Patents

Literature

127results about How to "Good flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

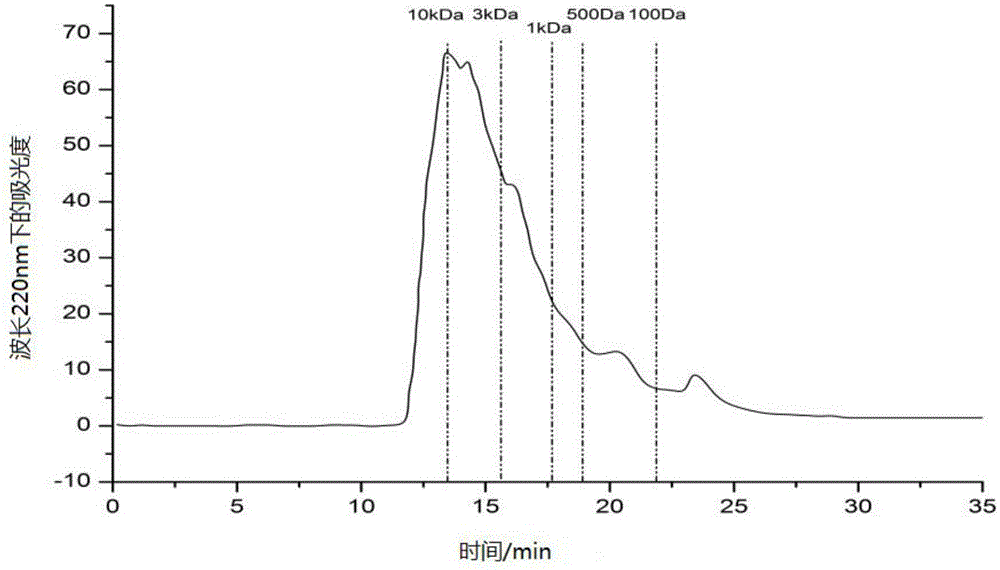

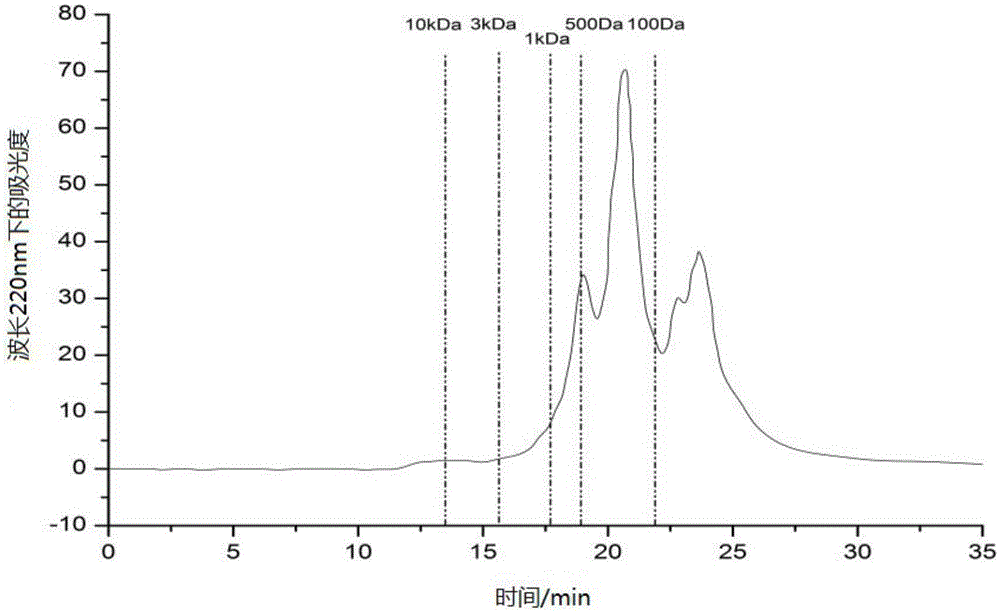

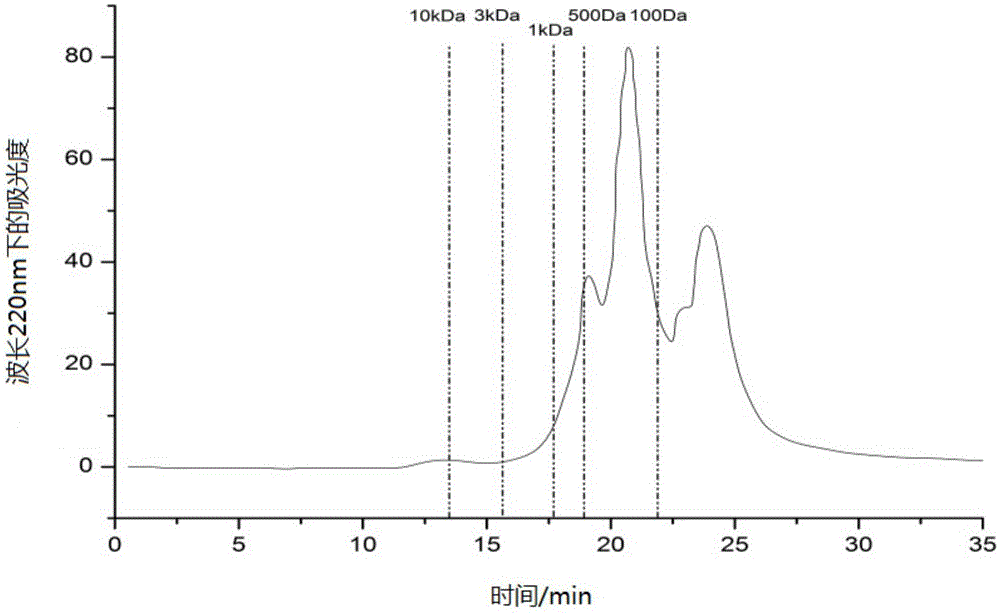

Soybean polypeptide without hydrolysis and bitter tastes as well as preparation method and application thereof

The invention discloses soybean polypeptide without hydrolysis and bitter tastes as well as a preparation method and application thereof. The preparation method provided by the invention comprises the following steps of: firstly producing a great deal of proteases by utilizing a solid microbial fermentation method, and removing the bitter taste and the hydrolysis taste in the polypeptide by utilizing the proteases produced by the microbial fermentation so that the favorable flavor of the soybean polypeptide is ensured, and decomposing a part of soybean protein into small-molecular polypeptide; and then preparing the soybean protein into a solution, converting a solid fermentation system into a liquid enzymolysis system, inhibiting the growth of microbes by improving the temperature of the enzymolysis system, adding high-efficiency protease, and hydrolyzing the polypeptide into the soybean polypeptide with less molecular weight by utilizing high efficiency, stability and specificity of an enzymolysis method. According to the invention, the hydrolysis degree of the soybean protein is 20-40 percent, and the prepared soybean polypeptide has the average length of 2.5-4.0 amino acid, the average molecular weight below 1,000Da and not bitter and hydrolysis tastes. The soybean polypeptide can be directly added into foods and also applied to cosmetics.

Owner:广州合诚实业有限公司

Waxberry ferment stock solution and preparation method thereof

InactiveCN104939073AMaintain effective nutrientsGood flavorFood ingredient functionsFood preparationChemistrySaline water

The invention discloses a manufacturing method of a waxberry ferment stock solution. The preparation method comprises the following steps: (1) preparing a fermentation base material: immersing freshly-picked waxberries with saline water; after washing the waxberries, adding proper amount of honey, sugar and water to form the fermentation base material; (2) carrying out primary fermentation: inoculating 1%-3% of probiotics into the fermentation base material of the step (1), and putting the fermentation base material into a fermentation container; sealing and fermenting for 25-30 days under the temperature condition of 25-30 DEG C; (3) carrying out solid-liquid separation: carrying out the solid-liquid separation on a mixture generated by the fermentation in the step (2), and separating a primary fermentation stock solution and the waxberry fruits; (4) carrying out secondary fermentation: putting the primary fermentation stock solution separated by the step (3) into the fermentation container; adding proper amount of the probiotics, the honey, the salt and table salt; sealing for fermenting for 80-100 days under the temperature condition of 25-30 DEG C; and (5) extracting a finished product: carrying out filtering treatment on a secondary fermentation stock solution generated by the fermentation in the step (4) by using diatomite to obtain the waxberry ferment stock solution. The invention further discloses the waxberry ferment stock solution prepared by the method.

Owner:杜雪梅

Fructose-free blueberry wine and preparation method thereof

InactiveCN101864351APure colorGood flavorAlcoholic beverage preparationMicroorganism based processesChemistryFruit juice

The invention discloses a fructose-free blueberry wine and a preparation method thereof. The manufacturing method comprises the following steps: (1) taking fresh blueberry, removing fruit stems and cleaning the fresh blueberry to obtain blueberry fruit grains; (2) dehydrating the blueberry fruit grains, getting juice and enabling the sugar degree of the blueberry juice to reach 21Brix-40Brix and preferably 24Brix-25Brix; (3) fermenting the blueberry juice; adding mushy state yeast into the blueberry juice by volume ratio of 1000:2 of blueberry juice to yeast; and then placing the blueberry juice at temperature of 28-32 DEG C and fermenting the blueberry juice for 14-20 days; (4) obtaining blueberry wine stock solution after completing fermenting, adding antacid in the blueberry wine stock solution by dosage which is 0.02-0.05 percent of the weight of the blueberry wine stock solution; and (5) removing impurities, filtering and filling to obtain fructose-free blueberry wine finished products. The fructose-free blueberry wine prepared through the method has the advantages that the color is pure, the flavor is good, the wine has certain alcoholic strength, the hangover can be reduced and the wine has even taste and fragrance.

Owner:裴光泰

Oil composition

InactiveUS7182971B2Excellent effectGood flavorOrganic active ingredientsEdible oils/fats ingredientsUnsaturated fatty acidFlavor

Disclosed herein is an oil composition comprising the following components (A) and (B):(A) 15 to 70% by weight of diglycerides in which less than 15% by weight of the constitutive fatty acids are (3 type unsaturated fatty acids; and (B) 30 to 85% by weight of a triglyceride in which at least 15% by weight of the constitutive fatty acids are (3 type unsaturated fatty acids. The oil composition is good in flavor, hard to be colored, excellent in hydrolytic stability and resistance to oxidation, good in emulsion stability and excellent in intake balance among fatty acids even under severe conditions that heating is performed at a high temperature for a long period of time, can be widely developed to medicinal preparations and foods and moreover exhibit an excellent inhibitory effect on accumulation of body fat by ingestion of a small amount of diglycerides.

Owner:KAO CORP

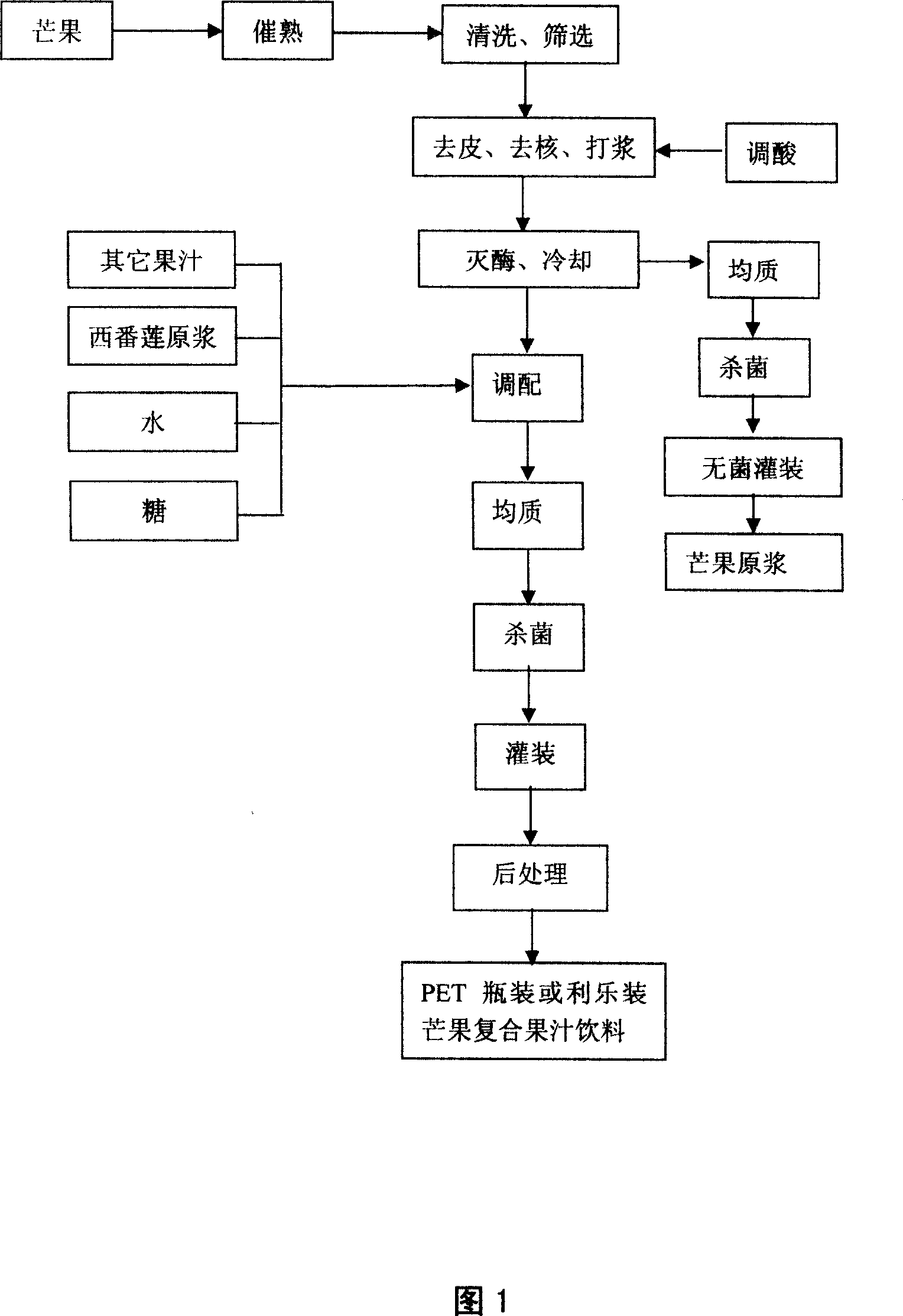

Prepn of composite mango juice beverage

The process of preparing composite mango juice beverage includes pulping mango while regulating the acidity to pH 3.5-4.0 with citric acid, fast deactivating enzyme and cooling to obtain stable mango pulp, homogenizing, sterilizing and pouring to obtain mango pulp; re-compounding the mango pulp with passionflower pulp or other fruit juice, homogenizing, sterilizing and packing to obtain composite mango juice beverage. The composite mango juice beverage can maintain its stable quality and excellent flavor though it contains no stabilizer.

Owner:GUANGXI UNIV

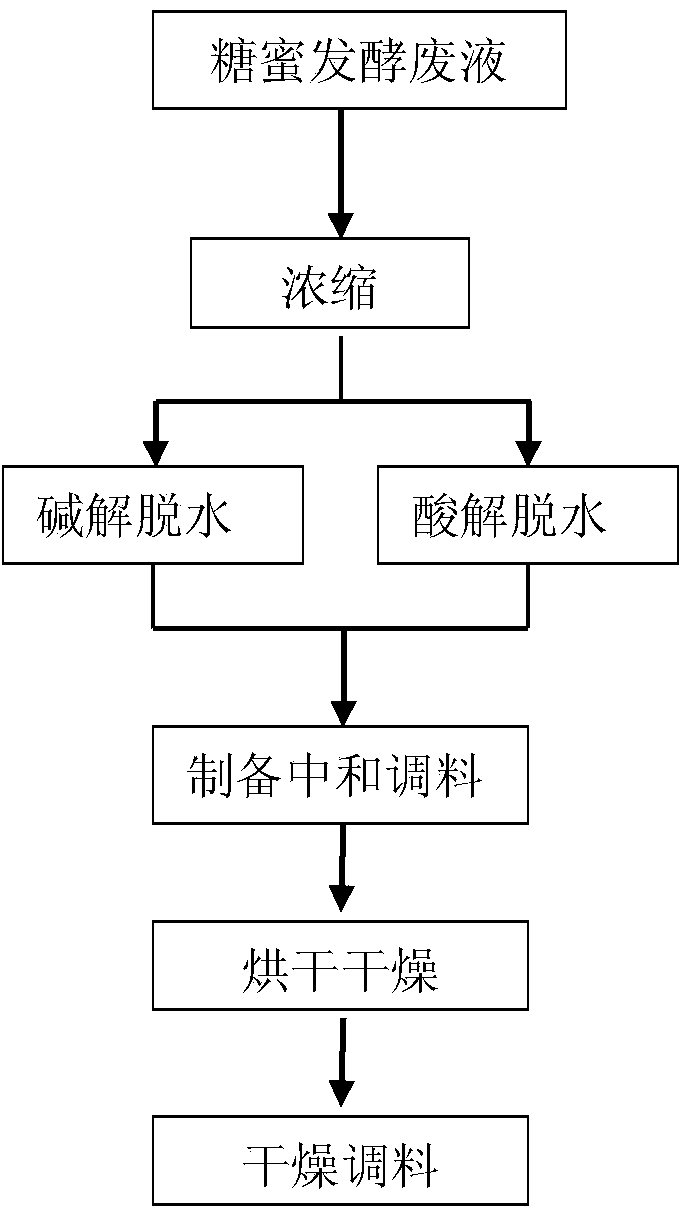

Treatment method for hyperosmosis concentrated mash waste liquor

ActiveCN103833425AGood flavorHigh in sugarClimate change adaptationBioloigcal waste fertilisersCombined methodWater content

The invention discloses a treatment method for hyperosmosis concentrated mash waste liquor. The treatment method comprises the steps of (1) concentration: concentrating molasses fermentation waste liquor, wherein one part of molasses fermentation waste liquor is used for alkaline hydrolysis dewatering and the other part is used for acidolysis dewatering; (2) alkaline hydrolysis dewatering: adding 10-35 percent of an alkaline hydrolysis agent into the concentrated liquor, performing low-speed stirring, adding 5-15 percent of a calcium magnesium phosphate fertilizer and 10-15 percent of a potash fertilizer and uniformly stirring to obtain an alkaline hydrolysis mixture; (3) acidolysis dewatering: adding 10-35 percent of an acidolysis agent into the concentrated liquor, and performing low-speed stirring to obtain an acidolysis mixture; (4) preparation of neutralizing mixture: mixing the alkaline hydrolysis mixture and the acidolysis mixture to generate acid-alkaline neutralization until the pH is 5-7; (5) drying: drying the neutralized mixture until the moisture content is less than or equal to 10 percent. By the adoption of an acidification-alkalization combined method, the concentrated hyperosmosis concentrated mash waste liquor is subjected to acid and alkaline humification respectively, so that a neutralizing agent which is added when acid and alkaline humifications are carried out separately is saved, and a dual-purpose effect is achieved.

Owner:GUANGXI XINTIANDE ENERGY +1

Processing process for low-salt air-dried geese marinated in rice wine

The invention discloses a processing process for a low-salt air-dried goose marinated in rice wine. A live goose is killed, unhaired, eviscerated and rinsed to obtain a goose whole. The processing process is characterized by comprising the following steps: soaking the goose whole in a marinating solution which takes vinasse as reference, and marinating for 18-24 hours at the temperature of 12-15 DEG C; then placing the goose whole in a workshop in which the temperature is 18-20 DEG C and the relative humidity is 65-70%, carrying out air drying for 2-3 days at the air speed of 6-8m / s, transferring into a workshop in which the temperature is 25-28 DEG C and the relative humidity is 70-75%, and carrying out air drying for 2-3 days at the air speed of 3-5m / s; placing the goose whole subject to air drying into a water tank with the temperature of 90-95 DEG C for 3-4 minutes, then completely tweezing the tiny feather on the surface of the goose whole, washing the goose whole clean, placing on a fixed frame, transmitting to halogen liquid with the temperature of 90-95 DEG C, and stewing for 45-60 minutes; and finally, carrying out vacuum packing and sterilization on the stewed goose whole to obtain the finished product. The low-salt air-dried geese marinated in rice wine has the advantages of unique flavor, delicious texture, strong bacon fragrance and mellow rice wine, and is beneficial to human health.

Owner:NINGBO UNIV

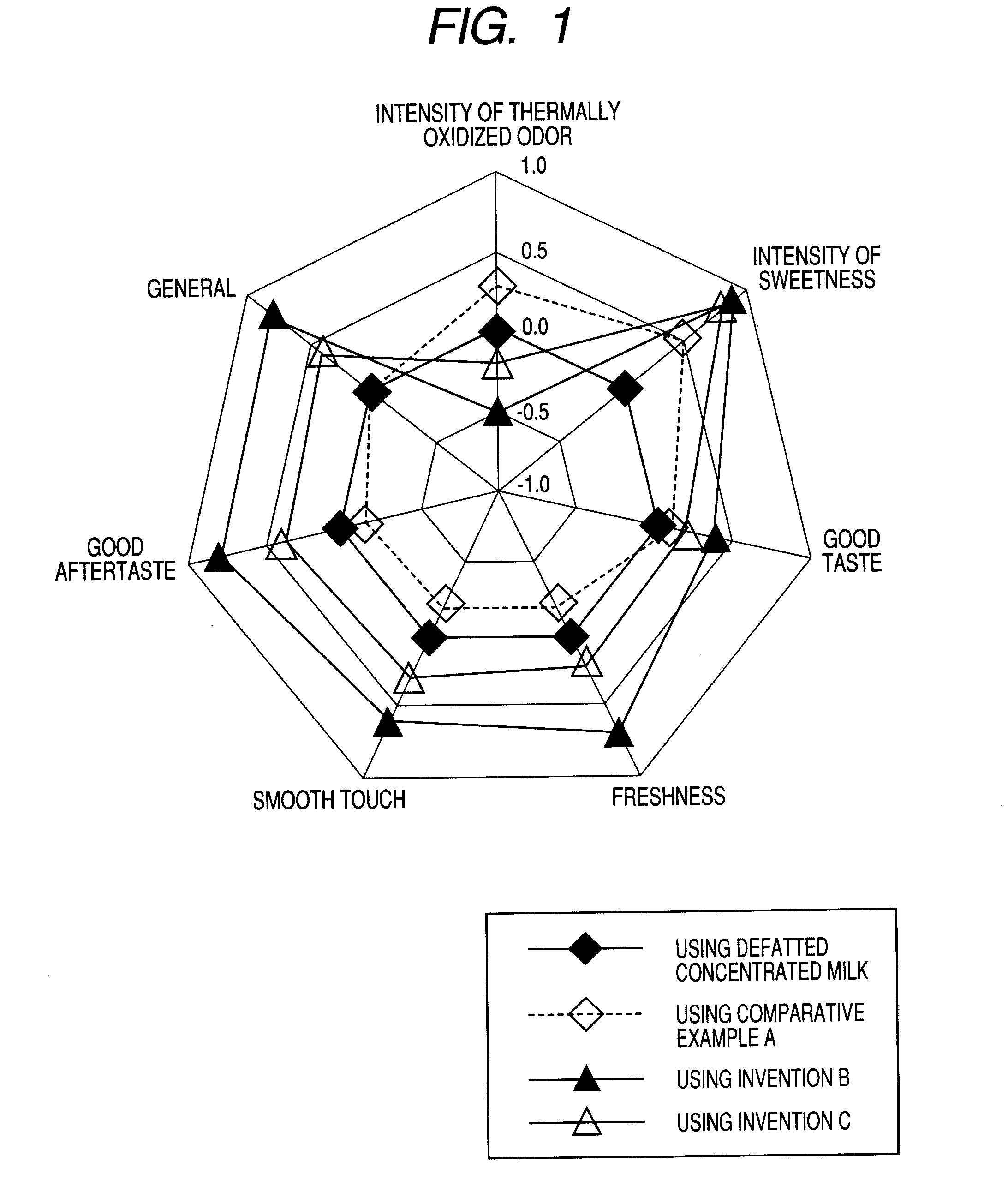

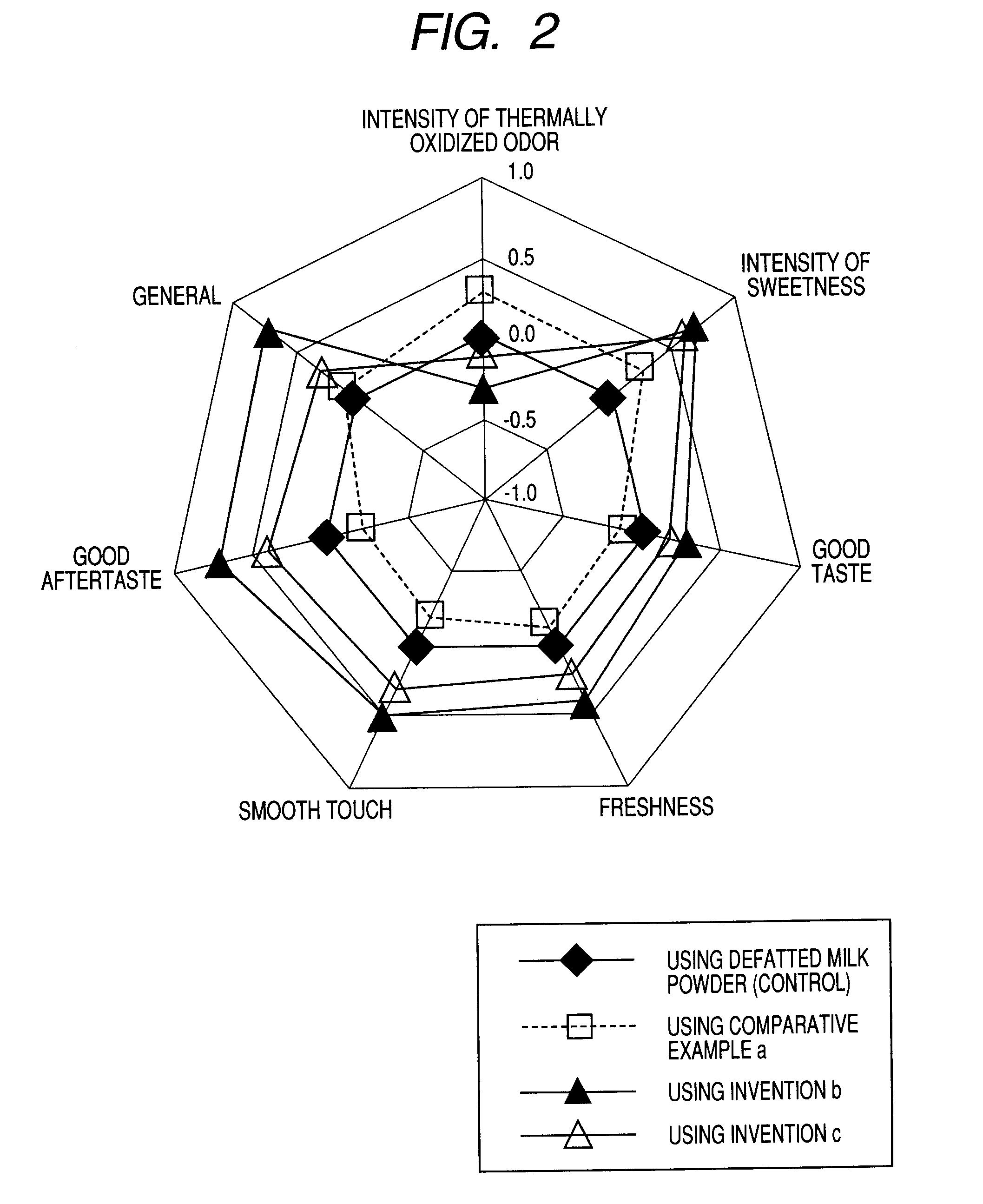

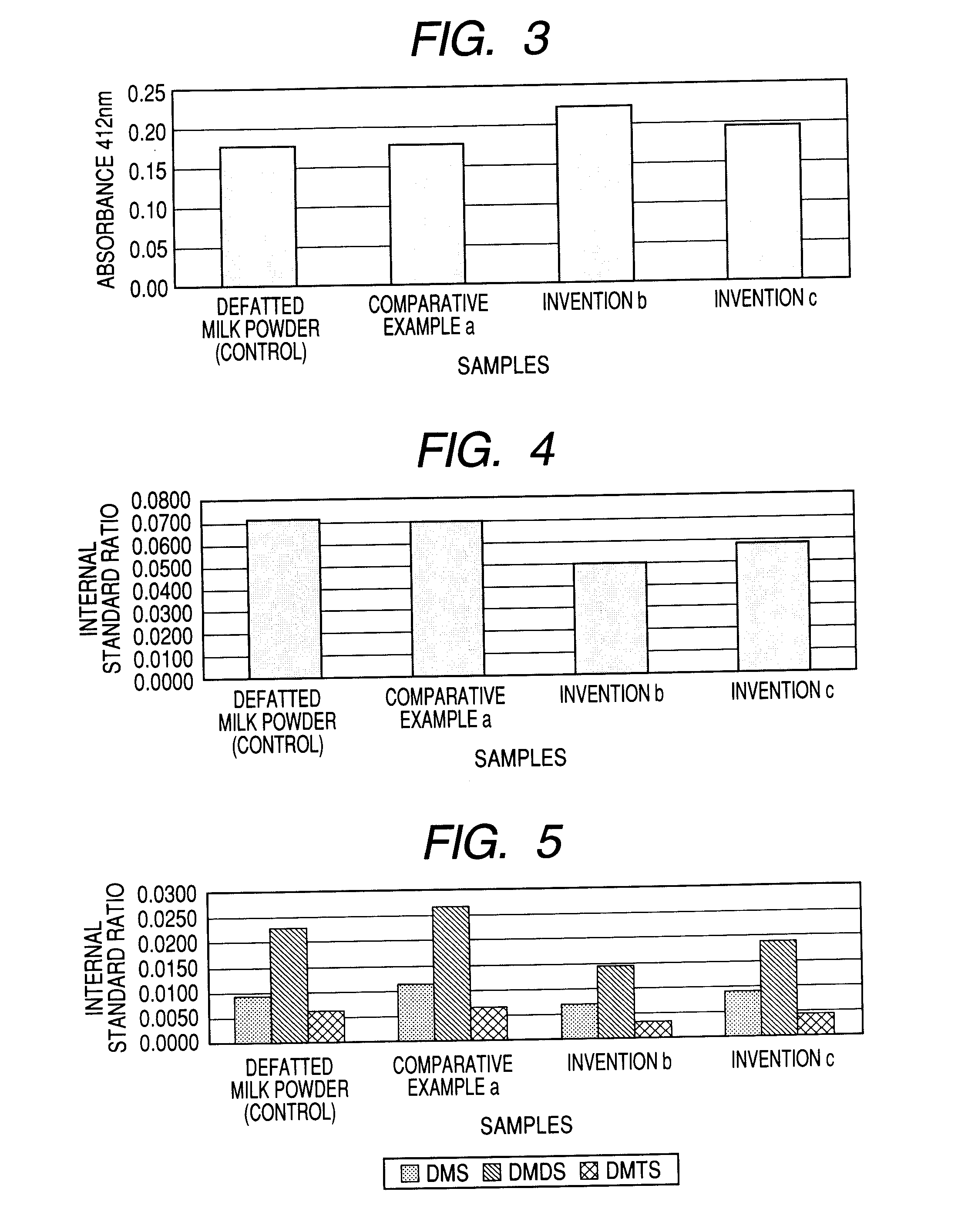

Milk material with good flavor and physico-chemical properties and process of producing the same

The invention relates to a process of producing fermented milk or milk powder, including removing ions from milk, and reducing the dissolved oxygen concentration in the milk, followed by subjecting the milk to a heat treatment, as well as concentrated milk and milk powder with good flavor and an effect of improving physico-chemical properties as a raw food material, which have never been found in conventional concentrated milk and milk powder.

Owner:MEIJI CO LTD

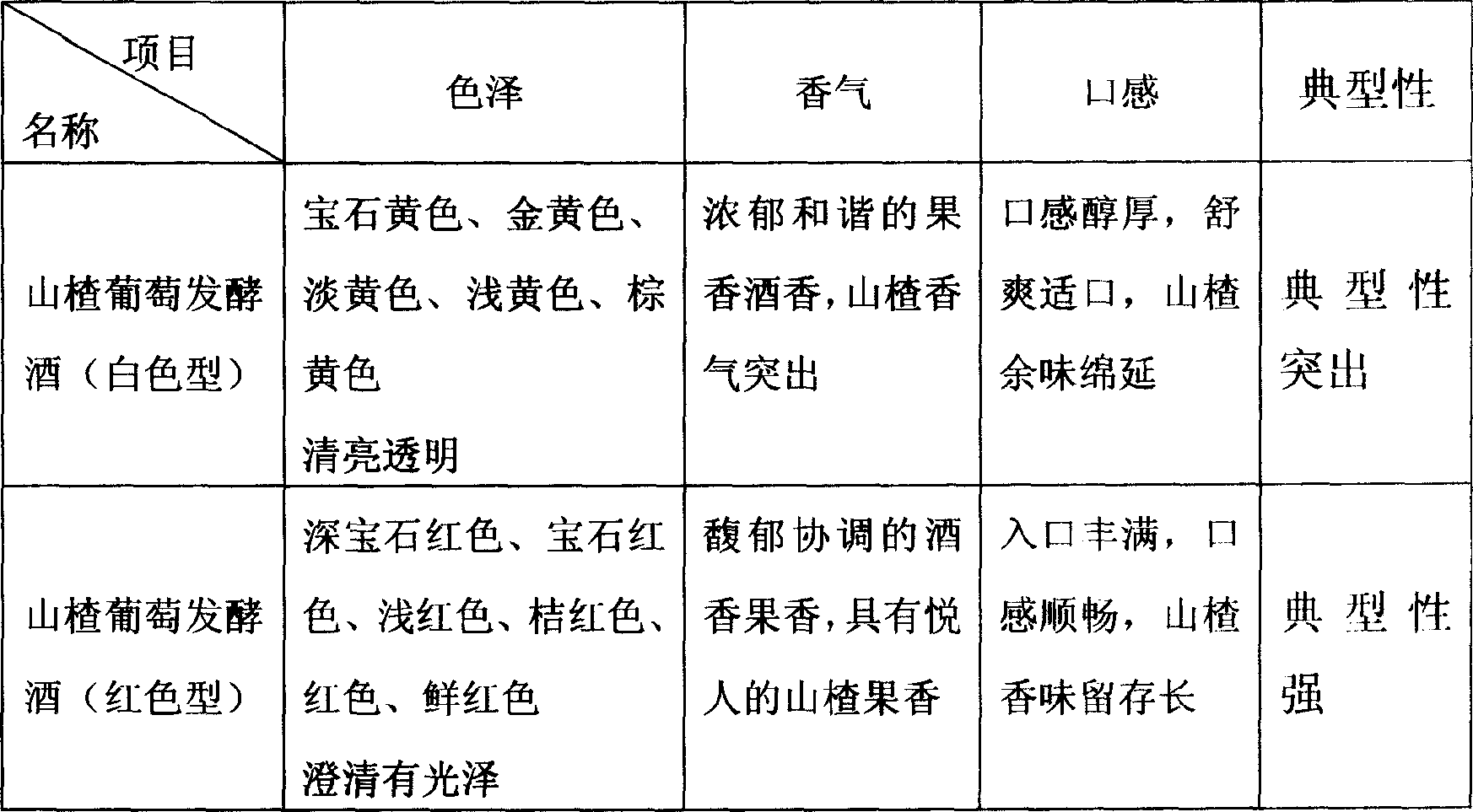

Crategus grape fermentation wine and its brewing technology

InactiveCN1912091AGood flavorReduce storage costsAlcoholic beverage preparationHealth protectionVitis vinifera

The invention relates to a haw grape fermented wine and the making process thereof, weighing haws and grapes in the weight ratio of (1%-99%) to (99%-1%), using grapes as raw material and fermenting into grape wine, then extracting haw juice and adding the haw juice in the made grape wine, further fermenting and mixing into fermented haw grape wine, then mixing into different sugar degrees, heat-treating, cold-treating, filtering, bottling, sterilizing and making it. And it has characters of double flavor of haw and grape, nutrition and health protection effects, excellent flavor, color and aroma, and quality, etc.

Owner:NANCHANG UNIV

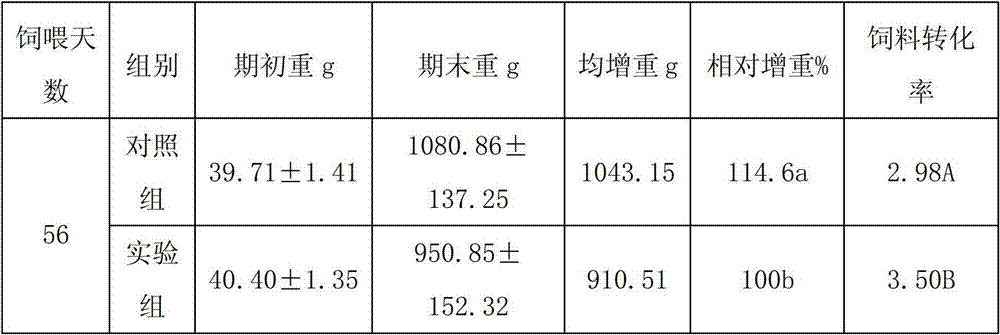

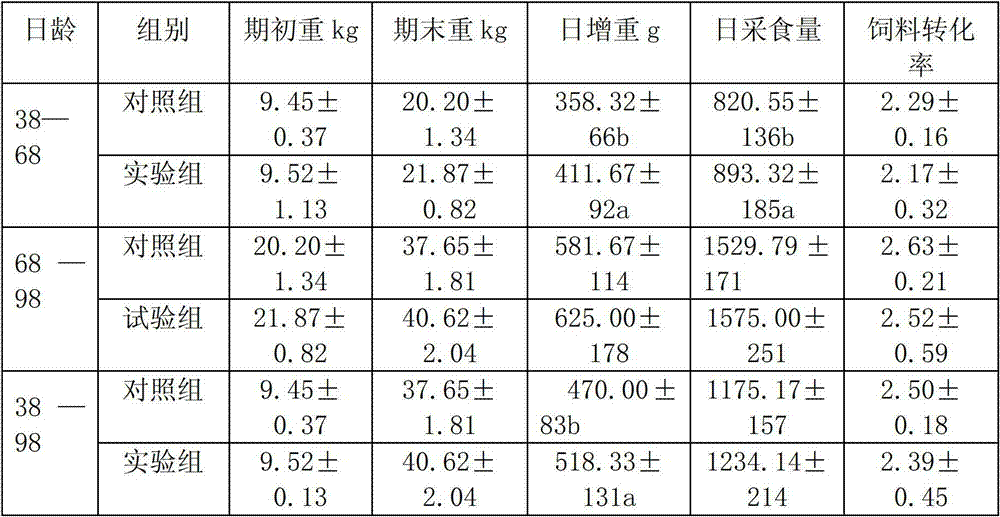

Preparation method of cordyceps feed additive

InactiveCN102783565AImprove conversion rateExtensive sources of raw materialsAnimal feeding stuffHorticultureDiseaseAnimal science

The invention relates to a preparation method of a feed additive, in particular to a preparation method of a cordyceps feed additive. According to the method, the cordyceps feed additive is prepared from cordyceps sinensis anamorphic strains of paecilomyces hepialid for inclined plane culture, liquid fermentation, solid fermentation and later-stage curing process, the cordyceps feed additive is different from microbial viable preparations and is different from ordinary cordyceps products, the defects of products in the prior art are overcome, the effect ingredients of the cordyceps is remained to the maximum degree, in addition, grain bran powder in production raw materials of products are converted into bifidus factors through microorganism via the degradation process in the specific high-temperature sterilization process, the animal growth can be preferably promoted, the feed conversion rate is improved, the cost is reduced, in addition, the animal immunity and the disease resistance can be improved on the premise of not using medicine or using little medicine, the survival rate is improved, and the cost is reduced.

Owner:XIAO COUNTY CHUANGYI LIVESTOCK BREEDING FARMERS SPECIALIZED COOP

Production process of rice with preserved meat

The invention relates to the technical field of catering foods and particularly relates to a production process of rice with preserved meat. The invention discloses a brand new process subverting the conventional home style dish making method on a series of links from raw material treatment, production and processing, storage and transportation to microwave making and the like. In order to achieve the aim, the technical scheme is adopted as follows: the production process of rice with preserved meat comprises the steps of (1) treating materials; (2) blanching and frying diced potatoes and diced carrots; (3) treating green beans; (4) blending rice; (5) packaging; (6) putting into storage; (7) distributing to storefronts in a cold storage way; (8) carrying out microwave sale.

Owner:陕西东东包餐饮食品有限公司

Peeling method of kiwi fruits and processing method of kiwi fruit slurry

InactiveCN107156877AThe peeling method is simple and easyThe method is simpleVegetable peelingActinidiaKiwi fruit

The present invention relates to the field of kiwi fruit deep processing and particularly relates to a peeling method of kiwi fruits and a processing method of kiwi fruit slurry. The peeling method of the kiwi fruits comprises the following steps: soft and mature kiwi fruits are frozen, surfaces of the frozen kiwi fruits are thawed, then the thawed kiwi fruits are peeled, then the peeled kiwi fruits are washed, and the washed kiwi fruits are sorted to obtain the peeled kiwi fruits. The provided peeling method of the kiwi fruits aims at a problem that the soft and mature kiwi fruits are hard in peeling. A scheme obtained by a large amount of investigation and exploration is as follows: specifically, firstly the soft and mature kiwi fruits are frozen, then the surfaces of the frozen kiwi fruits are thawed, the thawed kiwi fruits are peeled, then the peeled kiwi fruits are washed, and the washed kiwi fruits are sorted to obtain completely peeled kiwi fruits, wherein the peeling does not affect internal kiwi fruit flesh, and the peeling is clean and free of residues. The whole method is simple and easy to implement and low in peeling costs. Besides, the obtained kiwi fruits are complete and free of residues in peeling. The kiwi fruit slurry obtained by pulping is good in mouthfeel.

Owner:贵州修文瑞源酒庄有限公司

Plastic oil in water emulsified composition and its preparation method

PROBLEM TO BE SOLVED: To provide a plastic oil-in-water emulsified composition having smooth palate feeling, and excellent flavor, melting feeling in the mouth and preservability, hardly causing big changes in its appearance, physical properties and flavor according to season, and simple to use. SOLUTION: This plastic oil-in-water emulsified composition contains water, oil and fat, phospholipid, milk protein, calcium and one or at least two selected from the group consisting of low viscosity alginic acid, low viscosity alginate, middle viscosity alginic acid and middle viscosity alginate, and has pH2.5-6. COPYRIGHT: (C)2005,JPO&NCIPI

Owner:ADEKA CORP

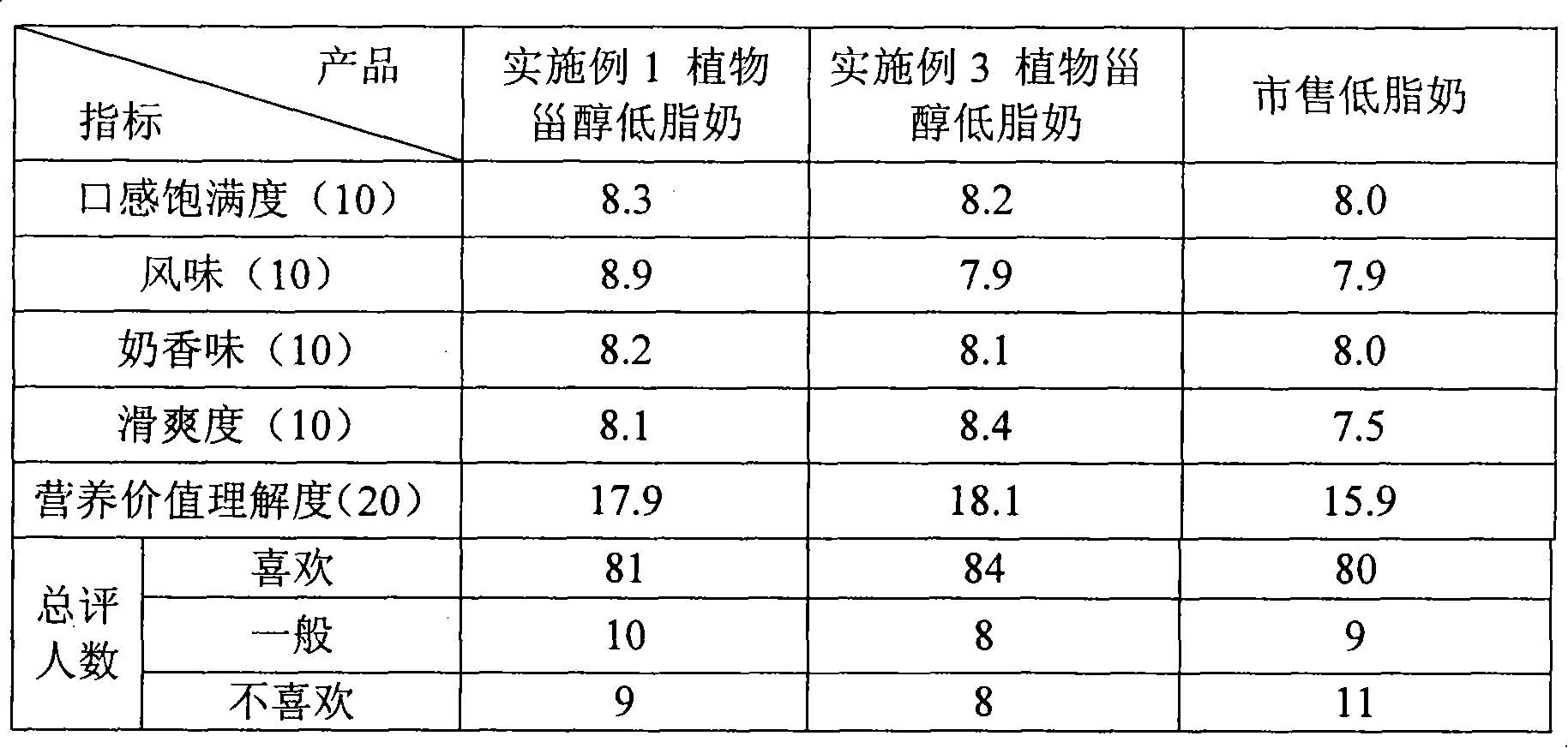

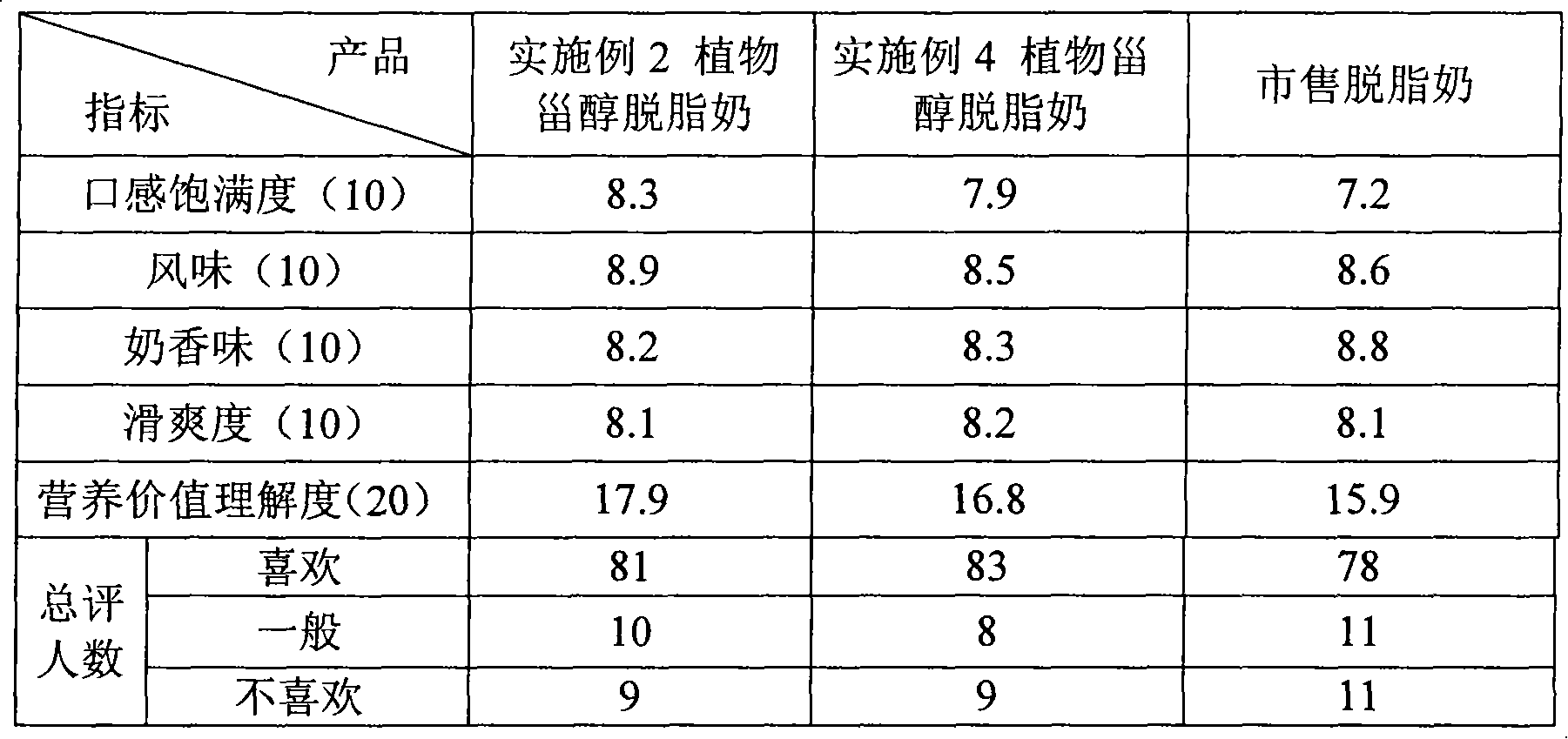

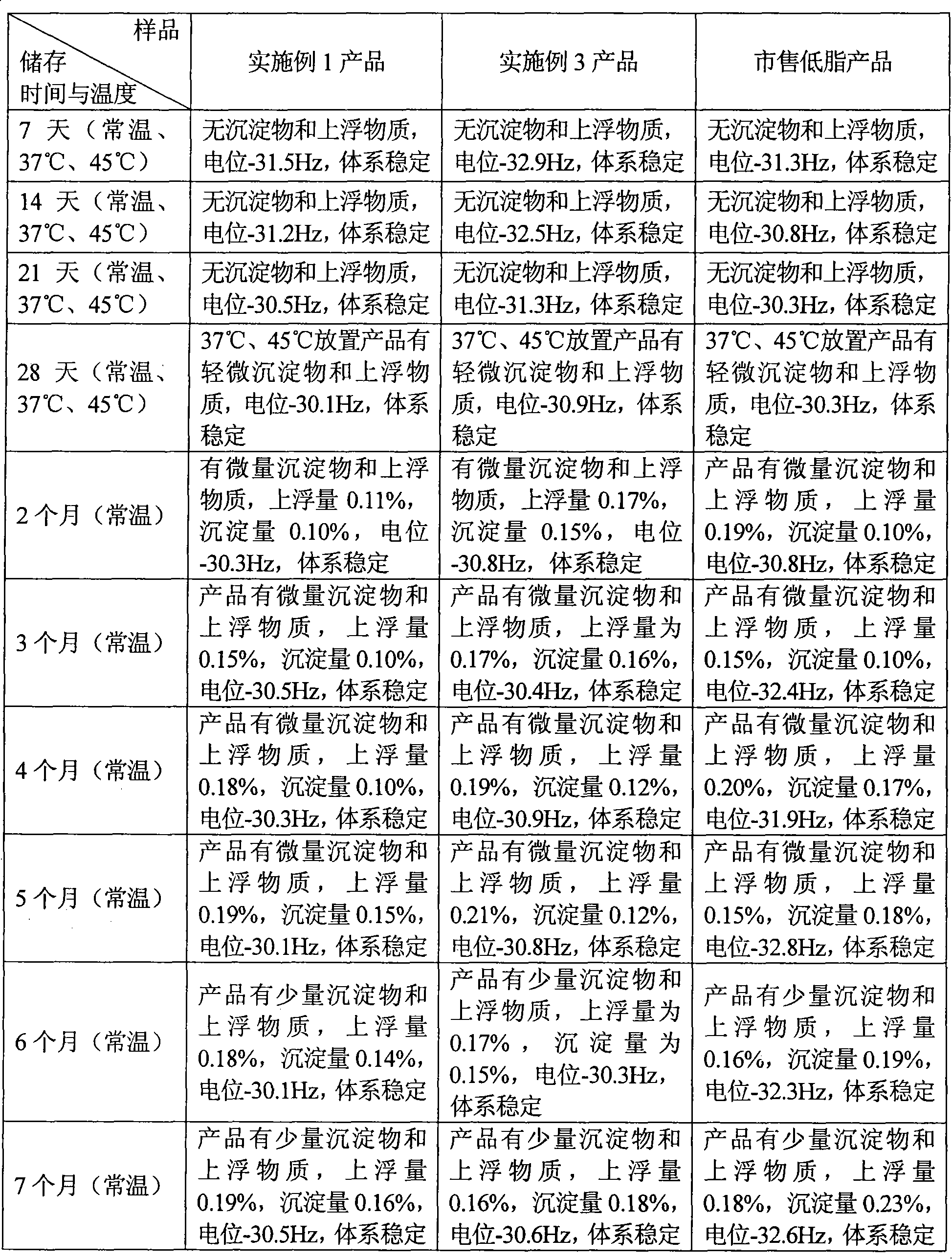

Phytosterol containing low-fat or defatted liquid milk and method for producing same

The invention provides a phytosterol containing low-fat or defatted liquid milk and a method for producing the same. The liquid milk comprises the following raw materials in percentage by weight: 98.50 to 99.54 percent of milk, 0.26 to 1.00 percent of phytosterol and 0.20 to 0.50 percent of stabilizer. The method comprises the following steps of: adding the stabilizer and the phytosterol in the milk, shear-stirring the milk for 15 to 30 minutes with a shear mixer having the high-speed shearing function, and after the homogeneous treatment of the milk, obtaining the finished product. The method adopts a reasonable formula and a proper process to ensure good stability and taste within the shelf time of the liquid milk produced by the method; and moreover, the liquid milk is a kind of food which is full of nutriments, meets flavors of Chinese people and helps human health.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Maca and ginseng beverage and preparation method thereof

InactiveCN105146645AGreat tasteGood flavorNatural extract food ingredientsFood ingredient functionsFlavorChemistry

The present invention discloses a Maca and ginseng beverage and a preparation method thereof. The Maca and ginseng beverage consists of the following raw materials in parts by weight: Maca 80-120 parts, ginseng tablets 6-15 parts, malic acids 1-3 parts, citric acids 1-3 parts, flavoring agent 1-5 parts, honey 500-650 parts, white sugar 80-120 parts, water 9000-12000 parts, carboxymethyl cellulose 1-3 parts, multi-vitamin 0.01-0.015 part, Chinese herbal medicine additive extract 15-30 parts, casein phosphopeptide 0.01-0.04 part and an appropriate amount of preservatives. The Maca and ginseng beverage preparation method produced products are good in taste and flavor, and high in nutritional value, and has functions of improving osteoporosis, preventing against aging, improving immunity and preventing bacteria and inflammation.

Owner:ANHUI LOVE ON YOUR FOOD

Probiotic lactobacillus rhamnosus fermented milk and preparation method thereof

InactiveCN105961588AStable qualityGood flavorMilk preparationLactobacillusStreptococcus thermophilusWhey protein powder

The invention relates to probiotic lactobacillus rhamnosus fermented milk and a preparation method thereof. The probiotic lactobacillus rhamnosus fermented milk comprises the following raw materials in percentage by mass: 0.8%-9% of sweet sugar, 0.8%-2.0% of whey protein powder, 0.10%-0.20% of lactobacillus rhamnosus grx10 inoculation fluid and 0.125%-1% of streptococcus thermophilus inoculation fluid and the balance of raw milk based on 100% of the raw material components. According to the probiotic lactobacillus rhamnosus fermented milk, a fermented milk formula of the lactobacillus rhamnosus grx10 is optimized, a fermentation process matched with the formula is screened out, a fermented milk product with stable quality and good mouth feel is obtained on the premise of not adding food additives such as a stabilizer and the like, the viable count of lactobacillus rhamnosus of the fermented milk product reaches the health care requirement, the fermented milk product lays a good foundation for large-scale fermentation production and widespread use of the lactobacillus rhamnosus grx10.

Owner:NEW HOPE DAIRY HLDG

Sour milk contg. high L-lactic acid, and its prepn. method

InactiveCN1718009AGood flavorIncrease the number of live bacteriaMilk preparationLactobacillus acidophilusStreptococcus thermophilus

A sour milk rich in L-lactic acid is prepared from the defatted or fresh milk through inoculating cheese lactobacillus, adding tomato juice and malt juice, fermenting, inoculating acidophilic lactobacillus and thermophilic streptococcus, fermenting and coagulating. It features high contents of living bacteria.

Owner:HARBIN UNIV OF COMMERCE +1

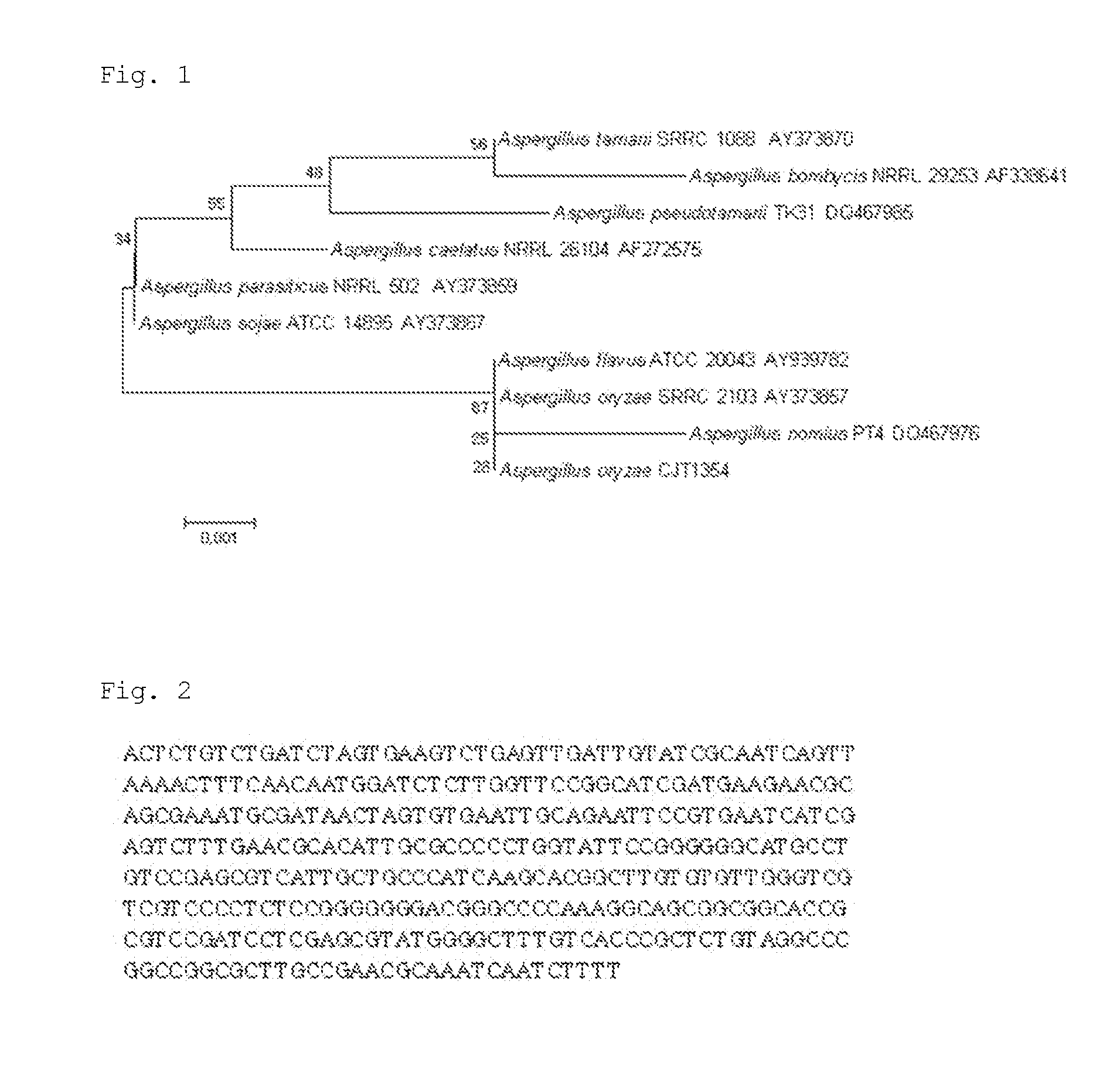

Novel Aspergillus oryzae CJ 1354 isolated from the Korean traditional meju, manufacturing method of a rice hot pepper paste using the same and the rice hot pepper paste prepared by the method

InactiveUS20150305376A1Good flavorExcellent and protease activityYeast food ingredientsMicroorganismsWater contentFlavor

The present invention relates to novel Aspergillus oryzae CJ 1354, isolated and identified from Korean traditional meju, exhibiting high enzymatic activities in rice as a substrate, a method for preparing a rice hot pepper paste having an improved flavor using the same, and a rice hot pepper paste prepared by the method. Specifically, the method comprises a process in which rice milled to have a certain whiteness is treated with high-pressure steam having a pressure of 2.0-4.0 kgf / cm2 in a steaming step to control the viscosity and water content of the steamed rice to thereby prevent agglomeration from occurring during transfer of the steamed rice. Also, in the method, novel Aspergillus oryzae CJ 1354 is used in a step of making rice koji.

Owner:CJ CHEILJEDANG CORP

Chinese herbal medicine preserved duck egg and preparation method thereof

InactiveCN103783564AMedicinal diet is effectiveGood flavorInorganic compound food ingredientsNatural extract food ingredientsOsmanthusStar Anises

The invention relates to a Chinese herbal medicine preserved duck egg and a preparation method thereof, and belongs to the technical field of food production. The method concretely comprises the following steps: pickling the fresh duck egg into preserved egg by a soaking method; decladding after the preserved egg is mature; soaking into an extracting solution, which is prepared from salt, tea, sodium hydroxide, zinc sulfate, liquorice, medlar, sweet-scented osmanthus, astragalus membranaceus, angelica sinensis, star anise, cinnamon, a clove Chinese herbal medicine and spice in manners of mixing, crushing, ultrasonic extracting and filtering; heating and infiltrating to prepare a medicated duck egg; coating and packaging the medicated duck egg in vacuum, so as to obtain the product. The product prepared by adopting the method has the advantages of whetting the appetite and clearing heat, taking the heart, and enhancing the immune function.

Owner:钟跃平

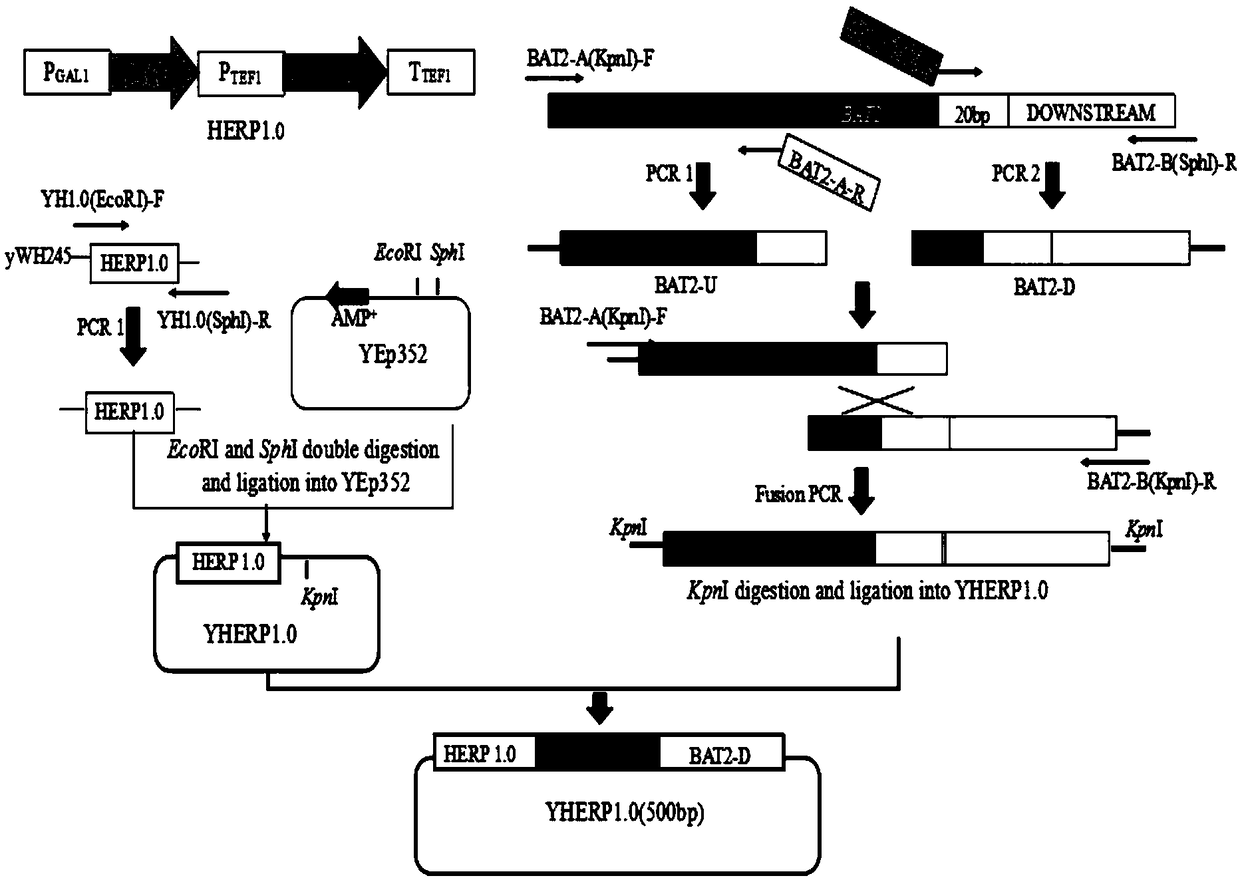

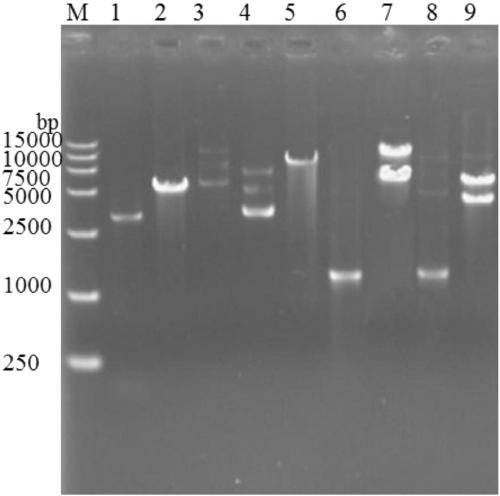

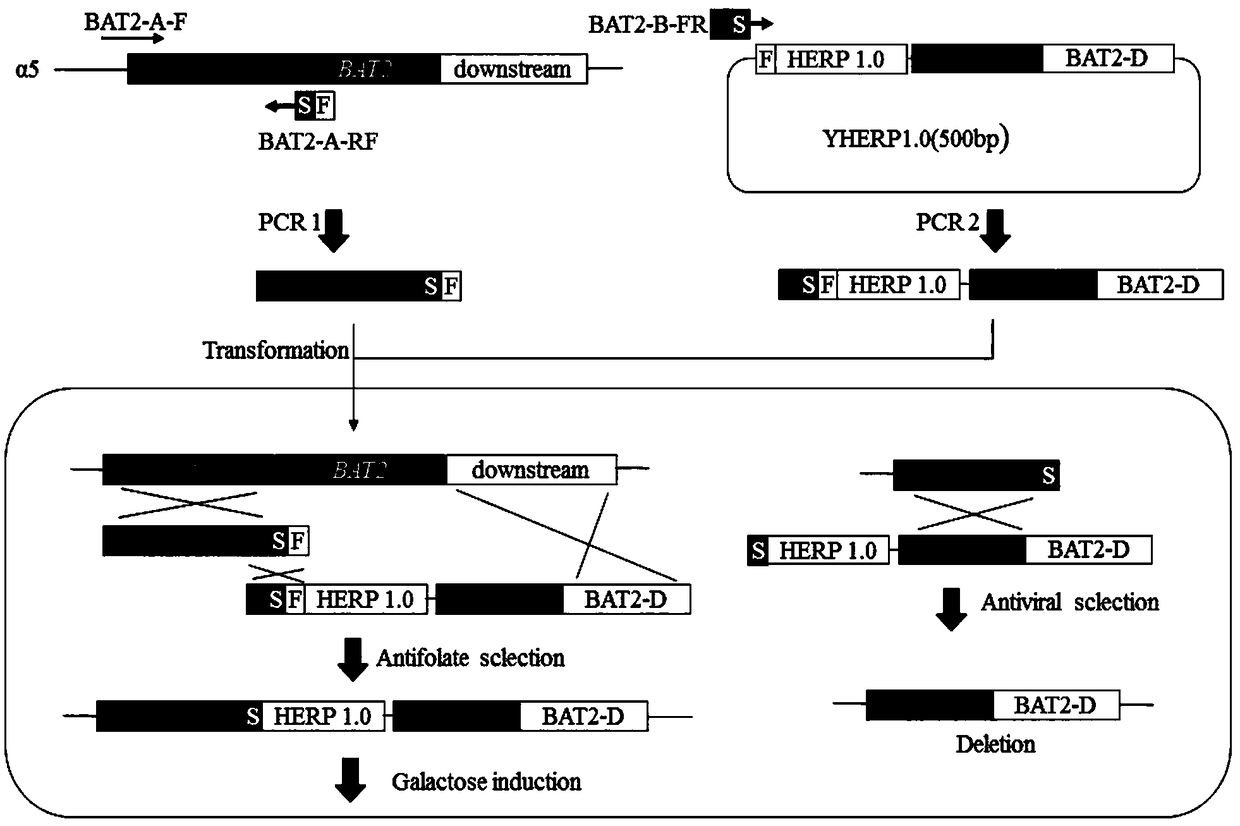

Efficient traceless gene knockout method for saccharomyces cerevisiae and application thereof

ActiveCN109136254AIsoamyl alcohol content decreasedGood flavorFungiMicroorganism based processesLactoseIsobutanol

The invention discloses an efficient traceless gene knockout method for saccharomyces cerevisiae. By optimizing the forward homologous sequence, galactose concentration and galactose induction time ina traceless gene knockout system, the probability of homologous recombination of the second step reaches 6.86*10<-4>. Haploids alpha 5 of saccharomyces cerevisiae AY15 serves as starting strains, BAT2 genes serves as the target gene, efficient and traceless knockout of wild saccharomyces cerevisiae genes BAT2 is achieved, through a liquor fermentation experiment, the contents of n-propanol, isobutanol and isoamyl alcohol of the modified strains are reduced by 20.32%, 47.85% and 23.14% respectively compared with these of parent strains, and the aim of low yield of higher alcohols is achieved.The method can be widely used in genetic modification of yeast and other microorganisms, because obtained mutants have no exogenous genes left and thus can be safely used in industrial production, anda useful reference is provided for gene knockout directly conducted on industrial strains.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Garlic sauce with intensified favor of fresh garlic without garlic odor

InactiveCN103932165AGood flavorRetain active ingredients and health functionsFood preparationVegetable dishesBiotechnology

The invention relates to the technical field of food making, and in particular to garlic sauce with intensified favor of fresh garlic without garlic odor. The making process of the fresh sauce comprises the following steps: preparing fresh garlic favor substances, making a half finished product, namely, garlic sauce without garlic odor, and making a finished product, namely, the garlic sauce with intensified fresh garlic favor. The garlic sauce made by using the process provided by the invention has the color of fresh garlic, is good in favor, maintains effective components and healthcare functions of garlic, can be used in cold vegetable dish in sauce, noodle and domestic cooking, and is stable in quality and long in expiration date, and the production process is applicable to industrial production.

Owner:贵州省轻工业科学研究所

Production method of instant green tea soybean milk powder

ActiveCN104351350AEasy to brewGood flavorPre-extraction tea treatmentMilk substitutesBiotechnologyInstant tea

The invention relates to a production method of instant green tea soybean milk powder, belonging to the technical field of instant tea beverages. In order to solve the problem that the mouthfeel and the waste are affected as two tastes of the soybean milk and the tea powder very well can not be very well mixed in an existing soybean milk tea powder product, and two different powdered objects are not easy to brew and dissolve, the invention provides the production method of the instant green tea soybean milk powder. The production method comprises the following steps: leaching green tea, filtering and concentrating to form a concentrated solution; then, mixing the concentrated solution with soybean milk powder, and mixing the concentrated solution and the soybean milk powder very well by adopting an ultrasonic dispersing technology; and finally, pressurizing spraying drying to obtain the instant green tea soybean milk powder. In the instant green tea soybean milk powder, the flavor and the active ingredients of the green tea are mixed so that the instant green tea soybean milk powder is relatively easy to dissolve in water, convenient to brew, and relatively good in flavor and nutrition.

Owner:SICHUAN YINGJING COUNTY TASHAN

Method for brewing persimmon vinegar beverage based on compound microorganisms

The invention provides a method for brewing persimmon vinegar beverage based on compound microorganisms. The method comprises the following steps: naturally softening and removing the astringency of fresh persimmons picked after frost's descent for 35 days; repeating treatment twice by utilizing a positive and negative temperature difference of 10 DEG C; increasing a sugar content of persimmon fruits to be 20% or above 20%; performing beating and separation, removing pedicles and cores of the persimmon fruits, and adding peel pomaces into a tank; adding pectinase, cellulase, wine yeast, acetic acid bacteria and lactic acid bacteria; performing stirring uniformly; fermenting at 30 DEG C; performing detection to obtain the total acid amount of 0.8%; adding potassium sorbate to reach 0.05% by mass, and terminating the fermentation; rapidly reducing the temperature to 5 DEG C or below 5 DEG C; adding diatomite for filtration, performing blending and sterilization, and then filling to obtain a finished product. The persimmon vinegar beverage is prepared by a purely natural brewing process without any chemical additive in the process from the treatment of raw materials to the completion of fermentation, so that the brewed persimmon vinegar beverage has all indexes completely meeting requirements of enterprise standards, and has good taste, flavor and nutrition.

Owner:SHAANXI FUSIFANG PERSIMMON IND

Preparation method of fish collagen peptide compound

The invention discloses a preparation method of a fish collagen peptide compound. The method includes: processing fish skin with citri acid at 80 to 100 DEG C to obtain collagen, hydrolyzing the collagen with alkaline protease and bromelain, and fermenting hydrolyzed collagen peptides with yeast to obtain the fish collagen peptide compound. By means of a combination of acid extraction and hot water extraction, the collagen is acquired from the fish skin and is then enzymatically hydrolyzed with food industry proteinases and fruit and vegetable juice proteases, microbial fermentation is then enabled to obtain collagen peptides, and the fish collagen peptide compound easy to digest and absorb and of good taste and flavor is prepared. The preparation method is simple and easy to operate and has high collagen extraction rate.

Owner:海南盛美诺生物技术有限公司

Method for producing rapid fermented type Miso-like food material with favorable taste and flavor

A rapid fermented type salt-free Miso-like food material which is favorable in taste and flavor, which has a strong umami, rich taste, thickness, and mouthfullness, and a reduced stuffy smell or astringent taste may be prepared in a method including: adding a Koji mold and a bacteriocin-producing lactic acid bacterium culture fluid or a supernatant thereof to a food material; making Koji in a hermetically sealed Koji-making equipment while continuously or intermittently supplying clean air; mixing the bacteriocin-producing lactic acid bacterium culture fluid or the supernatant thereof with the thus-resulting Koji, and further mixing one or more food materials as needed in an amount of 0.01 to 50 times weight of the Koji; forming a moromi-mash by making a paste from the mixture; and then hydrolyzing the moromi-mash in the absence of common salt, by adding any one of an alcoholic liquor, yeast, and dextrin to the Koji.

Owner:AJINOMOTO CO INC

Production method of instant green tea coffee powder

The invention relates to a production method of instant green tea coffee powder, belonging to the technical field of instant tea beverages. In order to solve the problem that the mouthfeel and the taste are affected as the two tastes of the green tea and the coffee can not be very well mixed in an existing coffee tea powder product, two different powered objects are not easy to brew and dissolve, the invention provides the production method of the instant green tea coffee powder. The production method comprises the following steps: leaching green tea, filtering and concentrating so as to obtain a concentrated solution, and then, mixing the concentrated solution with coffee powder; mixing the green tea and the coffee powder very well by adopting an ultrasonic dispersing technology; and finally, performing pressurizing spraying drying to obtain the instant green tea coffee powder. In the instant green tea coffee powder, the flavor and the active ingredients of the green tea are mixed, so that the instant green tea coffee powder is relatively easy to dissolve in water, convenient to brew, and relatively good in flavor and nutrition.

Owner:SICHUAN YINGJING COUNTY TASHAN

Membrane distillation quality-improved base liquor of strong-flavor distilled liquor and membrane distillation method thereof

The invention relates to a membrane distillation quality-improved base liquor of strong-flavor distilled liquor and a membrane distillation method thereof, and belongs to the technical field of brewing production. The membrane distilled base liquor of strong-flavor distilled liquor comprises the following components: 0.75-2.5g / L of ethyl hexanoate, 0.3-1.5g / L of ethyl lactate, and 0.24-1.2g / L of ethyl acetate, 0.05-0.25g / L of ethyl butyrate and 0.3-0.5g / L of isoamyl alcohol. The contents and proportions of all components in the base liquor are reasonably coordinated and quality and flavor of the base liquor are good, so that the quality of base liquor which cannot be used for blending pure kernel solid-state brewed liquor can be improved, the difficulty in blending liquor can be reduced, Chinese distilled liquor which is a system comprising complicated components can be optimized, the existing base liquor of strong-flavor distilled liquor, which contains unreasonable components, can be better balanced, the quality can be improved, the flavor can be more mellow and purer.

Owner:YIBIN JINXILAI LIQUOR

Preparation method of fermented soybean milk

The invention provides a preparation method of fermented soybean milk and relates to the technical field of food fermentation. The preparation method primarily comprises (1), cleaning soybeans, peeling, degerminating and soaking; (2), processing through a jet cavitation machine, separating milk from bean dregs, and flashing; (3), extracting soybean milk, adding stabilizers into the soybean milk and dissolving, blending, homogenizing, sterilizing and cooling; (4), fermenting. The fermented soybean milk is fermented based on full vegetation without any bean flavor, bitter taste or other bad smell, has smooth taste, thick fermented fragrance, rich nutrition, low production cost and good flavor, and is free of animal origins in production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Pork floss

The present invention discloses pork floss, which includes the following raw materials, by weight, 80 to 85 parts of lean meat, 10 to 15 parts of fat meat, 3 to 5 parts of sodium glutamate, 3 to 7 parts of salt, 6 to 8 parts of white sugar, 0.1 to 0.15 part of monosodium glutamate, 0.5 to 0.7 part of illicium verum, 0.2 to 0.25 part of fructus amomi, 0.2 to 0.3 part of Chinese prickly ash and 0.1 to 0.3 part of nutmeg. The pig floss is advantaged by comfortable taste, nice flavor, good nutrition and the like and is characterized by good safety, long shelf life and the like, and the production cost of the pork floss is relatively low. The pig floss meets the Chinese people's dietary habits, and the pig floss has a loose meat texture and is convenient to chew, absorb and digest so that the pork floss is especially suitable for the elderly and children to eat.

Owner:王玲

Herbal healthy beverage capable of benefiting throat, moistening lung and resisting haze

InactiveCN107691953AWide variety of sourcesLow costNatural extract food ingredientsFood ingredient functionsSeparation technologyHouttuynia

The invention provides a herbal healthy beverage capable of benefiting throat, moistening the lung and resisting haze. The beverage comprises the following components in parts by weight: 10-35 parts of honeysuckles, 10-35 parts of cordate houttuynia, 1-30 parts of mulberry leaves, 1-30 parts of fragrant solomonseal rhizomes, 1-24 parts of peppermint and 1-24 parts of licorice. The invention also provides a preparation method of the beverage. The main components of the six raw materials of the invention are water-soluble, and a production process of the wall-broken extraction takes water as a medium. In wall-broken extraction stage of the invention, a temperature is 65 DEG C or below, and a dissolution rate of active ingredients is high. A multi-stage membrane separation technology is alsoutilized so as to reserve the active ingredients and remove insoluble components such as residue. All the six raw materials of the present invention are both medicinal and edible raw materials, have along consumption history and clear formula efficacy, and are natural, safe and nontoxic. The beverage has significant efficacy of benefiting throat, moistening the lung, clearing heat and relieving toxicity, and can relieve symptoms such as cough, excessive phlegm, throat dryness, throat itching and difficulty in breathing caused by haze weather at the same time.

Owner:GUANGDONG AUTHENTEA BIOTECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com