Polyurethane foam with organosilicon modified expanded graphite as flame retardant

A technology of polyurethane foam and expanded graphite, applied in the field of polyurethane foam, can solve the problems of easily threatening life safety, poor flame retardant performance, poor high and low temperature resistance, etc., and achieves good thermal insulation effect, good flame retardant effect, and increased flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

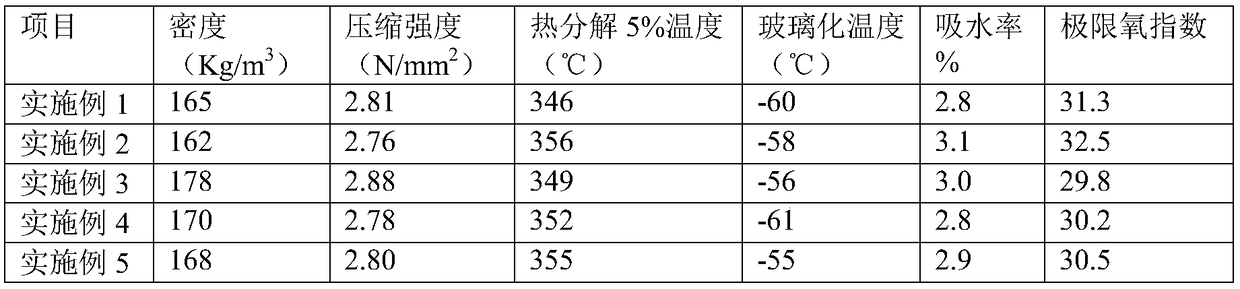

Examples

Embodiment 1

[0030] A polyurethane foam using organosilicon-modified expanded graphite as a flame retardant, comprising polyester polyol, 1,4-cyclohexane diisocyanate, organosilicon-modified expanded graphite, hydroxyl-terminated fluorine The mass ratio of silicone resin, stannous octoate, triethylenediamine, sodium dodecylbenzenesulfonate, antioxidant TNP and cobalt isooctanoate is 100:95:25:10:3:2 :2:2:1.

[0031] The preparation method of described organosilicon modified expanded graphite is as follows:

[0032] (1) Surface activation: in parts by weight, get 100 parts of expanded graphite, add 0.5 part of ferrous chloride therein, after mixing uniformly, place in the reactor, and replace the original air with nitrogen in the reactor, And pass into wherein the steam that contains 0.005% volume fraction acetic acid vapor, raise temperature to 105 ℃, keep the air pressure in the reactor to be 6.0MPa, be down to room temperature after stirring and activating for 45 minutes, wash with wate...

Embodiment 2

[0037] A polyurethane foam using organosilicon-modified expanded graphite as a flame retardant, comprising polyester polyol, 1,4-cyclohexane diisocyanate, organosilicon-modified expanded graphite, hydroxyl-terminated fluorine Silicone resin, stannous octoate, triethylenediamine, sodium octadecyl sulfate, antioxidant TPP and dibutyltin dilaurate, the mass ratio of the components is 100:120:35:25:8:6: 5:5:3.

[0038] The preparation method of described organosilicon modified expanded graphite is as follows:

[0039] (1) surface activation: according to parts by weight, get 100 parts of expanded graphite, add 2 parts of ferrous chloride wherein, after mixing uniformly, be placed in reactor, lead nitrogen to replace original air in reactor, And feed therein the water vapor containing the acetic acid vapor of 0.05% by volume, raise the temperature to 125°C, keep the air pressure in the reactor at 9.5MPa, stir and activate for 100 minutes and then drop to room temperature, wash wit...

Embodiment 3

[0044] A polyurethane foam using organosilicon-modified expanded graphite as a flame retardant, comprising polyester polyol, 1,4-cyclohexane diisocyanate, organosilicon-modified expanded graphite, hydroxyl-terminated fluorine The mass ratio of silicone resin, stannous octoate, triethylenediamine, zinc stearate, antioxidant 164 and zinc isooctanoate is 100:100:30:20:5:5:3:3 :2.

[0045] The preparation method of described organosilicon modified expanded graphite is as follows:

[0046] (1) Surface activation: according to parts by weight, get 100 parts of expanded graphite, add 1 part of ferrous chloride therein, after mixing uniformly, place in the reactor, and replace the original air with nitrogen in the reactor, And feed therein the water vapor containing the acetic acid vapor of 0.015% by volume, raise the temperature to 115°C, keep the air pressure in the reactor at 8.0MPa, stir and activate for 60 minutes and then drop to room temperature, wash with water until neutral,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com