Patents

Literature

30results about How to "Eliminate earthy smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fish head sauce with tea aroma and preparation method thereof

InactiveCN102178208ABroaden the way of processing and utilizationEliminate earthy smellFood preparationSaline waterFlavor

The invention discloses a fish head sauce with tea aroma and a preparation method thereof. The preparation method comprises the following steps of: (1) selecting a fresh fish head, removing a gill and cleaning; (2) pouring hot water on the tea to obtain tea water and adding common salt to obtain tea saline water; (3) soaking the fish head with the tea saline water; (4) heating and pressurizing tosoften fish head bone and crush into fish head paste; (5) chopping fresh pork and mushroom into small blocks, frying sesame to be cooked and frying diced meat to be cooked with oil; and (6) adding seasoning into hot pepper, green onion, ginger, diced mushroom, the fish head paste, flour paste and cooked diced pork, then frying to be cooked, adding crushed tea leaves and the cooked sesame, uniformly stirring the cooked sesame, packaging and sterilizing to obtain the fish head sauce with tea aroma. According to the fish head sauce, the processing and utilizing path of fresh fish head is widened. By adopting the tea for soaking treatment, the fishy flavor of the fish can be eliminated and the improvement on the quality of products is facilitated; and the fish head sauce has abundant nutrition, is produced by adopting a simple production process and is suitable for industrial production.

Owner:TIANJIN AGRICULTURE COLLEGE

Production technique for chicken powder with great freshness flavor

ActiveCN103689522AIncrease umamiImprove sensory qualityFood ingredientsFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a production technique for chicken powder with a great freshness flavor, and belongs to the technical field of processing food seasoning. The chicken powder comprises the following materials according to mass: 30kg of fresh chicken skeletons, 30kg of fresh chicken, 7kg of maltodextrin, 2.5kg of disodium nucleotide, 0.1kg of sodium citrate, 7kg of trehalose, 10kg of edible salt, 10kg of monosodium glutamate, 2kg of lentinula edodes, 1kg of radix puerariae, and 0.4kg of pepper; the production technique comprises the steps: pretreating active ingredients, and carrying out high-temperature high-pressure sealed cooking, fine treatment, enzymolysis for flavor, mixing, spray drying, filling and capping. According to the production technique, the processes are simple, the energy consumption can be reduced, the loss of flavor components can be effectively reduced and sufficient release of flavor substances is promoted, the chicken powder is rich in chicken flavor, harmonious in saline taste, delicate flavor and perfume, luminous in color, good in rehydration property, smooth in mouthfeeling, free from sand grains, and milkily white in soup feeling.

Owner:GUANGDONG JIALONG FOOD

Chicken feed additive for improving meet quality

InactiveCN102823767AImprove internal and external environmentImprove freshnessFood processingAnimal feeding stuffSodium bicarbonateCodonopsis

The invention relates to a chicken feed additive, especially to a chicken feed additive for improving meet quality. The chicken feed additive for improving the meet quality is prepared from the following components by weight parts: 5 to 15 parts of Radix Astragali, 5 to 15 parts of cumin, 15 to 30 parts of wormwood leaves, 15 to 30 parts of cassia bark, 15 to 30 parts of haw, 15 to 30 parts of Cortex Acanthopanax Radicis, 20 to 30 parts of white peony root, 20 to 30 parts of Radix Peucedani, 20 to 30 parts of dried orange peel, 1 to 5 parts of talcum, 20 to 30 parts of sodium bicarbonate, 1 to 5 parts of salt, 10 to 20 parts of poria peel, 10 to 20 parts of mulberry bark, 10 to 20 parts of ginger peel, 10 to 20 parts of areca peel, 5 to 10 parts of radix codonopsis and 5 to 10 parts of bighead atractylodes rhizome. 1.5 to 3 % by mass percent of the chicken feed additive for improving meet quality is added into a basal feed to feed chicken, so as to substantially improve delicious degree of the meat, increase growth speed, enhance immunity of the chicken, and increase utilization rate of the feed.

Owner:QINGDAO SENYUAN ANIMALS BIRDS CULTURE

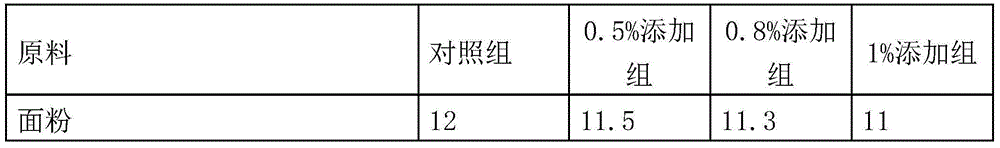

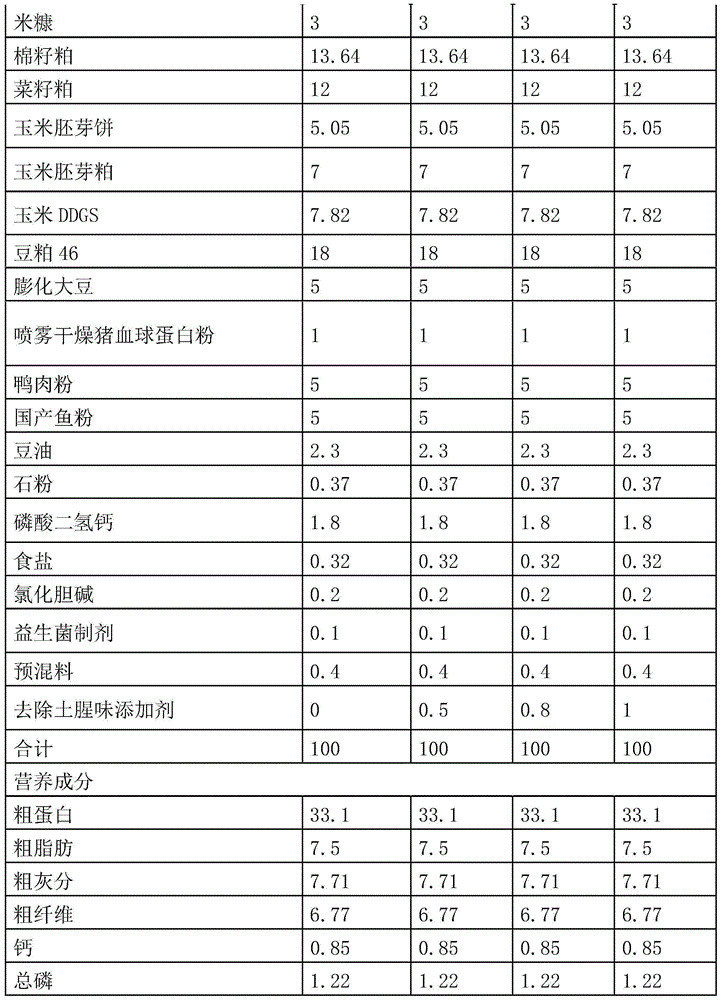

Feed additive for removing earthy taste of freshwater fish and application of feed additive

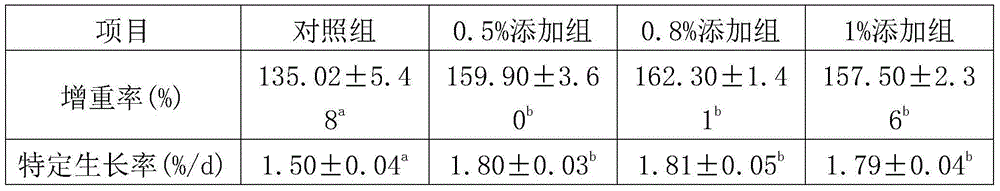

ActiveCN104304830AFast growthImprove antioxidant capacity and immune activityAnimal feeding stuffSide effectDisease

The invention aims to provide a feed additive for removing the earthy taste of freshwater fish. The feed additive comprises, by weight, 5%-10% of allicin, 2%-6% of perilla leaf extracts, 2%-6% of tea polyphenols, 2%-6% of ethyl maltol, 20%-40% of yeast cell walls and 20%-40% of yeast contents. Physical, chemical and biological methods are comprehensively adopted for removing the earthy taste of the freshwater fish effectively through the feed additive, no drug tolerance or toxic and side effect is generated, and the growth rate of fishes can be remarkably increased; antioxidant capacity and immunocompetence of the fishes are improved, disease resistance of fish bodies is enhanced, fish meat quality is improved, the market price of the fishes is increased, and production effectiveness is remarkably promoted.

Owner:山东百福生物科技有限公司

Processing process for low-salt air-dried geese marinated in rice wine

The invention discloses a processing process for a low-salt air-dried goose marinated in rice wine. A live goose is killed, unhaired, eviscerated and rinsed to obtain a goose whole. The processing process is characterized by comprising the following steps: soaking the goose whole in a marinating solution which takes vinasse as reference, and marinating for 18-24 hours at the temperature of 12-15 DEG C; then placing the goose whole in a workshop in which the temperature is 18-20 DEG C and the relative humidity is 65-70%, carrying out air drying for 2-3 days at the air speed of 6-8m / s, transferring into a workshop in which the temperature is 25-28 DEG C and the relative humidity is 70-75%, and carrying out air drying for 2-3 days at the air speed of 3-5m / s; placing the goose whole subject to air drying into a water tank with the temperature of 90-95 DEG C for 3-4 minutes, then completely tweezing the tiny feather on the surface of the goose whole, washing the goose whole clean, placing on a fixed frame, transmitting to halogen liquid with the temperature of 90-95 DEG C, and stewing for 45-60 minutes; and finally, carrying out vacuum packing and sterilization on the stewed goose whole to obtain the finished product. The low-salt air-dried geese marinated in rice wine has the advantages of unique flavor, delicious texture, strong bacon fragrance and mellow rice wine, and is beneficial to human health.

Owner:NINGBO UNIV

Method of removing fishy and refreshing for fresh water fish

InactiveCN101223904ASolve the heavy earthy smellAddressing CorruptionMeat/fish preservation using chemicalsFresh waterGingerol

The invention discloses a method for removing fishy smell and preserving freshwater fish. The method comprises the steps that: 1) preparation of fishy smell eliminating and preserving solution as following: 6-8 portions of ginger, 6-8 portions of garlic and 6-8 portions of onion are mixed, ground, hemogenated, and then 76-82 portions of rice wine is added to obtain a mixture; the mixture is extracted by ultrasonic wave and then filtered to obtain a filtrate, that is, the fishy smell eliminating and preservative solution; 2) freshwater fish which is killed, cleaned and directly soaked into the fishy smell eliminating and preserving solution; 3) the soaked freshwater fish can be stored for 7-9 days. The method of the invention can remove bilgy odour of freshwater fish and ensure that freshwater fish is not likely to rot.

Owner:ZHEJIANG UNIV

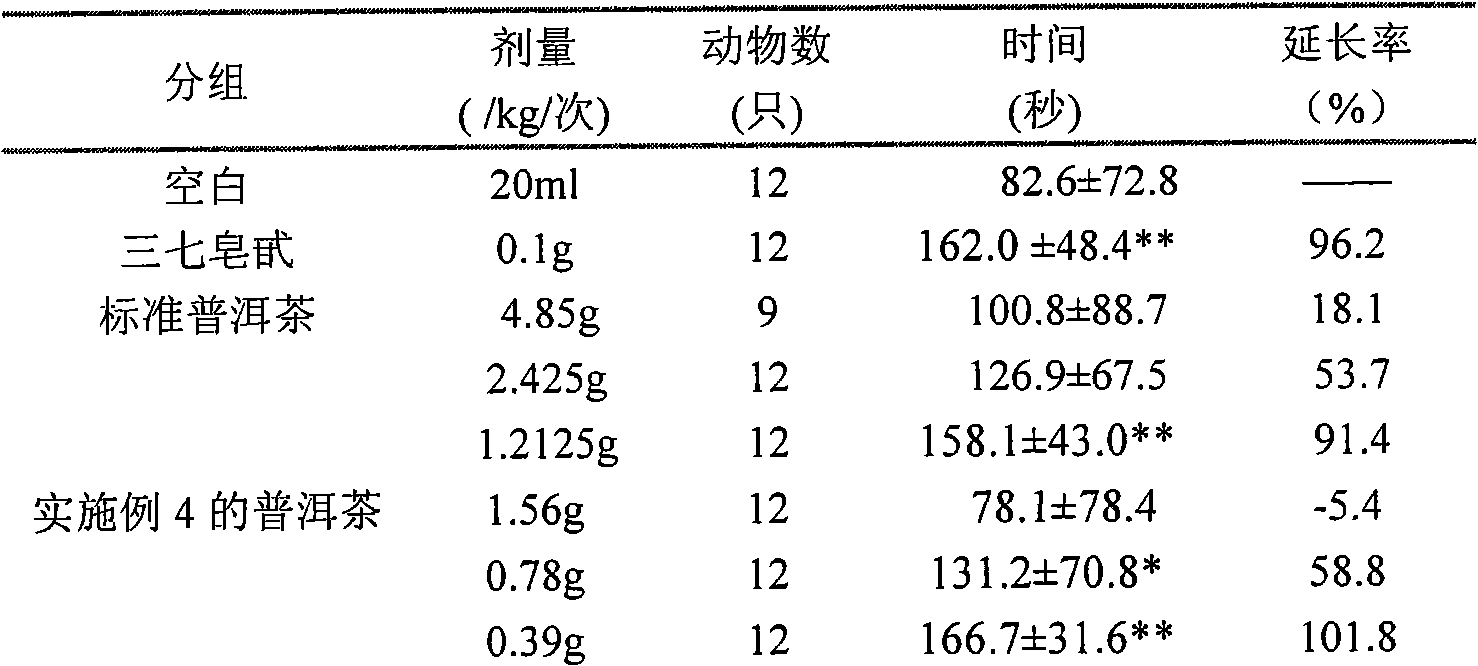

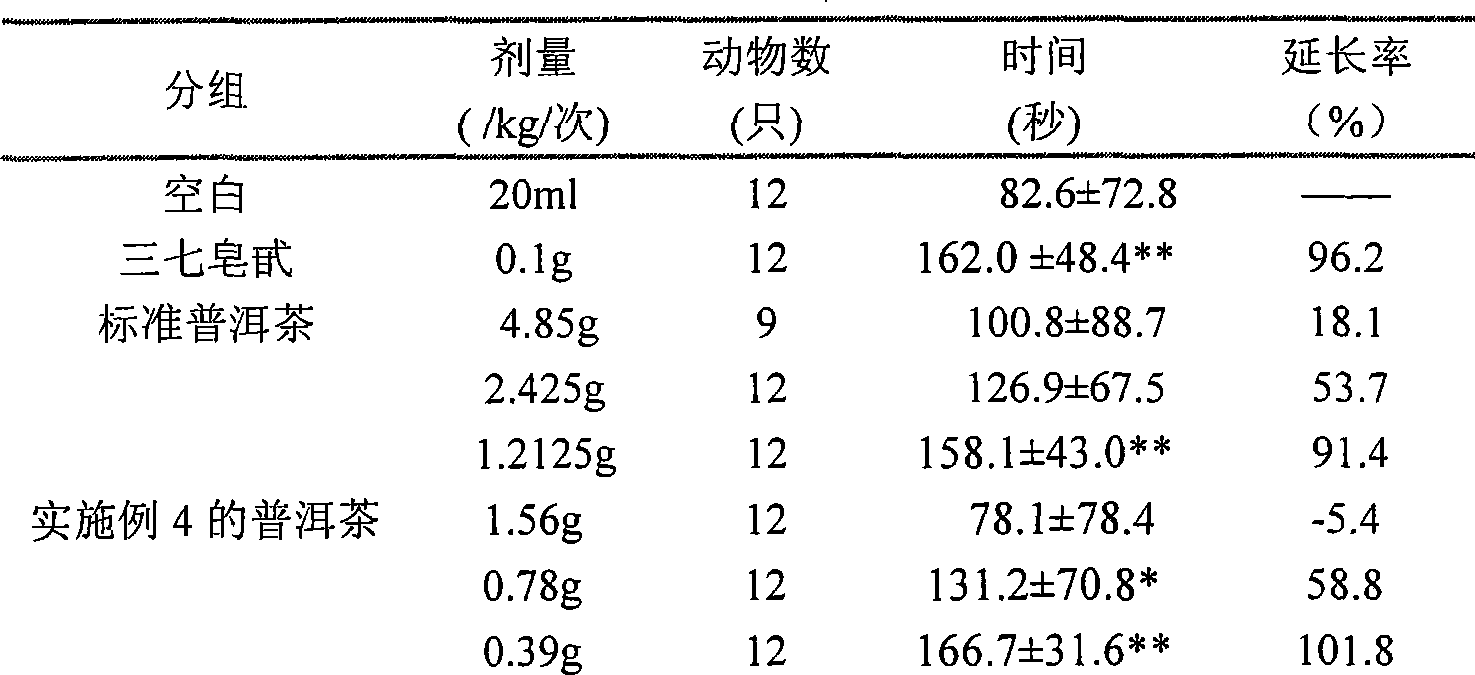

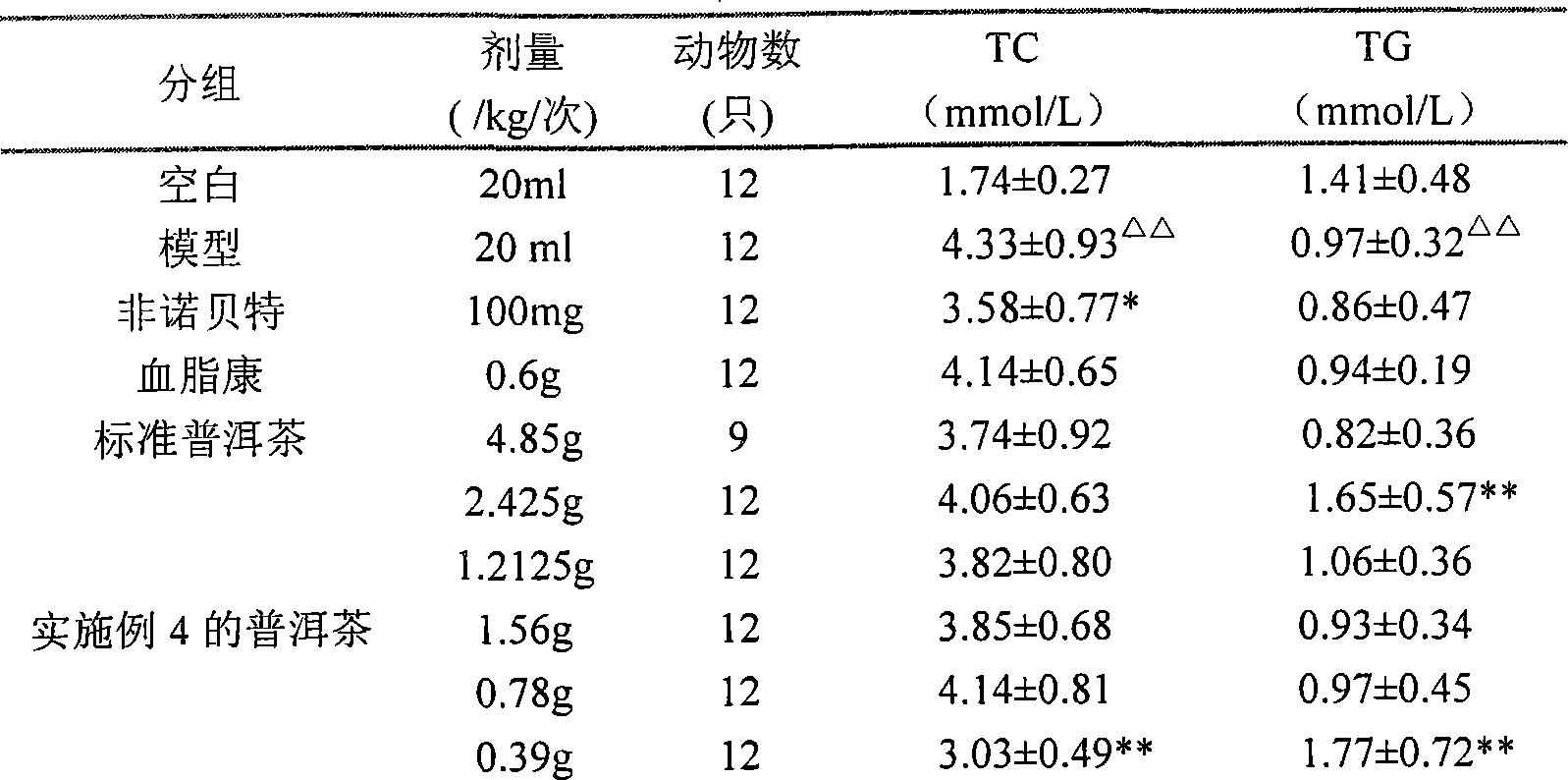

Fatigue-resisting health-care tea and preparation thereof

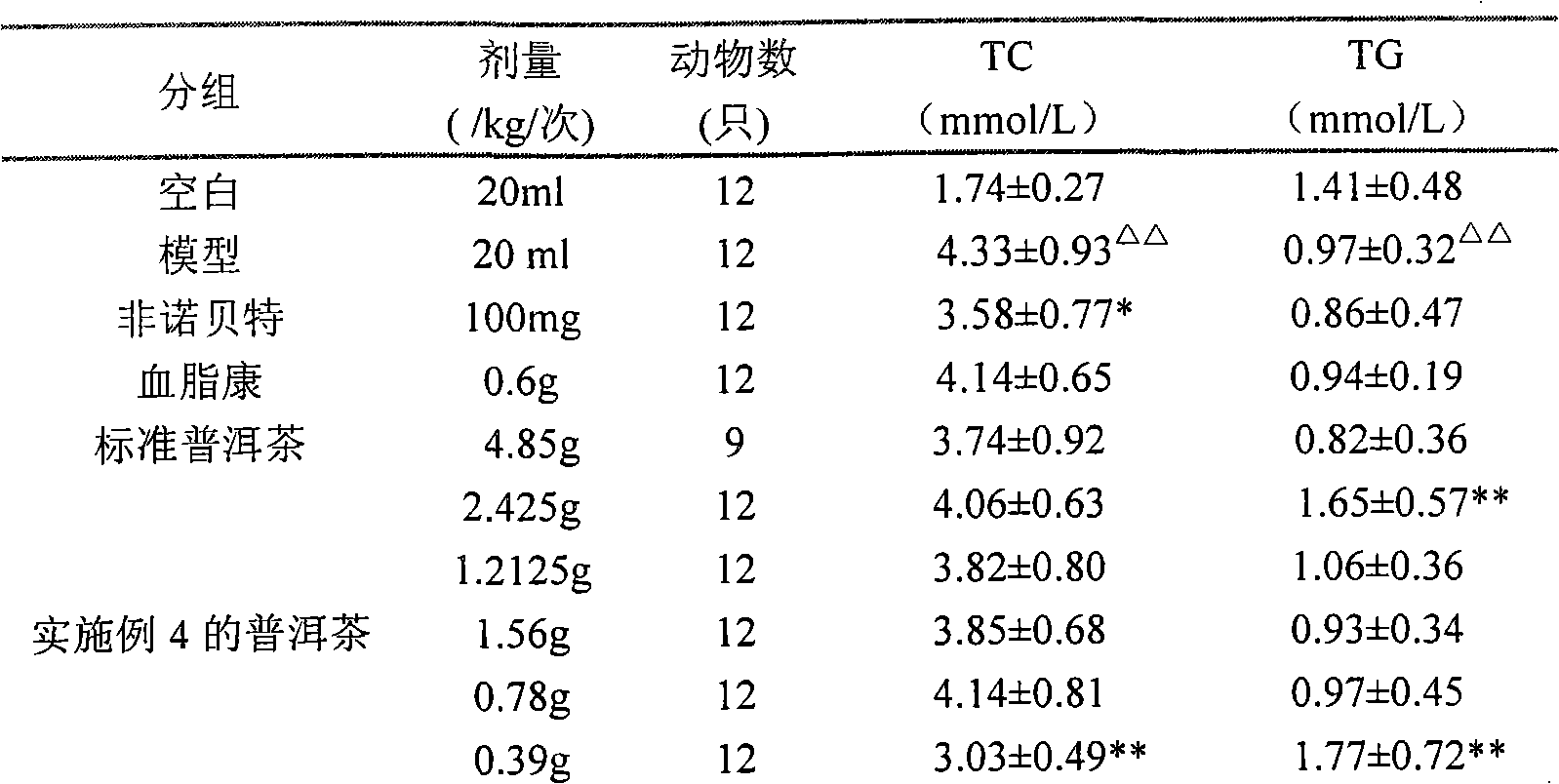

The invention discloses an anti-fatigue and health care tea, which is characterized in that: ethanol extraction of buckwheat sprout and the ethanol extraction of notoginseng are dissolved in purified water and evenly mixed with a crude tea; the mixture is fermented by the ordinary method, and the fermented Pu'er tea obtained is the anti-fatigue and health care tea. The health care tea has the advantages of refreshing taste, pure flavor, and having functions of reducing weight and fat and anti-fatigue for a long term drinking, and has obvious health care effect. The addition of the buckwheat sprout not only enriches the nutrient substances of the fermented tea, but also quickens the aging of the Puerh tea, shortens the fermentation period and removes the earthy smell of the Puerh tea without being added with other substances; therefore, the tea enlarges the people drinking the tea of the invention.

Owner:游文龙 +1

Functional poultry sausage having unique flavor, and preparation method thereof

The invention discloses a functional poultry sausage having a unique flavor, and a preparation method thereof. The method is characterized in that the method comprises the following steps: preparing a red date paste; preparing a Haematococcus pluvialis powder enzymatic hydrolysis product; adding salt and composite phosphate to poultry, and carrying out vacuum rolling; adding the Haematococcus pluvialis powder enzymatic hydrolysis product, the red date paste, a composite flavor enhancer, white wine, diced back fat pork, beta-cyclodextrine, white pepper powder, black pepper powder, welsh onion powder, Laurus nobilis powder and Holland celery powder; mixing; loading; air-drying; and carrying out vacuum packaging to obtain the functional poultry sausage having a red date flavor, having the oxidation resistance and immunity adjustment functions and containing polypeptide and astaxanthin active factors. The functional poultry sausage has the advantages of unique flavor, abundant nutrition, oxidation resistance and immunity adjustment functions, and richness in active substances comprising astaxanthin, polypeptides and flavonoids.

Owner:NINGBO UNIV

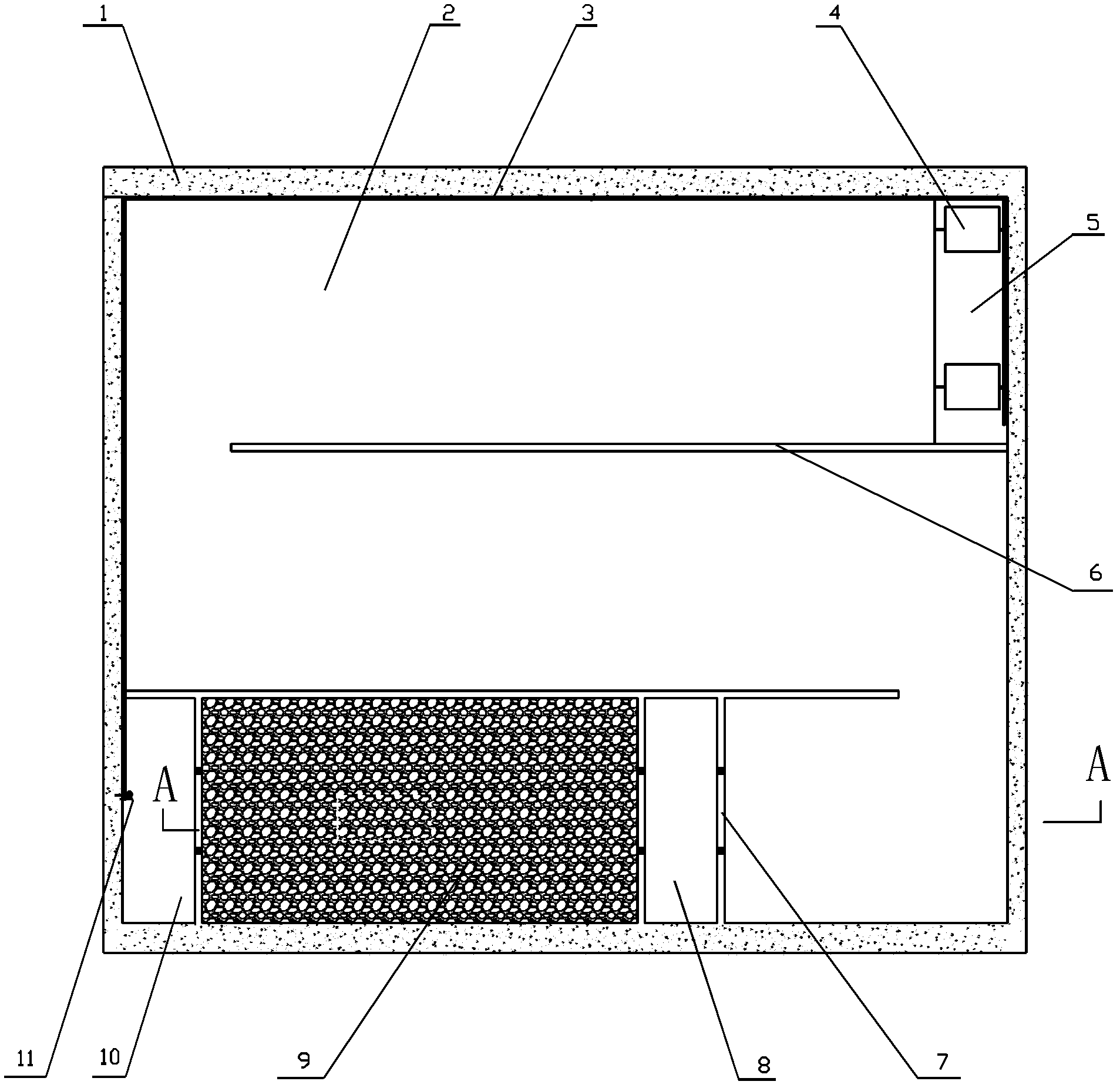

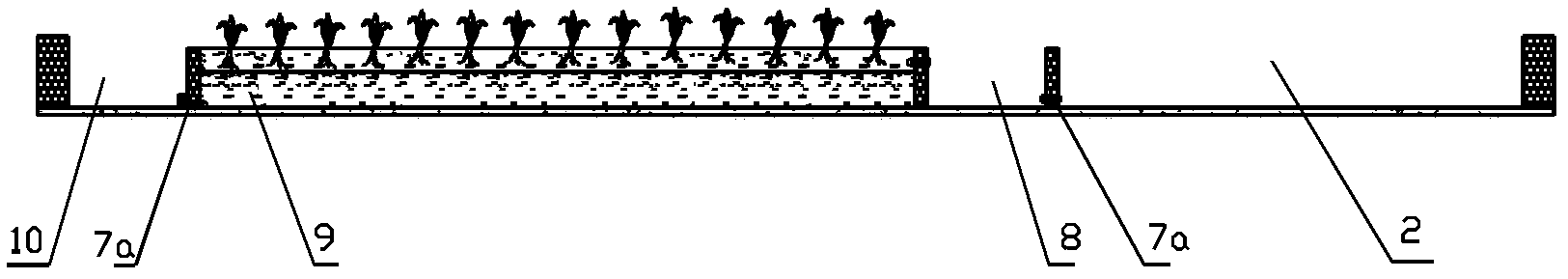

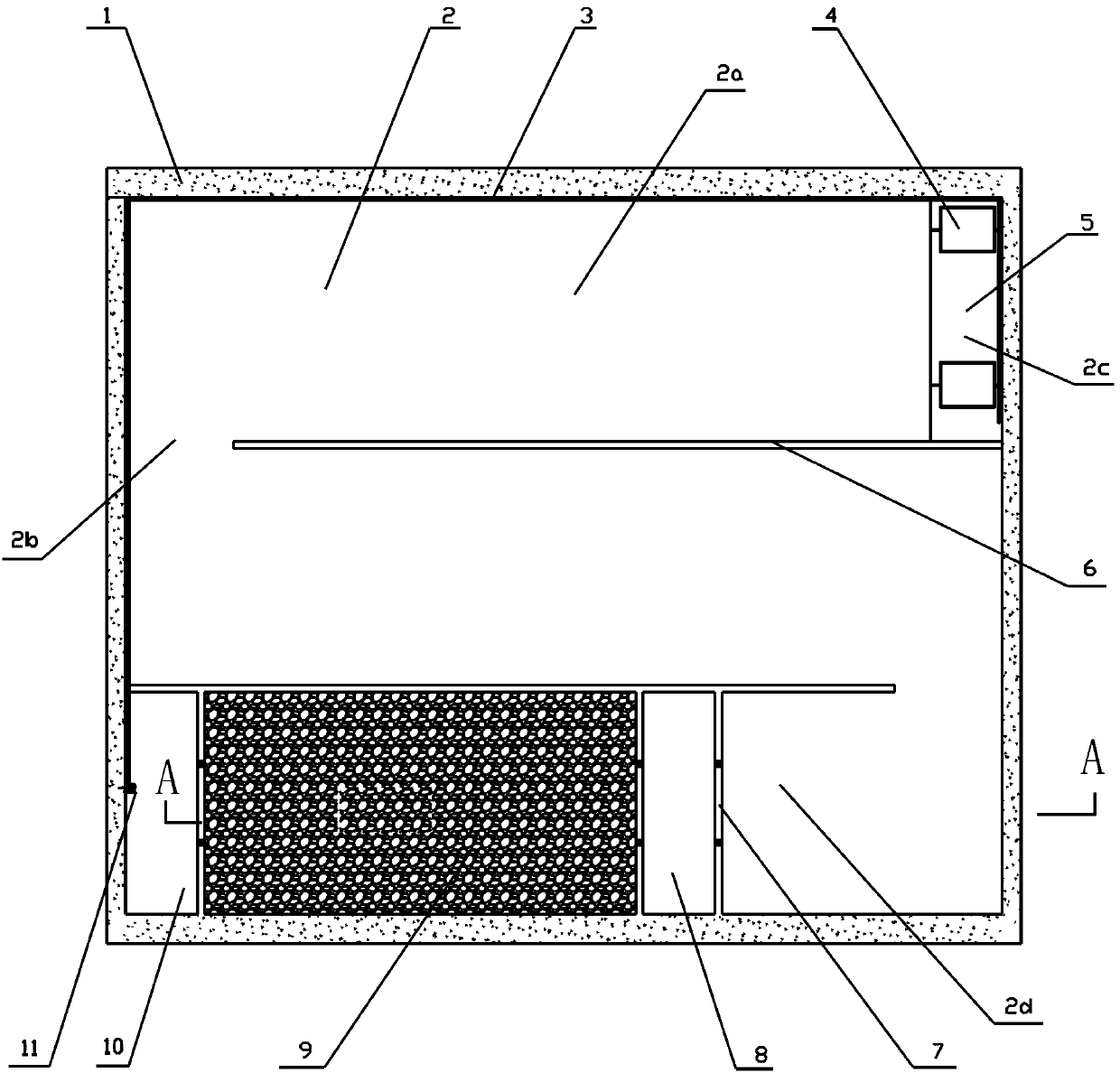

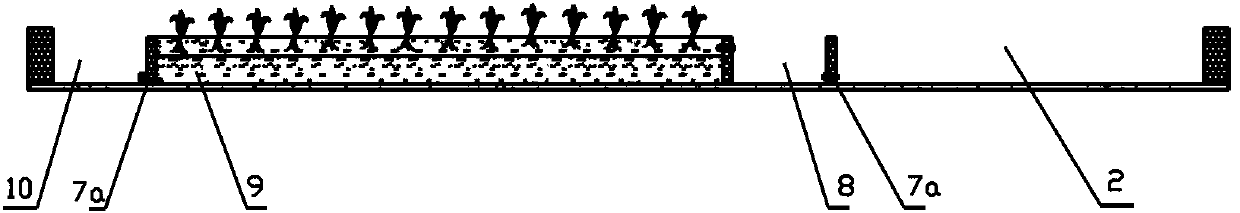

Aquiculture system for removing bilgy odor of fishes

InactiveCN102487873AReduce biomassEliminate earthy smellPisciculture and aquariaEcological environmentWater flow

The invention relates to aquiculture facilities for removing bilgy odor of fishes, in particular to an aquiculture system for removing the bilgy odor of the fishes. A rectangular aquiculture pond (1) is an S-shaped flow channel pond (2b). At least one biochemical filter box (4) is arranged at the starting end. Three blocks of horizontal partition wall (7) are arranged at the tail end of the tail-section straight flow channel pond (2d) in sequence to form a first water collecting ditch (10), an undercurrent wet land (9) and a second water collecting ditch (8) one after another. A water pump (11)is arranged in the first water collecting ditch (10), and water passes to an inlet of the biochemical filter box (4) through a pipeline (3) and finally flows into the flow channel pond (2d) through an outlet of the biochemical filter box (4). Base materials of a bottom layer of the undercurrent wet land (9) are ceramsite, and aquatic plants are planted on the ceramsite. The bottom of the flow channel pond (2) is coated with the ceramsite which has the depth of 10-15 centimeters and serves as biologic fillers, water plants occupying 30% area are planted in the flow channel pond (2), released density of cultured fishes is 6-15 kilograms / cubic meter, and water flow speed is 3-10 centimeters / minute. The aquiculture system for removing the bilgy odor of fishes is built for creating ecological environment and controlling negative factors influencing the bilgy odor of the fishes.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Processing method of instant crayfish claws

ActiveCN110269177AImprove absorbencyPromote penetration and tasteFood scienceChemistryUtilization rate

The invention discloses a processing method of instant crayfish claws. The processing method comprises the following steps: (1) selecting and cleaning raw materials; (2) taking claws, wherein crayfish claws are cut off along the joints by scissors and are cleaned for later use; (3) precooking wherein the crayfish claws are poured into boiling water for precooking, bubbles are scummed, the claws are taken out for cooling, and water is drained; (4) carrying out first-time drying; (5) tasting, wherein the crayfish claws are put into a pickling bag, pickling liquid is injected, the bag is sealed, ultrasonic treatment is carried out, the bag is taken out and opened for filtering and water draining after the treatment is completed; (6) carrying out second-time drying; (7) executing cooking, wherein the crayfish claws are steamed and cooked; (8) carrying out third-time drying, executing taking out and cooling; (9) packaging and sterilization. The method can effectively improve the crayfish utilization rate, is simple in process and convenient for industrial production, and the crayfish claws processed by the method are quick to taste and delicious in mouthfeel.

Owner:HUNAN AGRI PRODS PROCESSING INST

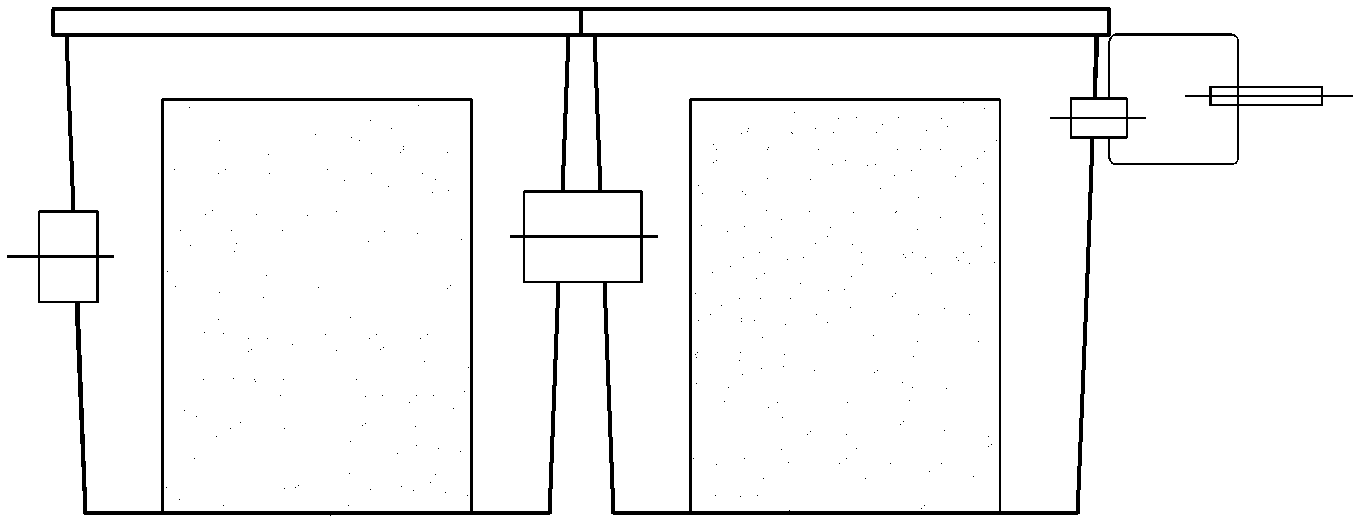

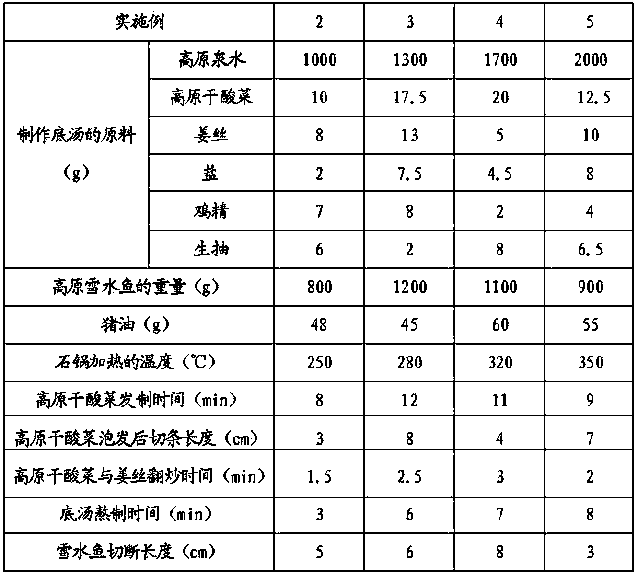

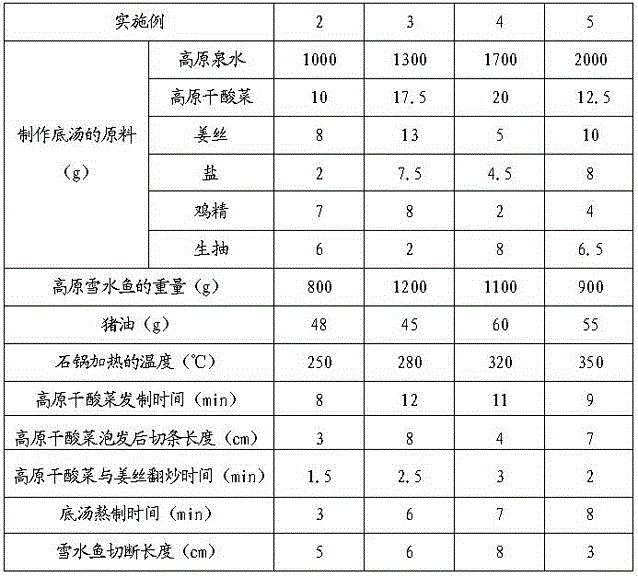

Cooking method of stone-pot fish

ActiveCN103549500AFix cooking timeSolve problems that are difficult to grasp in terms of heatFood thermal treatmentMulti-step food processesBiotechnologyCooking methods

The invention discloses a cooking method of stone-pot fish. The cooking method comprises the steps of heating a stone pot, boiling water, cooking soup ingredients, processing fish, cooking the stone-pot fish and packaging. According to the cooking method, the stone pot contains essential microelements, such as iron, magnesium, zinc and calcium, of a human body, and after the soup ingredients are poured into the hot stone pot, the stone pot can naturally release the microelements, so that the cooked fish is fresh and tender; meanwhile, as the constant-temperature stone pot is utilized for cooking the fish, the problems that the cooking time and the cooking temperature are difficult to handle are solved. The cooking method is simple and convenient to operate and is used for cooking fish foods.

Owner:王强

Method for making loach deep processing food

The invention provides a method for making loach deep processing food. The method comprises the steps that loach is adopted as a main raw material, ginger, orange peel, caraway seeds, sichuanese peppercorn, myrcia, sweet-scented osmanthus and other ingredients are matched according to the smell characteristics of meat of the loach, the low-temperature drying technology is adopted for processing on this basis, and the flavor level is increased on the basis of guaranteeing nutritional ingredients. The loach food made through the method is in a dried meat shape, fishbones can be directly eaten through the baking function, the food is yellow or light yellow, pure and delicious in taste and good in elasticity, earthy smells are thoroughly removed, the chewy feeling of the product is prominent, and the advantages of being high in protein, low in fat and the like are achieved. The prominent technical effect is achieved through relatively simple technological improvement, cost is low, the process is easy to control, the nutrition composition of the food is optimized on the basis of improving the taste, and a good foundation is laid for large-scale production of the loach food.

Owner:TIANJIN ZHENBANG AQUACULTURE

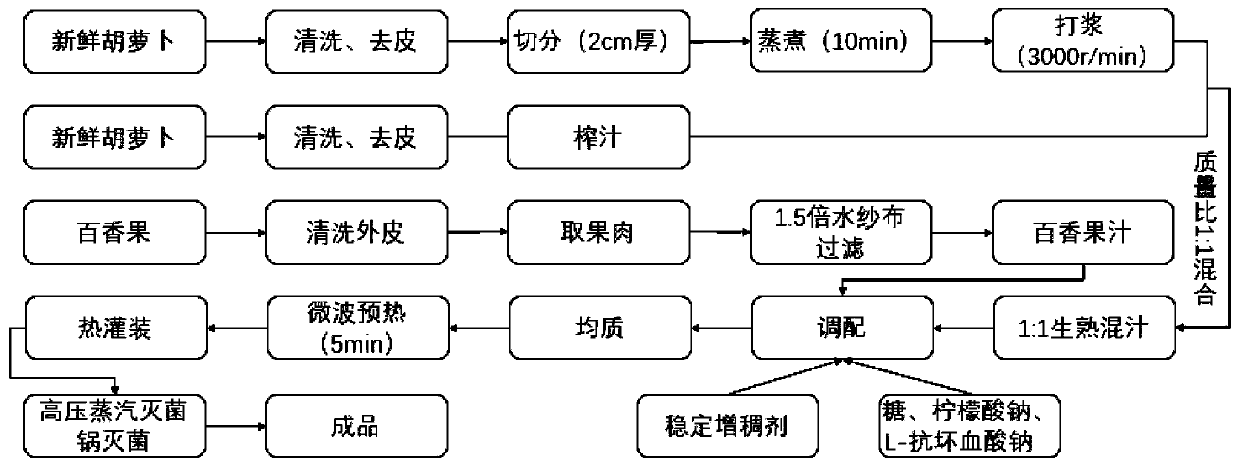

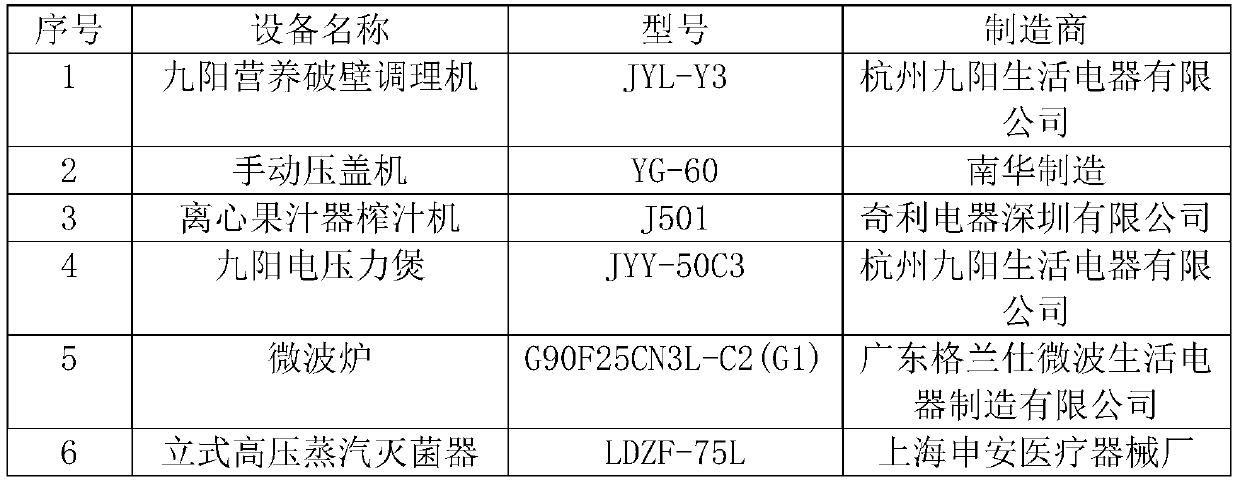

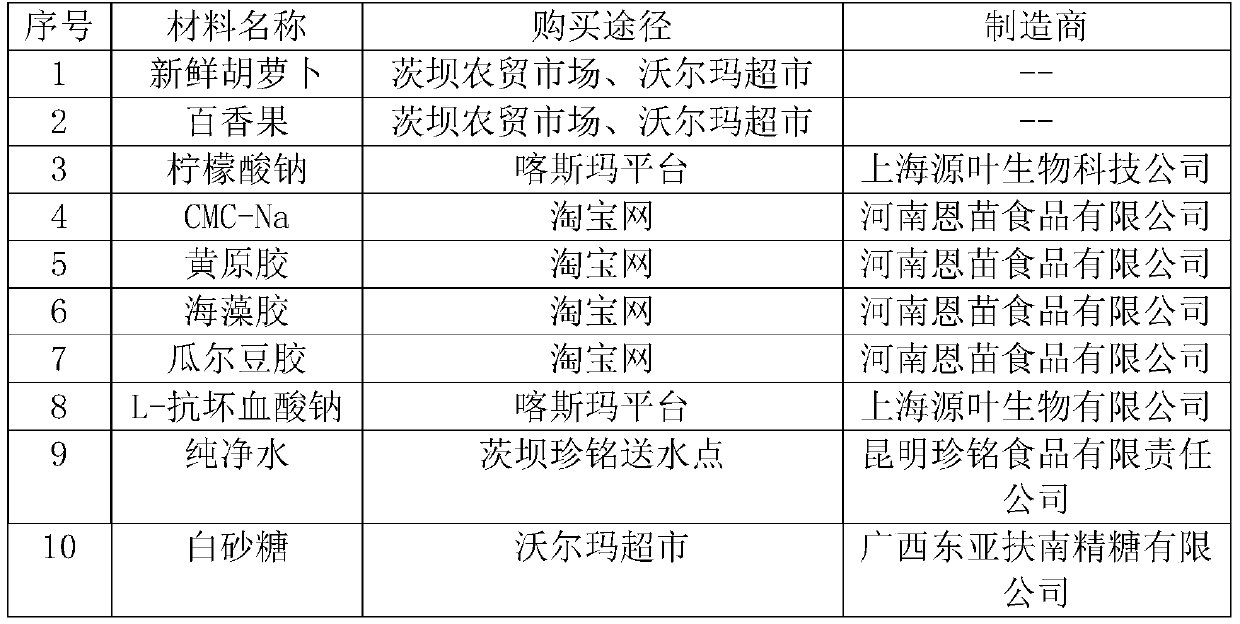

Non-reduced passion fruit-carrot juice composite beverage and preparation method thereof

The invention relates to a non-reduced passion fruit-carrot juice composite beverage and a preparation method thereof. According to the main adopted technical scheme, the beverage is prepared from thefollowing components: carrot juice, passion fruit juice, sugar, a color stabilizer, a thickening stabilizer and water, wherein in the beverage, the content of the carrot juice is 300-450 g / L, preferably 380-420 g / L, the content of the passion fruit juice is 30-60 g / L, preferably 35-50 g / L, the content of the sugar is 45-65 g / L, preferably 47-52 g / L, the content of the color stabilizer is 0.5-5 g / L, and the content of the thickening stabilizer is 0.5-5 g / L. According to the non-reduced passion fruit-carrot juice composite beverage, the taste is good, the color and stability are good, and the shelf life can be prolonged.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI +2

Spicy and hot cumin roasted rabbit and preparation method thereof

The invention discloses a spicy and hot cumin roasted rabbit. The spicy and hot cumin roasted rabbit is prepared from the following raw materials in parts by weight: 300 to 500 parts of fresh rabbit meat, 5 to 10 parts of onion, 3 to 5 parts of light soy sauce, 3 to 5 parts of dark soy sauce, 2 to 3 parts of edible salt, 1 to 2 parts of cumin powder, 2 to 3 parts of pepper powder, 5 to 8 parts of sesame oil, 1 to 2 parts of white sesame, 1 to 2 parts of Chinese prickly ash powder, 2 to 3 parts of Baijiu, 1 to 2 parts of baking powder, 30 to 50 parts of apple, and a proper amount of water. The spicy and hot cumin roasted rabbit has the advantages that the preparation technology is simple, the selected materials are green and healthy, and the baked rabbit meat is tasty; in the rabbit treatment phase, after the baking powder is adopted, the meat of the rabbit is more puffy; before the rabbit meat is put into an oven, the apple cubes are added, so that the earthy smell of the rabbit meat is removed, the roasted rabbit has certain fresh fragrance of apple, and the mouth feel of the spicy and hot cumin roasted rabbit is improved.

Owner:DAOZHEN COUNTY YUNZHUANG AGRI DEVCO LTD

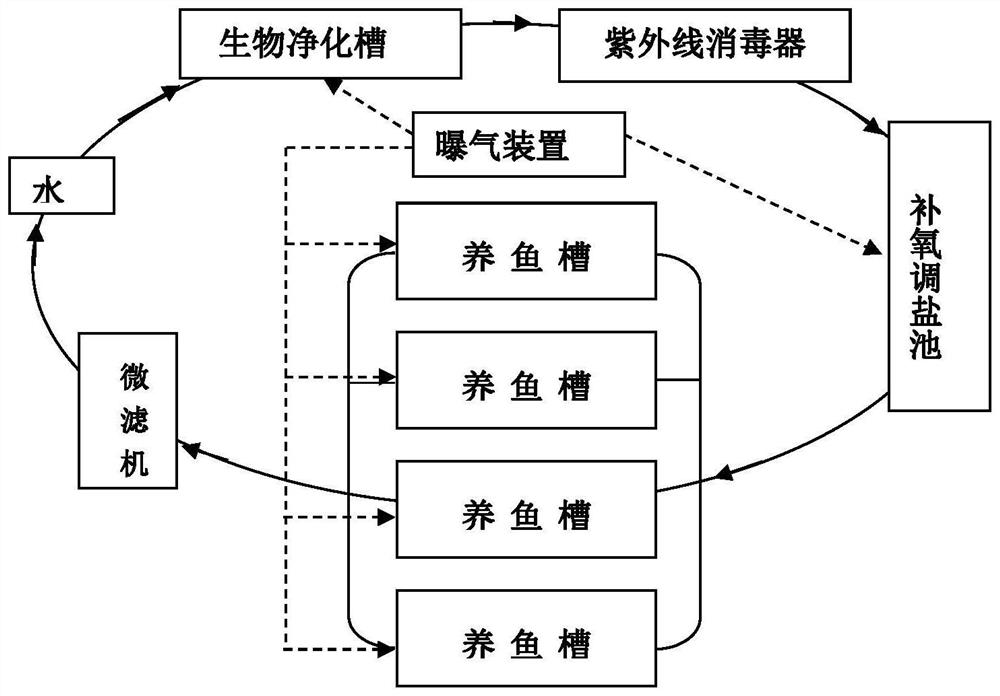

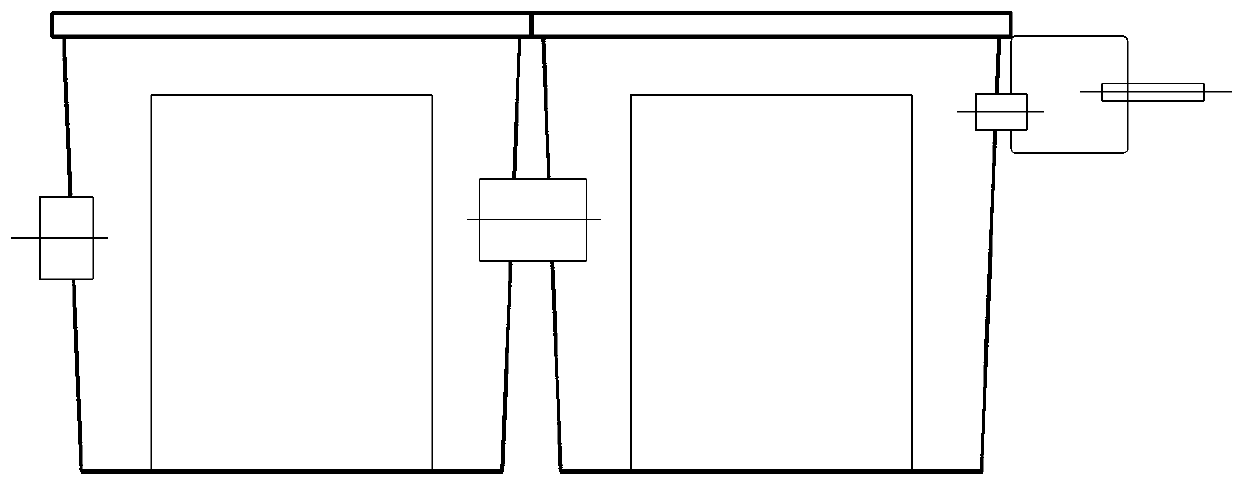

Purifying and quality-improving temporary rearing equipment for snakeheads and production process

PendingCN112913759AReduced responseReduce deaths and other emergenciesClimate change adaptationPisciculture and aquariaUv disinfectionEngineering

The invention discloses purifying and quality-improving temporary rearing equipment for snakeheads and a production process. The purifying and quality-improving temporary rearing equipment for the snakeheads comprises a fish culture tank, a microfilter, a biological purification tank, an ultraviolet sterilizer and an oxygen supplementing and salt adjusting pond. According to the production process, the feeding quantity is gradually increased, so that a circulating water culture system has enough time to enable microorganisms to grow, fish excrement and residual feed in water are purified and treated, and the situations that a water treatment system runs in an overload mode, and ammonia nitrogen is increased are avoided; a feed feeding temporary rearing strategy of stopping feeding, feeding a small amount of feed and stopping feeding is adopted, so that the exercise amount of the snakeheads can be increased, the snakeheads are matched with relocation of fish bodies, a new environment is adapted, fat consumption is promoted, meat is compact, and the taste of the snakeheads is improved. According to the purifying and quality-improving temporary rearing equipment for the snakeheads and the production process, culture water is subjected to continuous microbial purification and ultraviolet disinfection strategies, so that the earthy smell in snakehead meat can be removed; by controlling the salinity of the culture water to be 2-3 per thousand, the sterilization effect on the fish bodies and the water can be achieved, the meat quality of the snakeheads can be more compact, and the taste of the snakeheads is improved.

Owner:ZHEJIANG FISHERIES TECH EXTENSION STATION

A kind of preparation method of fermented duck leg

ActiveCN108740818BEnhanced inhibitory effectEliminate earthy smellClimate change adaptationFood scienceBiotechnologyMonosodium glutamate

The invention discloses a preparation method of fermented duck leg, which is characterized in that adding salt, sodium nitrite, ascorbic acid, sucrose, glucose, monosodium glutamate, white pepper powder, cooking wine, Chinese prickly ash, onion powder, The step of pickling tea polyphenols and soy sauce; Lactobacillus plantarum, Saccharomyces cerevisiae, Debaria hansenii and Staphylococcus xylosus in volume ratio (1‑3): (2‑3): (1‑3) 2): Mix the ratio of (1‑2) to obtain a mixed starter, add the mixed starter to the marinated duck legs with an inoculation amount of 1.5%‑2% by volume, and put the duck legs at 20‑25 ℃ The step of continuous fermentation for 32-35 hours in a constant temperature and humidity box; finally, the step of cooking the fermented duck legs for 30-35 minutes to obtain the finished product of fermented duck legs. The advantage is that the product has a unique flavor, no earthy smell, and no nitrite. And biogenic amine residues are low, with antioxidant function.

Owner:NINGBO UNIV

Duck feed additive for improving meat quality and preparation method of duck feed additive

InactiveCN109198240AAdjustment functionPromote circulationFood processingAnimal feeding stuffSide effectOfficinalis

The invention discloses a duck feed additive for improving meat quality. The duck feed additive is prepared from the following raw materials in parts by weight: 10-20 parts of dried orange peel, 1-5 parts of radix codonopsis, 5-15 parts of fructus gardeniae, 3-8 parts of pseudo-ginseng, 10-15 parts of haws, 2-6 parts of atractylodes rhizomes, 1-3 parts of cortex magnoliae officinalis, 3-8 parts ofhoneysuckle flowers, 5-10 parts of common andrographis herbs, 1-5 parts of vine tea, 7-12 parts of radix scutellariae, 1-3 parts of cogongrass roots and 4-9 parts of argy wormwood leaves. The duck feed additive disclosed by the invention is a natural combination, does not have toxic or side effects, does not have drug residues, is safe and reliable, and can strengthen the immunity of meat ducks,stimulate appetite and increase growth speed.

Owner:柳州市得凤家禽养殖场(微型企业)

Preparation method of functional minced fillet product stored at normal temperature

InactiveCN113854480AReduce cholesterolSimple and fast operationFood ingredient as flavour affecting agentBiotechnologyFresh water fish

The invention provides a preparation method of a functional minced fillet product stored at the normal temperature, namely a preparation method of minced fillet noodles containing calcium glucarate and konjak and stored at the normal temperature. The preparation method comprises the steps of preparation of calcium glucarate, preparation of konjac gum, preparation of enzymolysis minced fillet, powder mixing, curing, forming and drying. The minced fillet used in the product is obtained through enzymolysis, so that the earthy smell of a freshwater fish product is removed, in addition, the minced fillet contains the calcium glucarate, so that the minced fillet not only is used for supplementing calcium to the human body, but also has a functional effect for preventing and treating diseases of patients with hyperglycemia, high cholesterol, obesity and cancers; and the konjak has multiple functions of reducing blood sugar, blood fat and blood pressure, dispersing poison, beautifying, dredging collaterals, losing weight, relaxing the bowels, appetizing and the like, so that the functionality of the minced fillet noodles is further improved.

Owner:XUZHOU UNIV OF TECH

Production technique for chicken powder with great freshness flavor

ActiveCN103689522BIncrease umamiImprove sensory qualityFood ingredientsFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a production technique for chicken powder with a great freshness flavor, and belongs to the technical field of processing food seasoning. The chicken powder comprises the following materials according to mass: 30kg of fresh chicken skeletons, 30kg of fresh chicken, 7kg of maltodextrin, 2.5kg of disodium nucleotide, 0.1kg of sodium citrate, 7kg of trehalose, 10kg of edible salt, 10kg of monosodium glutamate, 2kg of lentinula edodes, 1kg of radix puerariae, and 0.4kg of pepper; the production technique comprises the steps: pretreating active ingredients, and carrying out high-temperature high-pressure sealed cooking, fine treatment, enzymolysis for flavor, mixing, spray drying, filling and capping. According to the production technique, the processes are simple, the energy consumption can be reduced, the loss of flavor components can be effectively reduced and sufficient release of flavor substances is promoted, the chicken powder is rich in chicken flavor, harmonious in saline taste, delicate flavor and perfume, luminous in color, good in rehydration property, smooth in mouthfeeling, free from sand grains, and milkily white in soup feeling.

Owner:GUANGDONG JIALONG FOOD

Cooking method of stone-pot fish

ActiveCN103549500BRich in proteinLow in fatFood thermal treatmentMulti-step food processesProcess engineeringCooking methods

The invention discloses a preparation method of stone pot fish, which comprises the steps of heating the stone pot, boiling water, making bottom soup, processing fish, making stone pot fish, packaging and the like. The stone pot of the present invention contains trace elements necessary for the human body such as iron, magnesium, zinc, calcium, etc. After pouring the bottom soup into the hot stone pot, the stone pot will naturally release these trace elements, making the fish more tender; at the same time , using a constant temperature stone pot to cook fish, which solves the difficult problem of cooking time and heat. The invention is easy to operate and is used for cooking fish food.

Owner:王强

Fish head sauce with tea aroma and preparation method thereof

InactiveCN102178208BBroaden the way of processing and utilizationEliminate earthy smellFood preparationSaline waterFlavor

The invention discloses a fish head sauce with tea aroma and a preparation method thereof. The preparation method comprises the following steps of: (1) selecting a fresh fish head, removing a gill and cleaning; (2) pouring hot water on the tea to obtain tea water and adding common salt to obtain tea saline water; (3) soaking the fish head with the tea saline water; (4) heating and pressurizing tosoften fish head bone and crush into fish head paste; (5) chopping fresh pork and mushroom into small blocks, frying sesame to be cooked and frying diced meat to be cooked with oil; and (6) adding seasoning into hot pepper, green onion, ginger, diced mushroom, the fish head paste, flour paste and cooked diced pork, then frying to be cooked, adding crushed tea leaves and the cooked sesame, uniformly stirring the cooked sesame, packaging and sterilizing to obtain the fish head sauce with tea aroma. According to the fish head sauce, the processing and utilizing path of fresh fish head is widened. By adopting the tea for soaking treatment, the fishy flavor of the fish can be eliminated and the improvement on the quality of products is facilitated; and the fish head sauce has abundant nutrition, is produced by adopting a simple production process and is suitable for industrial production.

Owner:TIANJIN AGRICULTURE COLLEGE

Preparation method of dried loach meat floss

The invention provides a preparation method of dried loach meat floss. According to the method, a salting step before steaming is specially added and makes stir-fried dried meat floss filiform, fluffy and soft and have a good taste, and the conditions of processing steps are mild, so that the nutrient substances of the dried loach meat floss are retained well. What's more important is that the salting step facilitates fishbone softening and then is matched with a follow-up specific drying process, and fish bones can be crisp and can be integrated with meat. Therefore, a special fishbone removing step is not needed, the meat floss can be stir-fried after direct mincing, and the taste of the product is not affected. In conclusion, the outstanding technical effect is achieved through an ingenious technical concept. In addition, the cost is low, the process is easy to enlarge, the preparation method is especially suitable for large-scale production. Therefore, the preparation method has outstanding popularization prospect.

Owner:TIANJIN ZHENBANG AQUACULTURE

Processing process for low-salt air-dried geese marinated in rice wine

The invention discloses a processing process for a low-salt air-dried goose marinated in rice wine. A live goose is killed, unhaired, eviscerated and rinsed to obtain a goose whole. The processing process is characterized by comprising the following steps: soaking the goose whole in a marinating solution which takes vinasse as reference, and marinating for 18-24 hours at the temperature of 12-15 DEG C; then placing the goose whole in a workshop in which the temperature is 18-20 DEG C and the relative humidity is 65-70%, carrying out air drying for 2-3 days at the air speed of 6-8m / s, transferring into a workshop in which the temperature is 25-28 DEG C and the relative humidity is 70-75%, and carrying out air drying for 2-3 days at the air speed of 3-5m / s; placing the goose whole subject to air drying into a water tank with the temperature of 90-95 DEG C for 3-4 minutes, then completely tweezing the tiny feather on the surface of the goose whole, washing the goose whole clean, placing on a fixed frame, transmitting to halogen liquid with the temperature of 90-95 DEG C, and stewing for 45-60 minutes; and finally, carrying out vacuum packing and sterilization on the stewed goose whole to obtain the finished product. The low-salt air-dried geese marinated in rice wine has the advantages of unique flavor, delicious texture, strong bacon fragrance and mellow rice wine, and is beneficial to human health.

Owner:NINGBO UNIV

Production method of plant compound beverage

InactiveCN110250387APreserve basic nutritional valueStable stateFood preservationNatural extract food ingredientsOrganic sulfide compoundThiosulfinate

The invention discloses a production method of a plant compound beverage. The production method has the advantages that burdock and corn stigma are used as the raw materials, the compound beverage is formed by corn stigma extract and burdock extract, modified chitosan immobilization complex enzymes are used as the clarifying agent to adsorb substances such as pectin and protein with negative charges in the beverage, adsorption of bioactive substances such as flavonoids is reduced, nutritional value keeping is achieved, protease catalyzes protein to hydrolyze, flocculent precipitation is avoided, recycling in process is achieved, and production cost is lowered; by adding black garlic powder, thiosulfinate is mainly formed, various decomposition and transformation reaction is generated to form various organic sulfide, the amount of oxygen which can be utilized is reduced, beverage browning is further inhibited, and the compounding of the trace black garlic powder and the corn stigma extract amazingly eliminates the earthy smell of the burdock.

Owner:XUZHOU COLLEGE OF INDAL TECH

Feed additive for removing earthy taste of freshwater fish and application of feed additive

The invention aims to provide a feed additive for removing the earthy taste of freshwater fish. The feed additive comprises, by weight, 5%-10% of allicin, 2%-6% of perilla leaf extracts, 2%-6% of tea polyphenols, 2%-6% of ethyl maltol, 20%-40% of yeast cell walls and 20%-40% of yeast contents. Physical, chemical and biological methods are comprehensively adopted for removing the earthy taste of the freshwater fish effectively through the feed additive, no drug tolerance or toxic and side effect is generated, and the growth rate of fishes can be remarkably increased; antioxidant capacity and immunocompetence of the fishes are improved, disease resistance of fish bodies is enhanced, fish meat quality is improved, the market price of the fishes is increased, and production effectiveness is remarkably promoted.

Owner:山东百福生物科技有限公司

A kind of processing method of instant crayfish shrimp tongs

The invention discloses a processing method of ready-to-eat crayfish shrimp tongs, comprising the following steps: (1) selecting raw materials and cleaning; (2) taking the tongs: using scissors to cut the crayfish shrimp tongs along the joints, cleaning for use; (3) ) Pre-cooking: Pour the crayfish and shrimp claws into boiling water for pre-cooking, skim off the foam, remove it to cool, and drain the water; (4) Do the first drying; (5) Taste: put the crayfish and shrimp claws in Pickle the bag, pour it into the pickling liquid, seal it, and perform ultrasonic treatment. After completion, take out the bag to filter and drain; (6) Carry out the second drying; (7) Cooking: steam the crayfish and shrimp tongs for cooking (8) Drying for the third time, taking out and cooling; (9) Packaging and sterilization. The method of the invention can effectively improve the utilization rate of the crayfish, the process is simple, and the industrial production is convenient.

Owner:HUNAN AGRI PRODS PROCESSING INST

Chicken feed additive for improving meet quality

InactiveCN102823767BImprove internal and external environmentImprove freshnessFood processingAnimal feeding stuffSodium bicarbonateCodonopsis

The invention relates to a chicken feed additive, especially to a chicken feed additive for improving meet quality. The chicken feed additive for improving the meet quality is prepared from the following components by weight parts: 5 to 15 parts of Radix Astragali, 5 to 15 parts of cumin, 15 to 30 parts of wormwood leaves, 15 to 30 parts of cassia bark, 15 to 30 parts of haw, 15 to 30 parts of Cortex Acanthopanax Radicis, 20 to 30 parts of white peony root, 20 to 30 parts of Radix Peucedani, 20 to 30 parts of dried orange peel, 1 to 5 parts of talcum, 20 to 30 parts of sodium bicarbonate, 1 to 5 parts of salt, 10 to 20 parts of poria peel, 10 to 20 parts of mulberry bark, 10 to 20 parts of ginger peel, 10 to 20 parts of areca peel, 5 to 10 parts of radix codonopsis and 5 to 10 parts of bighead atractylodes rhizome. 1.5 to 3 % by mass percent of the chicken feed additive for improving meet quality is added into a basal feed to feed chicken, so as to substantially improve delicious degree of the meat, increase growth speed, enhance immunity of the chicken, and increase utilization rate of the feed.

Owner:QINGDAO SENYUAN ANIMALS BIRDS CULTURE

Aquiculture system for removing bilgy odor of fishes

InactiveCN102487873BReduce biomassEliminate earthy smellPisciculture and aquariaEcological environmentWater flow

The invention relates to aquiculture facilities for removing bilgy odor of fishes, in particular to an aquiculture system for removing the bilgy odor of the fishes. A rectangular aquiculture pond (1) is an S-shaped flow channel pond (2). At least one biochemical filter box (4) is arranged at the starting end. Three blocks of horizontal partition wall (7) are arranged at the tail end of the tail-section straight flow channel pond (2) in sequence to form a first water collecting ditch (10), an undercurrent wet land (9) and a second water collecting ditch (8) one after another. A water pump (11) is arranged in the first water collecting ditch (10), and water passes to an inlet of the biochemical filter box (4) through a pipeline (3) and finally flows into the flow channel pond (2) through an outlet of the biochemical filter box (4). Base materials of a bottom layer of the undercurrent wet land (9) are ceramsite, and aquatic plants are planted on the ceramsite. The bottom of the flow channel pond (2) is coated with the ceramsite which has the depth of 10-15 centimeters and serves as biologic fillers, water plants occupying 30% area are planted in the flow channel pond (2), released density of cultured fishes is 6-15 kilograms / cubic meter, and water flow speed is 3-10 centimeters / minute. The aquiculture system for removing the bilgy odor of fishes is built for creating ecological environment and controlling negative factors influencing the bilgy odor of the fishes.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com