Plastic oil in water emulsified composition and its preparation method

An emulsified composition and oil-in-water type technology, which is applied in the field of plastic oil-in-water emulsified composition of sandwich cream, can solve the problems of inability to have mouth-melting shape retention, difficulty of sandwich cream, inconvenient use, etc., and achieve good Flavor, good storage stability, dehydration inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

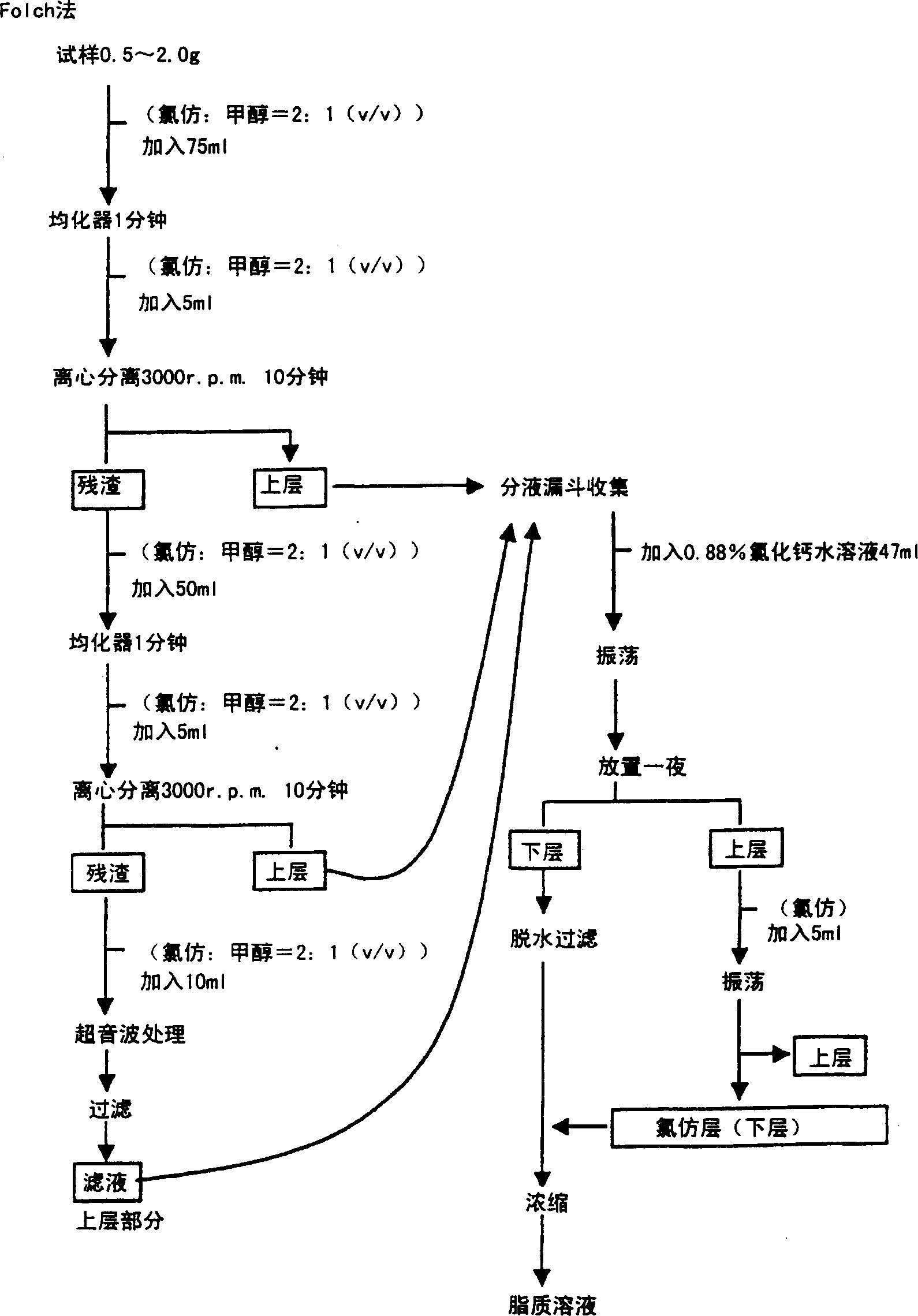

Method used

Image

Examples

Embodiment 1

[0094] Mix 7 parts by weight of whole milk protein, 50 parts by weight of granulated sugar, 10 parts by weight of sorbitol, and 21 parts by weight of the concentrate (38% by weight of solid content, 38% by weight of solid content, The phospholipid content is 4.89% by weight), 2.5 parts by weight of corn oil and 6.19 parts by weight of water, heated to 55°C, using a 2-stage homogenizer manufactured by Izumifu-Domasinaly in the homogenization of the first stage 5MPa and the second stage 10MPa Homogenized under pressure to prepare an oil-in-water emulsion (1). To this oil-in-water emulsion (1), add 0.01 parts by weight of low-viscosity alginic acid (the viscosity of a 10% by weight aqueous solution is 30 mPa·s, and the viscosity of a 1% by weight aqueous solution is 3 mPa·s), 0.25 parts by weight Guar gum, 0.25 parts by weight of locust bean gum, 2 parts by weight of sunflower oil and 0.8 parts by weight of lemon juice were mixed in a mixing bucket to prepare an oil-in-water emul...

Embodiment 2

[0115] Mix 2.5 parts by weight of whey powder, 1.5 parts by weight of whole milk protein, 30 parts by weight of syrup, and 5 parts by weight of the concentrate of the aqueous phase components produced when milk fat is produced from cream (38% by weight of solid content, 38% by weight of solid content, The phospholipid content is 4.89% by weight), 10 parts by weight of soybean oil and 39.2 parts by weight of water, heated to 45°C, using a 2-stage homogenizer manufactured by Izumifu-Domasinaly in the homogenization of the first stage 100MPa and the second stage 0MPa Homogenized under pressure to prepare an oil-in-water emulsion (1). In this oil-in-water emulsion (1), add 0.5 parts by weight of medium viscous sodium alginate (the viscosity of an aqueous solution of 1% by weight is 30mPa·s), 10 parts by weight of rapeseed oil, 0.3 parts by weight of lactic acid and 1 The starch in parts by weight is mixed in a mixing hopper to prepare an oil-in-water emulsion (2). This was heat-s...

Embodiment 3

[0120]Mix 0.1 weight part of protein concentrated whey powder, 0.35 weight part of whole milk protein, 2.7 weight parts of the concentrate (40% by weight of solid content, the phospholipid content in the solid content is 4.89% by weight), 20 parts by weight of rice bran oil, 0.025 parts by weight of calcium chloride dihydrate, and 49.625 parts by weight of water, heated to 60°C, using a 2-stage homogenizer manufactured by Izumifu-Domasinaly in the first stage of 30MPa, Homogenization was performed under a homogenization pressure of 5 MPa in the second stage to prepare an oil-in-water emulsion (1). In this oil-in-water emulsion (1), add 2 parts by weight of low-viscosity sodium alginate (the viscosity of a 10% by weight aqueous solution is 30 mPa·s, and the viscosity of a 1% by weight aqueous solution is 3 mPa·s), 20 Parts by weight of palm oil, 2 parts by weight of LM pectin, 0.05 parts by weight of citric acid, 0.05 parts by weight of sodium bicarbonate, 3 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com