Purifying and quality-improving temporary rearing equipment for snakeheads and production process

The technology of snakehead snakehead and equipment is applied in the field of purification and quality improvement and temporary raising process and equipment field of snakehead snakehead, which can solve the problems of poor body color and taste, increased risk of drug residues, stubby body and other problems, so as to promote fat consumption and meat quality, The effect of reducing the light intensity and increasing the amount of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

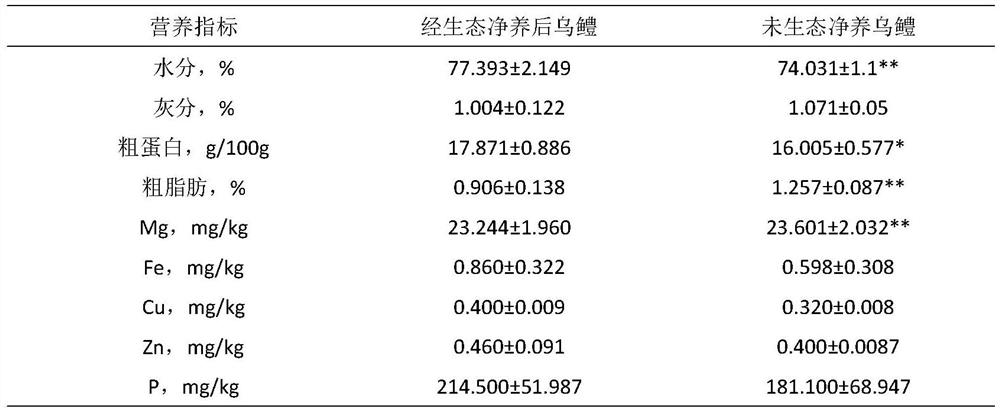

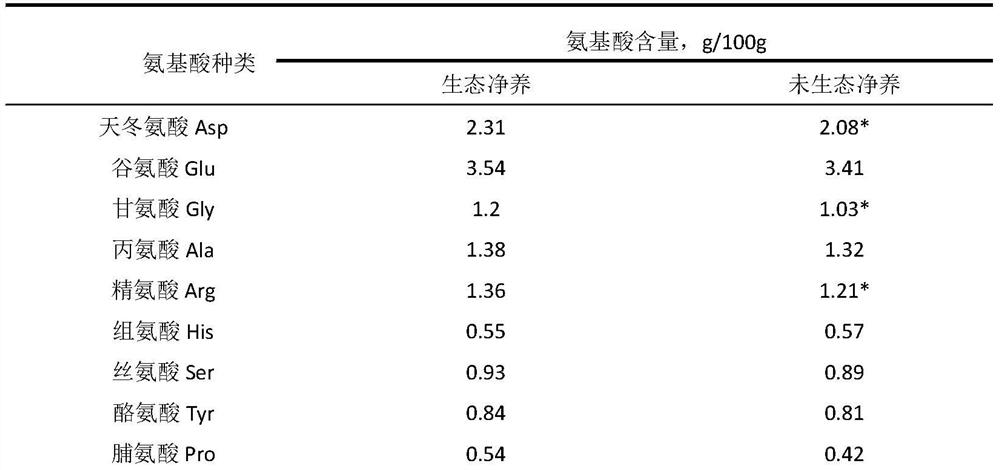

Examples

Embodiment 1

[0047] Embodiment 1: a kind of purifying and quality-improving temporary raising process of snakeheads based on the above-mentioned equipment, specifically:

[0048] Step (1), placing the snakehead to be listed in the fish tank.

[0049] C) stocking density

[0050] The stocking density of snakehead is 20kg / m on the first day 3 (Because the biofilm in the system needs a certain amount of time to build up, enough fish cannot be stocked at one time, and it will be increased after the biofilm is partially constructed), and increase to 40-50kg / m on the second day 3 ;

[0051] D) Feeding strategy

[0052] No feeding was used for the first two days, and the compound feed was fed on the third day. The amount of feed was 30-50% of normal breeding (before temporary breeding), and gradually decreased from the sixth day until it was reduced to zero on the tenth day;

[0053]C) Water quality control technology

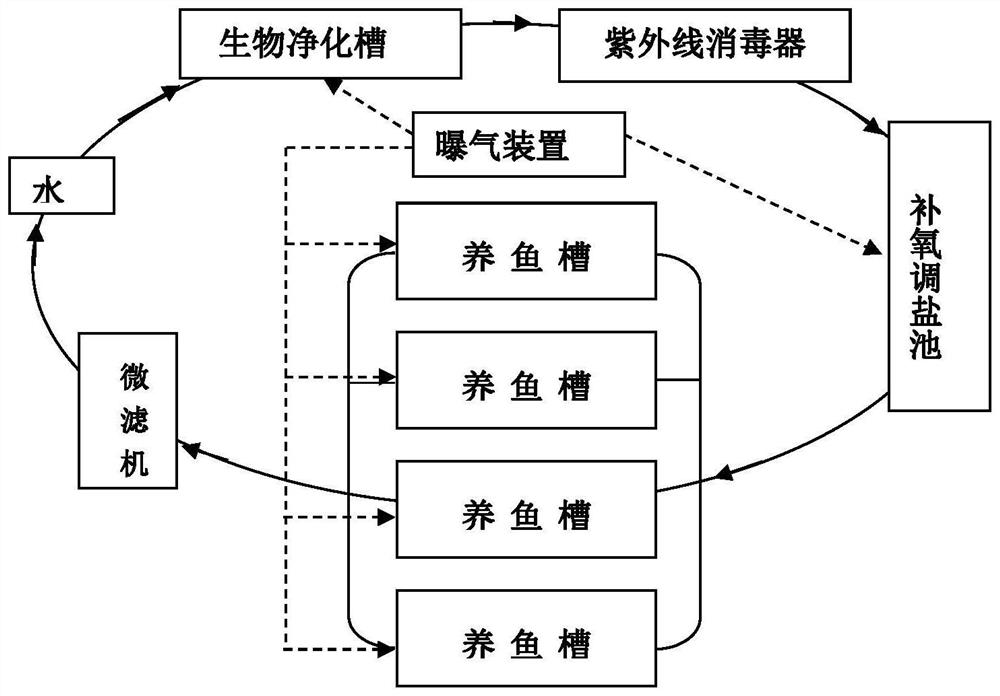

[0054] Microfiltration machine, ultraviolet sterilizer, water pump norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com