Hydroxymethylated lignin and application thereof

A technology of hydroxymethylation and lignin, which is applied in the application of said hydroxymethylation lignin, hydroxymethylation lignin, and the application field in the preparation of polyurethane foam, to reduce costs, reduce particle size, highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

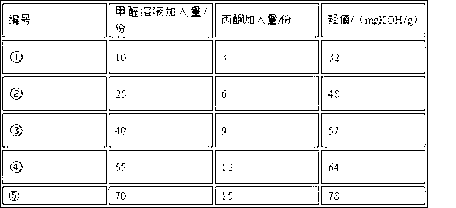

[0038] Take corn cob lignin black liquor with 100 parts of absolute dry lignin, add it to the reaction bottle, add 10 parts, 25 parts, 40 parts, 55 parts, and 70 parts of formaldehyde solution respectively, and react at 70 °C for 1 hour. Add 3 parts, 6 parts, 9 parts, 12 parts, and 15 parts of acetone, respectively numbered ①, ②, ③, ④, ⑤, continue the reaction for 1 hour, cool to room temperature, acidify, filter, and dry to obtain hydroxymethyl lignin. The hydroxyl value data of the obtained hydroxymethyl lignin are shown in Table 1.

[0039] Table 1

[0040]

[0041] Known by above-mentioned data, when taking absolute dry lignin as 100 parts of corn cob lignin black liquor, when formaldehyde solution add-on is 70 parts, the hydroxyl value of gained hydroxymethylated lignin in the value range of formaldehyde solution is maximum, Due to the consideration of the cost of raw materials, the amount of 70 parts of formaldehyde solution is used as an appropriate amount.

Embodiment 2

[0043] Take corncob lignin black liquor with 100 parts of absolute dry lignin, add it to the reaction bottle, add 70 parts of formaldehyde solution, and react for 1 hour at 70°C, add 4 parts, 8 parts, 12 parts, and 15 parts of Acetone, respectively numbered ⑥, ⑦, ⑧, ⑨, continued to react for 1 hour, cooled to room temperature, acidified, filtered, and dried to obtain hydroxymethylated lignin. In the process of filtering, see Table 2 for the influence of the amount of acetone added on the filtration rate.

[0044] Table 2

[0045] Numbering Amount of formaldehyde solution / part Addition amount of acetone / part Filtration rate / (mL / min) ⑥ 70 4 102 ⑦ 70 8 120 ⑧ 70 12 150 ⑨ 70 15 152

[0046] It can be seen from the above data that the dispersion uniformity is improved after adding acetone. When the amount of acetone added is 12 parts, the filtration rate of the modified lignin is significantly improved, and after continuing to add ace...

Embodiment 3

[0049] Take 10 parts of hydroxymethylated lignin numbered ⑧ in Example 2, dry it in vacuum at 50°C for 2 hours, add 100 parts of polyethylene glycol 400, 1.5 parts of triethylenediamine, 0.1 part of dibutyldiamine Lauric acid, 0.5 parts of water, 25 parts of cyclopentane, 2.5 parts of silicone oil, mix evenly under stirring, quickly add 110 parts of PM 200, stir and mix evenly, pour into a mold preheated to 40-50°C, and carry out After foaming, take out the foam body and cure at room temperature to obtain a hydroxymethylated lignin modified polyurethane rigid foam with a thermal conductivity of 0.0193 w / m k (25°C) and a closed cell rate of 93.7%. The intensity is 230.98Kpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com