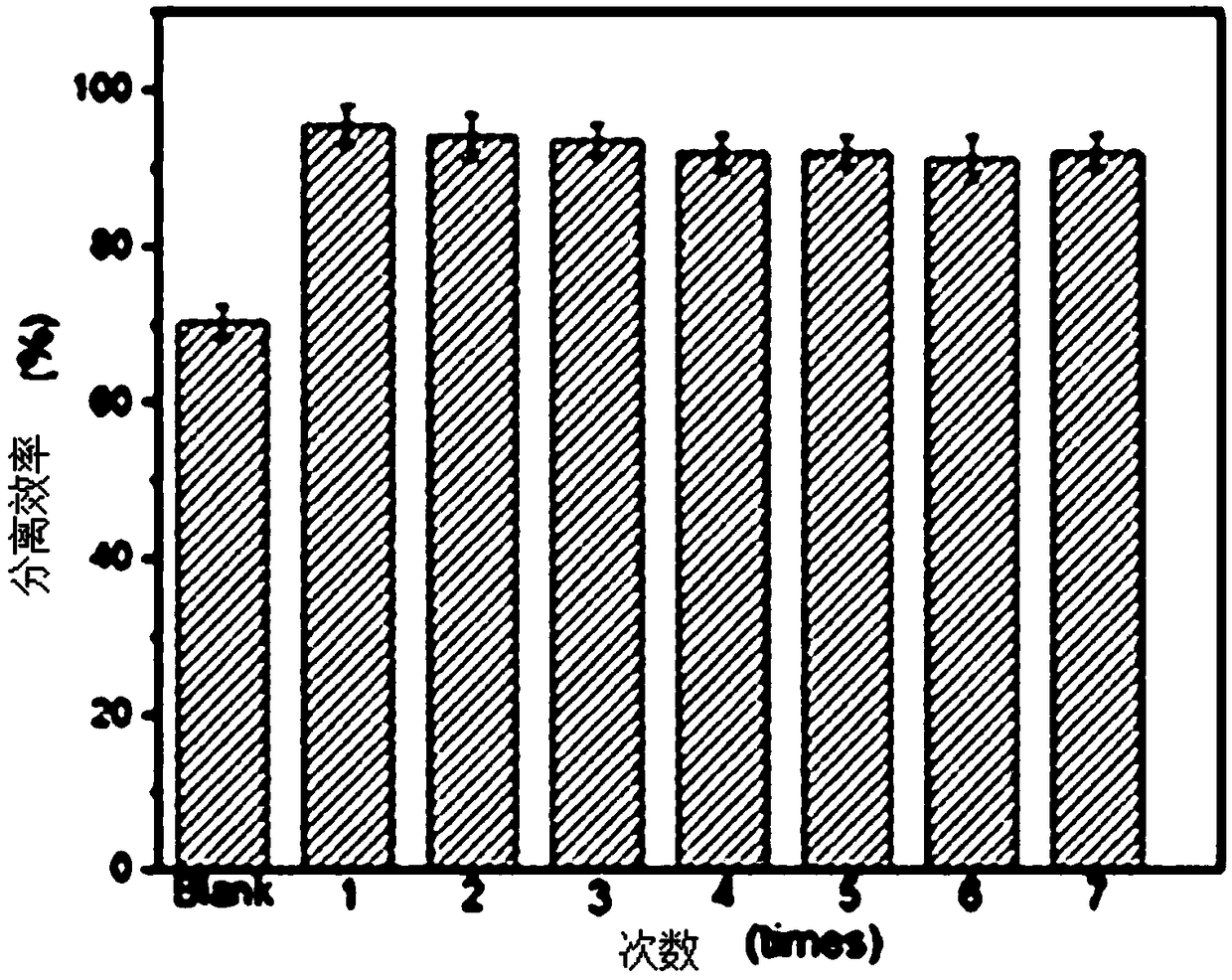

Metal organic skeleton/graphene oxide oil-water separation membrane and preparation method thereof

InactiveCN108176254AEasy to separateImprove separation efficiencyUltrafiltrationNon-miscible liquid separationMetal-organic frameworkOil water

The invention relates to a metal organic skeleton / graphene oxide oil-water separation membrane and a preparation method thereof. The metal organic skeleton / graphene oxide oil-water separation membranecomprises a PVDF bottom membrane and a ZIF-8 / GO composite material, wherein the ZIF-8 / GO composite material is firmly loaded on the PVDF bottom membrane through the bonding between the ZIF-8 / GO composite material and trimesoyl chloride, the bonding between trimesoyl chloride and dopamine, and the combination between dopamine and the PVDF bottom membrane. According to the present invention, GO isintegrally compounded through the multi-level pore channels and the regular hexagonal window of ZIF-8, and the oil-water separation effect is substantially improved by matching the pores of ZIF-8 andthe channels in the GO lamella, wherein the oil-water separation efficiency is up to more than 99.5%; and the bonding between trimesoyl chloride and dopamine is firm and is not easily disconnected, and the reusability of the oil-water separation membrane is strong, wherein the oil-water separation efficiency is not basically changed after repeated use seven times, and is still above 96%.

Owner:SHANDONG UNIV

Probiotic lactobacillus rhamnosus fermented milk and preparation method thereof

InactiveCN105961588AStable qualityGood flavorMilk preparationLactobacillusStreptococcus thermophilusWhey protein powder

The invention relates to probiotic lactobacillus rhamnosus fermented milk and a preparation method thereof. The probiotic lactobacillus rhamnosus fermented milk comprises the following raw materials in percentage by mass: 0.8%-9% of sweet sugar, 0.8%-2.0% of whey protein powder, 0.10%-0.20% of lactobacillus rhamnosus grx10 inoculation fluid and 0.125%-1% of streptococcus thermophilus inoculation fluid and the balance of raw milk based on 100% of the raw material components. According to the probiotic lactobacillus rhamnosus fermented milk, a fermented milk formula of the lactobacillus rhamnosus grx10 is optimized, a fermentation process matched with the formula is screened out, a fermented milk product with stable quality and good mouth feel is obtained on the premise of not adding food additives such as a stabilizer and the like, the viable count of lactobacillus rhamnosus of the fermented milk product reaches the health care requirement, the fermented milk product lays a good foundation for large-scale fermentation production and widespread use of the lactobacillus rhamnosus grx10.

Owner:NEW HOPE DAIRY HLDG

Granulated feed producing and processing equipment and method

PendingCN109480319AMessy layoutHigh energy consumptionFeeding-stuffProcess equipmentProcess engineering

The invention relates to granulated feed producing and processing equipment and method. The granulated feed producing and processing equipment comprises a raw material receiving system, a crushing system, a mixing machine, a granulating system and a quantitative packaging system, wherein the raw material receiving system comprises a feeding device, a dosing device, a stirring barrel, an impurity removing device and a dust removing device; the crushing system comprises a crusher and an ozone generating device; the granulating system comprises a conditioning device, a granulator and a cooler; and the quantitative packaging system comprises a sorting machine and a quantitative packaging mechanism. Through adoption of the granulated feed producing and processing equipment disclosed by the invention, the defects that in the prior art, a set of perfect feed producing and processing equipment does not exist, most conventional equipment has single equipment working procedure, the equipment layout is in disorder, the energy consumption is high, the production process is complex, the production efficiency is low, and the product quality cannot be guaranteed, are solved; and the granulated feed producing and processing equipment disclosed by the invention is high in automation degree, simple in structure, high in production efficiency and low in cost, and can produce multi-grade products,and the grade quality is high.

Owner:韶关正邦农牧科技有限公司

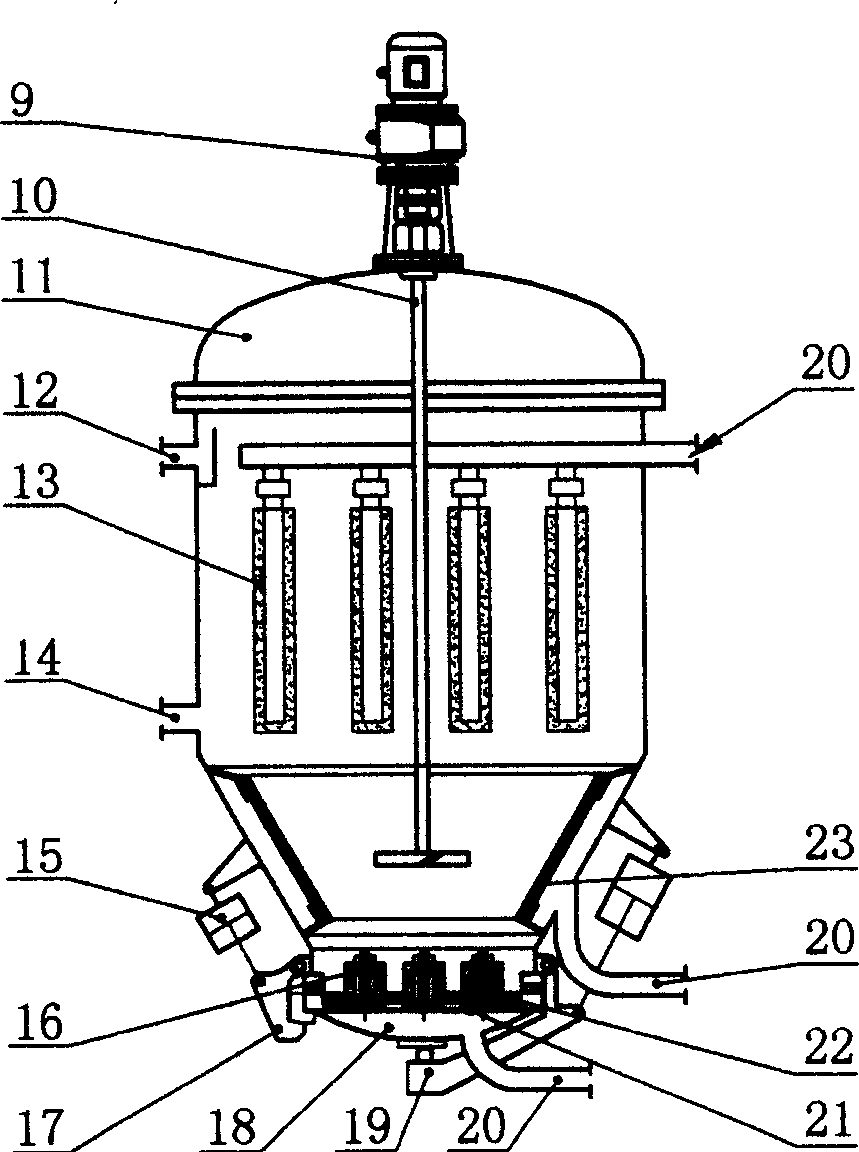

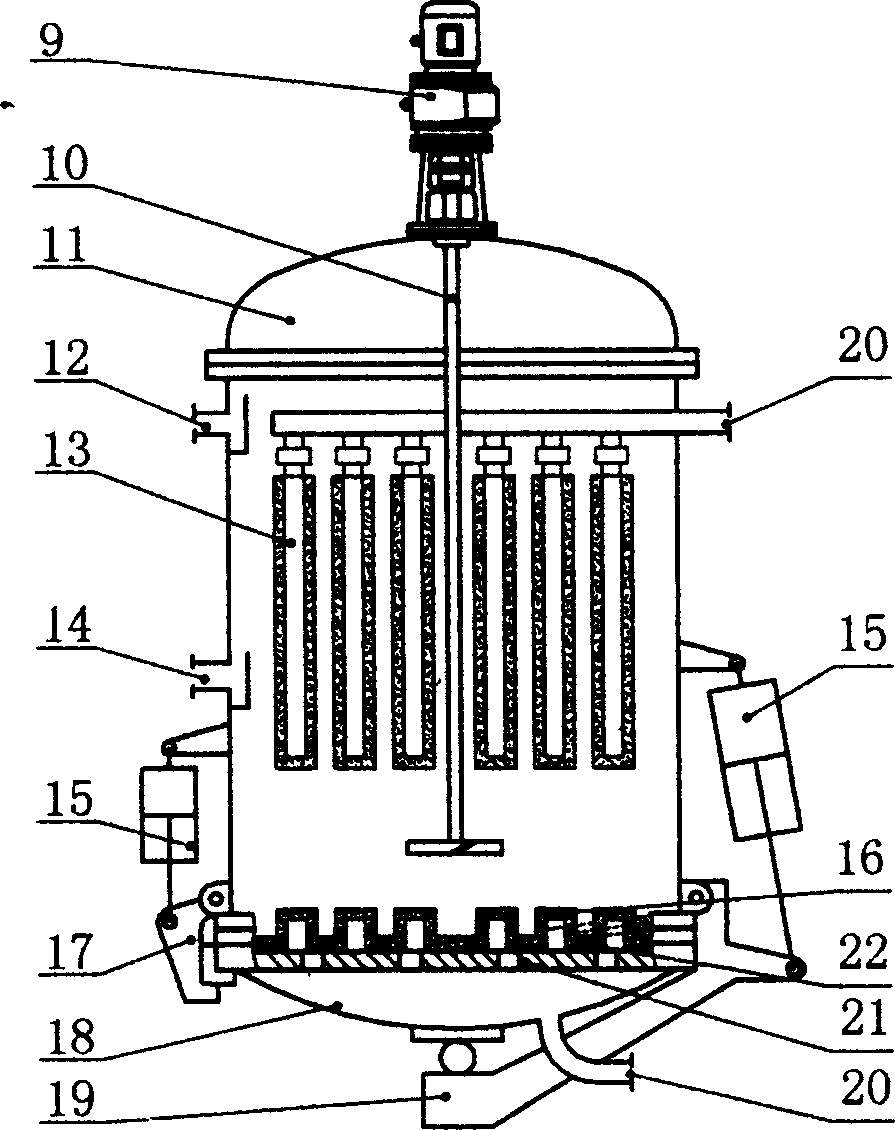

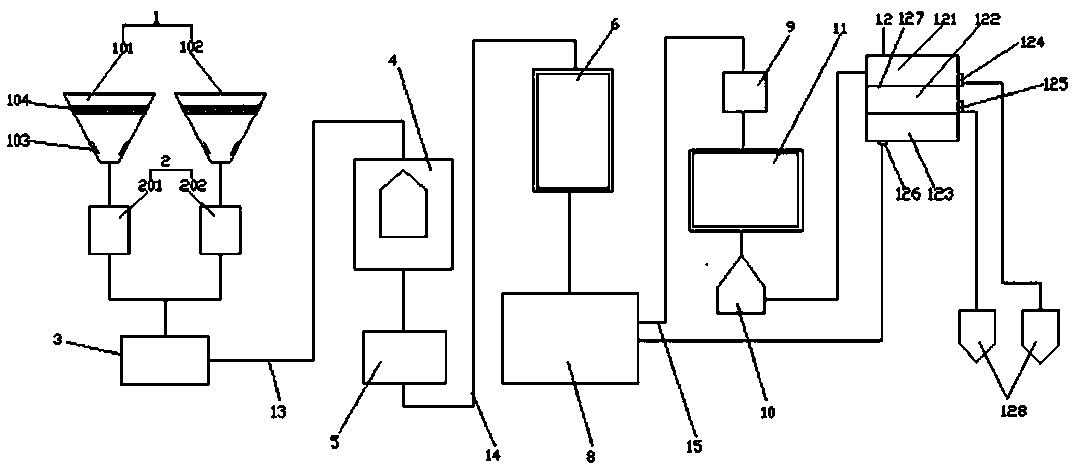

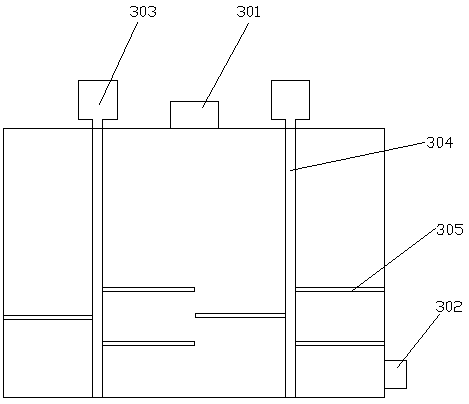

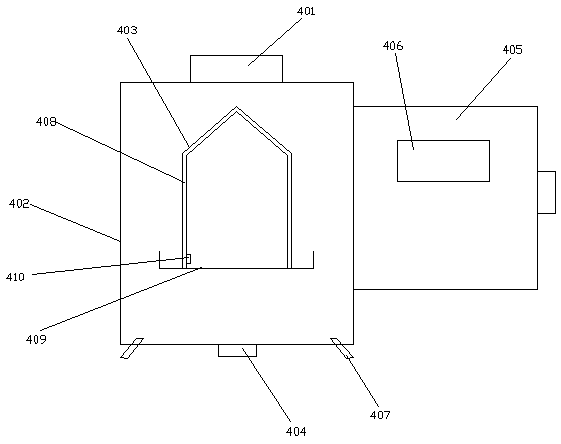

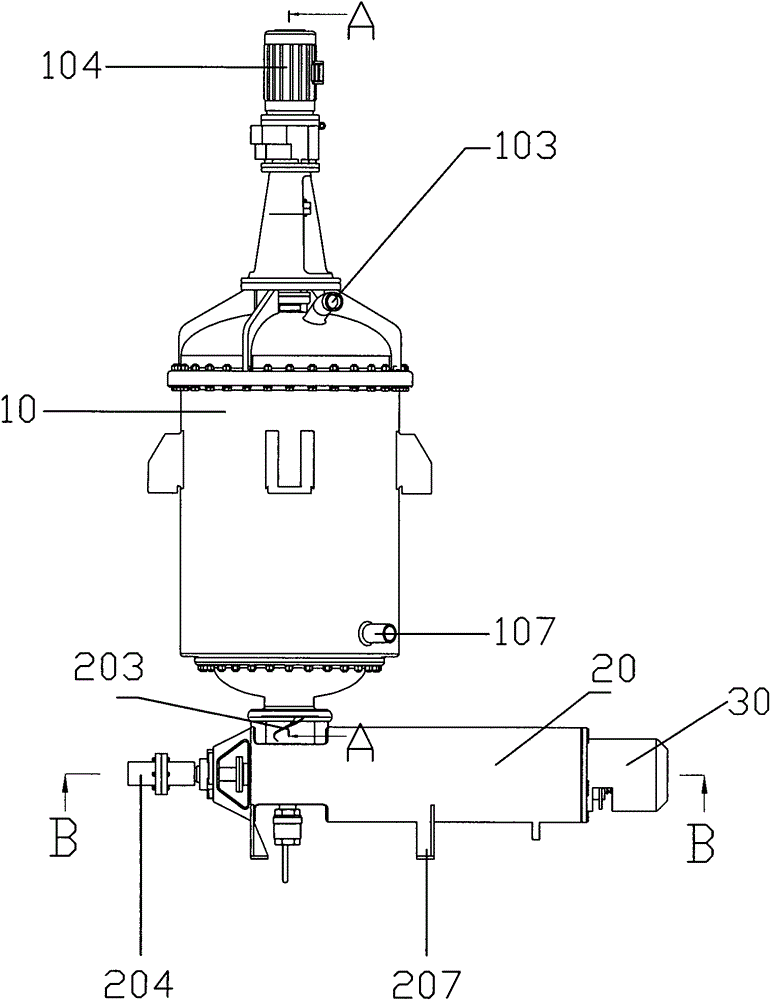

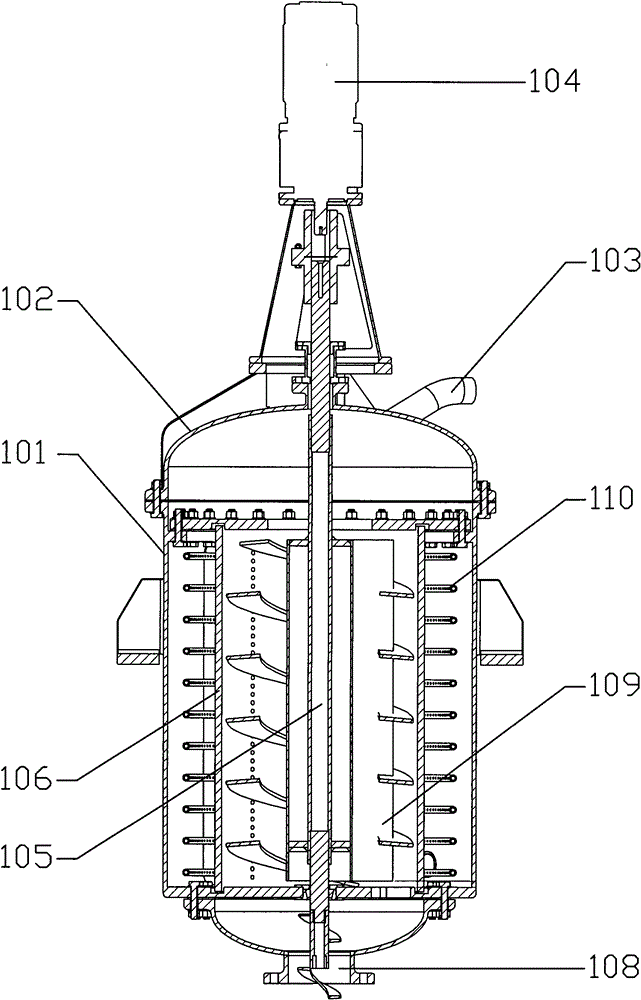

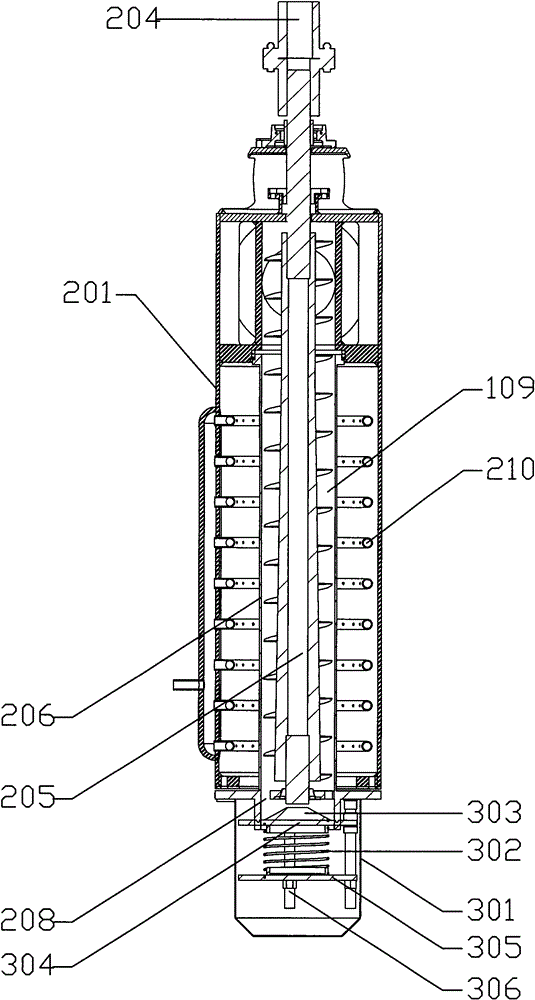

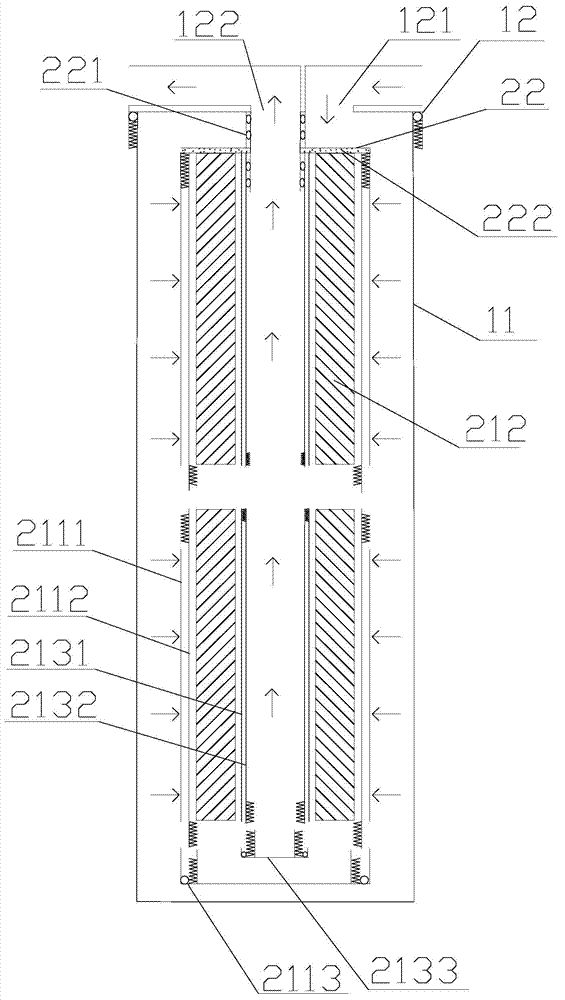

Full-automatic continuous filtering and filter pressing slag unloading machine

The invention relates to a full-automatic continuous filtering and filter pressing slag unloading machine comprising a filtering device, wherein the filtering device comprises a filter cartridge, a filtering stirring shaft and a first filtering medium; a liquid inlet is arranged on the top end of the filter cartridge; the filtering stirring shaft is installed in the filter cartridge through a sealing bearing, and a helical blade is arranged on the filtering stirring shaft; the first filtering medium is arranged between the inner wall of the filter cartridge and the filtering stirring shaft; a liquid outlet is arranged on the bottom end of the filter cartridge; and a press filtering device, the press filtering device comprises a press filter cartridge, a press filtering stirring shaft and a second filtering medium; a slag inlet is arranged on the top end of the press filter cartridge, and the slag inlet is communicated with the liquid outlet; the press filtering stirring shaft is installed in the press filter cartridge through a sealing bearing, and a helical blade is arranged on the press filtering stirring shaft; the second filtering medium is arranged between the inner wall of the press filter cartridge and the press filtering stirring shaft; and a slag outlet is arranged on the bottom end of the press filter cartridge, and an automatic resetting switch is arranged at the slag outlet. The full-automatic continuous filtering and filter pressing slag unloading machine provided by the invention can be conducted with continuous pressure filtration, can automatically feed and automatically discharge and unload slag and is consistently located at a thin layer filtering environment, so that the filtering speed is high, and the machine is operated under a complete sealed state, and the operation environment is excellent.

Owner:王启

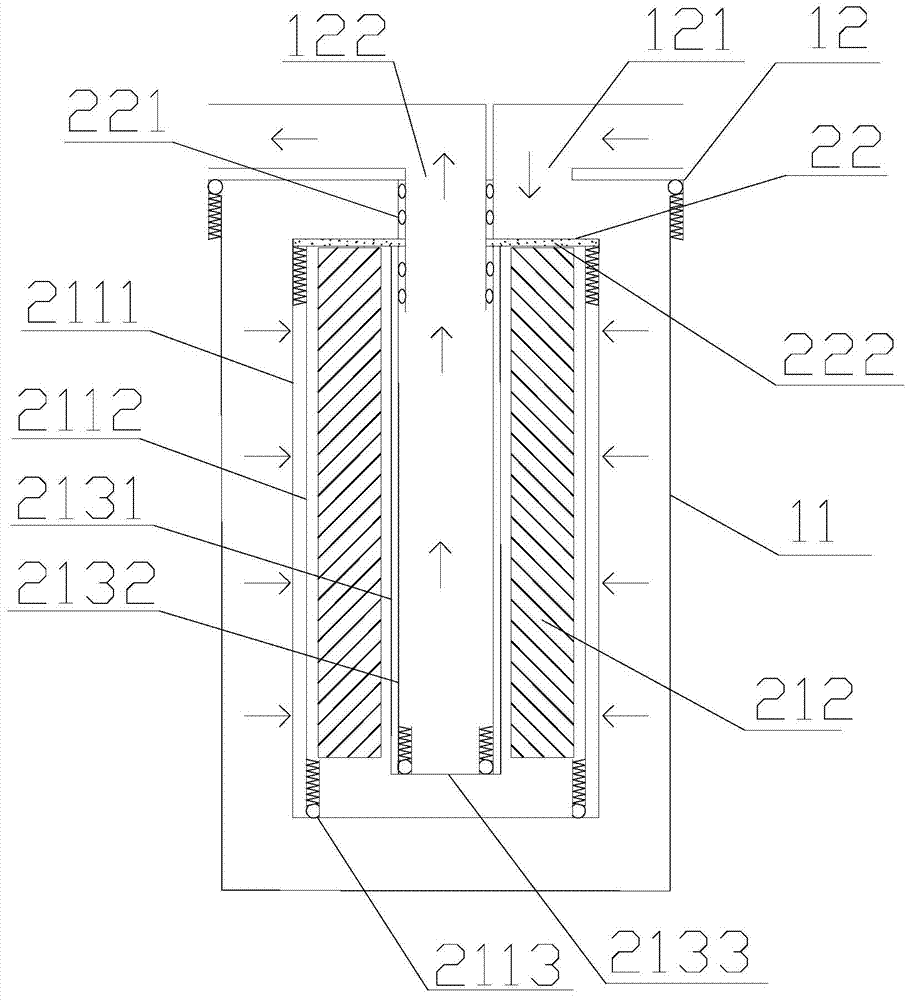

Multilayer water purification filter core and its water purifier

ActiveCN104291459AIncrease filtration rateIncrease the number of filter layersWater/sewage treatmentMultistage water/sewage treatmentActivated carbonWater filter

The invention discloses a multilayer water purification filter core and its water filter. The filter core includes a filter layer and a filter core cover, the filter layer comprises an outer filter screen layer, an activated carbon layer and an inner filter screen layer, and the activated carbon layer is positioned between the outer filter screen layer and the inner filter screen layer. The outer filter screen layer includes an outer filter screen, an outer frame and an outer sealing cover, and the outer frame is the support frame of the outer filter screen. The upper portion of the outer frame is in threaded connection with the filter core cover, and the lower portion of the outer frame is in threaded connection with the outer sealing cover. The inner filter screen layer comprises an inner filter screen, an inner frame and an inner sealing cover, and the lower portion of the inner frame is in threaded connection with the inner sealing cover. The filter core and the water purifier have the following advantages: the increase of the number of the filter layer and the compressed activated carbon makes discharged water clean; structure between the outer filter screen and the inner filter screen and between the outer filter screen and the filter core cover are detachable, so cleaning is convenient, and the filter area is increased; and when the middle compressed activated carbon layer reaches saturated adsorption, only the activated carbon layer is individually replaced, so the use cost is reduced.

Owner:宁国市吉思知识产权运营有限公司

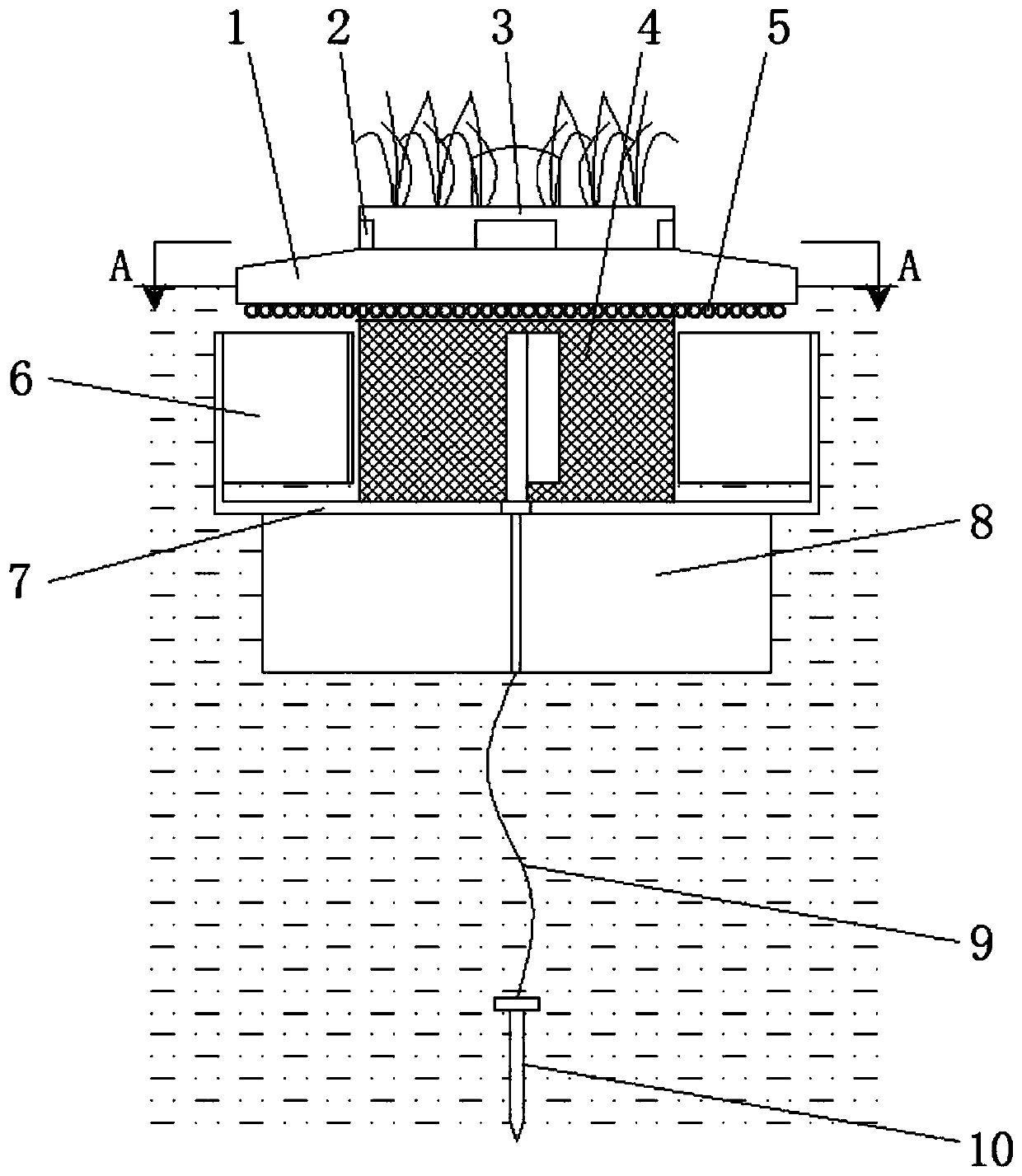

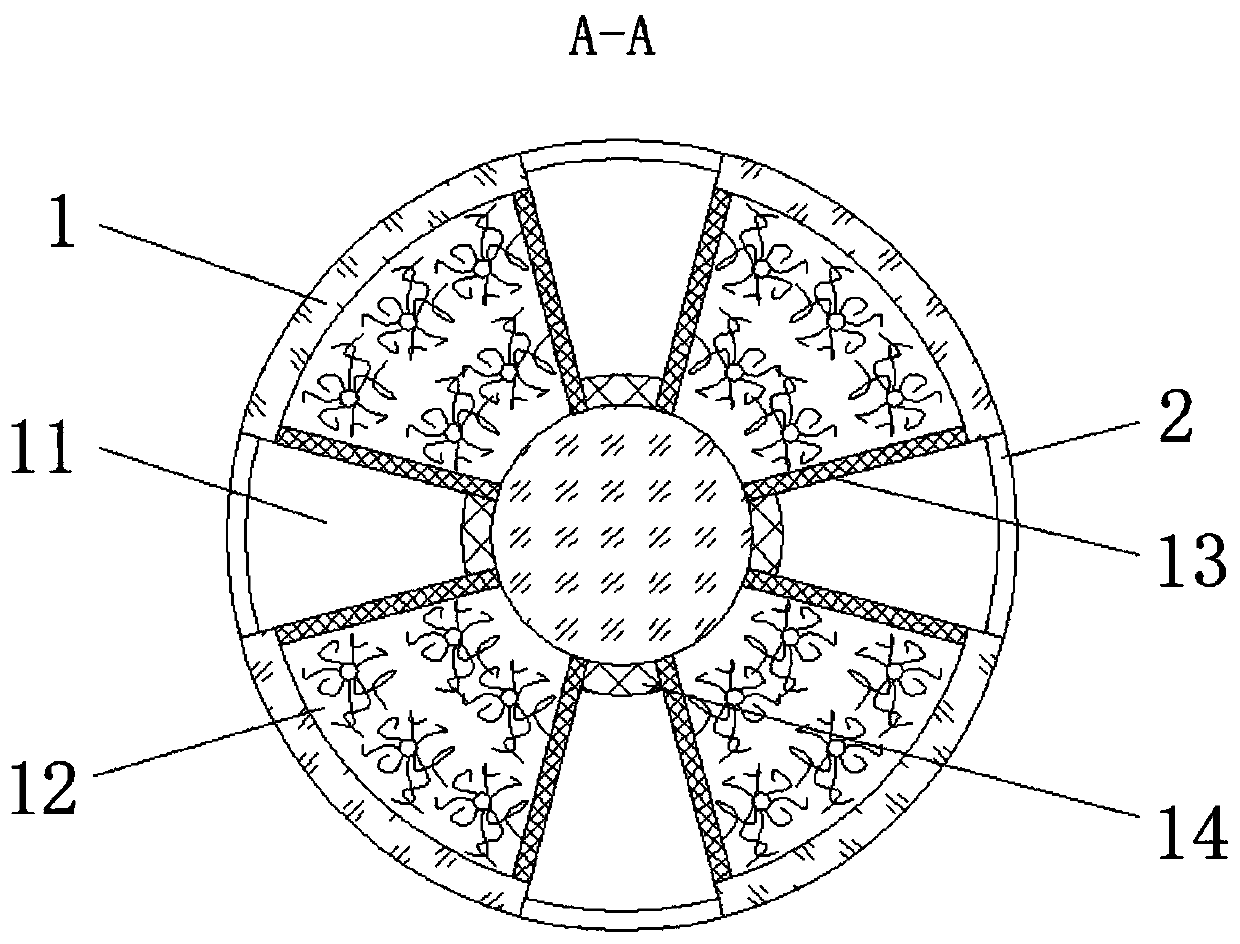

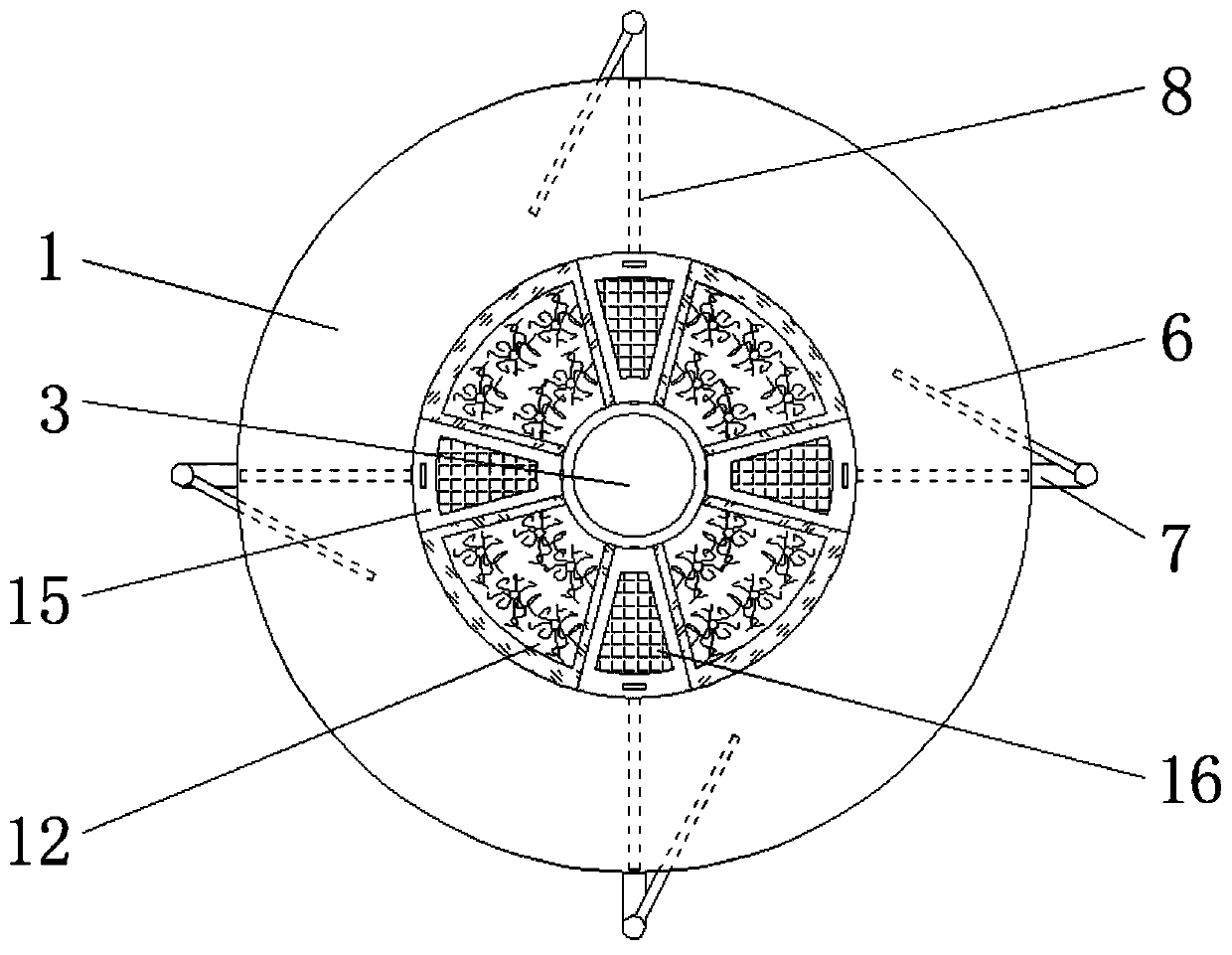

Ecological floating island for remediation and treatment of black and odorous water

ActiveCN110282745APurify the surrounding environmentImprove flotationSpecific water treatment objectivesWater/sewage treatment apparatusSewageDrive motor

The invention discloses an ecological floating island for remediation and treatment of black and odorous water. The ecological floating island comprises a floating base, a net-shaped cylinder base, a floating ball, a balance frame, a steel wire rope and a fixing rivet, the net-shaped cylinder base is welded with the bottom of a purification base, and the floating base is fixed to the junction of the purification base and the net-shaped cylinder base and located on the outer side wall of the purification base; a driving motor is installed in a top protrusion of the purification base, and one end of a rotary shaft extends to the bottom of the net-shaped cylinder base and is provided with a rotary rack; the balance frame is installed at the bottom of the rotary rack, the steel wire rope is connected with the center of the bottom of the balance frame, and the fixing rivet is fixed to one end of the steel wire rope. According to the ecological floating island for remediation and treatment of the black and odorous water, by installing the floating base, the purification base and the floating ball and forming ecological planting grooves, the black and odorous water can be effectively adjusted through the rhizomes of aquatic plants, floating objects on the surface of the water can be effectively collected through the floating island, and the area of the purified water is increased. The problems are solved that a traditional sewage purification device is single in function, small in purification area, long in treatment time, low in purification speed, high in maintenance cost and the like.

Owner:ANHUI LANDING ENVIRONMENTAL PROTECTION ENERGY TECH

Autotrophic denitrification synchronous sludge fermentation coupled denitrification device and method for sewage with low nitrogen ratio

ActiveCN103739066AStrong practicality and reliabilityIncrease fermentation rateWater contaminantsSludge processingEnvironmental chemistryCarbon source

The invention relates to an autotrophic denitrification synchronous sludge fermentation coupled denitrification device and method for sewage with low nitrogen ratio. A raw water tank, a sludge storage pool and a sedimentation pool are connected with an autotrophic denitrification synchronous sludge fermentation coupled denitrification reactor; the autotrophic denitrification synchronous sludge fermentation coupled denitrification reactor is provided with a self-circulation pipeline. The method comprises the following steps: enabling raw material, shortcut nitrification reflux liquid and fresh remaining sludge to enter the autotrophic denitrification synchronous sludge fermentation coupled denitrification reactor together, enabling part of ammonia nitrogen and nitrite to perform autotrophic denitrification through anaerobic ammonium oxidation bacteria, enabling the remaining nitrite and nitrate nitrogen to utilize organic matters in the raw water and a carbon source produced by fermentation of the remaining sludge to perform denitrification, nitrifying outlet water in a shortcut nitrification reactor, performing sludge-water separation by the sedimentation pool, and then enabling part of nitrification liquid to reflux into the autotrophic denitrification synchronous sludge fermentation coupled denitrification reactor. According to the device and the method, provided by the invention, the high ammonia nitrogen load impact can be effectively resisted, the raw water and the carbon source produced by fermentation are fully utilized, the denitrification efficiency of waste water is improved, and the production of sludge can be simultaneously reduced.

Owner:TSINGHUA UNIV +3

Method for producing fuel ethanol by low temperature pretreatment mode of corn

The invention relates to a new method for producing fuel ethanol by a low temperature pretreatment mode of corn. The method comprises the following steps: crushing corns into granules with granularity of 100%; sieving by a 40 mesh sieve; preparing a powder syrup whose dry material concentration is 33 m% with water and clear liquid; adding 15-20 U / g dry basis of acid protease and 30-40 U / g dry basis of alpha-amylase, adding 3 ppm of bacterial depressant; adjusting pH to 4.5; stirring at 60-65 DEG C for 0.5-1 hour; preparing a pretreatment mash; rapidly cooling the pretreatment mash to 30-35 DEG C; adding 0.2 m% of yeast and 400-500 U / g dry basis of complex glucoamylase, and adding nutritive salts; fermenting for 75-85 hours. Compared with the traditional high temperature boiling technology, the invention can save about 35% of steam consumption with high mature mash ethanol content and high starch liquor yield.

Owner:COFCO GROUP +2

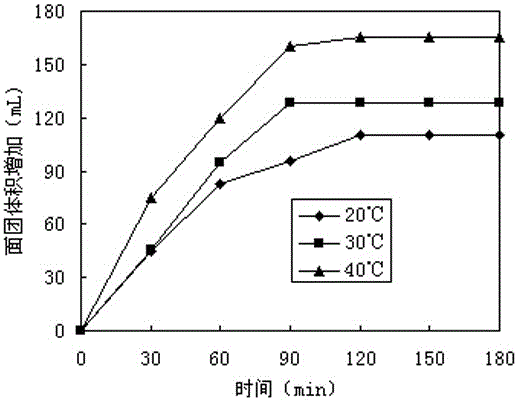

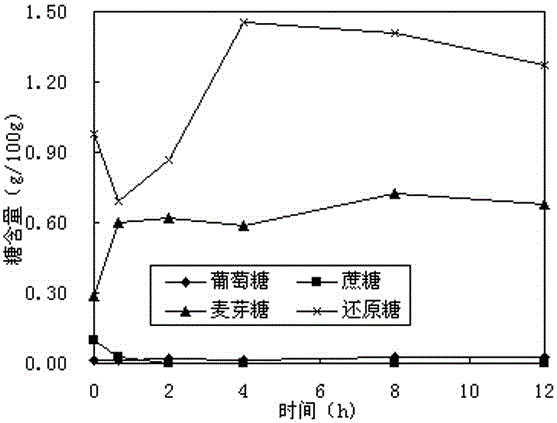

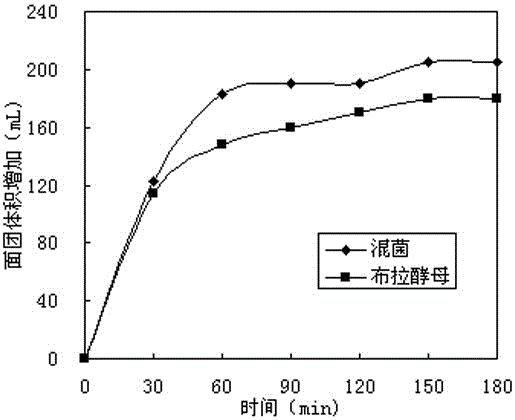

Low-temperature-resistant high-sugar-yield Torulaspora delbrueckii strain and application thereof

InactiveCN105062903ARich in nutrientsTo promote metabolismFungiBacteriaBiotechnologyMicrobiological culture

The invention relates to a low-temperature-resistant high-sugar-yield Torulaspora delbrueckii strain and application thereof. The invention is characterized in that the strain is named YT-22, the classification designation is Torulaspora delbrueckii, the strain is collected by China General Microbiological Culture Collection Center on July 3rd, 2014, and the collection number is CGMCC No.9408. The Torulaspora delbrueckii has normal fermenting property at 15-40 DEG C, can generate abundant reducing sugar in the dough fermentation process. When being mixed with other microbes, the Torulaspora delbrueckii can provide abundant nutrient substances for other strains in the fermentation process, promote metabolism of the other strains and obviously enhance the fermentation characteristics of the other microzymes and lactobacillus. When being added into the dough, the Torulaspora delbrueckii can lower the toughness of the dough under the fermentation action and improve the ductility of the dough, so that the finally obtained steamed bread has favorable quality.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

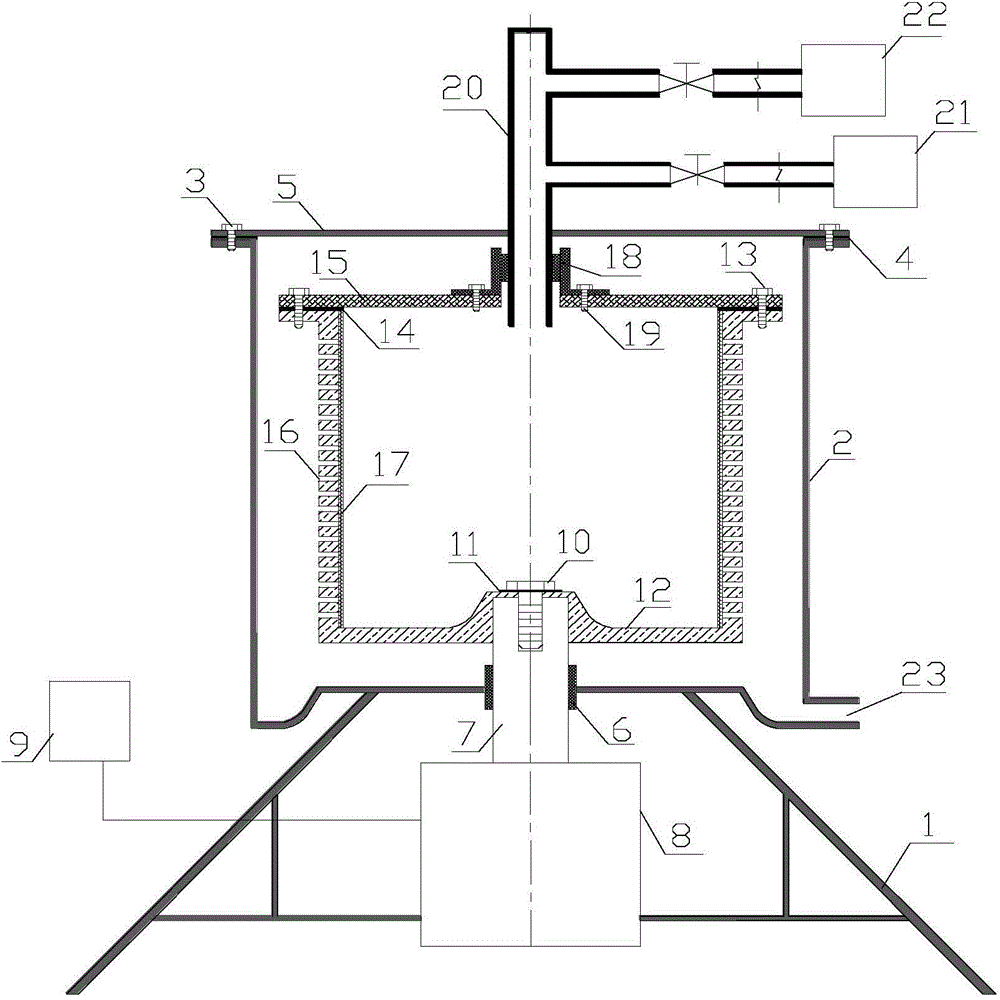

Fine-grain material centrifugal filtering and dewatering device

InactiveCN103977915AHigh centrifugal forceAdjustable centrifugal factorRotary centrifugesFilter mediaCentrifugal force

A fine-grain material centrifugal filtering and dewatering device comprises a frame, a housing, a motor, a drum and a speed regulator. A spindle of the motor penetrates the bottom of the housing to be connected with the drum, the spindle penetrates the housing to be provided with a sealing component, the upper portion of the housing is provided with an upper housing cover, the lower portion of the housing is provided with a liquid discharge outlet, the side wall of the drum is provided with a plurality of filtrate holes, and filter medium is attached to the inner wall of the drum. The upper portion of the drum is provided with an upper drum cover, the housing is provided with a feed pipe penetrating the upper housing cover and the upper drum cover to enter the drum, a mechanical sealing component is arranged at an inlet of the upper drum cover, the feed pipe is respectively provided with a suspension liquid feed system and an air feed system through pipelines, and the pipelines are provided with flow control valves. By coordinating pressurized filtering and centrifugal filtering, filtering speed can be accelerated by centrifugal force, dewatering speed is accelerated by compressed air, therefore dewatering process of a centrifugal filter is enhanced, solid-liquid separation efficiency is improved, residual water in centrifugal filter cakes is reduced and centrifugal dewatering effect of fine-grain materials is improved.

Owner:CHINA UNIV OF MINING & TECH

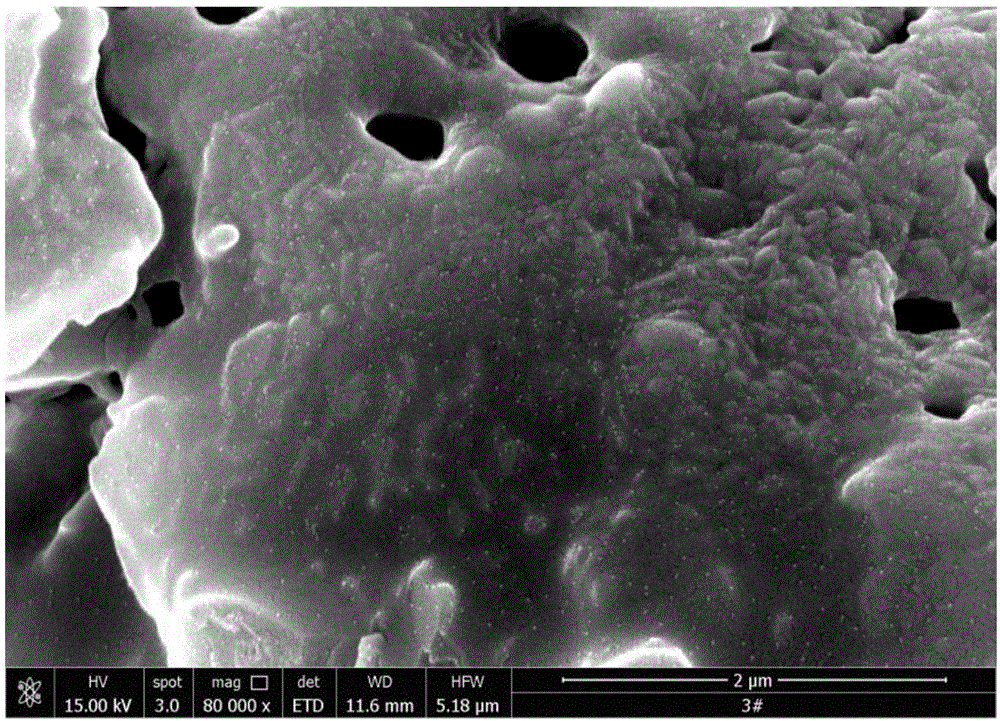

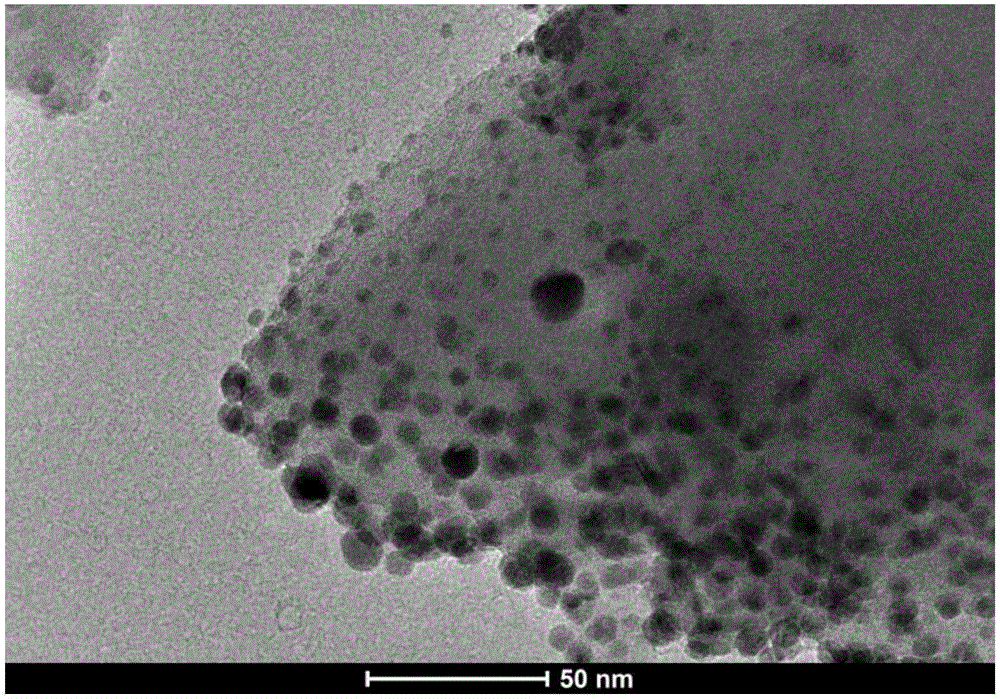

In-situ composite antibacterial filtering ceramic as well as preparation method and application thereof

InactiveCN106518006AImprove antibacterial propertiesGood dispersionTreatment involving filtrationMembrane filtersMicroorganismAdhesive

The invention relates to antibacterial filtering ceramic, in particular to in-situ composite antibacterial filtering ceramic as well as a preparation method and application thereof. The composite antibacterial filtering ceramic is prepared from the following components in percentage by mass: 60 to 75 percent of kieselguhr, 10 to 20 percent of hydroxyapatite, 10 to 30 percent of purple sand, 0.1 to 2 percent of silver and 1 to 5 percent of an adhesive, and the mass percentage sum of the five components is 100 percent. The diameter of the silver is 3 to 20 nm, and the silver is located on the surface and in gaps of the kieselguhr. According to the in-situ composite antibacterial filtering ceramic, combination of nano silveer and porous kieselguhr, combination of the silver and the hydroxyapatite and combination of silver-carried hydroxyapatite and the porous kieselguhr are realized under a hydrothermal condition, so that the dispersivity of the silver and the binding force of the silver and a material are improved. The material is high in filtering performance, antibacterial property and antibacterial endurance, can effectively filter out microorganisms, impurity particles and organic matters from water, and can be widely applied to the field of water treatment and relevant industries.

Owner:JIANGXI UNIV OF SCI & TECH

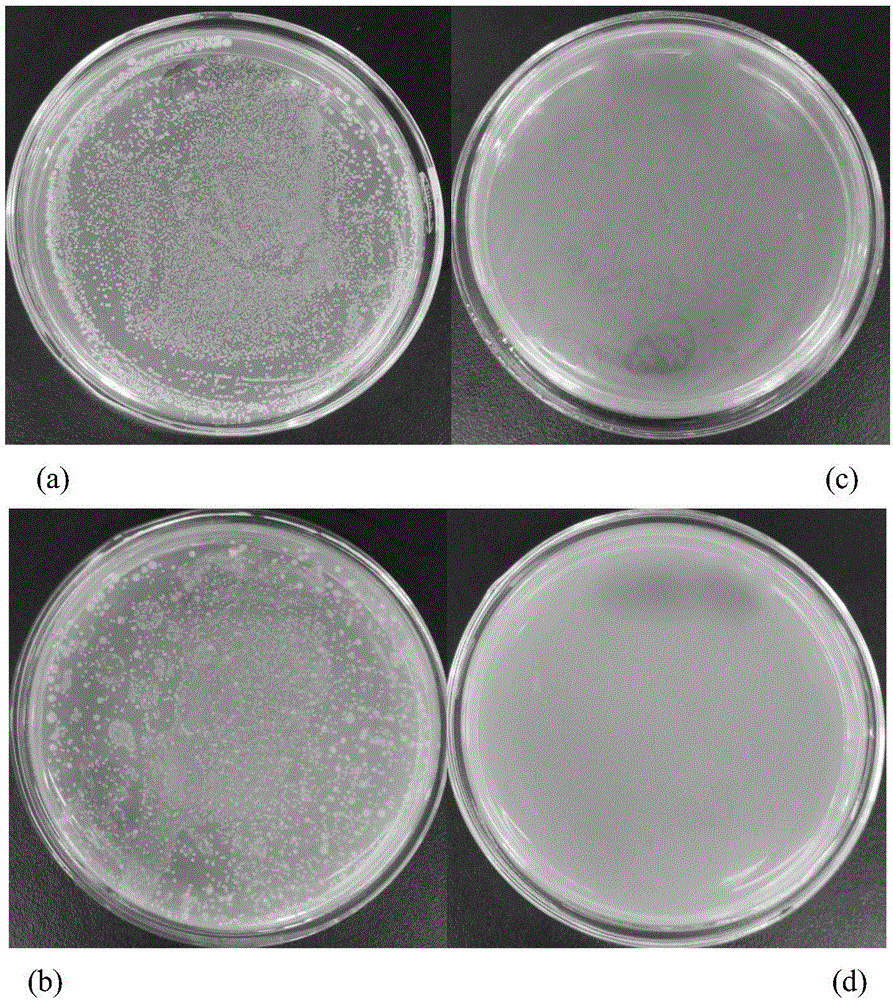

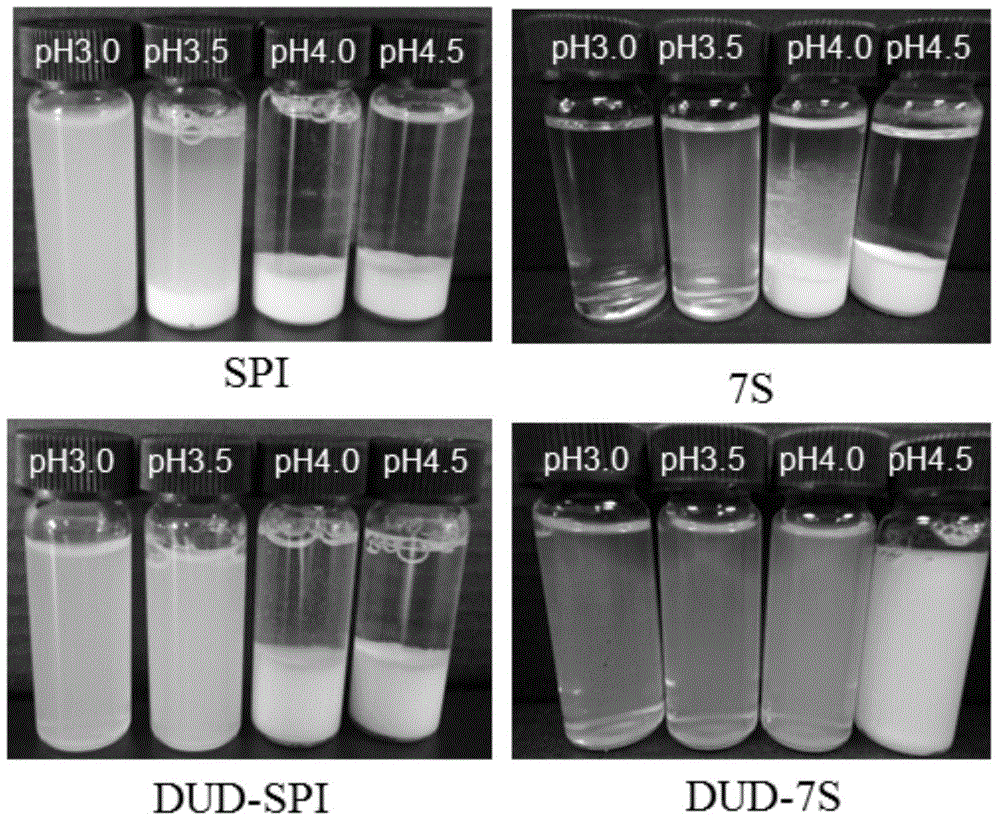

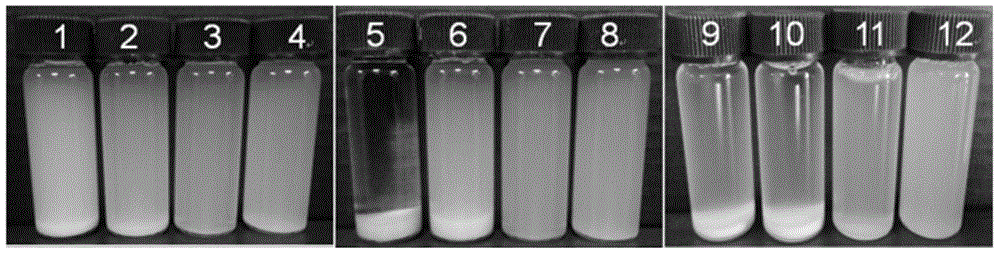

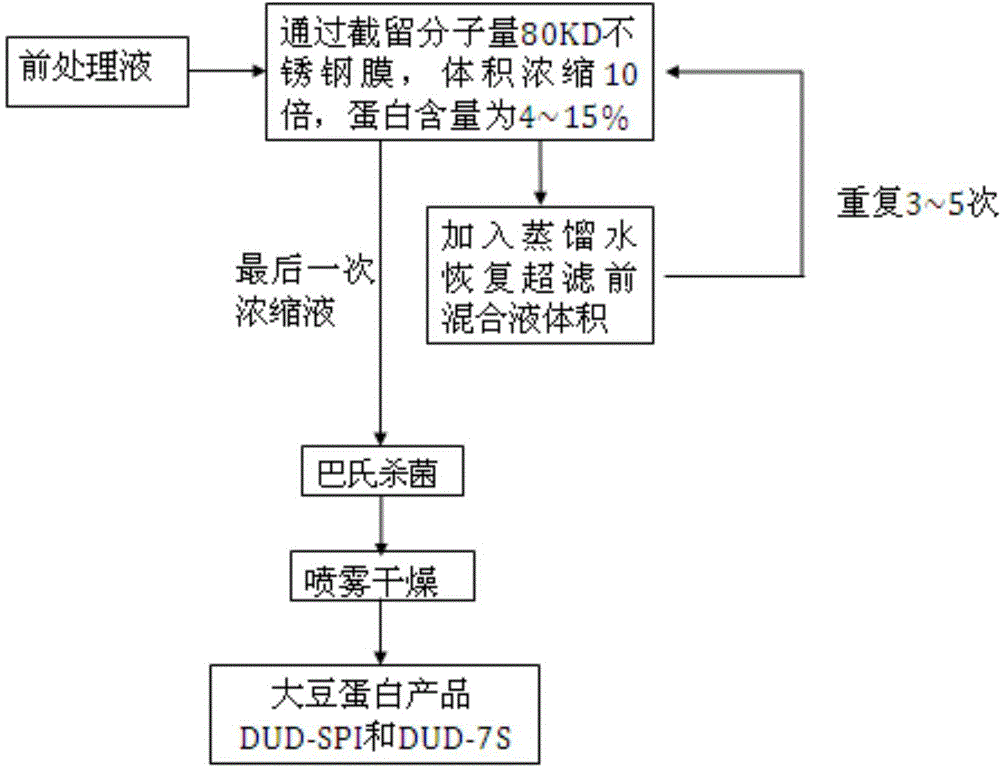

Acid-soluble soybean protein and preparation method and application of acid-soluble soybean protein in acid beverage

ActiveCN104543329AHigh protein purityFine foamProtein composition from vegetable seedsFood preparationSolubilityWater baths

The invention belongs to the fields of soybean protein deep processing and functional beverage, and discloses acid-soluble soybean protein and a preparation method and application of the acid-soluble soybean protein in acid beverage. The method comprises the following steps: firstly, mixing extract liquid with bean pulp, centrifugally separating and removing insoluble residues; taking supernatant liquid, adding phytase to the supernatant liquid to carry out enzymolysis, and adjusting the pH value; and carrying out cyclic ultrafiltration percolation concentration under a water bath condition, repeatedly diluting and concentrating protein for a plurality of time, and carrying out pasteurization and spray drying on the concentrated protein liquid, so as to obtain an acid-soluble soybean protein product. The purity of the obtained protein can be 90%-99%; the content of phytic acid is only 0.665%-0.694%; the nitrogen solubility index within the pH being 3.0-4.0 is 45%-90%; enzymatic hydrolysate is relatively good in foaming property, relatively excellent in foam stability; the acid-soluble soybean protein can be applied to preparation of various functional beverage when being dissolved into sports beverage, carbonated beverage, fruit juice and the like.

Owner:SOUTH CHINA UNIV OF TECH

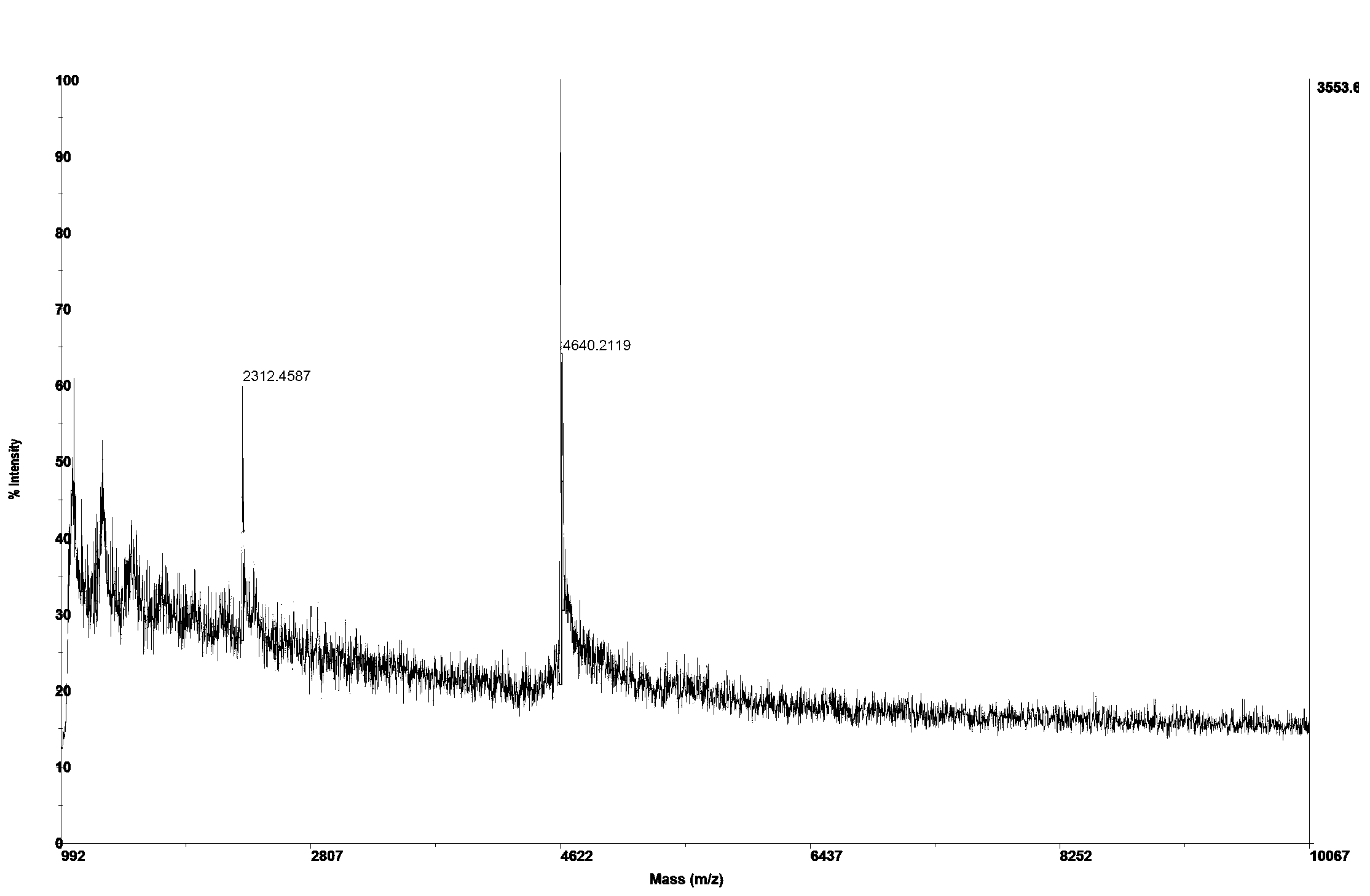

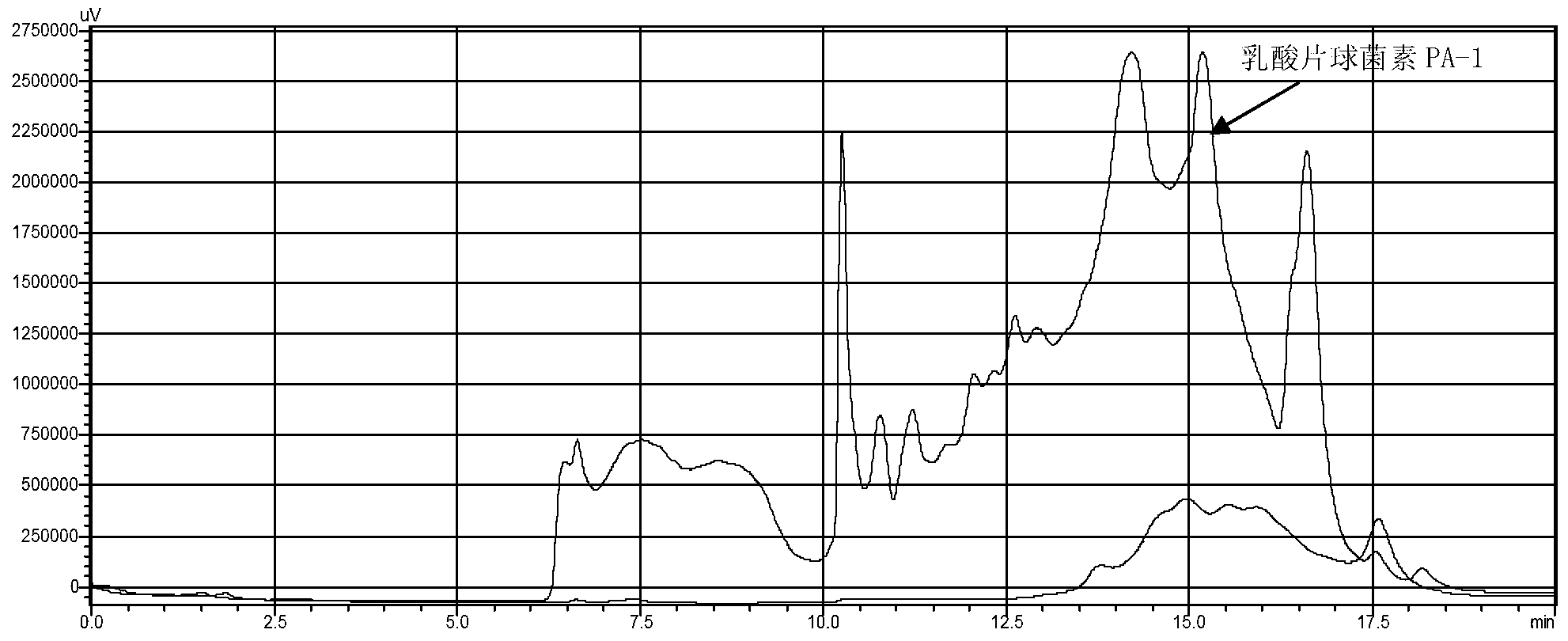

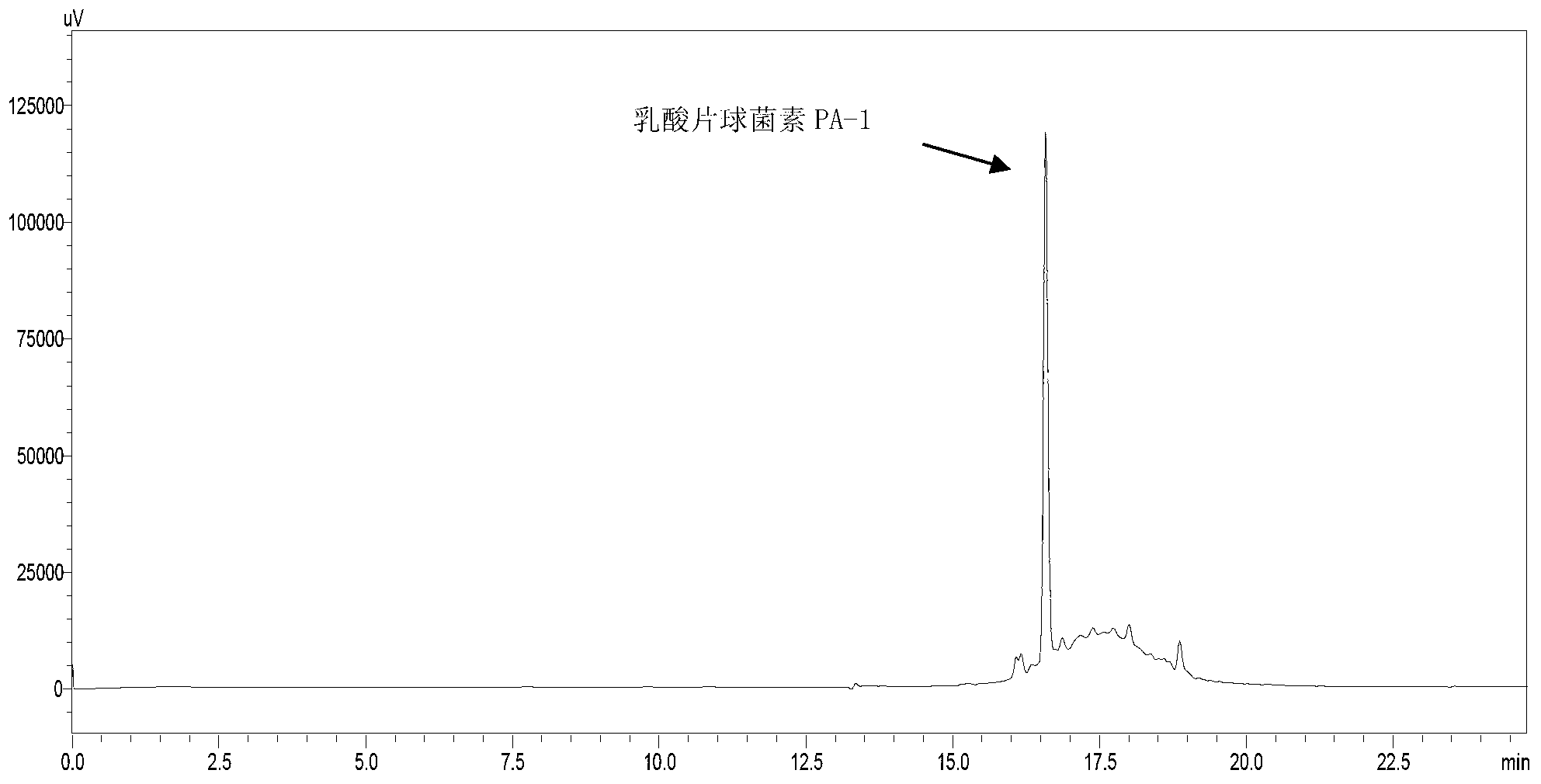

Method for separating and extracting pediocin PA-1 from fermentation solution

InactiveCN103288932AEasy to handleSpeed up filteringPeptide preparation methodsBacteria peptidesEnvironmental resistancePurification methods

The invention relates to a method for separating and extracting pediocin PA-1 from a fermentation solution. The method comprises the following steps: inactivating protease of the fermentation solution, releasing the pediocin PA-1 in the fermentation solution, performing plate-frame filtration to remove bacteria and granular impurities, performing microfiltration to remove high molecular weight impurities and performing two-step ultrafiltration: namely, the first step: selecting an ultrafiltration membrane with the molecular weight cutoff of 10000-30000 daltons with the main purpose of removing high molecular weight proteins, nucleic acid, colloid and the like; the second step: selecting the ultrafiltration membrane with the molecular weight cutoff of 1000-3000 daltons with the main purposes of removing small molecular weight impurities and concentrating. A concentrated solution is finally purified by C18 preparation chromatography and freeze-dried or added with common salt filler for spray-drying to get a powdery finished product. The process method disclosed by the invention has the advantages of whole-process fluid operation, low energy consumption, low labor intensity, mild conditions, easy industrial amplification, stable product quality, no consumption of an organic solvent, safety and environment-friendly property, and is suitable for a variety of follow-up purification methods.

Owner:TIANJIN UNIV OF SCI & TECH

Anti-clogging sewage treatment device

InactiveCN108101255AEffective filteringFiltering does not affectSpecific water treatment objectivesTreatment involving filtrationDisinfectantEngineering

The invention discloses an anti-clogging sewage treatment device, which comprises a tank body. A top tank is slidably connected to the top part of an inner wall of the tank body through a connecting block; a bottom tank is fixedly connected to the bottom part of the inner wall of the tank body; a disinfectant tank is fixedly connected to the left side of the tank body; a moving tank is fixedly connected to the top part of the right side of the tank body; a motor tank is fixedly connected to the bottom part of the right side of the tank body; a separation tank is fixedly connected to the bottompart of the top tank; net bags are rotatably connected to two sides of an inner wall of the top tank through buffer devices; vertical pipes penetrate through two sides of the bottom part of the top tank; one ends, far away from the top tank, of the vertical pipes penetrate through the bottom tank and extend into the bottom tank; a feed hopper penetrates through the top part of the tank body. Theanti-clogging sewage treatment device provided by the invention relates to the technical field of sewage treatment devices, and can be used for secondarily filtering and disinfecting filtered sewage,so that the sewage can be treated thoroughly, the disinfecting time is shortened at the same time, and a contact area between the device and the sewage is increased.

Owner:陈卫

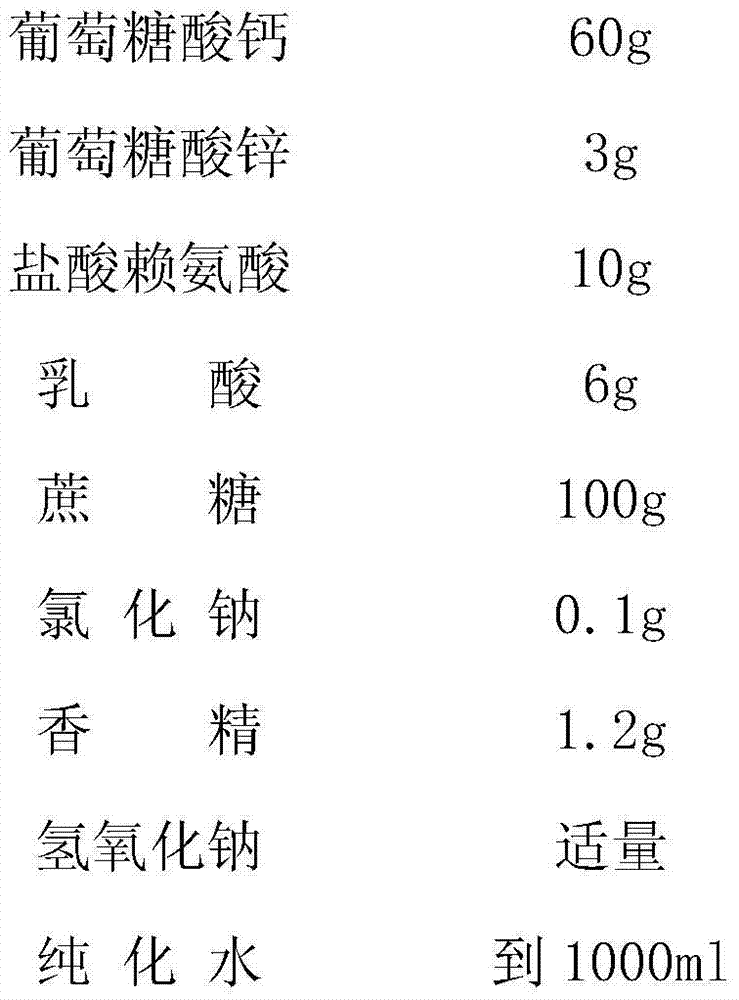

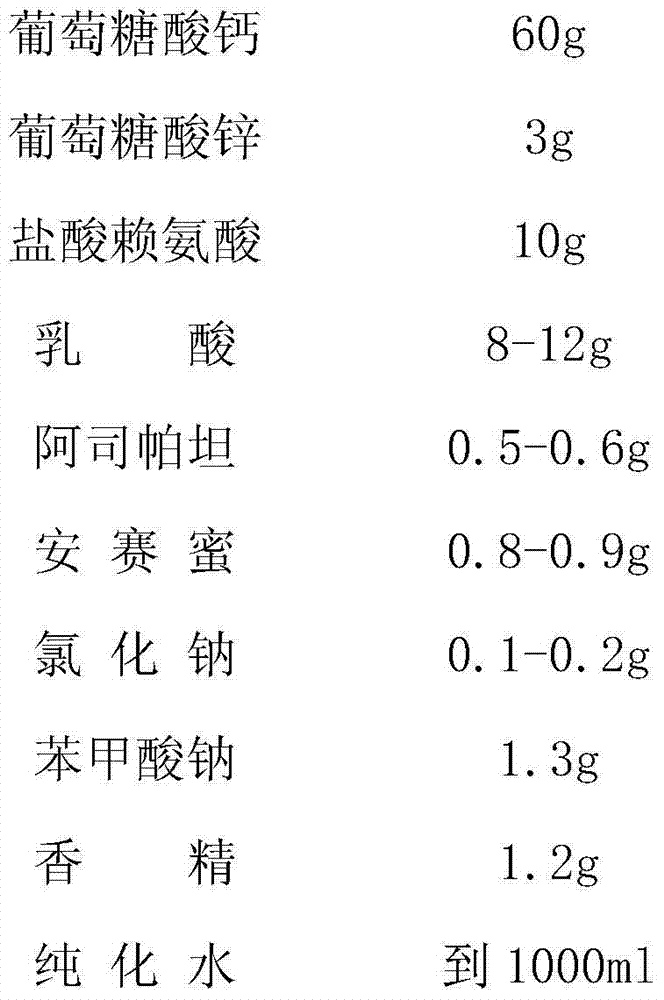

Calcium zinc gluconate oral solution

ActiveCN103690521AImprove stabilityReduce riskOrganic active ingredientsMetabolism disorderGluconic acidOral solutions

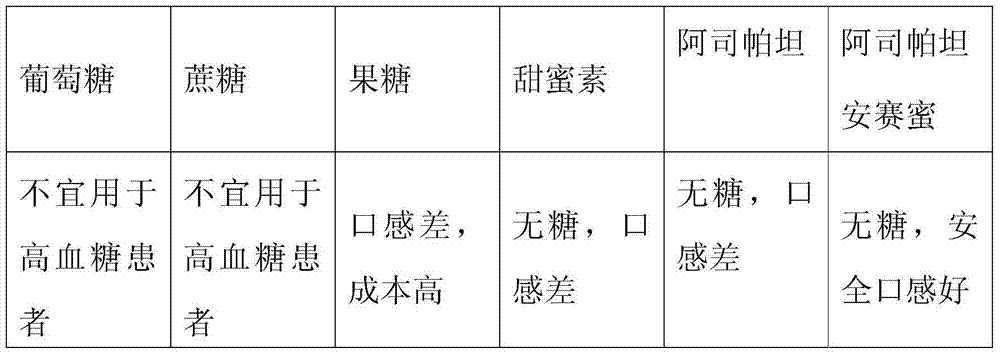

The invention relates to a medicinal preparation composition, and in particular relates to a calcium zinc gluconate oral solution. The composition comprises the following components: calcium gluconate, zinc gluconate, lysine hydrochloride, lactic acid, aspartame, acesulfame, sodium chloride, sodium benzoate, essence, sodium hydroxide and purified water.

Owner:HUBEI FUREN JINSHEN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com