Preparation method of fish collagen peptide compound

A fish collagen and collagen technology, which is applied in the field of preparation of fish collagen short peptide complexes, can solve problems such as lack of collagen peptide complex extraction process, and achieve the effects of easy operation, high extraction rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

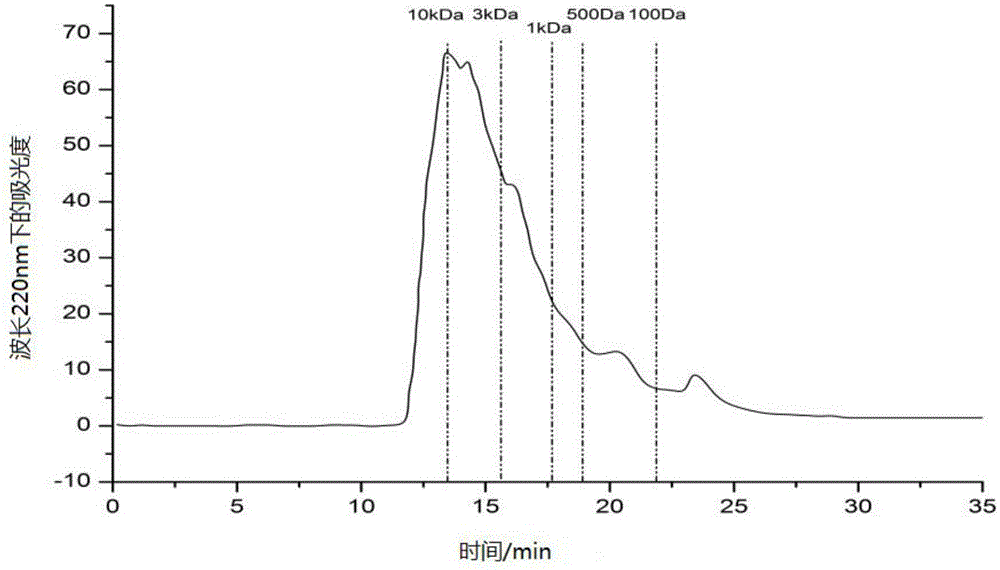

Embodiment 1

[0053] Step 1, fish skin pretreatment:

[0054] Take an appropriate amount of tilapia skin, remove the scales and clean it, soak it in 1mol / L HCl for 24 hours, control the ratio of solid to liquid at 1:10g / ml, and then rinse the skin after acid soaking with clean water to remove the pigment on the surface of the skin. Cut the fish skin into cubes about 1.5×1.5cm in size, soak in 0.1mol / L NaOH solution for 24 hours, control the material-liquid ratio to 1:20g / ml, and stir with a magnetic stirrer at the same time , to remove miscellaneous protein and fat.

[0055] Step 2, prepare collagen solution:

[0056] Soak the pretreated fish skin with an appropriate amount of distilled water for 1 hour to wash away the residual lye. Then soak in citric acid solution with a mass concentration of 1% until the fish skin softens at room temperature, so that the gelatin swells and facilitates the extraction of the gelatin. The ratio of solid to liquid is controlled to be 1:15g / ml. Rinse the ...

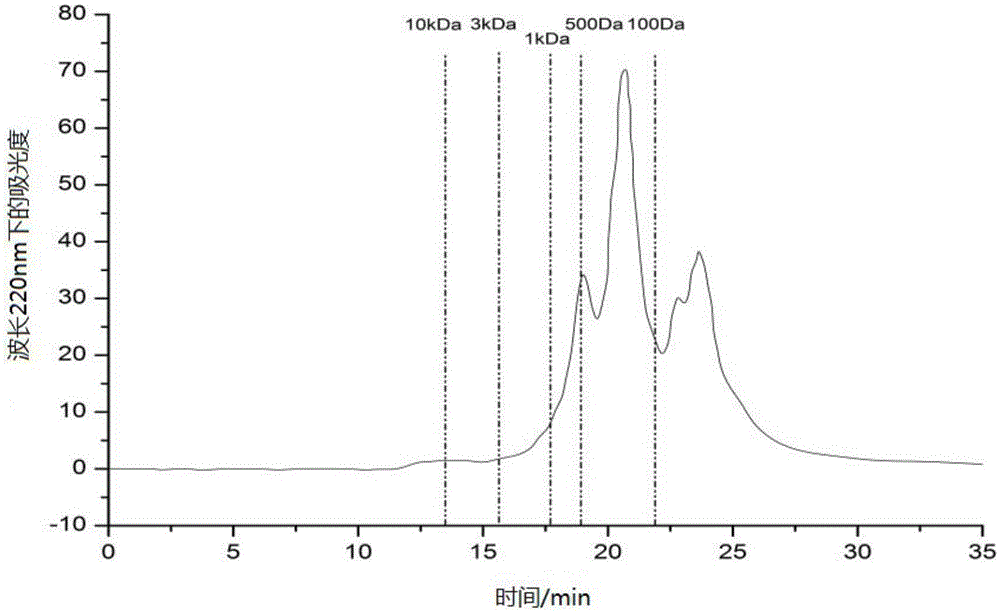

Embodiment 2

[0069] Step 1, fish skin pretreatment:

[0070] Take cod skin, descale and clean it, soak it in 0.8mol / L HCl solution for 20 hours, control the ratio of solid to liquid to 1:8g / ml, and then rinse the acid-soaked fish skin with clean water to remove the pigment on the surface of the fish skin. Cut the fish skin into cubes about 1.5×1.5cm in size, soak in 0.15mol / L NaOH solution for 48 hours, control the material-liquid ratio to 1:10g / ml, and stir with a magnetic stirrer at the same time , to remove miscellaneous protein and fat.

[0071] Step 2, prepare collagen solution:

[0072] Soak the pretreated fish skin with appropriate amount of distilled water for 2 hours to wash away the residual lye. Then soak in citric acid solution with a mass concentration of 0.5% at room temperature until the fish skin softens, making the gelatin swell, which is beneficial to gelatin extraction, and the ratio of solid to liquid is controlled to be 1:10g / ml. Rinse the citric acid-treated fish s...

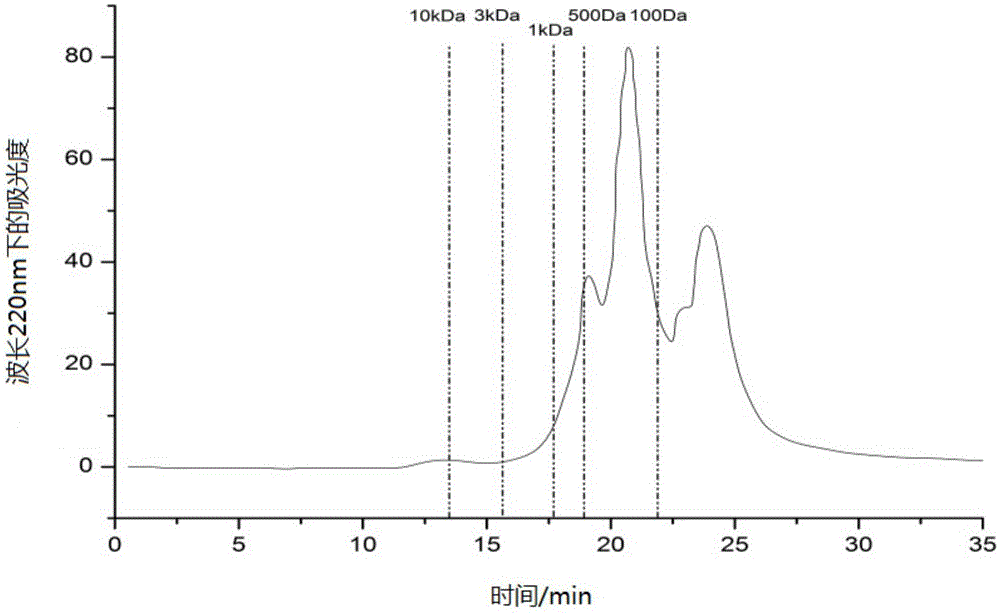

Embodiment 3

[0085] Step 1, fish skin pretreatment:

[0086] Take the grass carp skin, remove the scales and clean it, soak it in 1.2mol / L HCl solution for 26 hours, control the ratio of solid to liquid to 1:9g / ml, and then rinse the acid-soaked fish skin with clean water to remove the pigment on the surface of the fish skin. Cut the fish skin into cubes about 1.5×1.5cm in size, soak in 0.12mol / L NaOH solution for 36 hours, control the material-liquid ratio to 1:15g / ml, and stir with a magnetic stirrer at the same time , to remove miscellaneous protein and fat.

[0087] Step 2, prepare collagen solution:

[0088] Soak the pretreated fish skin with an appropriate amount of distilled water for 1.5 hours to wash away the residual lye. Then soak in a citric acid solution with a mass concentration of 2% at room temperature until the fish skin softens to make the gelatin swell and facilitate gel extraction. The ratio of solid to liquid is controlled to be 1:13g / ml. Rinse the citric acid-treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com